Patents

Literature

39results about How to "Reduce motor load" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

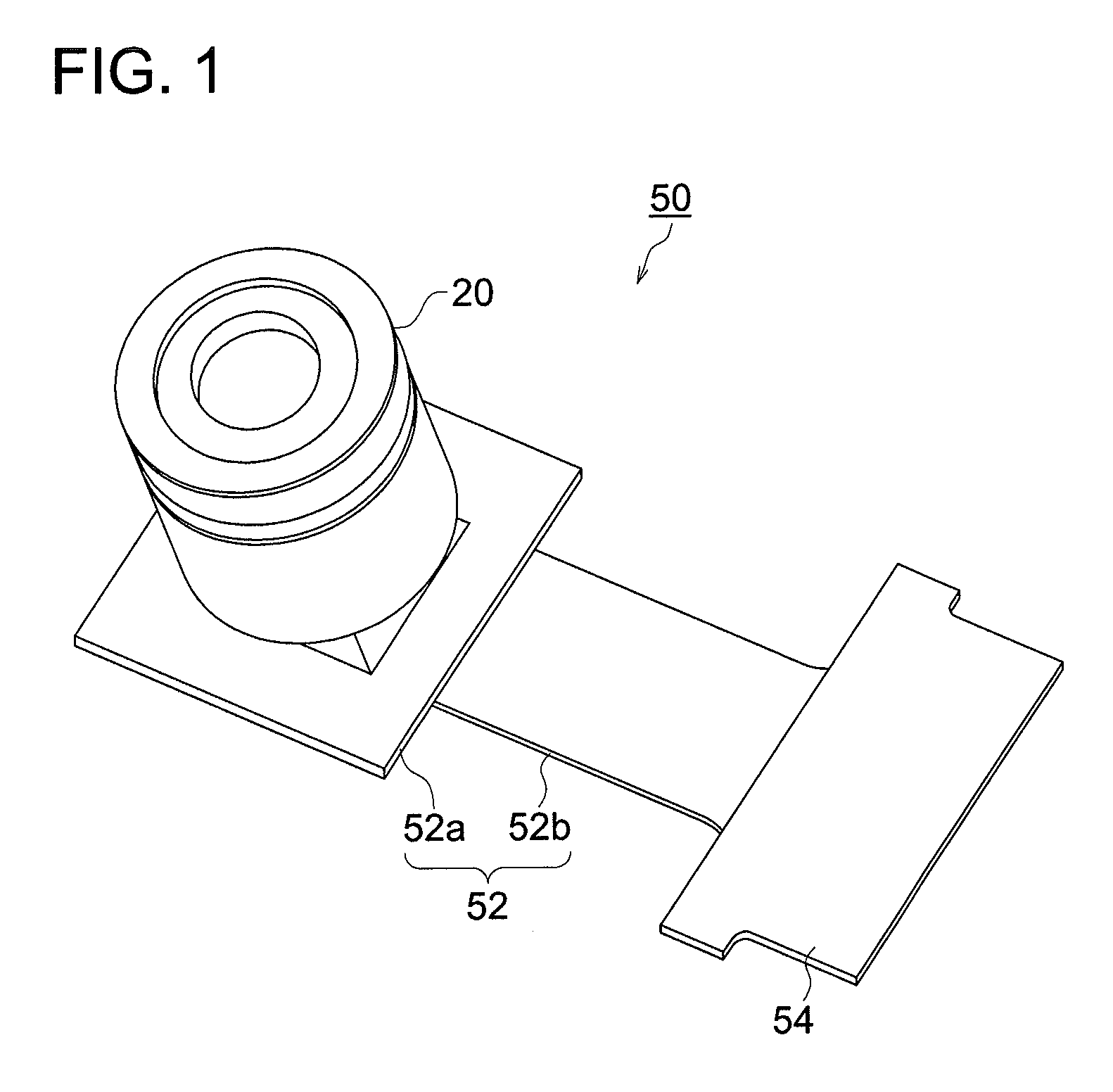

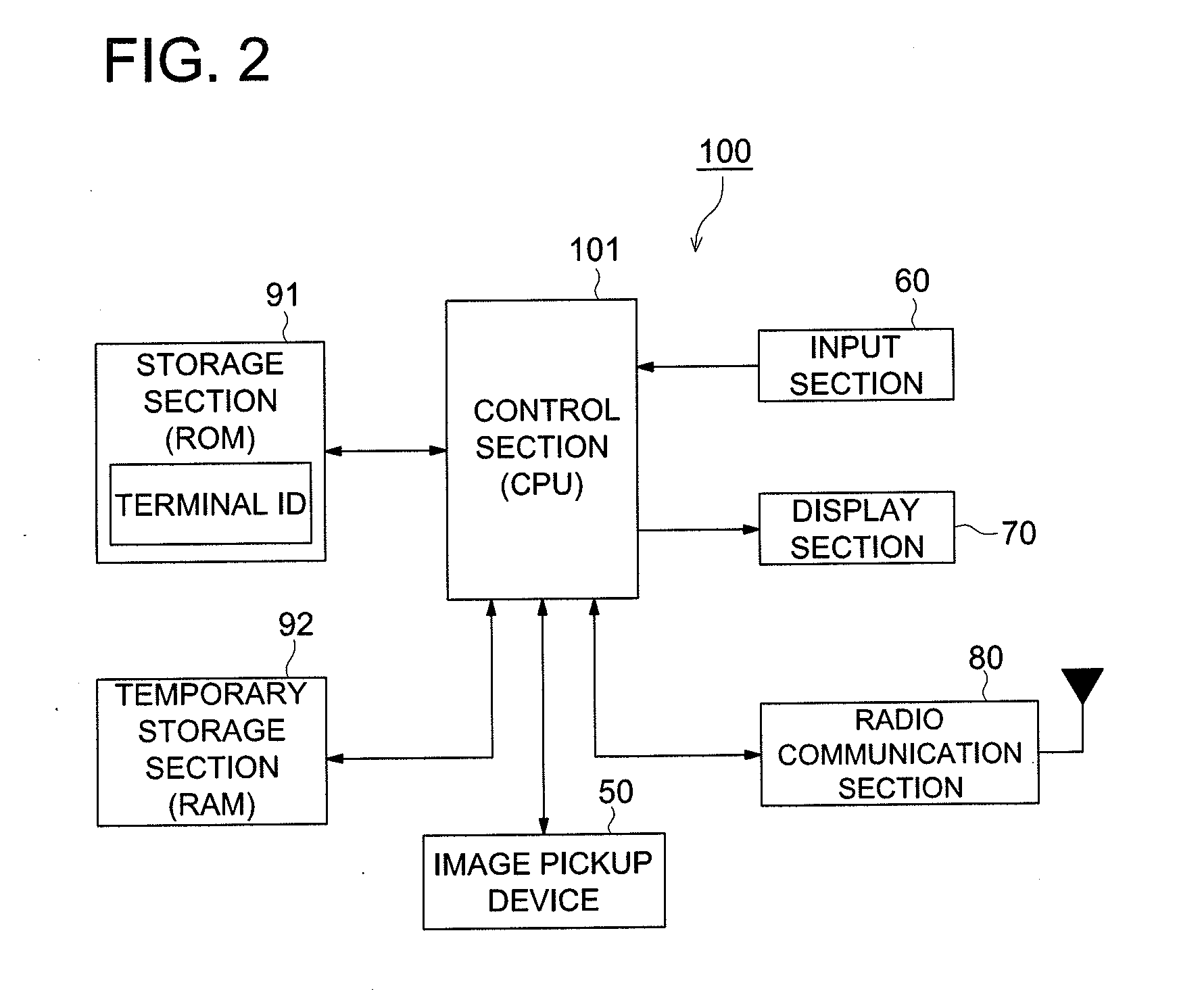

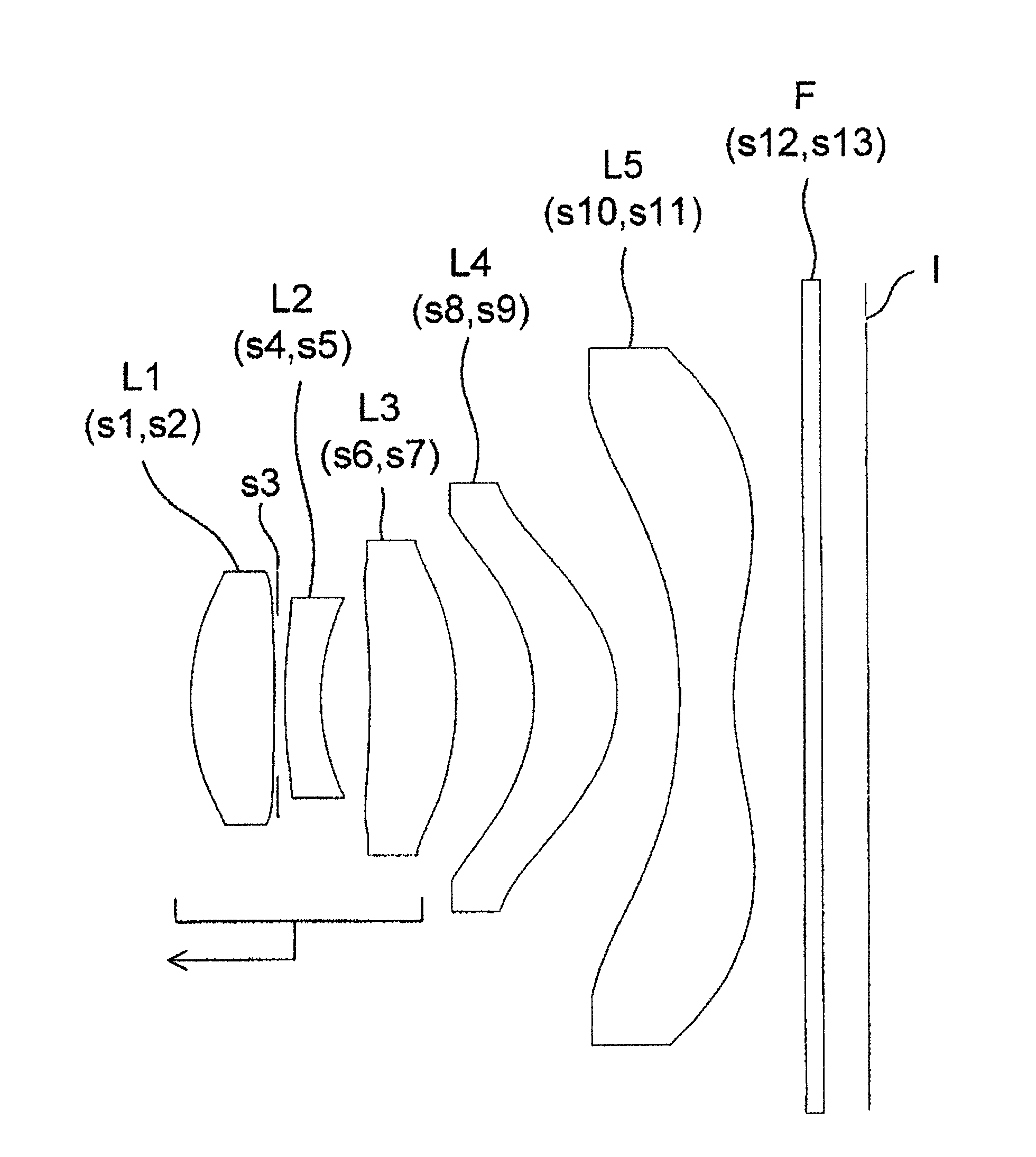

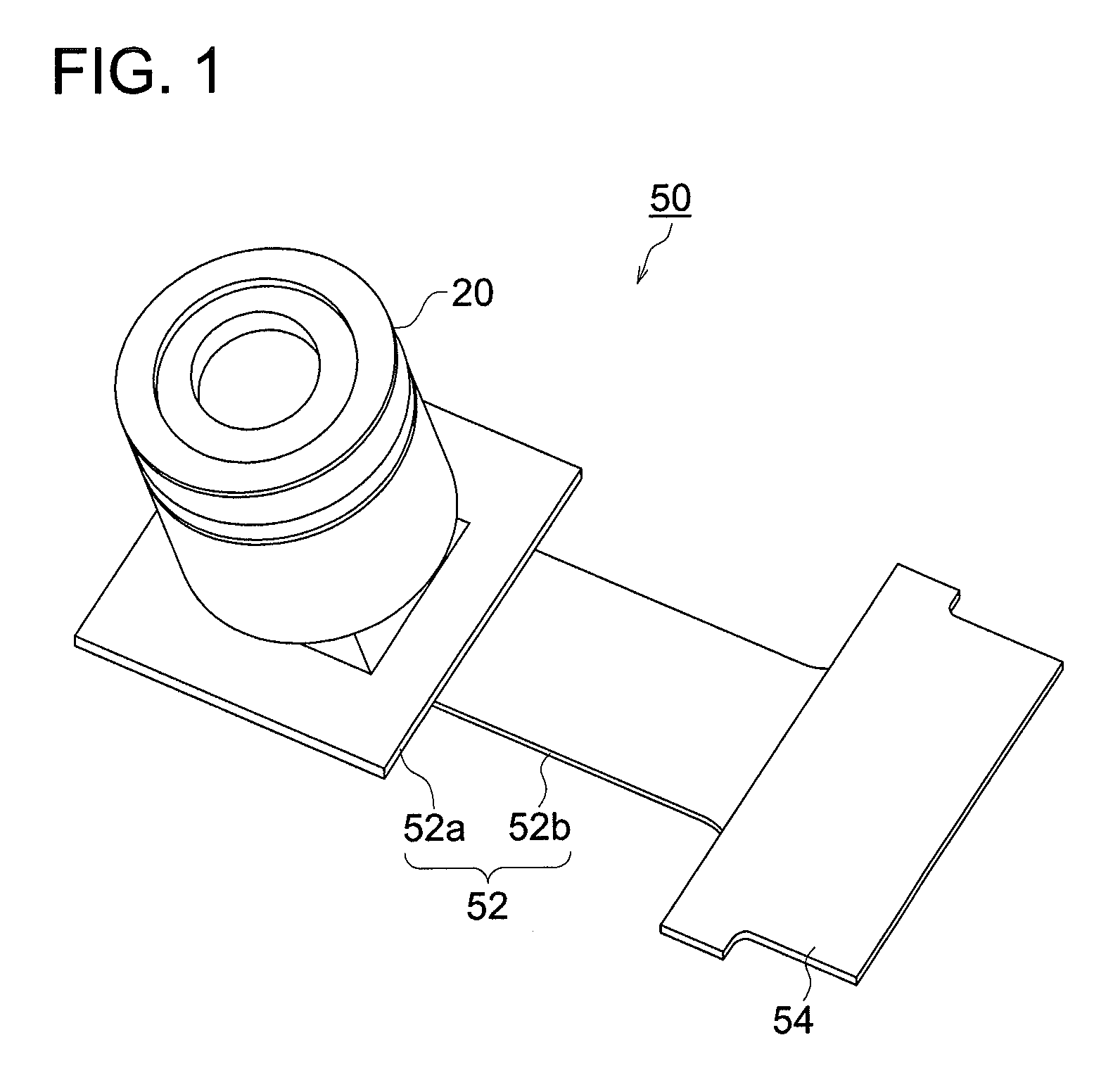

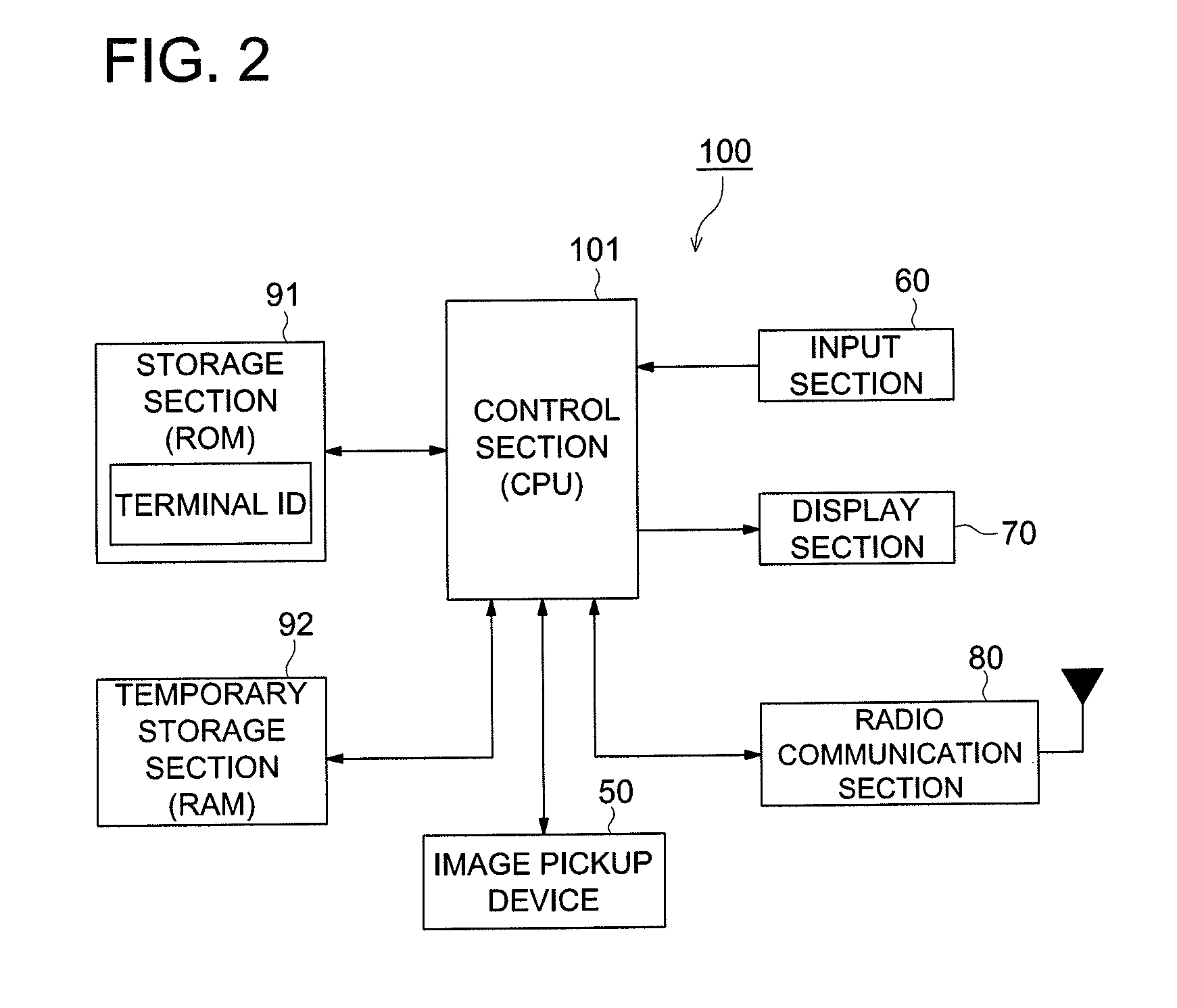

Image Pickup Lens, Image Pickup Device Provided with Image Pickup Lens, and Mobile Terminal Provided with Image Pickup Device

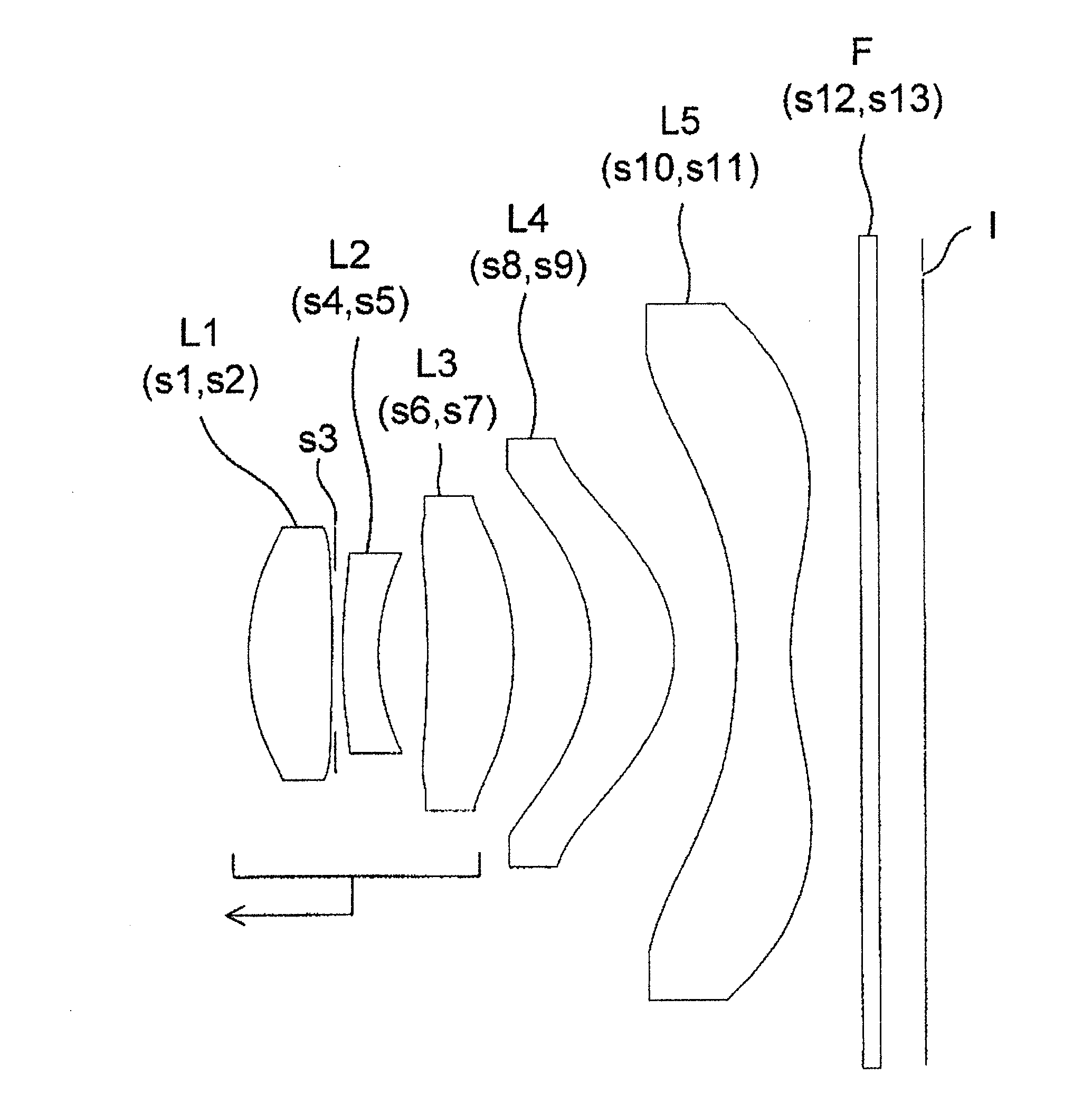

Provided is an image pickup lens that forms an image on an image pickup element with light from a subject. In the image pickup lens, a lens that is disposed on an image pickup element side is fixed in position, and a focusing lens group having a plurality of lenses including a lens closest to the subject is moved in an optical axis direction, thereby performing focusing.

Owner:KONICA MINOLTA OPTO

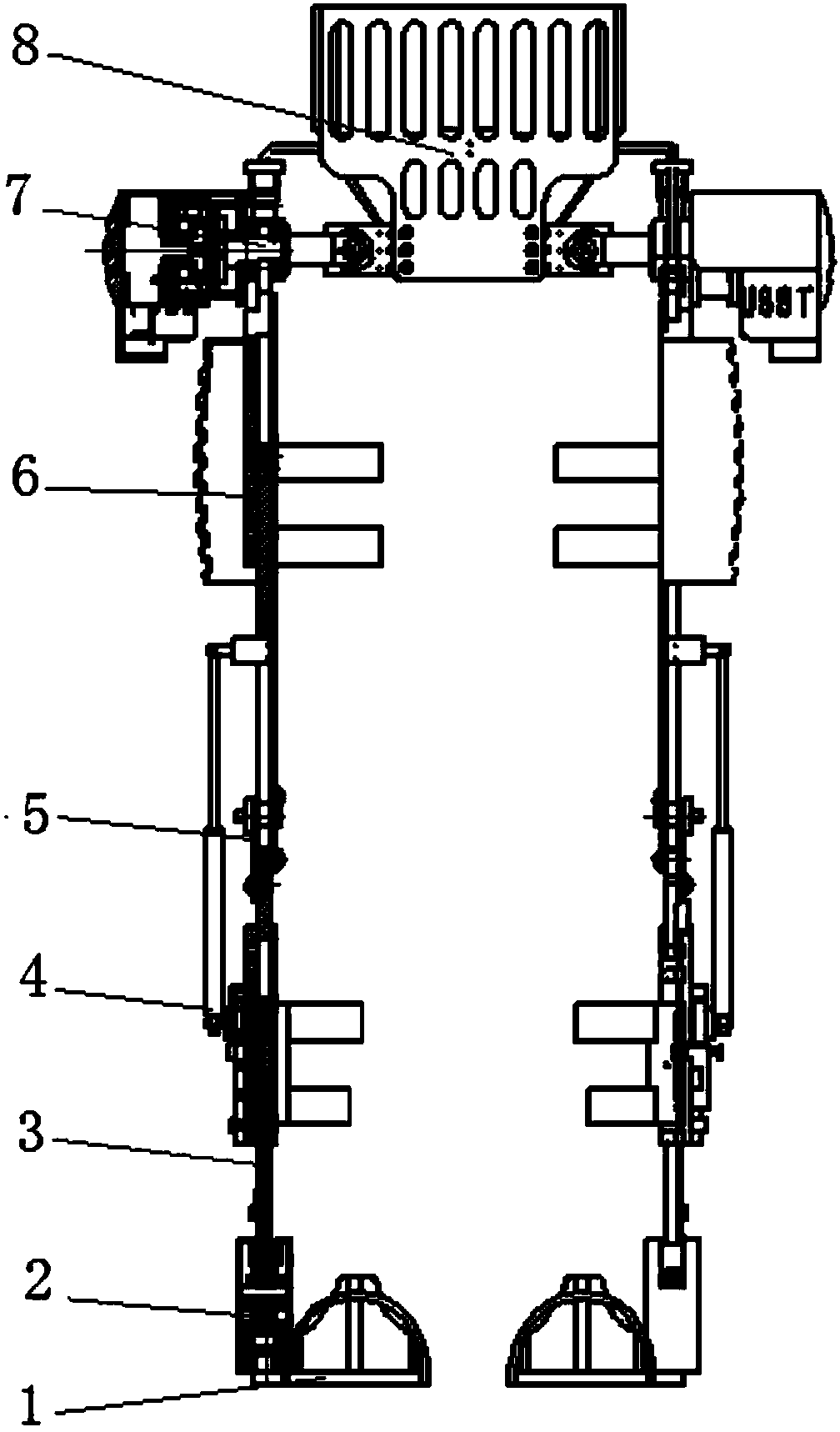

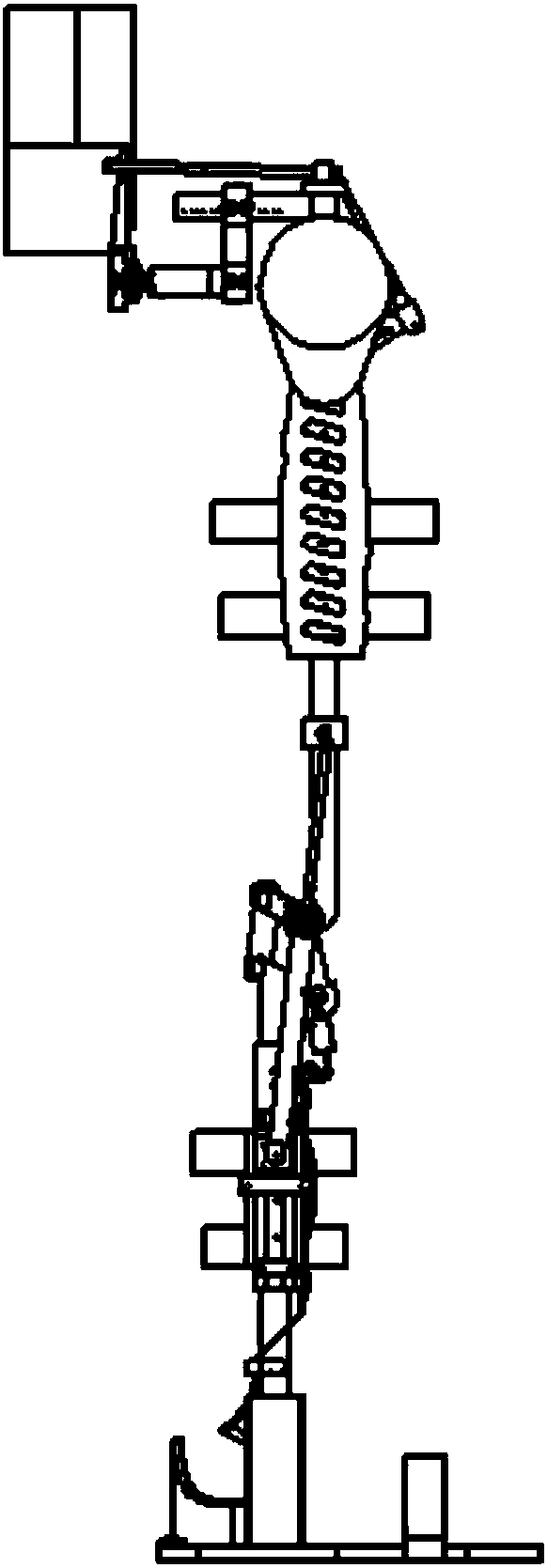

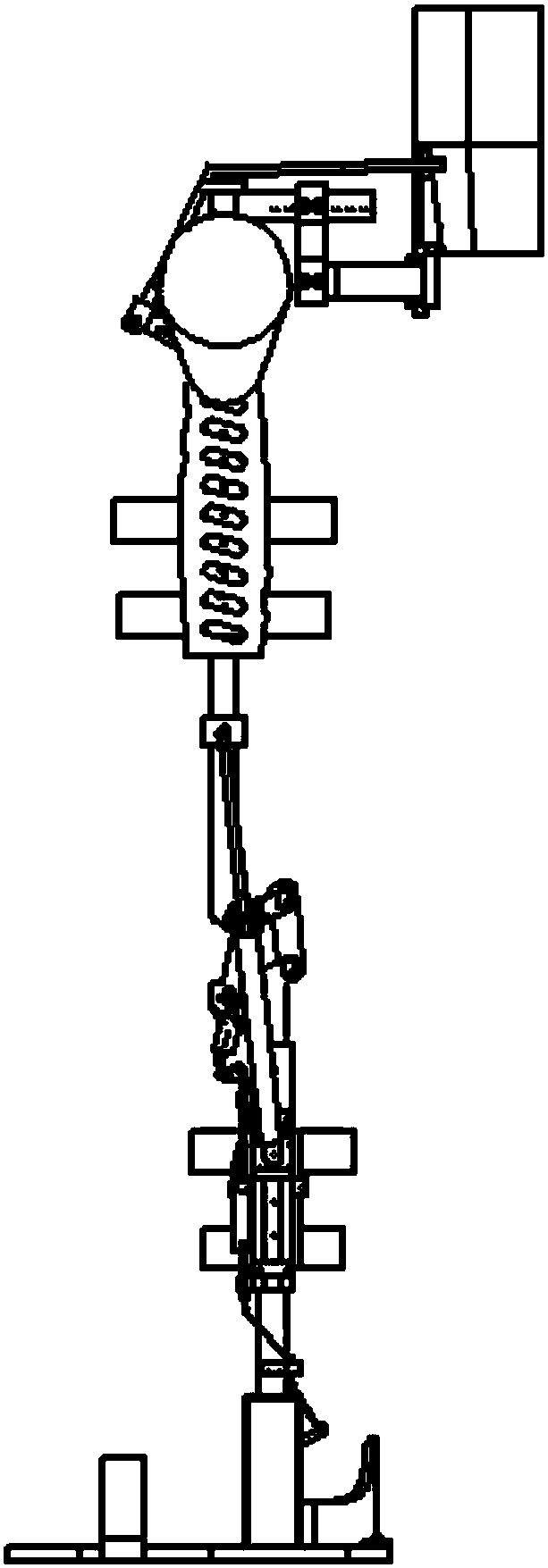

Wearable lower limb exoskeleton rehabilitation robot

ActiveCN107811805AReduce weightReduce motor loadChiropractic devicesWalking aidsExoskeletonLinkage concept

The invention relates to a wearable lower limb exoskeleton rehabilitation robot. A hip joint component comprises a motor, a harmonic reducer and an output shaft, wherein the motor is connected with the output shaft by virtue of the harmonic reducer, the output shaft is connected with thigh components by virtue of keys, and motor torque is transmitted. The two thigh components are connected together by virtue of a mooring rope passing through a back component, and gravity center shift in a walking process is utilized for helping bulking and extension of each hip joint. The bulking and extensionof each hip joint are driven by adopting the motor and are helped by adopting the mooring rope, and the structure not only reduces weight of an exoskeleton but also converts potential energy of the gravity center shift in the walking process of a human body into kinetic energy of thighs swinging forward, so that energy loss is effectively reduced, and power consumption of the motor is reduced. Each knee joint is designed to be a four-bar mechanism, the stability of a standing phase and the flexibility of a swinging phase are guaranteed. A knee-ankle linkage mode enables a wearer to naturallybuckle the knee joints when swinging and automatically lock the knee joints when standing. A gas spring mechanism is adopted for providing help for conversion of sitting and standing postures.

