Patents

Literature

30results about How to "Reduce power shock" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

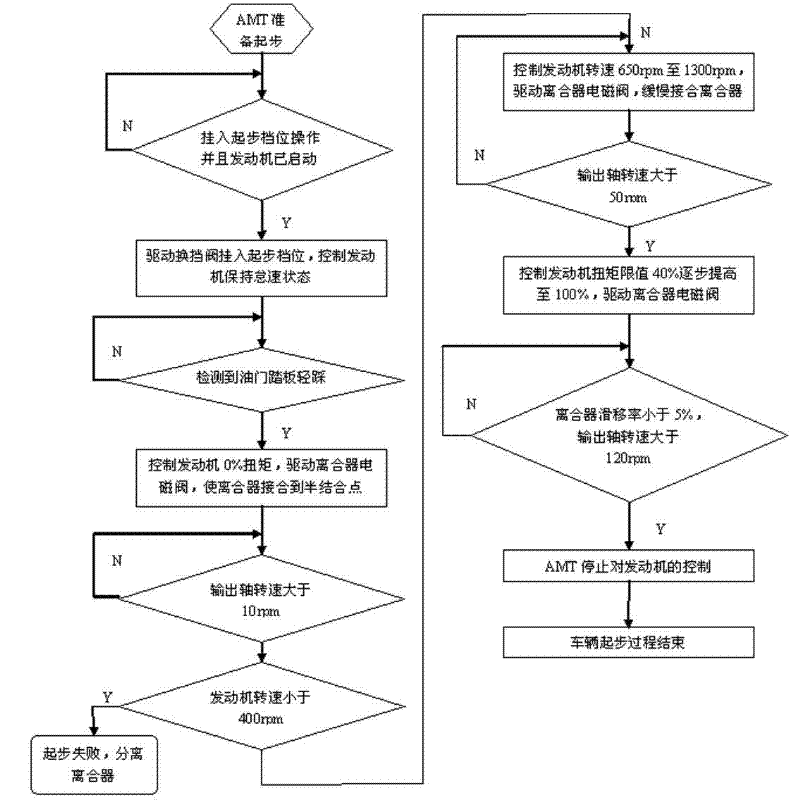

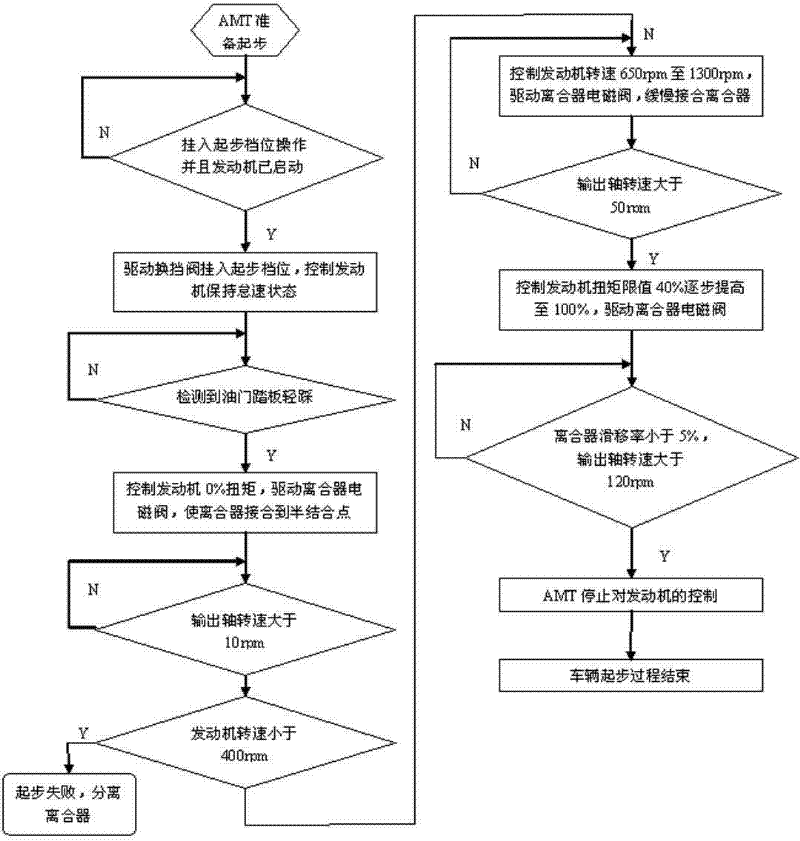

Engine idle speed control-based AMT (Automated Mechanical Transmission) vehicle start control method

The invention relates to an engine idle speed control-based AMT (Automated Mechanical Transmission) vehicle start control method, which comprises the following steps of: a, starting an engine, shifting to a start gear, controlling the engine to maintain an idle speed state by an electric control AMT, gently stamping a throttle to send out a starting signal; b, after receiving the starting signal, controlling a power source to drive a clutch to a semi-combined point; c, controlling an engine speed to be in a range of 650-1300 rpm by the electric control AMT, and detecting whether the ROTATING speed of an output shaft is more than 50 rpm or not; d, controlling the torque limit value of the engine to BE increaseD from 40% to 100% progressively by the electric control AMT and controlling the power source to drive the clutch to gradually combine, detecting whether the clutch sliding rate is less than 5% or not and whether the rotating speed of the output shaft is more than 120 rpm or not; and e, stopping controlling the engine by the electric control AMT, and ending a vehicle start process. The engine idle speed-control based AMT vehicle start control method has the beneficial effects of reducing abrasion of the clutch, increasing the comfort and economy as much as possible on the premise of maintaining dynamic property, and the like.

