Patents

Literature

297results about How to "Reduce speed fluctuation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

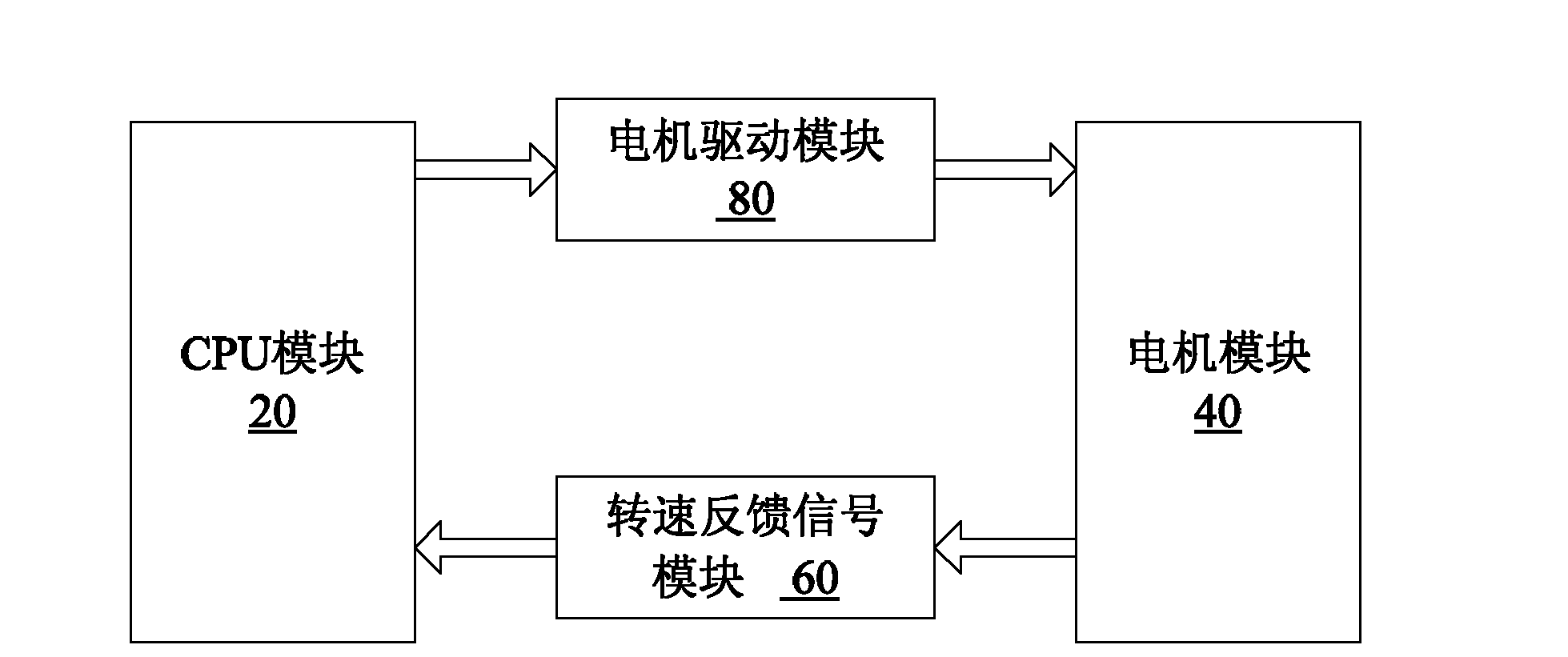

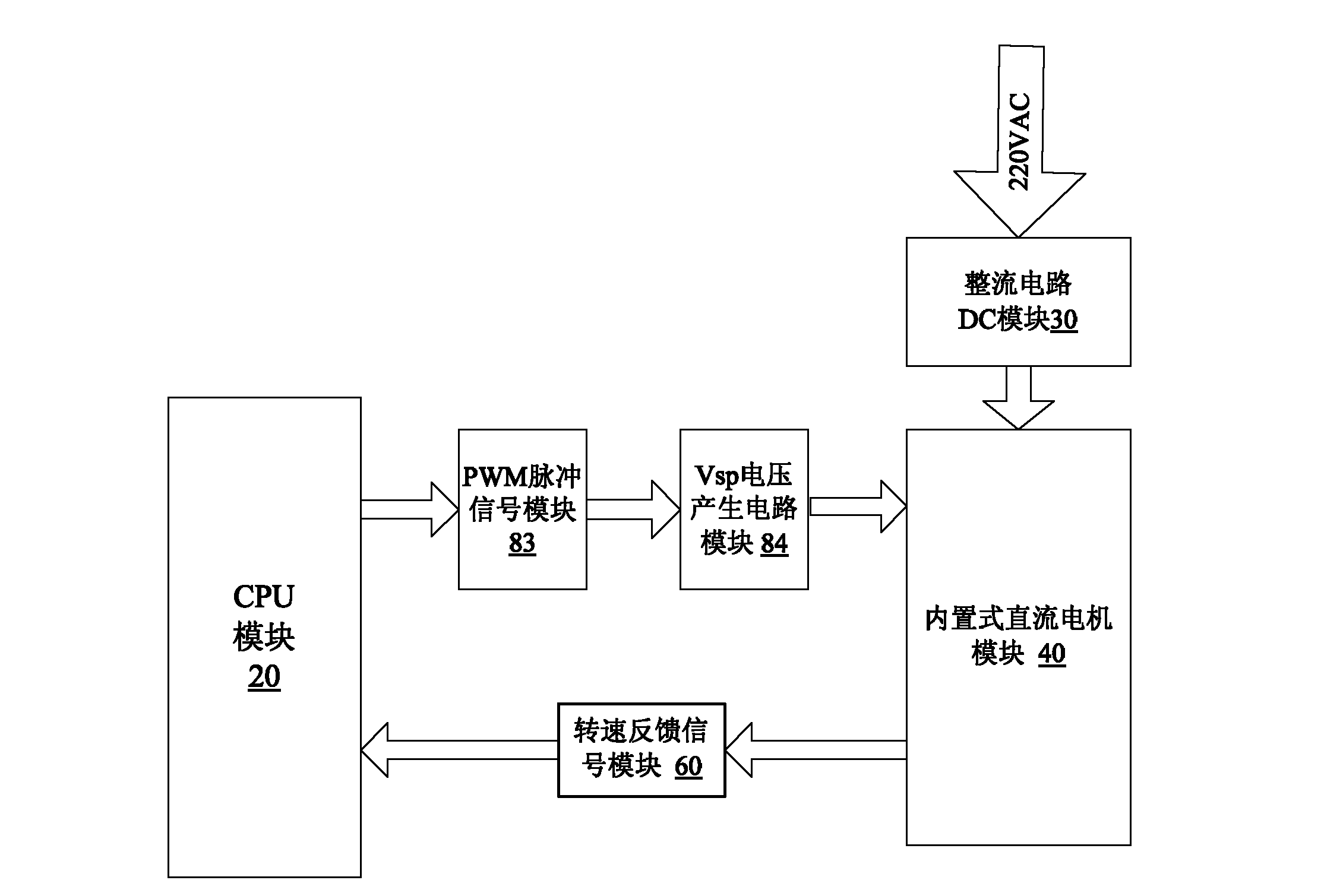

Method and device for adjusting rotating speed of inner fan of air conditioner

ActiveCN103185016AStable speedSolve the problem of slow startup speed and abnormal noise during operationAC motor controlElectric motor controlControl theoryStatic error

The invention discloses a method and a device for adjusting the rotating speed of an inner fan of an air conditioner. The adjusting method is used for adjusting the rotating speed of the inner fan by means of a PI algorithm via a P parameter and an I parameter according to a difference value between the practical rotating speed and the target rotating speed of the inner fan. In the process of adjusting the rotating speed of the inner fan, the method comprises the following steps: detecting the practical rotating speed of the inner fan; calculating the rotating speed difference of the inner fan, wherein the rotating speed difference is the difference between the practical rotating speed and the target rotating speed; correcting the I parameter and / or the P parameter according to the rotating speed difference; and adjusting the rotating speed difference of the inner fan by means of the PI algorithm via a corrected parameter according to the rotating speed difference. Due to the adoption of the method and the device, the rotating speed response of an indoor motor is quick, the static errors and dynamic overshoot are lowered, high anti-interference performance is achieved, the aim of mute drive is fulfilled, and the comfort of the air conditioner is improved.

Owner:GREE ELECTRIC APPLIANCES INC

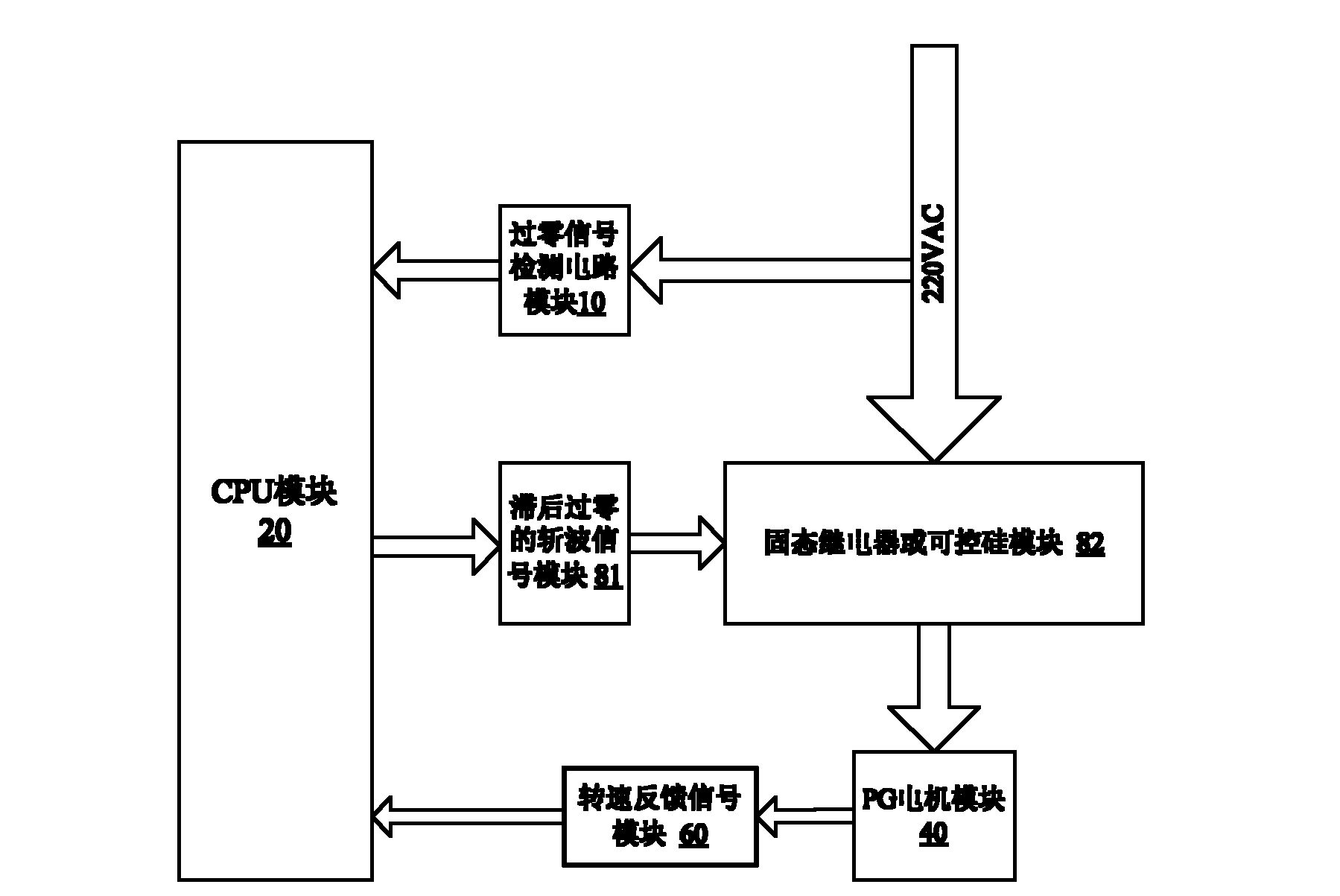

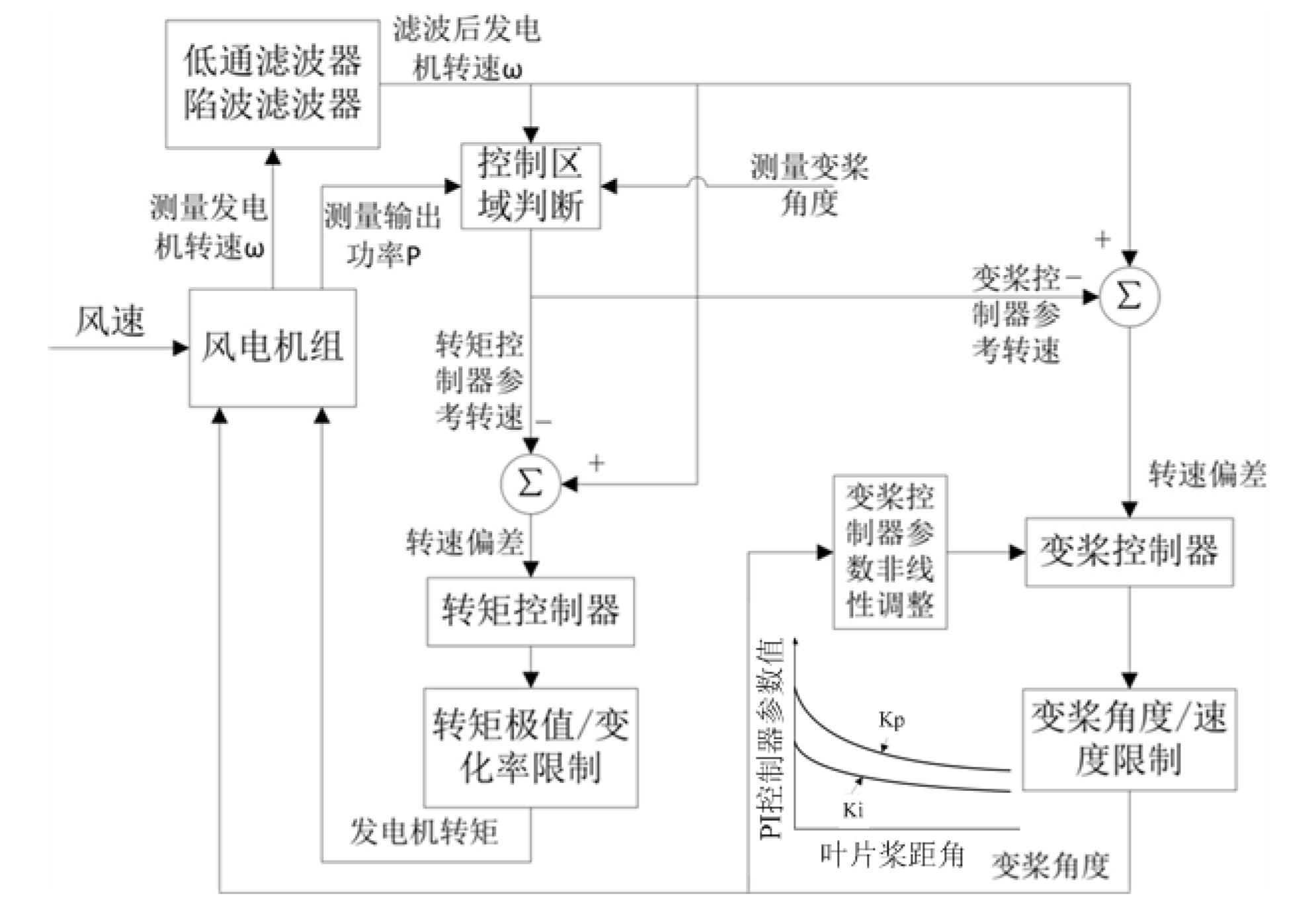

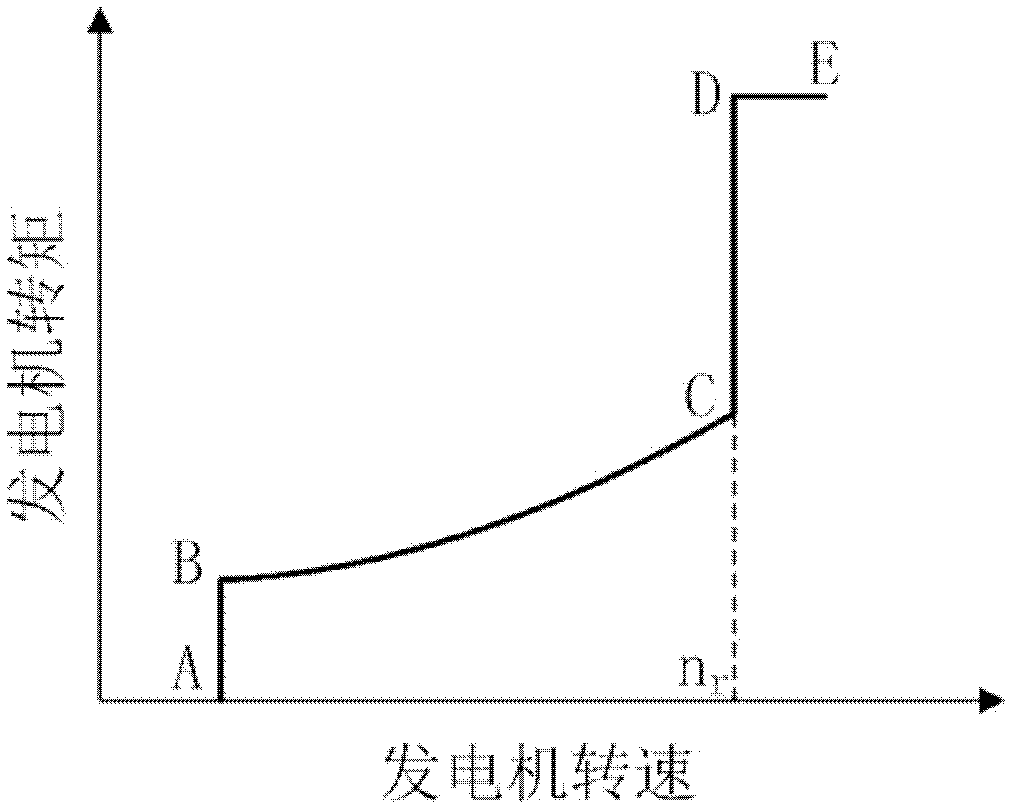

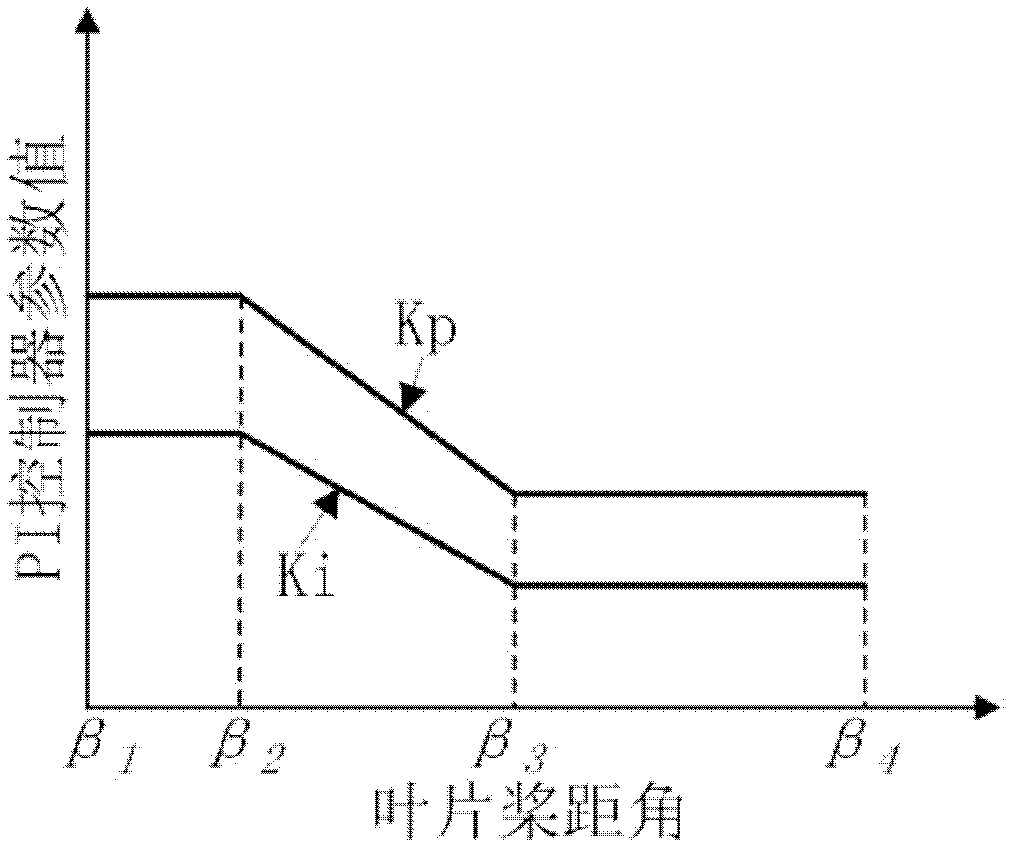

Rotational speed and torque control device and method of wind turbine generator set

ActiveCN102635499AEasy to implement flexible switchingReduce speedWind motor controlMachines/enginesConstant powerAngular degrees

The invention discloses a rotational speed and torque control method of a wind turbine generator set. Under the situation that the measured rotational speed of a power generator is higher than the rated rotational speed and the measured power exceeds the rated power, the torque is switched from a PI (proportional-integral) control way to a constant power control way; under the situation that the pitch angle is smaller than the optimal pitch angle and the measured rotational speed is lowered below the rated rotational speed, the toque is converted from the constant power control way to the PI control way; and the pitch angle is controlled in a PI control parameter non-linear adjustment way, and the pitch control is in an activated state within the whole normal working rotational speed range. According to the rotational speed and torque control method of the wind turbine generator set provided by the invention, the problem of greater fluctuation in the rotational speed caused by desynchrony of the two types of control can be avoided by changing control target points of two controllers in a transition region, the transition region is improved from the original points to a curve, the flexible switching of the control states is easier to realize, and the stability in operation of the unit and the power output of the unit can be ensured.

Owner:CSIC CHONGQING HAIZHUANG WINDPOWER EQUIP

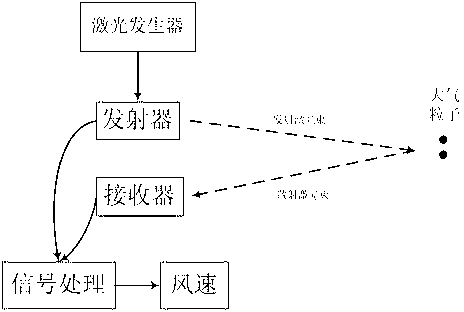

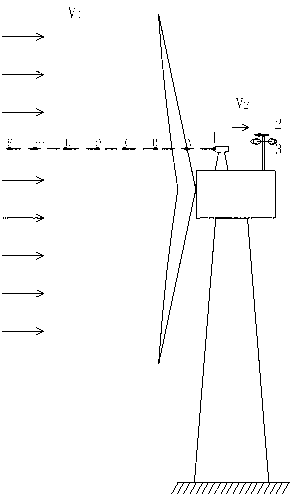

Feed-forward control system and feed-forward control method for wind generating set based on laser wind finding radar

InactiveCN103061980AImprove output characteristicsImprove securityWind motor controlMachines/enginesDelta-vEngineering

The invention provides a feed-forward control system and a feed-forward control method for a wind generating set based on a laser wind finding radar. The feed-forward control system comprises a laser wind finding radar and a feed-forward controller. The feed-forward controller comprises a data processing unit and a feed-forward logical unit. The data processing unit calculates and sends a real-time wind speed fluctuating value delta V to the feed-forward logical unit; and the feed-forward logical unit calculates the wind speed fluctuating value delta V to obtain an append command vane angle beta which is added to an original variable-pitch controller command vane angle alpha to obtain and send a final variable-pitch command signal theta to a variable-pitch controller. The wind speed feed-forward control is added, so that loads of relevant parts of the wind generating set are reduced, output characteristics of the wind generating set are improved, and the safety of the wind generating set under extreme wind conditions is improved; and a prior running fan system is not needed to be transformed too much, the feed-forward control system and the feed-forward control method have wide adaptability simultaneously and are capable of being used in different environments and easy to implement, loads of parts are reduced, the wind energy utilization rate is improved, and the cost is reduced.

Owner:DONGFANG TURBINE CO LTD

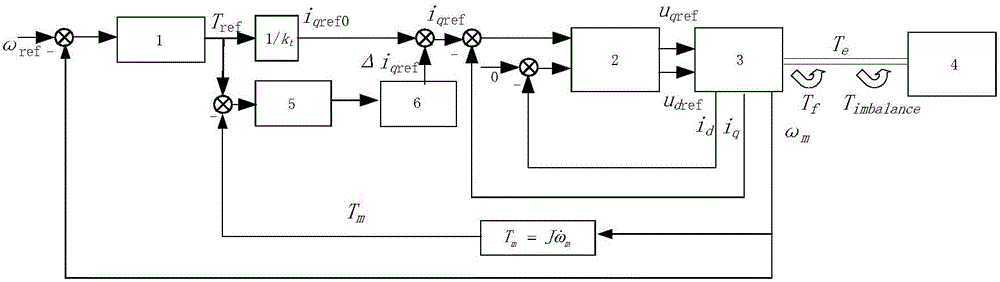

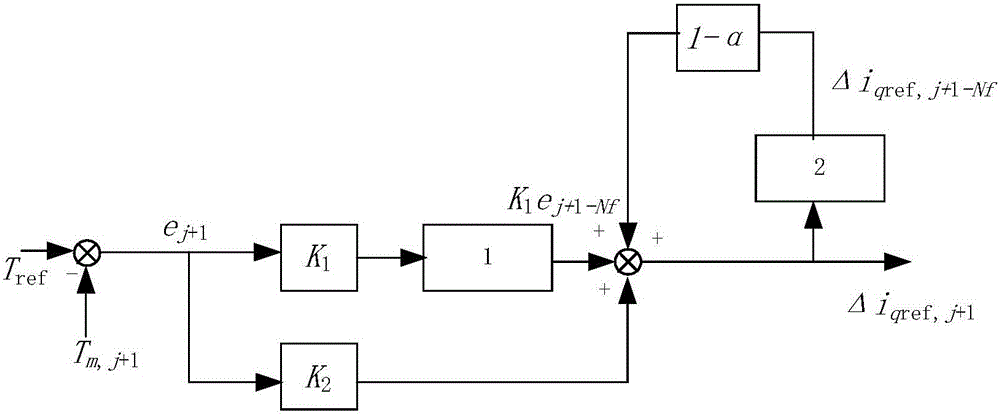

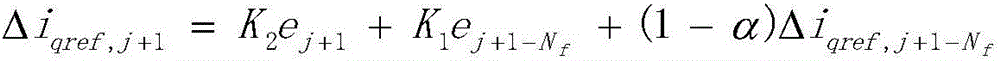

Control moment gyroscope framework control system and control moment gyroscope framework control method for restraining dynamic unbalance disturbance of rotor

ActiveCN105786036AGuaranteed dynamic performanceReduce the disturbing torqueSpeed/accelaration control with auxillary non-electric powerControl systemElectric machine

A control moment gyroscope (CMG) framework control system and a CMG framework control method for restraining dynamic unbalance disturbance of a rotor are provided. A feed-forward compensation module and an algorithm switching module are embedded on the basis of a double-loop PI control system. In preset Ng control cycles, the whole framework control system is set to a PI control mode; in each control cycle from the (Ng+1)th control cycle, the speed precision of a CMG framework in the current control cycle is calculated through the algorithm switching module, and whether there is a need to switch the control mode of the current control cycle is determined; if the control mode is a feed-forward compensation mode after switching, subtraction operation is carried out on a moment reference value output by a speed loop PI controller and a fed-back torque of a framework motor to get the mechanical torque error e(j+1) of the current control cycle, and the feed-forward compensation module calculates the current feed-forward compensation value Delta i(qref, j+1) of the current control cycle according to e(j+1) and adds Delta i(qref, j+1) to the double-loop PI control system; and if the control mode is a PI control mode after switching, current feed-forward compensation is blocked, and control is performed according to the double-loop PI control system.