Owner:上海理工资产经营有限公司

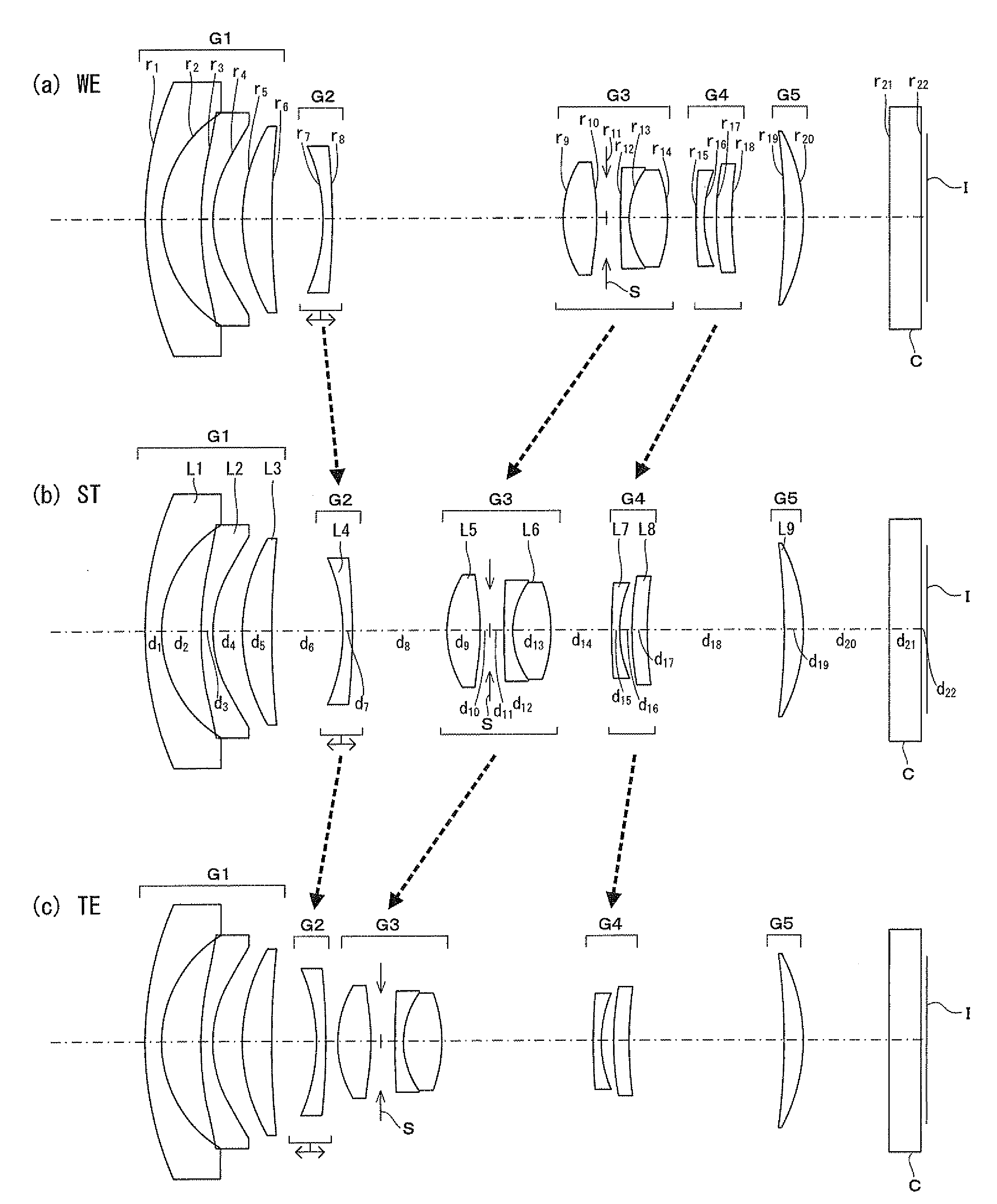

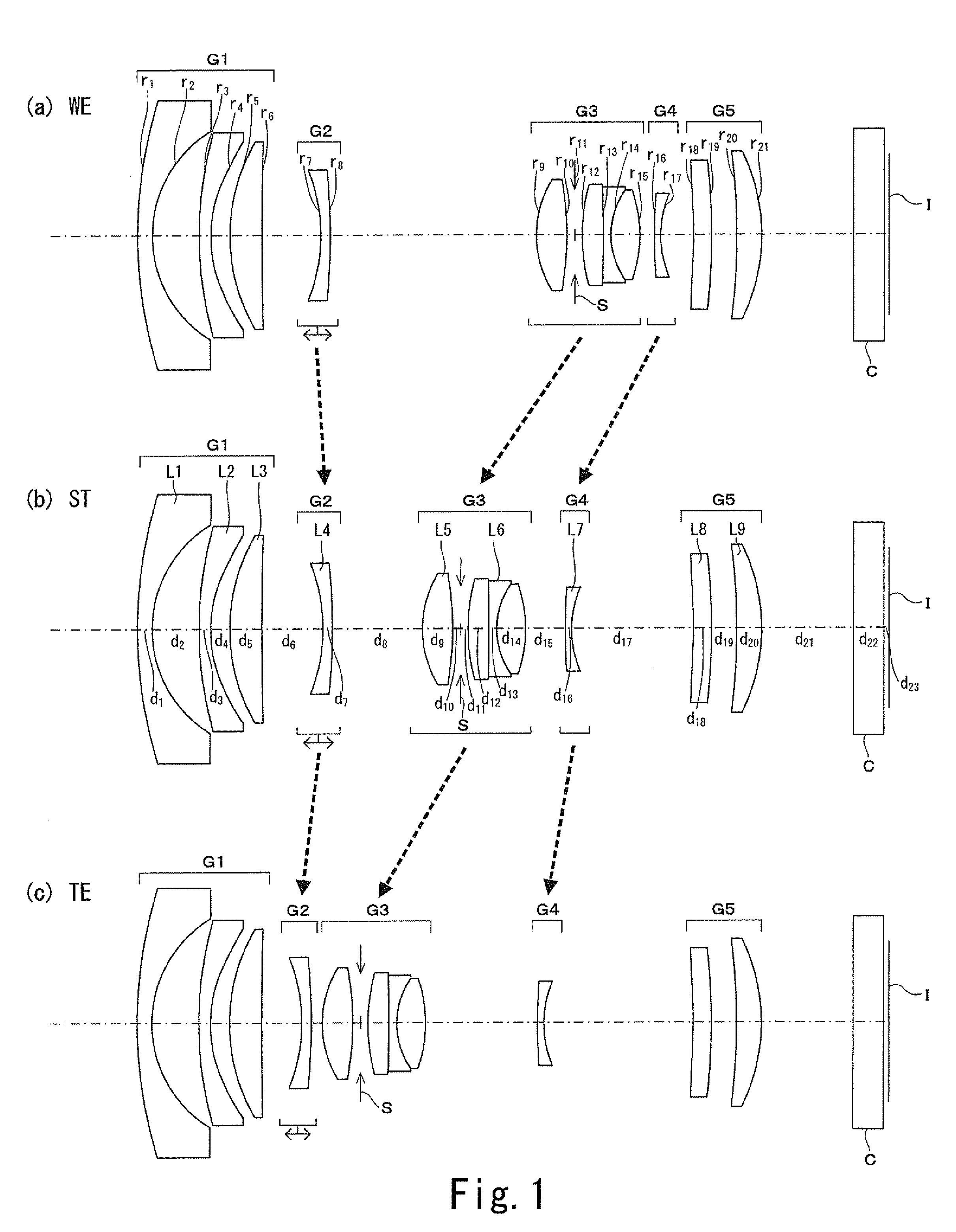

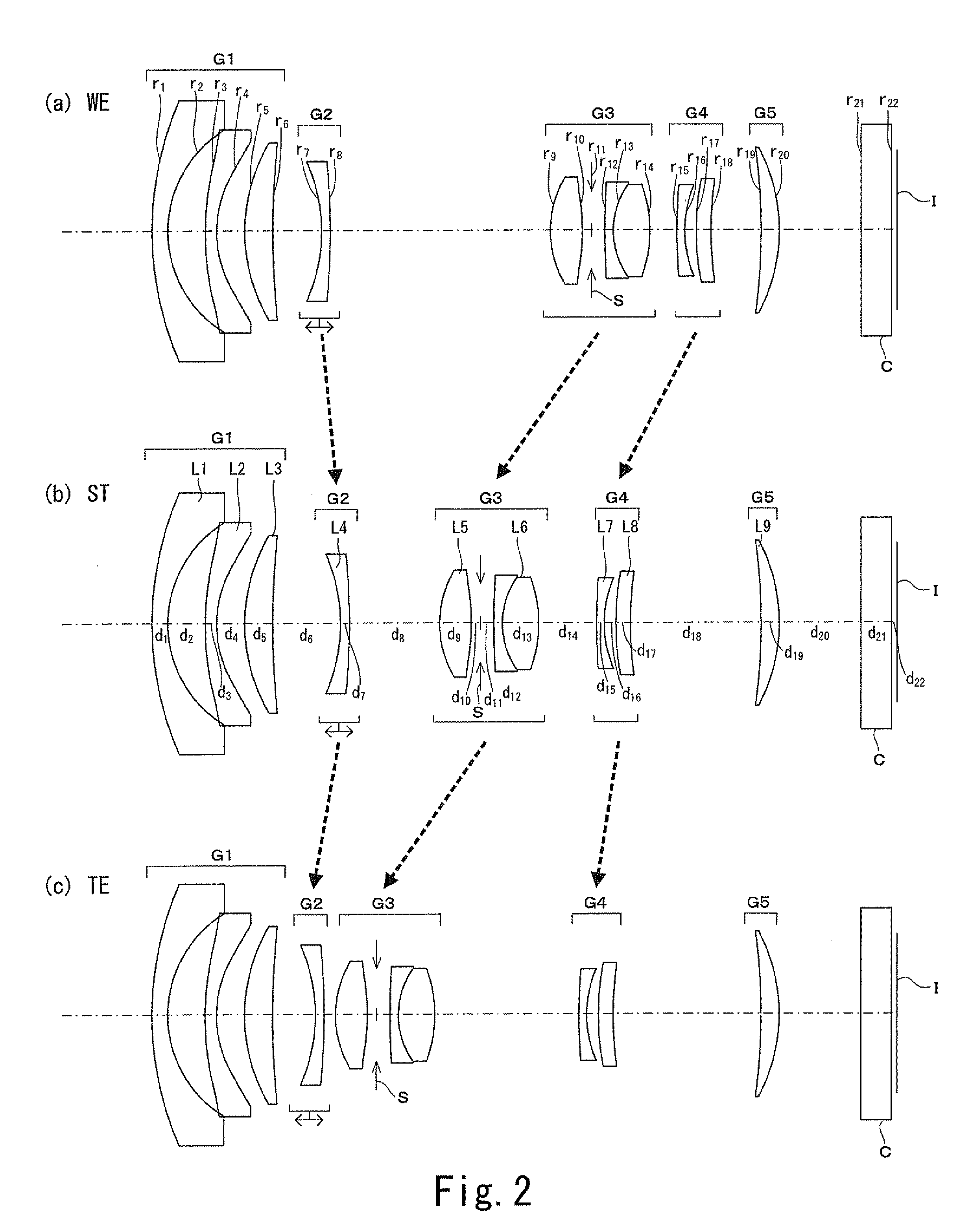

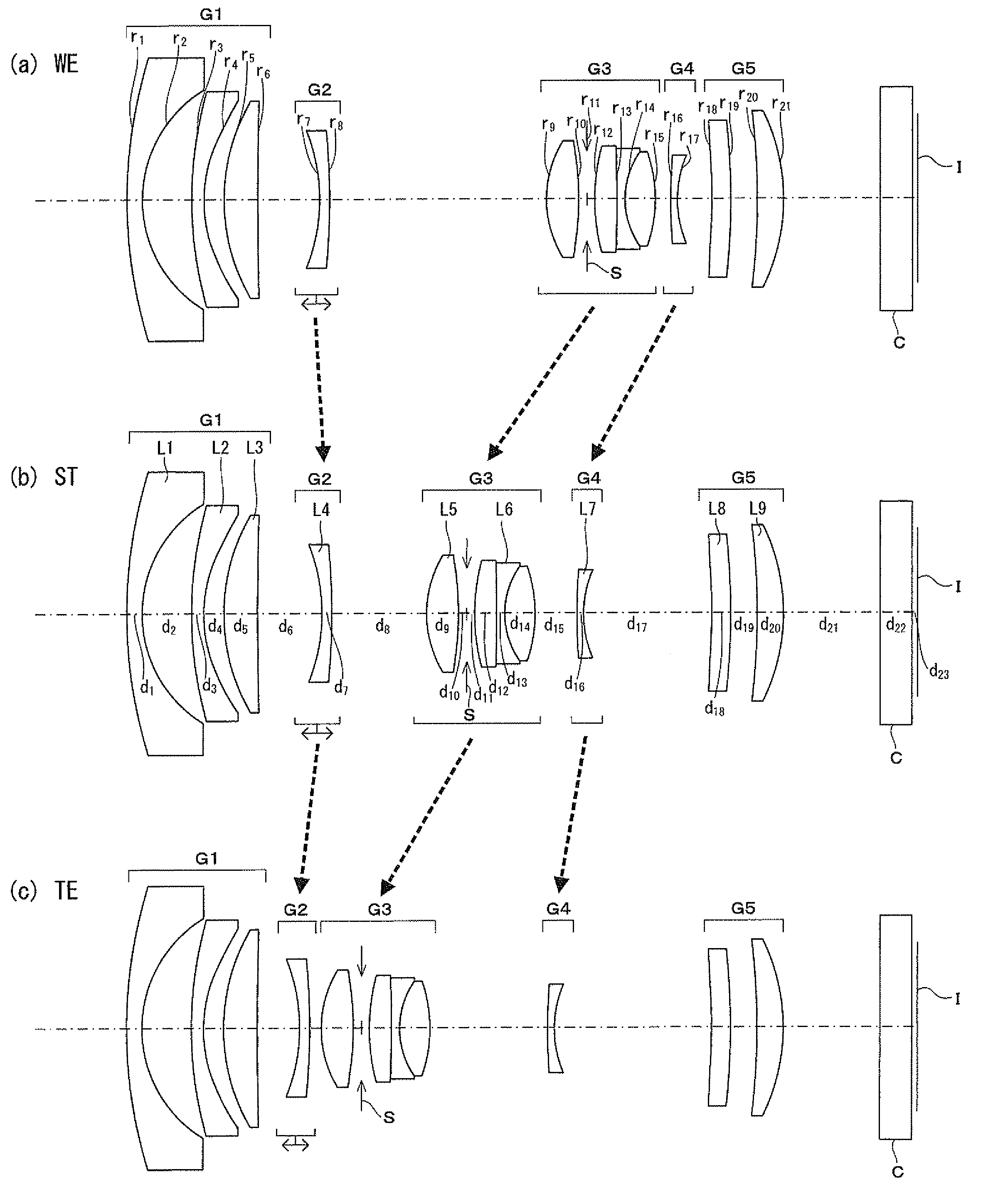

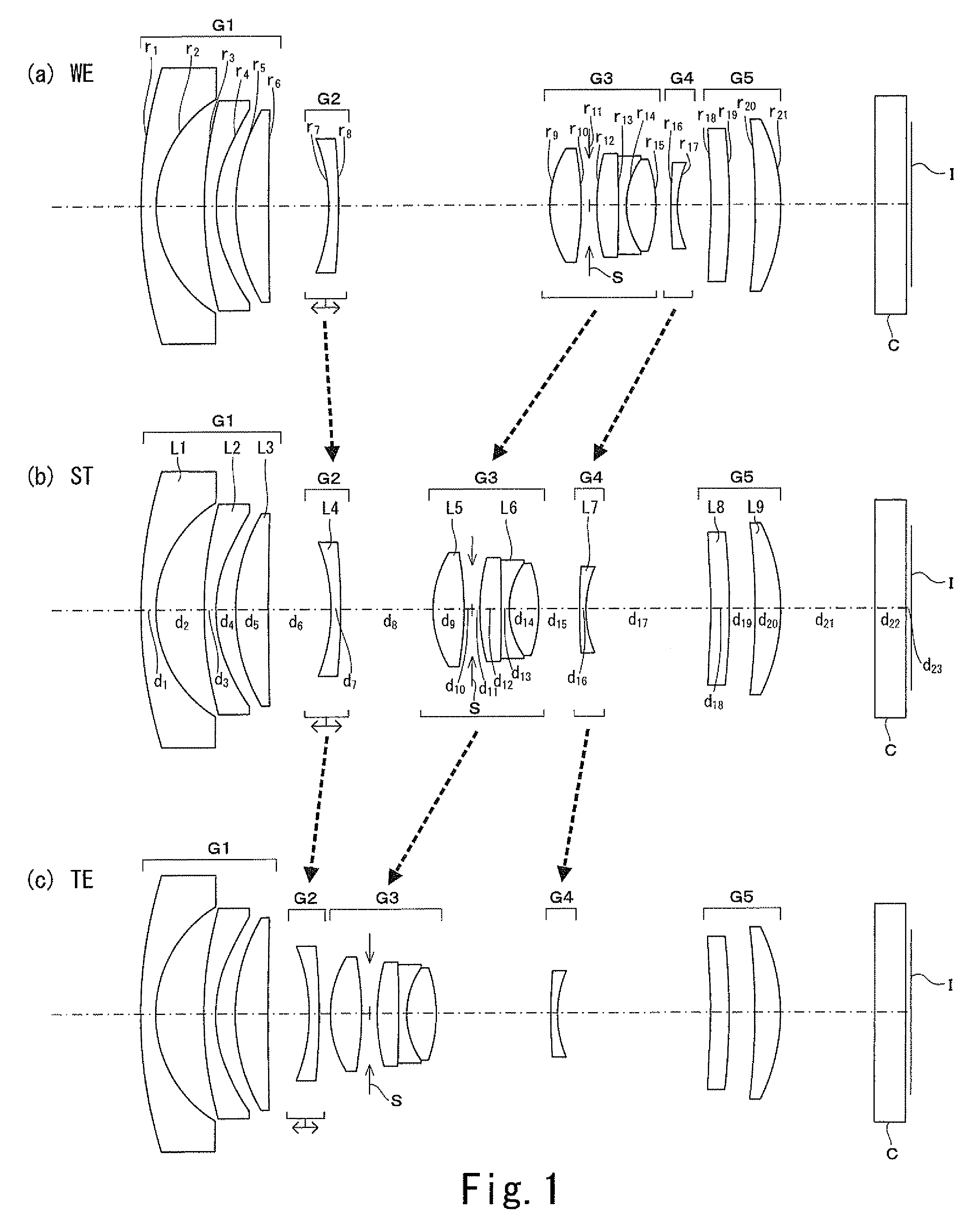

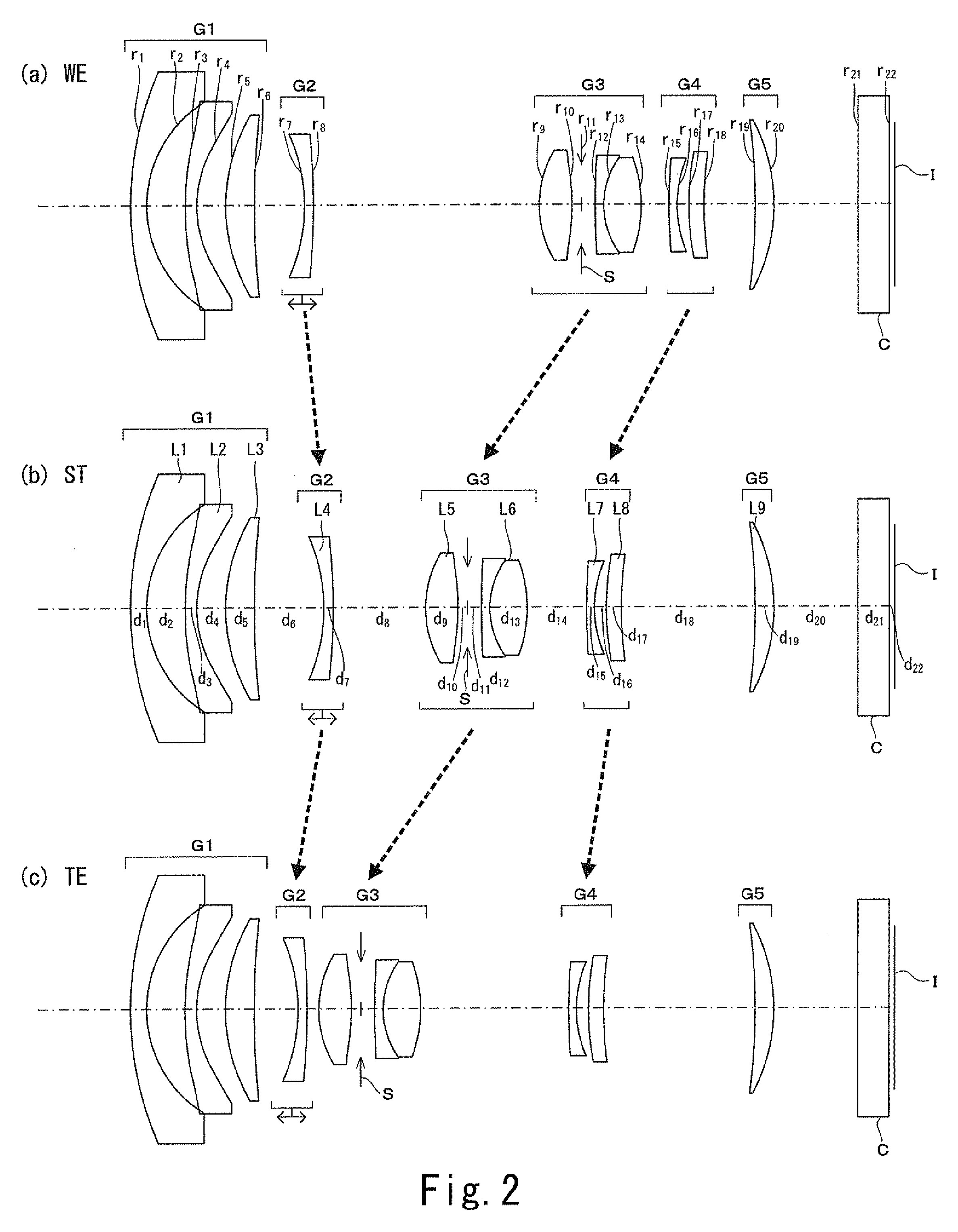

Zoom lens

In a zoom lens of a fixed total length, at the time of changing the magnification from the wide-angle end toward the telephoto end, the first lens group is anchored while the second lens group is moved, and the third and fourth lens groups are moved so as to be located at the object side of the telephoto end relative to the wide-angle end, such that: the interval between the second and third lens groups is decreased at the telephoto end relative to the wide-angle end; the interval between the third and fourth lens groups is increased at the telephoto end relative to the wide-angle end; and the interval between the fourth and fifth lens groups is increased at the telephoto end relative to the wide-angle end, and at the time of focusing a near object point from a remote object point, the second lens group is moved.

Owner:OM DIGITAL SOLUTIONS CORP

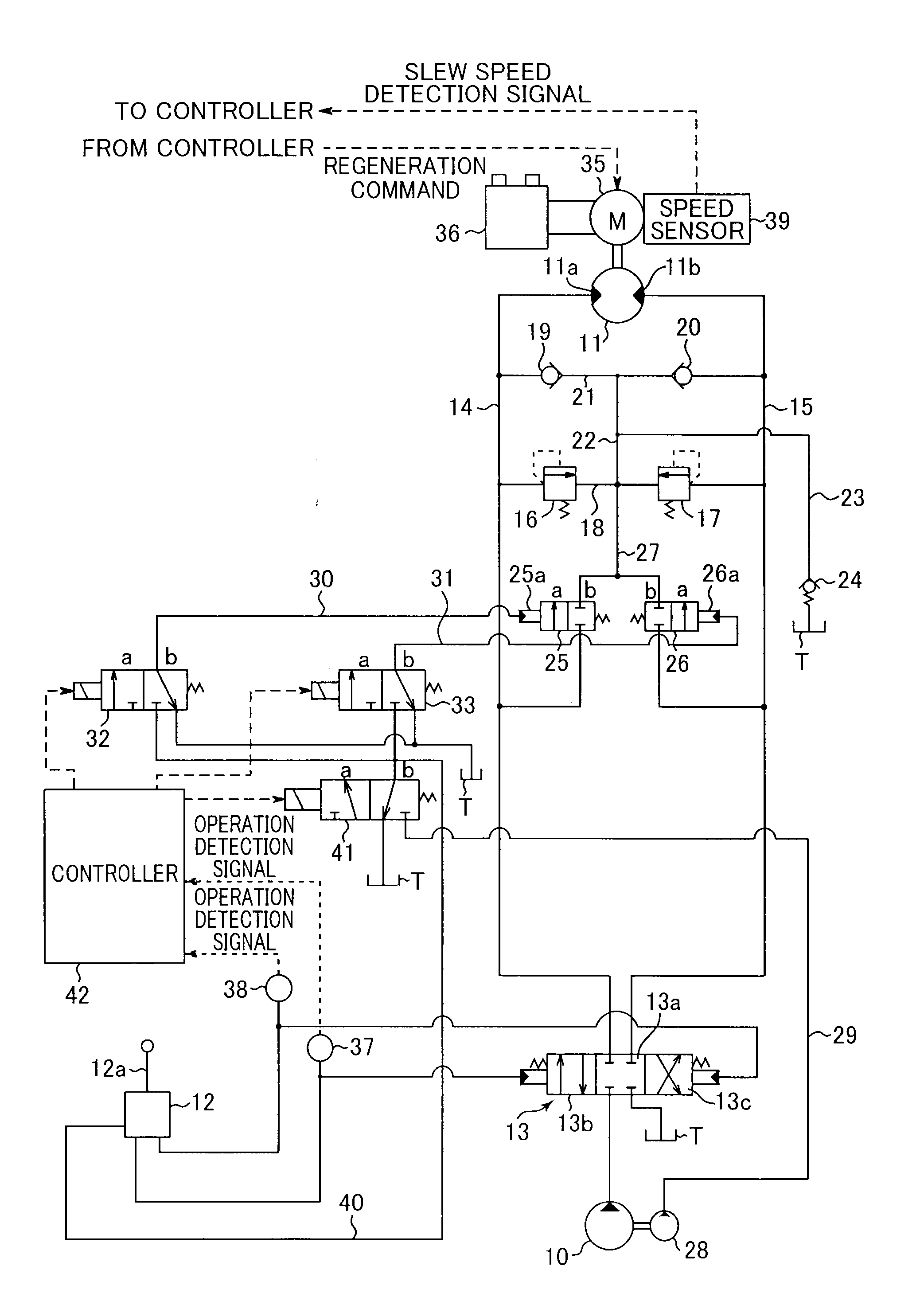

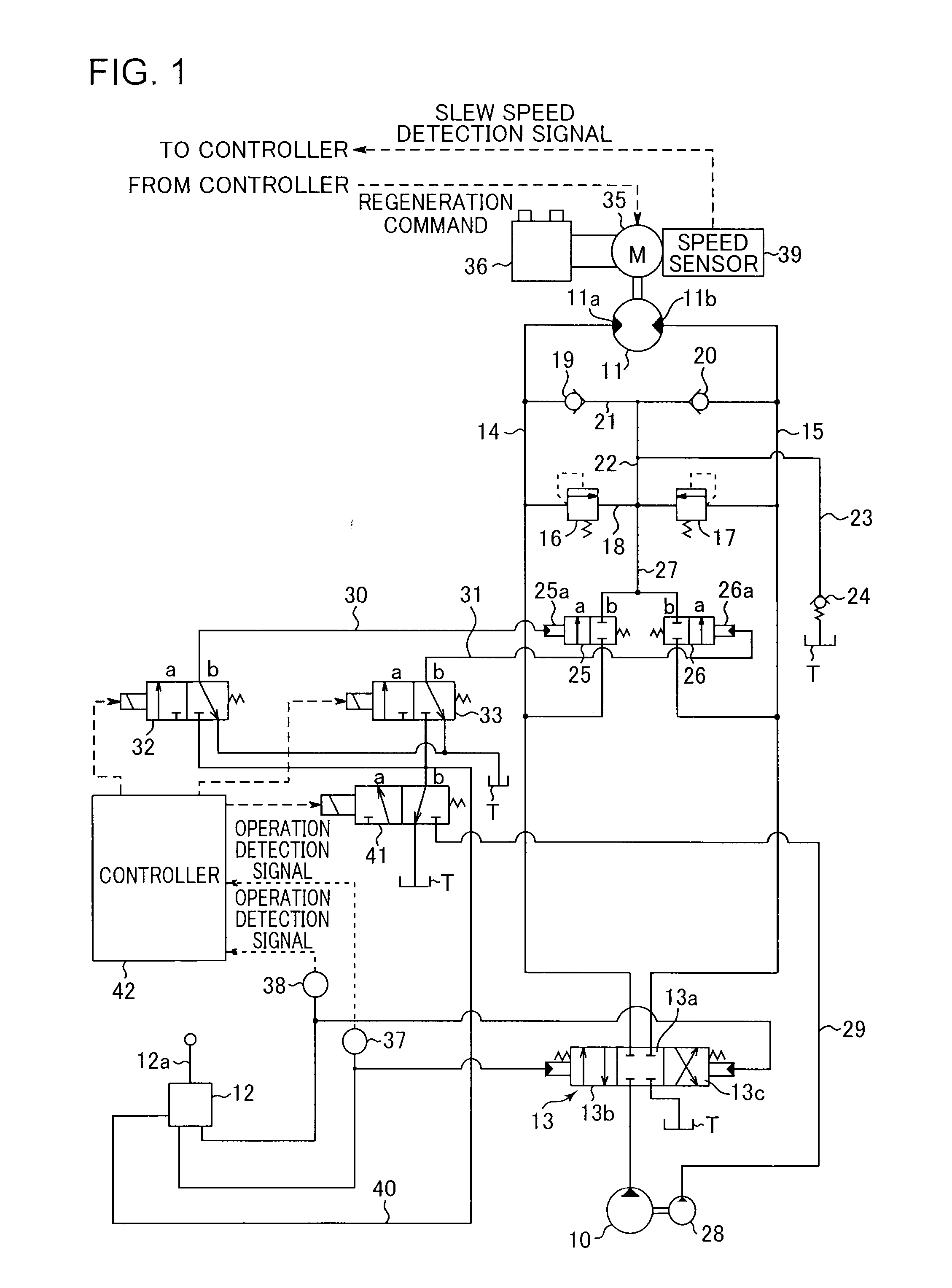

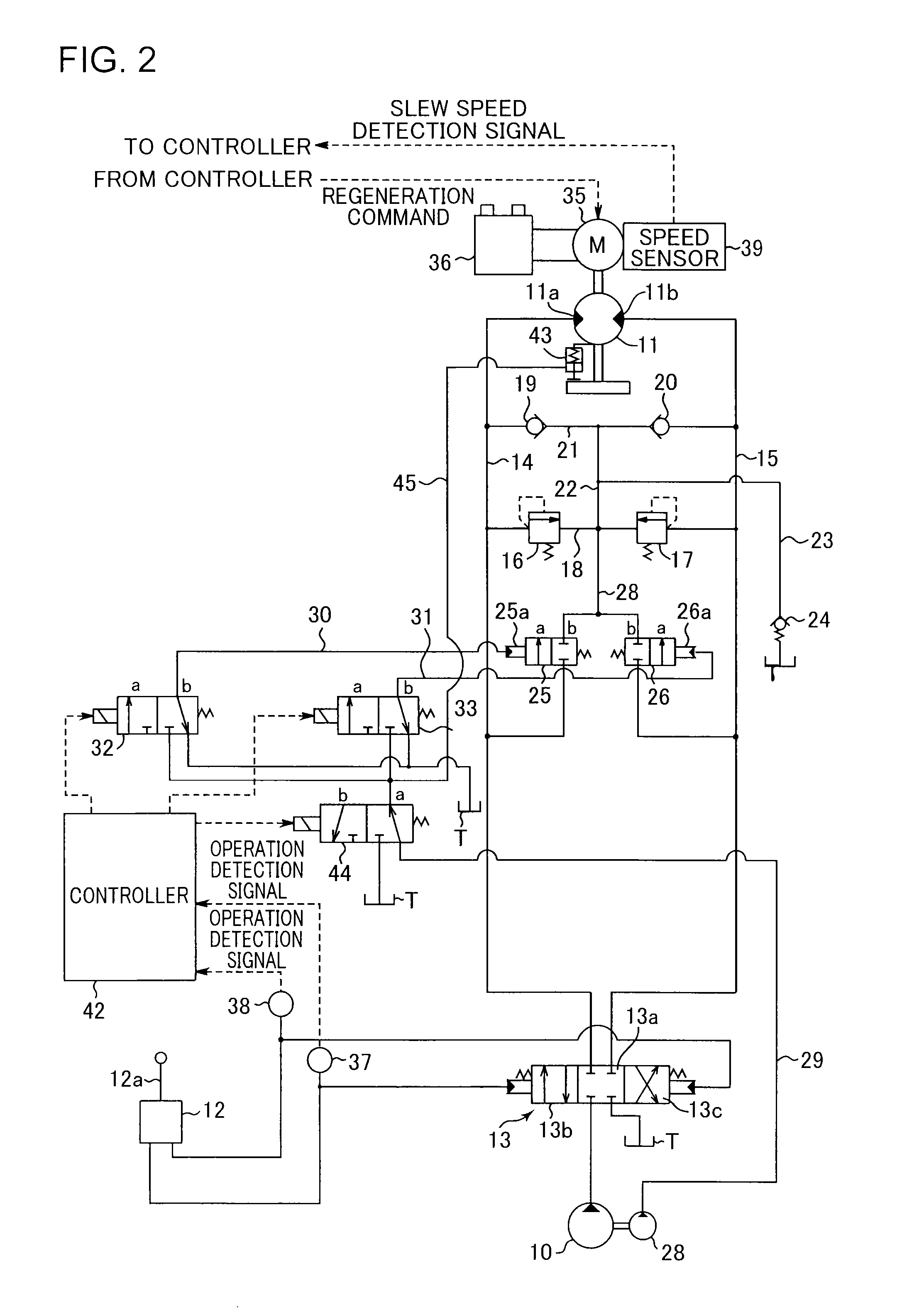

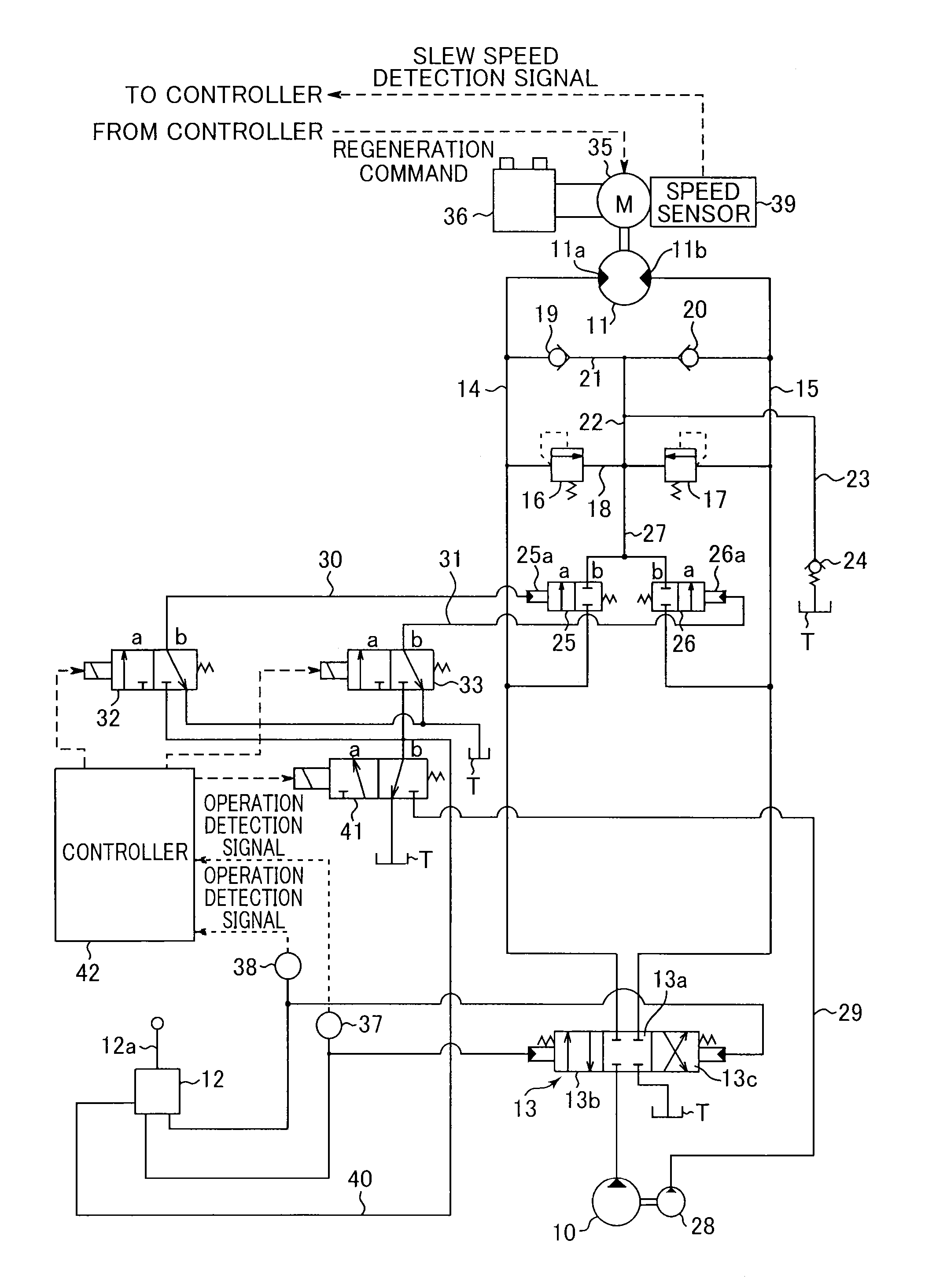

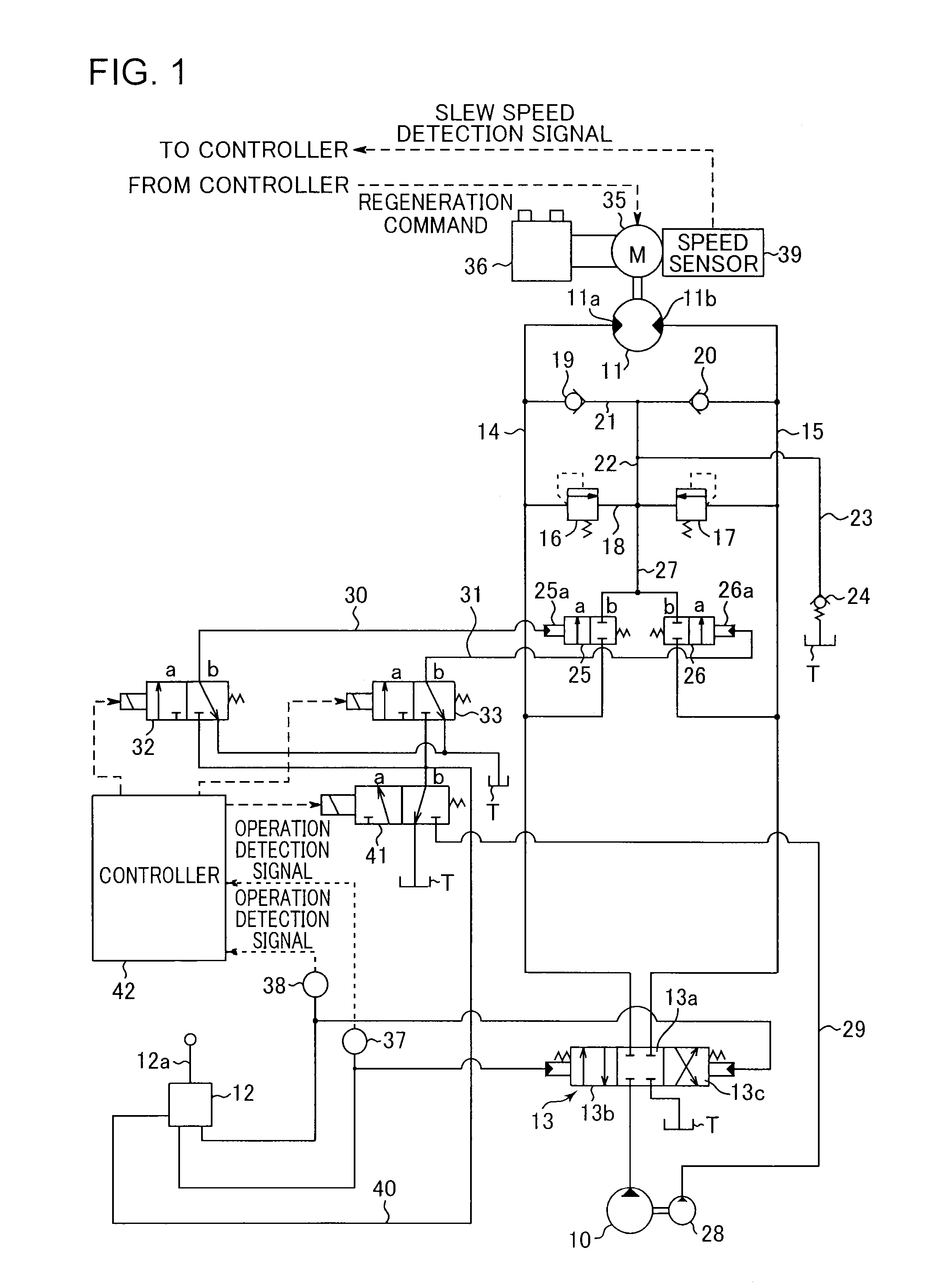

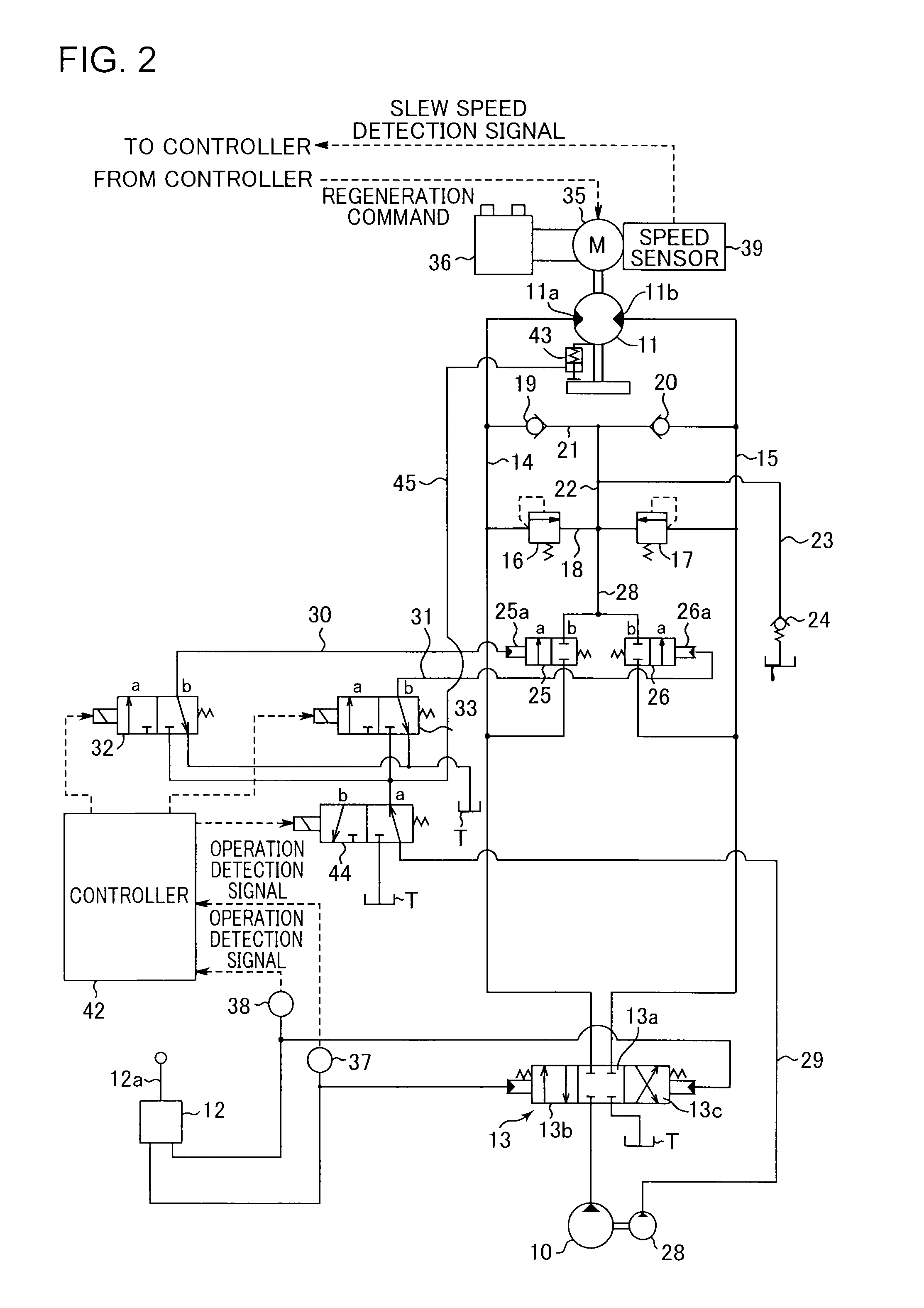

Slewing type working machine

InactiveUS20140007565A1Energy recovery efficiency can be enhancedReduce motor loadFluid couplingsServomotorsHydraulic motorHydraulic pump

A slewing-type working machine, including a base, an upper slewing body, a hydraulic motor slewing the upper slewing body, a hydraulic pump, a slewing operation device, a control valve controlling the hydraulic motor, pipe-lines connecting the hydraulic motor to the control valve, a hydraulic pressure source, communication valves switching communication and cutoff between the pipe-lines and a tank by pilot pressure, an electric motor, an electric storage device, communication selector valves on inlet sides of the communication valves, a switching control valve on an inlet side of the communication selector valves, and a controller. During slewing deceleration, the controller signals to switch the switching control valve to a connecting position and switch the communication selector valves to a pilot pressure supply position. In a slewing stopped state, the controller signals to switch the communication selector valves to a cutoff position and switch the communication valves to a communication cutoff position.