Owner:SINO TRUK JINAN POWER

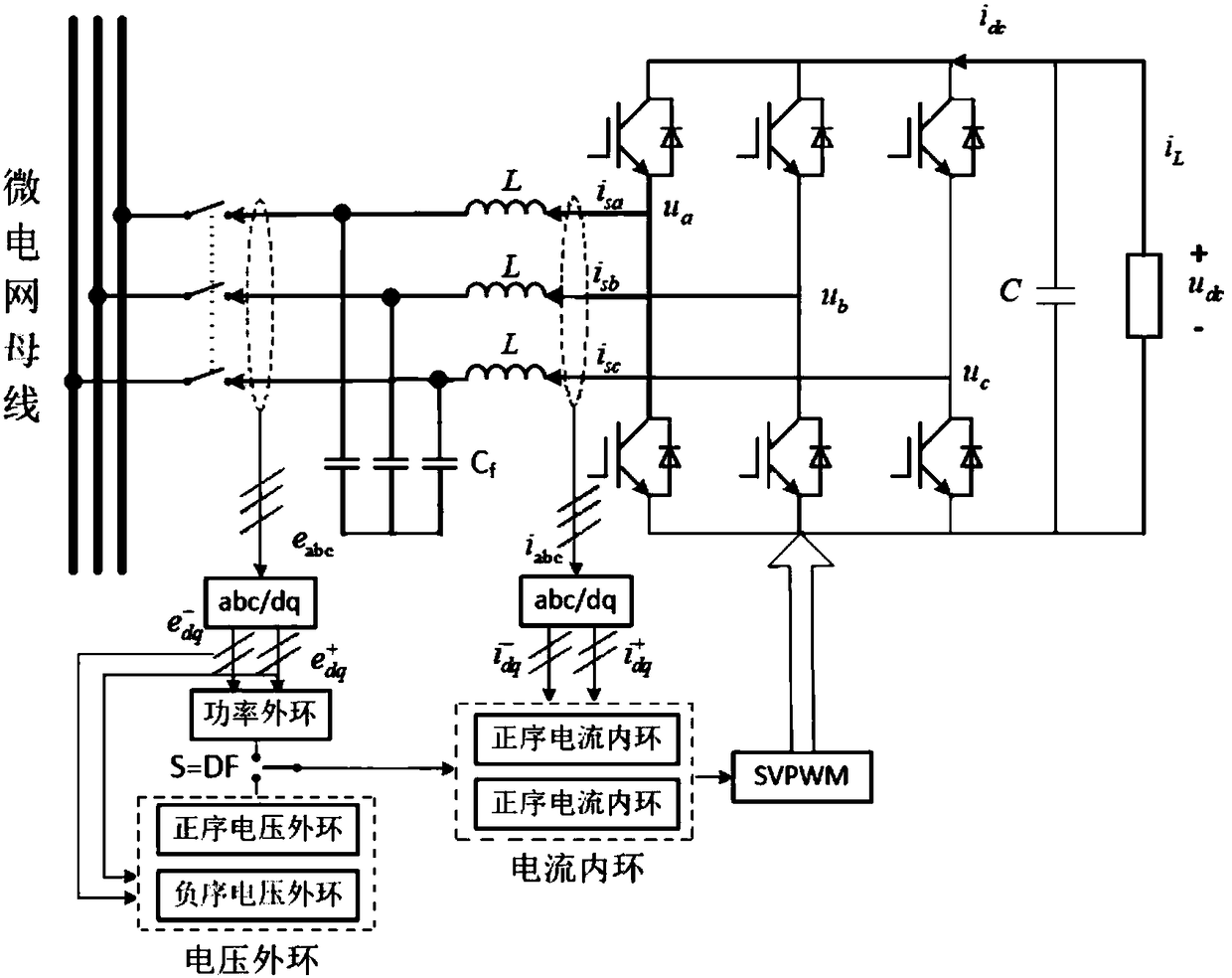

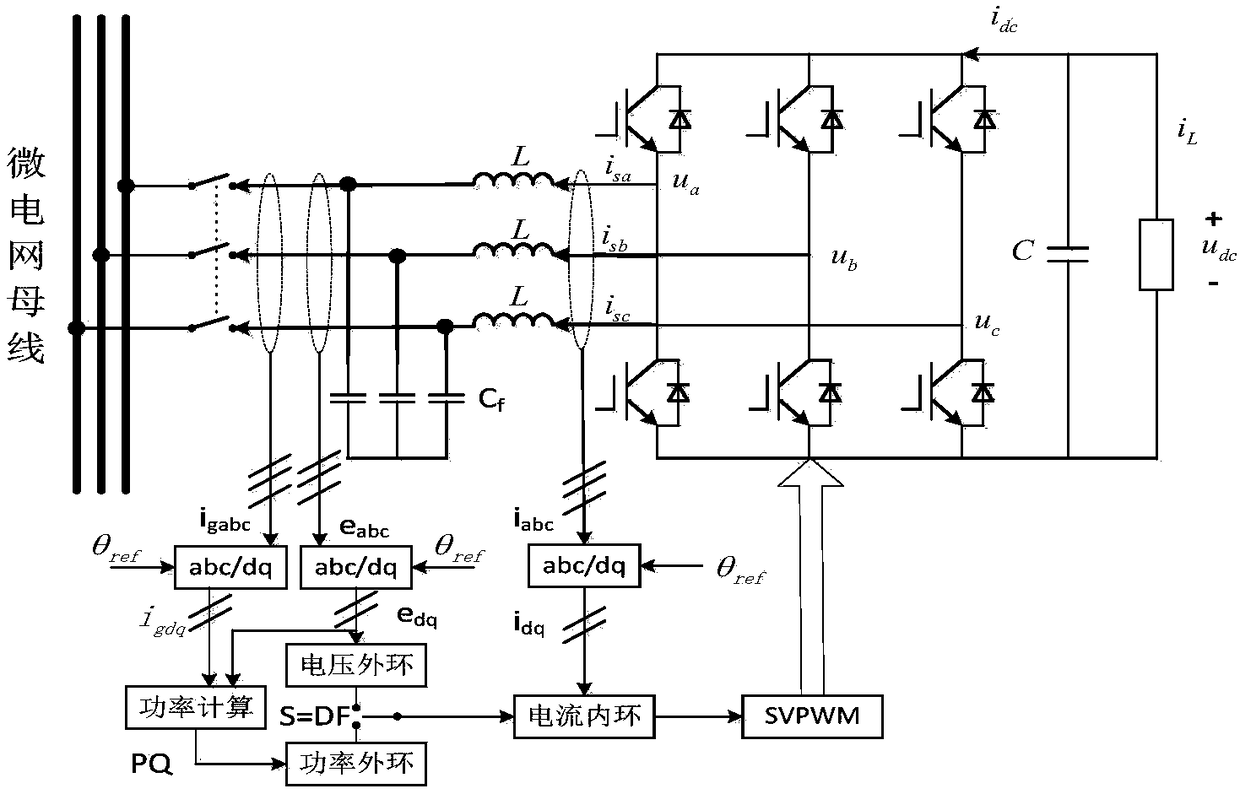

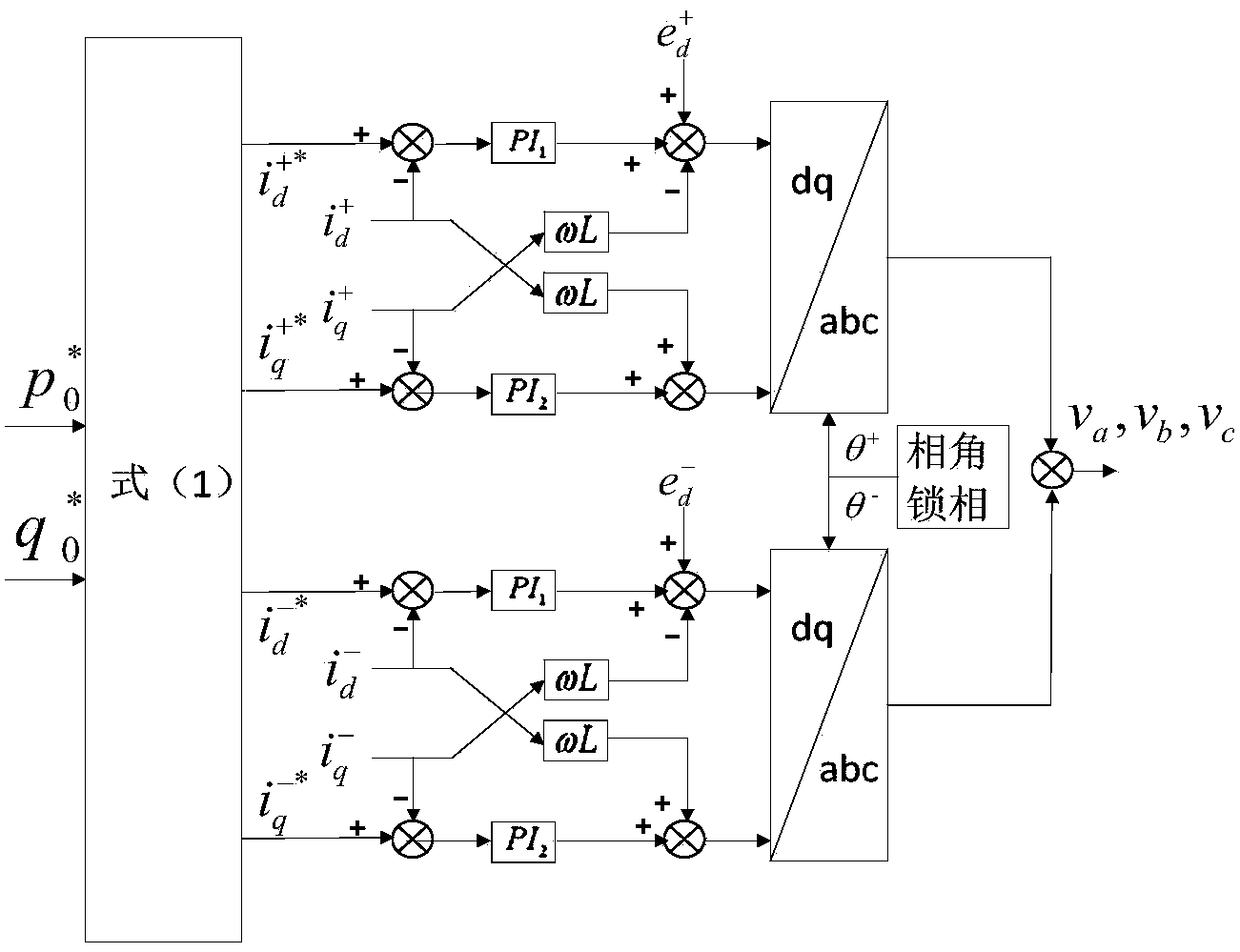

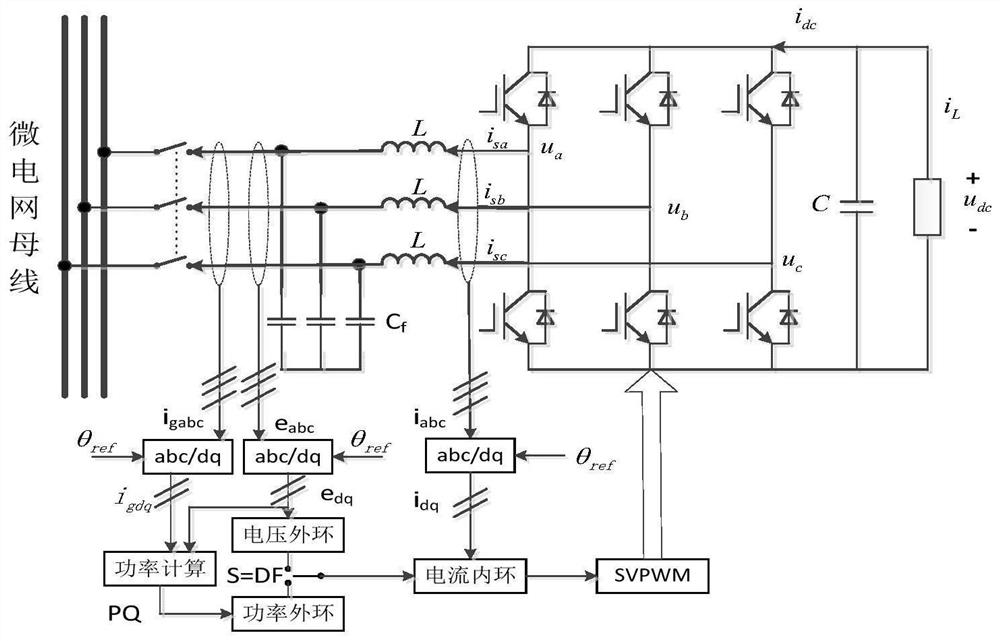

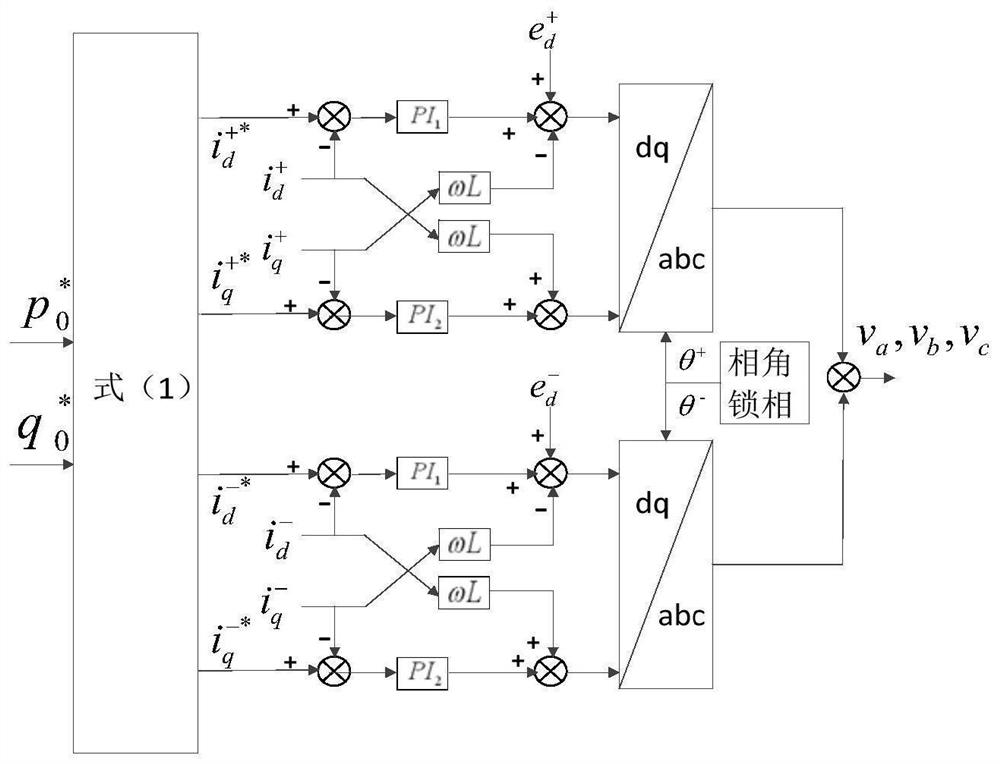

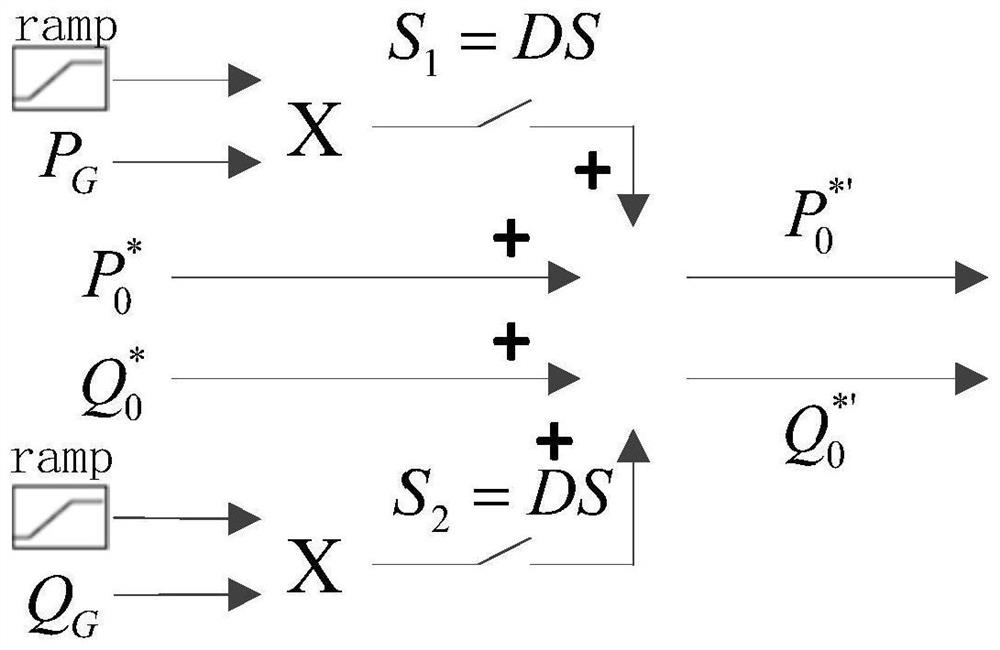

An on-grid and off-grid switching method and device for a microgrid cell energy storage system

ActiveCN108448607AEnsure power supply reliabilityImprove power qualityFlexible AC transmissionSingle network parallel feeding arrangementsPower qualityPower compensation

The invention provides an on-grid and off-grid switching method and device for a microgrid cell energy storage system. During on-grid running, a current value and a voltage value are calculated according to positive and negative sequence components of the voltage of an on-grid point and positive and negative sequence components of the output electric current of an inverter under a PQ control modem, so that the output power of the inverter is controlled; at the instant from the on-grid to the off-grid, a state following method is adopted by a VF control mode, the output power of a power grid istransferred to the inverter by increasing a power compensation control link, During on-grid running, the voltage and frequency support are provided for a system by a voltage outer ring under the VF control mode, and the device includes a PQ control module and a VF control module. The control of the negative sequence voltage is realized when the off-grid is switched through the provided technicalscheme, the reliability of power supply is assured, and the quality of the electric energy is improved.