Owner:BEIJING INST OF CONTROL ENG

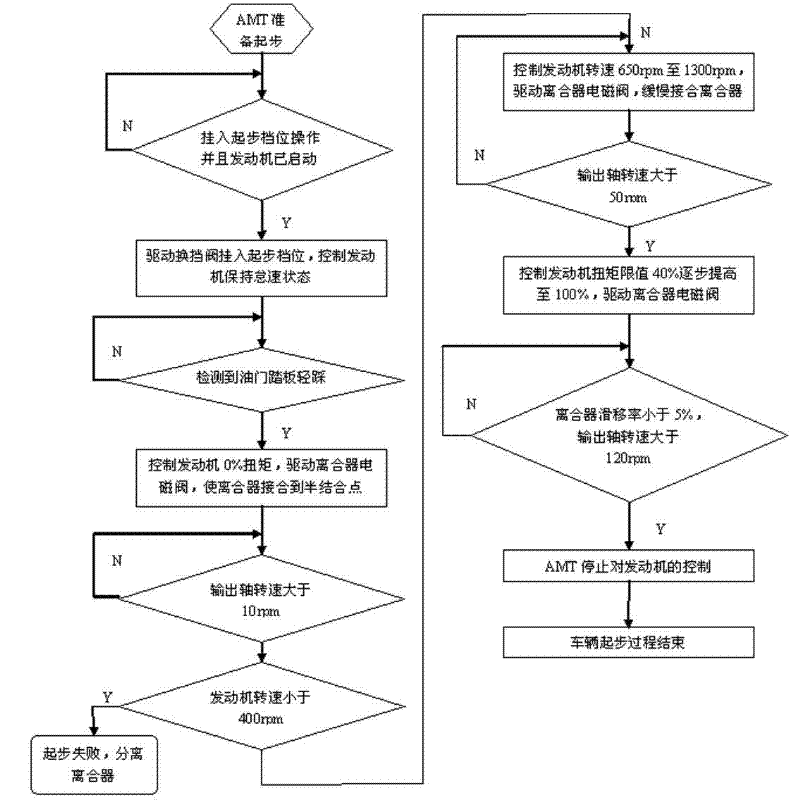

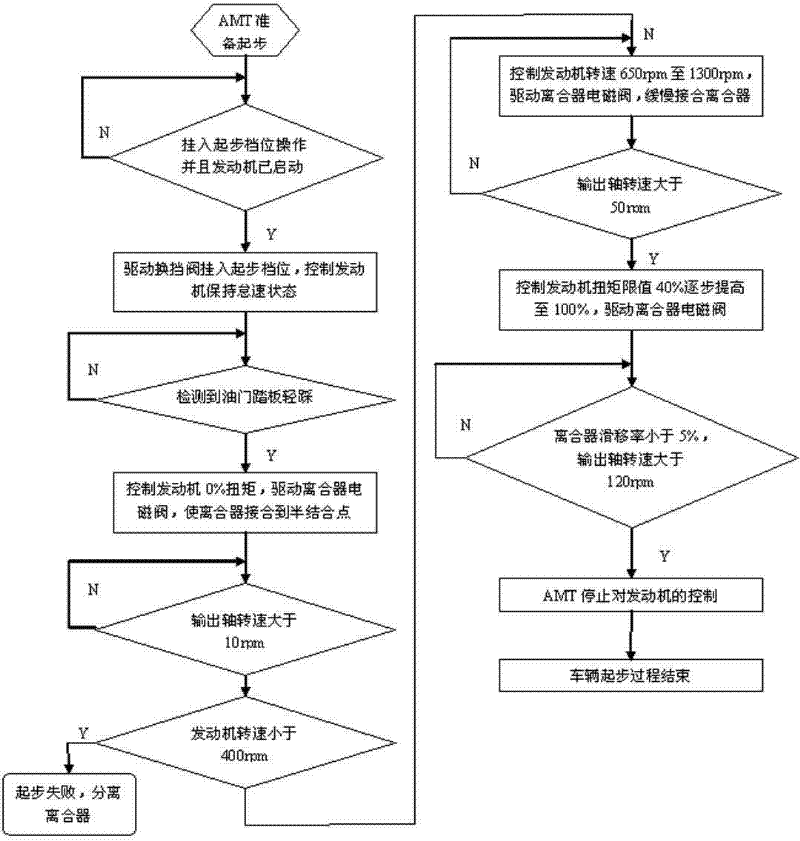

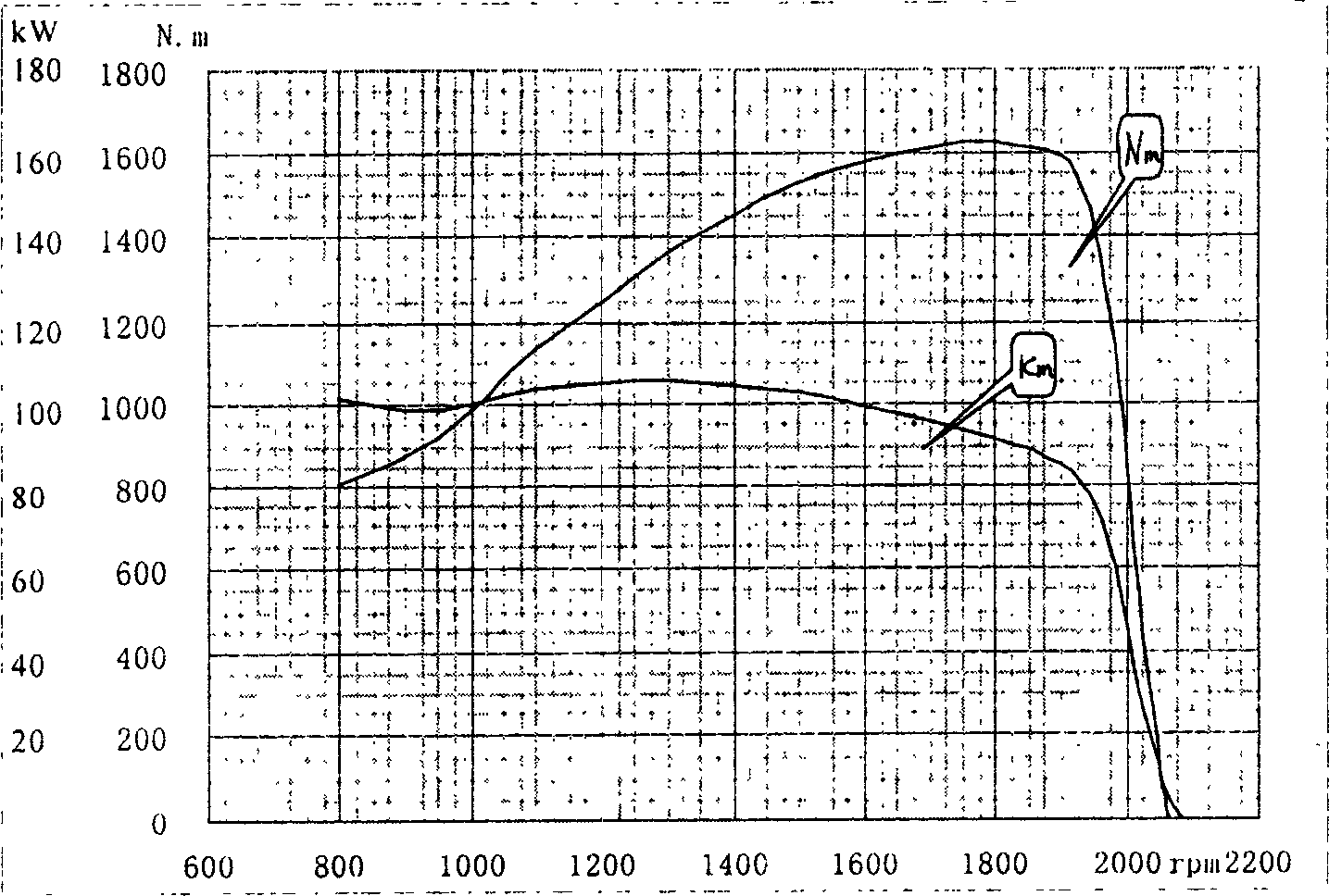

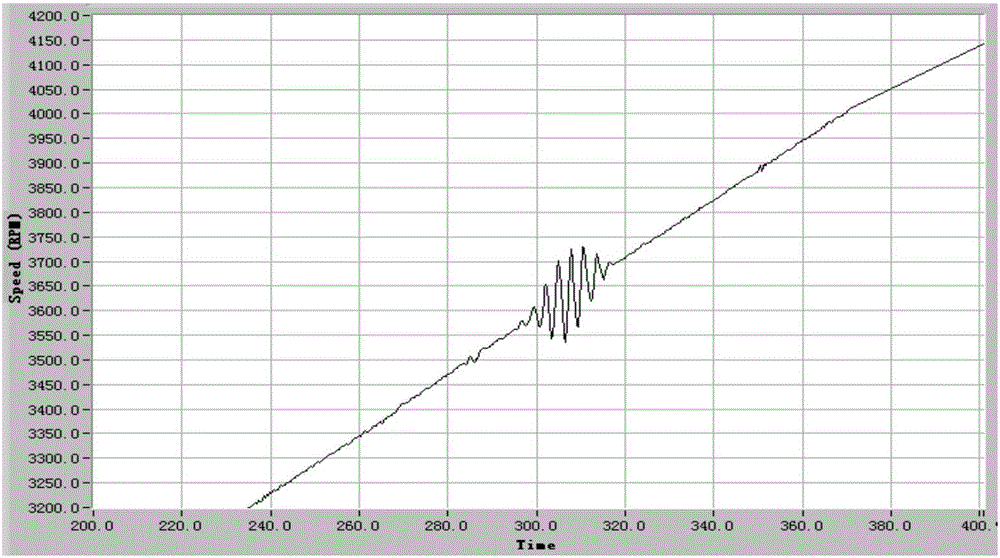

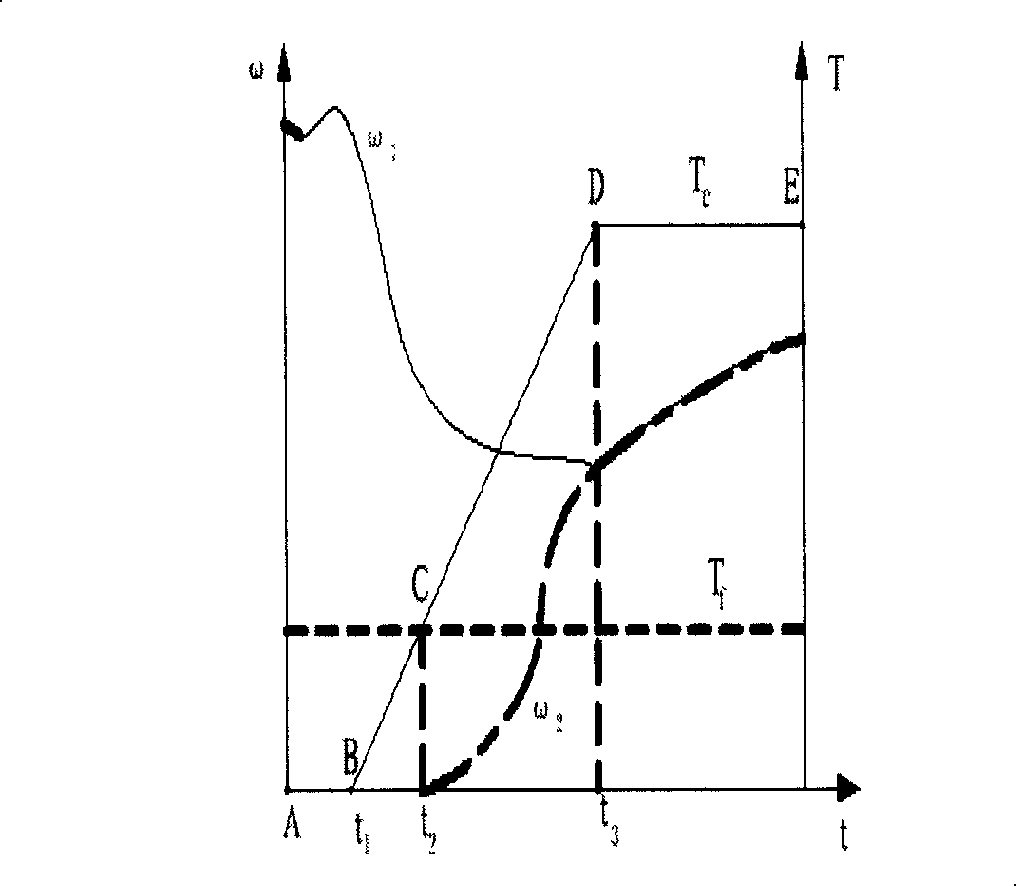

Engine idle speed control-based AMT (Automated Mechanical Transmission) vehicle start control method

The invention relates to an engine idle speed control-based AMT (Automated Mechanical Transmission) vehicle start control method, which comprises the following steps of: a, starting an engine, shifting to a start gear, controlling the engine to maintain an idle speed state by an electric control AMT, gently stamping a throttle to send out a starting signal; b, after receiving the starting signal, controlling a power source to drive a clutch to a semi-combined point; c, controlling an engine speed to be in a range of 650-1300 rpm by the electric control AMT, and detecting whether the ROTATING speed of an output shaft is more than 50 rpm or not; d, controlling the torque limit value of the engine to BE increaseD from 40% to 100% progressively by the electric control AMT and controlling the power source to drive the clutch to gradually combine, detecting whether the clutch sliding rate is less than 5% or not and whether the rotating speed of the output shaft is more than 120 rpm or not; and e, stopping controlling the engine by the electric control AMT, and ending a vehicle start process. The engine idle speed-control based AMT vehicle start control method has the beneficial effects of reducing abrasion of the clutch, increasing the comfort and economy as much as possible on the premise of maintaining dynamic property, and the like.

Owner:SINO TRUK JINAN POWER

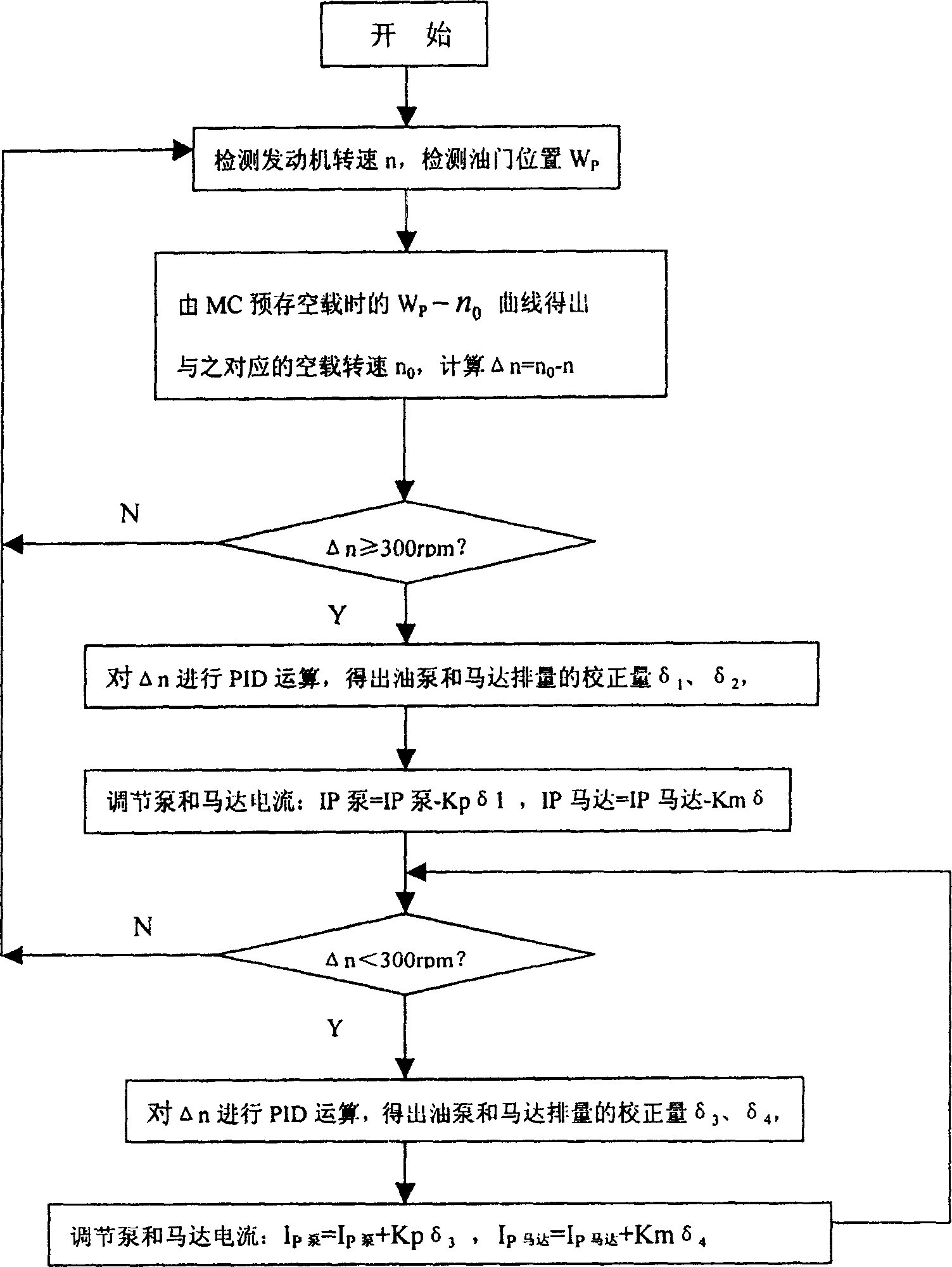

Limit load adjustment method of all hydraulic bulldozer and apparatus thereof

InactiveCN1558048AReduce in quantityNo pausesSoil-shifting machines/dredgersMotor speedPosition sensor

The present invention is limit load regulating method and apparatus for hydraulic bull dozer. The present invention features that by means of connecting the throttle valve sensor, the engine rotation speed sensor, walking motor rotation speed sensor and motor proportion valve to the micro controller (MC), connecting the engine to variable displacement oil pump and MC, the calculation in MC of the difference between practical rotation speed and the set value of the engine and the motor based on the signals from the sensors, the data processing and PID operation, the limit load regulating apparatus regulates the current of the electric proportion valve in the variable displacement oil pump and the current of the electric proportion valve in the motor to maintain the rotation speed of the engine in the constant value. The present invention makes the hydraulic bull dozer operate in optimal rotation speed with less fluctuation in high response speed.

Owner:SANY HEAVY IND CO LTD (CN)

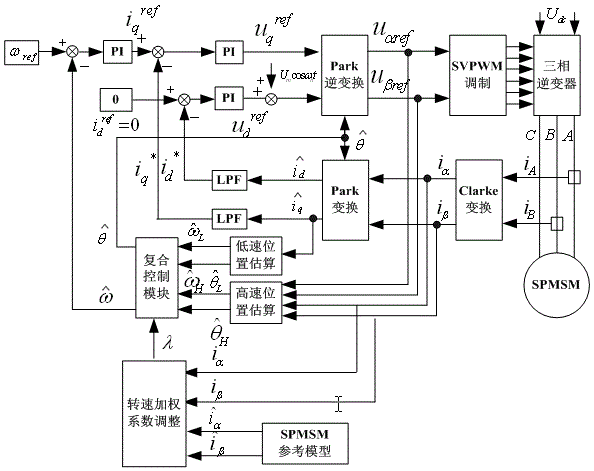

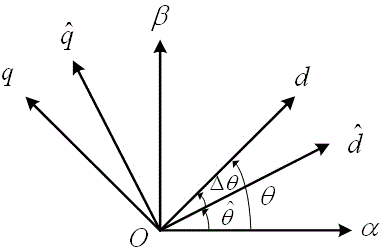

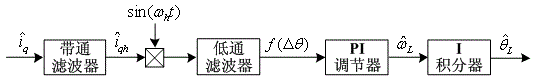

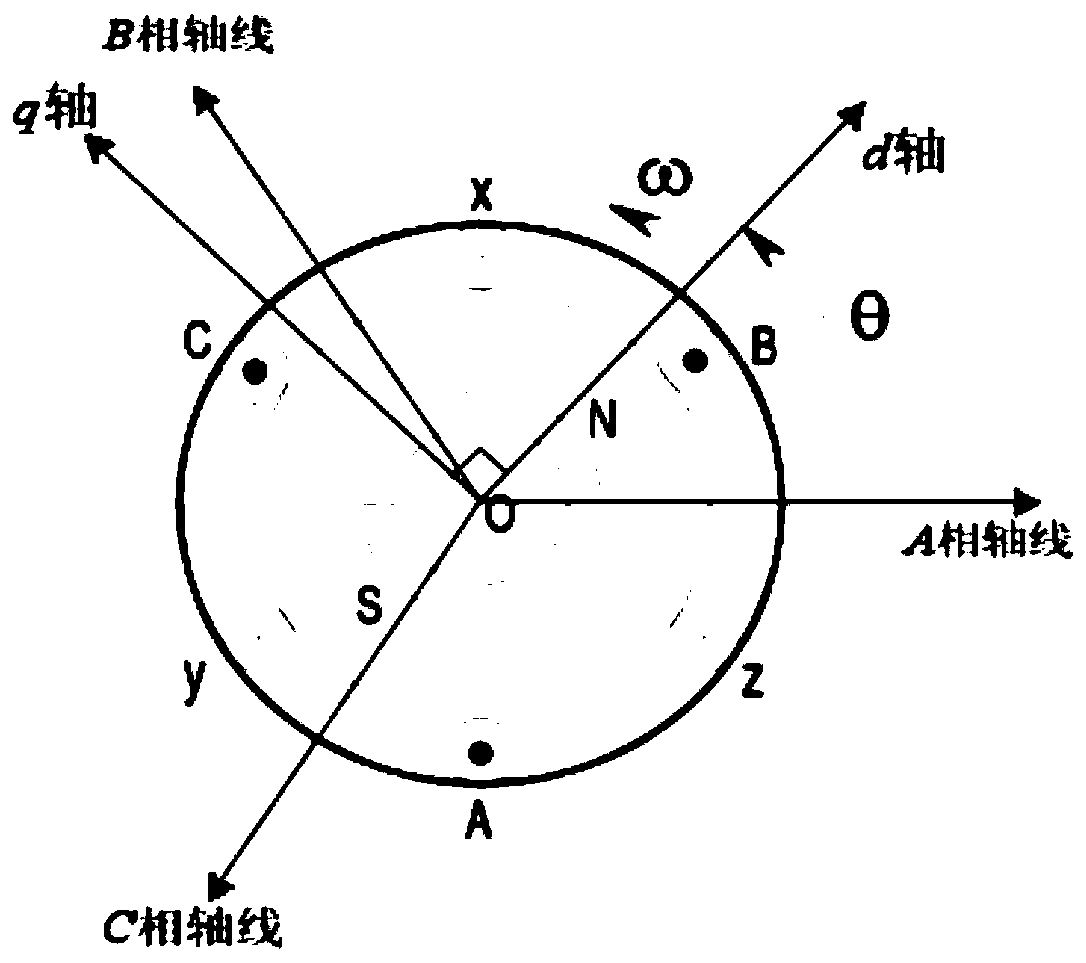

Sensorless control method of permanent magnet synchronous motor in wide rotating speed scope

ActiveCN104901600AReduce jitterImprove speed estimation accuracyElectronic commutation motor controlAC motor controlVoltage vectorLow speed

The invention discloses a sensorless control method of a permanent magnet synchronous motor in a wide rotating speed scope and belongs to the field of permanent magnet synchronous motor technology. The method comprises steps of acquiring output current of the motor and establishing a slip form observer for estimating a stator current desired value; correcting weighting coefficient according to difference between the stator current desired value and the actual value and estimate value between the rotator angular velocity and rotor position; determining estimating value between the rotator angular velocity and rotor position according to the weighing coefficient, a low-speed position estimate value and a high-speed position estimate value; determining stator voltage reference value according to estimate value of the rotator angular velocity and the rotator position and the actual value of stator current; and obtaining three-phase inverter driving signal using space voltage vector modulation technology. The motor operates by the driving signal until the rotator angular velocity is converged to the estimate value. According to the invention, precision of rotating speed estimation, stability of the system and precision of a switching process are increased, fluctuation of rotating speed and shaking of the motor in the switching process of the rotating speed are reduced and the switching process is smoother.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

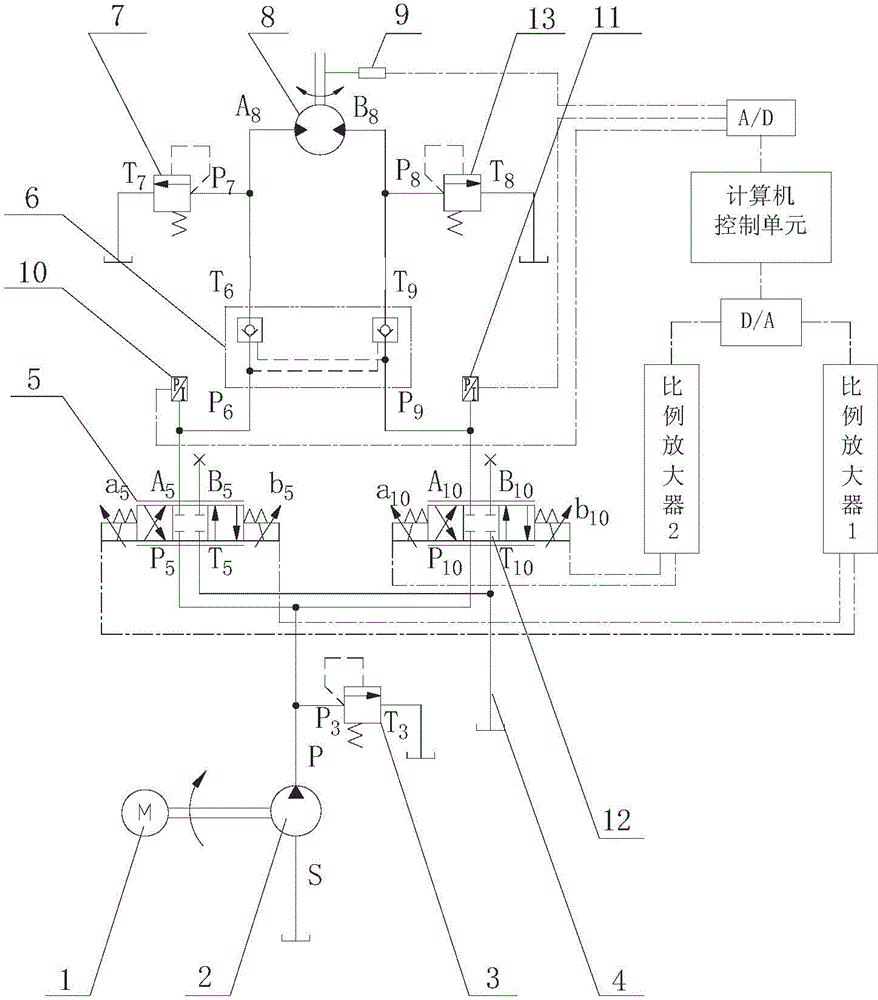

Electrohydraulic control system for rotation motion of pipe splicing machine

InactiveCN104564863AHigh accelerationReduce speed fluctuationUnderground chambersServomotorsBack pressureEnergy consumption

The invention discloses an electrohydraulic control system for rotation motion of a pipe splicing machine. The electrohydraulic control system comprises a motor, a constant displacement pump, three overflow valves, an oil return pipe, two three-position four-way proportional reversing valves, a hydraulic lock, a hydraulic motor, a force moment and rotating speed sensor and two pressure sensors. Since the electrohydraulic control system disclosed by the invention adopts the two three-position four-way proportional reversing valves to carry out independent control on the flow of an oil inlet of the hydraulic motor and the backpressure of an oil return port of the hydraulic motor; by controlling the backpressure of the oil return port of the hydraulic motor during an accelerated motion process, a constant motion process and a decelerated motion process of the rotation motion of the pipe splicing machine, the acceleration during the accelerated motion process of the rotation motion of the pipe splicing machine can be increased, the energy consumption during the constant motion process of the rotation motion of the pipe splicing machine and the speed fluctuation under the action of external load variation interference can be reduced, and the stability and the locating accuracy during the decelerated motion process of the rotation motion of the pipe splicing machine can be increased, so that the dynamic characteristic and the stability accuracy of the electrohydraulic control system for the rotation motion of the pipe splicing machine can be increased.