Owner:KOBELCO CONSTR MASCH CO LTD

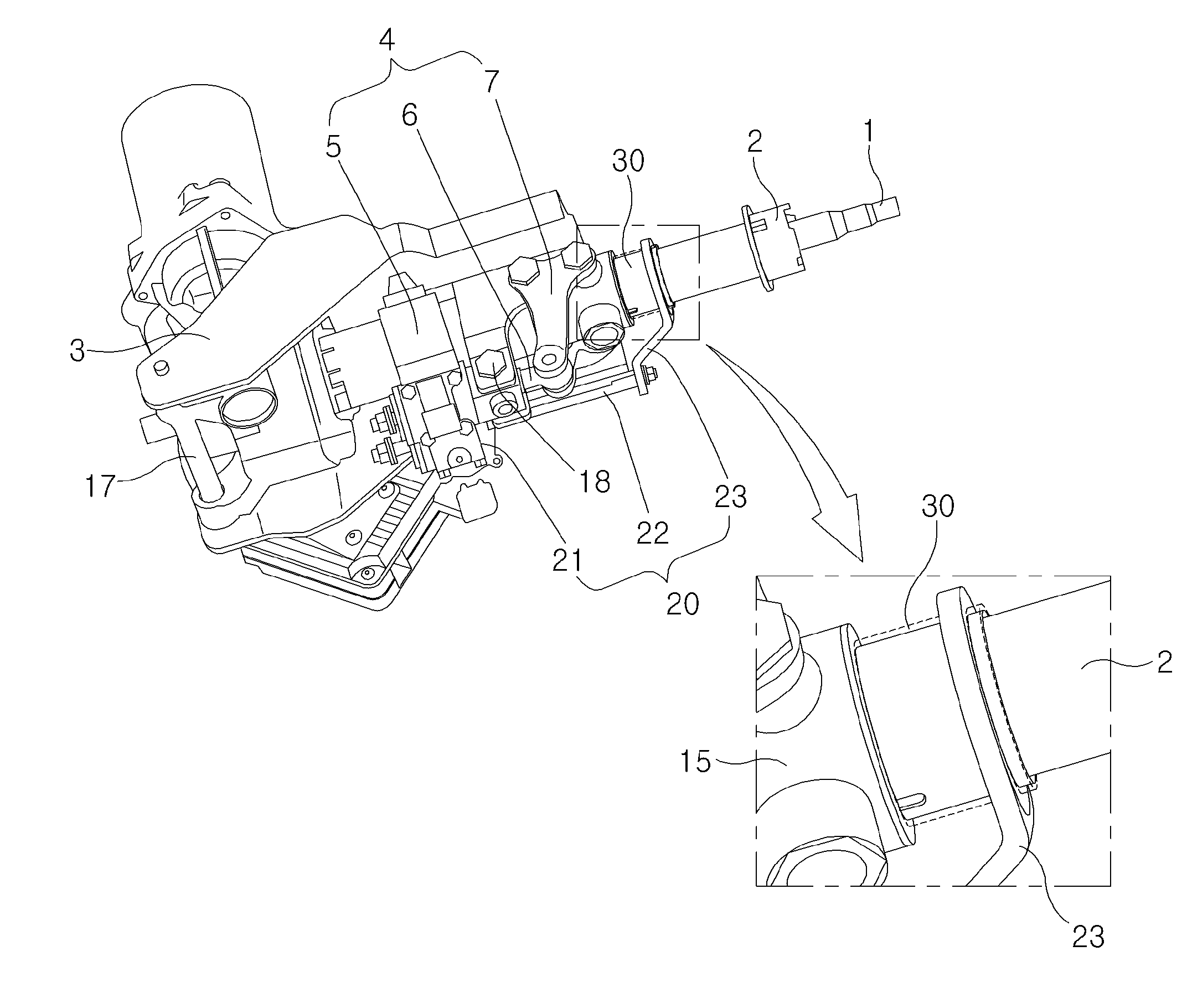

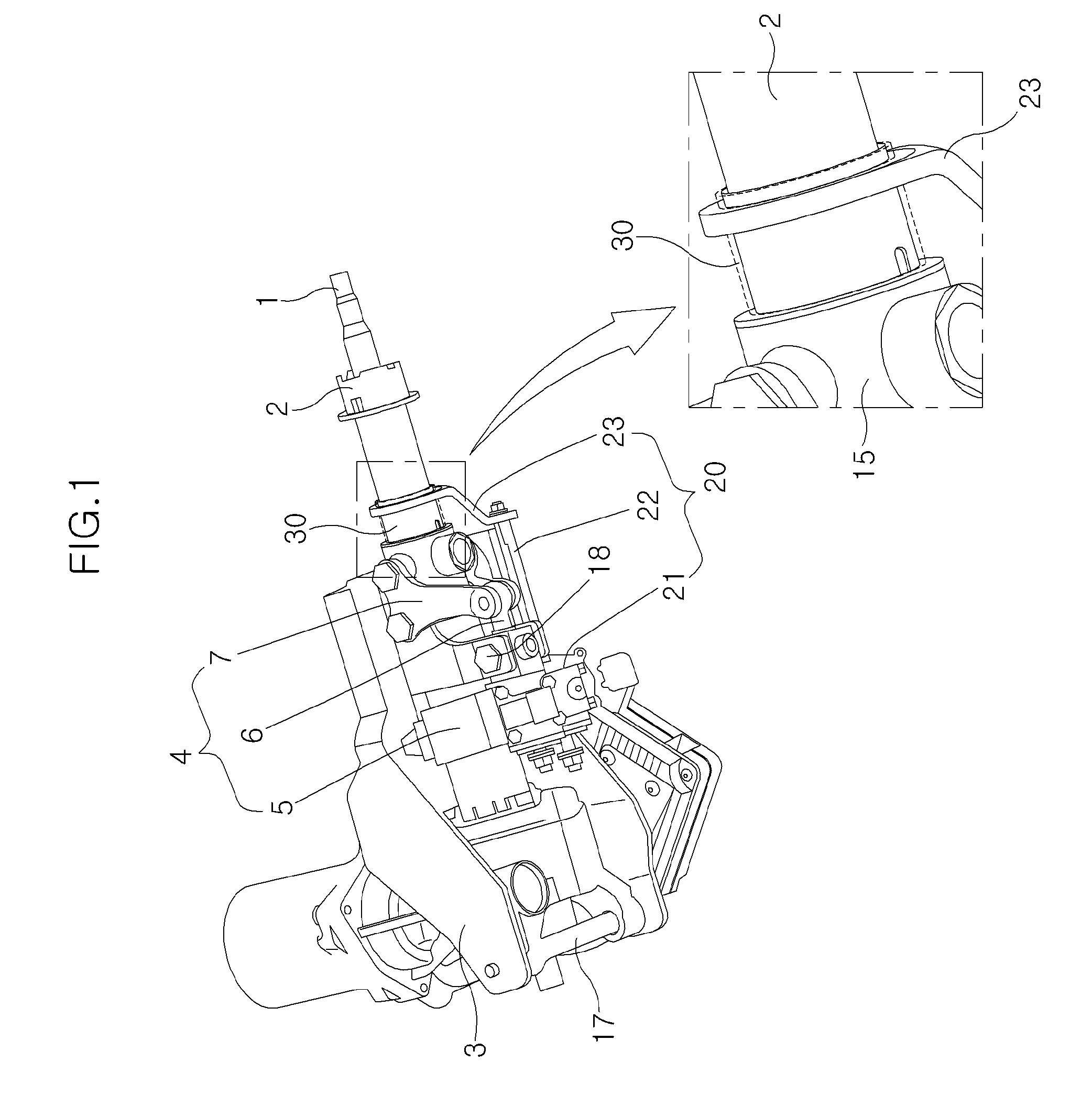

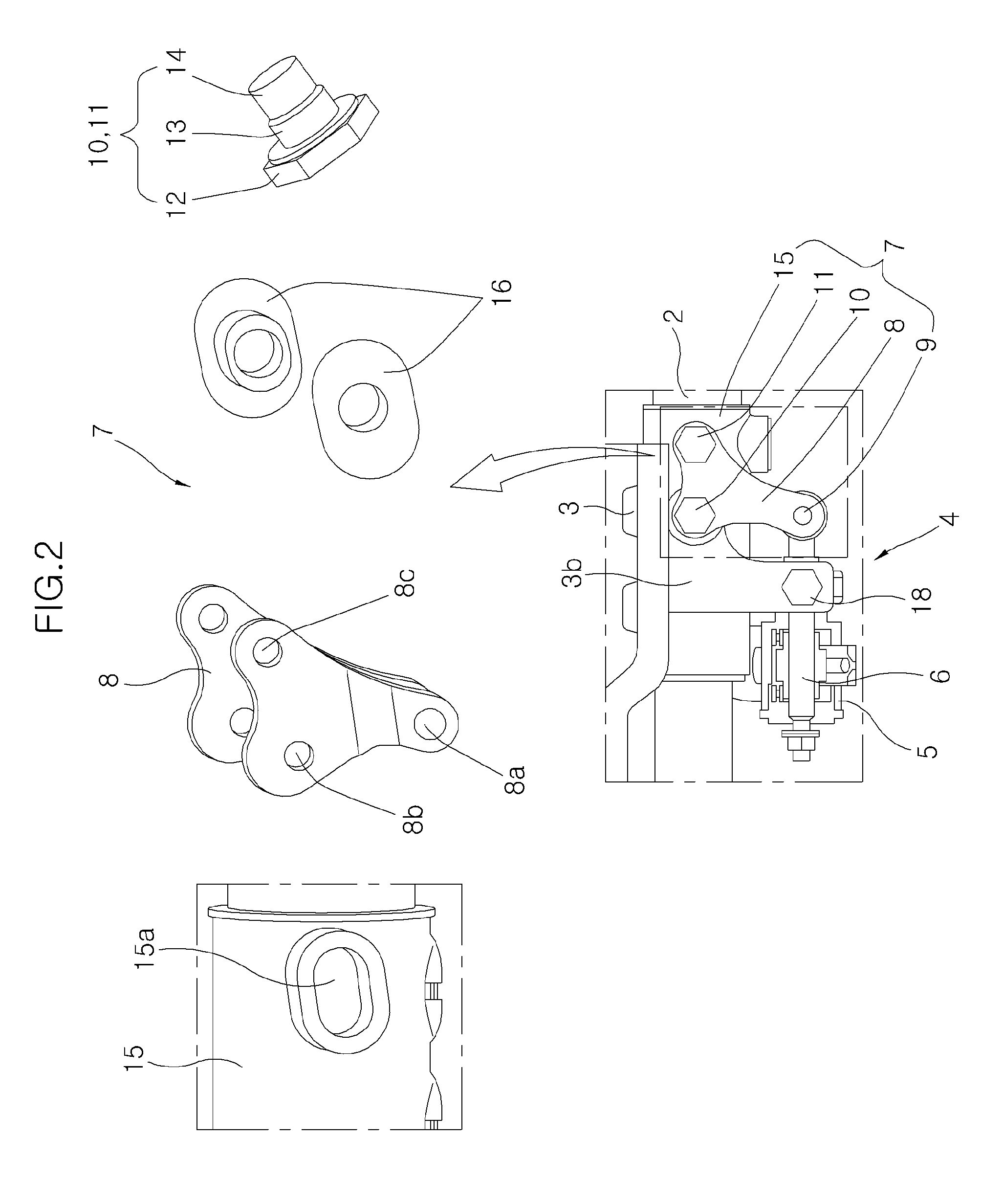

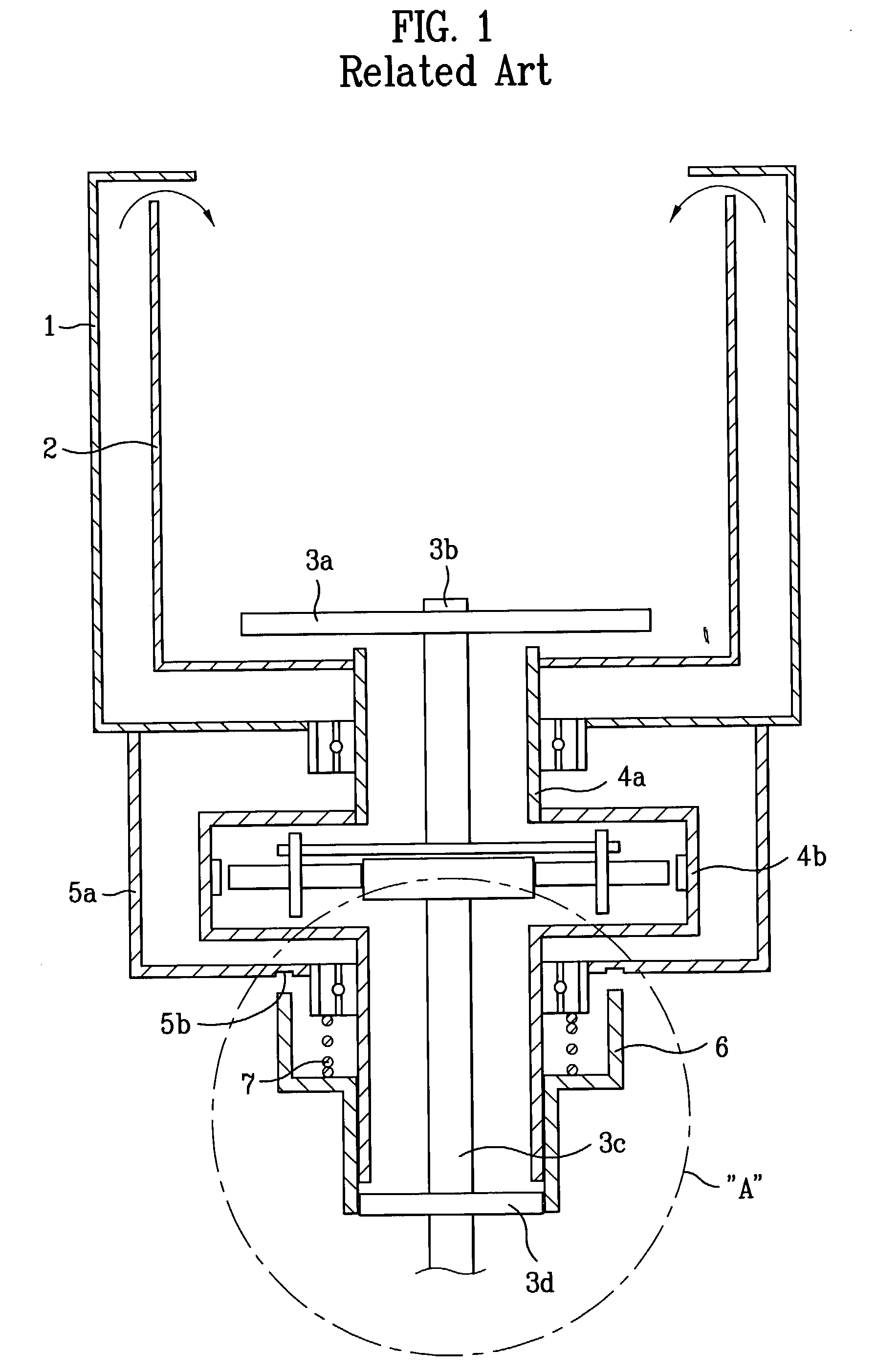

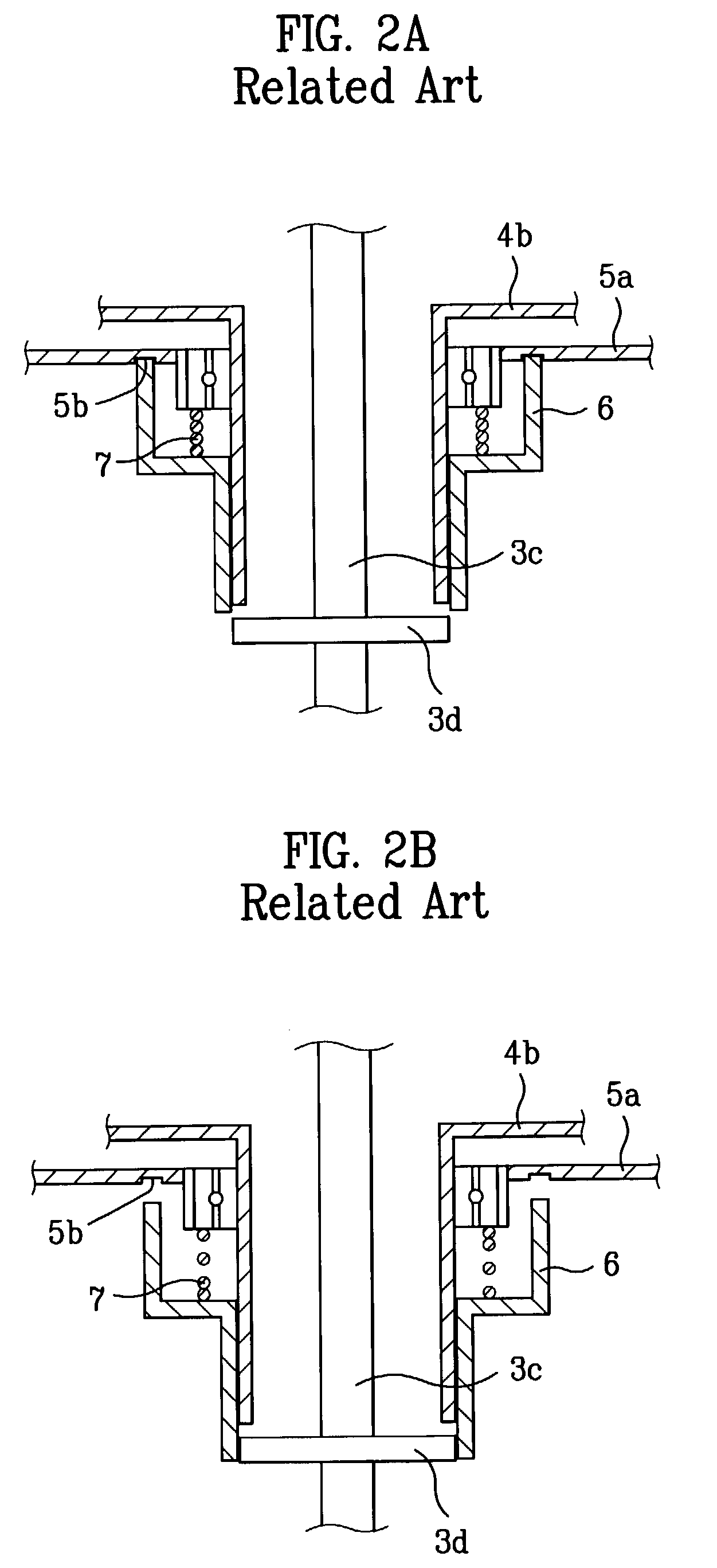

Lower type motor driven column apparatus

ActiveUS20110162904A1Easy to useSave fuelElectrical steeringSteering columnsSteering wheelMotor drive

A lower type motor-driven column apparatus includes a tilt unit having a column tube and a tilt link forming a plurality of hinge fixed points in order to tilt up / down a steering wheel by vertical motion generated with rotation due to straight motion of a tilt rod through a tilt motor, a telescopic unit implementing telescopic movement pushing or pulling the column tube by means of straight motion of a tele-rod through a tele-motor, and a shock-absorbing member absorbing and attenuating a shock stroke of the column tube, ahead of the tilt unit and the telescopic unit, in which the operation mechanism of the tilt unit and the operation mechanism of the telescopic unit are individually implemented, such that the MDPS can be easily used for middle-sized and large-sized vehicles which are difficult to use the upper type and it is possible to save fuel of the middle-sized and large-sized vehicles.

Owner:HYUNDAI MOTOR CO LTD +2

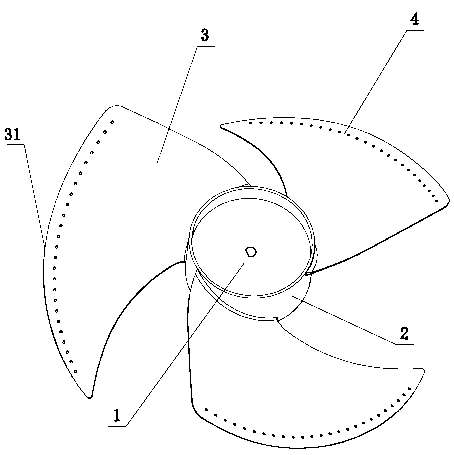

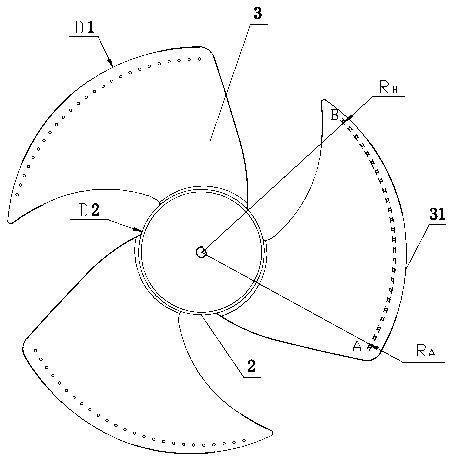

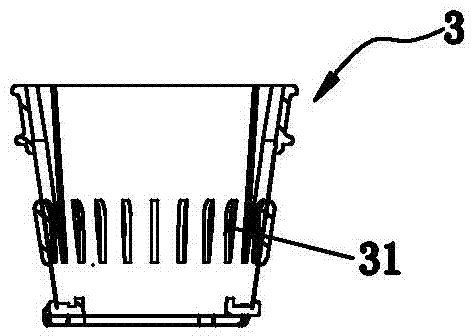

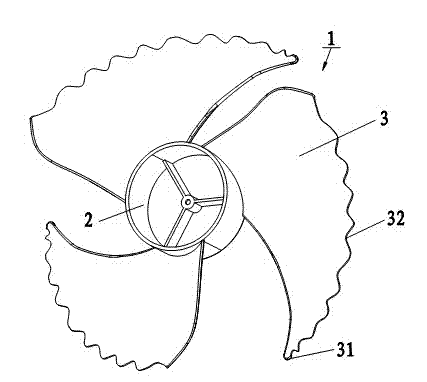

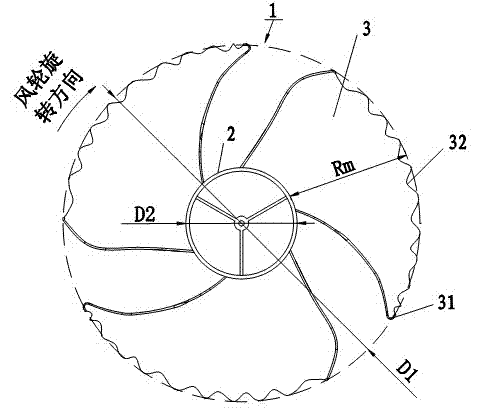

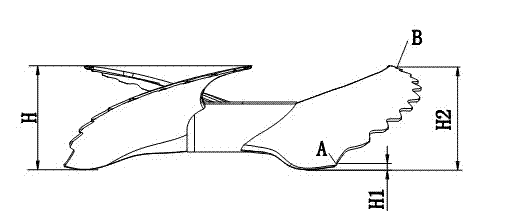

Axial flow rotor blade

The invention discloses an axial flow rotor blade. The axial flow rotor blade comprises at least two vanes (3) arranged on a hub (2), wherein each vane (3) is provided with a hole area with a plurality of through holes (4). The vanes (3) are distributed on the hub (2) by taking a rotation central axis as a center at equal or unequal intervals; and the area of a vane outer edge (31) of each vane (3) is the hole area. When the axial flow rotor blade rotates, the hole structure of the adjacent area of each vane outer edge ensures that air on the pressure surface of each vane flows into a suction surface through the through holes, so that kinetic energy of air on the suction surface of each vane is increased, and the growth of a boundary layer is inhibited; eddy noise is effectively reduced, and the voice is more soft and comfortable; and meanwhile, by the hole structure of the adjacent area of each vane outer edge, the weight of the rotor blade and the load of a motor are reduced, and the cost of the rotor blade and the powder of the motor are reduced. The axial flow rotor blade is particularly suitable for an air conditioner outdoor unit.

Owner:MIDEA GRP CO LTD

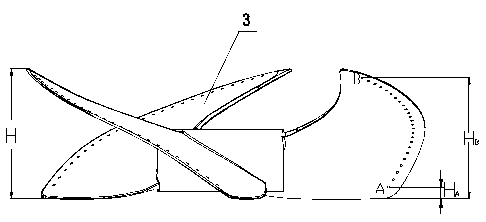

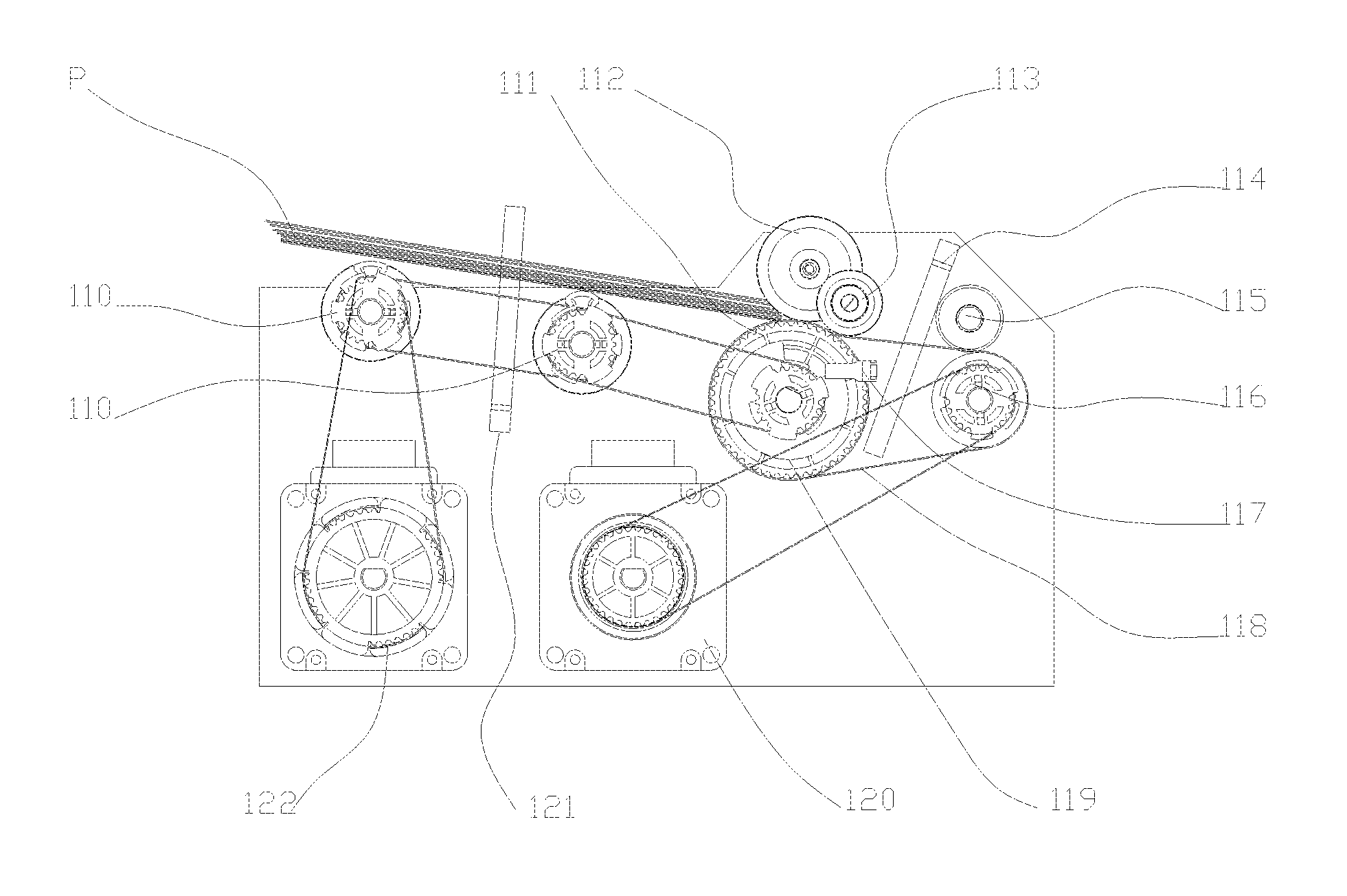

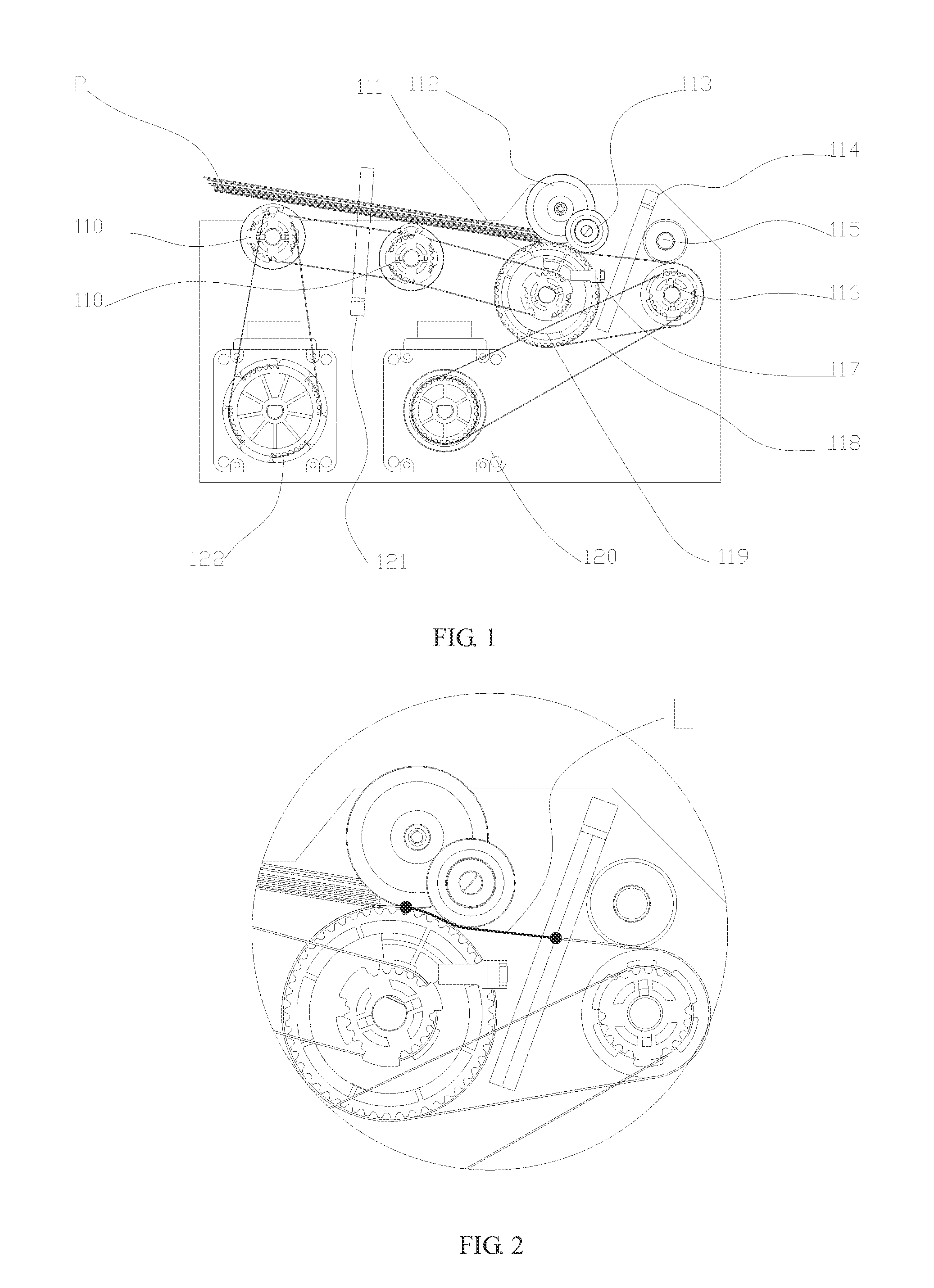

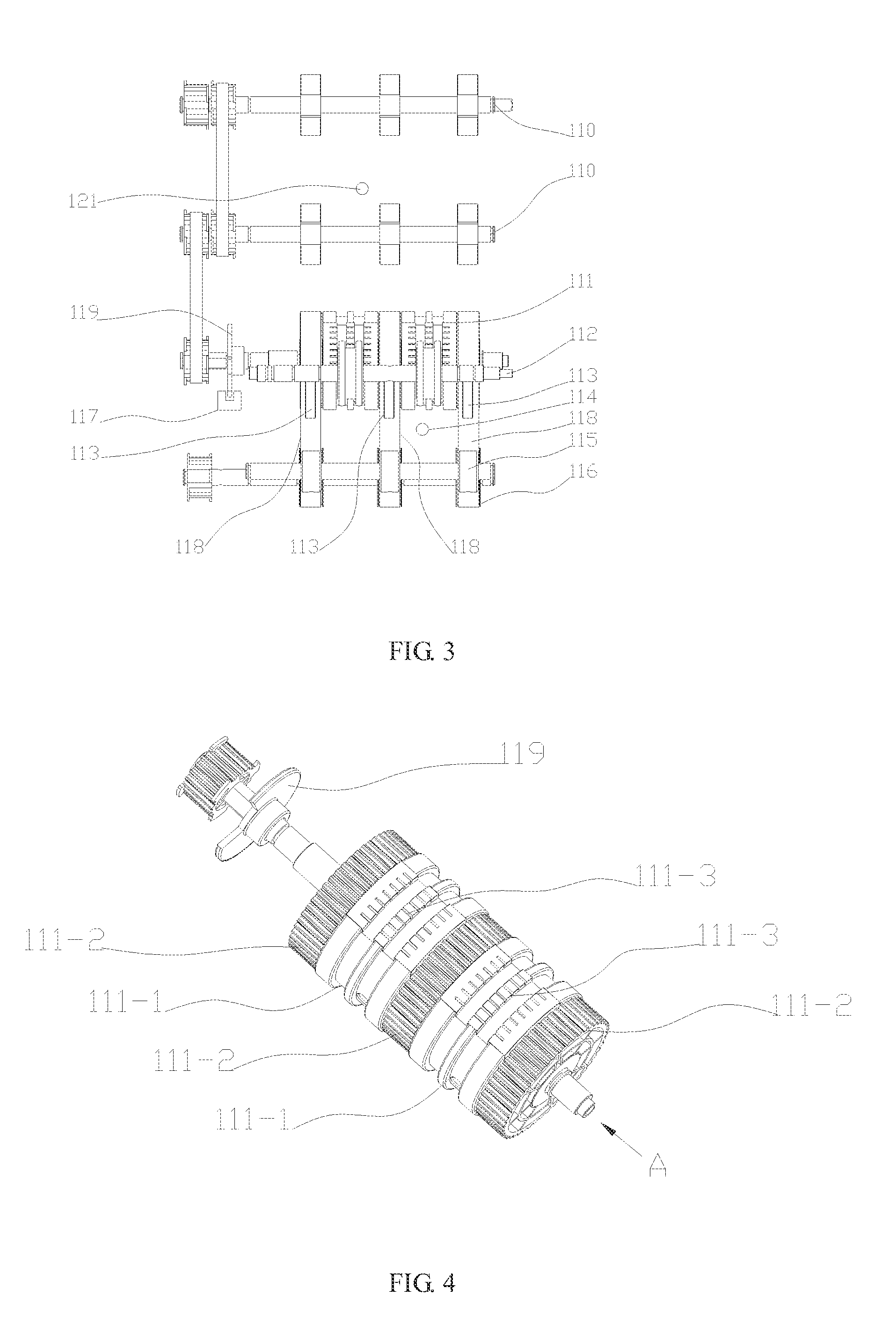

Sheet article separating mechanism and control method and control system thereof

InactiveUS20130221606A1Lower the volumeReduce motor loadFunction indicatorsArticle feedersControl systemEngineering

A sheet medium separating mechanism and a control method and a control system thereof. When the head part of a currently separated medium reaches the front boundary of a preset speed regulating region in front of a money distributing wheel (111) and the tail part of the currently separated medium leaves the back boundary of a preset speed regulating region on the money distributing wheel, relative speeds of a money distributing wheel motor (122) and a back money distributing power wheel motor (120) are regulated, so that a preset medium separating distance is kept between the tail part of the currently separated medium and the head part of a next separated medium. Therefore, the sheet medium separating mechanism is adapted to sheet media of different shapes and different specifications, the money distributing wheel size and rotary inertia of longitudinal deposit equipment are reduced, and the motor load is effectively lowered.