Owner:CHINA ELECTRIC POWER RES INST +2

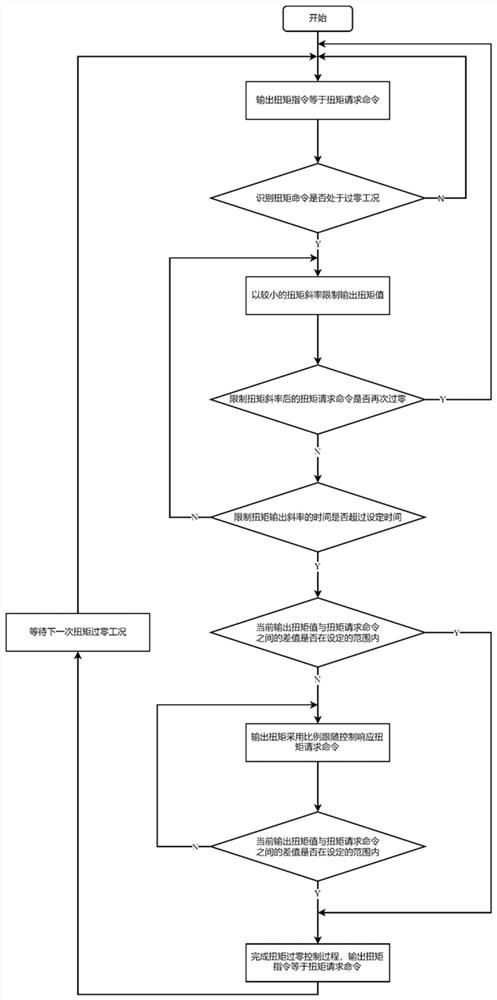

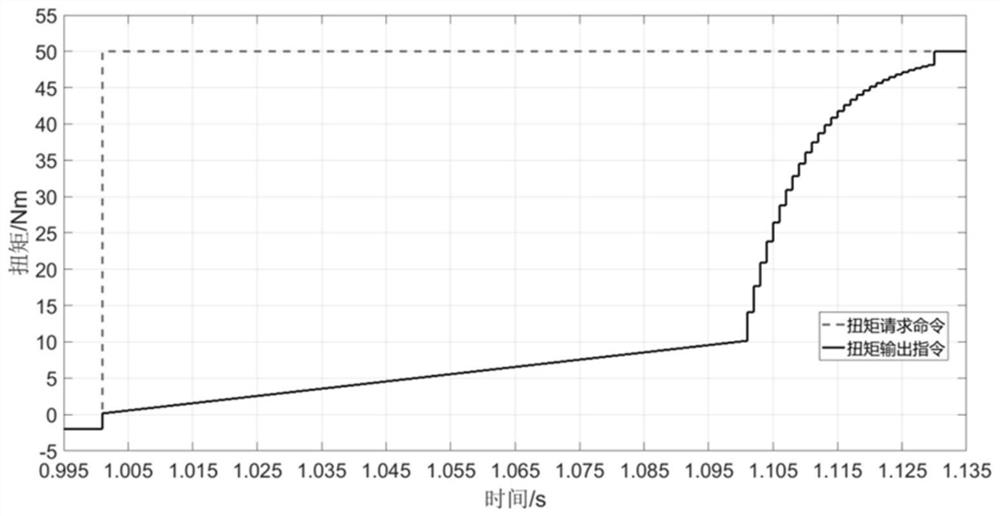

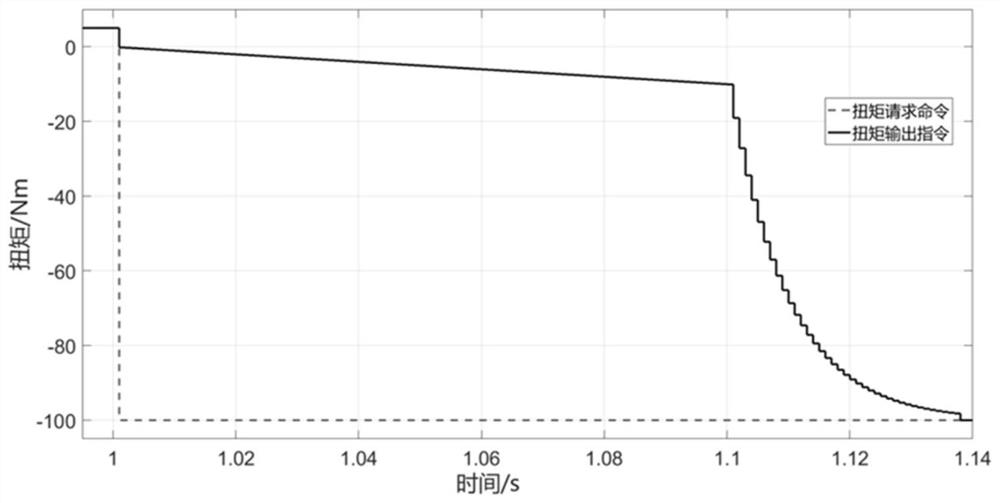

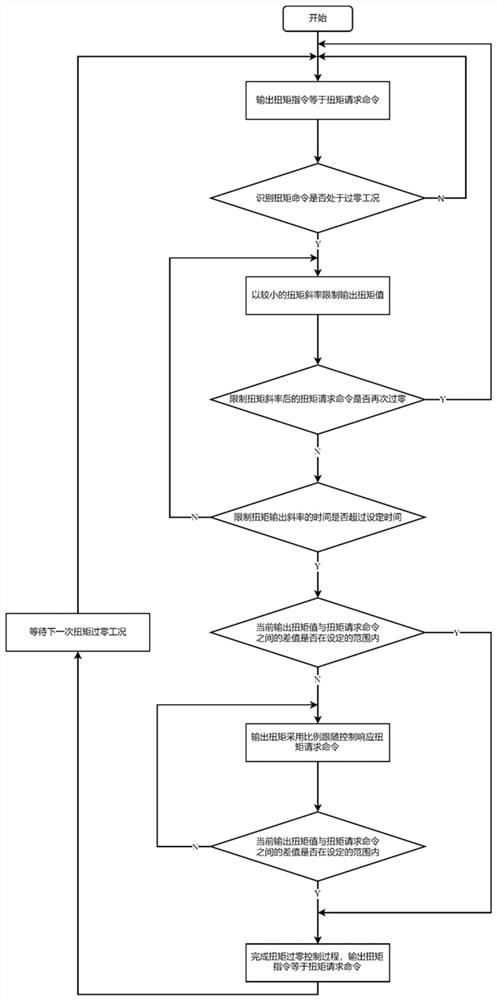

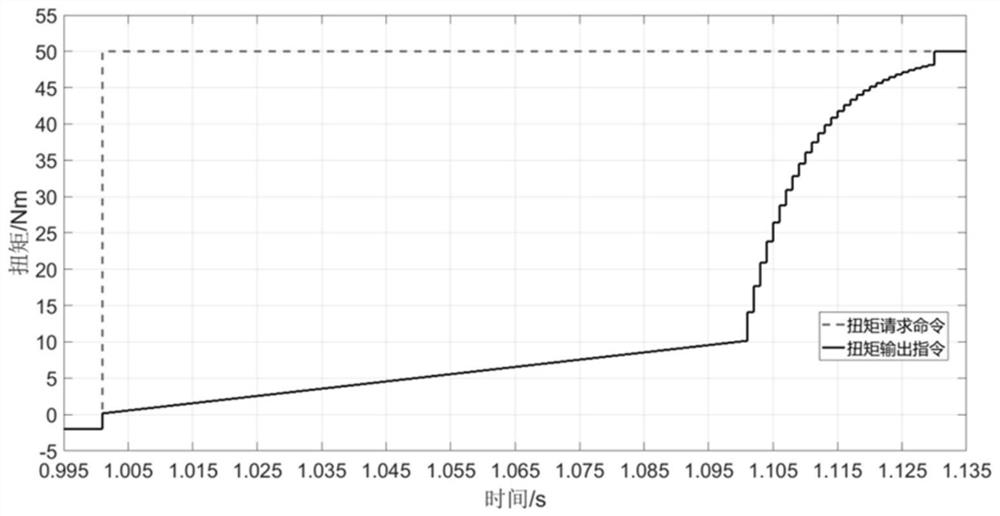

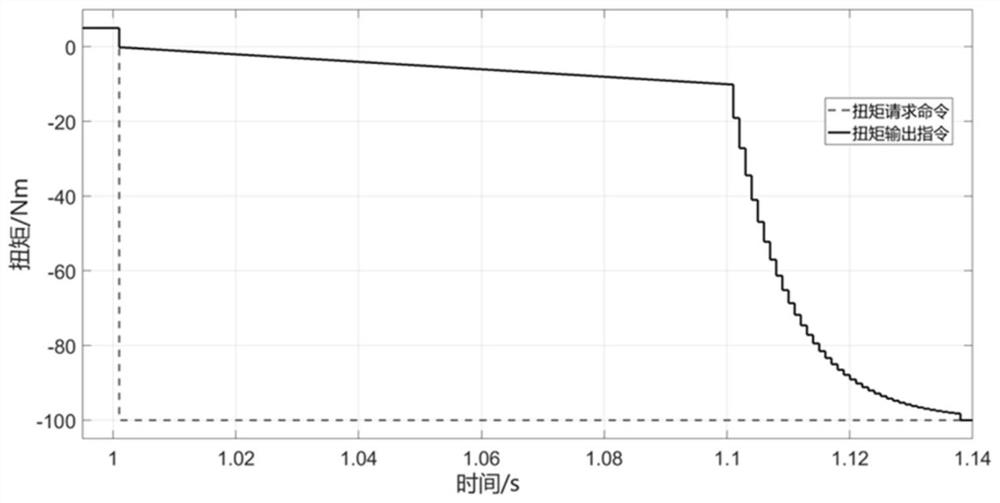

Motor torque zero-crossing anti-shake control method for new energy vehicles

ActiveCN111731111ASmooth torque changeReduce power shockSpeed controllerElectric energy managementNew energyElectric machinery

The invention relates to a motor torque zero-crossing anti-shake control method for new energy vehicles. The motor torque zero-crossing anti-shake control method comprises the steps that 1, judging whether motor torque is in a zero-crossing working condition; 2, limiting the torque output slope, and reducing torque zero-crossing impact; 3, judging whether the request torque generates the zero-crossing working condition again within the time of limiting the torque output slope; 4, judging whether the time for limiting the torque output slope is overtime or not; 5, judging whether a torque difference value between the request torque and the limited torque output slope is smaller than a first preset threshold value; 6, obtaining an output torque by adopting a following control algorithm; 7, judging whether the difference value between the current output torque and the request torque is smaller than a second preset threshold value; and step 8, completing torque zero-crossing control, returning to the step 1, and waiting for a next torque zero-crossing working condition. Compared with the prior art, the method has the advantages that the torque zero-crossing working condition can be predicted, the torque response speed is high, and the driving experience and the automobile dynamic property are improved.