Owner:DALIAN UNIV OF TECH

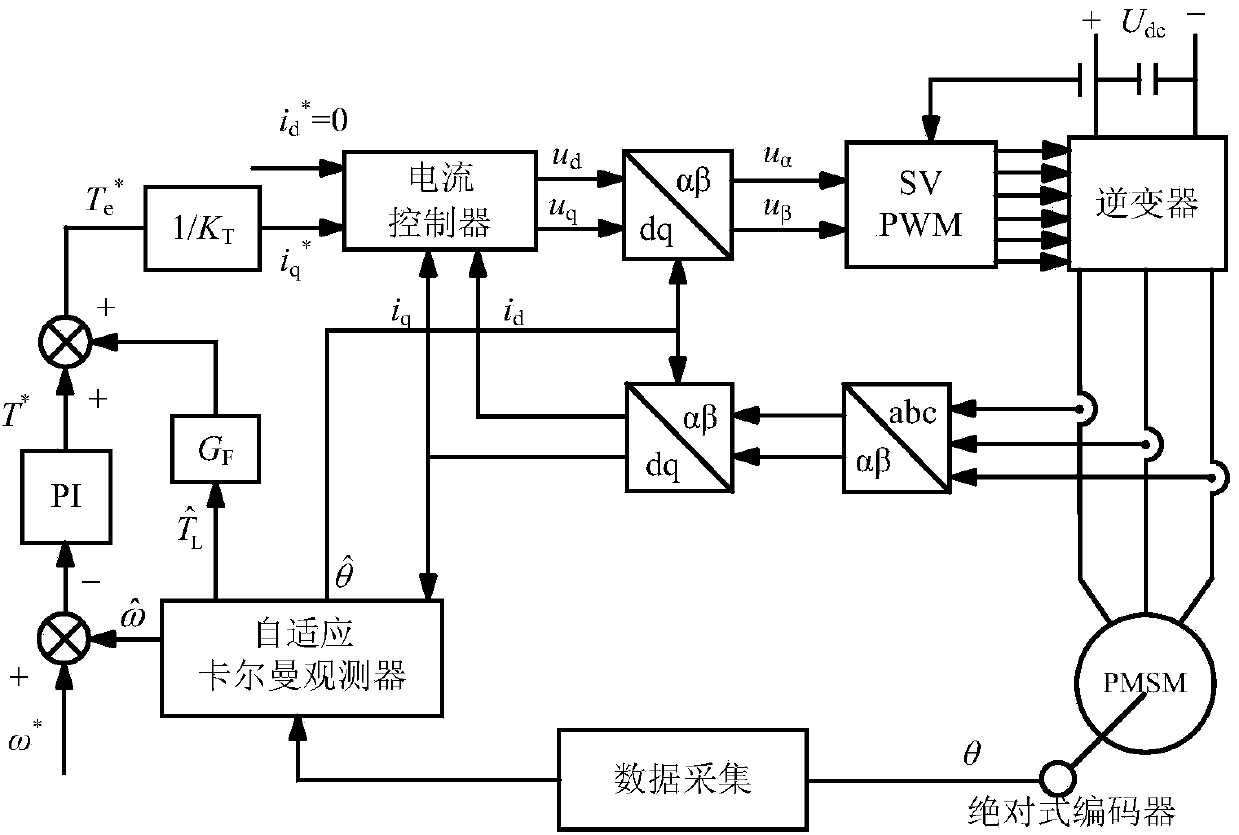

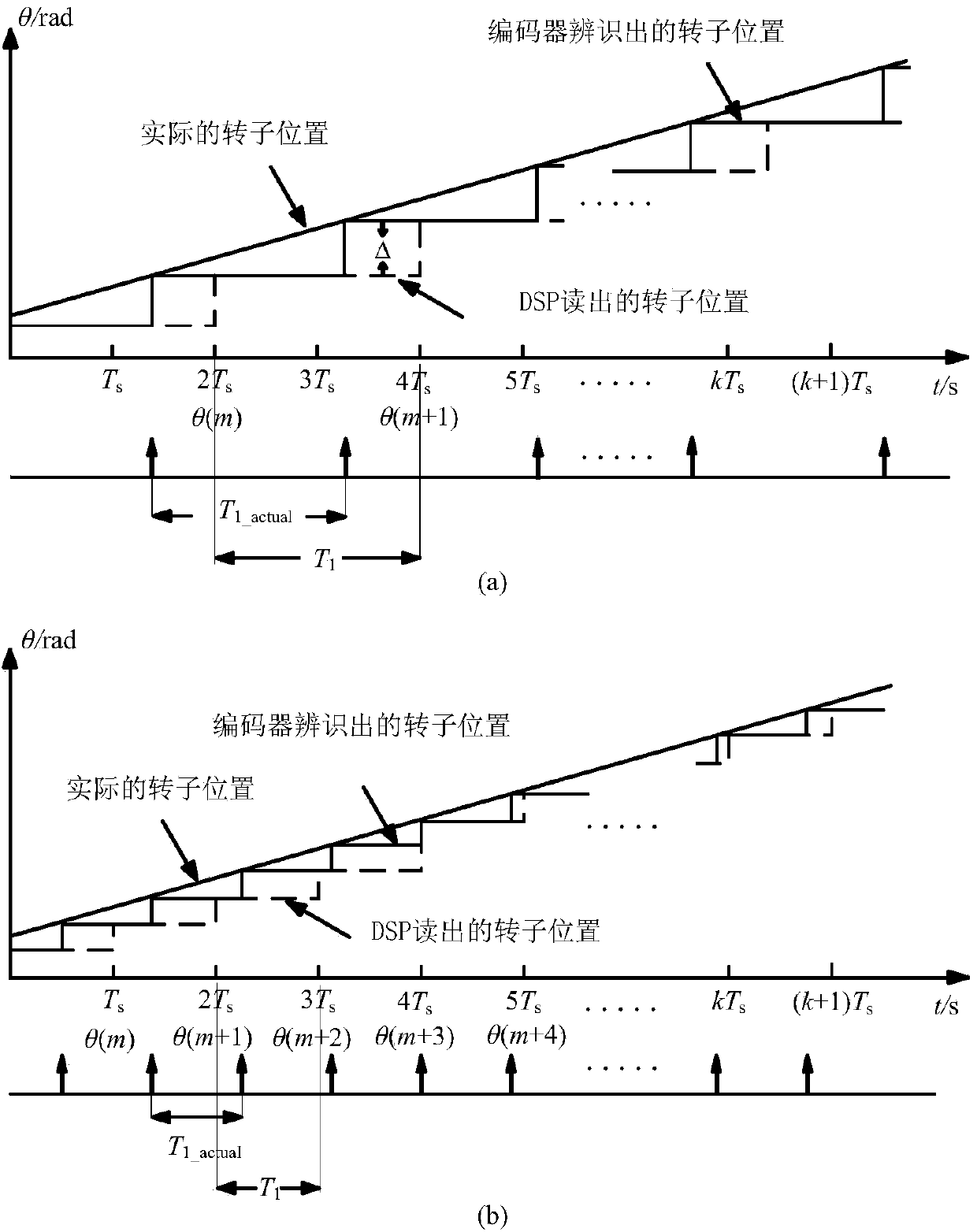

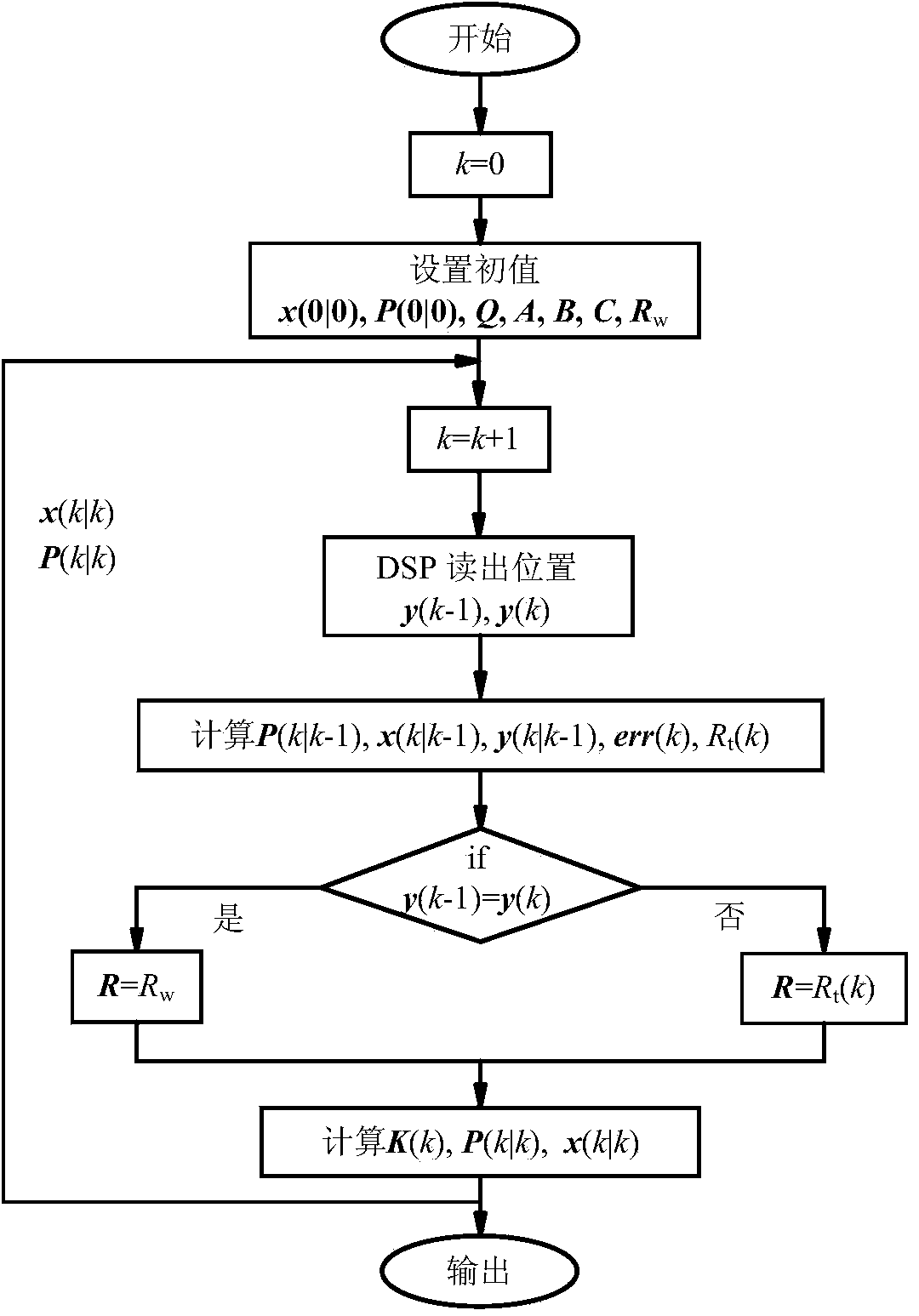

Method for observing speed of permanent magnet motor

ActiveCN104184382AFast trackRealize identificationElectronic commutation motor controlVector control systemsLoad torquePermanent magnet synchronous motor

The invention discloses a method for observing the speed of a permanent magnet motor, and relates to the field of speed observation and speed control for motors. The method comprises the steps of combining the rotor position acquired by an absolute type encoder with three parts of a designed kalman observer, observing the rotating speed of a rotor and a load torque of the motor, and using the observed rotating speed as feedback signals of a rotating speed ring of a permanent magnet synchronous motor control system; regarding the suddenly changed load torque of a permanent magnet synchronous motor as a system disturbance variable, using the motor load torque observed by the constructed kalman observer as feed-forward signals of a current loop, and constructing a feed-forward control system; acquiring the switching sequence of an inverter through a current controller and a space vector pulse width modulation method, then acquiring three-phase voltage inputting into the permanent magnet synchronous motor, and finally enabling the permanent magnet motor to rotate by a certain rotating speed. The method disclosed by the invention adopts the load torque acquired by the adaptive kalman observer, thereby being capable of timely reflecting load variation conditions of the system, carrying out feed-forward control on the estimated load torque, and being capable of improving an accurate tracking ability for the rotating speed.

Owner:TIANJIN UNIV

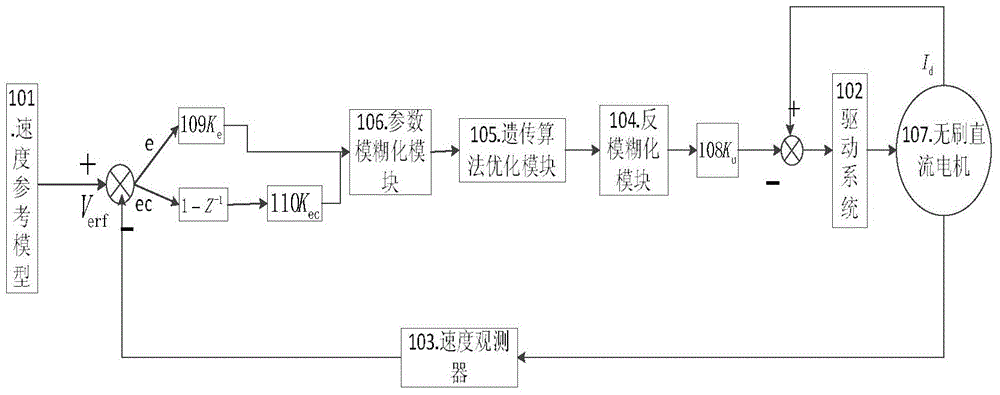

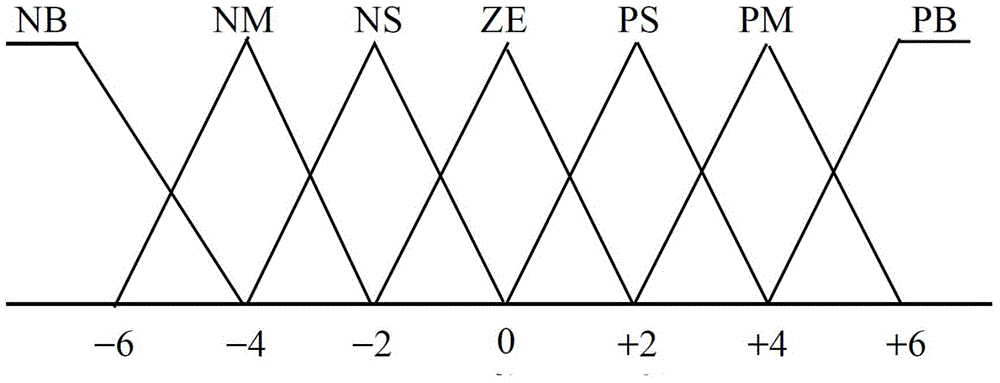

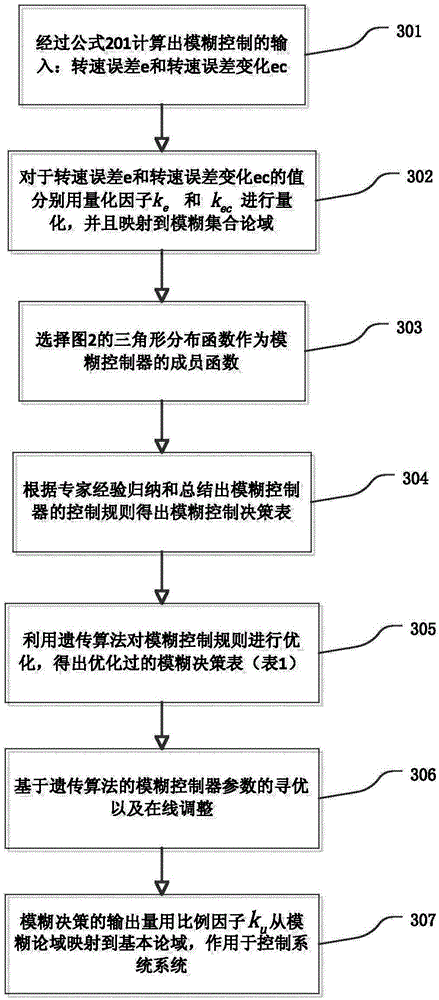

Brushless DC motor fuzzy control system based on genetic algorithm and control method thereof

InactiveCN104155877AFast speed responseFaster speed responseAdaptive controlReference modelDefuzzification

The present invention discloses a brushless DC motor fuzzy control system based on a genetic algorithm and a control method thereof. The control system comprises a drive system used for driving a brushless DC motor, a speed observer used for collecting the rotation speed of the brushless DC motor, a rotation speed reference model which provides the reference data of a motor rotation speed and compares the reference data of a motor rotation speed with the collected motor rotation speed so as to obtain a rotation speed error and an error change rate, a parameter fuzzification module which receives the rotation speed error and the error change rate, carries out quantification on the rotation speed error and the error change rate, and maps the rotation speed error and the error change rate to a fuzzy set discourse domain, a genetic algorithm optimization module which uses the genetic algorithm to carry out online optimization on a module control rule, adjusts related parameters in the fuzzy set discourse domain and makes a fuzzy decision, and a defuzzification module which maps the output amount of the fuzzy decision to a basic discourse domain. According to the system and the method, the genetic algorithm is used to carry out online adjustment of the parameter of the fuzzy controller, and the controller can have good static and dynamic performance in different operation environments.

Owner:JIANGSU UNIV OF SCI & TECH

Control for decreasing idling generating rotation-speed fluctuation of engine for mixed-kinetic automobile

InactiveCN1896476ASmall fluctuationReduce speed fluctuationBatteries circuit arrangementsEngine controllersElectric generatorElectricity

This invention relates to a kind of controlling method to reduce rotation speed fluctuation of the mixed power vehicle engine when idling generating electric power. The whole car controller is electric connected to other components. The mixed power system electric power generation operating mode is split into engine driven running state and non-engine driven running state. According to the different state, controller uses different power generation load adjusting speed to change the generator and engine load synchronously.

Owner:FAW GROUP

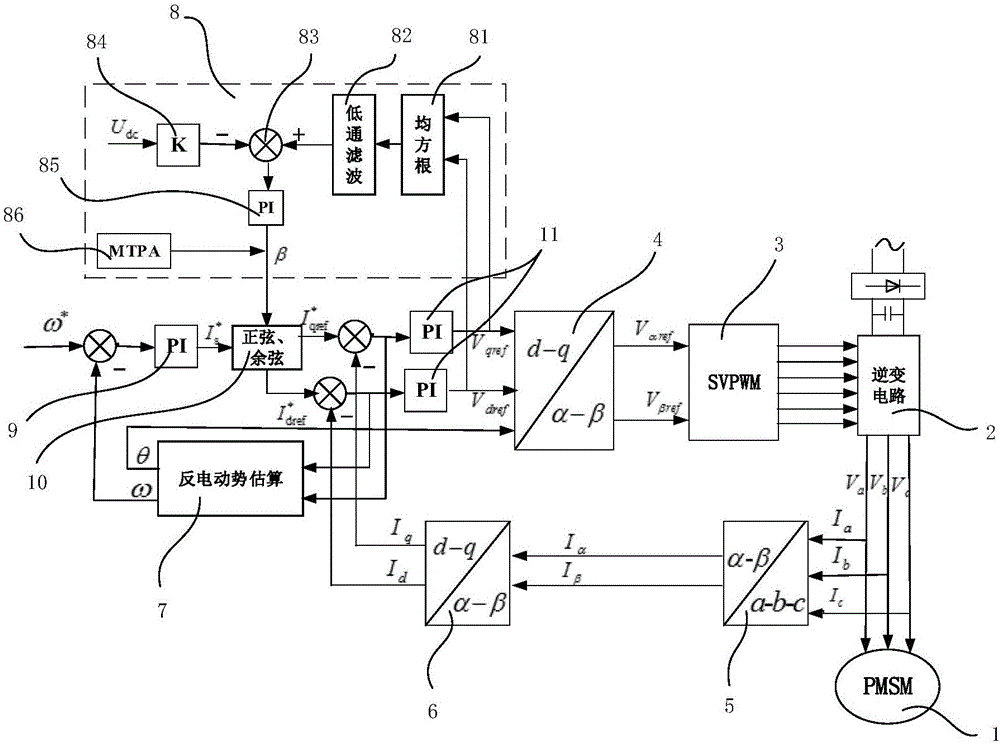

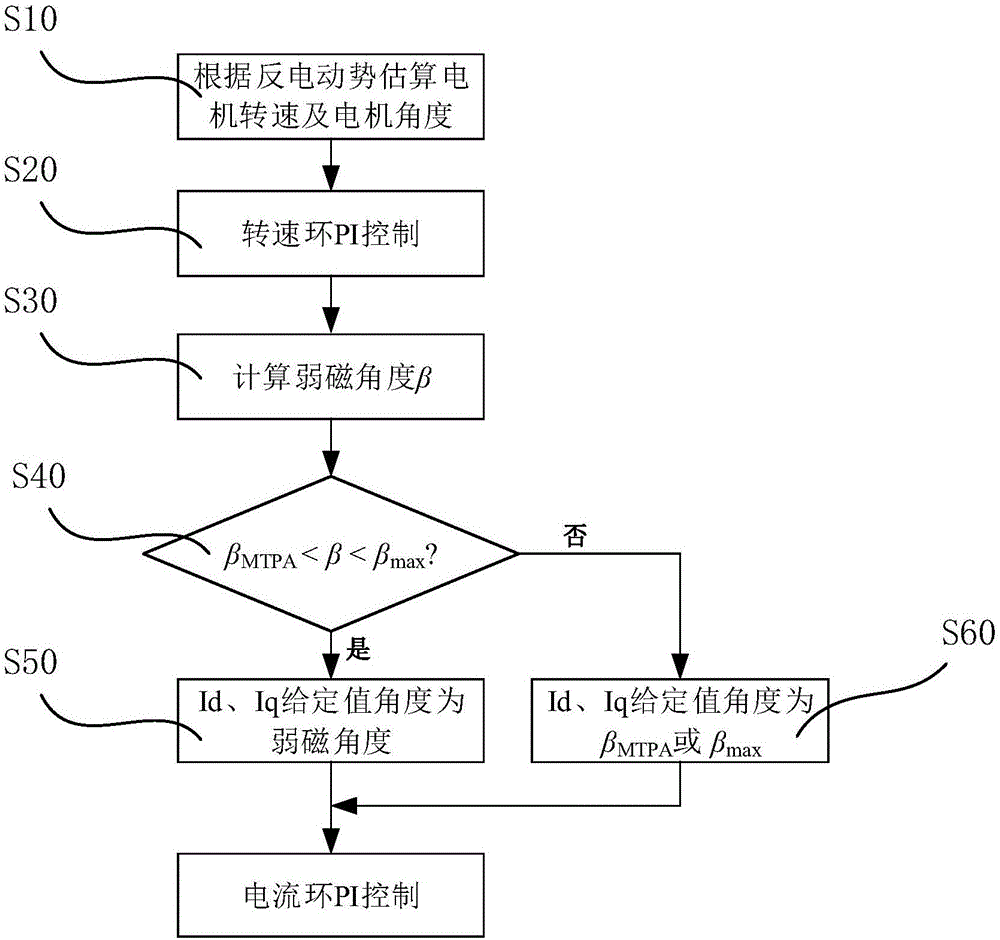

Field weakening control system and method for PMSM, refrigerator controller and refrigerator

ActiveCN106452243AReduce speed fluctuationSmall fluctuationElectronic commutation motor controlVector control systemsControl vectorControl system

The invention provides a field weakening control system and method for a PMSM (Permanent Magnet Synchronous Motor). The field weakening control system and method for a PMSM are used for performing vector control on the PMSM. The field weakening control system includes a rotating speed loop and an electric current loop, wherein output of the rotating speed loop is the given input of the electric current loop; and output of the electric current loop is a d shaft voltage given value Vdref and a q shaft voltage given value Vqref. The field weakening control system also includes a filed weakening angle loop, wherein the field weakening angle loop calculates a field weakening angle Beta according to the output of the electric current loop and a field weakening gain K, and determines the angle of a motor d shaft current given value I*dref and the angle of a q shaft current given value I*qref according to the field weakening angle Beta. The field weakening control system and method for a PMSM can reduce the fluctuation of rotating speed of the PMSM at frequency points opening field weakening. The invention also provides a refrigerator controller and a refrigerator.

