Spring hydraulic operating mechanism for high voltage circuit breaker

A high-voltage circuit breaker and spring hydraulic technology, which is applied in the field of power transmission and transformation, can solve the problems of the energy storage piston and the energy storage cylinder being stuck together, the mechanism cannot store energy normally, and the energy storage piston cannot move. Reliable links and fewer parts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

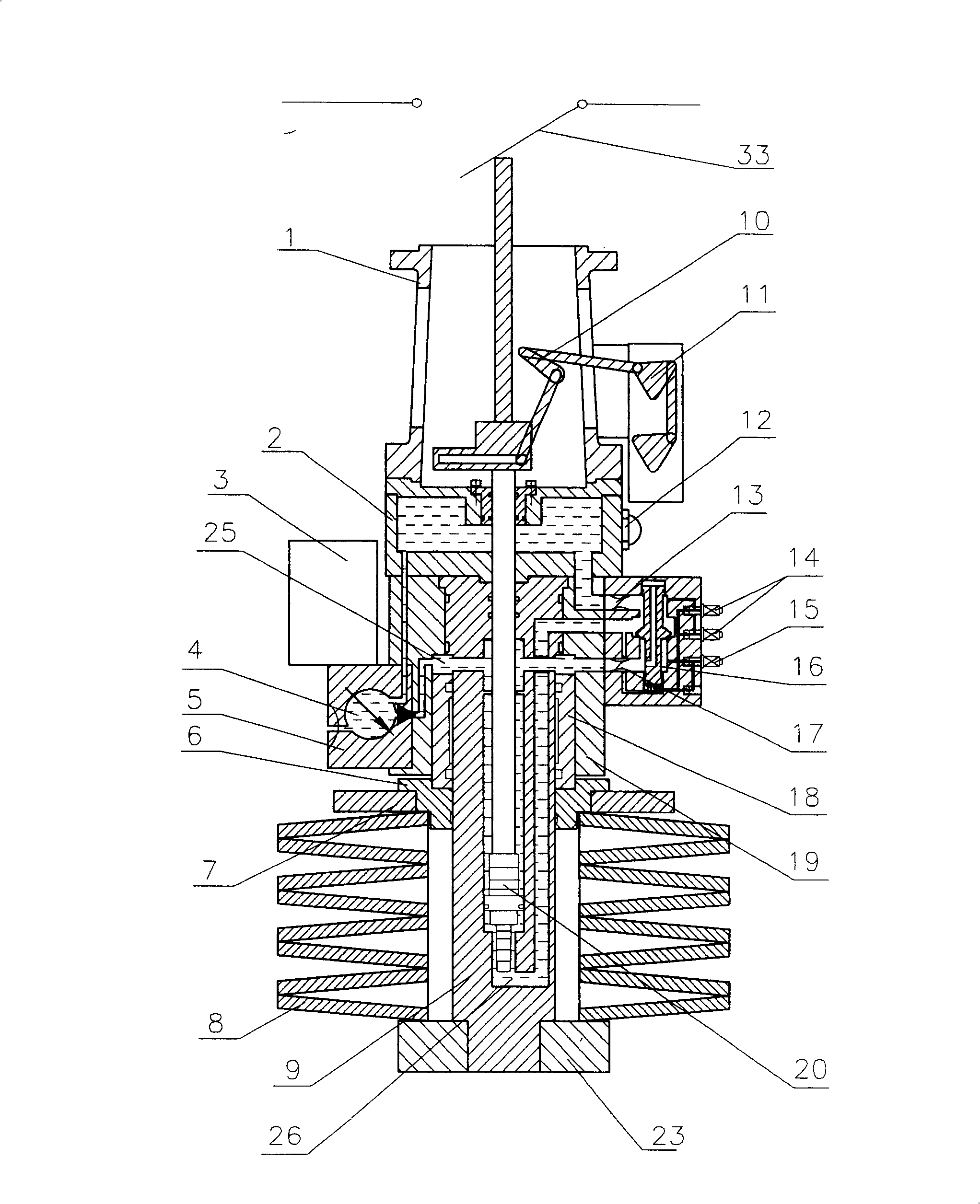

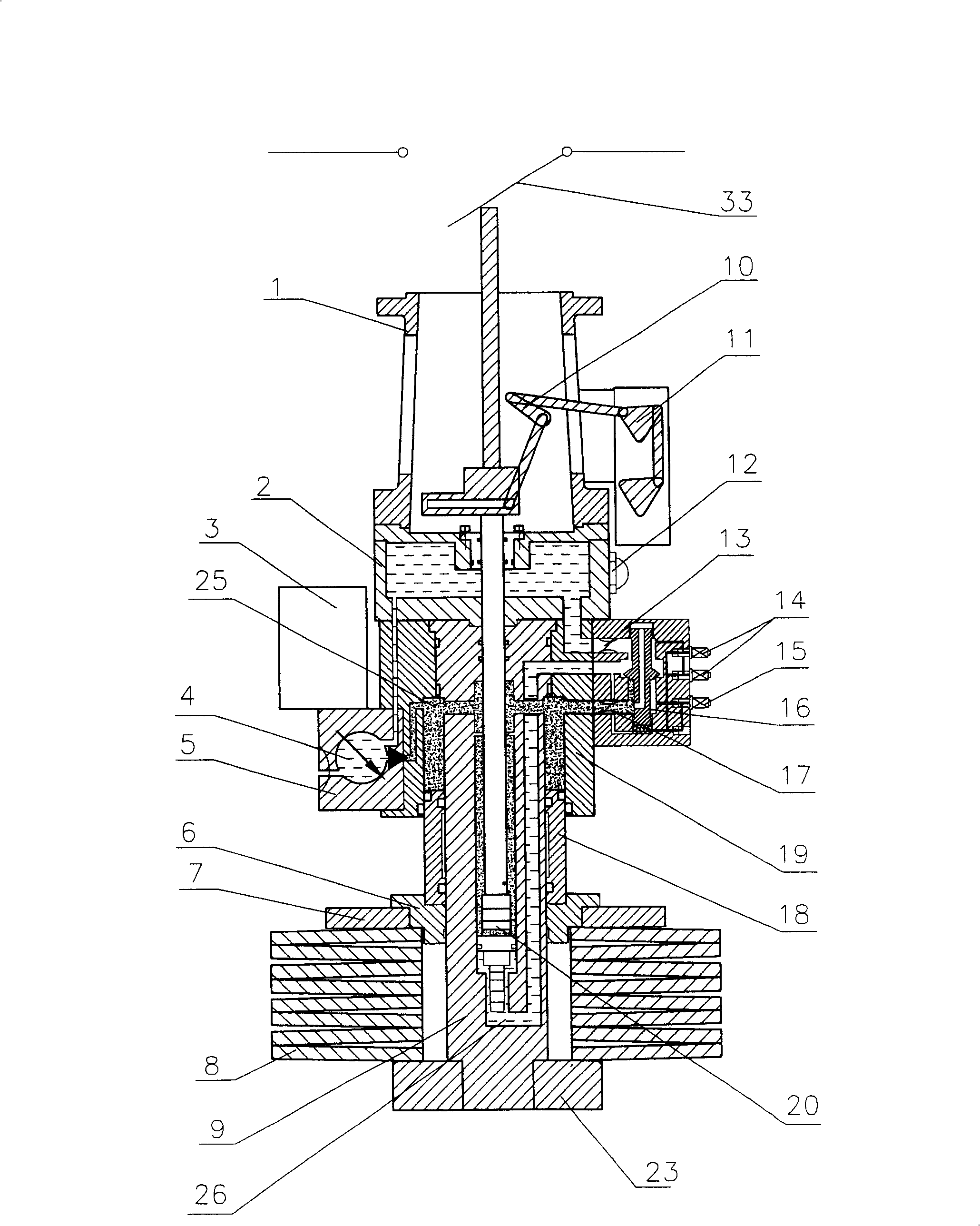

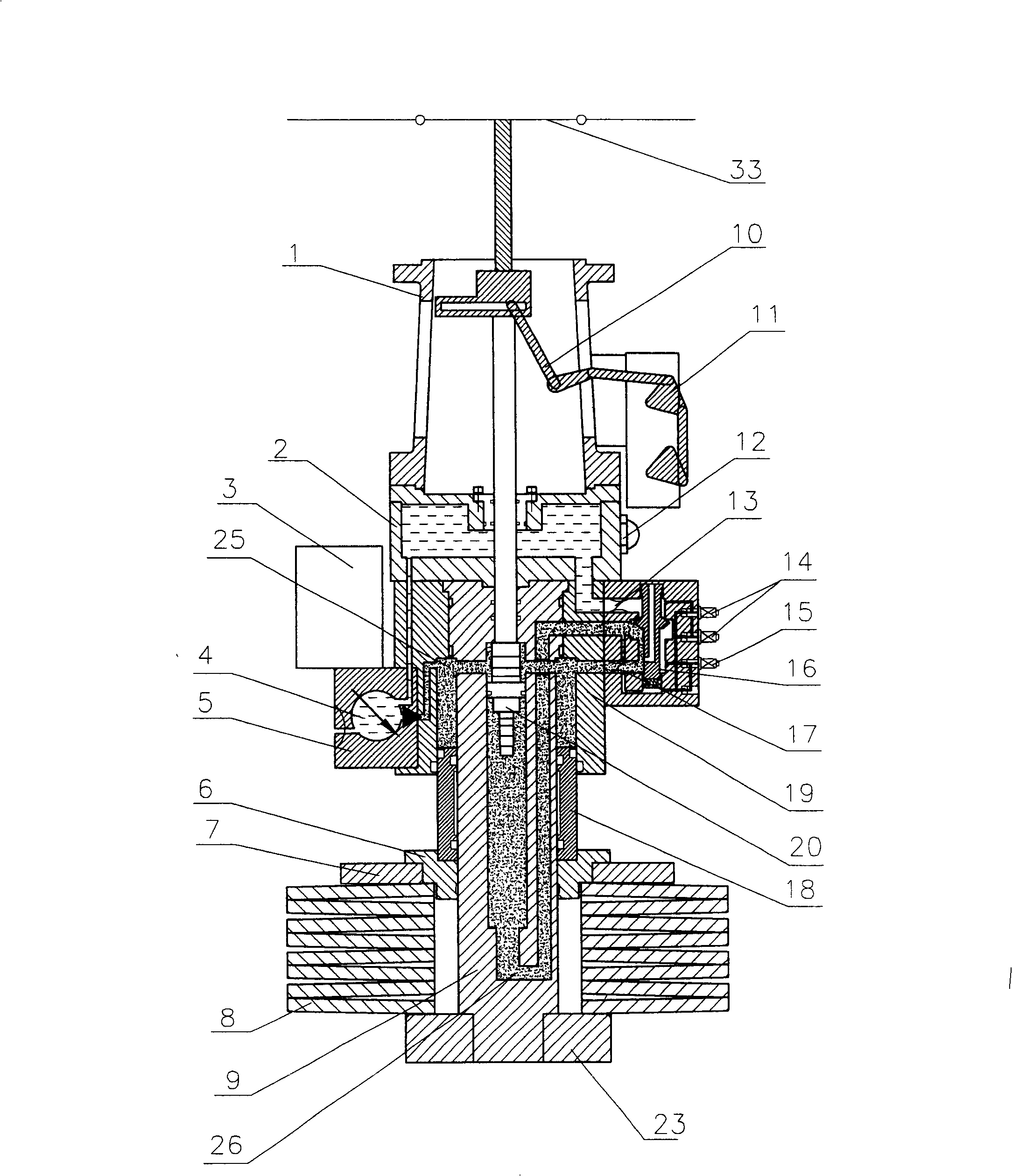

[0023] Embodiment 1: as figure 1 As shown, the mechanism pressure is released and it is in the opening position. The structure of the present invention includes a fuel tank 2, a motor 3, an oil pump 4, a disc reed group 8, a working cylinder 9, an energy storage piston 18, and a cylinder 19. The auxiliary switch 11 is fixed on the bracket 1, and one end of the working cylinder piston 20 passes through the The auxiliary switch connecting rod 10 is connected with the auxiliary switch 11, and the other end is placed inside the working cylinder 9, and the working cylinder 9 is placed in the hole of