Owner:DELPHI TECH SUZHOU CO LTD

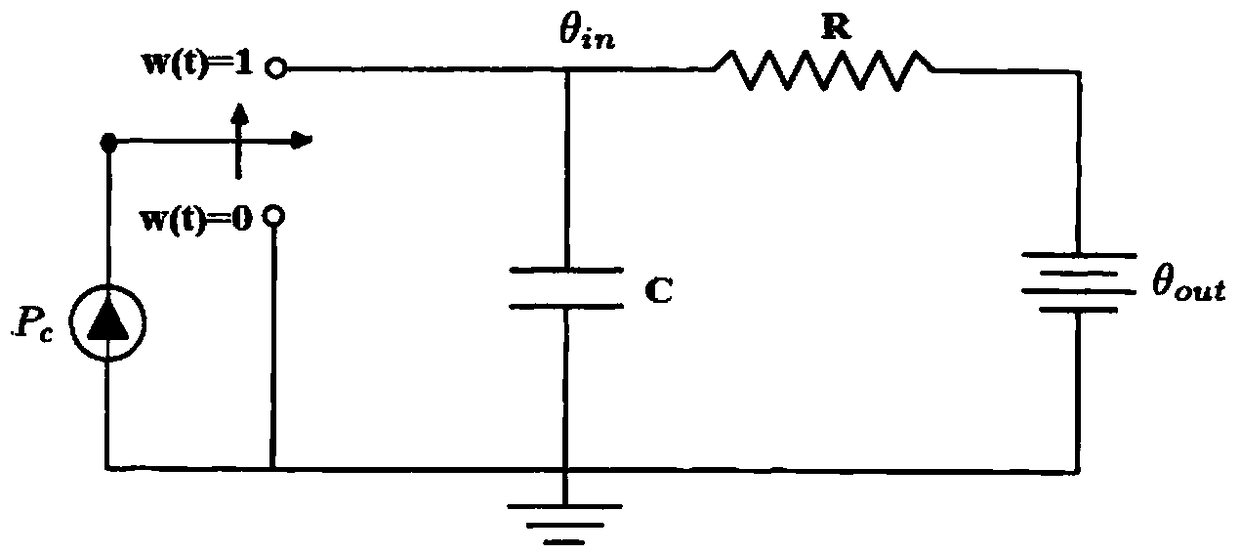

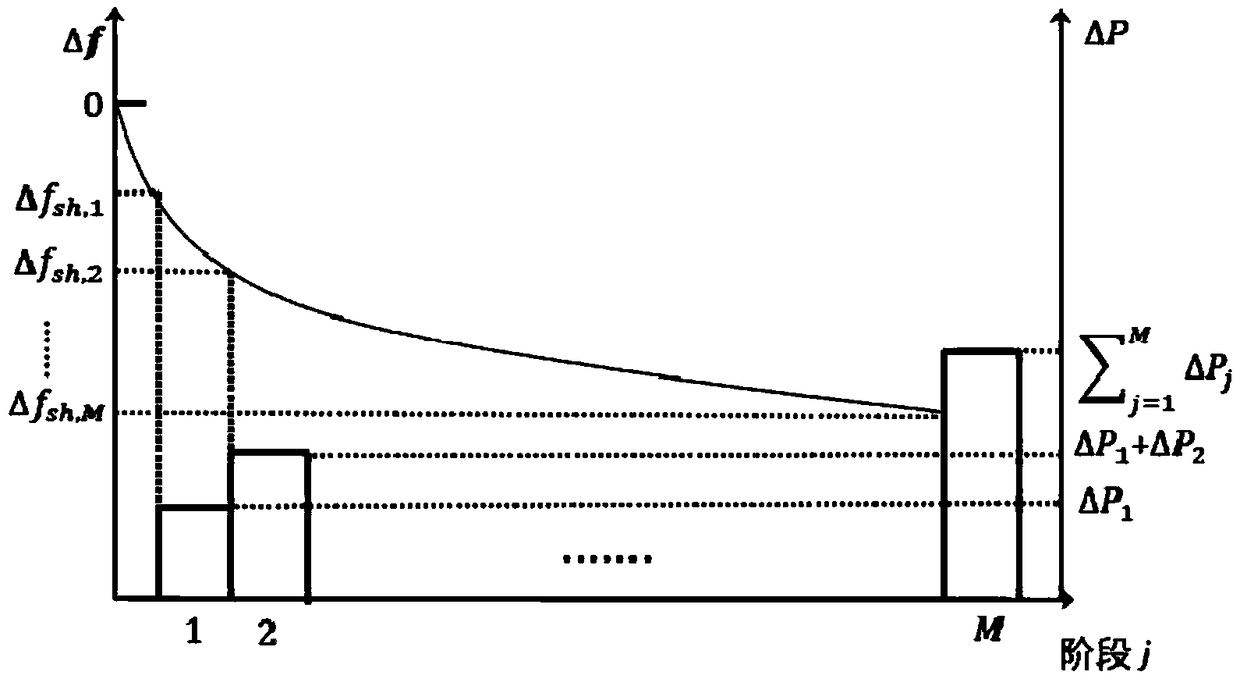

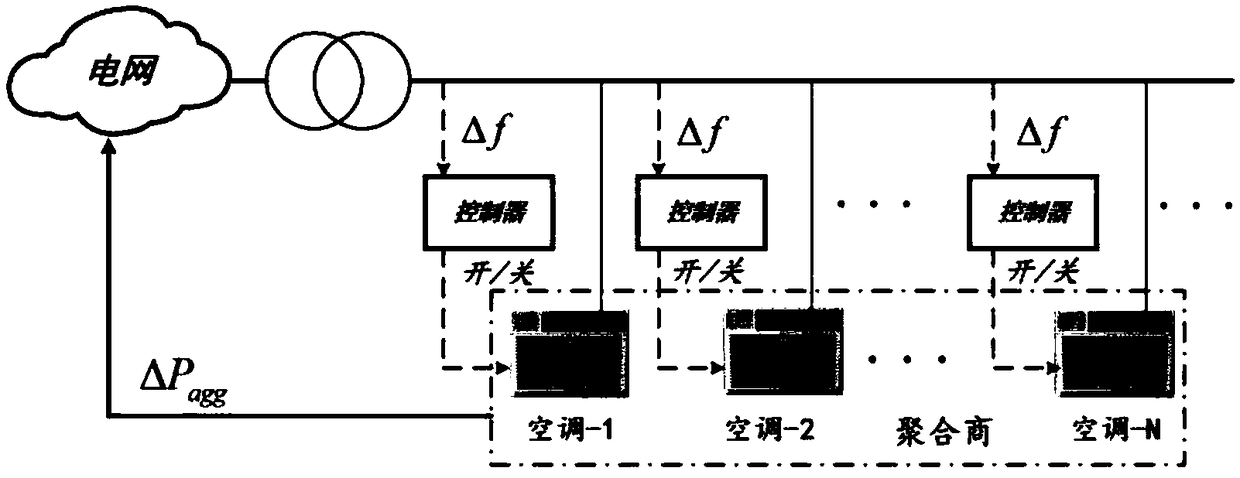

Decentralized control method for heterogeneous air conditioning clusters based on frequency response

InactiveCN109028499AWithout compromising comfortReduce control communication costsMechanical apparatusSpace heating and ventilation safety systemsPower gridDynamic models

The invention discloses a decentralized control method for heterogeneous air conditioning clusters based on frequency response. Firstly, a dynamic model of a single device is given according to the physical characteristics of the air conditioning load involved in the demand response, and based on the dynamic model, the steady polymerization power estimation changed along with the external temperature of the heterogeneous air conditioning clusters is given; then, according to the emergency fault response level of the power grid, the frequency threshold of the air conditioning participating in demand response is divided, and the polymerization power adjustment of the air conditioning clusters under different frequency deviation values is given; and finally, a frequency-based decentralized stochastic control method of the single air conditioner based on the parameters of the known system model is given. By means of the decentralized control method, the heterogeneous air conditioning clusters can quickly and accurately compensate the power mismatch of the power grid under the emergency fault, the communication cost is saved, and the frequency recovery of the power grid and the safe andstable operation of the system are facilitated.