Owner:GREE ELECTRIC APPLIANCES INC

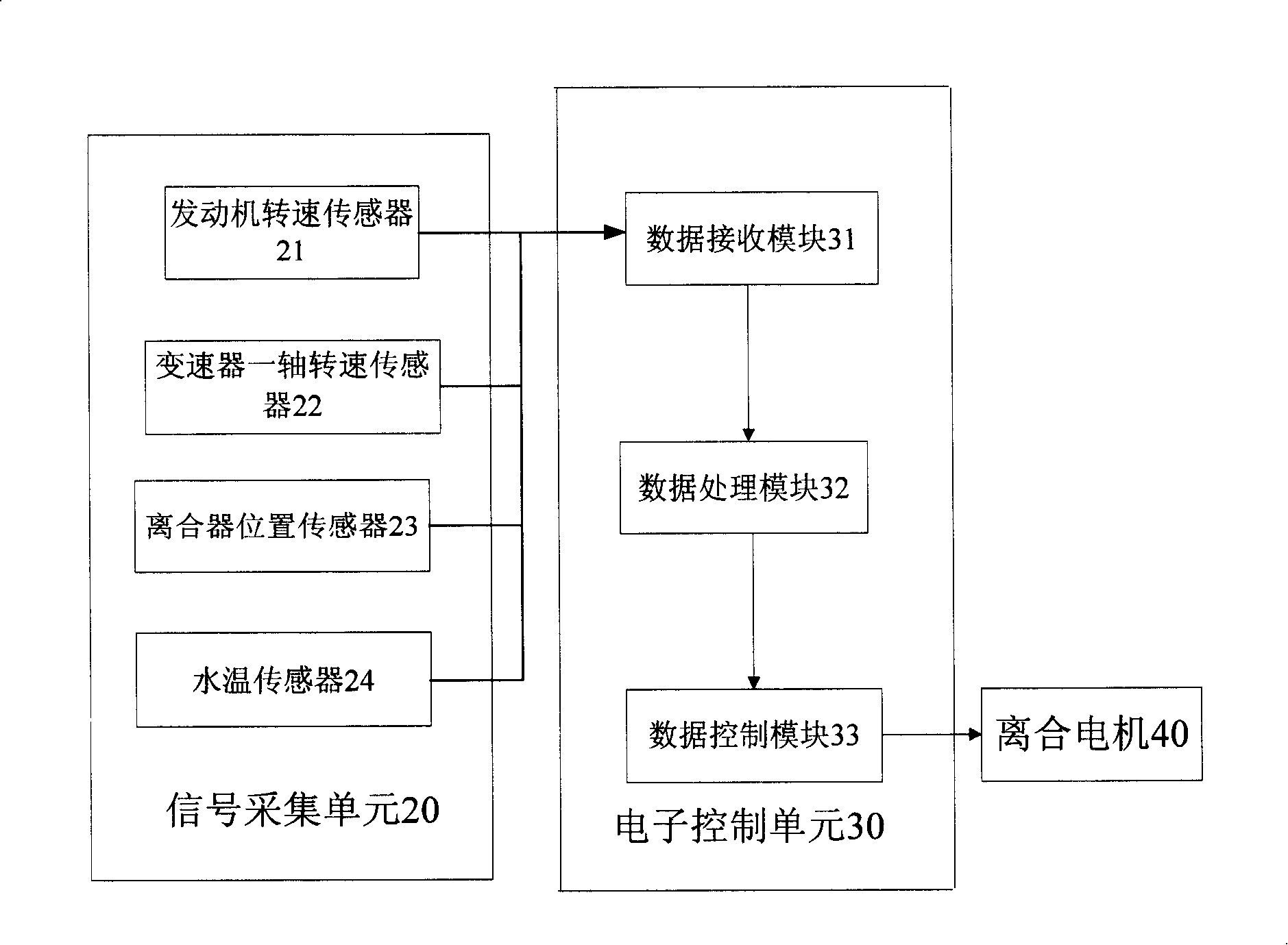

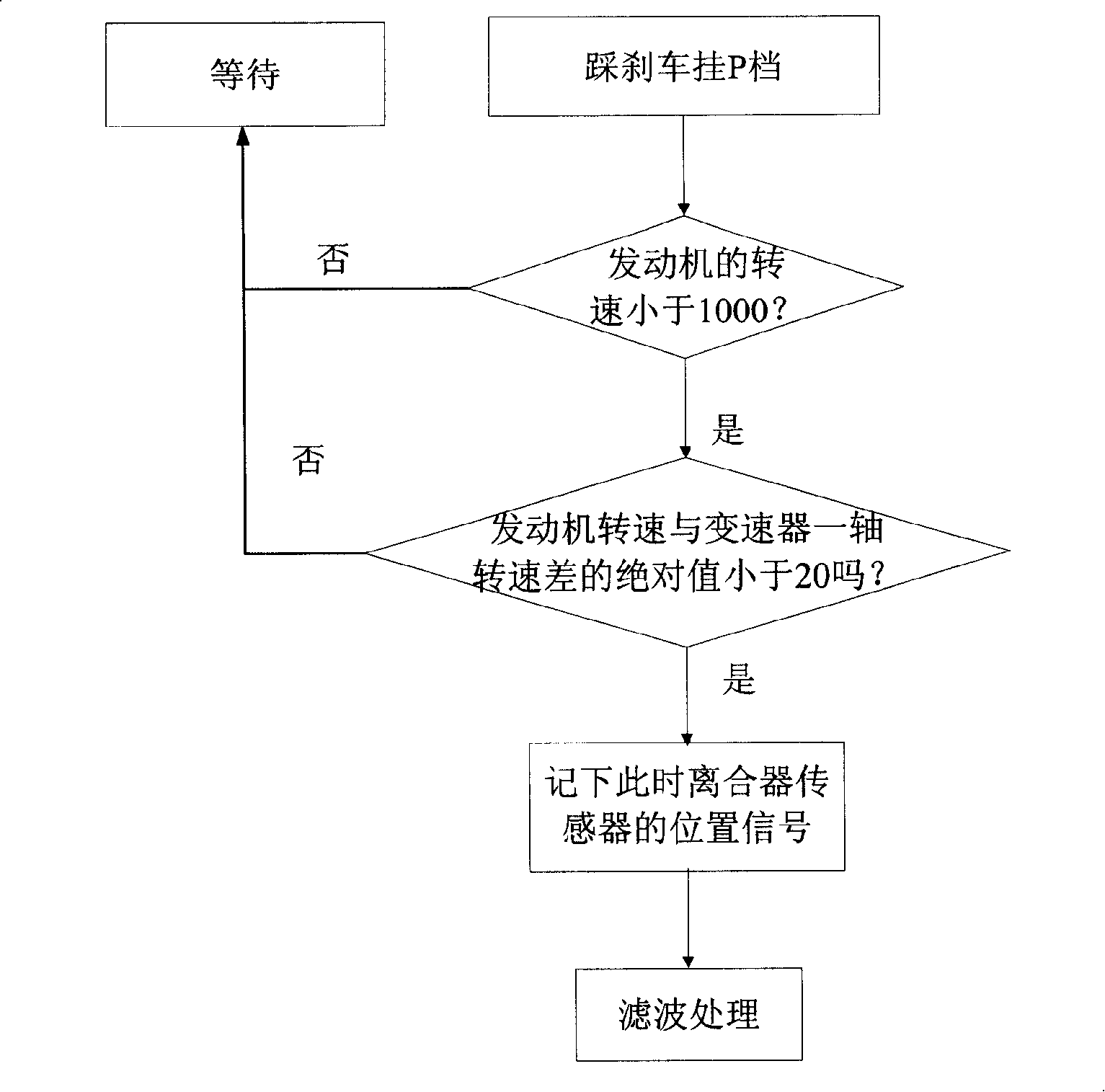

Device and method for judging AMT vehicle clutch half-bonding point

The invention discloses a device and a method for judging AMT vehicle clutch half joint. The device comprises a signal collecting unit and an electronic control unit, wherein the signal collecting unit comprises an engine speed sensor, a speed change gear shaft speed sensor and a clutch position sensor which are respectively connected with an electronic control unit. The control unit is used for collecting a clutch position signal sent by the clutch position sensor when the engine speed is less than a first preset value after an AMT vehicle enters P shift and the absolute value of the speed change gear shaft speed difference is less than a second preset value. The invention can improve the accuracy of collected clutch half joint, thereby improving the running smoothness of the vehicle, reducing clutch wear, prolonging clutch service life, ensuring steady running of the engine and reducing engine speed fluctuation.

Owner:BYD CO LTD

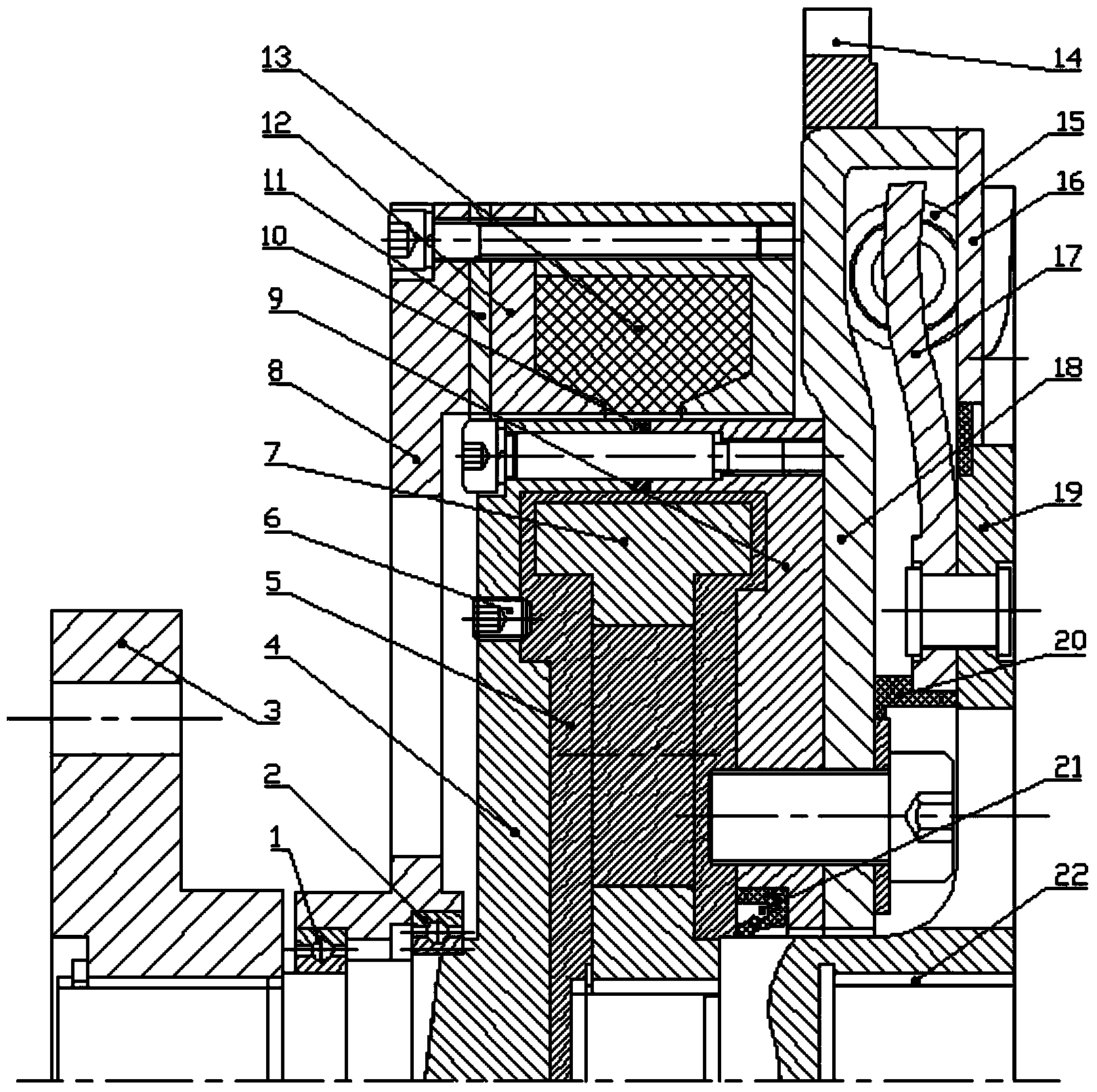

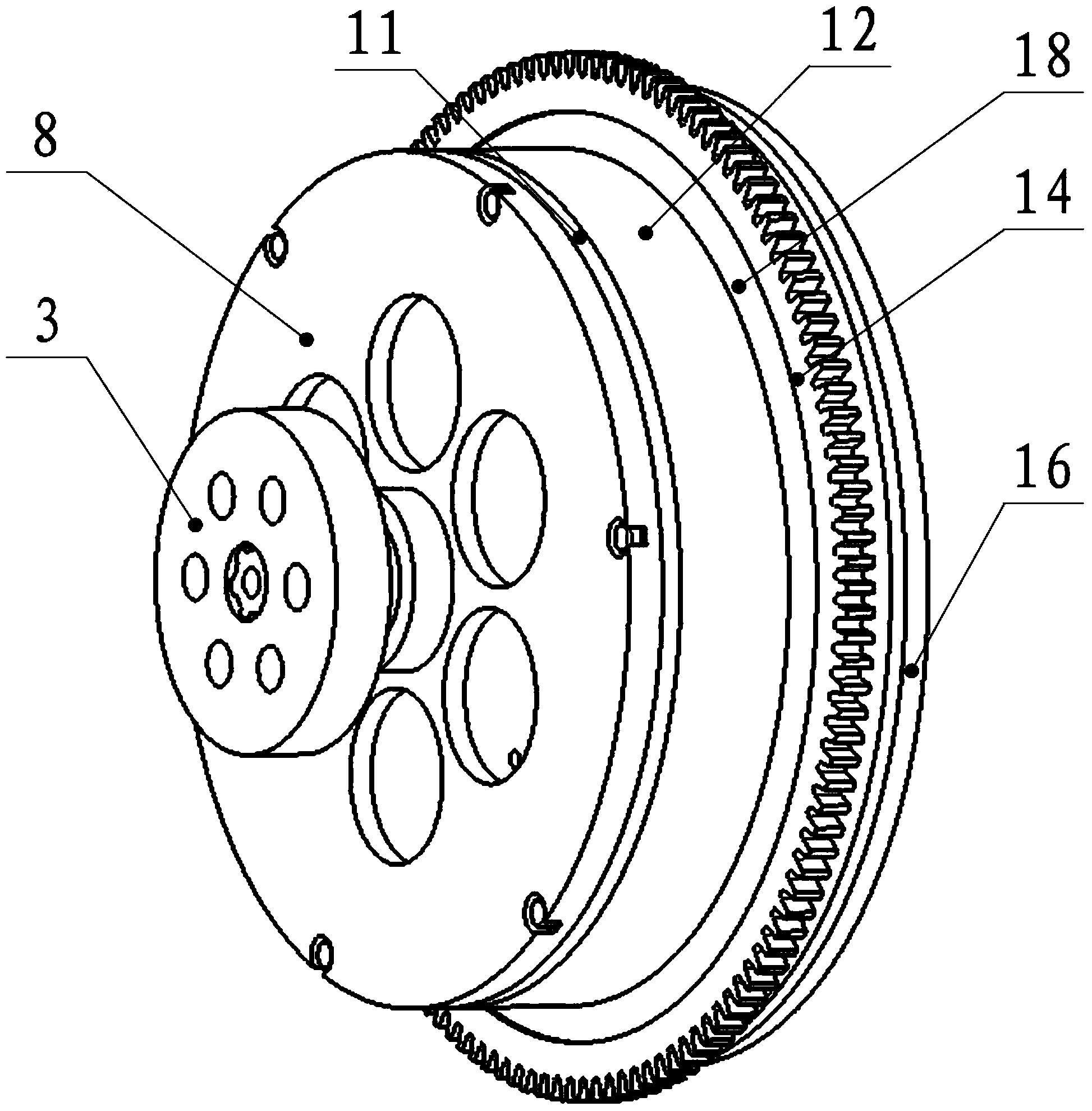

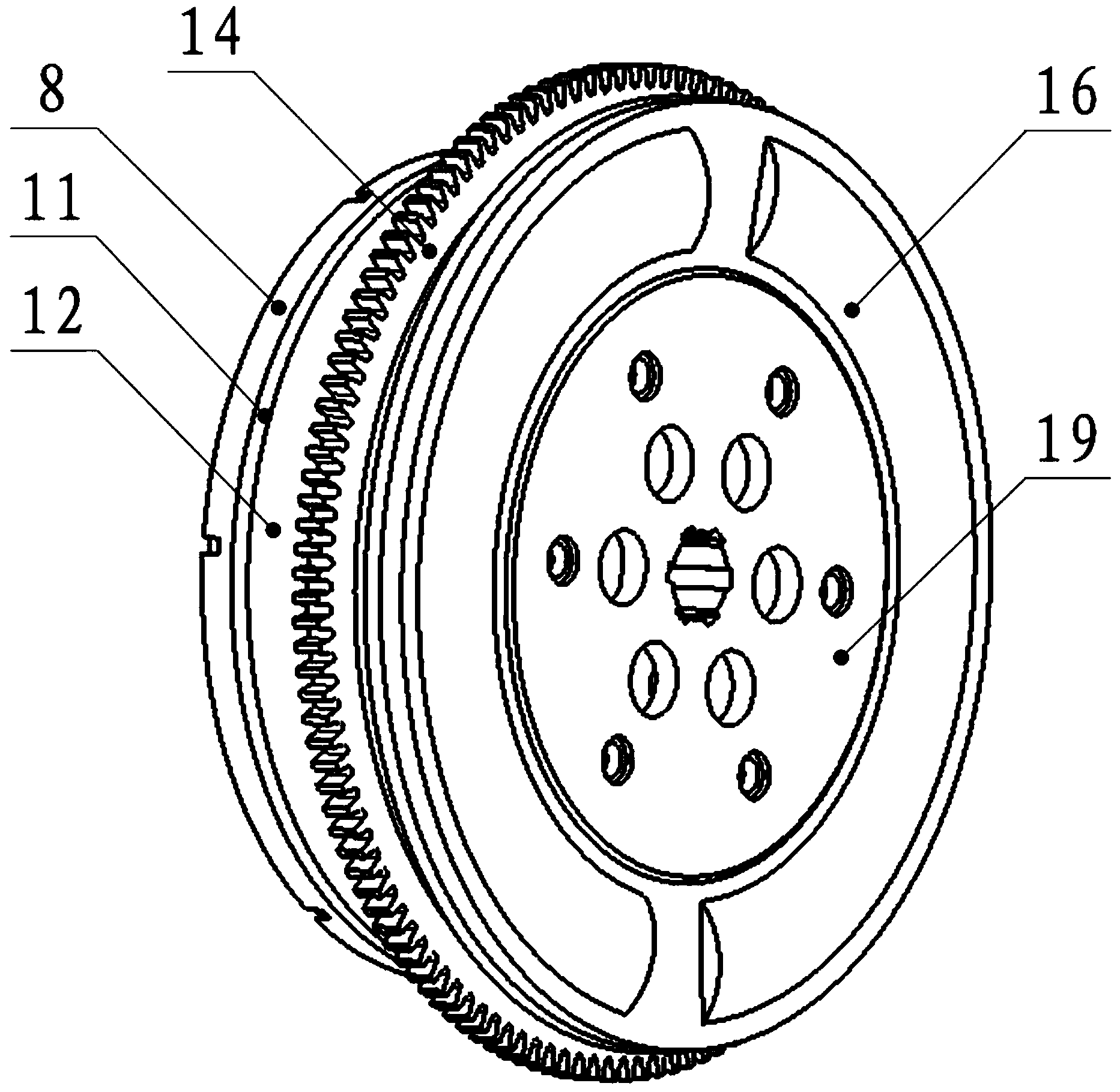

Intelligent magnetorheological fluid dual-mass flywheel

InactiveCN103758923AGood vibration reduction effectExtended service lifeRotating vibration suppressionSpringsFlywheelEngineering

The invention discloses an intelligent magnetorheological fluid dual-mass flywheel. The intelligent magnetorheological fluid dual-mass flywheel aims to overcome the problem that the damping of a dual mass flywheel is incontrollable in the prior art. The intelligent magnetorheological fluid dual-mass flywheel comprises an outer rotor assembly, magnetorheological fluid (5), an inner rotor (7), an excitation device and a dual-mass flywheel assembly. The external rotor assembly is mounted on the left side of the dual-mass flywheel assembly, a sealing cavity rear cover (9) in the outer rotor assembly is fixedly connected with a first flywheel (18) in the dual-mass flywheel assembly through bolts, the inner rotor (7) is mounted on a second flywheel stepped shaft of a second flywheel (19) in the dual-mass flywheel assembly in a sleeved mode and is connected through a spline pair, the inner rotor (7) is mounted inside the outer rotor assembly, and the clearance among the outer circle surface of the inner rotor (7), the inner circle surface of a sealing cavity front cover (4) in the outer rotor assembly and the inner circle surface of the sealing cavity rear cover (9) in the outer rotor assembly forms a working clearance, namely, a sealing cavity. The sealing cavity is filled with the magnetorheological fluid (5), and the excitation device is fixedly mounted on the periphery of the outer rotor assembly.

Owner:JILIN UNIV

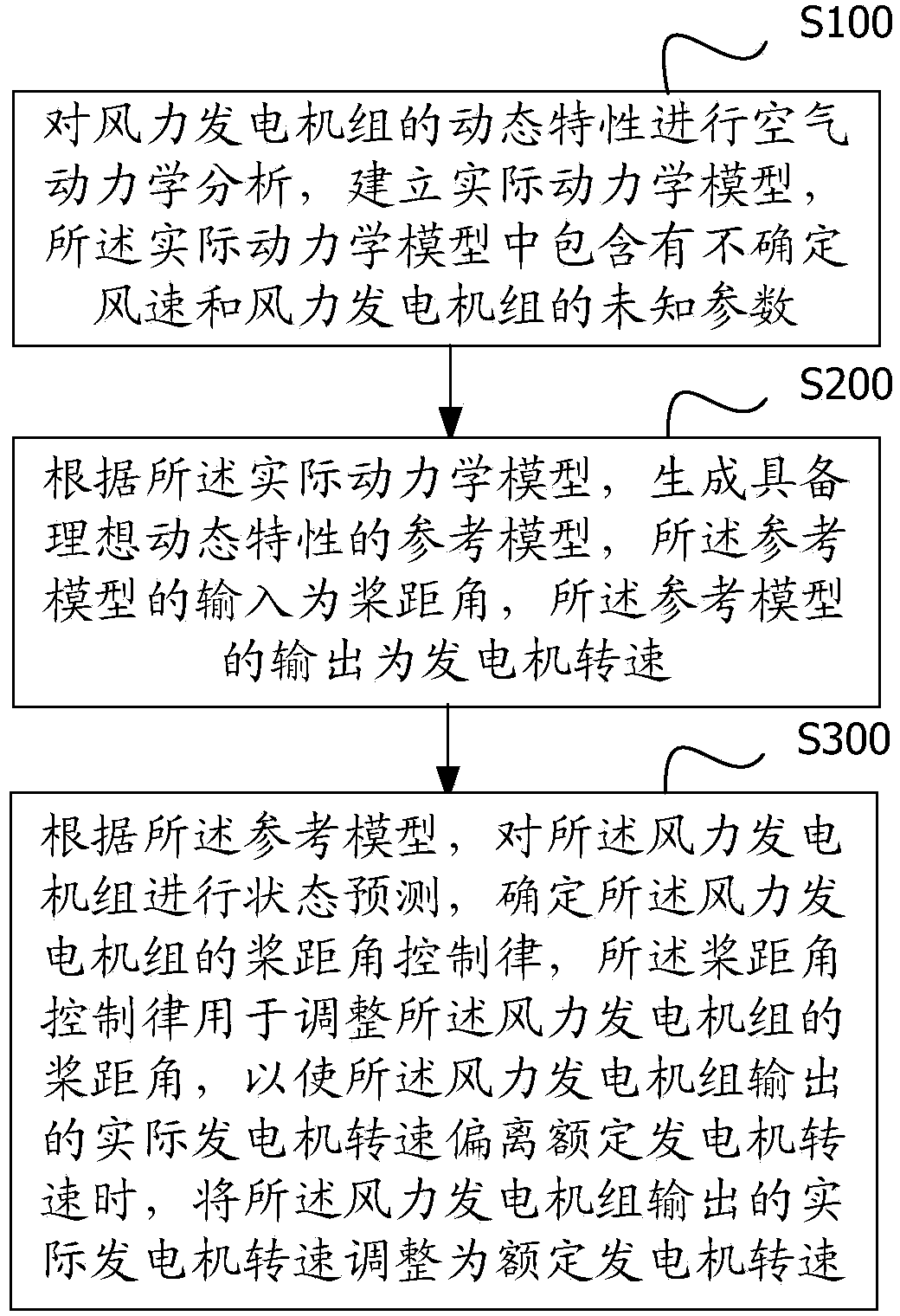

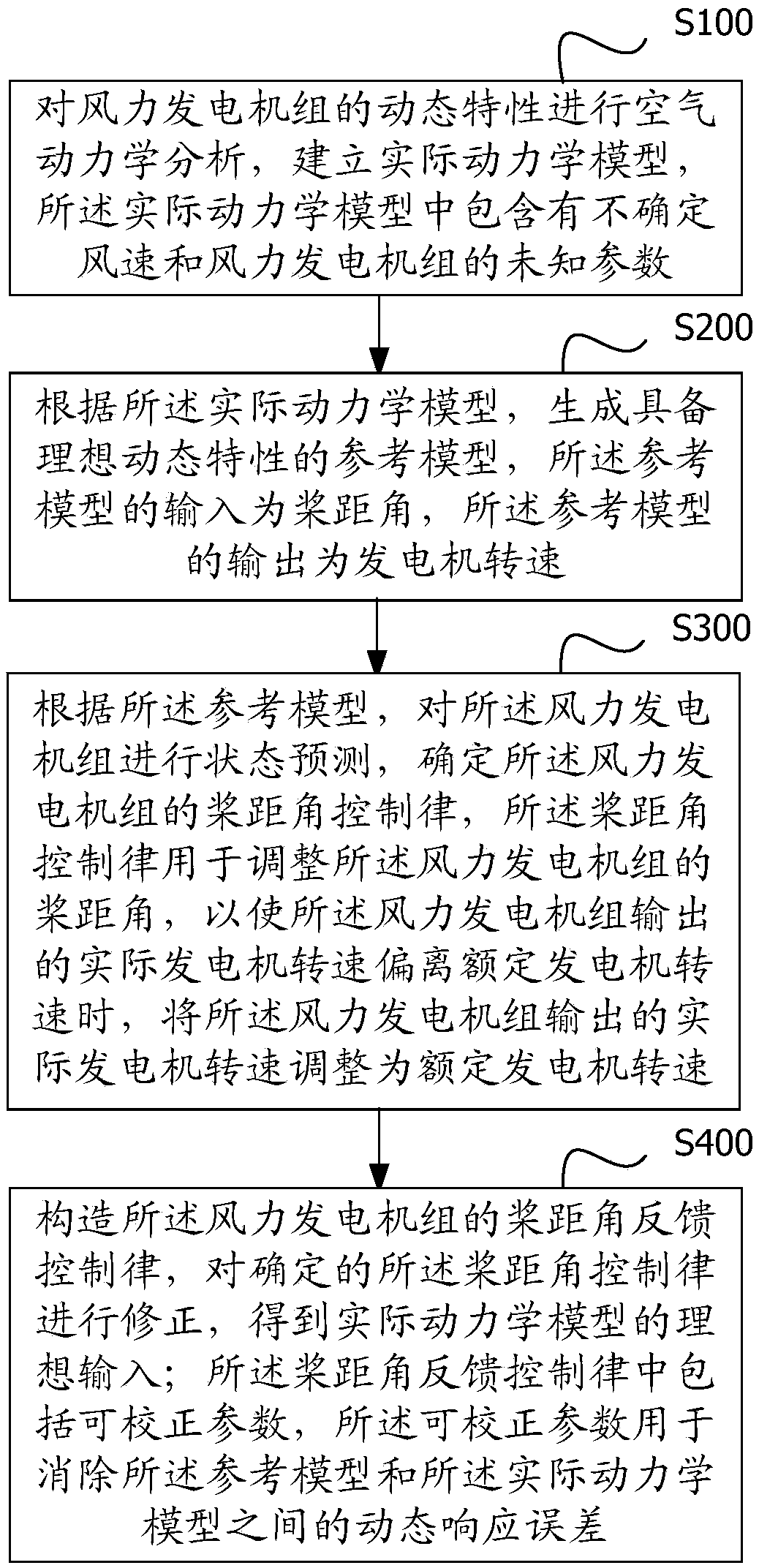

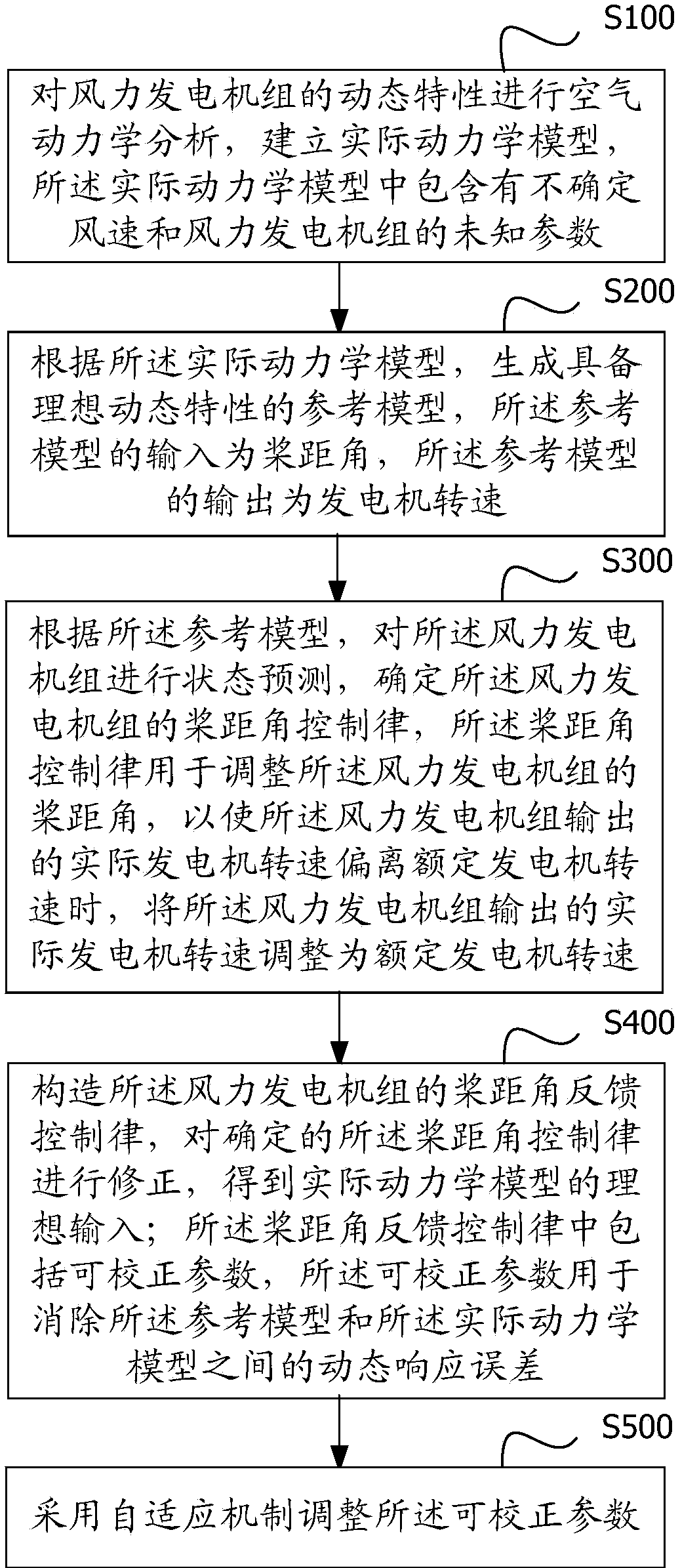

Pitch angle control method and pitch angle controller of wind generating set

ActiveCN103758699AReduce speed fluctuationEasy to adjustWind motor controlMachines/enginesReference modelMean square

The invention discloses a pitch angle control method and a pitch angle controller of a wind generating set. Aerodynamics analysis is carried out on dynamic properties of the wind generating set, a practical dynamical model is set up; according to the practical dynamical model, a reference model with ideal dynamic properties is generated, input of the reference model is the pitch angle and output of the reference model is the rotation speed of a generator; according to the reference model, state predicting is carried on the wind generating set, the pitch angle control law of the wind generating set is determined and the pitch angle control law is used for adjusting the pitch angle of the wind generating unit. Thus, when the practical generator revolution speed output by the wind generating set exceeds the rated generating set revolution speed, the practical generator revolution speed output by the wind generating set is adjusted to be the rated generator revolution speed. Therefore, when the wind speed changes, the generator revolution speed can be well maintained around the rated revolution speed, errors of mean square are small, parameters can be conveniently adjusted, the fluctuation of the revolution speed of the generator is little and control precision and reliability are high.