Owner:GRG BAKING EQUIP CO LTD

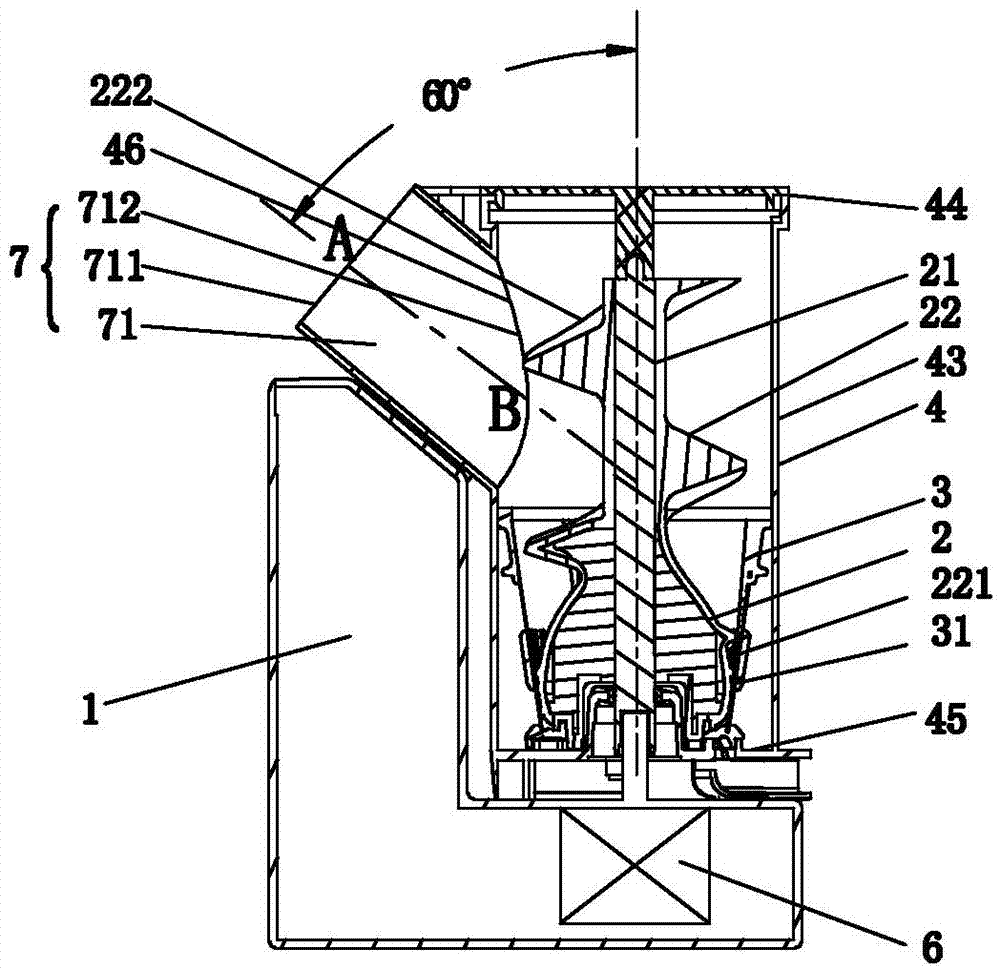

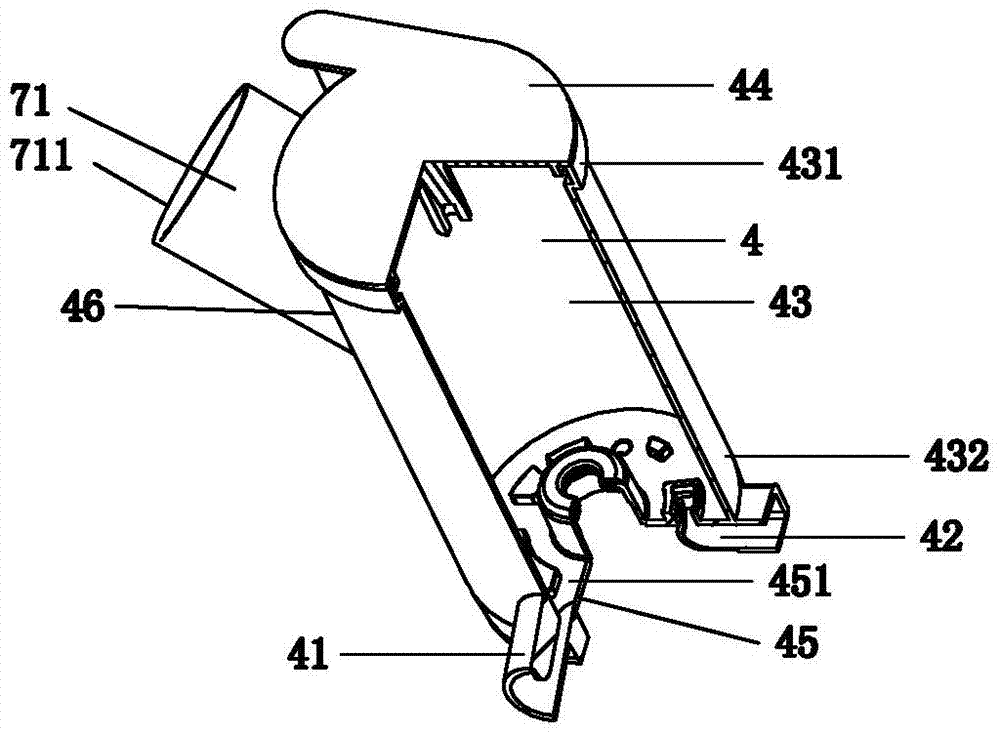

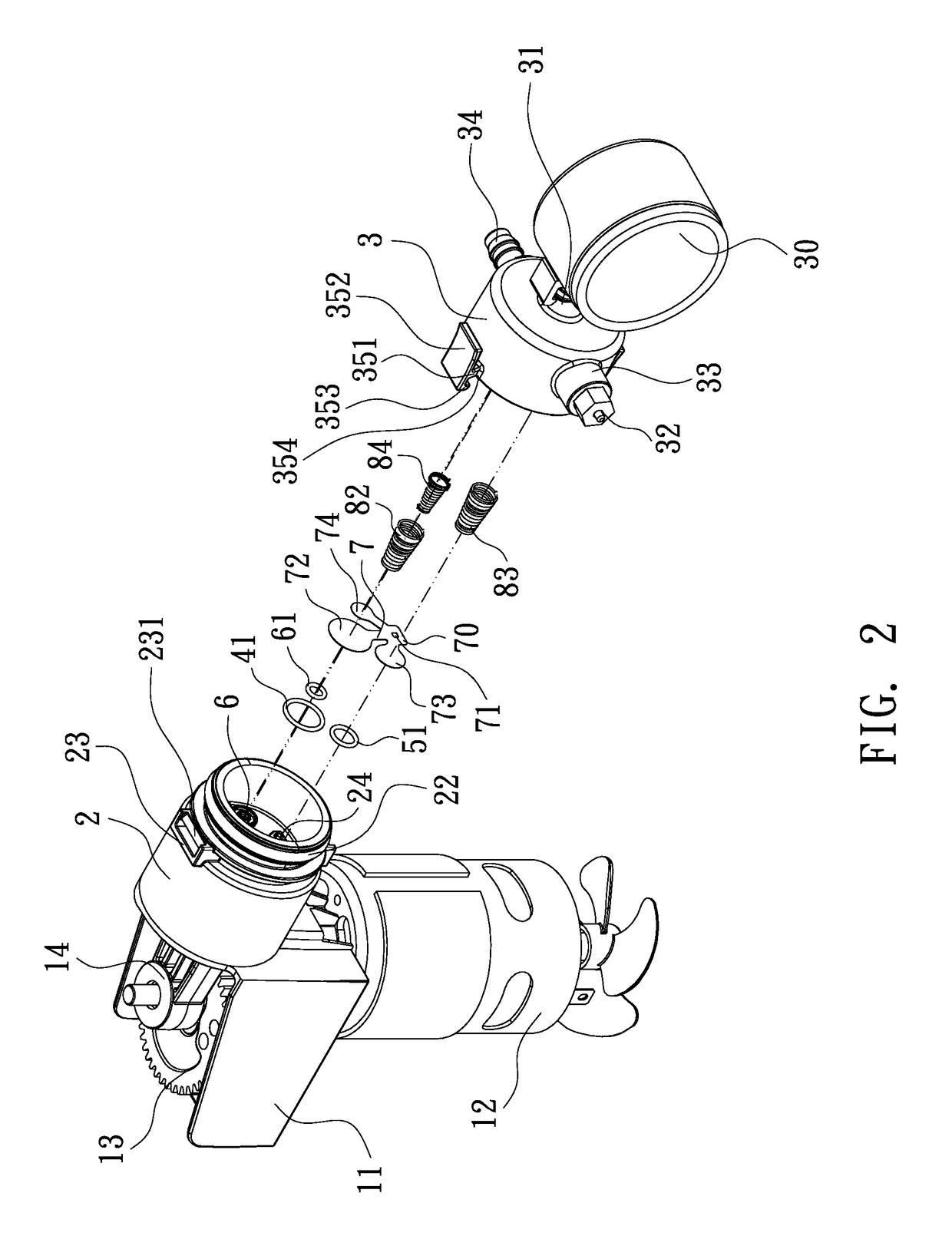

Rapidly-and-automatically-fed extrusion type juice extractor

The invention discloses a rapidly-and-automatically-fed extrusion type juice extractor. The juice extractor comprises an extractor base, a motor arranged in the extractor base, a driving unit arranged in the extractor base, an extrusion screw, a squeezing assembly matched with the extrusion screw to extrude materials and a feeding assembly; the squeezing assembly comprises a squeezing cavity; a feeding opening is formed in the lateral wall of the squeezing cavity; the feeding assembly comprises a feeding channel communicated with the feeding opening; the juice extractor further comprises a material pushing part for downwards guiding the materials; the material pushing part is arranged corresponding to the feeding opening of the squeezing cavity; and an included angle between a connecting line of geometric centers of two ports of the feeding channel and the vertical direction and an included angle between the connecting line and a vertical panel are alpha, wherein the alpha is larger than or equal to 0 degree and smaller than or equal to 80 degree. By means of the structure, rapid and automatic feeding can be achieved, and large-caliber feeding can be easily achieved.

Owner:JOYOUNG CO LTD

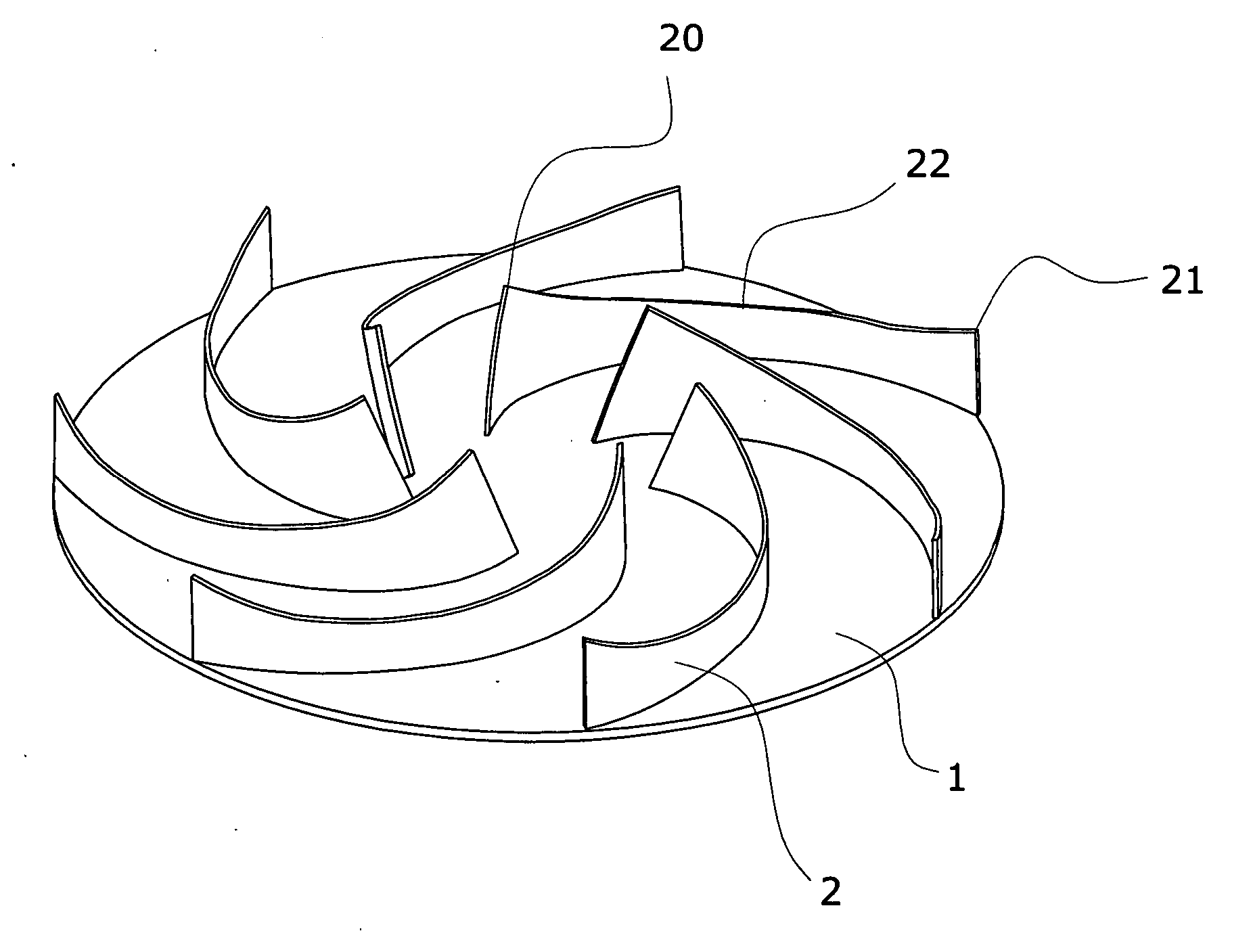

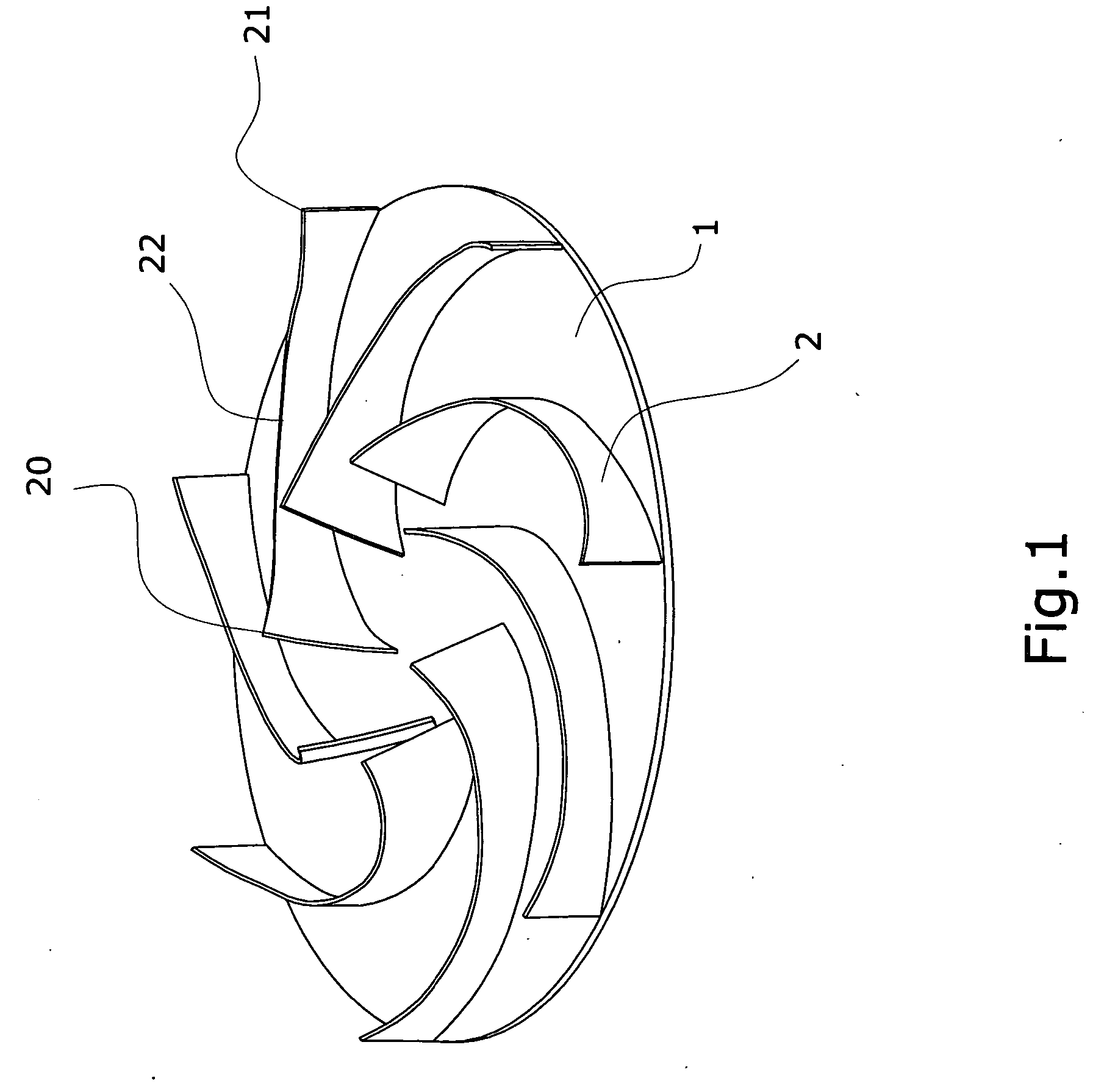

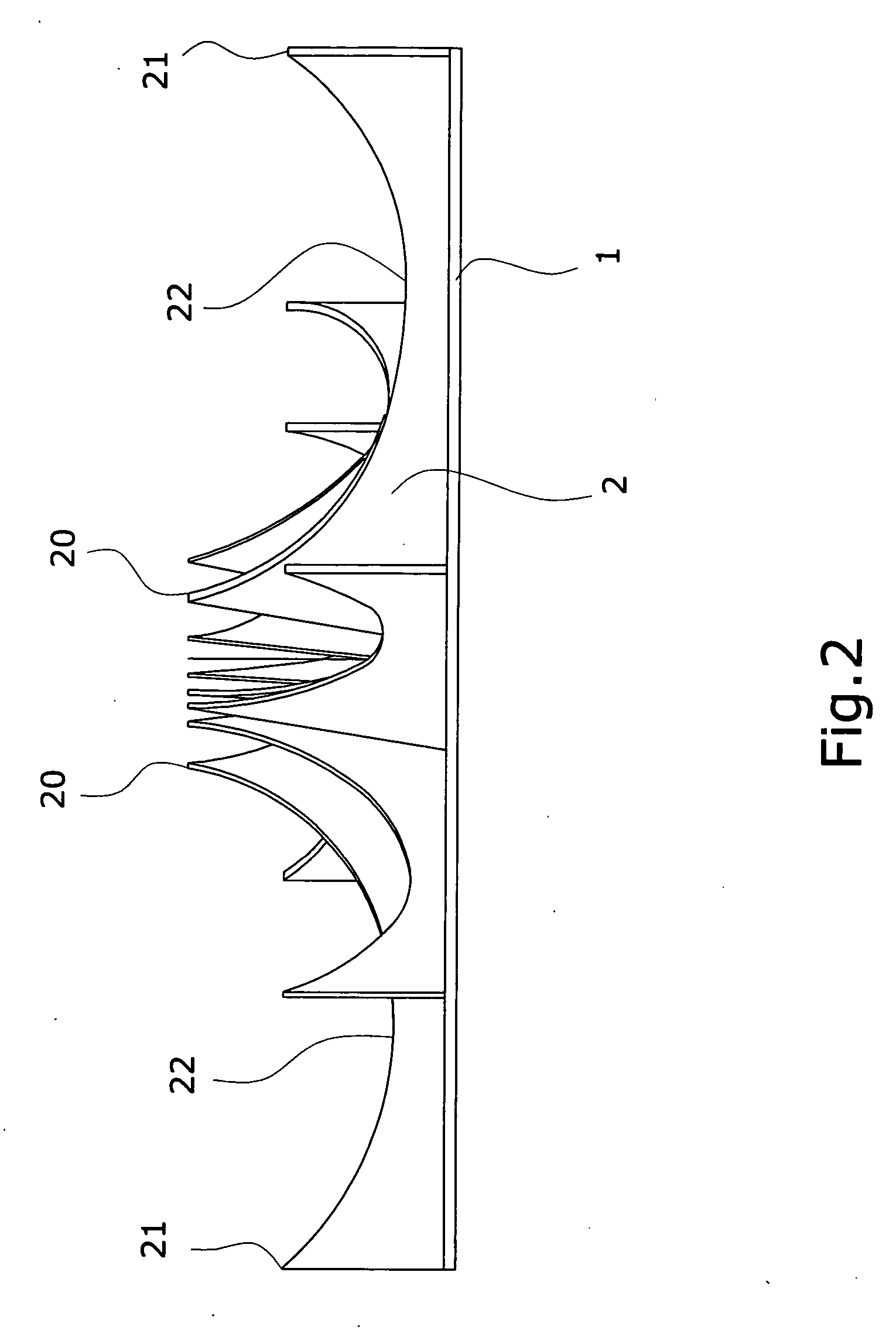

Structure of turbine blower

“An improved structure of turbine blower”, is mainly about installing several impellers in the form of a radial arrangement on a round bottom board. The characteristic of the design is that, the height of the impeller starts from the front of the impeller, near the center of the bottom board, lowers down to the corresponding low point in the middle section and elevates gradually to the front of the impeller. The top brim between the front and the rear of the impeller is in a curve shape. According to the above structure, when the air inlet or air outlet is obstructed, the power consumption will decrease automatically, so that the loading of the motor will be reduced.

Owner:CHEN GING CHUNG

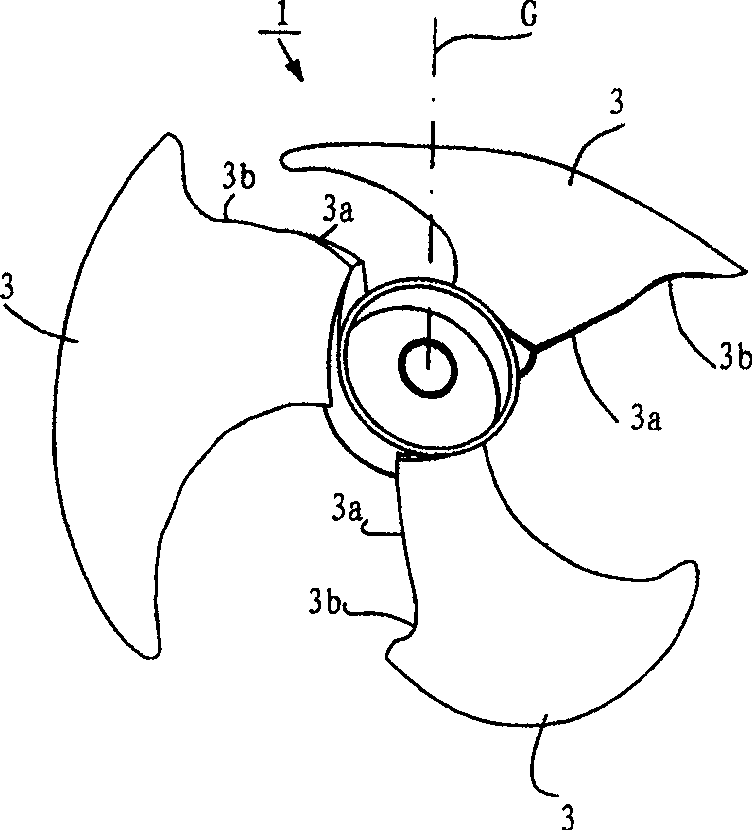

Axial flow wind wheel

ActiveCN102374194AReduce eddy current noiseSuppression of eddy current noisePump componentsPumpsWave shapeEngineering

The invention relates to an axial flow wind wheel, which comprises more than two blades arranged on a hub, wherein the blades are distributed on the hub at equal intervals or unequal intervals by taking the rotating central axis of the wind wheel as the center. The axial flow wind wheel is characterized in that: the outer edge shape of each blade is in a wave-shaped space curve. When the axial flow wind wheel rotates, gas of the pressure surfaces of the blades flows into the suction surface in different degrees through the wave-shaped outer edges of the blades due to the wave shapes of the outer edges of the blades, so that the pressure distribution of the blades is changed, the kinetic energy of the gas on the suction surface is increased, low-energy fluid can be prevented from accumulating at the annular walls of the blades, large eddy turbulence is destructed, blade tip vortex and trailing edge falloff are effectively refined, the energy strength of the vortex is reduced, and the vortex noise of the wind wheel is restricted, therefore the noise of the wind wheel is effectively reduced, the acoustic quality is softer and more comfortable, meanwhile, the wind wheel weight and the motor load are lightened by wave shapes of the outer edges of the blades, and the wind wheel cost and the motor power are reduced. The invention is especially suitable for an outdoor unit of an air-conditioner.

Owner:MIDEA GRP CO LTD

Image pickup lens, image pickup device provided with image pickup lens, and mobile terminal provided with image pickup device

Owner:KONICA MINOLTA OPTO

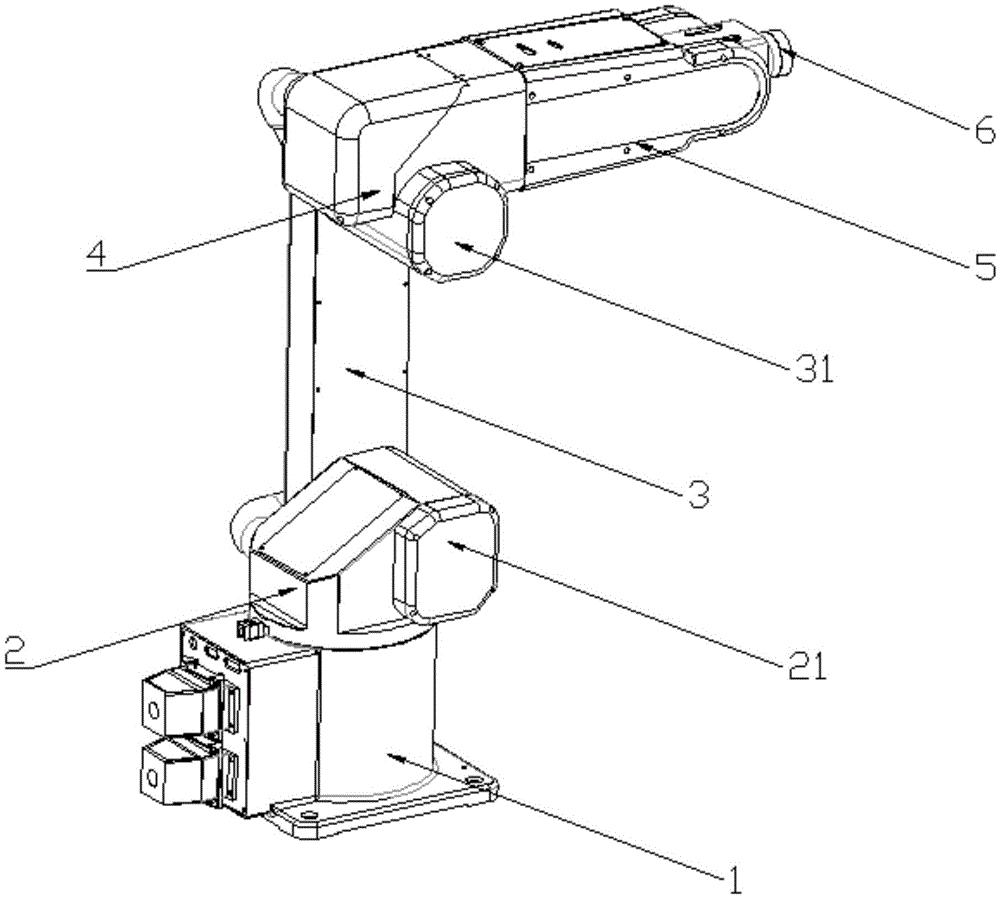

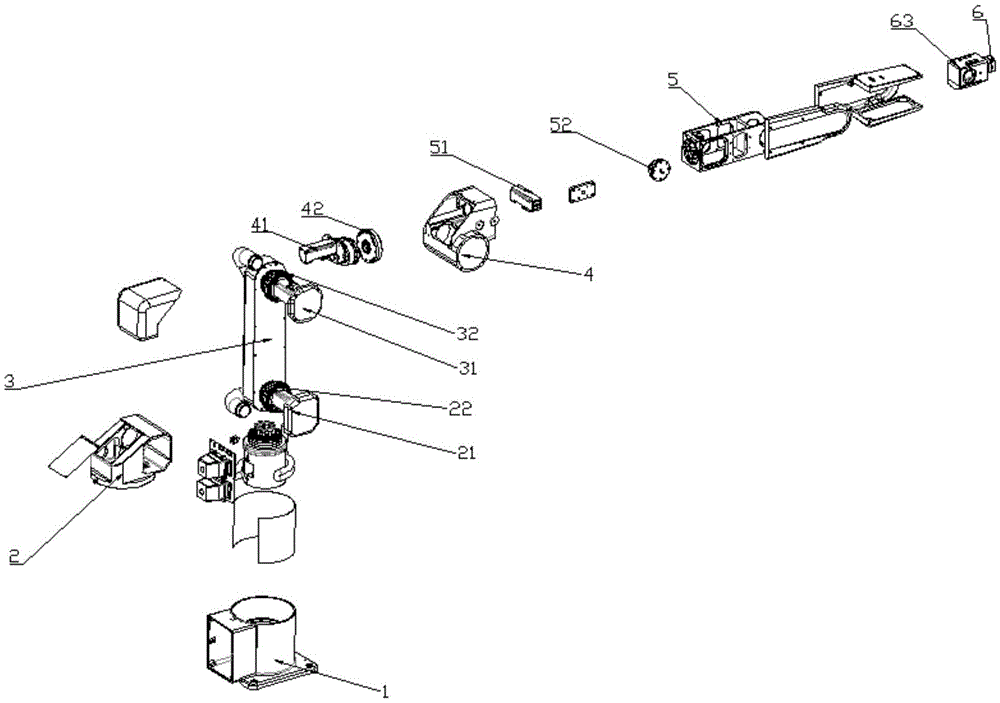

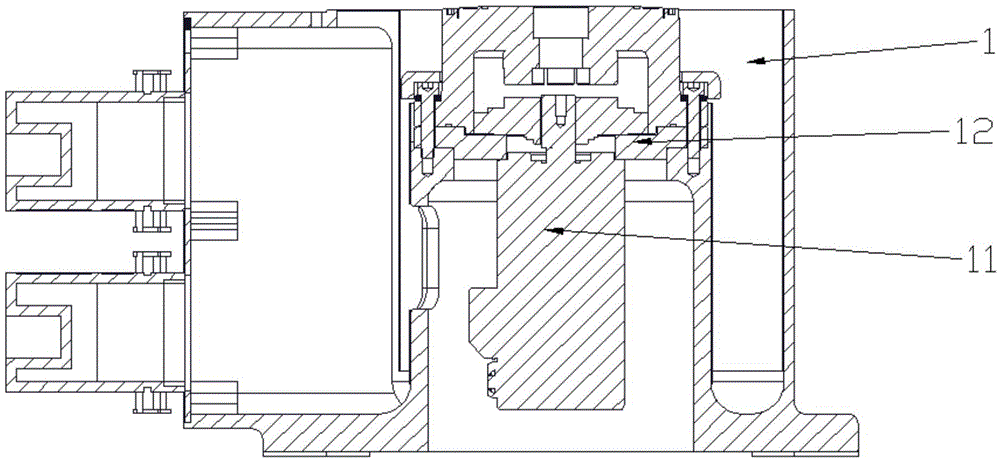

Multifunctional six-axis manipulator

InactiveCN105522567ALight weightReduce energy consumptionProgramme-controlled manipulatorRobotic armControl system

The invention provides a multifunctional six-axis manipulator. The multifunctional six-axis manipulator comprises a base, an upper arm, a lower arm, a first rotating seat, a second rotating seat, a first transmission mechanism, a second transmission mechanism, a third transmission mechanism, a fourth transmission mechanism, a fifth transmission mechanism and a sixth transmission mechanism. The whole manipulator structure adopts aluminium alloy castings, the weight of the manipulator is reduced, the motor load is reduced, a high-precision harmonic reducer is arranged on each of the six axes, a first-axis servo motor, a second-axis servo motor, a third-axis servo motor and a sixth-axis servo motor and the reducers are directly connected, errors are effectively reduced, and the precision is improved. An automatic compensation module monitors dynamic feedback of the servo motors at any time for position correcting compensation. The performance of the servo motors is optimized by adjusting internal parameters of drivers, so that the servo motors can work stably. A control system sends various pulse commands to the servo drivers through efficient and accurate calculation so as to control the manipulator to complete various actions efficiently and accurately, and the accuracy is improved.

