Rapidly-and-automatically-fed extrusion type juice extractor

An automatic feeding and extruding technology, which is applied in household machinery for filtering food, household utensils, applications, etc., can solve the problems of increasing motor work load, slow feeding, easy material jams, etc., to reduce motor load, Reduced motor torque, stable and long life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

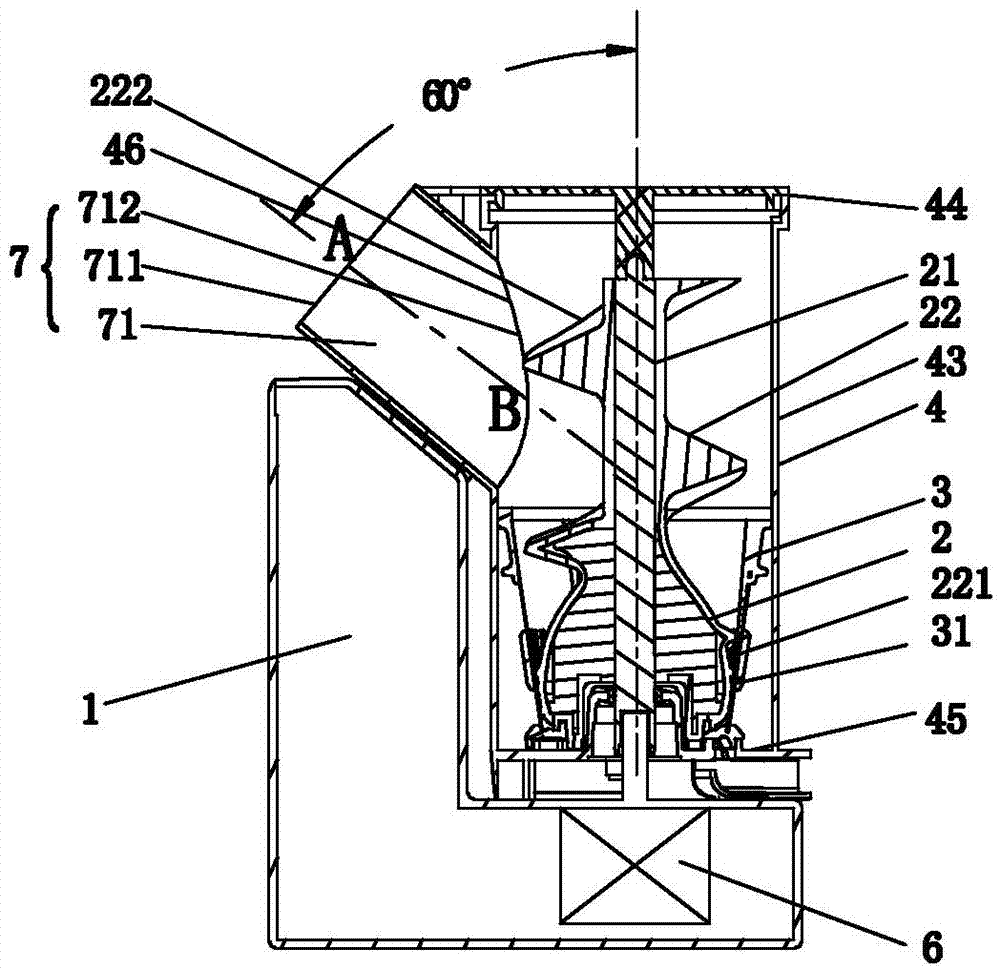

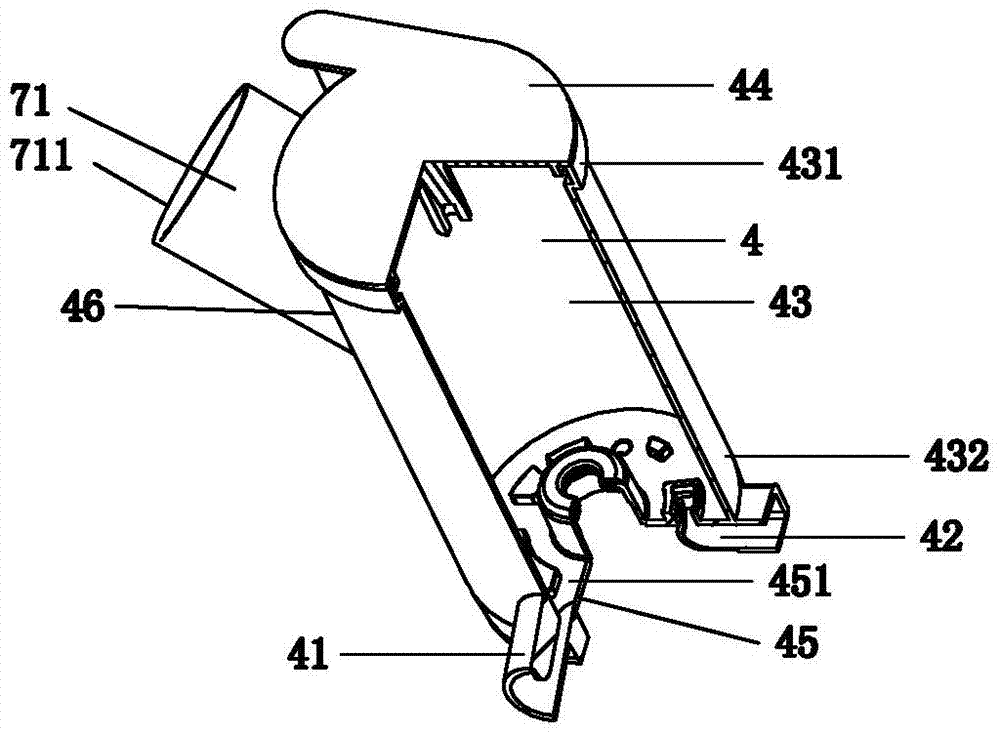

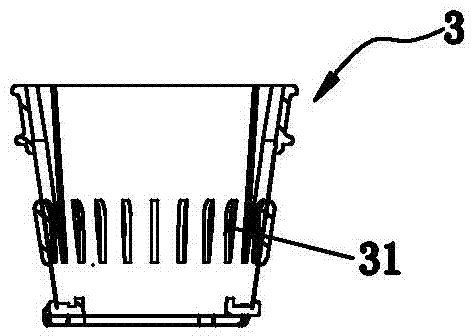

[0042] As the first embodiment of the fast automatic feeding juice extractor of the present invention, as figure 1 , figure 2 and image 3 As shown, it includes a machine base 1, a motor 6 and a drive unit (not shown in the figure) arranged in the machine base 1, an extrusion screw 2, a press assembly that cooperates with the extrusion screw 2 to extrude materials, and a feed assembly 7 , the squeezing assembly is installed on the machine base 1, the squeezing assembly includes a squeezing chamber 4, the squeezing chamber 4 is provided with a juice outlet 41 and a slag outlet 42, and the extrusion screw 2 includes a screw shaft 21 and a screw body 22 , the screw body 22 includes a material propulsion part and an extruding part that guides the material downward, and an extruding screw 221 is arranged on the extruding part, and the extruding cavity 4 is set outside the extruding screw 2, and the extruding cavity 4 includes a press chamber body 43, a press chamber upper cover ...

Embodiment 2

[0050] As the second embodiment of the juice extractor of fast automatic feeding according to the present invention, as Figure 4 and Figure 5 As shown, it includes a machine base 1, a motor 6 and a drive unit (not shown in the figure) arranged in the machine base 1, an extrusion screw 