Owner:ZHEJIANG WINDEY

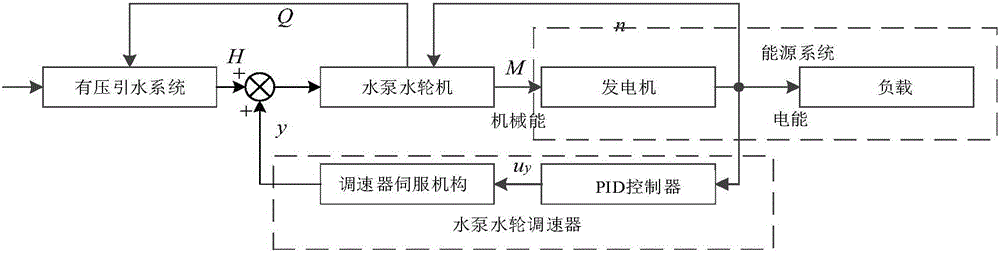

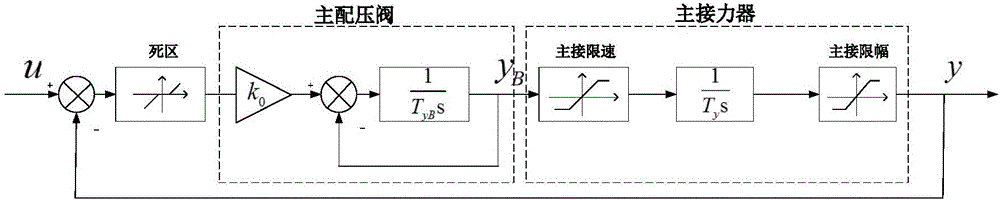

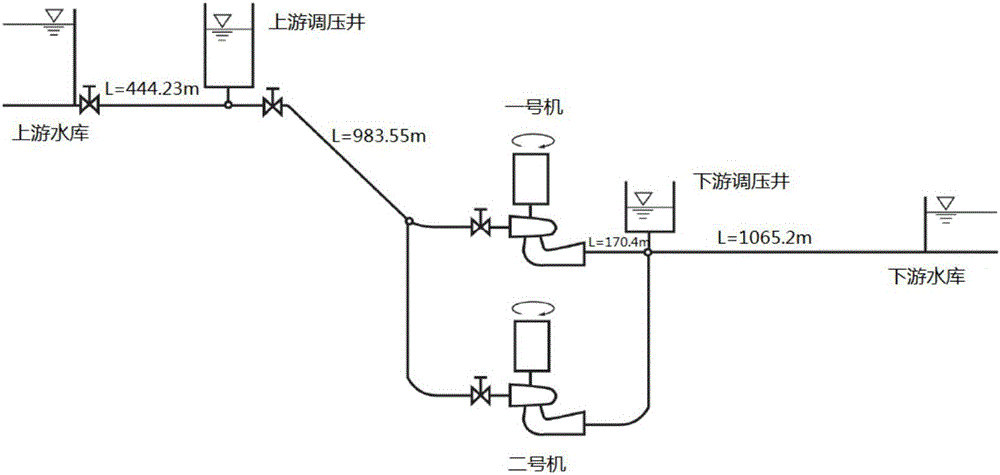

Method for intelligently starting water turbine of pump storage unit under working condition

ActiveCN106485064AImprove the start-up quality of working conditionsReduce boot timeHydro energy generationMachines/enginesWater turbineThree stage

The invention discloses a method for intelligently starting a water turbine of a pump storage unit under a working condition. The method comprises the steps of (1) building a pump turbine adjustment system simulation model of the pump storage unit; (2) setting a three-stage startup control principle in the pump turbine adjustment system simulation model; (3) establishing a startup process control parameter optimization target function by adopting an index of an integral of discrete time multiplied by an error absolute value as a target function of control parameter optimization according to the three-stage startup control principle; and (4) solving the startup process control parameter optimization target function by applying a heuristic optimization method, and obtaining optimal control parameters. According to the method, the control parameters are optimized and applied to simulation calculation, so that the working-condition startup quality of the water turbine of the pump storage unit under different water heads is remarkably improved, the startup time is shortened, the overshoot is reduced, and indexes of speed fluctuation and the like are reduced.

Owner:HUAZHONG UNIV OF SCI & TECH

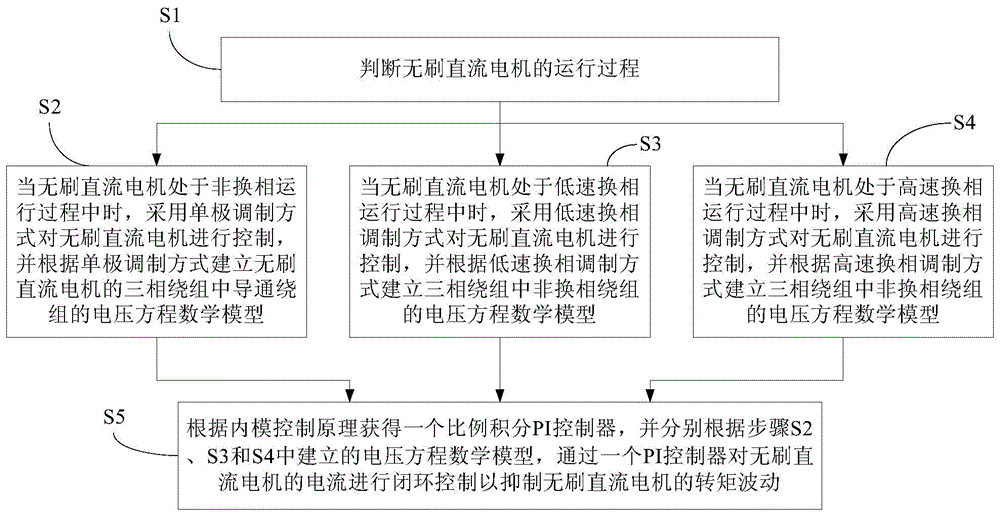

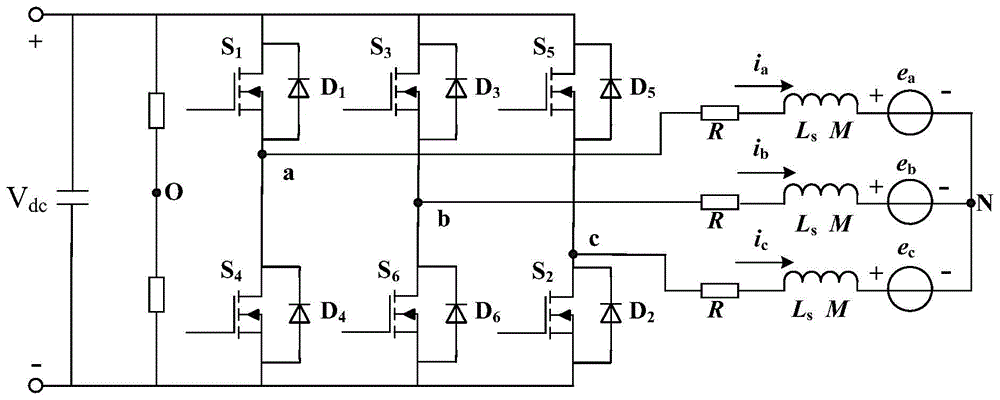

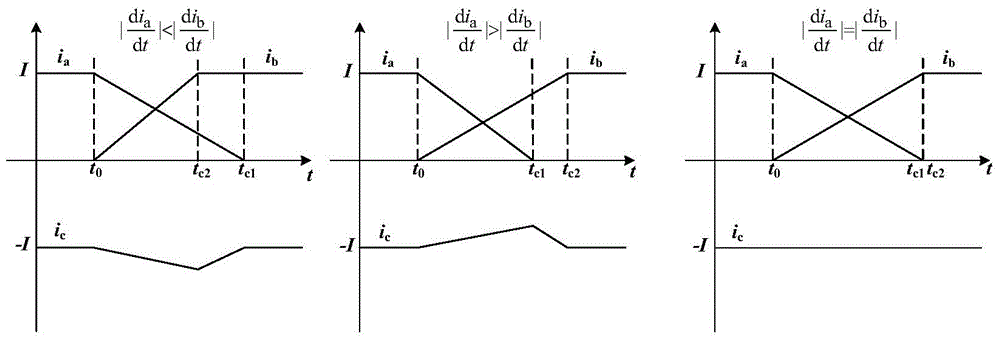

Torque ripple suppression method and control system of brushless DC motor

ActiveCN105529962ASuppression of rotational fluctuationsReduce speed fluctuationTorque ripple controlLow speedPower flow

The invention discloses a torque ripple suppression method of a brushless DC motor. The torque ripple suppression method comprises the steps of: judging operating processes of the brushless DC motor; adopting a corresponding modulating method for controlling the brushless DC motor according to each operating process of the brushless DC motor, and establishing a voltage equation mathematical model of a conduction winding according to the corresponding modulating method; and acquiring a PI controller according to an internal model control principle, and performing closed-loop control on current of the brushless DC motor through the single PI controller for suppressing torque ripples according to the established voltage equation mathematical models. The torque ripple suppression method adopts the single PI controller to achieve closed-loop control on non-commutation operating process, low-speed commutation operating process and high-speed commutation operating process of the brushless DC motor, effectively suppresses torque ripples of the brushless DC motor, simplifies design and debugging processes of the PI controller, and reduces cost. The invention further discloses a control system of the brushless DC motor.

Owner:GD MIDEA AIR-CONDITIONING EQUIP CO LTD

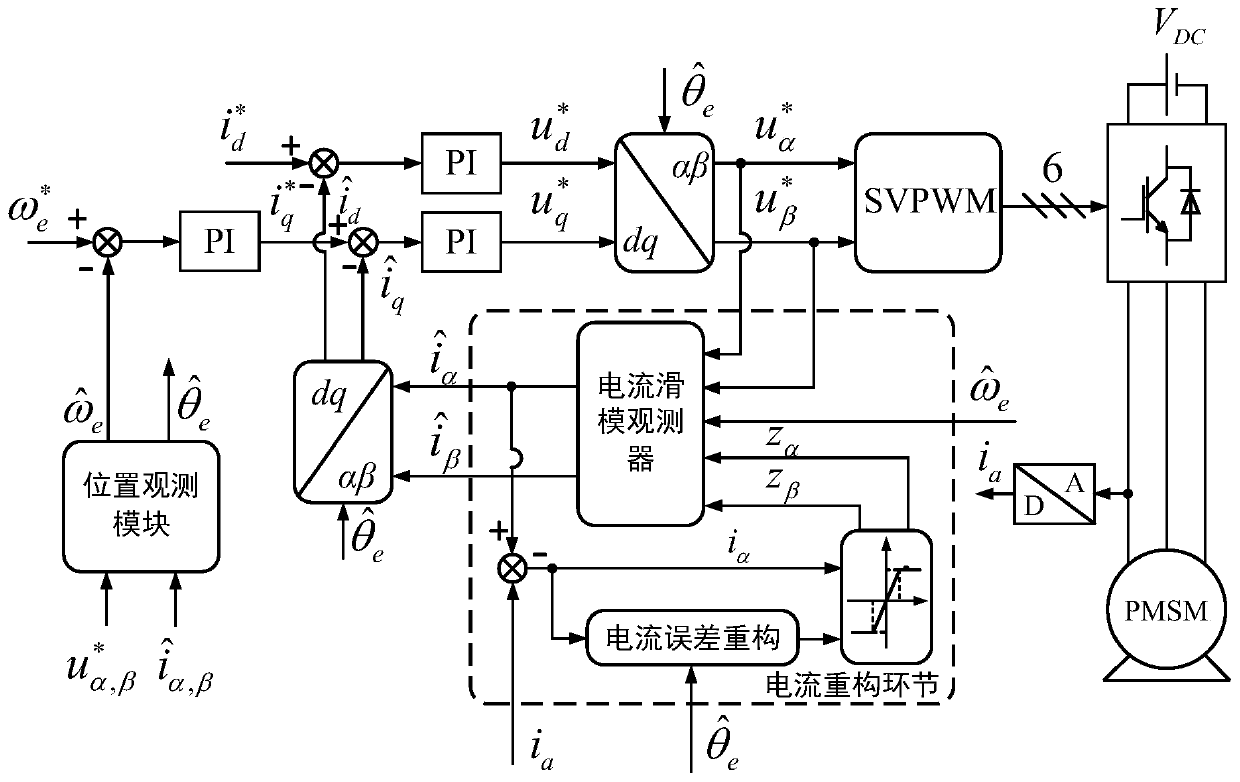

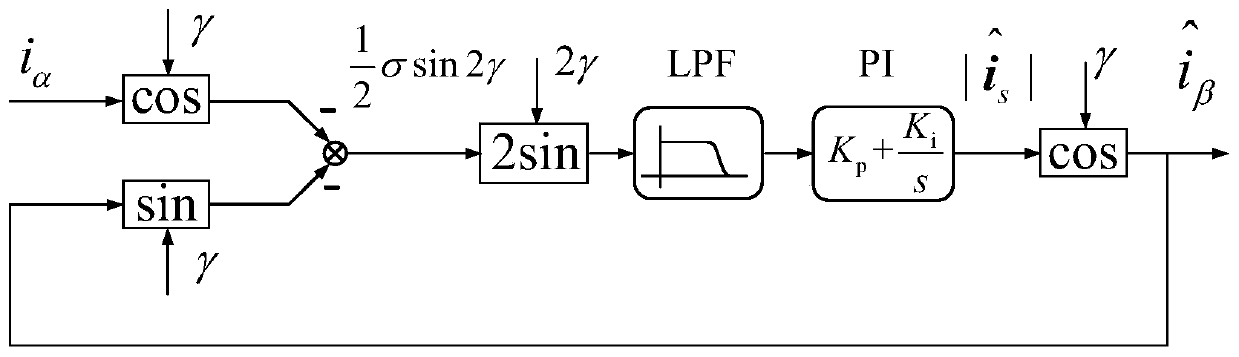

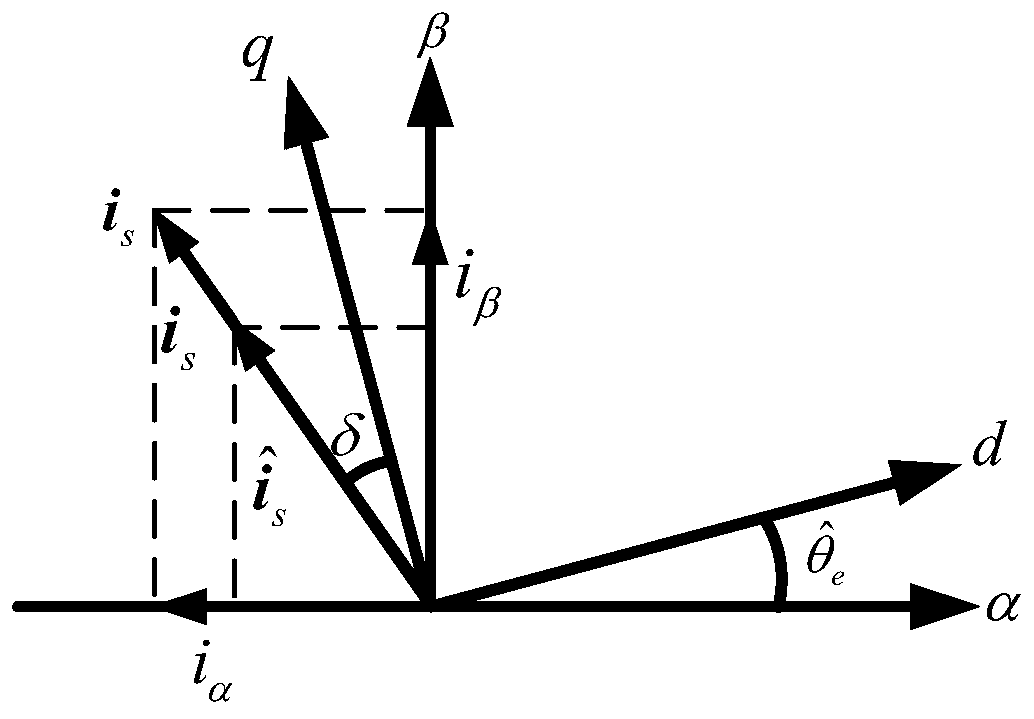

Current space vector error projection correction-based fault-tolerant method for current sensor of position sensorless driving system

ActiveCN110022107AGuaranteed uptimeImprove stabilityElectronic commutation motor controlElectric motor controlPhase currentsControl vector

The invention discloses a current space vector error projection correction-based fault-tolerant method for a current sensor of a position sensorless driving system, and relates to the field of motor control, and aims to solve the problem that in an existing vector control technology of a permanent magnet synchronous motor, a sensor is required to collect a signal to guarantee reliable driving of the permanent magnet synchronous motor, but once the sensor breaks down, the permanent magnet synchronous motor cannot normally run, so that the reliability is poor. An estimated speed and estimated position information of the permanent magnet synchronous motor are obtained; when a certain phase current sensor breaks down, a current error reconstruction link is used for obtaining a current space vector error according to a phase current error, and projecting the error to obtain a reconstructed phase current error; according to the reconstructed phase current error, the phase current error, theestimated speed, an alpha-axis voltage and a beta-axis voltage, an estimated alpha-axis current value and an estimated beta-axis current value are obtained; and performing closed-loop control on the permanent magnet synchronous motor by using values obtained after conversion of the estimated values. The method is used for correcting a phase current to control the motor.

Owner:HARBIN INST OF TECH

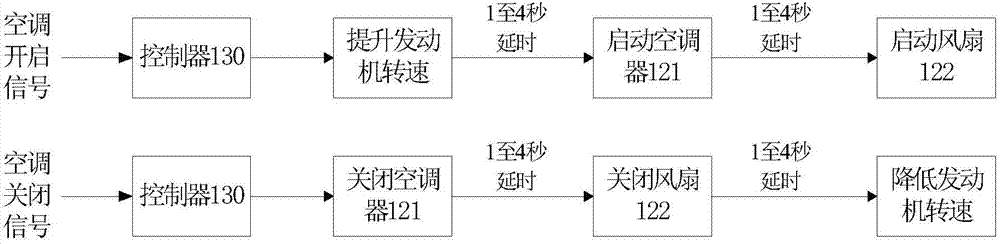

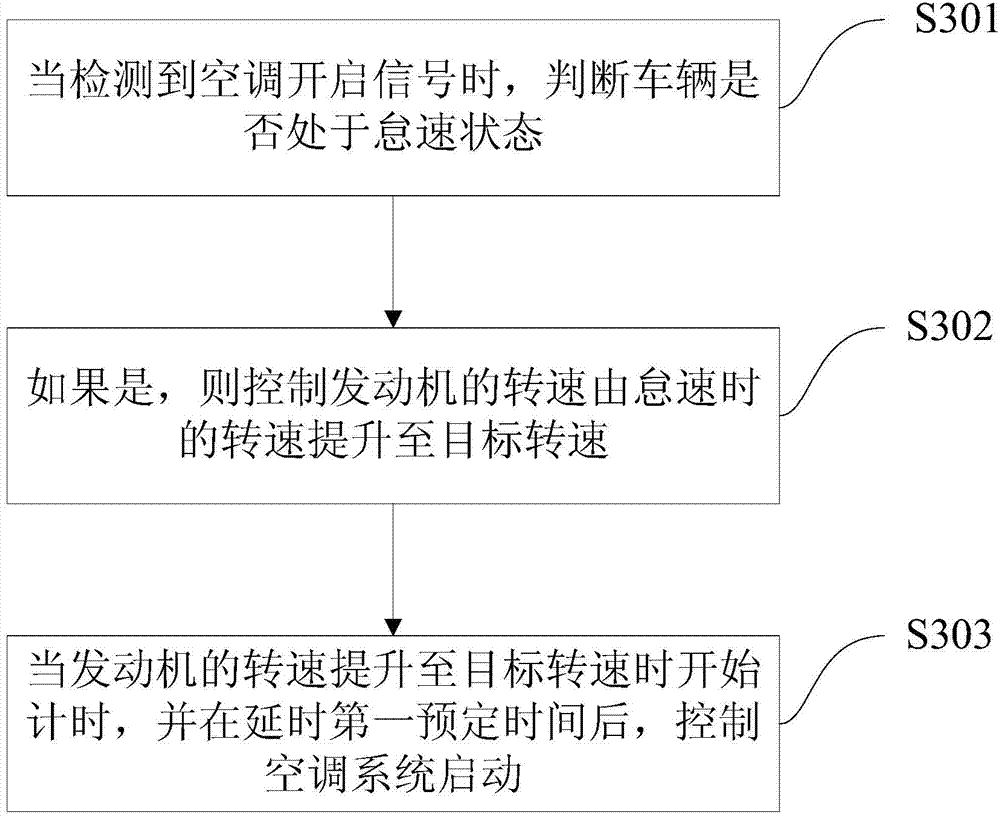

Vehicle control system, vehicle and control method

InactiveCN104842739AAvoid large speed fluctuationsImprove idle stabilityAir-treating devicesVehicle heating/cooling devicesOil consumptionControl system

The invention proposes a vehicle control system, a vehicle and a control method. The control system comprises an engine, an air conditioning system comprising an air conditioner and a fan, and a controller for judging if the vehicle is located in an idling state after detecting an air conditioner opening signal and controlling the rotating speed of the engine to raise from the idling rotating speed to the target rotating speed when judging that the vehicle is located in the idling state, wherein when the rotating speed of the engine rises to the target rotating speed, the timing is began; and the air conditioning system is controlled to be started after delaying by a first preset time. According to the vehicle control system of the embodiment of the invention, when the vehicle is in the idling state, the air conditioner is opened, and the rotating speed fluctuation of the engine can be lowered, so that the oil consumption and the emission are reduced to a certain extent, the vehicle taking comfort is enhanced, the engine noise is reduced, and the service life of the engine is prolonged.