Owner:DONGGUAN TENGMAI HARDWARE & PLASTIC PROD CO LTD

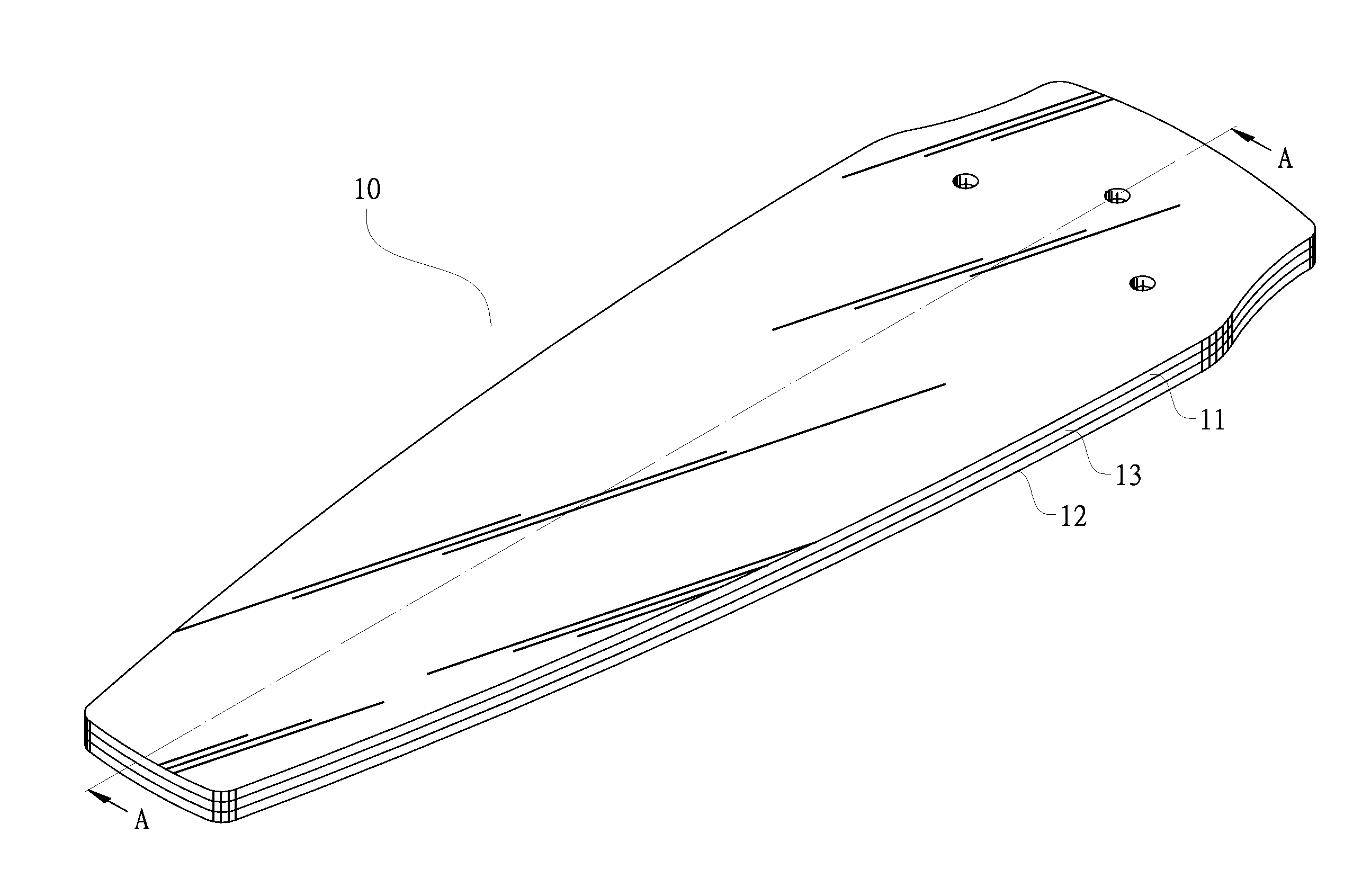

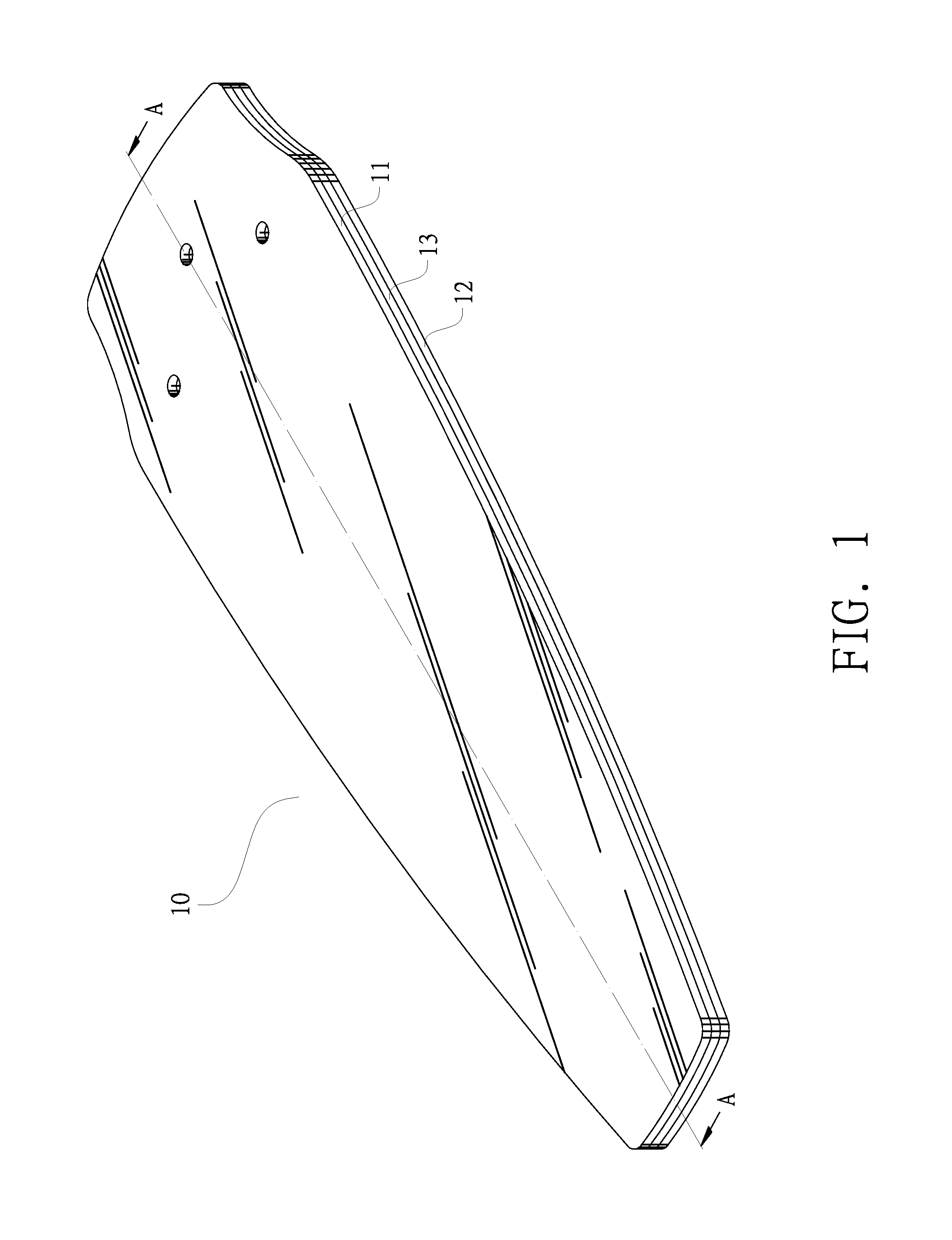

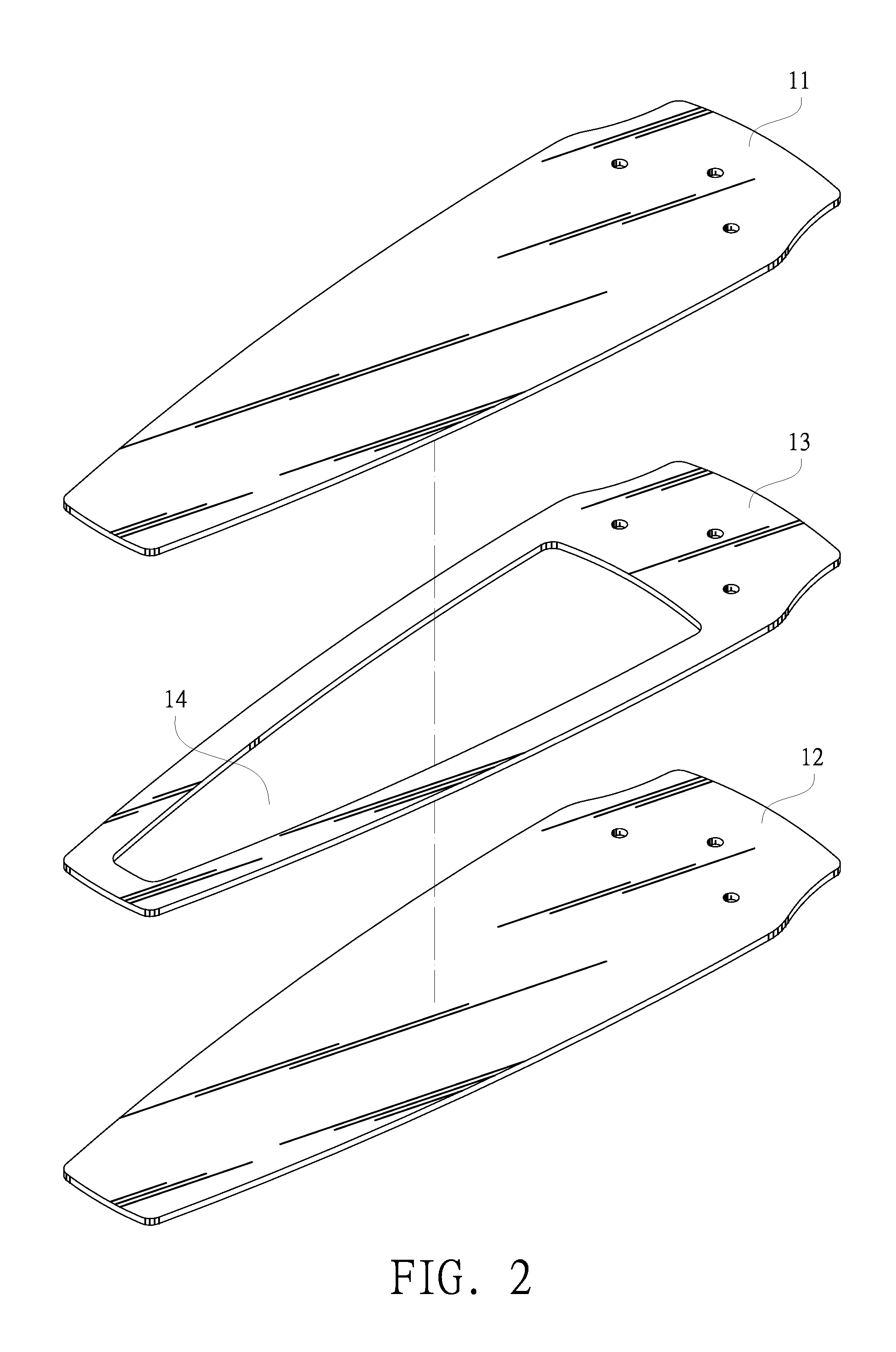

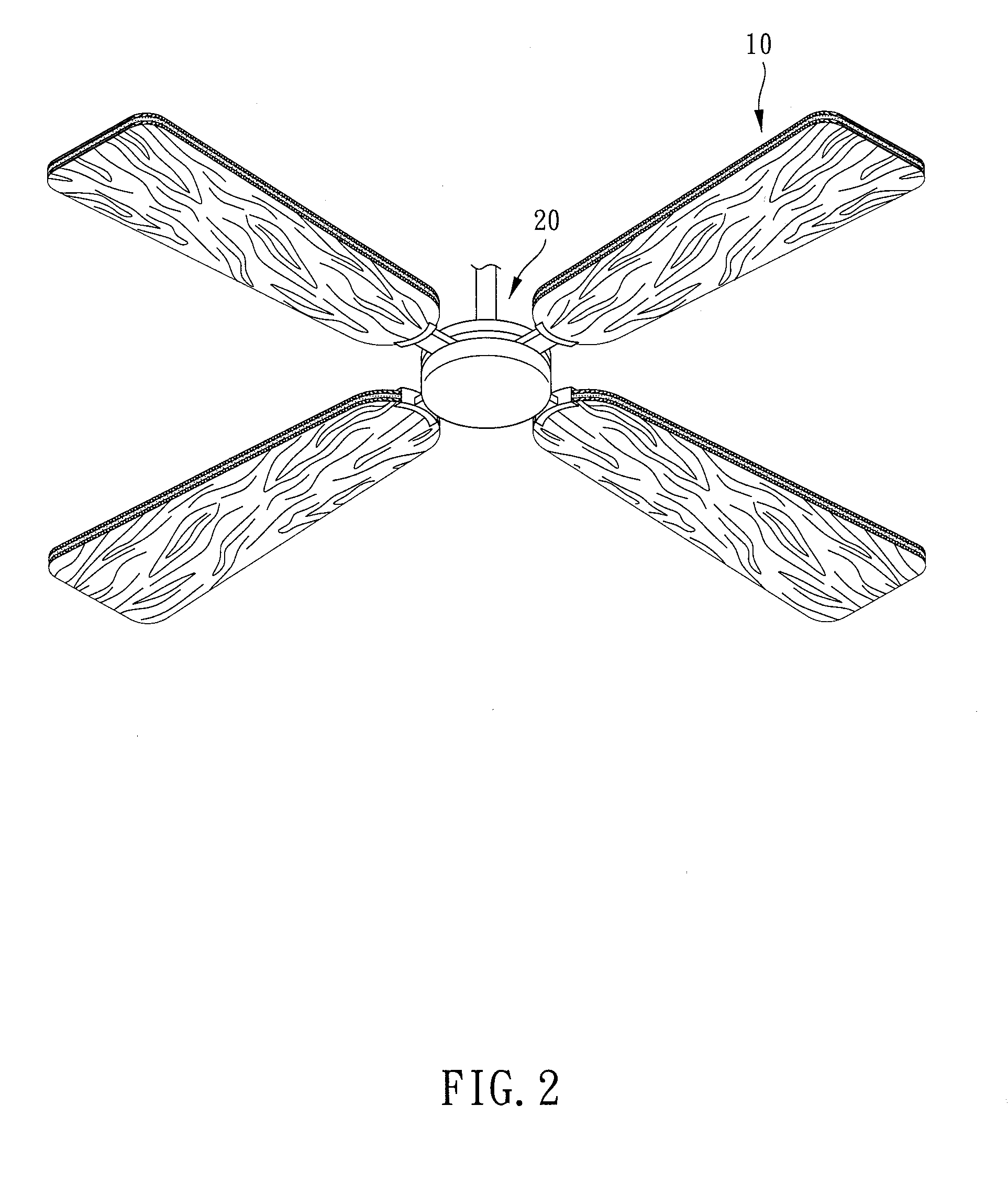

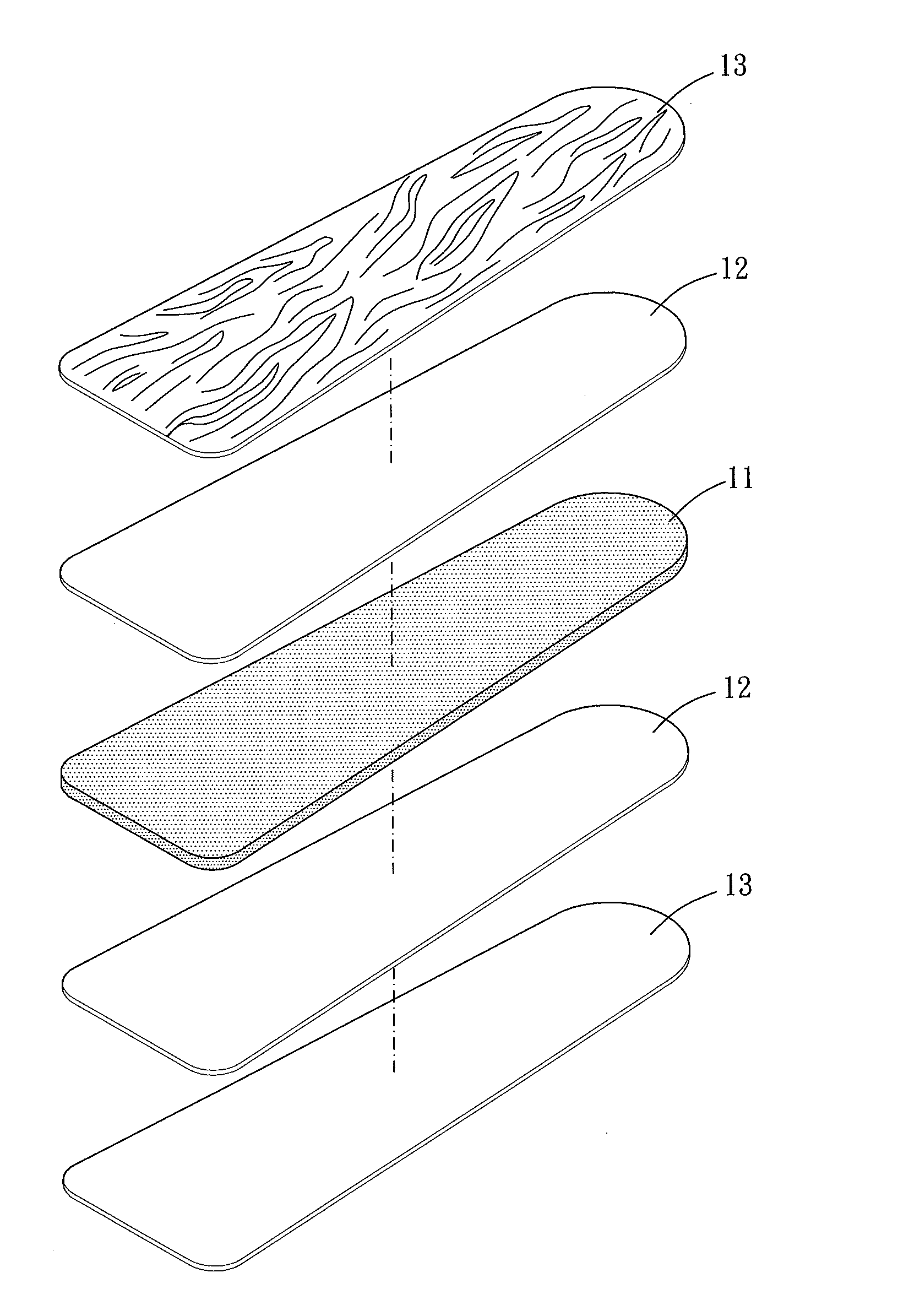

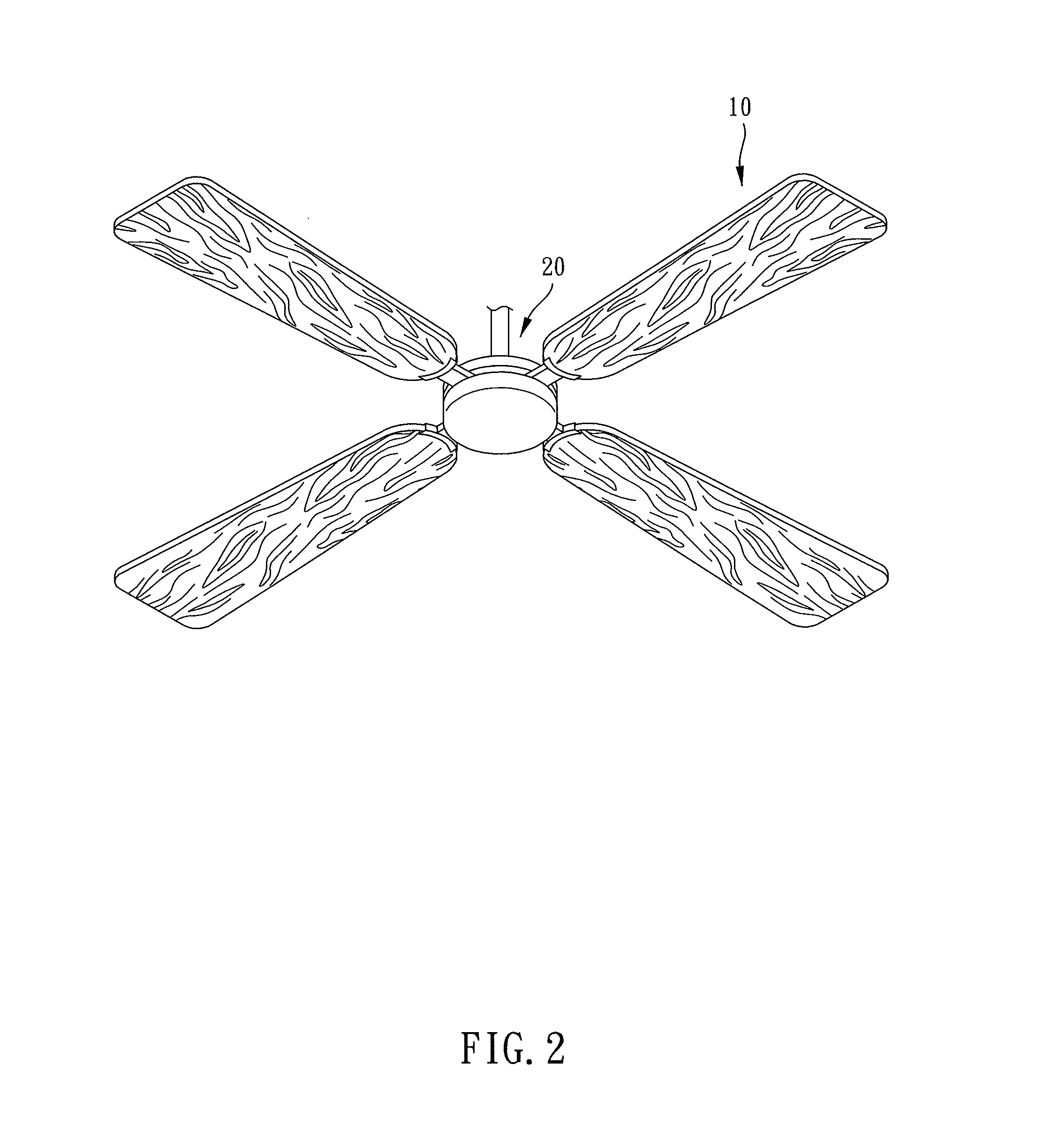

Ceiling fan vane structure

InactiveUS20110305581A1Reduce weightReduce motor loadPropellersPump componentsGlass fiberCeiling fan

An improved ceiling fan vane structure minimizes the weight of vanes to reduce to loads and achieve a power saving effect without affecting the structural strength of the vanes. The structural design includes the vanes, each being formed by combining a plurality of laminated plates, in which a middle laminated plate has a hollow slot, and a hollow chamber is created after the vanes are formed. The hollow chamber is maintained hollow or filled with a lightweight material such as glass fiber, cotton, or foam to achieve the effect of reducing the weight of the vanes, so that when a motor of the fan is operated to drive the vanes to rotate and produce air turbulence, the lightweight vanes can reduce the load of the motor to improve its operation efficiency, and achieve the effects of saving power and extending the lifespan of the motor.

Owner:ZHONGSHAN HSIANGYUAN WOOD

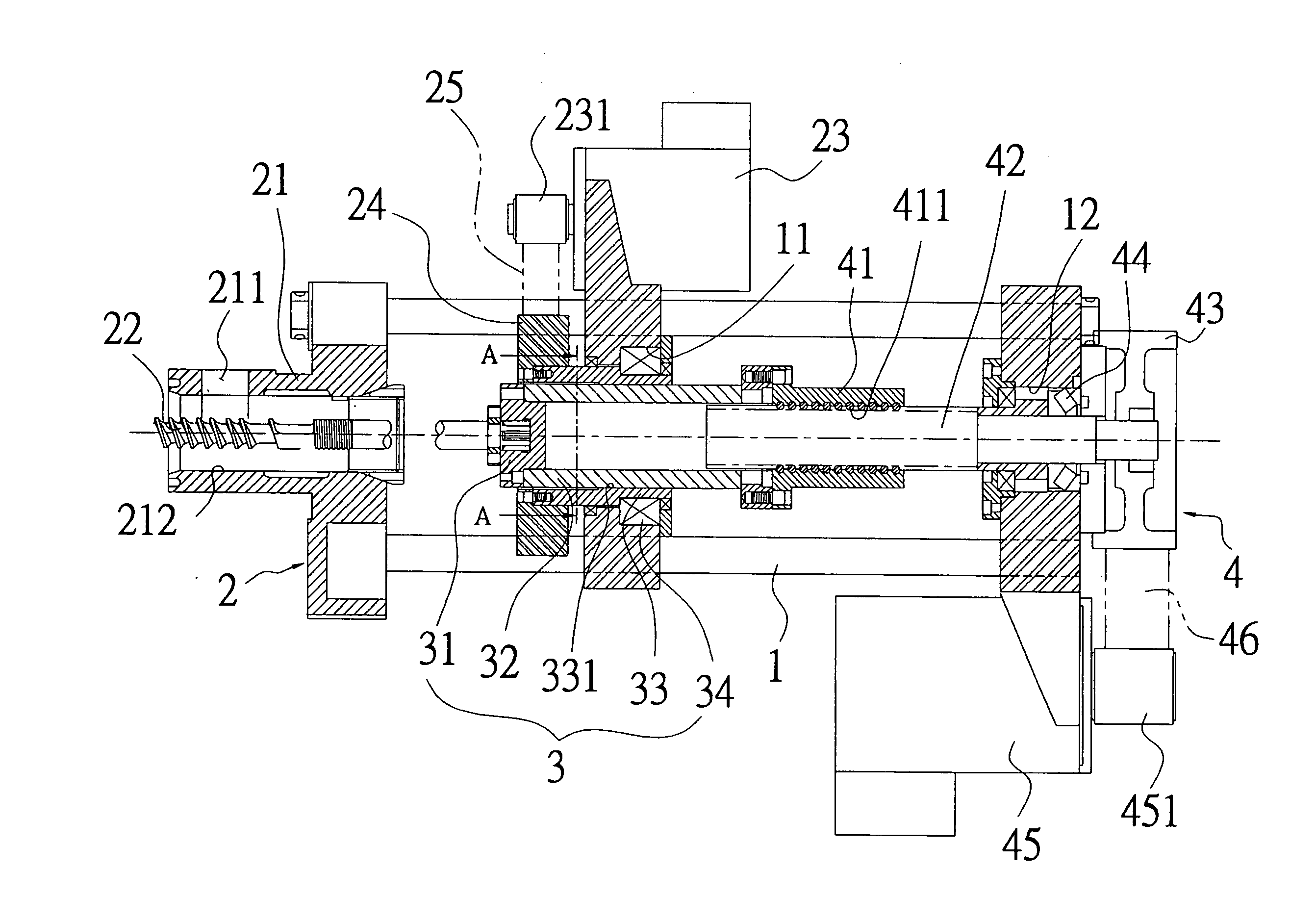

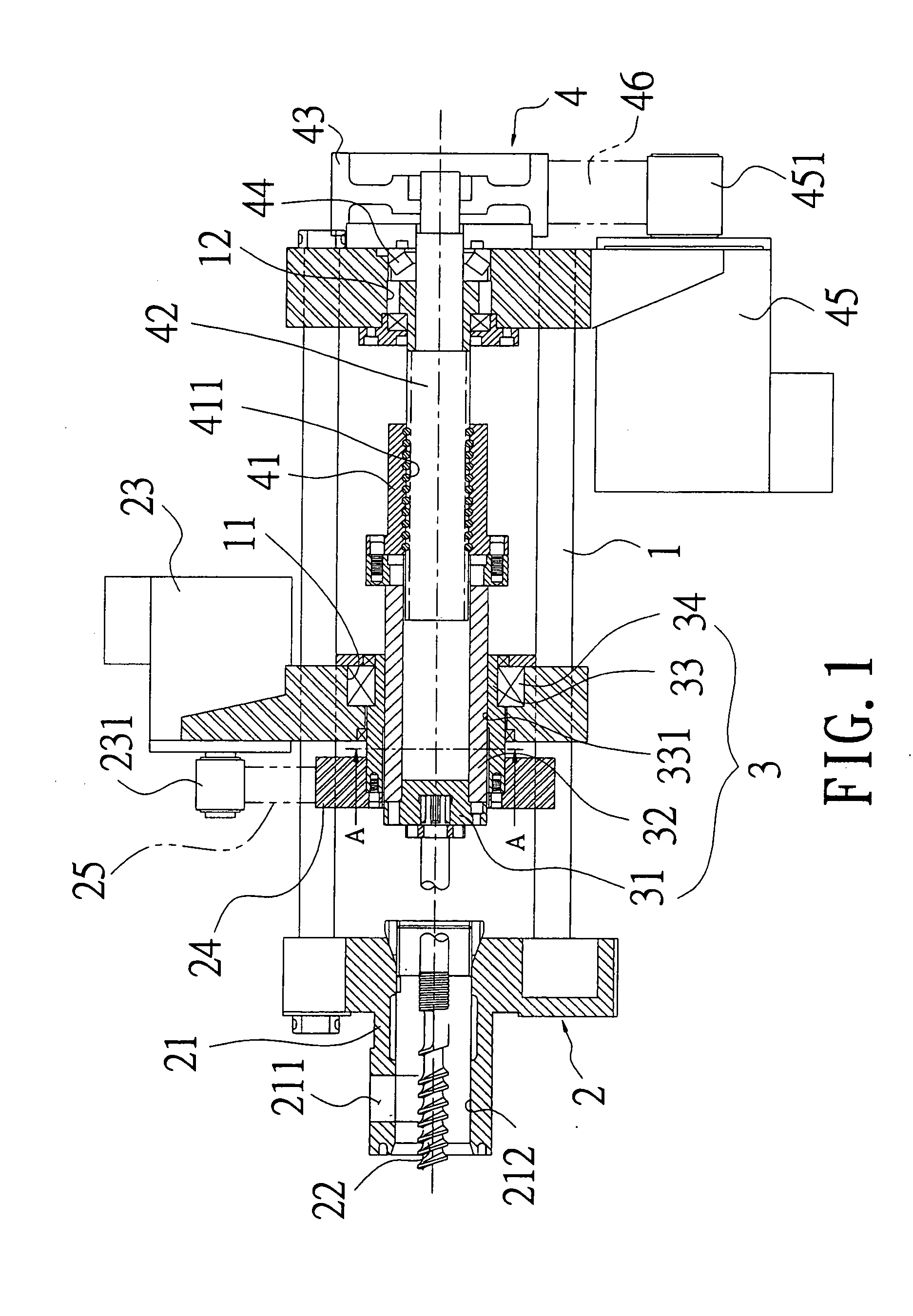

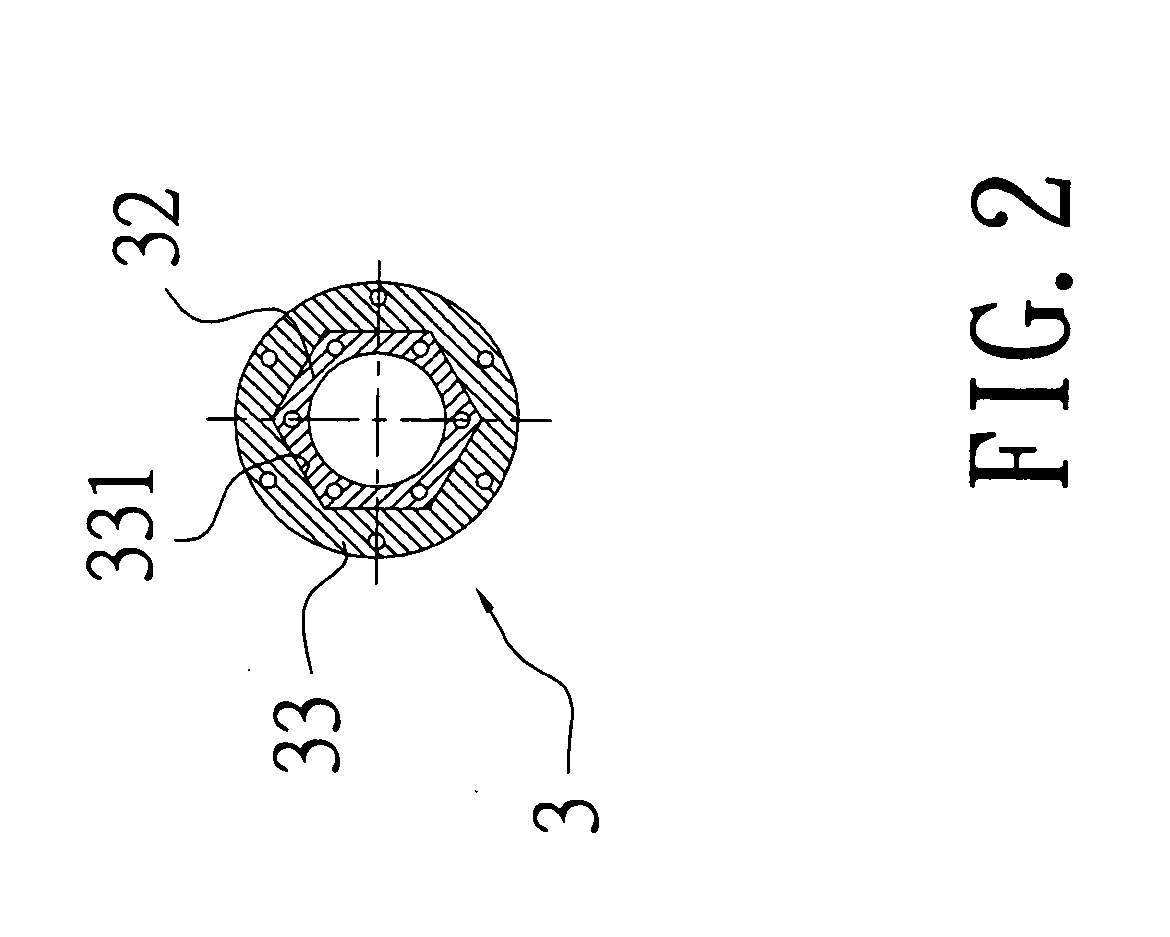

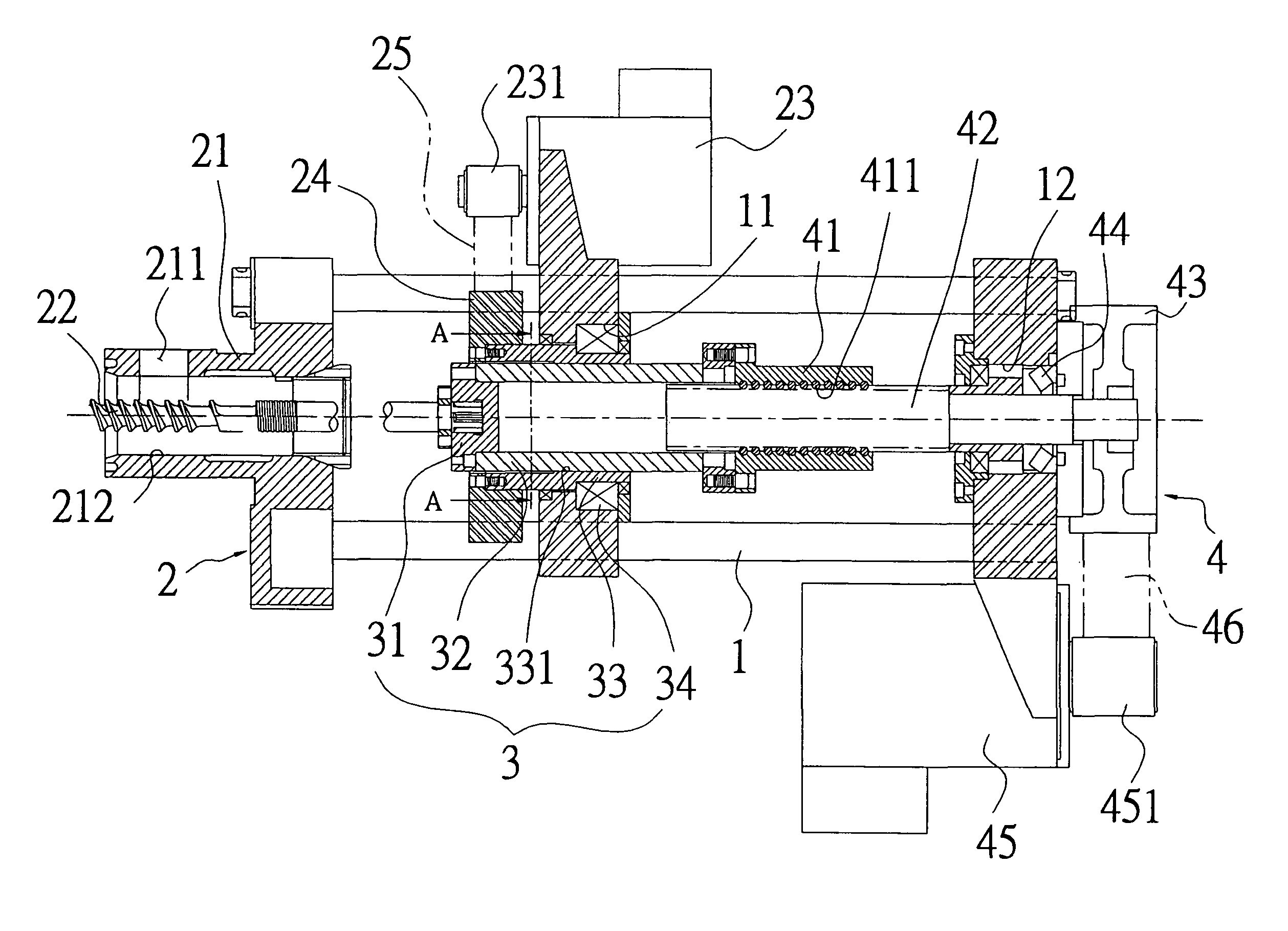

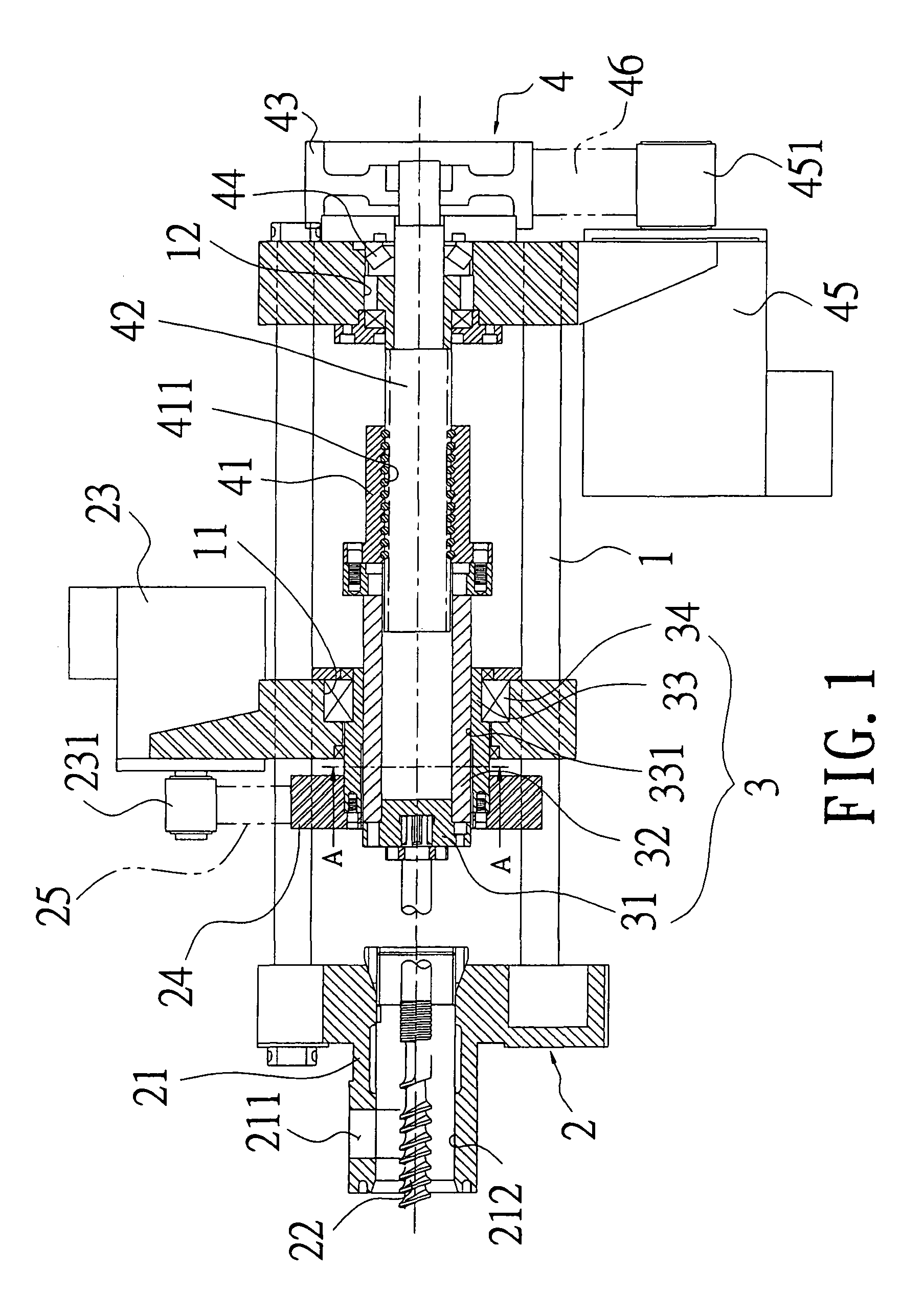

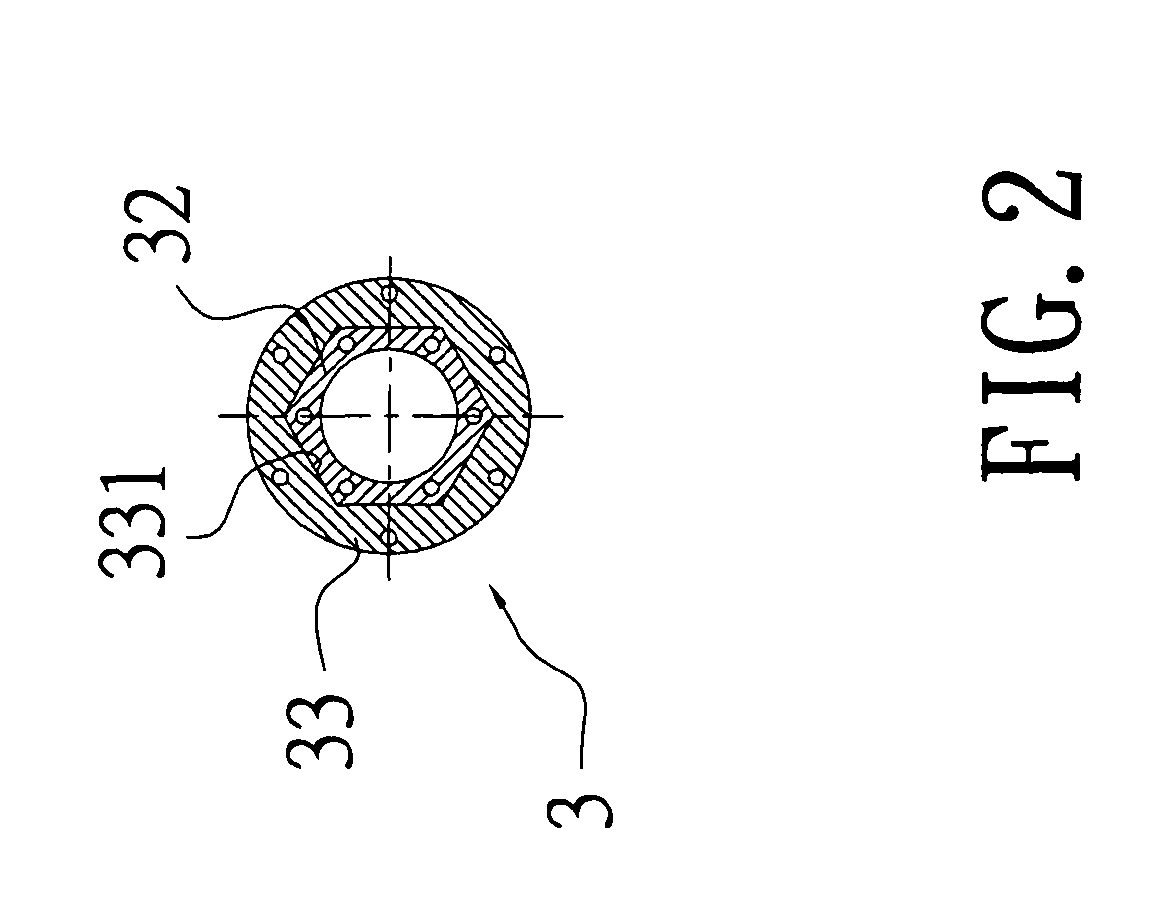

Injection drive apparatus for injection molding machine

ActiveUS20110086125A1Reduce loadImprove yieldAuxillary shaping apparatusFood shapingEngineeringInjection molding machine

An injection drive apparatus for injection molding machines is revealed. Liquid material is fed into a mold smoothly by a material feeding screw of a material feeding mechanism. Then a reaction force is generated to push the material feeding screw when the material feeding hole is nearly full of the material. Thus the material feeding screw and the slide mechanism assembled therewith are pushed to move backward. Later the injection mechanism is driven by the slide mechanism to move and act on the drive screw. Thus the slide mechanism threaded with the drive screw is driven to push the material feeding screw moving forward and squeezing the material for injection molding. Therefore, the load of the motor is reduced dramatically and the yield rate of the products produced by injection molding is increased due to the two-stage action-feeding of the material and squeezing of the material for injection.