2, a press assembly that cooperates with the extrusion screw 2 to extrude materials, and a feed assembly 7 , the pressing assembly is installed on the machine base 1, the pressing assembly includes a pressing chamber 4, and the pressing chamber 4 is provided with a juice outlet (not shown in the figure) and a slag outlet (not shown in the figure), the said The extrusion screw 2 includes a screw shaft 21 and a screw body 22. The screw body 22 includes a material propulsion portion and an extrusion portion that guides the material downward. An extrusion screw 221 is provided on the extrusion portion. The extrusion chamber 4 Sleeved on the extrusion screw 2, the squeeze chamber 4 includes a squee...

Embodiment 3

[0056] Such as Figure 6 As shown, as the third embodiment of the fast automatic feeding juice extractor of the present invention, the difference from the second embodiment is that the geometric centers of the two ports of the feeding passage 71 are respectively A and B, and the connecting The line is AB, the angle a between AB and the vertical plane is 55°, and the inner diameter of the feed channel is 70mm. The inclination and diameter of the feeding channel make the feeding effect better. The juice extractor is also provided with an auxiliary feeding port 73 , and the auxiliary feeding port 73 is arranged on the feeding channel cover 72 . By setting the auxiliary feed port on the cover of the feed channel, it is convenient to add materials that have been cut into small pieces or smaller materials such as red fruits, grapes, apricots, etc., without opening the cover and stopping the machine. It is very convenient and practical for making mixed juices of materials of differ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| The inside diameter of | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com