Owner:BEIJING BORGWARD AUTOMOBILE CO LTD

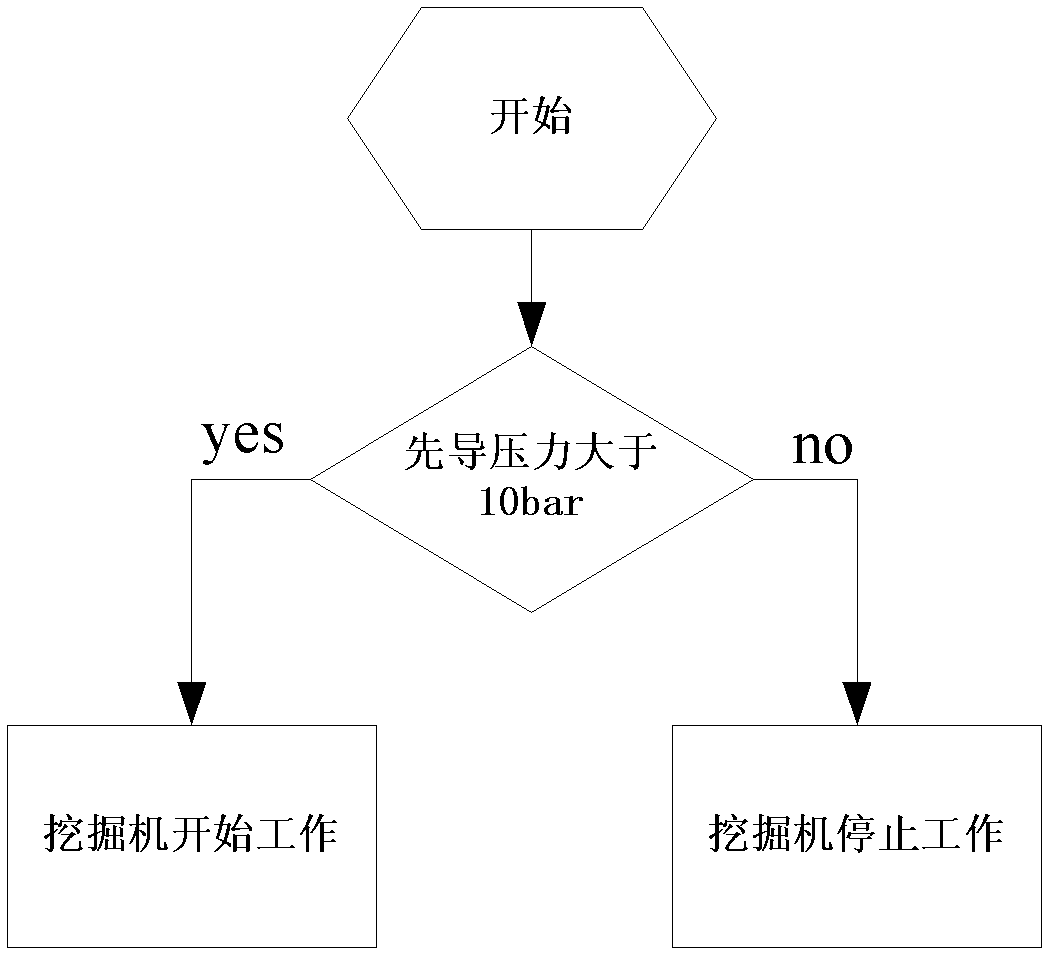

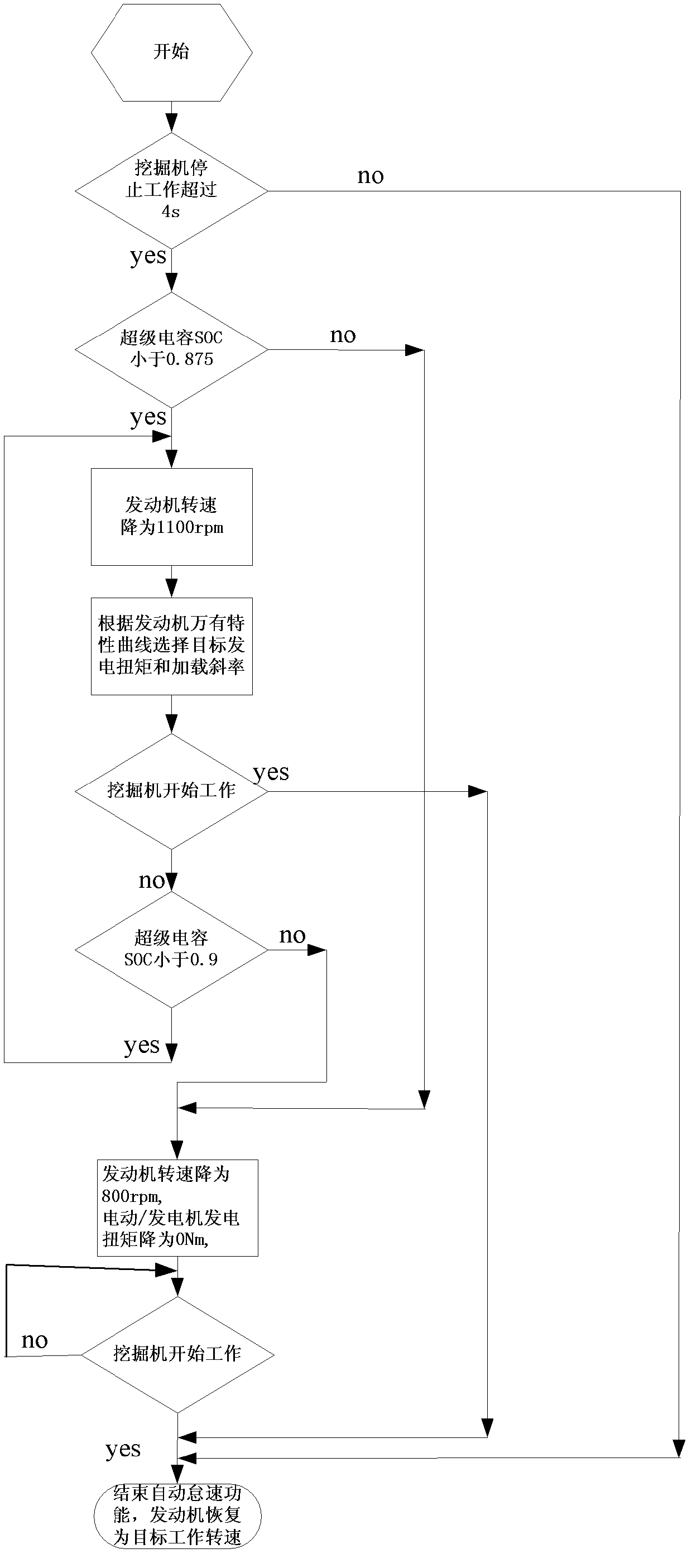

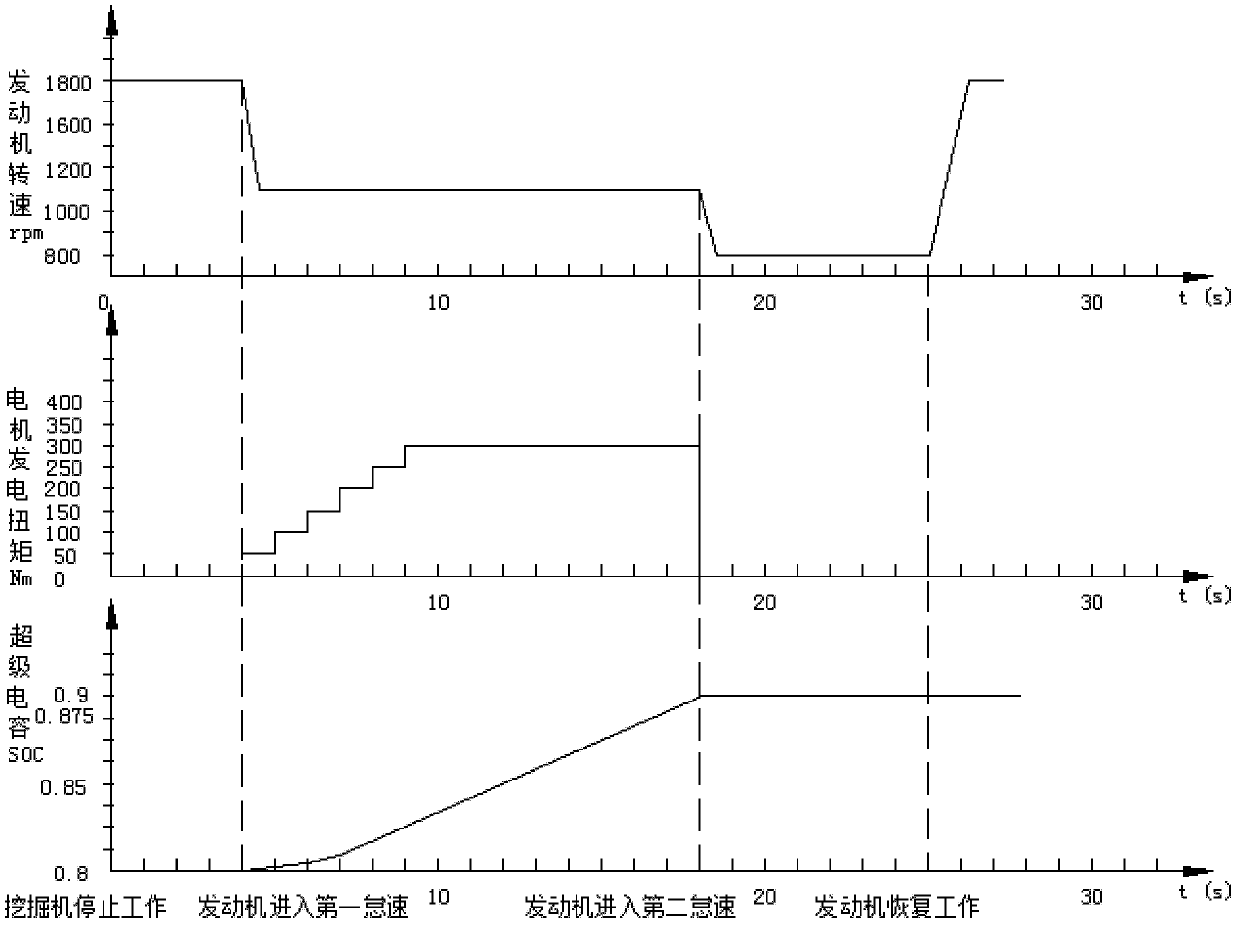

Automatic idle speed control method of hybrid power excavating machine

InactiveCN102383453AReduce energy consumptionEasy loadingSoil-shifting machines/dredgersStopped workCapacitance

The invention discloses an automatic idle speed control method of a hybrid power excavating machine, which comprises the following steps of: firstly, setting idle time and other various numerical values; secondly, judging whether the excavating machine stops working or not by detecting pilot pressure; thirdly, when the work stopping time of the excavating machine exceeds the set idle speed time, turning into the fourth step, and otherwise, exiting an automatic idle speed control program and adjusting the rotating speed of an engine to be a target work rotating speed; fourthly, detecting a current SOC (State of Charge) value of a super capacitor; fifthly, judging whether the excavating machine starts working or not by detecting the pilot pressure in the loading process; sixthly, detecting the current SOC value of the super capacitor; seventhly, adjusting the engine to be a second idle speed; and eighthly, judging whether the excavating machine starts working or not by repeatedly detecting the pilot pressure. According to the method, the fuel economy of the engine can be effectively improved and the phenomenon that the rotating speed of the engine fluctuates in a wide range during loading under the work condition of idle speed is prevented.

Owner:ZHEJIANG UNIV

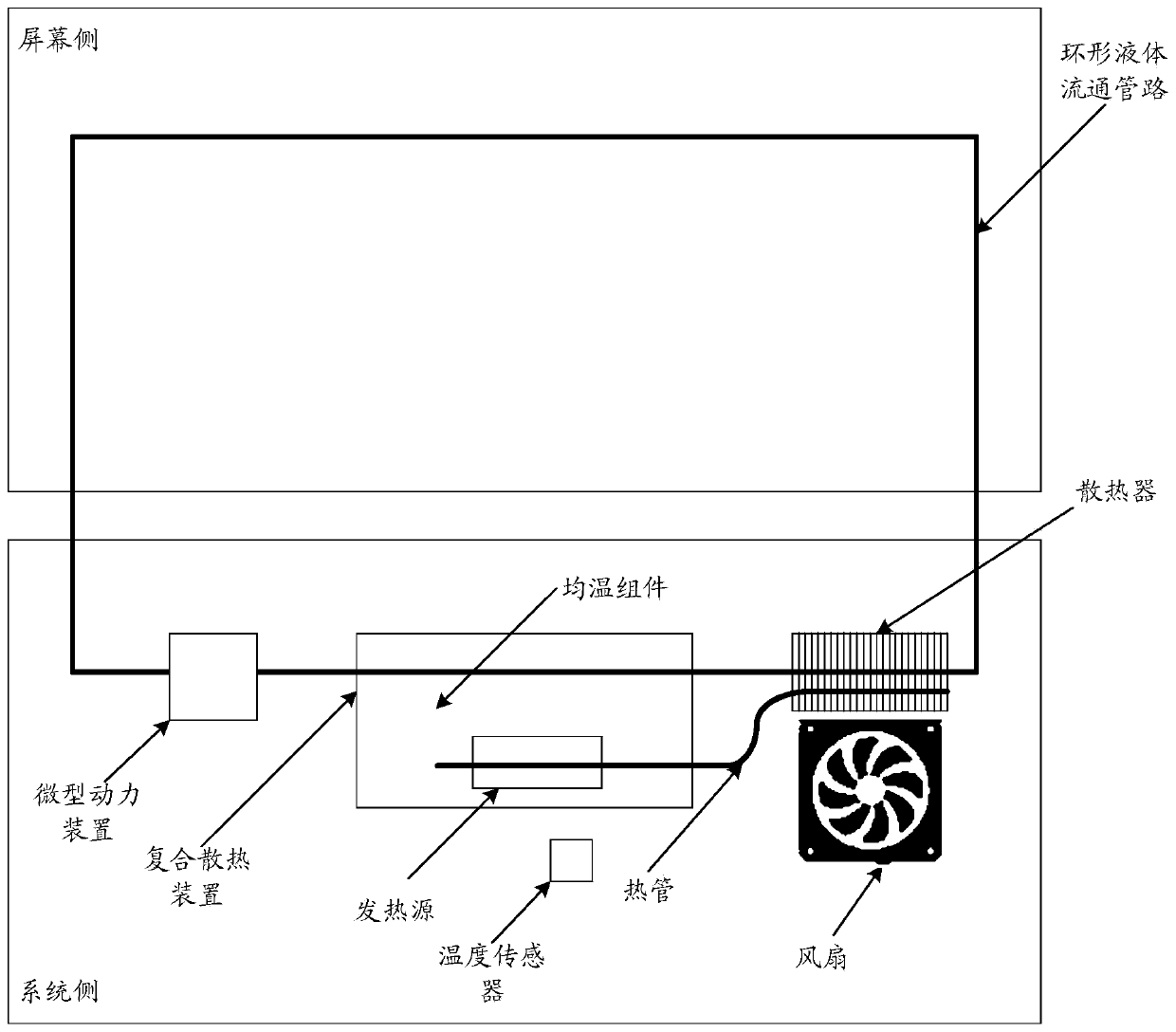

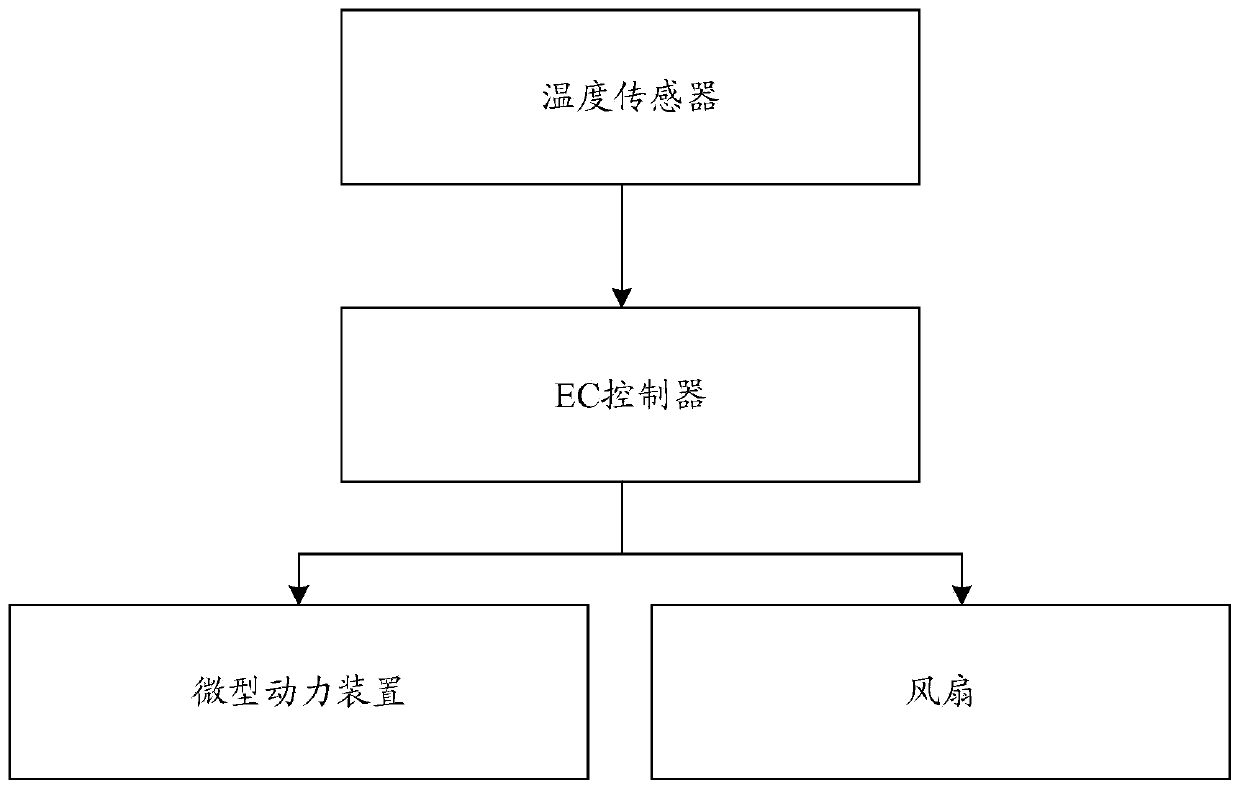

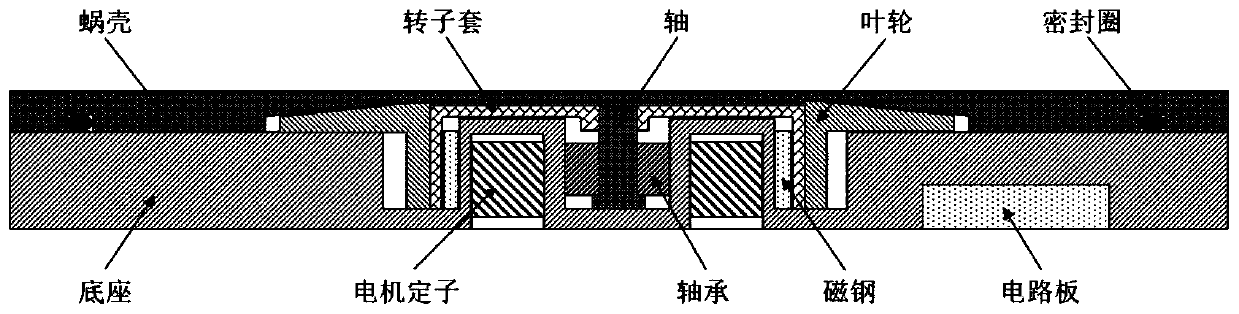

Heat dissipation method and electronic equipment

PendingCN110989803AHigh precisionLow spin speedDigital data processing detailsEngineeringThermal threshold

The invention provides a heat dissipation method and electronic equipment. For example, the heat dissipation method can be applied to a notebook computer or a tablet computer. The electronic equipmentcomprises a controller, a temperature sensor, a heat conduction assembly, a liquid cooling device and an air cooling device; the liquid cooling device comprises a pump and an annular pipeline; cooling liquid is stored in the annular pipeline, the heating part transmits heat to the cooling liquid, and the pump is used for driving the cooling liquid to circulate; the air cooling device comprises aheat pipe, a fan and a radiator, wherein cooling liquid is stored in the heat pipe, the heating part transmits heat to the cooling liquid, and the radiator is connected with one end of the heat pipe.The method comprises the steps that the controller receives a temperature value, detected by the temperature sensor, of the heating part; when the temperature value is greater than or equal to the temperature threshold value, the controller adjusts the rotating speed of the pump and the rotating speed of the fan through pulse width modulation PWM, so the heat of the heating part is dissipated intothe environment through the annular pipeline and the heat pipe. According to the embodiment of the invention, the medium-low load noise requirement and the high load performance requirement of the electronic equipment can be met.

Owner:HUAWEI TECH CO LTD

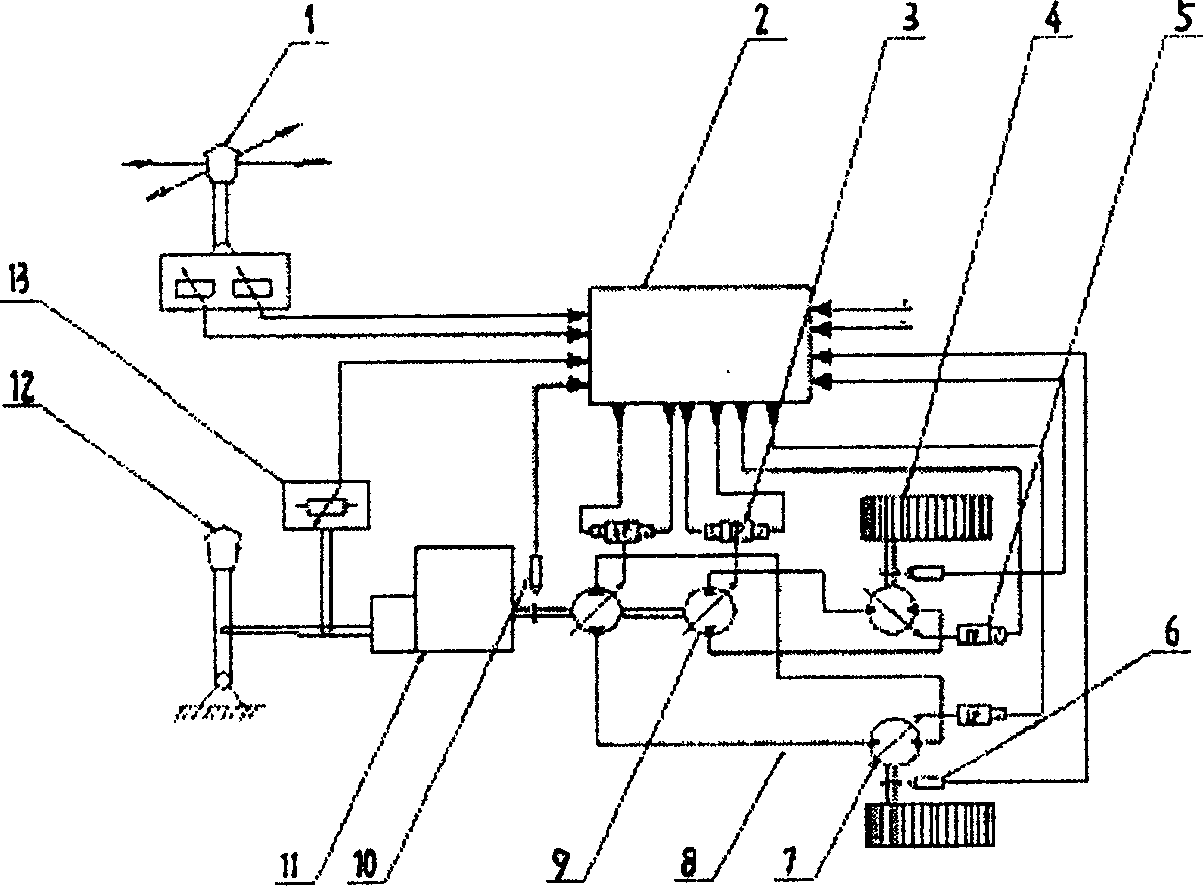

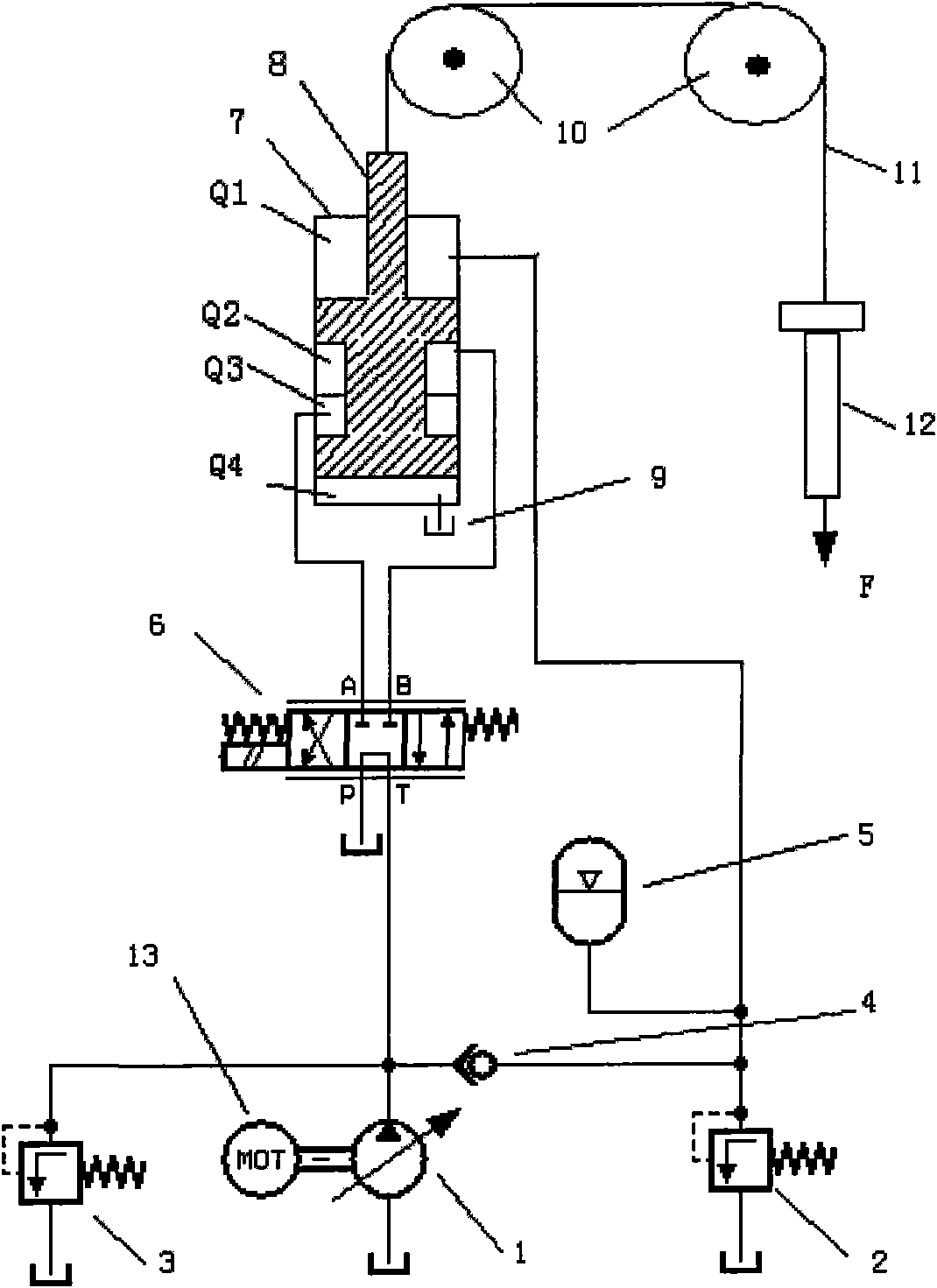

Novel energy-saving hydraulic pumping unit

The invention relates to a novel energy-saving hydraulic pumping unit, which comprises a hydraulic pump 1, an overflow valve 2, an overflow valve 3, a one way valve 4, an energy accumulator 5, an electro-hydraulic direction-changeover valve 6, a compound cylinder 7, a piston rod 8, an oil tank 9, a pulley 10, a rope 11, a pumping rod 12, a motor 13 and the like. The novel energy-saving hydraulic pumping unit adopts a hydraulic driving system and an energy accumulator balanced system, utilizes the energy accumulator 5 to collect gravitational potential energy released by the pumping rod 12 system and store the energy of the motor 13 in the down stroke, releases the energy in the up stroke, and can effectively reduce the installed power and the speed fluctuation of the motor to achieve the energy-saving effect. The novel energy-saving hydraulic pumping unit also has the advantages of large lifting force, light weight, convenient adjustment of stroke length and stroke frequency and the like of the conventional hydraulic pumping unit.