Owner:HWA CHIN MACHINERY +1

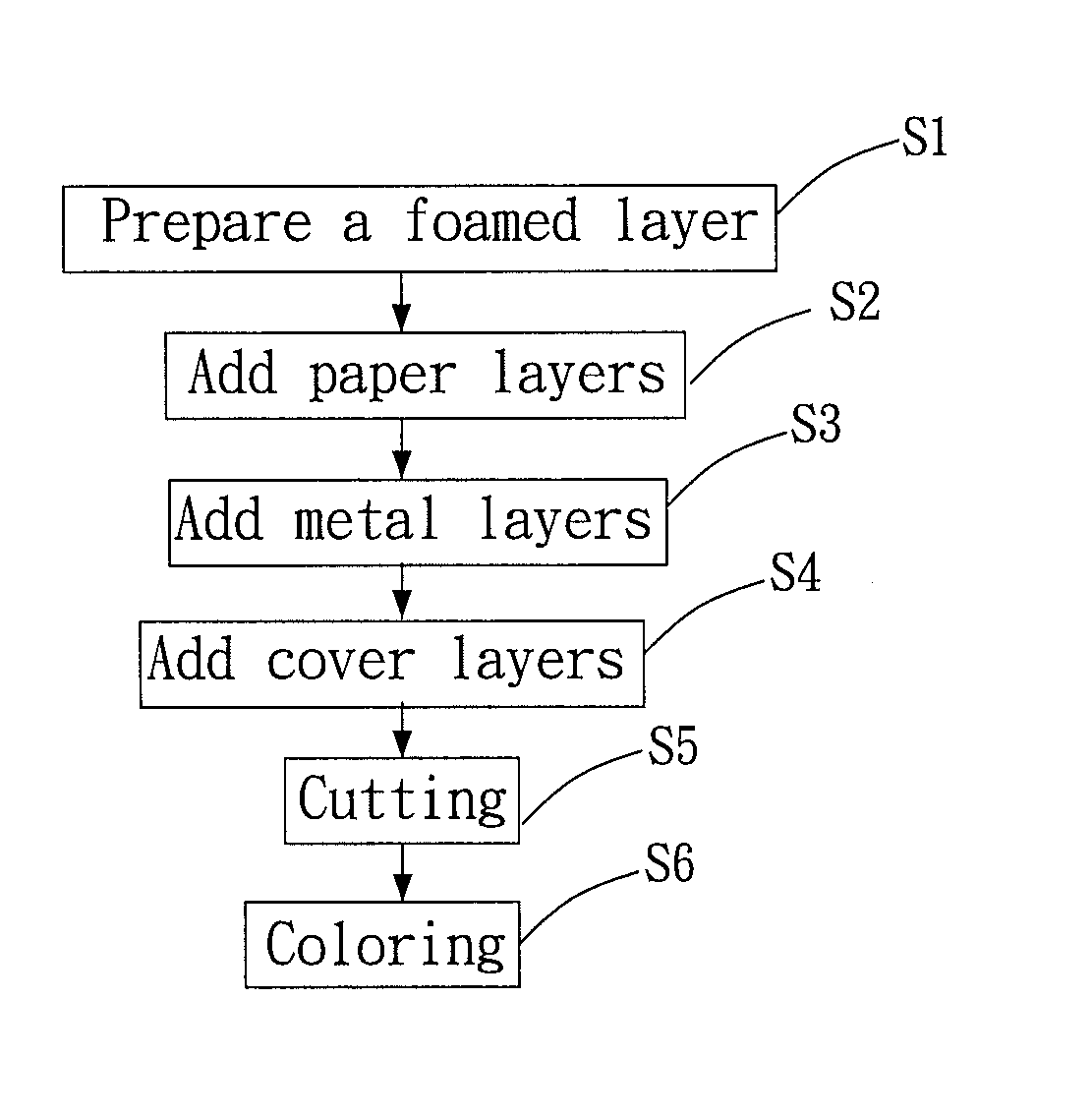

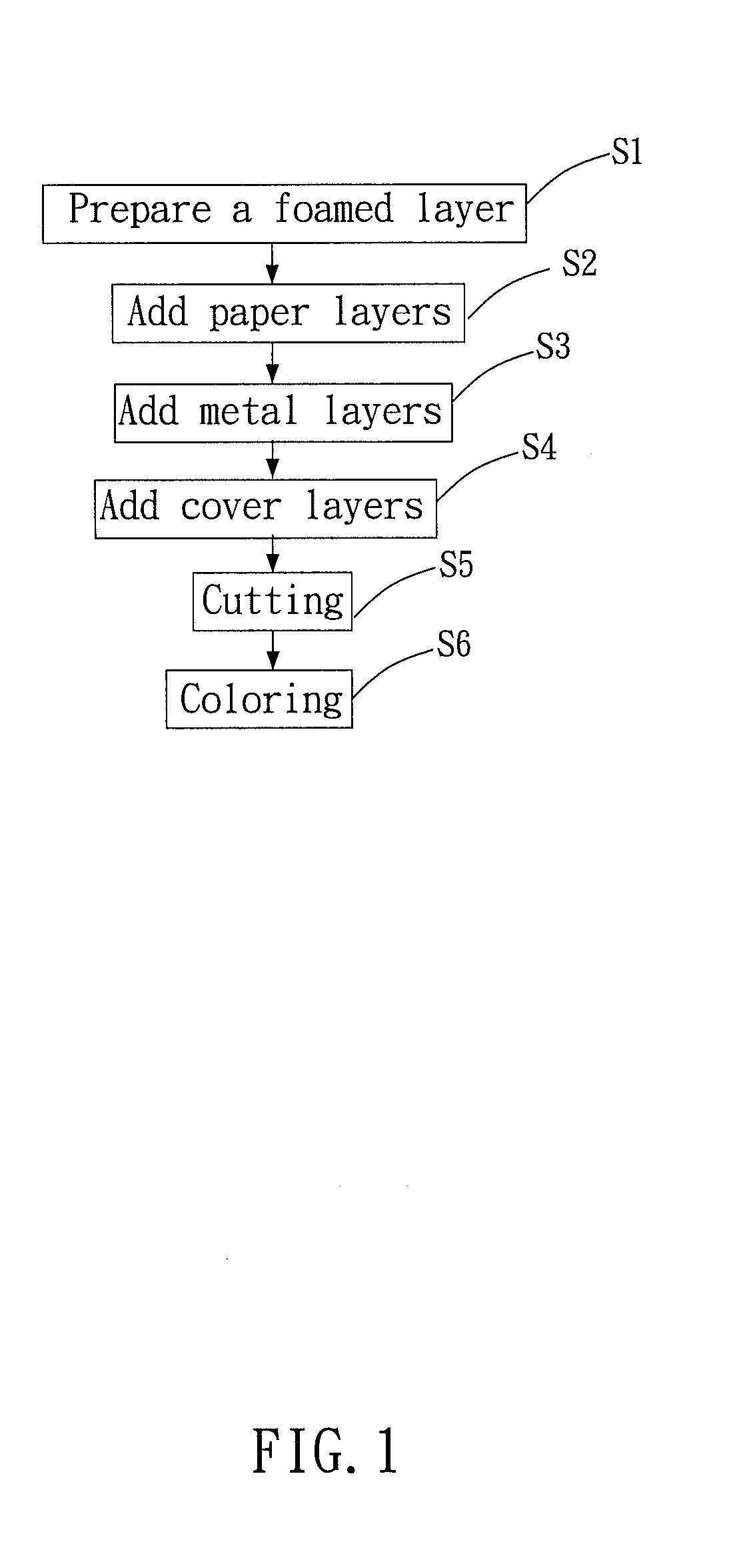

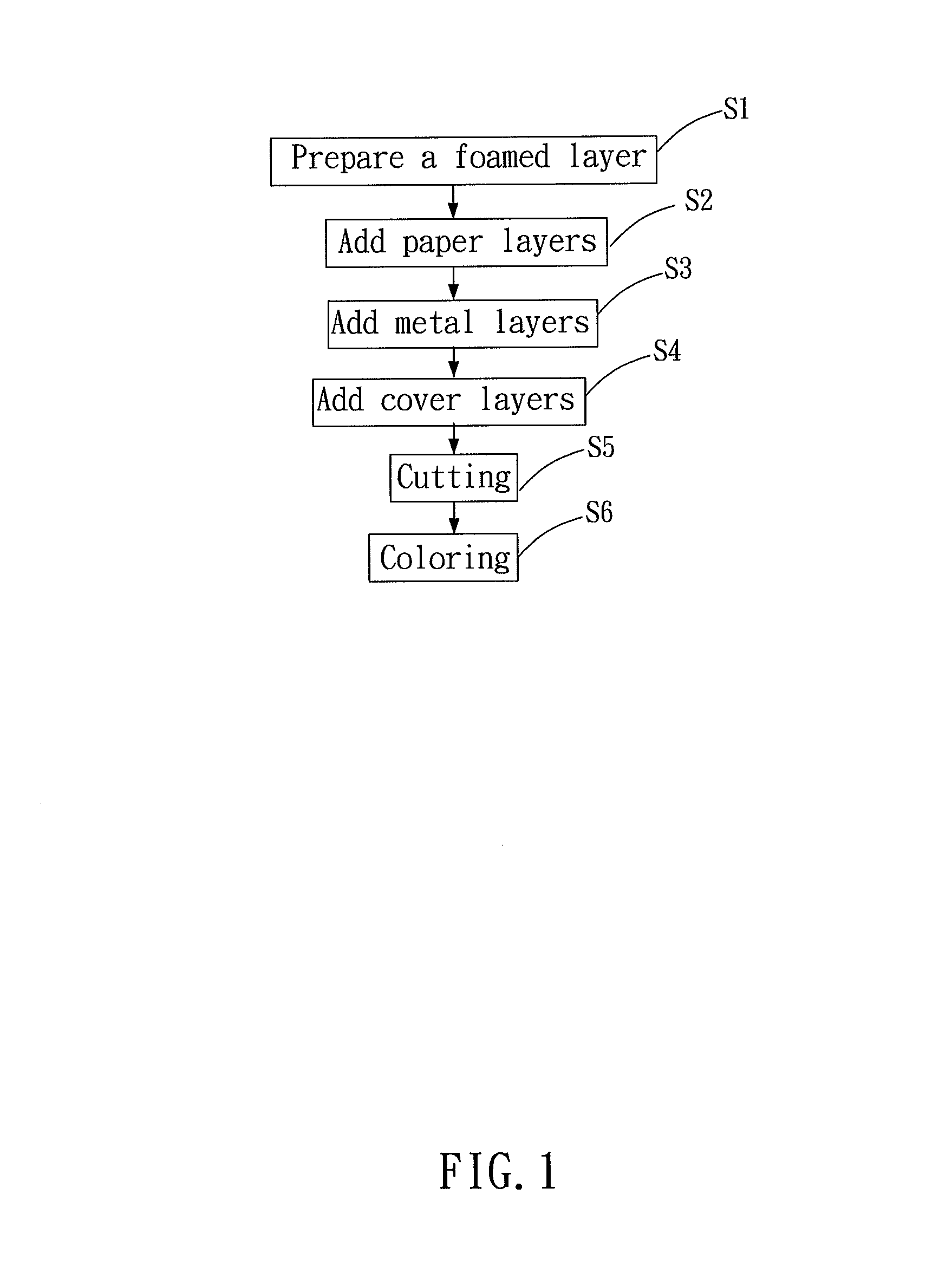

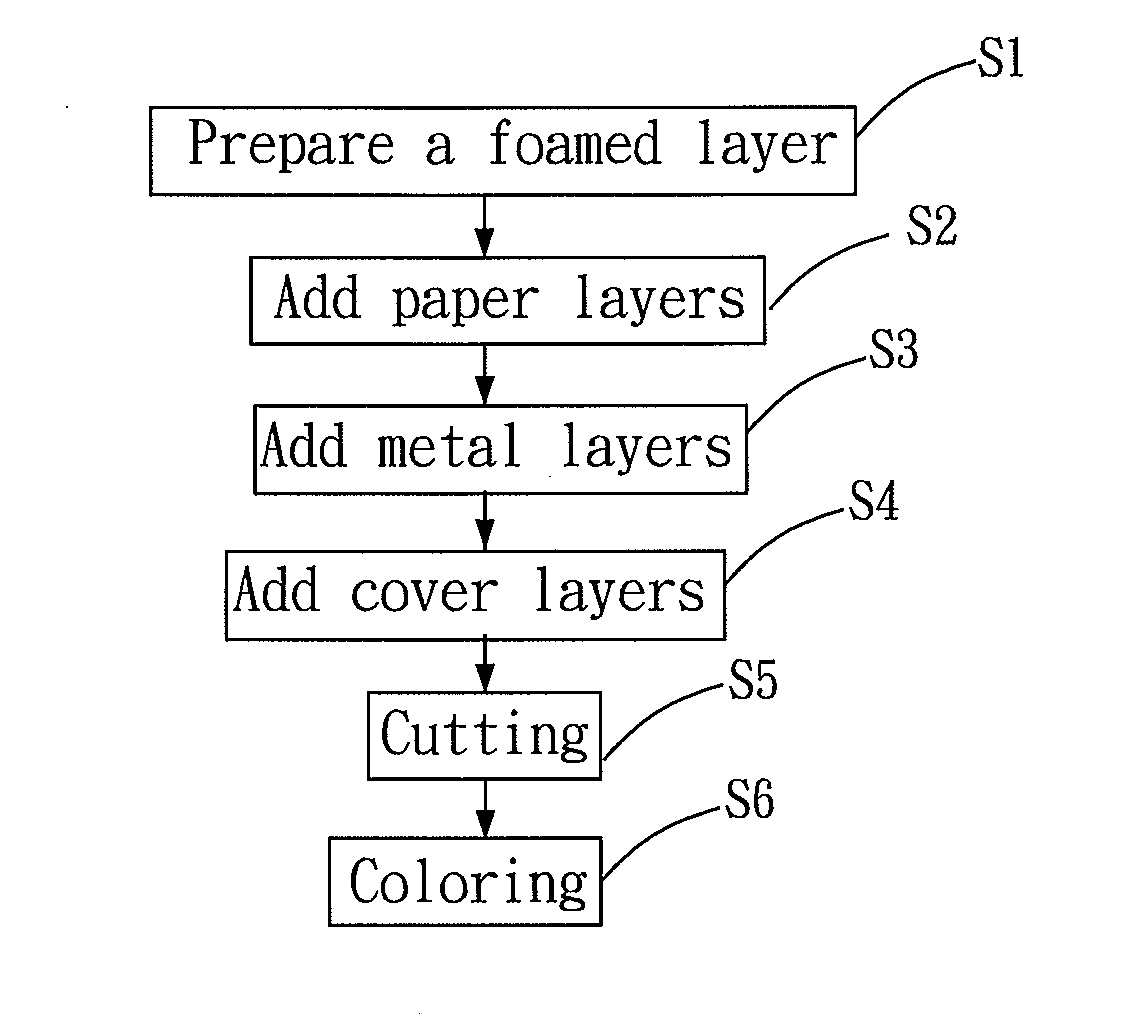

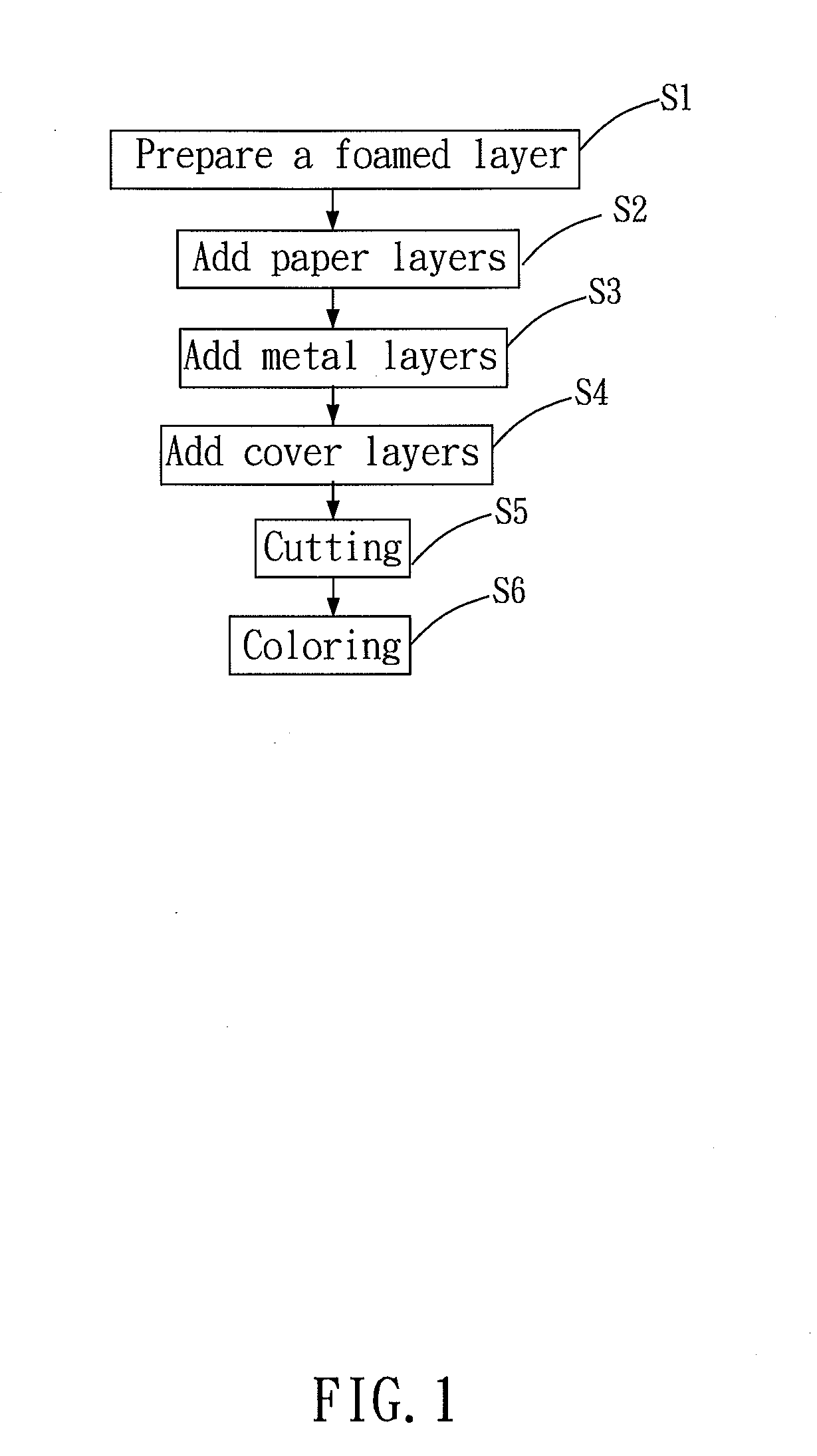

Method for manufacturing ceiling fan blade

InactiveUS20170021462A1Easy to manufactureLow costPump componentsBlade accessoriesCeiling fanPolystyrene

A ceiling fan blade includes a foamed layer, two paper layers, and two cover layers. The foamed layer is formed by foaming a polystyrene material. The paper layers are positioned on two opposite faces of the foamed layer respectively The cover layers are positioned on the paper layers respectively so that each paper layer is sandwiched between the foamed layer and one of the cover layers. Thereby, the ceiling fan blade of the present invention is light-weight, low-cost, and easy to manufacture. In addition, energy to rotate the ceiling fan is reduced.

Owner:CHUN WEI CHIANG

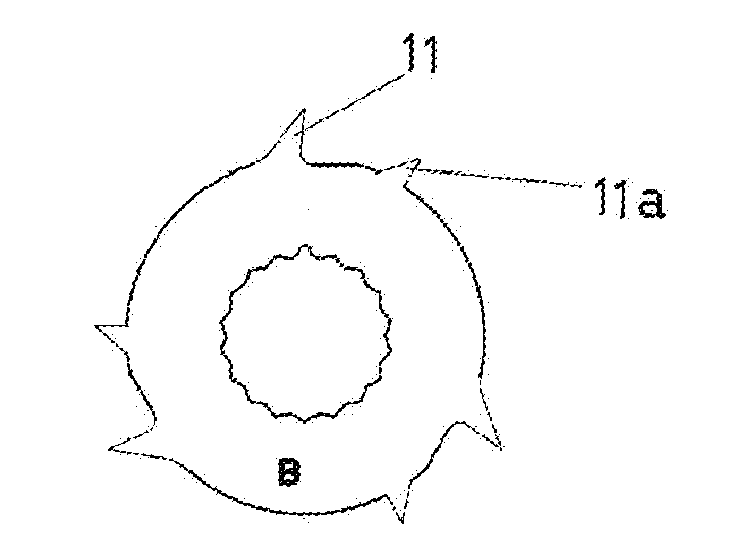

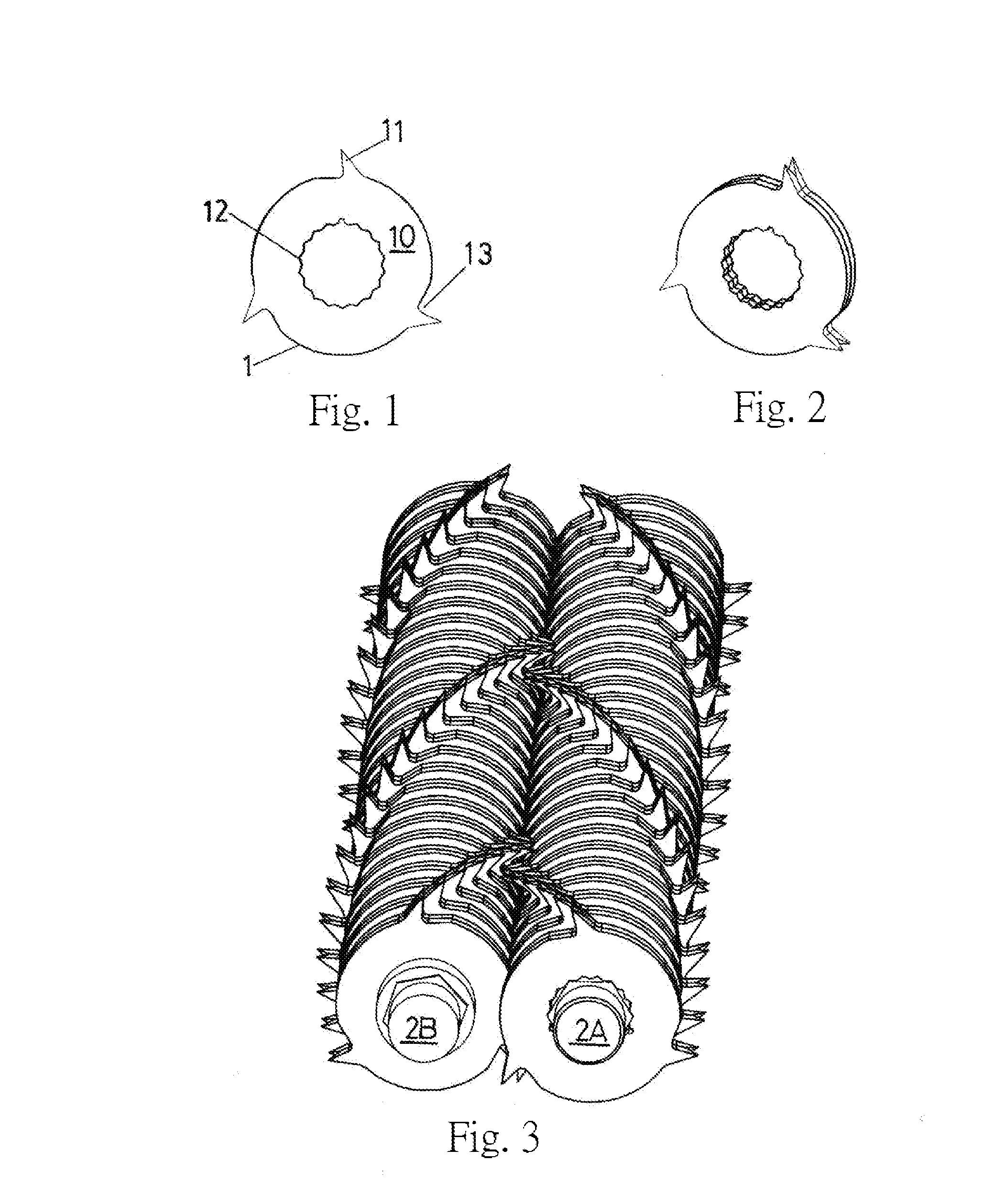

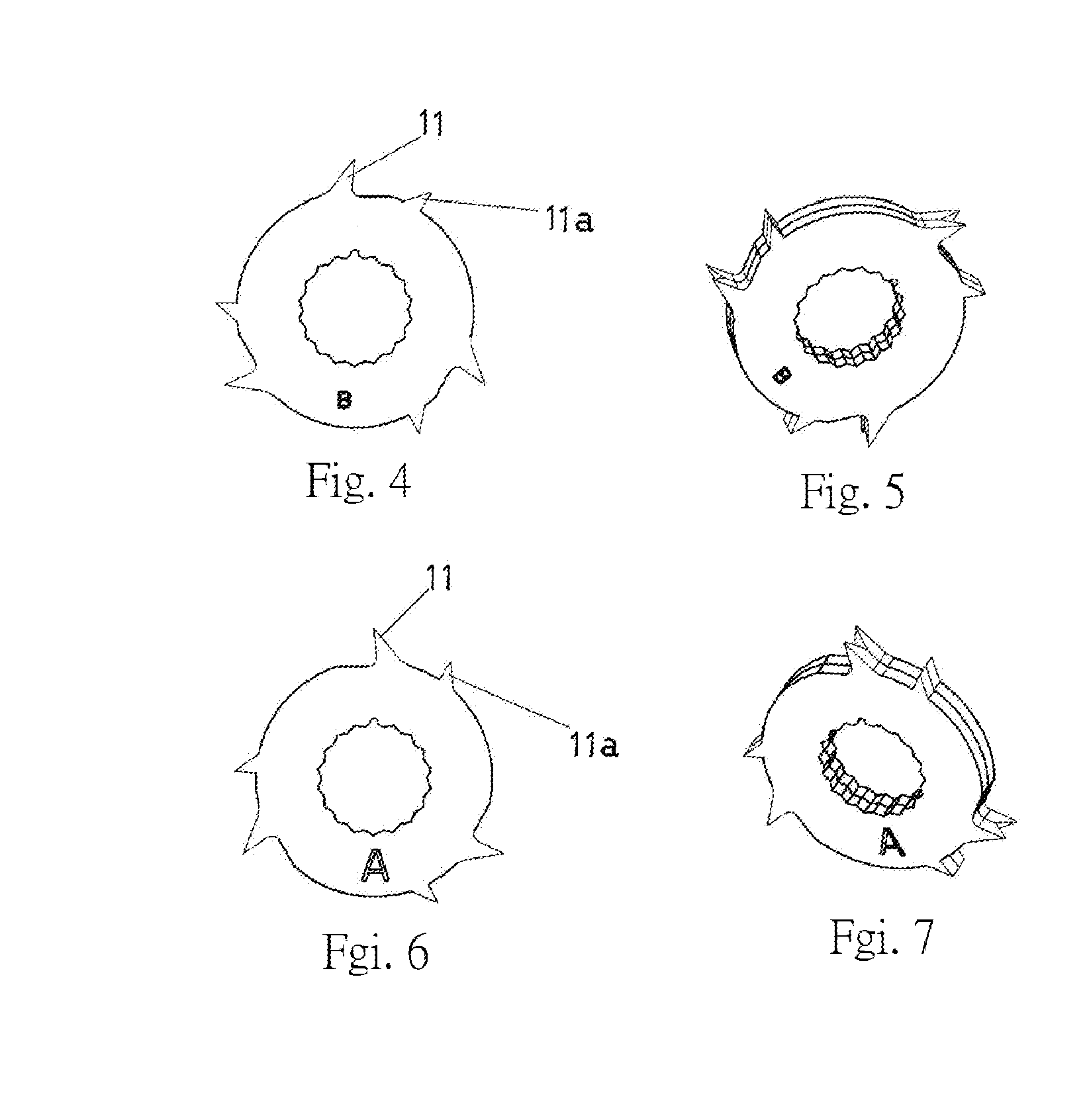

Blade of crosscut shredder

InactiveUS20120037738A1Reduce motor loadReduce power consumptionGrain treatmentsRotational axisShoot

A blade of the crosscut shredder has the feature that any of a plurality of blades on rotary shafts rotating in opposite directions has a plurality of primary shoots. A plurality of auxiliary shoots are provided in the vicinity of the primary shoot. The distance between the primary shoot and the blade center is slightly larger than the distance between the auxiliary shoot and the blade center. When the blades rotate in opposite directions with the rotary shafts, the auxiliary shoots of any blade on either rotary shaft pushes the paper to be shredded toward the primary shoots on the opposite blade. The primary shoots thus pierce the paper at a lower power.