Owner:SOUTHEAST UNIV

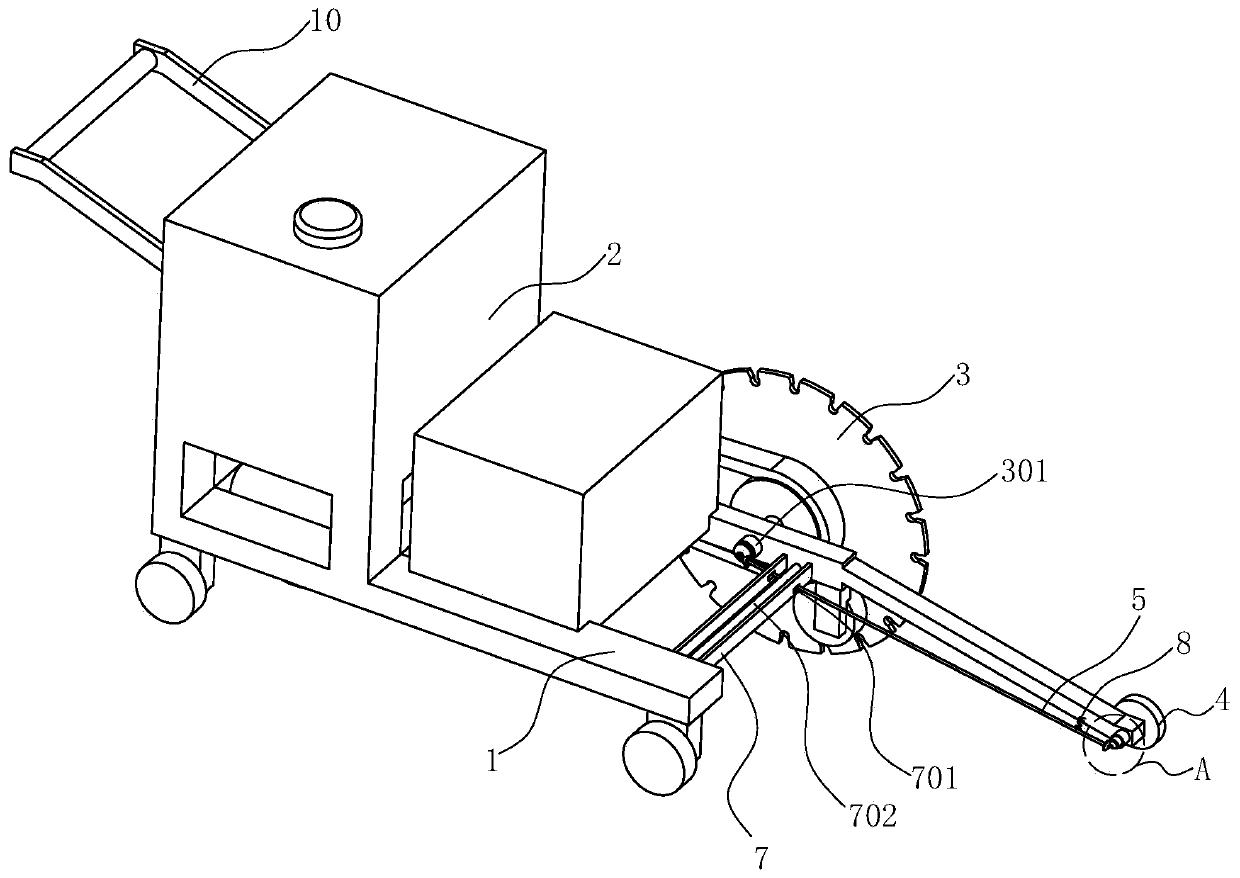

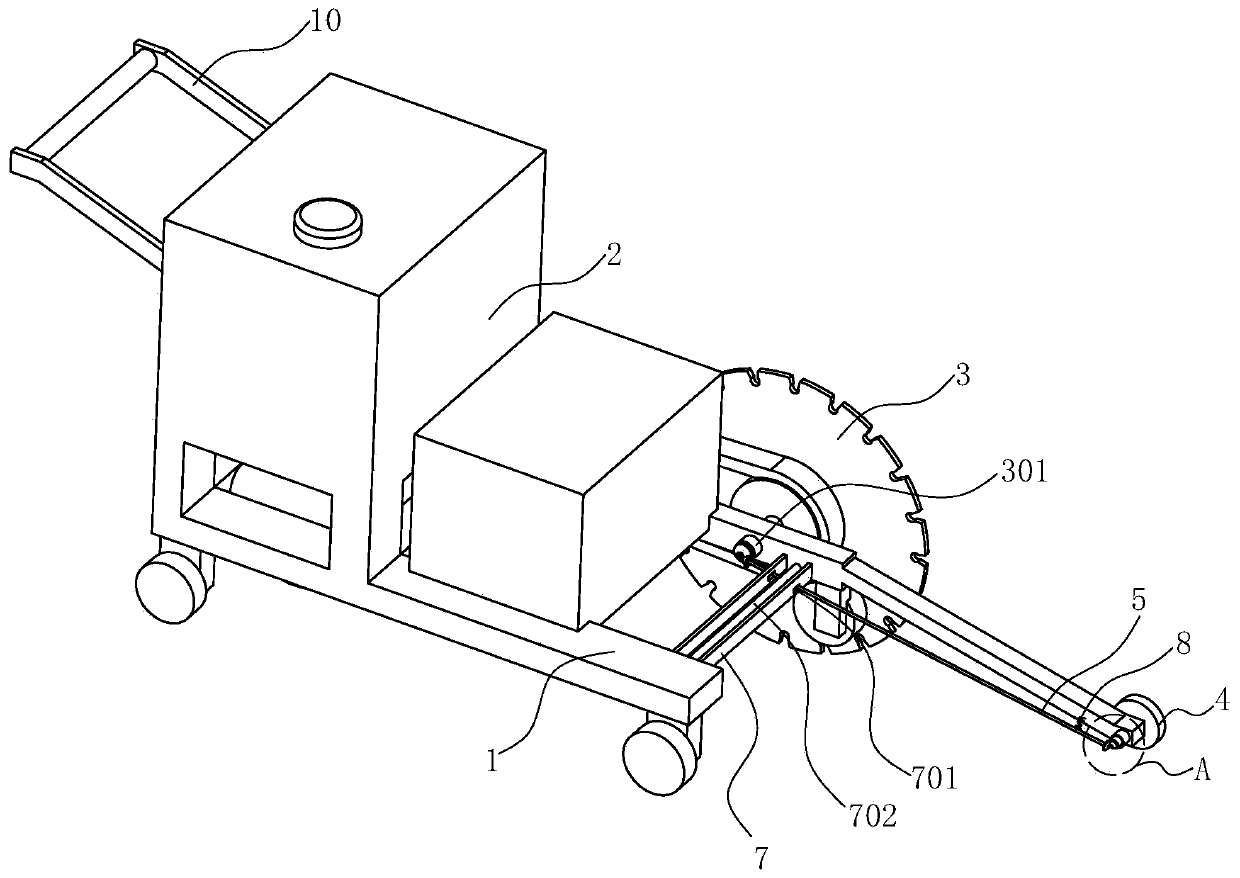

Road surface cutting equipment and method for road construction

InactiveCN109837828AAchieve cleanupImprove construction efficiencyRoads maintainenceDrive shaftRoad surface

The invention relates to road surface cutting equipment and method for road construction, and belongs to the technical field of road surface construction equipment. The road surface cutting equipmentcomprises a frame body; a driving machine and a cutting blade driven by the driving machine are mounted on the frame body; a guide wheel is arranged at the front part of the frame body, the guide wheel and the cutting blade are coplanar, the guide wheel and the cutting blade are respectively and correspondingly supported by a guide shaft and a saw blade shaft which are movably arranged on the frame body; a transmission shaft for connecting the cutting blade and the guide wheel is arranged on the frame body, and