Owner:SICHUAN UNIV

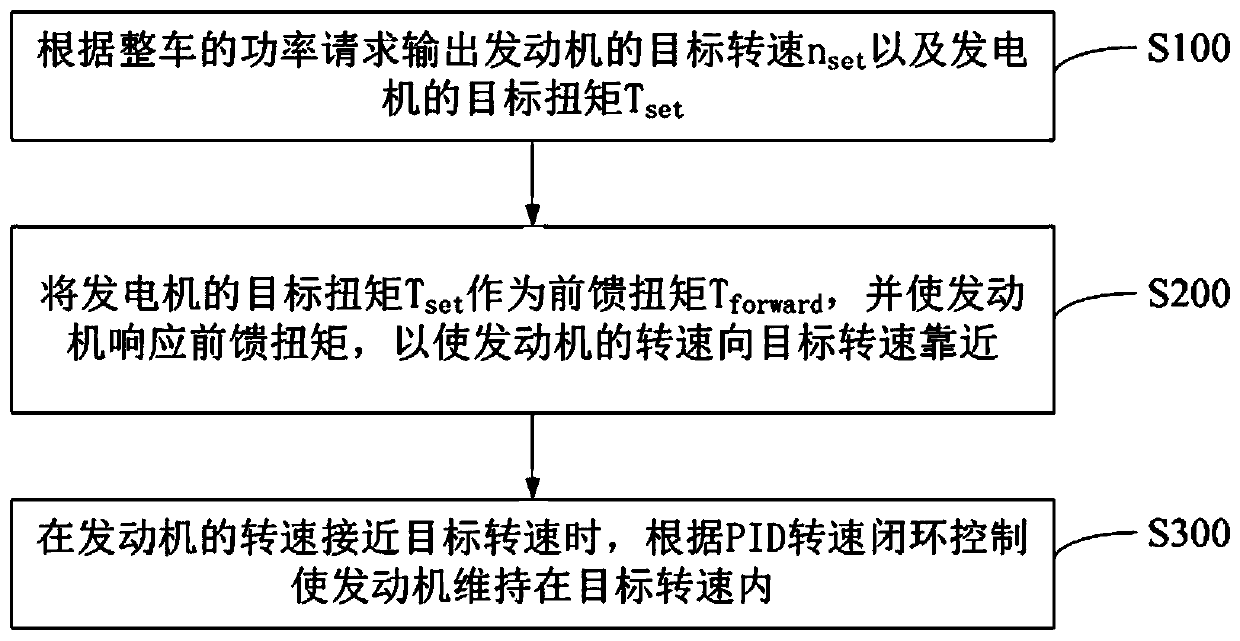

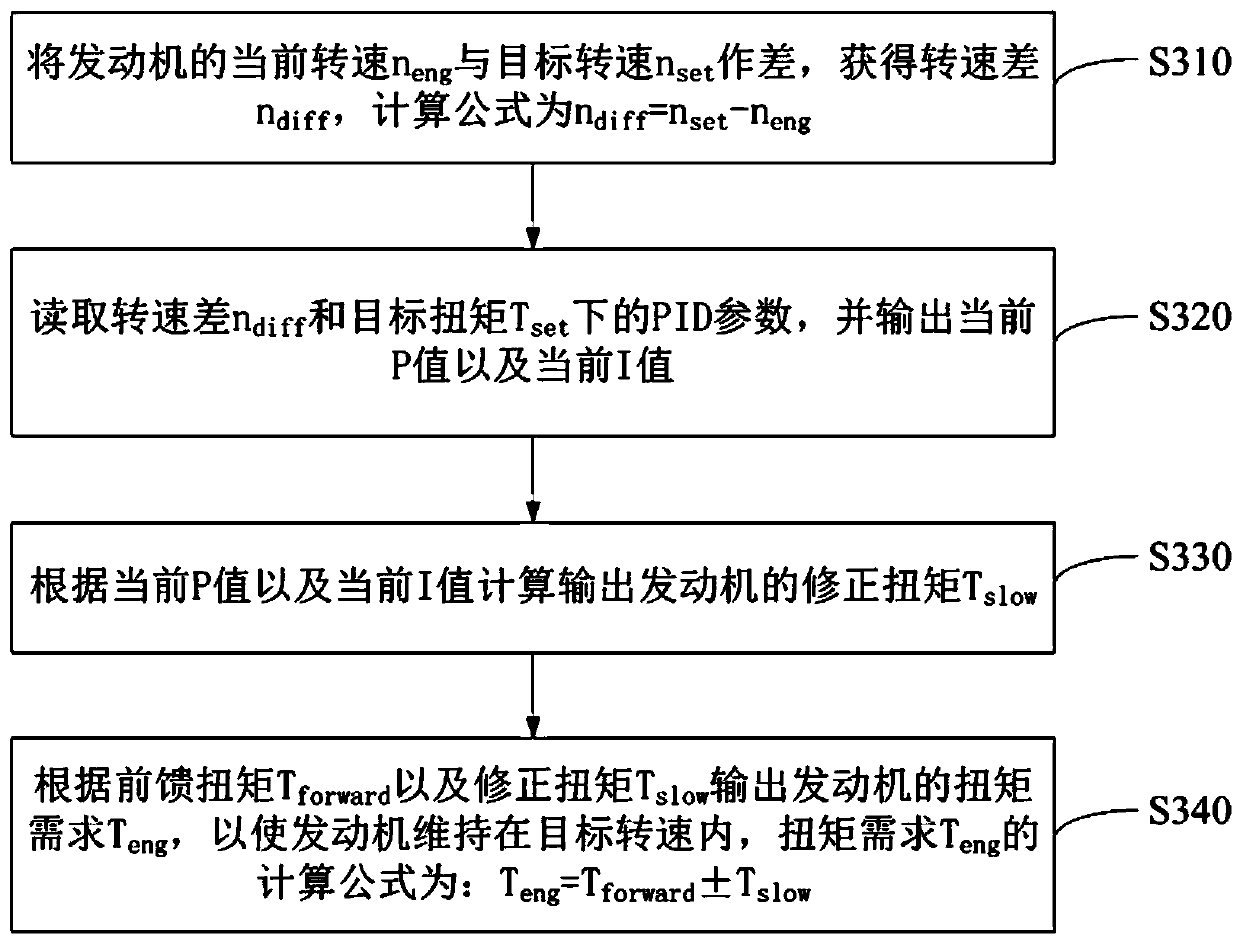

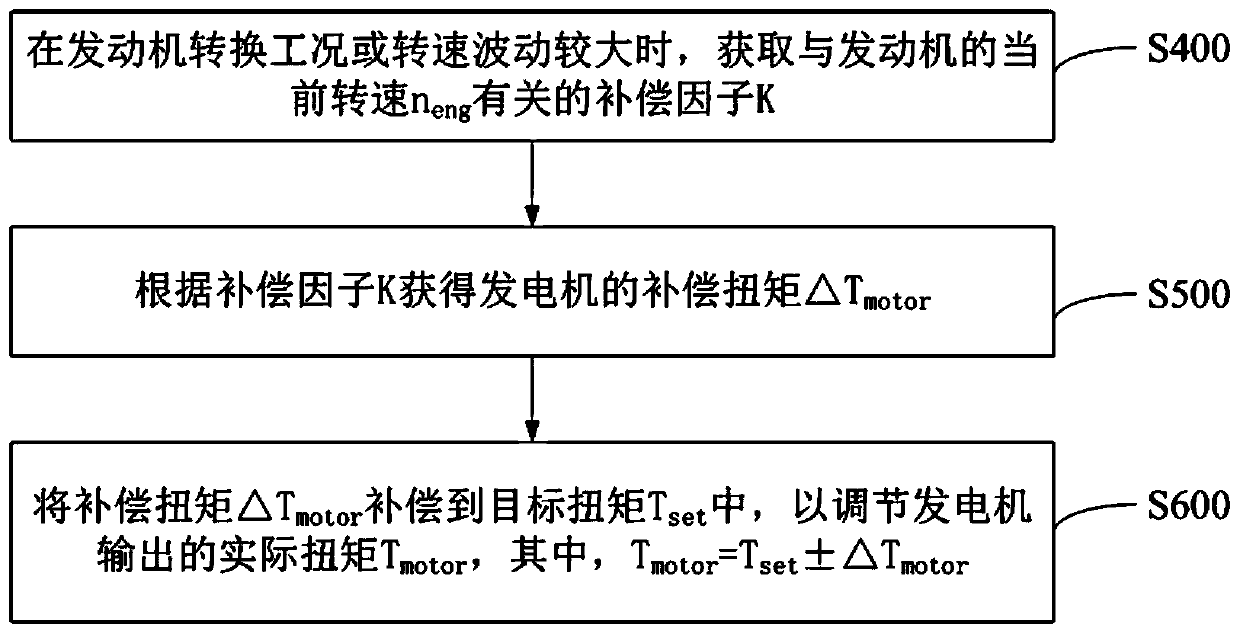

Control method and system for adjusting rotating speed stability of range extender

ActiveCN111267643AFast response to speed requirementsReduce rateHybrid vehiclesSpeed controllerLoop controlElectric generator

The invention provides a control method and system for adjusting rotating speed stability of a range extender. The control method comprises the following steps that: the target rotating speed nset ofthe engine and the target torque Tset of the generator are output according to a power request of a whole vehicle; the target torque Tset of the generator is taken as a feed-forward torque Tforward, and the engine responds to the feed-forward torque so as to enable the rotating speed of the engine to be close to the target rotating speed; and when the rotating speed of the engine is close to the target rotating speed, the engine is maintained within the target rotating speed according to PID rotating speed closed-loop control. Through the generator real-time torque compensation control methodand PID rotating speed closed-loop accurate control, the rotating speed of the range extender can be continuously and stably output under the target power, the fluctuation of the rotating speed of theengine is reduced, and then the purposes of reducing vibration of a range extender system and improving the overall NVH performance of the range extender are achieved.

Owner:ZHEJIANG GEELY NEW ENERGY COMML VEHICLES CO LTD +3

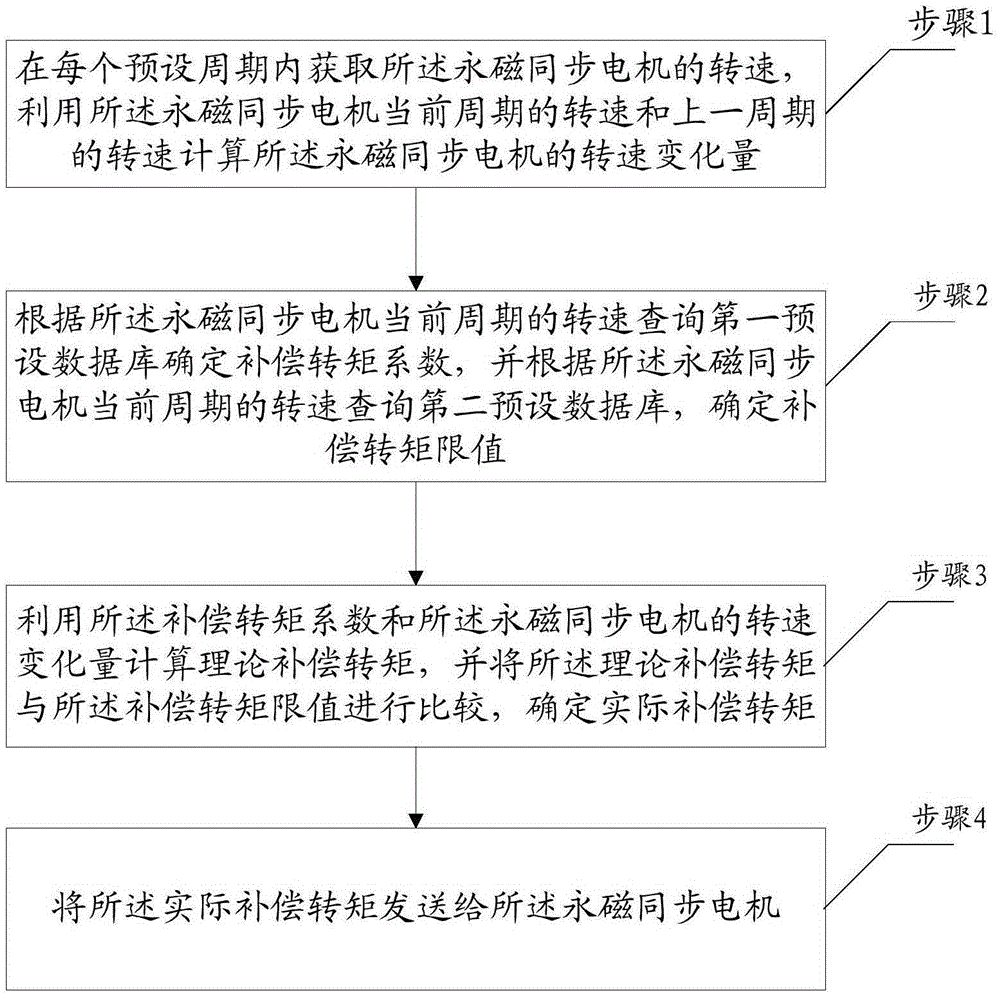

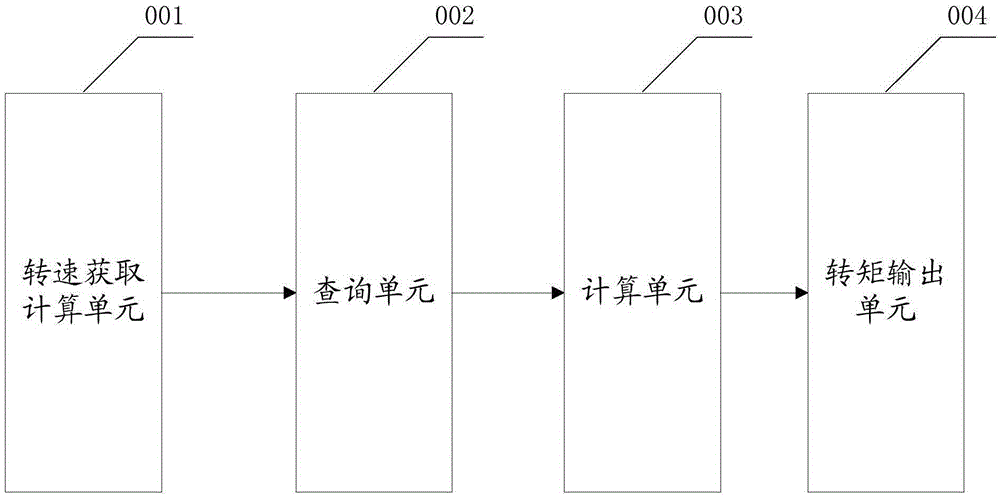

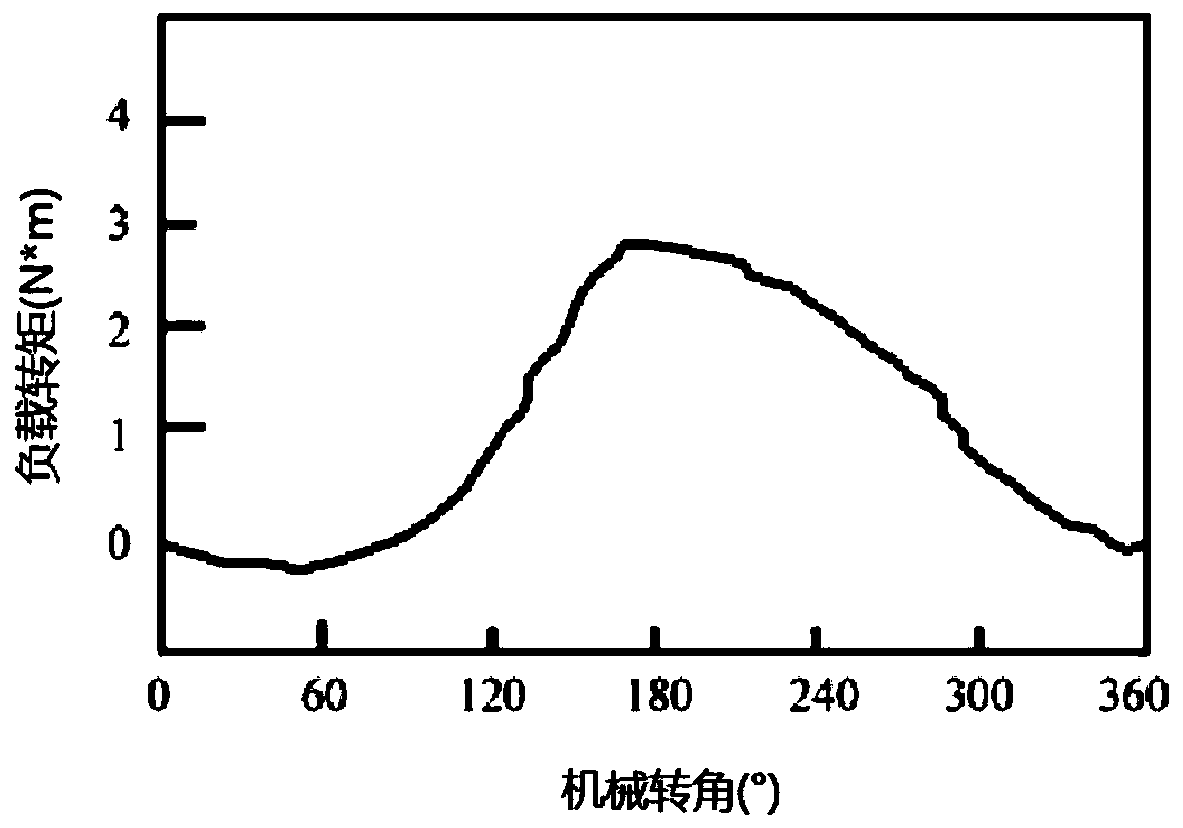

Electric vehicle, suppression method and suppression system of rotation speed fluctuation of permanent magnet synchronous motor

ActiveCN105305893AReduce jitterImprove comfortTorque ripple controlCar drivingPermanent magnet synchronous motor

The embodiment of the invention provides a suppression method and suppression system of the rotation speed fluctuation of a permanent magnet synchronous motor. The method includes the following steps that: the rotation speed of the permanent magnet synchronous motor is obtained in each preset period, and the variation quantity of the rotation speed of the permanent magnet synchronous motor is calculated through using the rotation speed of the permanent magnet synchronous motor in the current period and the rotation speed of the permanent magnet synchronous motor in the last period; a first preset database is queried according to the rotation speed in the current period, so that a compensation torque coefficient can be determined, and a second preset database is queried according to the rotation speed in the current period, so that a compensation torque limit value can be determined; theoretical compensating torque is calculated through utilizing the compensation torque coefficient and the variation quantity of the rotation speed of the permanent magnet synchronous motor, and the theoretical compensating torque is compared with the compensation torque limit value, so that actual torque compensation torque can be determined; and the actual compensation torque is transmitted to the permanent magnet synchronous motor. With the method adopted, jigger generated when the permanent magnet synchronous motor is applied to an electric vehicle can be reduced, and the driving comfort of the electric vehicle can be improved.

Owner:深蓝汽车科技有限公司

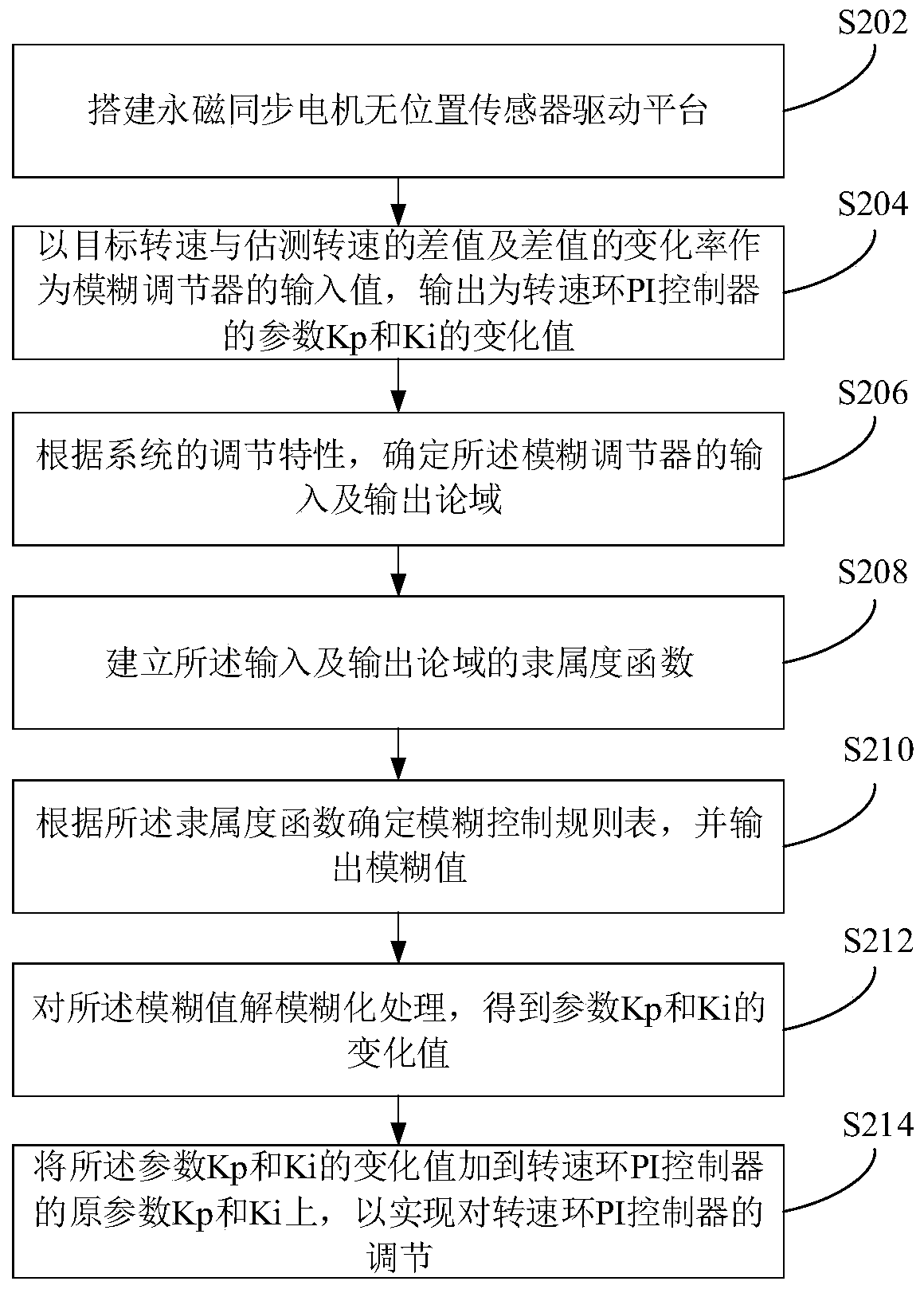

Permanent magnet synchronous motor control method and system based on fuzzy control, and storage medium

InactiveCN110492805AImprove control characteristicsReduce speed fluctuationElectronic commutation motor controlAC motor controlElectric machinePermanent magnet synchronous motor

The invention provides a permanent magnet synchronous motor control method and system based on fuzzy control, and a storage medium. On the basis of a rotating speed loop PI controller, a difference value between the target rotating speed and the estimated rotating speed and a change rate of the difference value are taken as input; the change values of parameters of Kp and Ki of the rotating speedloop PI controller are taken as output; and the control characteristic of the motor is improved by optimizing the rotating speed loop PI controller of the permanent magnet synchronous motor through the fuzzy regulator, so that the rotating speed fluctuation of the compressor caused by load change is effectively reduced, and the effect of reducing the vibration noise of the compressor is further achieved.

Owner:HANGZHOU ZHOUJU ELECTRONICS TECHNOLOGICAL

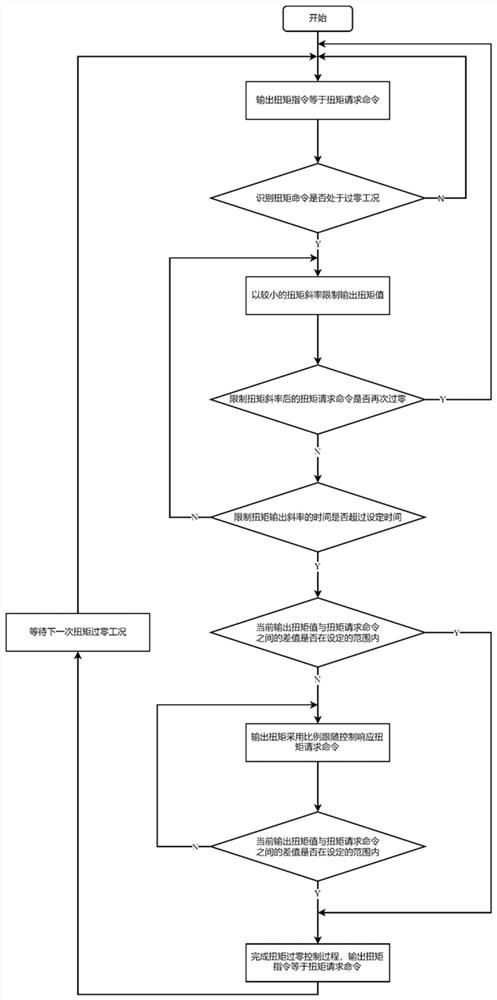

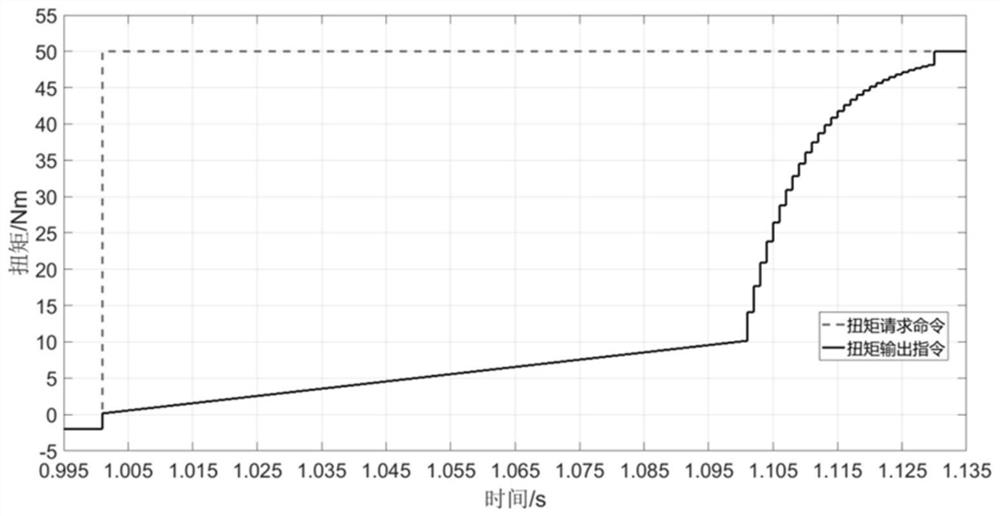

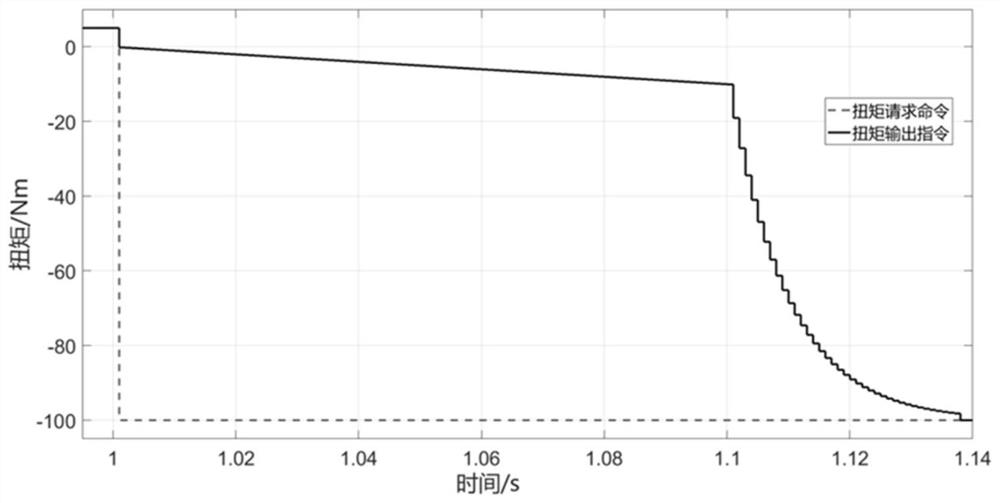

Motor torque zero-crossing anti-shake control method for new energy vehicles

ActiveCN111731111ASmooth torque changeReduce power shockSpeed controllerElectric energy managementNew energyElectric machinery

The invention relates to a motor torque zero-crossing anti-shake control method for new energy vehicles. The motor torque zero-crossing anti-shake control method comprises the steps that 1, judging whether motor torque is in a zero-crossing working condition; 2, limiting the torque output slope, and reducing torque zero-crossing impact; 3, judging whether the request torque generates the zero-crossing working condition again within the time of limiting the torque output slope; 4, judging whether the time for limiting the torque output slope is overtime or not; 5, judging whether a torque difference value between the request torque and the limited torque output slope is smaller than a first preset threshold value; 6, obtaining an output torque by adopting a following control algorithm; 7, judging whether the difference value between the current output torque and the request torque is smaller than a second preset threshold value; and step 8, completing torque zero-crossing control, returning to the step 1, and waiting for a next torque zero-crossing working condition. Compared with the prior art, the method has the advantages that the torque zero-crossing working condition can be predicted, the torque response speed is high, and the driving experience and the automobile dynamic property are improved.