Owner:MICHILIN PROSPERITY

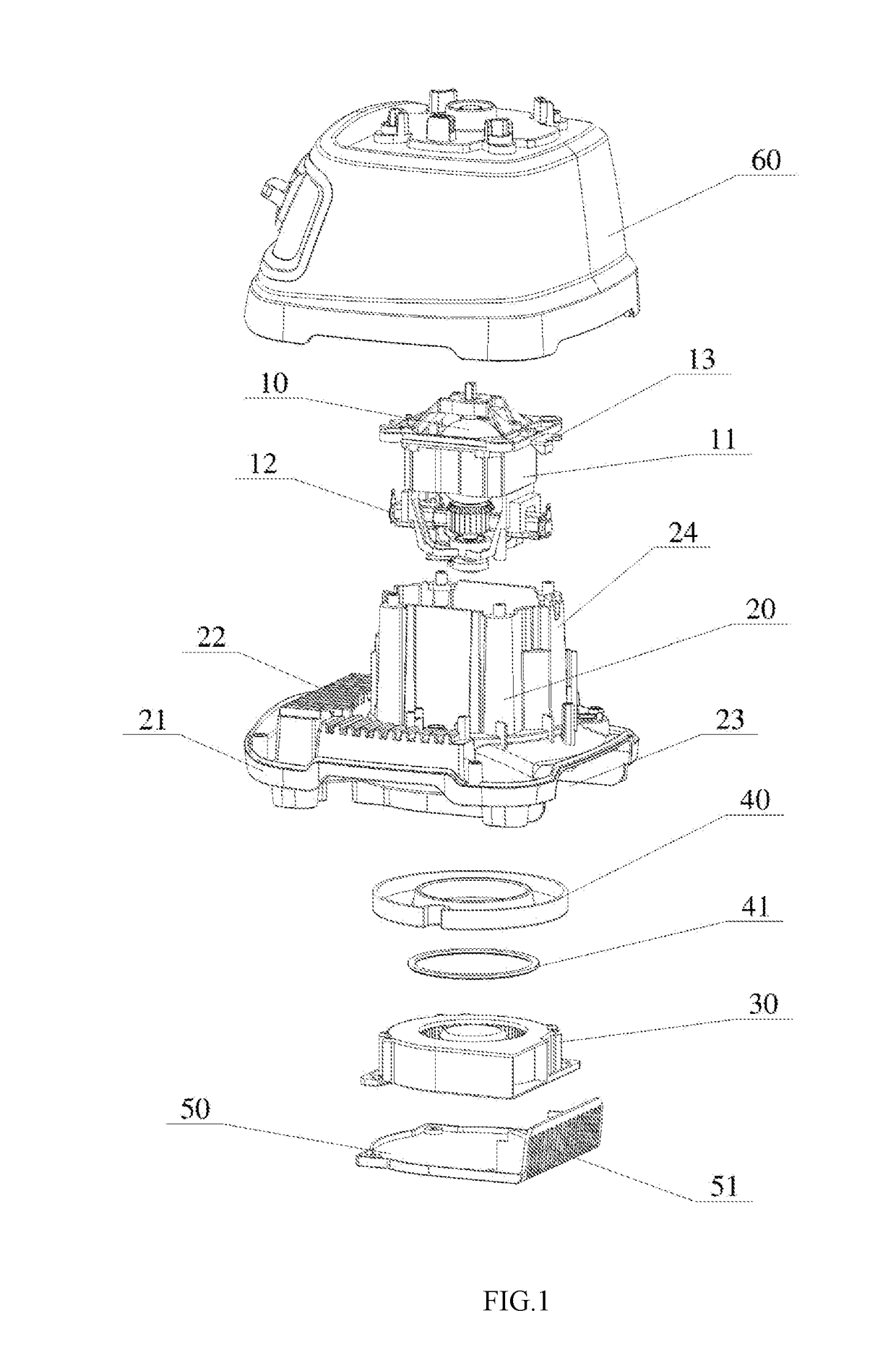

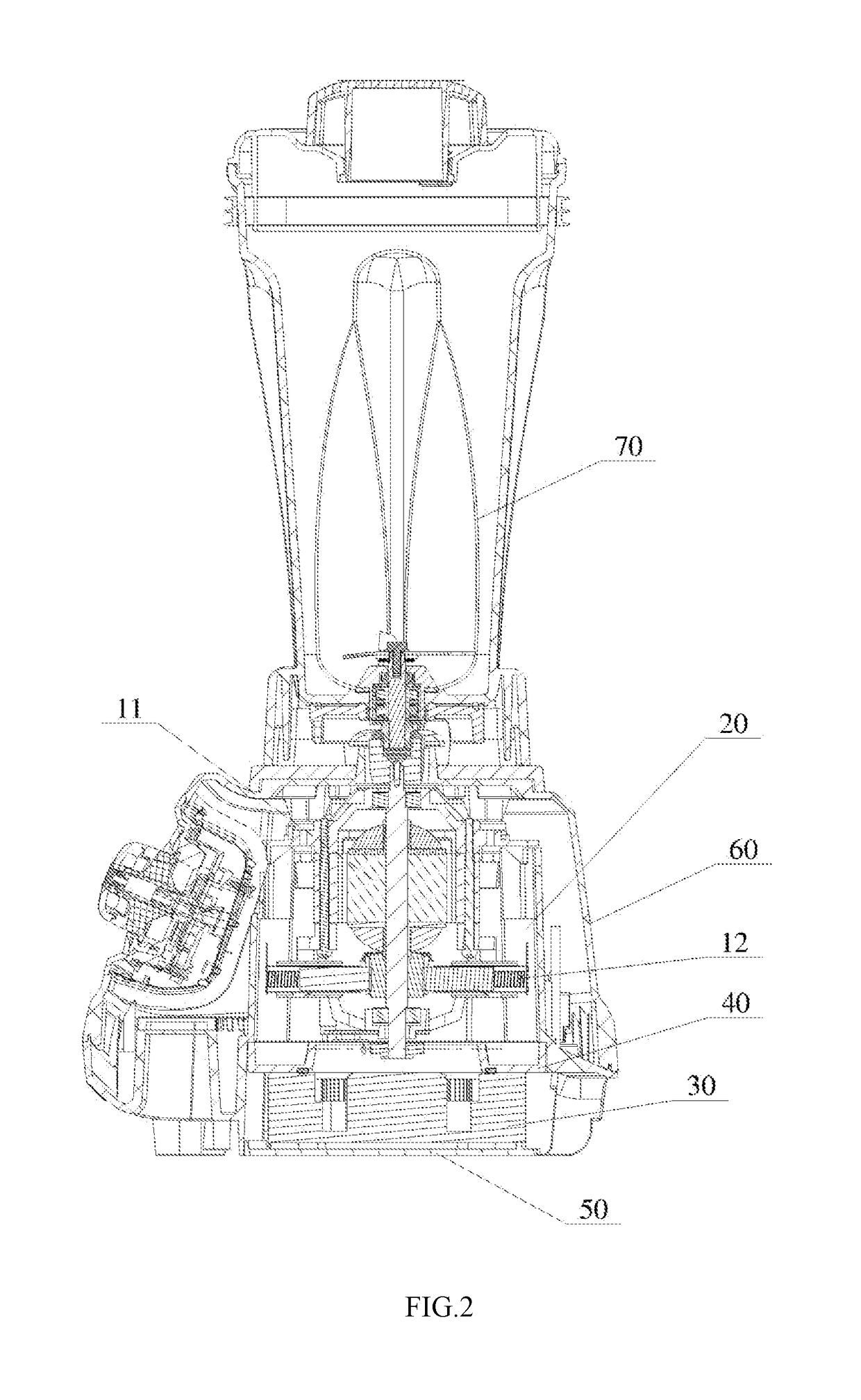

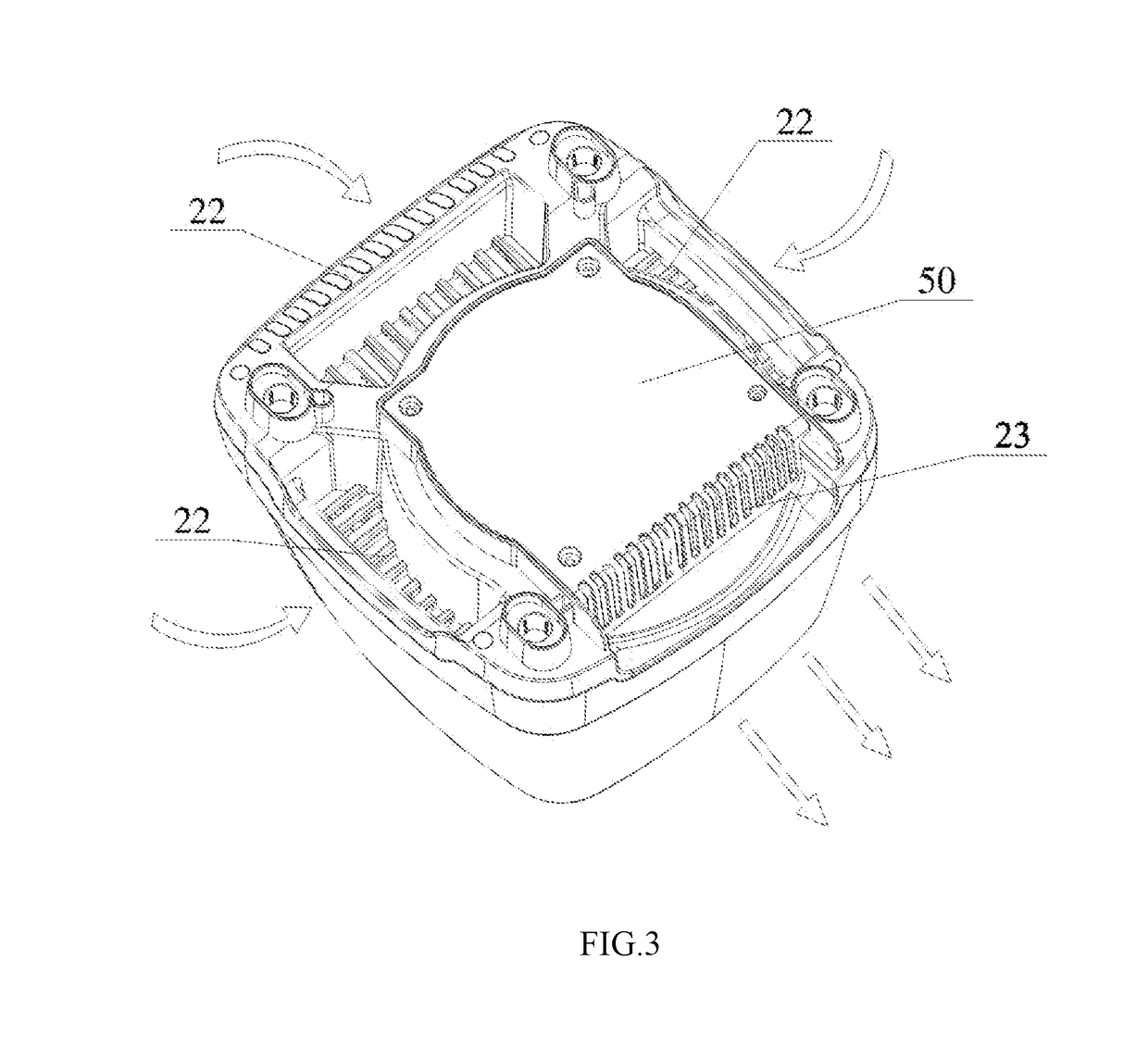

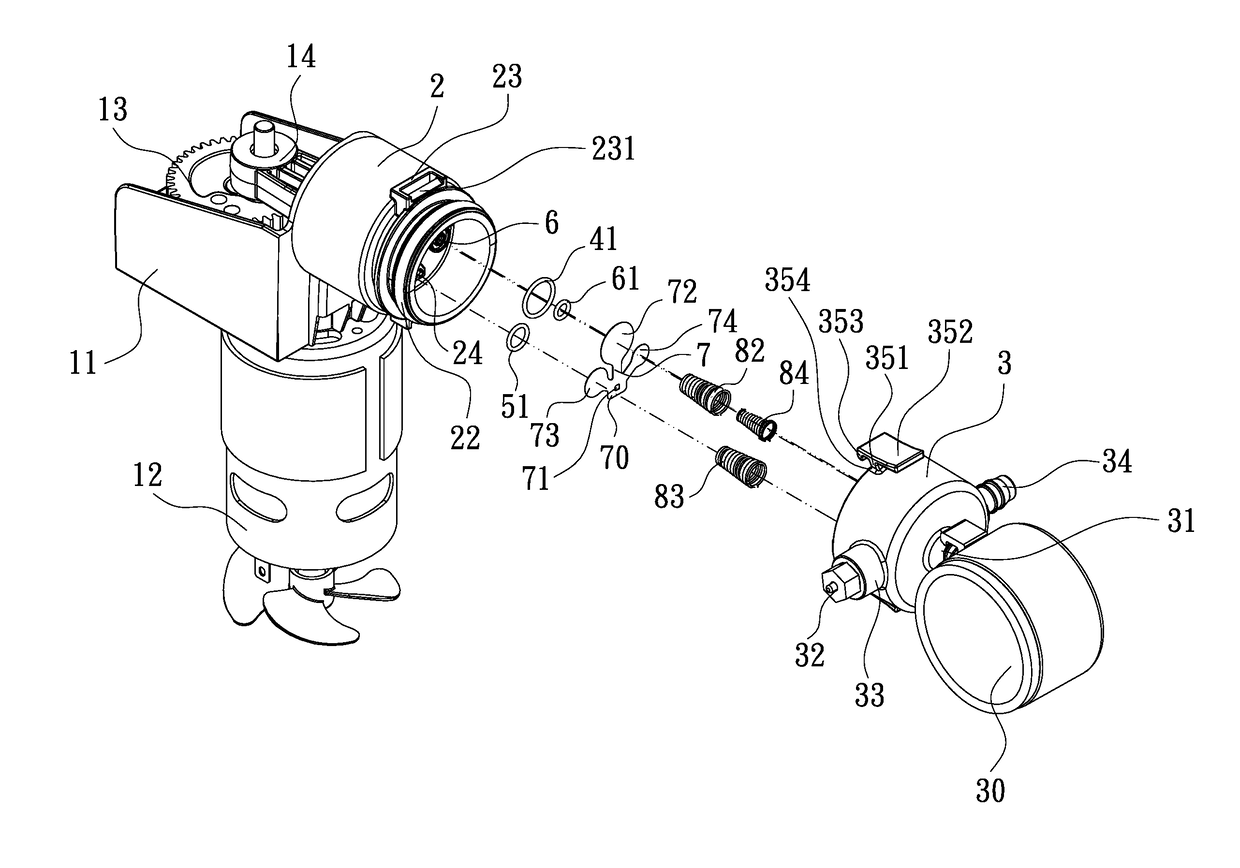

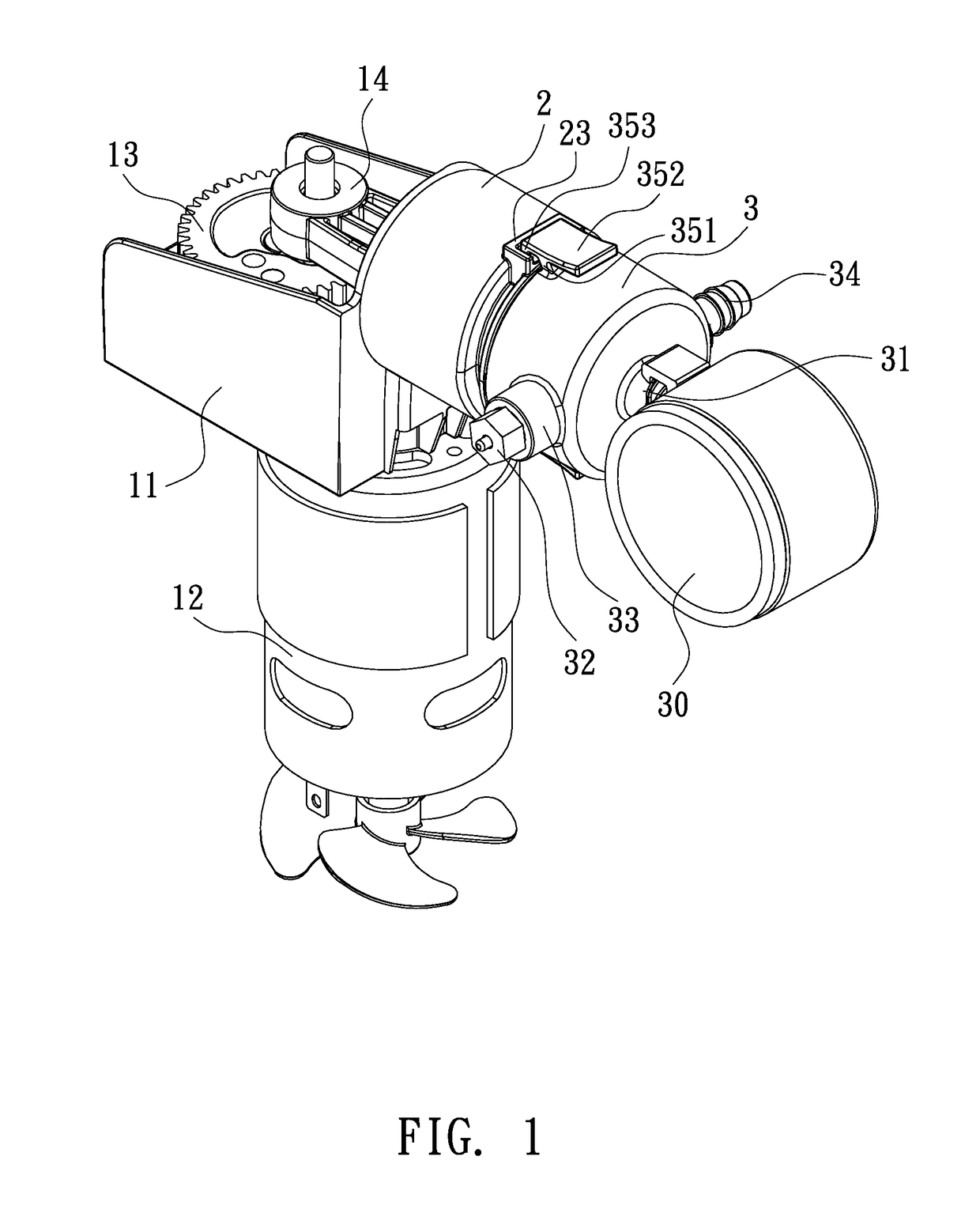

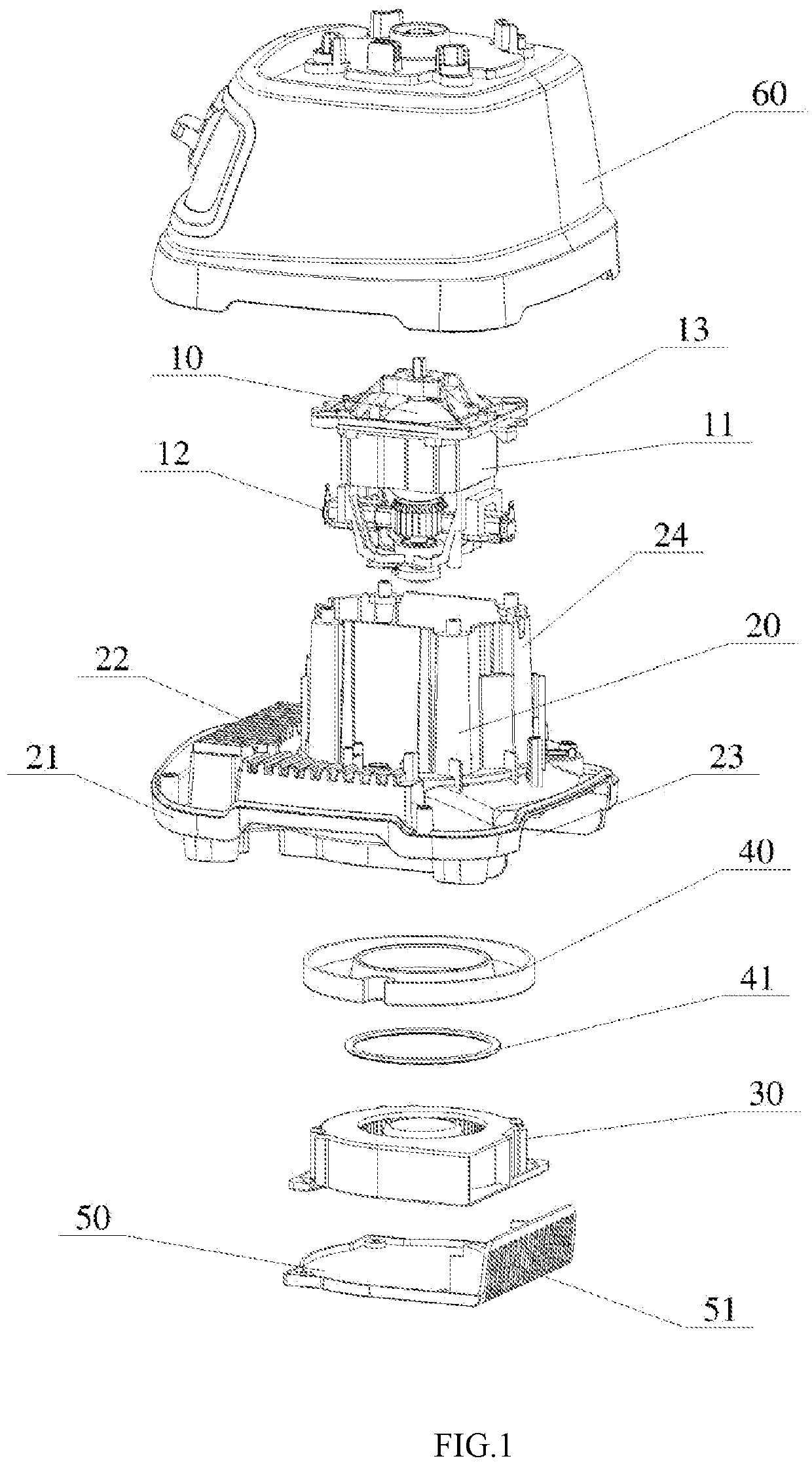

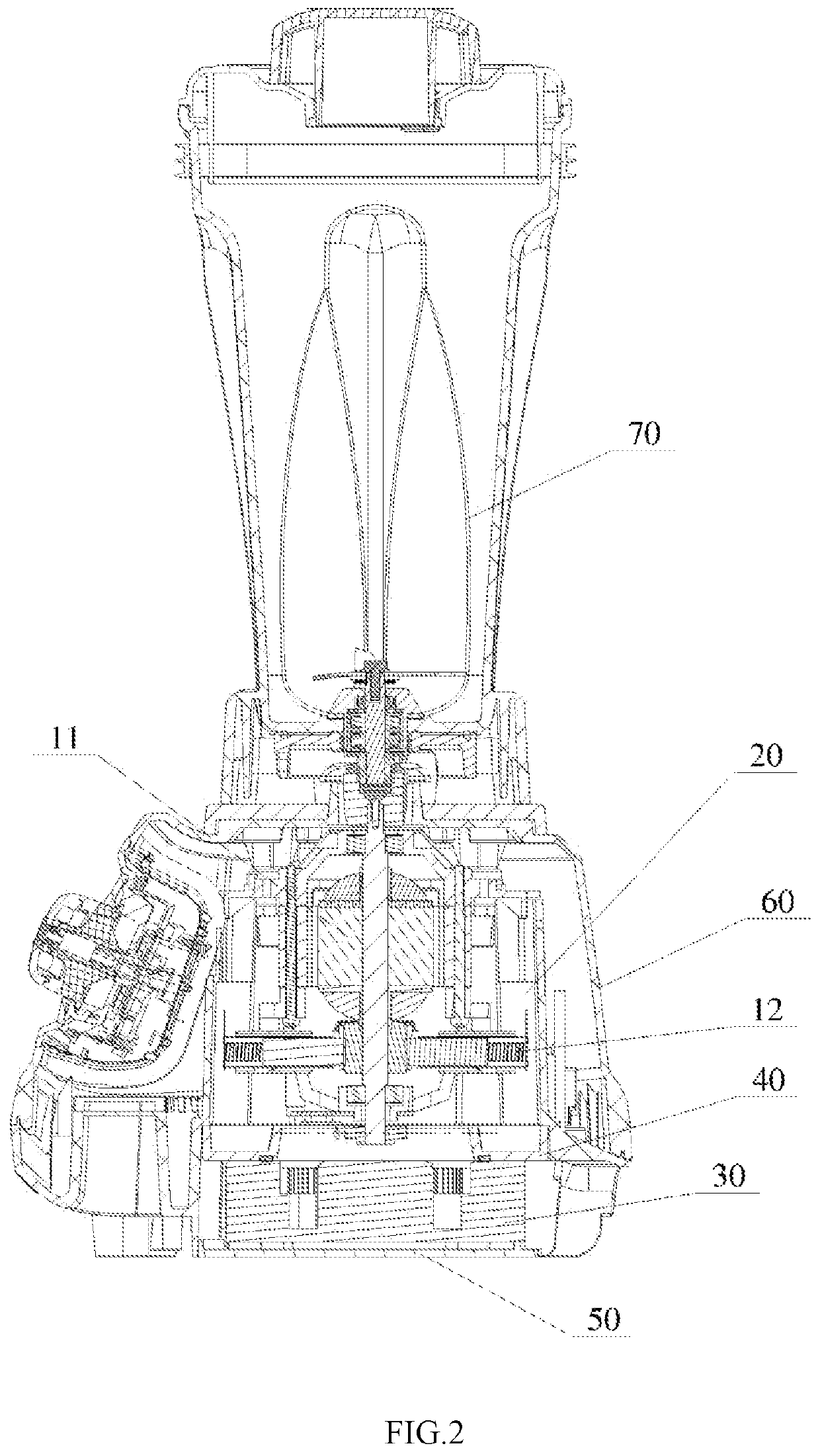

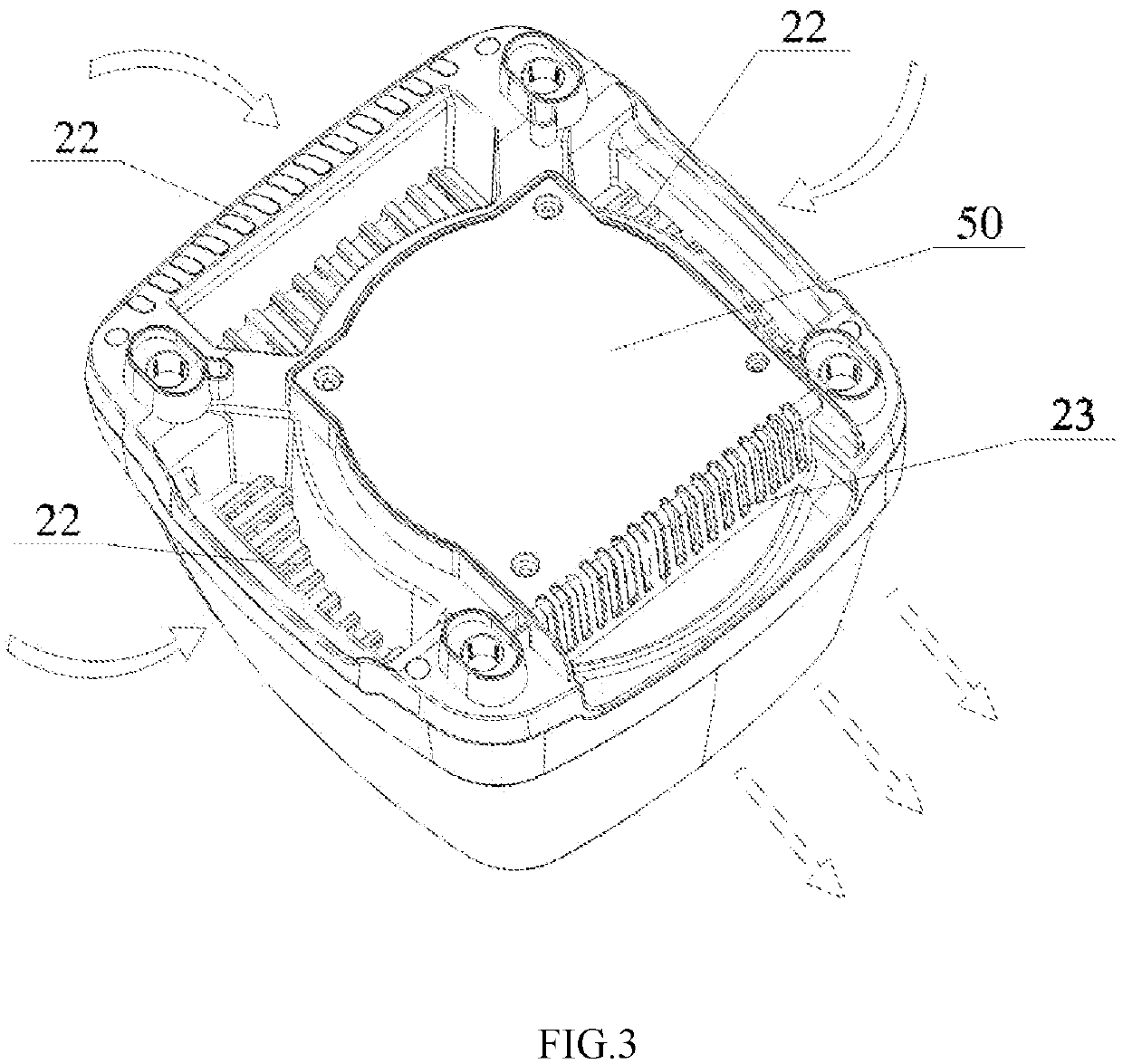

Air circulation and ventilation apparatus for food processing machine

ActiveUS20190021551A1Not occupy extra spaceStructure design is simple and convenientKitchen equipmentCooling/ventillation arrangementDrive motorCooling down

An air circulation and ventilation apparatus for a food processing machine (70), and the air circulation and ventilation apparatus comprises: a motor (10) and a fan (30), in which the motor (10) is used for driving an agitating or pulverizing assembly and is arranged within a base of the machine, and a body (60) of the machine is disposed outside the base, and the gap between the body (60) and the outer side wall of the base forms an air inlet passage; the fan (30) is equipped with a driving motor and is arranged within the base, and under the effect of the fan (30), airflow enters the air inlet passage by means of an air inlet port (22) on the base and flows through the motor (10) within the base and is discharged from an outlet port (23) on the base. By independently and separately providing the motor (10) for driving the agitating or pulverizing assembly of the food processing machine (70) and the fan (30) for ventilation, the load on the motor (10) and the vibration of the food processing machine (70) maybe be reduced, while also reducing noise; the fan (30) drives the operation thereof, and can independently adjust the rotational speed thereof according to ventilation needs, thus preventing waste of resources; further, when an operation problem occurs with the motor (10), the motor (10) may be effectively cooled down, thus maintaining good heat-dissipation efficiency, thereby prolonging the service life of the food processing machine (70).

Owner:GUANGDONG XINBAO ELECTRICAL APPLIANCES HLDG CO LTD

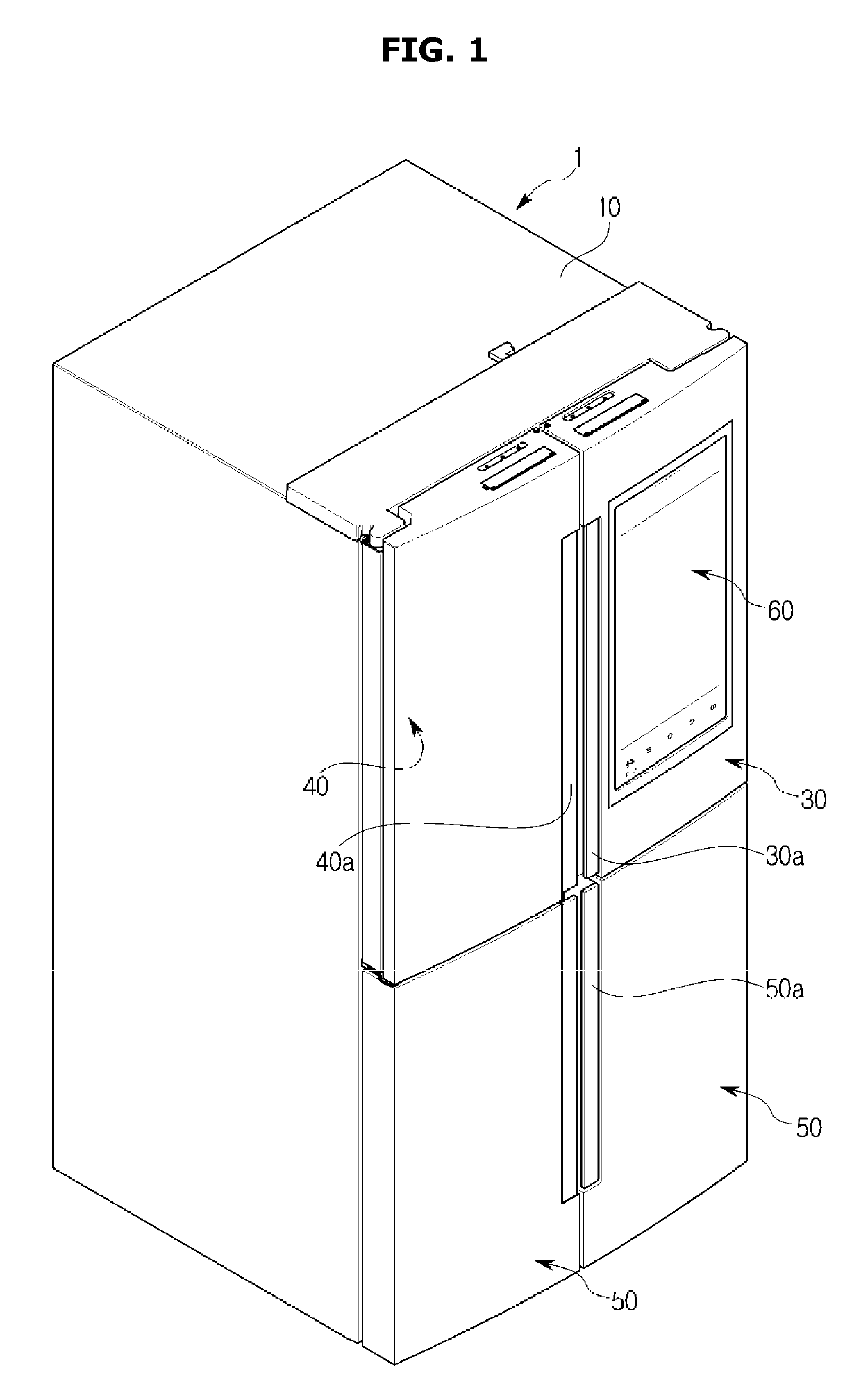

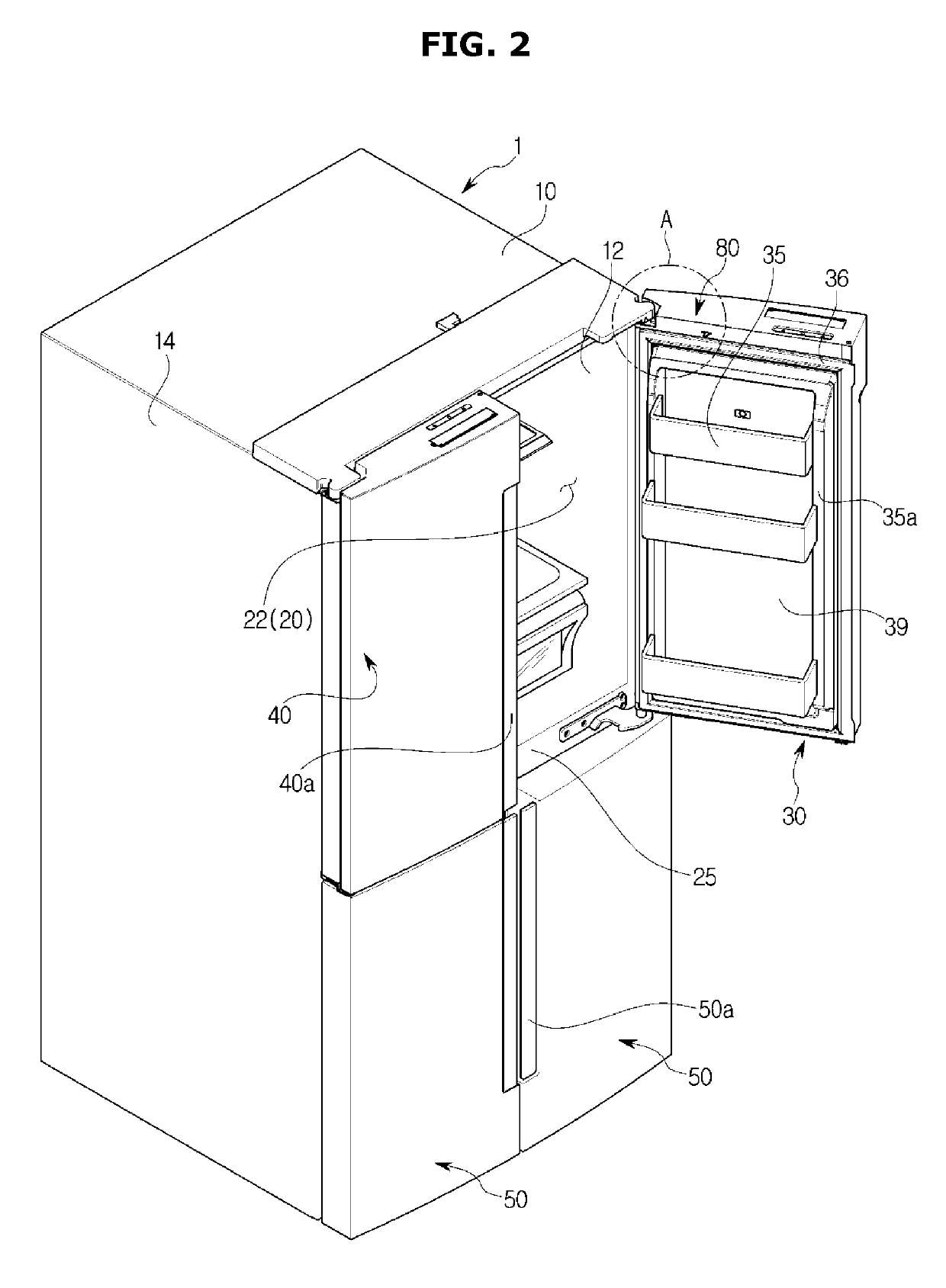

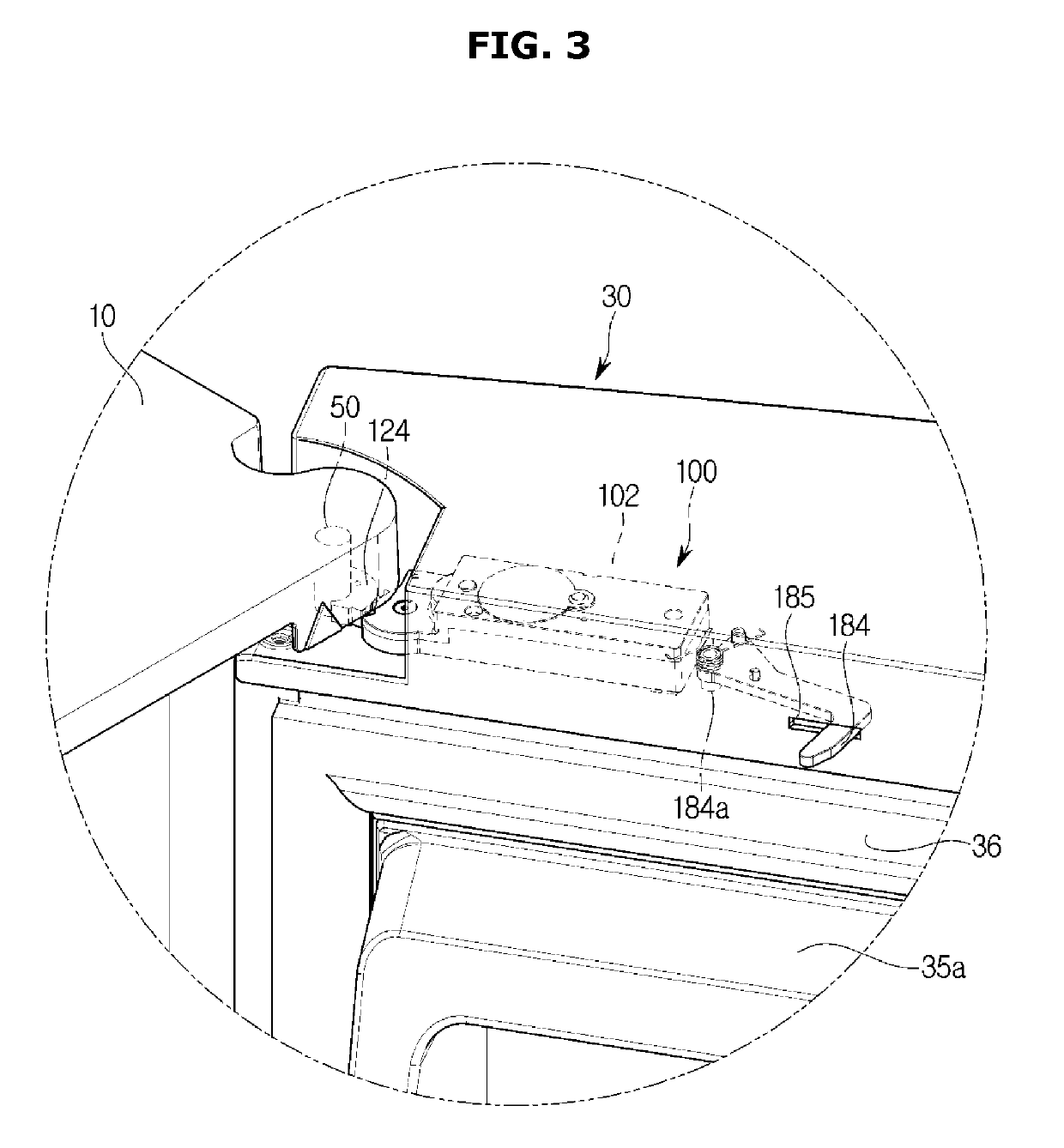

Refrigerator

InactiveUS10309143B2Simple structureIncreased durabilityLighting and heating apparatusDomestic refrigeratorsEngineeringRefrigerated temperature

Owner:SAMSUNG ELECTRONICS CO LTD

Zoom lens

InactiveUS8711489B2Reduce motor loadObstruction is producedOptical elementsObject pointMagnification

In a zoom lens of a fixed total length, at the time of changing the magnification from the wide-angle end toward the telephoto end, the first lens group is anchored while the second lens group is moved, and the third and fourth lens groups are moved so as to be located at the object side of the telephoto end relative to the wide-angle end, such that: the interval between the second and third lens groups is decreased at the telephoto end relative to the wide-angle end; the interval between the third and fourth lens groups is increased at the telephoto end relative to the wide-angle end; and the interval between the fourth and fifth lens groups is increased at the telephoto end relative to the wide-angle end, and at the time of focusing a near object point from a remote object point, the second lens group is moved.

Owner:OM DIGITAL SOLUTIONS CORP

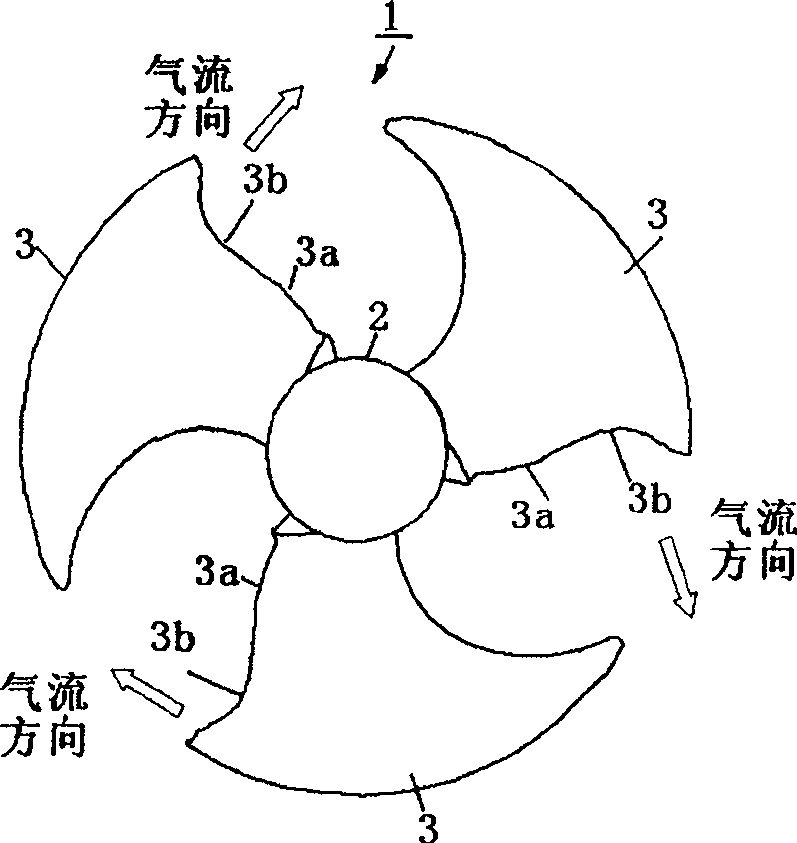

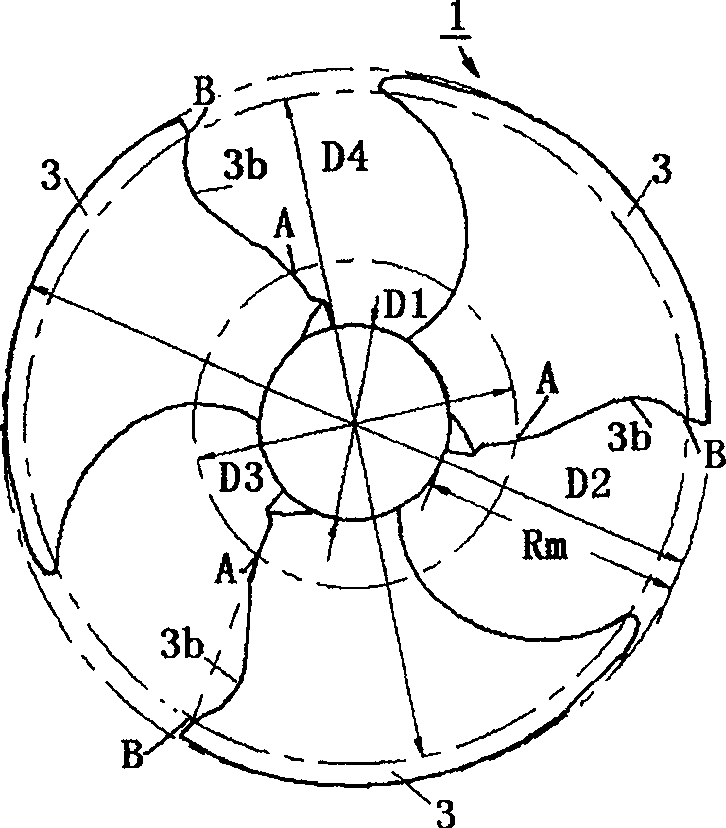

An axial-flow windwheel

InactiveCN100465458CDecrease the strength of the wakeEasy to separatePump componentsPumpsLow noiseLeading edge

An axial-flow wind wheel comprises three blades set on a hub, wherein, the end area of the blades is dishing toward to the costal air-in direction; the three blades use the rotary central axis of the wind wheel as center each other and they allocate equal-spaced or unequal-spaced in the 120degree+-15degree. The external diameter of the axial-flow is defined as D2, the hub diameter is defined as D1, the height of the blade Rm is defined as (D2-D1) / 2, the circumference diameter in which there is the beginning dishing place A is defined as D3, (D3-D1) / 2=(0.10-0.47)Rm. Since the high-middle part of the trailing edge change the distribution of pressure of the blades before the blade root part, the high pressure draught compartment of the blades flow direction low pressure surface advanced to make local pressure ascending, to reduce boundary layer separating, to make the boundary layer turn into turbulent flow before getting the front of the blade end, to reduce convolution noise and rotor wake, thereby having low noise and big air quantity.