the cylinder 19. An oil tank 2 is fixed above the body 19 by bolts, an energy storage piston 18 is installed between the working cylinder body 9 and the cylinder body 19, and a pressure plate 6 is installed below the energy storage piston 18 on the working cylinder body 9. The φm end surface of the pressure plate 6 It is in contact with the end surface of the energy storage piston 18, ...

Embodiment 2

[0026] Embodiment 2: structure of the present invention is identical with embodiment 1, as figure 1 As shown, wherein the structure of the working cylinder 9 is as Figure 7 , Figure 8 Shown, the full length L of working cylinder body 9 1 540mm, the distance X between the end surface of the sealing groove I 27 opened between the outer diameter φa and φb near the end of φa and the end surface with the outer diameter of φa 1 30mm, the end with outer diameter φc has an external thread with diameter φg, the length L of external thread φg 3 is 80mm. The structure of cylinder block 19 is as Figure 5 , Image 6 As shown, in the sealing groove II 30 opened on the inner wall with the inner diameter of φc, the distance between the end surface near the end of the inner diameter φc and the end surface of the inner diameter φc is X 4 is 5mm. Energy storage piston 18 is a hollow cylinder, such as Figure 9 , Figure 10 As shown, its full length L 2 is 240mm, the minimum distance...

Embodiment 3

[0027] Embodiment 3: structure of the present invention is identical with embodiment 1, as figure 1 As shown, wherein the structure of the working cylinder 9 is as Figure 7 , Figure 8 Shown, the full length L of working cylinder body 9 1 540mm, the distance X between the end surface of the sealing groove I 27 opened between the outer diameter φa and φb near the end of φa and the end surface with the outer diameter of φa 1 54mm, the end with outer diameter φc has an external thread with diameter φg, the length L of external thread φg 3 100mm. The structure of cylinder block 19 is as Figure 5 , Image 6 As shown, in the sealing groove II 30 opened on the inner wall with the inner diameter of φc, the distance between the end surface near the end of the inner diameter φc and the end surface of the inner diameter φc is X 4 20mm. Energy storage piston 18 is a hollow cylinder, such as Figure 9 , Figure 10 As shown, its full length L 2 is 240mm, the minimum distance X b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com