Owner:DELPHI TECH SUZHOU CO LTD

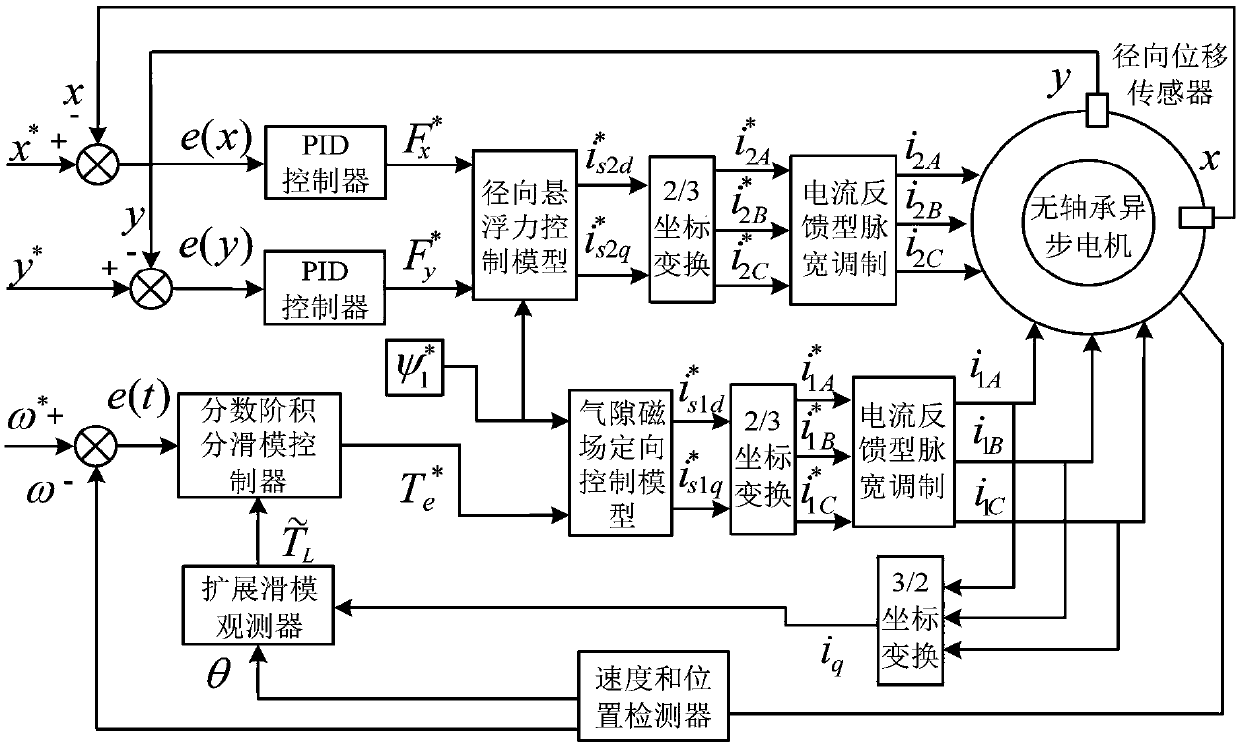

Sliding mode variable structure-based load disturbance resistance control system of bearingless induction motor

InactiveCN108712119AImprove dynamic and static performanceImprove the ability to resist load disturbanceElectronic commutation motor controlVector control systemsControl modelsPulse width modulated

The invention discloses a sliding mode variable structure-based load disturbance resistance control system of a bearingless induction motor. Output ends of a speed and position detector and a third 2 / 3 coordinate transformation module of a torque control section are connected to an input end of an extension sliding mode observer; an output end of the extension sliding mode observer is connected toan input end of a fractional order integration sliding mode controller; an output end of the fractional order integration sliding mode controller is connected to a second current feedback-type pulsewidth modulator through an air gap field orientation control model and a second 2 / 3 coordinate transformation module in order; the output end of the second current feedback-type pulse width modulatoris separately connected to a motor and the third 2 / 3 coordinate transformation module; and the output end of the third 2 / 3 coordinate transformation module is connected to the fractional order integration sliding mode controller through the extension sliding mode observer. Fractional order integration sliding mode is employed for substituting for an integer order integration link, and therefore, interference in a system by external disturbance is effectively reduced, rotating speed can prevent from being disturbed by load changes, and the dynamic and static performance and the load disturbanceresistance capability of the system are improved.

Owner:JIANGSU UNIV

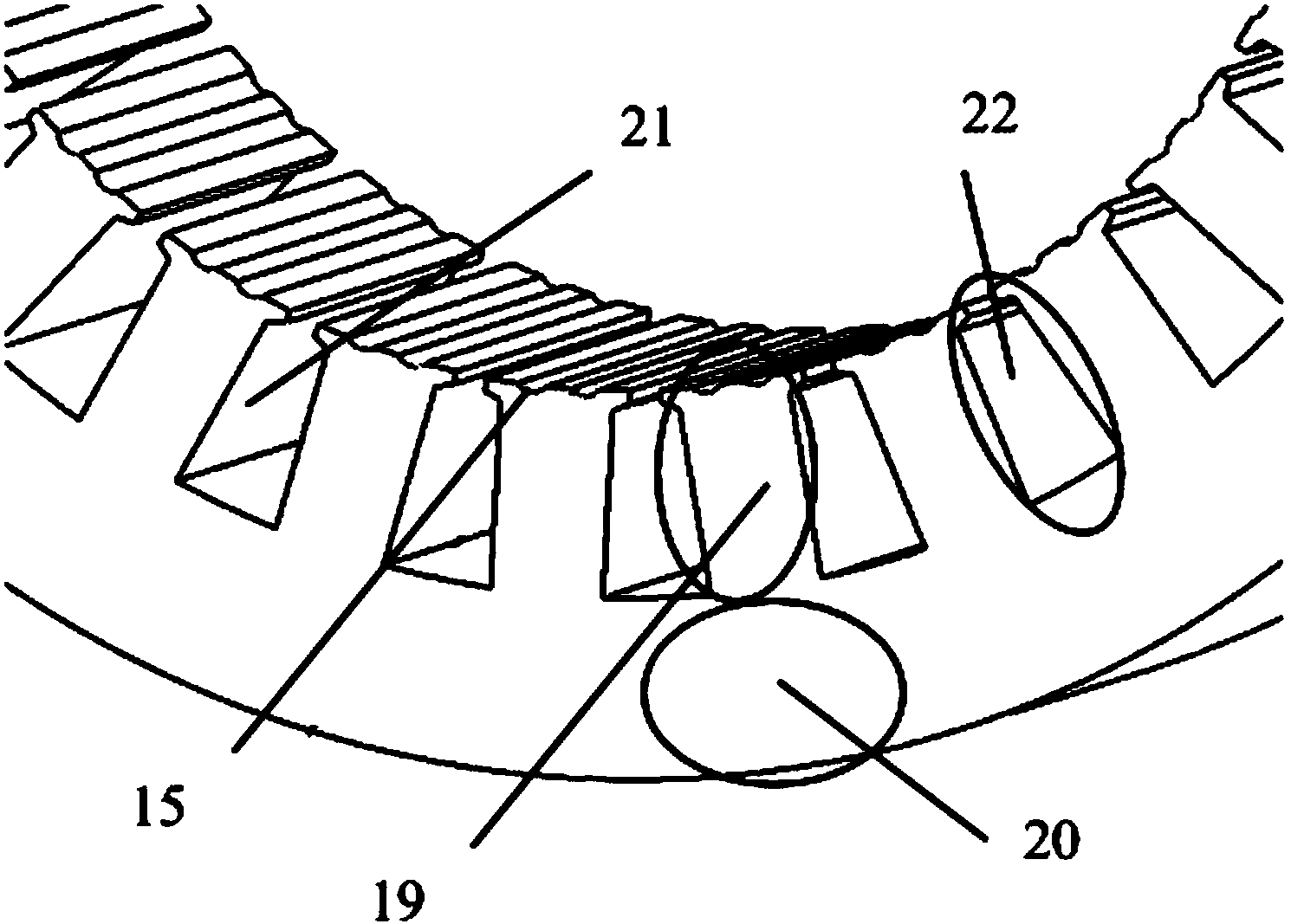

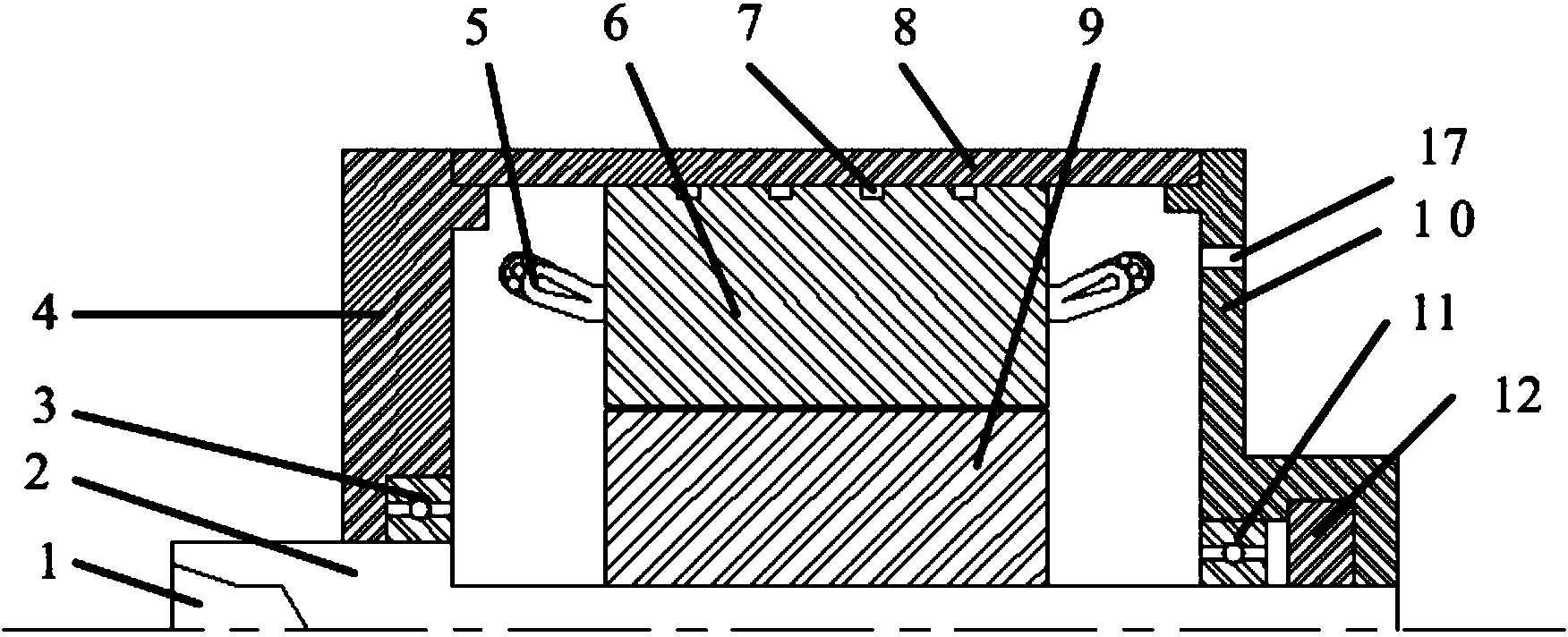

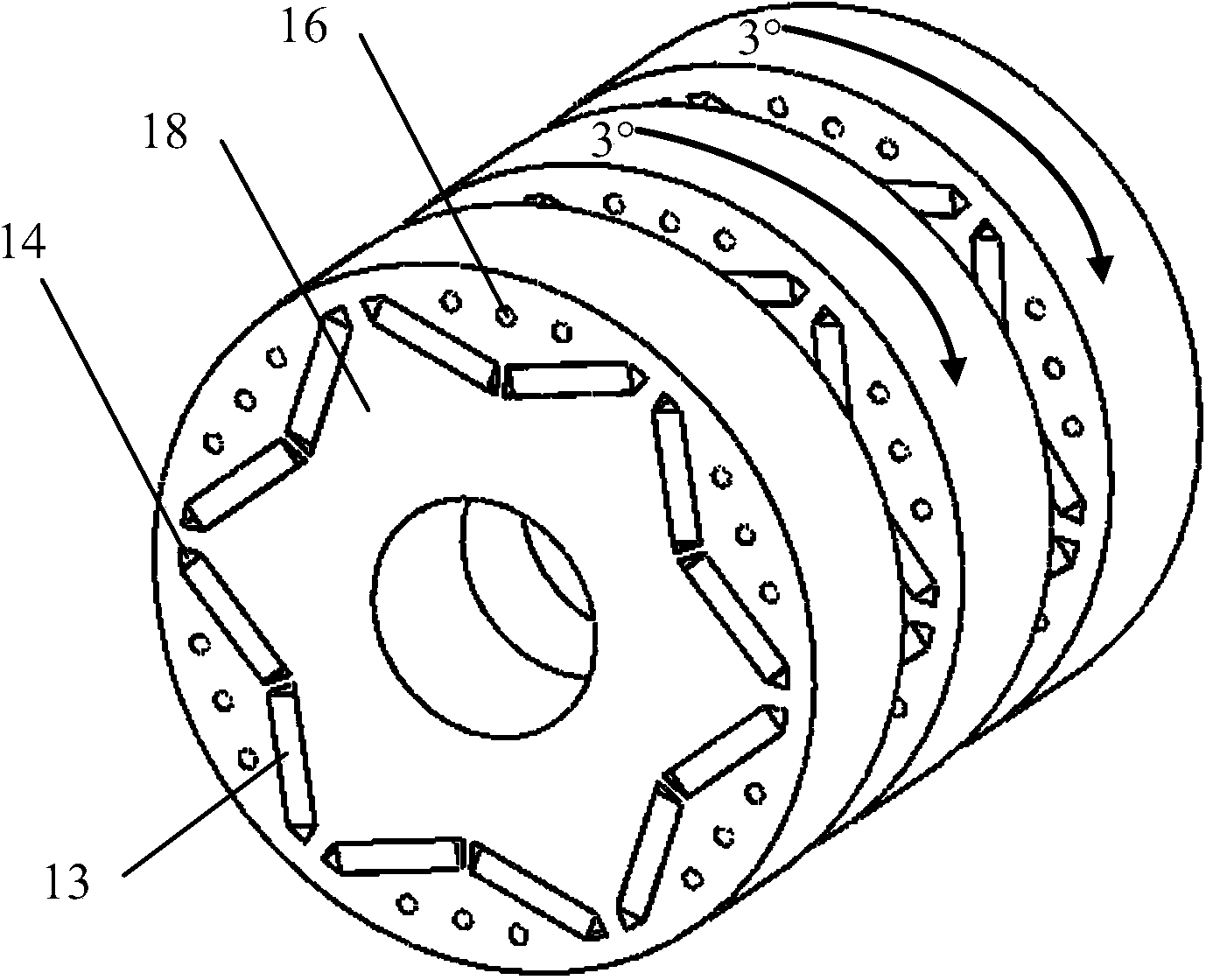

Embedded PMSM for turning-type electric main shaft

InactiveCN104113154AReduce air gap magnetic field harmonicsIncrease sineMagnetic circuit rotating partsMagnetic circuit stationary partsNumerical controlHarmonic

The invention discloses an embedded PMSM for a turning-type electric main shaft. The embedded PMSM comprises a rotation shaft, a front bearing, a front end cover, a rear bearing, a rear end cover, a photoelectric encoder, a rotor and a stator. The rotor is of a sectional type inclined pole structure and comprises multiple rotor iron cores which are axially distributed at intervals, a multicolor magnetic pole circumferentially arranged along the rotor iron cores, and each stage of the magnetic pole is arranged in a V-shaped structure and is embedded in a corresponding permanent magnet groove; multiple magnet through holes are correspondingly arranged between each stage of the magnetic pole and the outer circumference of the rotor iron cores; and the stator comprises a cooling pipeline groove disposed in the outer wall of the stator, a stator iron core with multiple stator teeth, and a stator groove formed between adjacent stator teeth. The embedded PMSM provided by the invention has the advantages of high torque density, high power density, rapid response, small air gap magnetic field harmonic waves, high counterelectromotive force sine degree, small torque ripples and wide speed ratio, thereby being suitable for application in a turning-type electric main shaft system for a high-grade numerical control machine tool.

Owner:HUAZHONG UNIV OF SCI & TECH

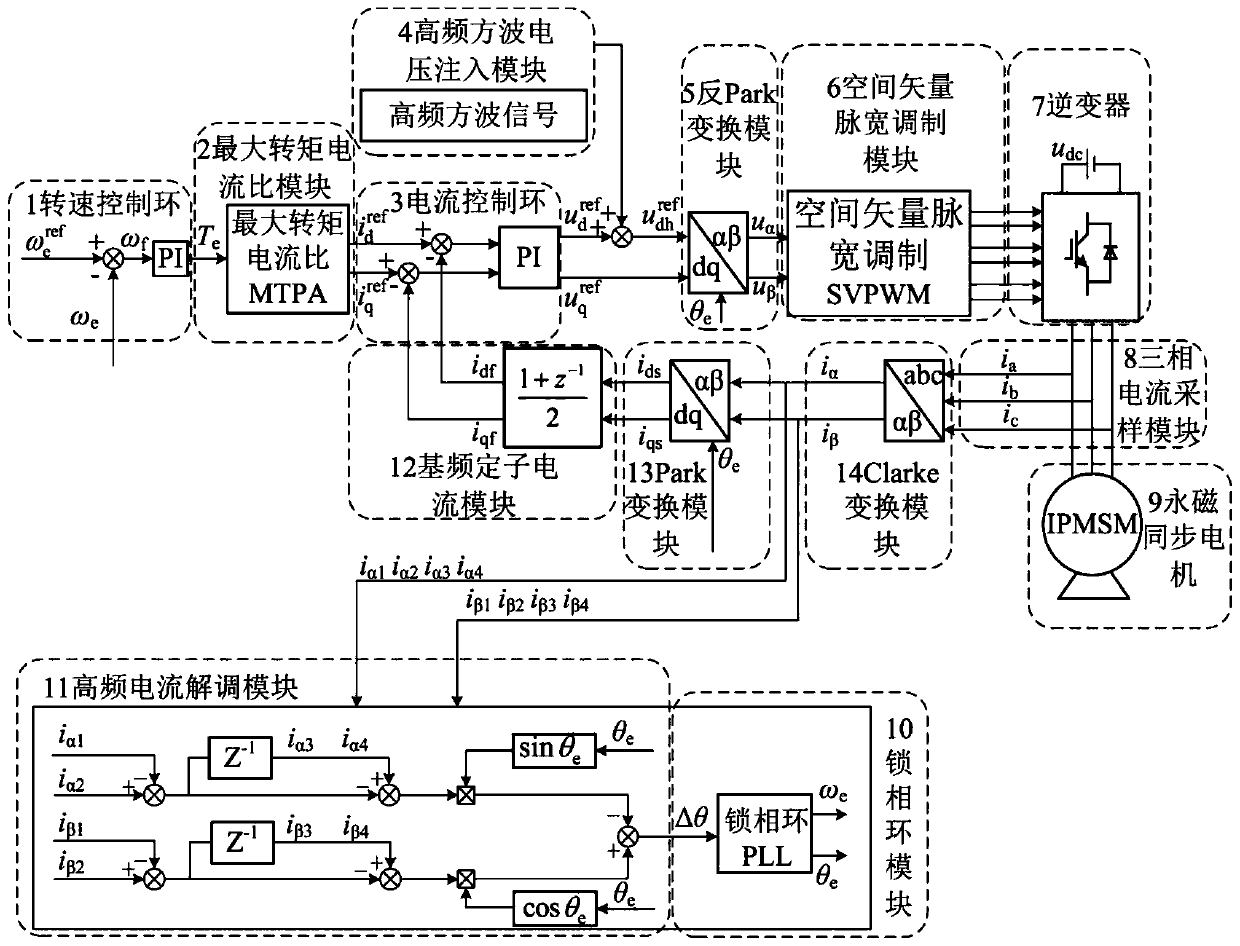

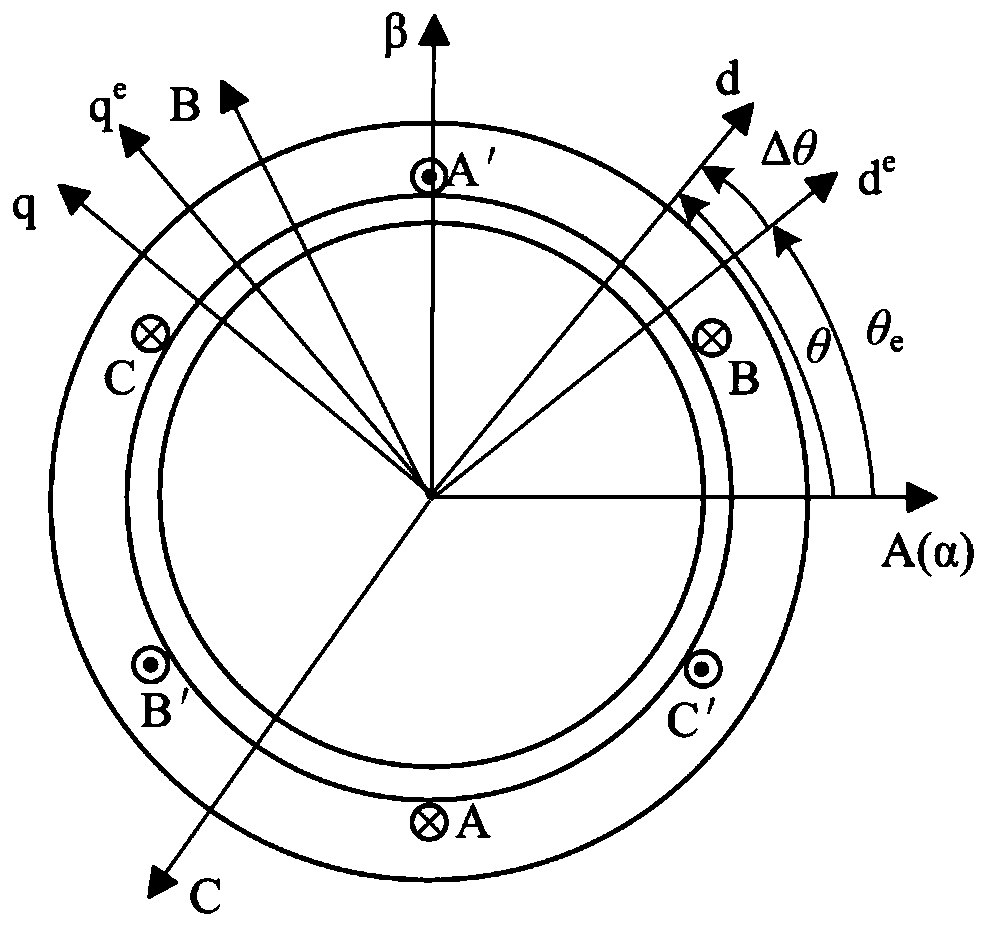

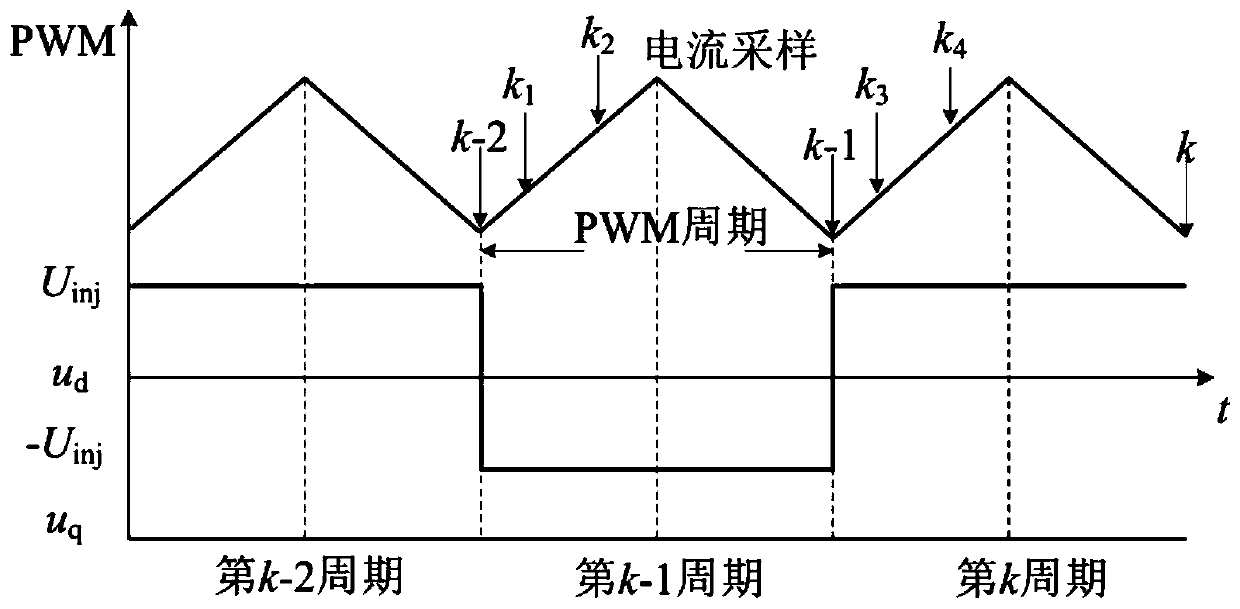

Permanent magnet motor square wave injection position sensorless control method based on oversampling

PendingCN111245330AExtended speed rangeImprove accuracyElectric motor controlVector control systemsComputational physicsMagneto

According to a permanent magnet motor square wave injection position sensorless control method based on oversampling, a high-frequency square wave signal is injected into a de axis, and rotor positioninformation is obtained through PLL according to the relation between high-frequency response current in a winding and a rotor position angle theta e. The period of a position angle is shortened, thespeed of updating the position angle is higher, and the current change at the two ends of the effective vector is in linear change, so that when the position angle is calculated, the model is more accurate, and the obtained position angle is more accurate. The method is simple in algorithm, free of a filter in the implementation process and easy to implement, the accuracy of motor rotor positiondetection can be effectively improved, the initial position information of the rotor can be accurately detected, and the system response frequency is improved. When the rotating speed is high, the calculation precision of the rotor position is higher, the speed range of the motor under the condition of no position sensor operation is improved, and the rotating speed range is broadened. When a large load is suddenly added, the rotating speed fluctuation is smaller, and the dynamic performance of the system is improved.

Owner:TIANJIN POLYTECHNIC UNIV

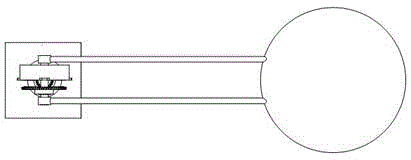

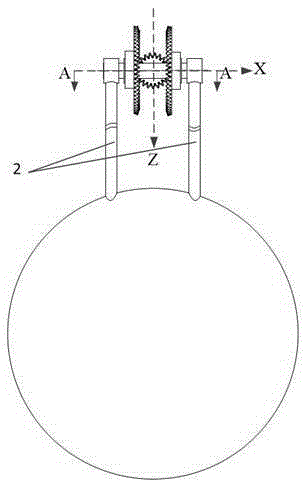

Mechanical transmission type swinging wave power generating device

The invention discloses a mechanical transmission type swinging wave power generating device. An ellipsoidal swinging body is connected with the two ends of a rotating shaft through two swinging arms. A first large conical gear at one end of the rotating shaft is in key connection with a first one-way clutch outer ring, a first one-way clutch inner ring is in key connection with the rotating shaft, and a second large conical gear is in key connection with a second one-way clutch outer ring. A second one-way clutch inner ring at the other end of the rotating shaft is in key connection with the rotating shaft, the first large conical gear and the second large conical gear are engaged with a small conical gear simultaneously. The two ends of the rotating shaft are connected with an upper shell through corresponding conical roller bearings respectively. A small conical gear shaft is connected with one end of a planet speed increaser through a first coupler, and the other end of the planet speed increaser is connected with a power generator through a second coupler. The power generator is installed in a lower shell. The mechanical transmission type swinging wave power generating device is simple in structure, high in transmission efficiency, small in fluctuation, high in anti-wave capacity and low in cost, and accordingly wave power can become important reproducible clean energy for coastal regions.

Owner:ZHEJIANG UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com