Owner:GD MIDEA AIR-CONDITIONING EQUIP CO LTD

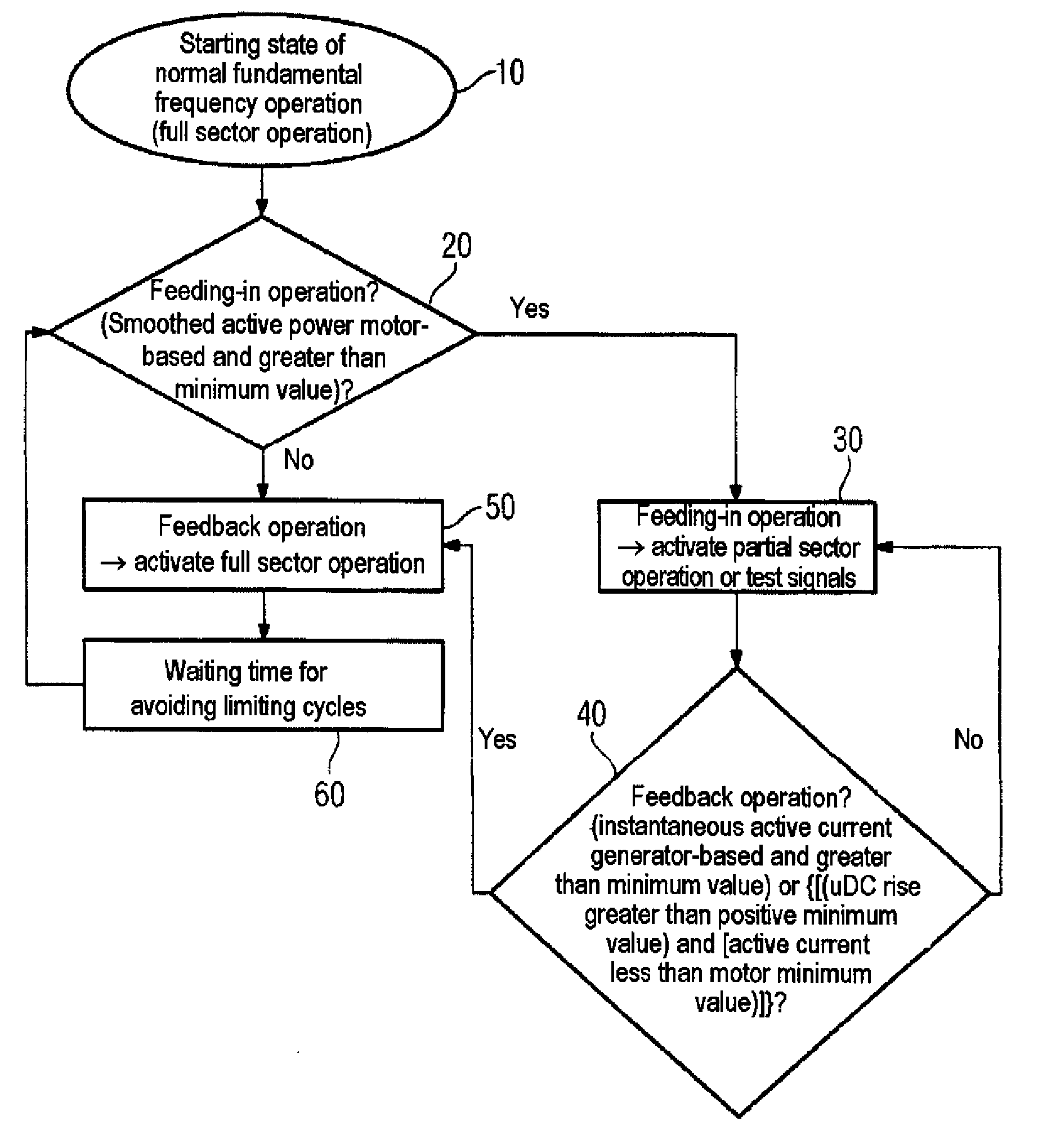

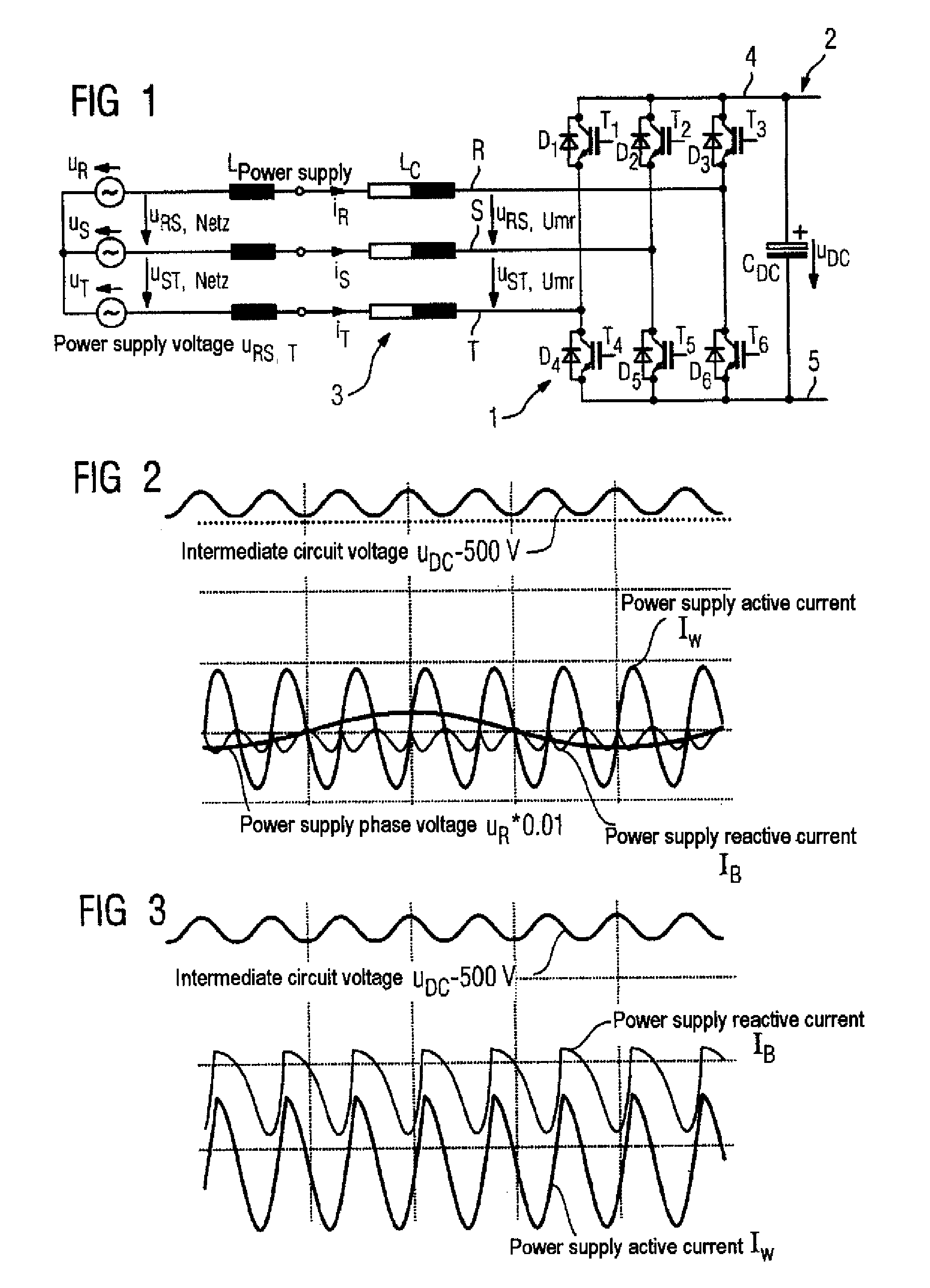

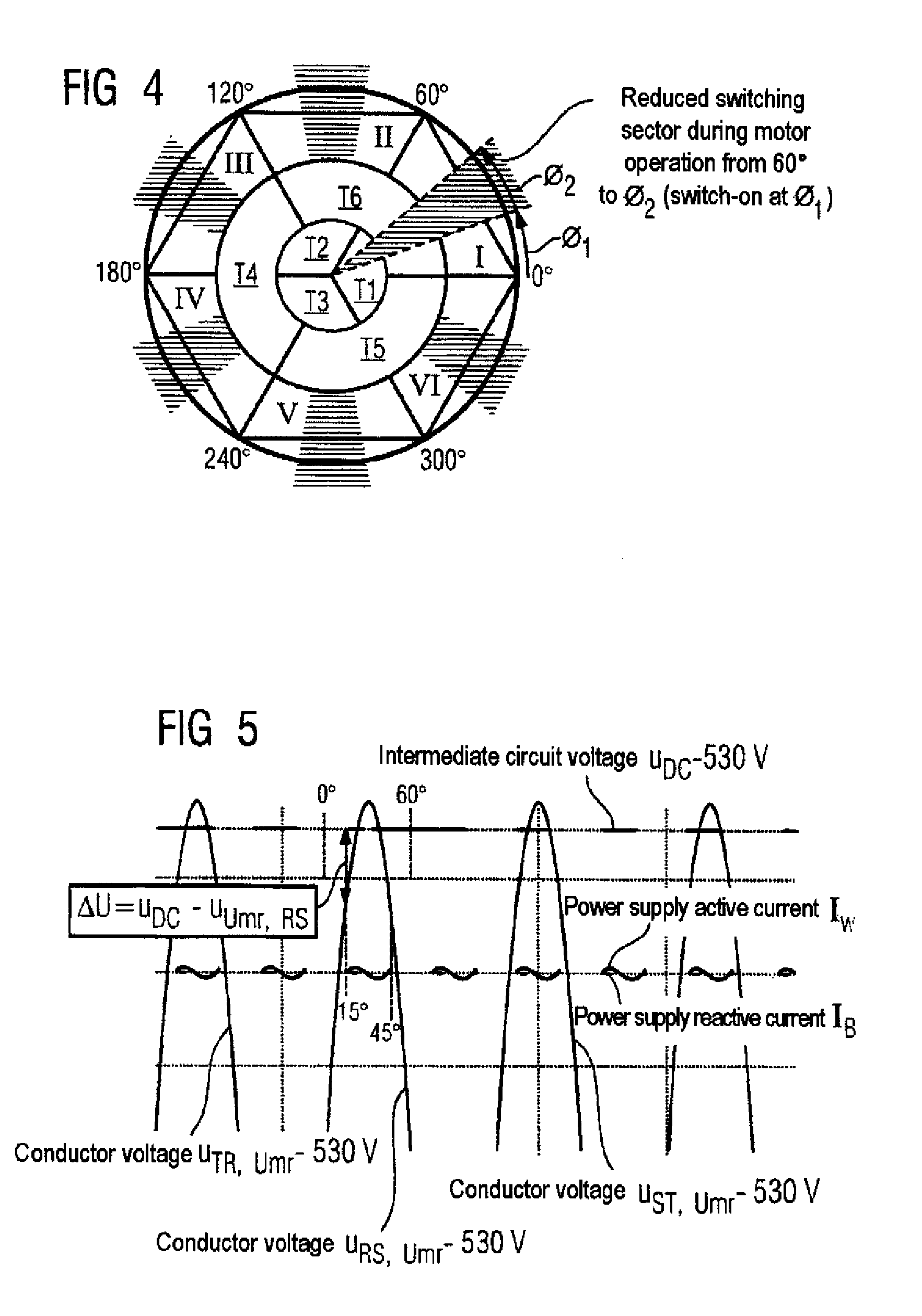

Method for reducing the reactive power requirement of a fundamental frequency clocked power supply side converter under no load and with low motor loading

ActiveUS7983060B2Reducing reactive power requirementReduce motor loadAC motor controlEfficient power electronics conversionFundamental frequencyEngineering

The invention relates to a method for reducing the idle current requirement of a base frequency clocked supply side converter (1) on idle and with low motor loads, provided with controllable semiconductors (T1,T2,T3,T4, T5,T6), wherein the base frequency clocking of the semiconductor switches (T1,T2,T3,T4,T5,T6) occurs depending on the desired direction of flow of power. A converter (1) for carrying out said method is also disclosed.

Owner:SIEMENS AG

Method for manufacturing ceiling fan blade and ceiling fan blade

InactiveUS20160169244A1Easy to manufactureLow costPump componentsMetal-working apparatusCeiling fanPolyvinyl chloride

A ceiling fan blade includes a foamed layer, two paper layers, and two cover layers. The foamed layer is formed by foaming a polyvinyl chloride material. The paper layers are positioned on two opposite faces of the foamed layer respectively The cover layers are positioned on the paper layers respectively so that each paper layer is sandwiched between the foamed layer and one of the cover layers. Thereby, the ceiling fan blade is light-weight, low-cost, and easy to manufacture. In addition, energy to rotate the ceiling fan is reduced.

Owner:CHIANG CHUN WEI

Method for manufacturing ceiling fan blade and ceiling fan blade

InactiveUS20150211371A1Easy to manufactureLow costPump componentsBlade accessoriesCeiling fanPolystyrene

A ceiling fan blade includes a foamed layer, two paper layers, and two cover layers. The foamed layer is formed by foaming a polystyrene material. The paper layers are positioned on two opposite faces of the foamed layer respectively. The cover layers are positioned on the paper layers respectively so that each paper layer is sandwiched between the foamed layer and one of the cover layers. Thereby, the ceiling fan blade of the present invention is light-weight, low-cost, and easy to manufacture. In addition, energy to rotate the ceiling fan is reduced.

Owner:CHUN WEI CHIANG

Slewing type working machine

InactiveUS8752373B2Improve recycling efficiencyReduce motor loadFluid couplingsSoil-shifting machines/dredgersHydraulic motorHydraulic pump

A slewing-type working machine, including a base, an upper slewing body, a hydraulic motor slewing the upper slewing body, a hydraulic pump, a slewing operation device, a control valve controlling the hydraulic motor, pipe-lines connecting the hydraulic motor to the control valve, a hydraulic pressure source, communication valves switching communication and cutoff between the pipe-lines and a tank by pilot pressure, an electric motor, an electric storage device, communication selector valves on inlet sides of the communication valves, a switching control valve on an inlet side of the communication selector valves, and a controller. During slewing deceleration, the controller signals to switch the switching control valve to a connecting position and switch the communication selector valves to a pilot pressure supply position. In a slewing stopped state, the controller signals to switch the communication selector valves to a cutoff position and switch the communication valves to a communication cutoff position.

Owner:KOBELCO CONSTR MASCH CO LTD

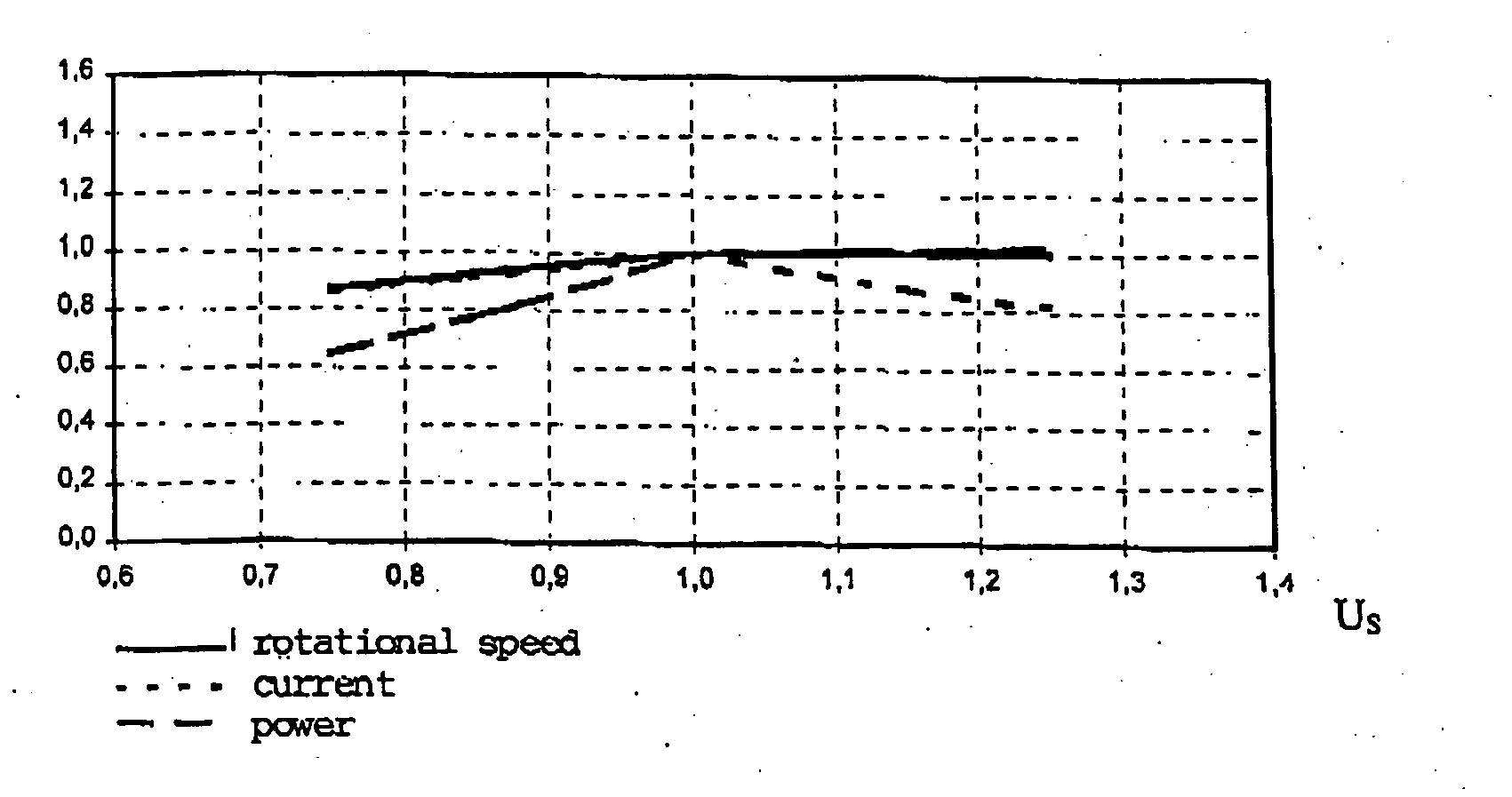

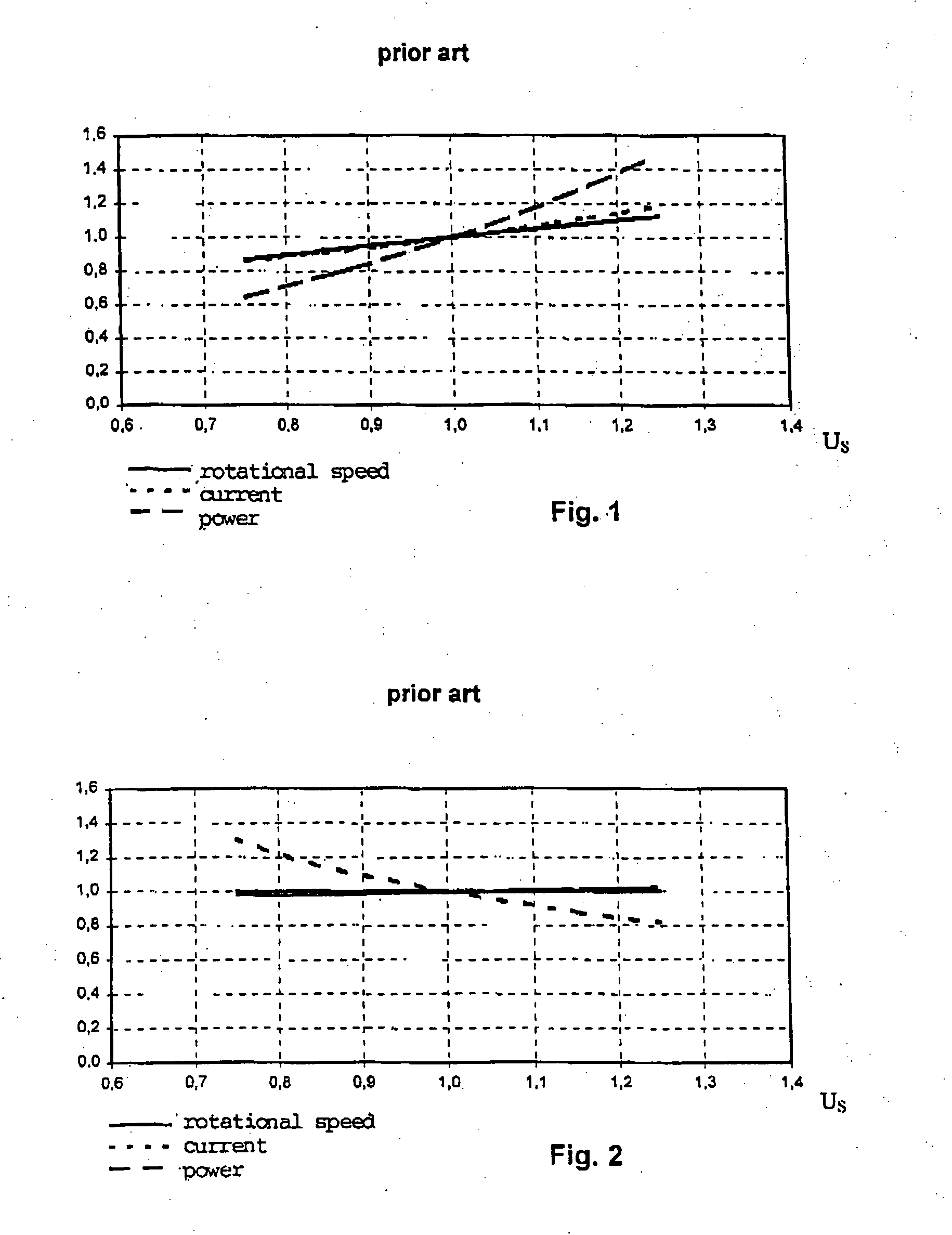

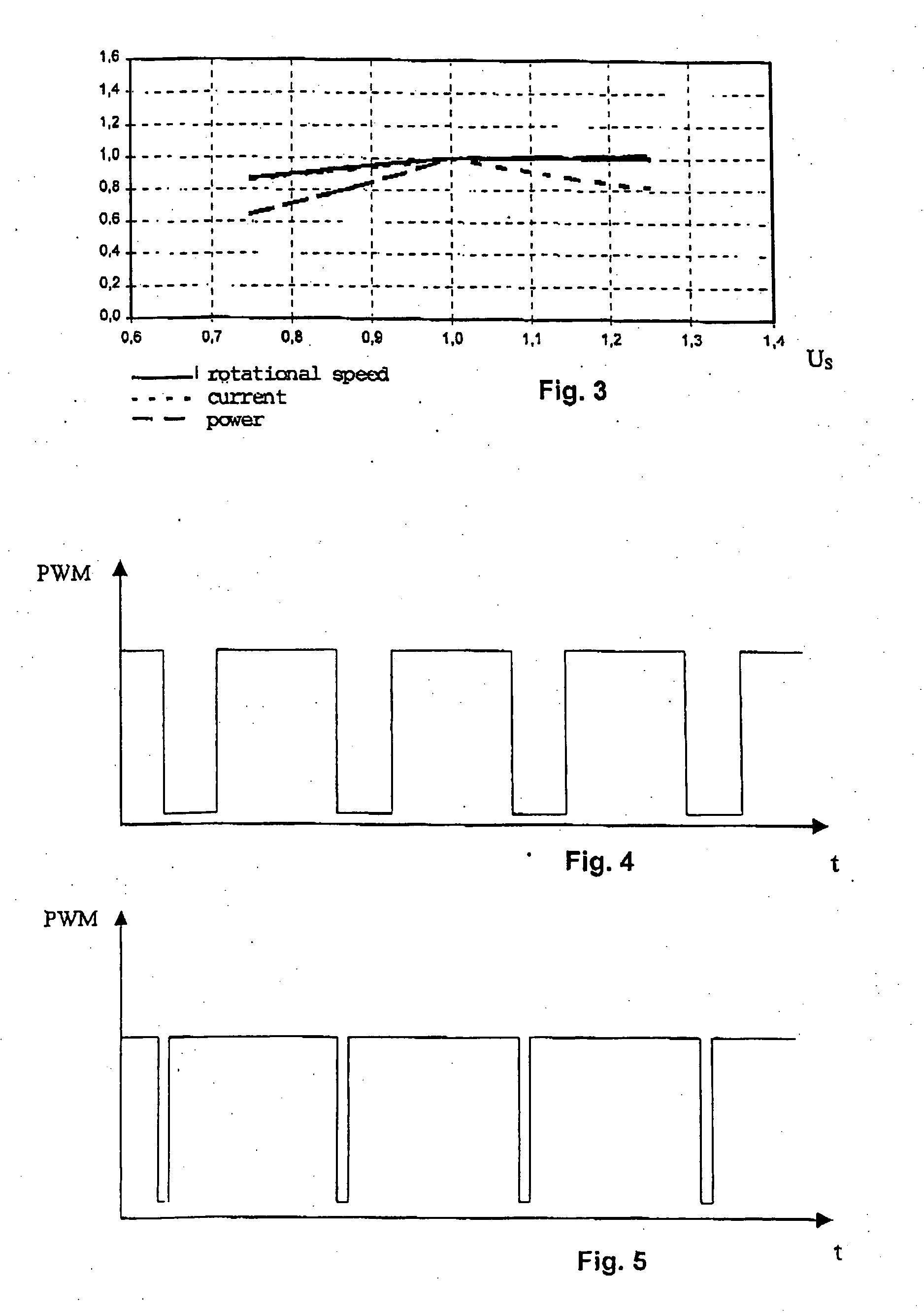

Method for controlling a brushless electric motor

ActiveUS20050231139A1Reduce the ratioReduce motor loadAC motor controlSynchronous motors startersOperating pointVoltage range

The invention relates to a method for controlling a brushless electric motor for operation within a specified supply voltage range, a motor control controlling the winding voltage by means of pulse width modulation (PWM) and regulating the rotational speed to a specified speed. According to the invention, the motor is so rated that the nominal rotational speed is just achieved at the nominal operating point at the nominal supply voltage and at the maximum PWM ratio.

Owner:MINEBEAMITSUMI INC

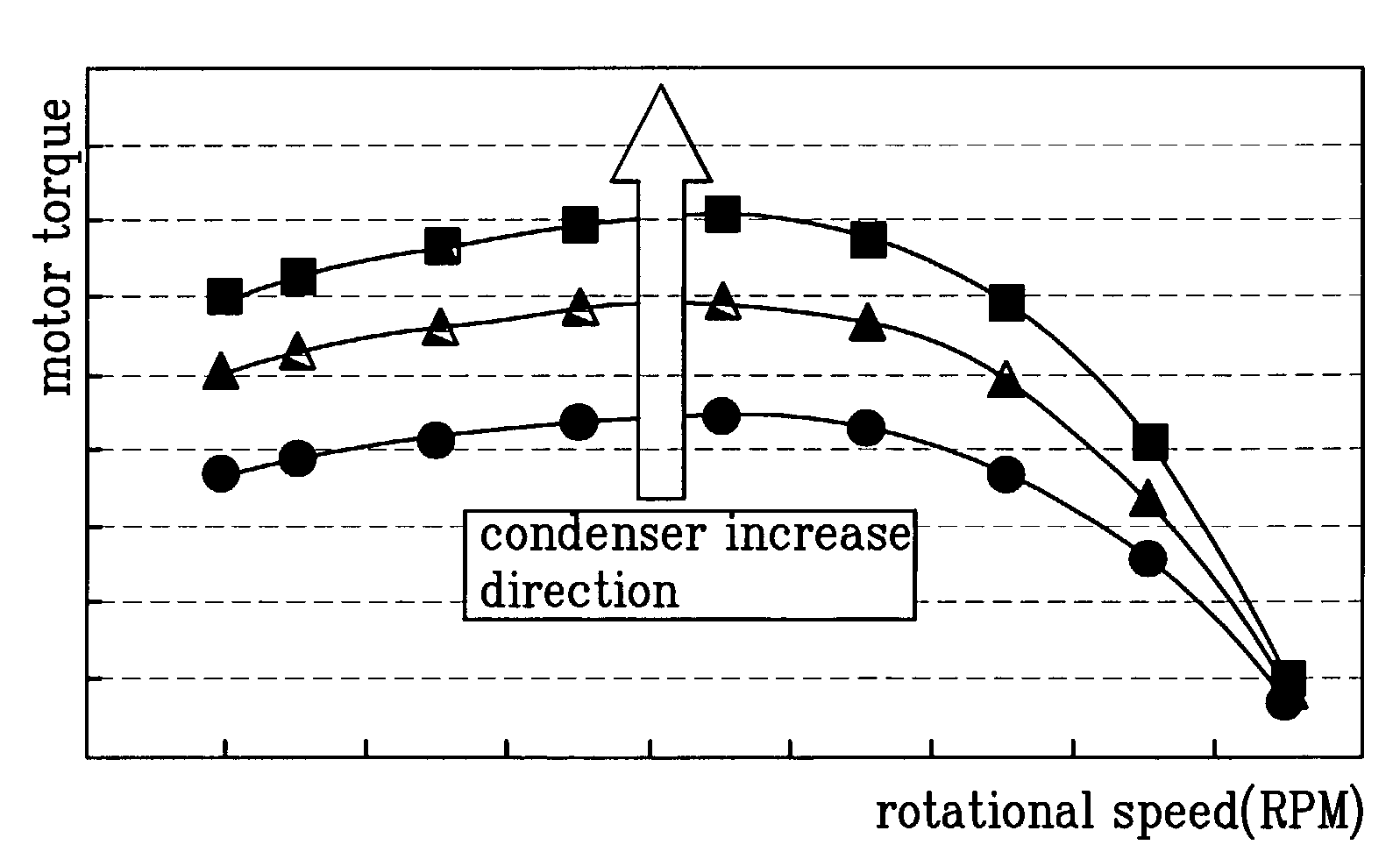

Device for controlling motor in washing machine and method for controlling process of washing machine by using the same

ActiveUS7299664B2Reduce motor loadImprove energy efficiencyOther washing machinesControl devices for washing apparatusElectric machineControl theory

Device for controlling a motor in a washing machine and a method for controlling a process of a washing machine by using the same, the device including a motor, a power source part for supplying a voltage to the motor, a plurality of torque varying parts parallel to each other and electrically connected to the motor for varying a rotation torque of the motor, a plurality of switching part connected to the torque varying parts respectively and electrically connected to the power source part, a driving part for switching the switching parts, and a controlling part for controlling the driving part so as to vary the rotation torque of the motor according to a mode of user's selection.

Owner:LG ELECTRONICS INC

Air compressor

ActiveUS10132310B2Increase flow rateFast inflationPositive displacement pump componentsPump controlGas compressorReciprocating motion

An improved motor includes a cylinder defining multiple exit holes of different diameters, which are respectively controlled by a resilient sheet having multiple branches to communicate with an air storage container. In operation, when a piston body conducts reciprocating motion in the cylinder, the compressed air produced in the cylinder can quickly enter the air storage container. The branches of the resilient sheet are subjected to different back force resulting from the compressed air in the air storage container, wherein the smallest branch of the resilient sheet is subjected to a smallest back force, so that the compressed air produced in the cylinder can enter the air storage container more easily through the smallest exit hole, so that the piston body can conduct reciprocating motion more smoothly and thus the performance of the air compressor can be increased.

Owner:CHOU

Injection drive apparatus for injection molding machine

ActiveUS7942659B2Reduce loadImprove yieldAuxillary shaping apparatusFood shapingInjection molding machineYield rate

An injection drive apparatus for injection molding machines is revealed. Liquid material is fed into a mold smoothly by a material feeding screw of a material feeding mechanism. Then a reaction force is generated to push the material feeding screw when the material feeding hole is nearly full of the material. Thus the material feeding screw and the slide mechanism assembled therewith are pushed to move backward. Later the injection mechanism is driven by the slide mechanism to move and act on the drive screw. Thus the slide mechanism threaded with the drive screw is driven to push the material feeding screw moving forward and squeezing the material for injection molding. Therefore, the load of the motor is reduced dramatically and the yield rate of the products produced by injection molding is increased due to the two-stage action-feeding of the material and squeezing of the material for injection.

Owner:HWA CHIN MACHINERY +1

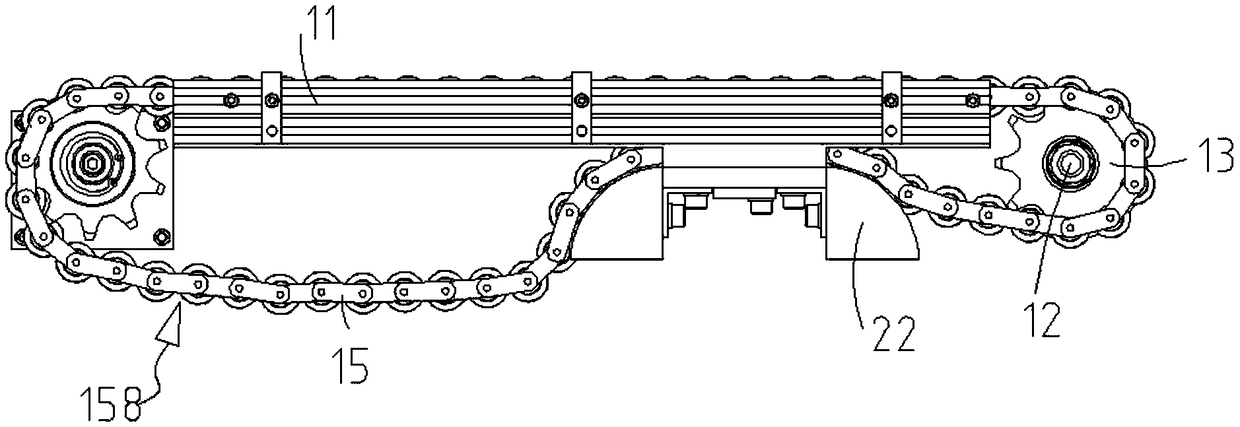

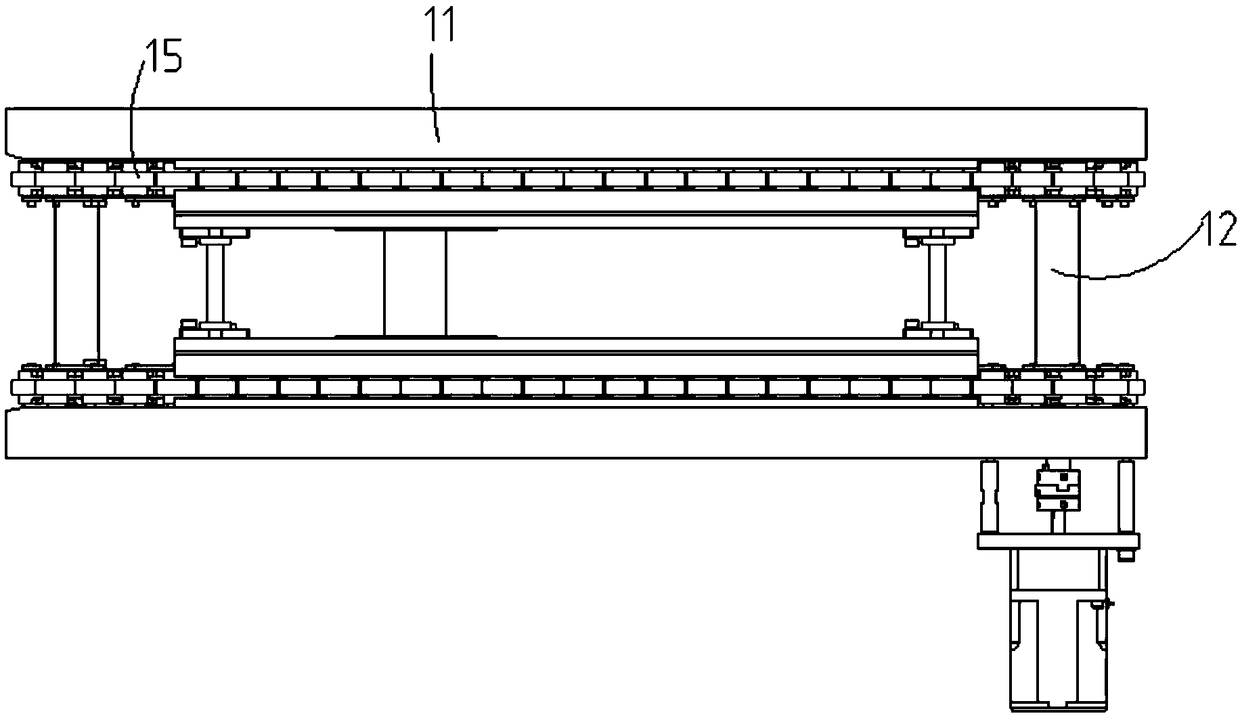

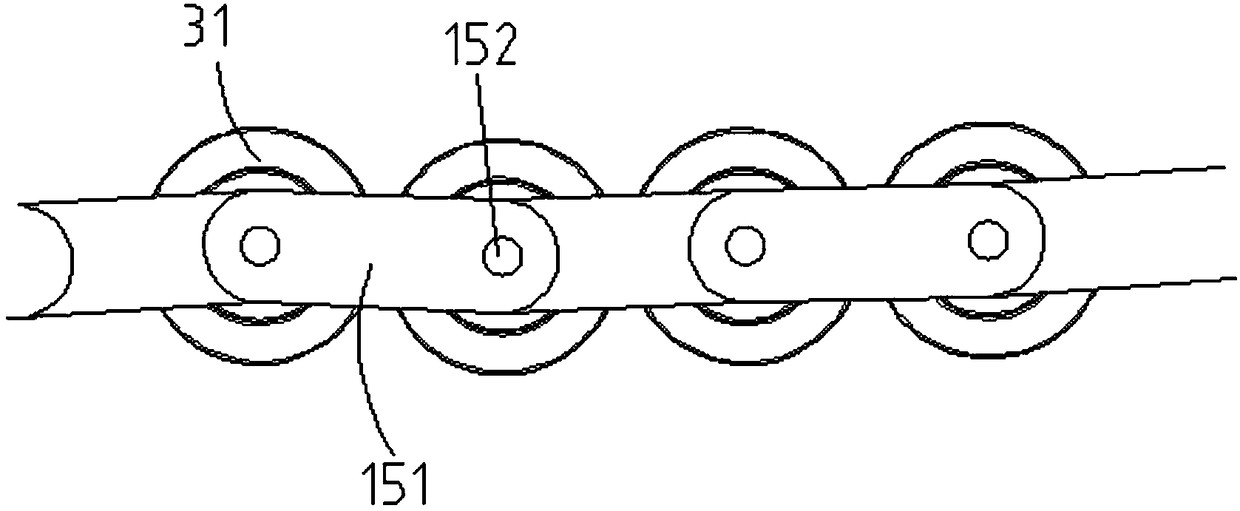

Horizontal chain type conveyor structure for conveying wood

The invention discloses a horizontal chain type conveyor structure for conveying wood. Two rotating shafts are parallelly and rotatably connected to a mounting rack, two chain wheels are respectivelyfixed to each rotating shaft, both ends of chains are correspondingly engaged with one chain wheel on the two rotating shafts, and each chain forms two upper and lower driving side belts in opposite driving directions; a motor is fixed to the mounting rack, and an output shaft of the motor is fixedly connected with one rotating shaft by virtue of a speed reducer; and support rollers are respectively arranged on each connecting pin shaft in the chains, a support seat is put below the mounting rack, the lower driving side belt in the chains is supported on the support seat, and the support roller in the lower driving side belt rolls on the support seat. According to the horizontal chain type conveyor structure, two chains are used for conveying wood at the same time, so that the structural stability of the whole conveyor is guaranteed. When the chains return, the lower driving side belt of the chains is supported on the support seat, so that the load of the motor is reduced, and the support roller rolls in a positioning groove of the support seat, so that the chains cannot deflect during movement.

Owner:NANJING ZMAKE MACHINERY CO LTD

Air circulation and ventilation apparatus for food processing machine

ActiveUS11337557B2Reduce motor loadExtended service lifeKitchen equipmentCooling/ventillation arrangementAir cycleElectric machinery

An air circulation and ventilation apparatus for a food processing machine (70), and the air circulation and ventilation apparatus comprises: a motor (10) and a fan (30), in which the motor (10) is used for driving an agitating or pulverizing assembly and is arranged within a base of the machine, and a body (60) of the machine is disposed outside the base, and the gap between the body (60) and the outer side wall of the base forms an air inlet passage; the fan (30) is equipped with a driving motor and is arranged within the base, and under the effect of the fan (30), airflow enters the air inlet passage by means of an air inlet port (22) on the base and flows through the motor (10) within the base and is discharged from an outlet port (23) on the base. By independently and separately providing the motor (10) for driving the agitating or pulverizing assembly of the food processing machine (70) and the fan (30) for ventilation, the load on the motor (10) and the vibration of the food processing machine (70) maybe be reduced, while also reducing noise; the fan (30) drives the operation thereof, and can independently adjust the rotational speed thereof according to ventilation needs, thus preventing waste of resources; further, when an operation problem occurs with the motor (10), the motor (10) may be effectively cooled down, thus maintaining good heat-dissipation efficiency, thereby prolonging the service life of the food processing machine (70).

Owner:GUANGDONG XINBAO ELECTRICAL APPLIANCES HLDG CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com