two ends of the transmission shaft are respectively and correspondingly connected with the guide shaft and the saw blade shaft through a bevel gear transmission set; a supporting rod is arranged on the frame body, a strip-shaped hole is formed in the supporting rod, and the transmission shaft penetrates through the strip-shaped hole; a push rod is arranged in the supporting rod. A motor is adopted to drive the push rod to rotate, and the push rod is in threaded connection with asliding sleeve, so that the rotating push rod can push the sliding sleeve and the transmission shaft penetrating through the sliding sleeve to one side close to the cutting blade, the bevel gear transmission sets at two ends of the transmission shaft are correspondingly connected with the cutting blade and the guide wheel respectively, and power transmission is achieved.

Owner:郭二艳

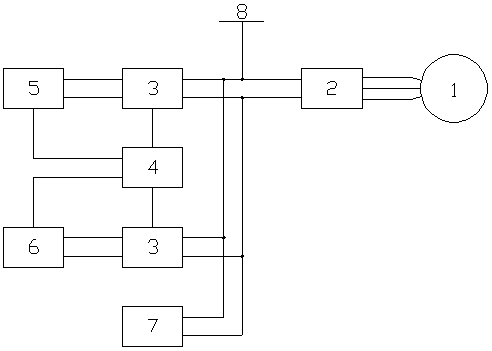

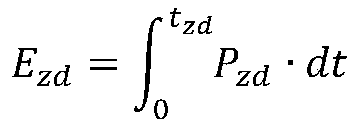

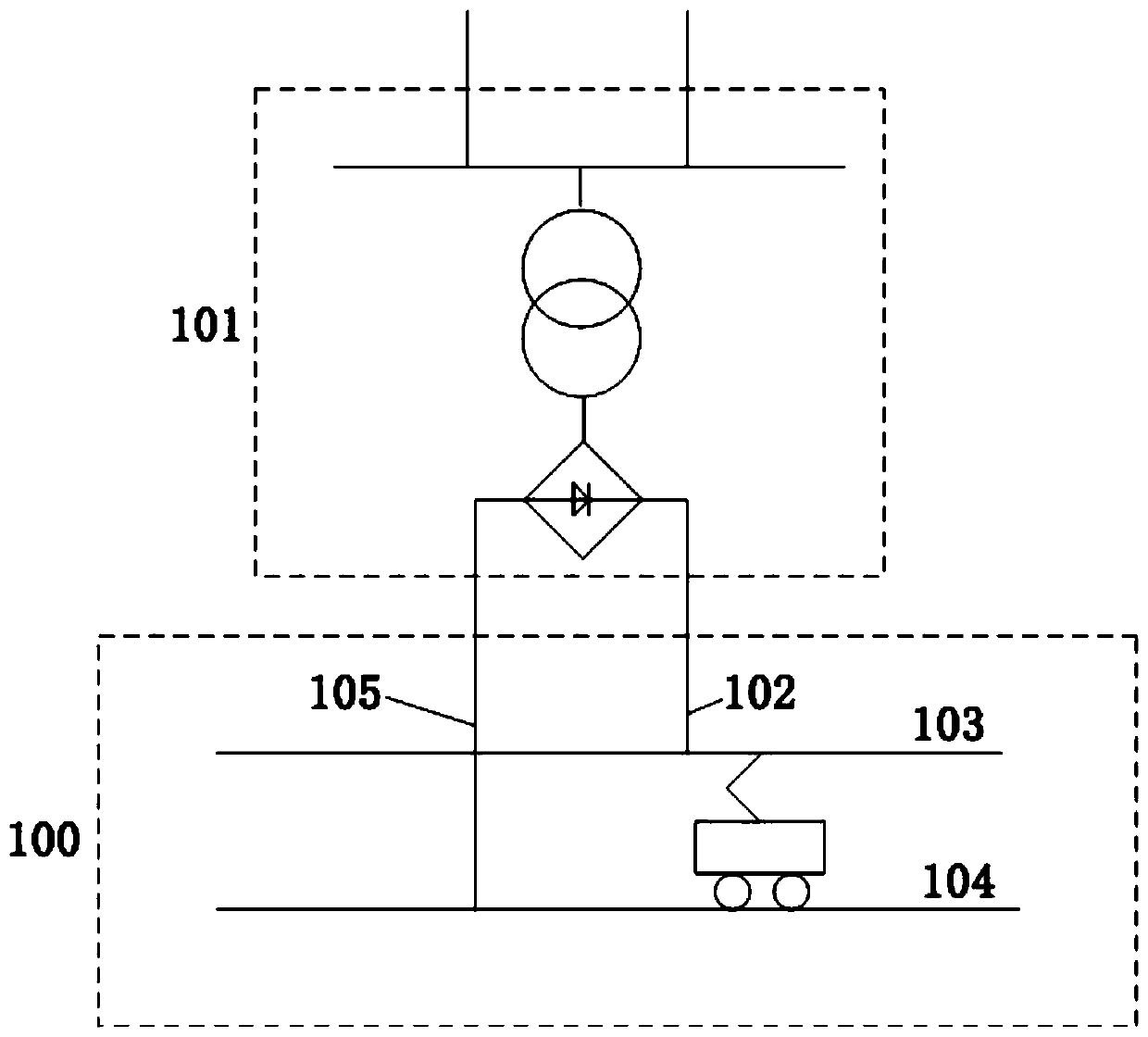

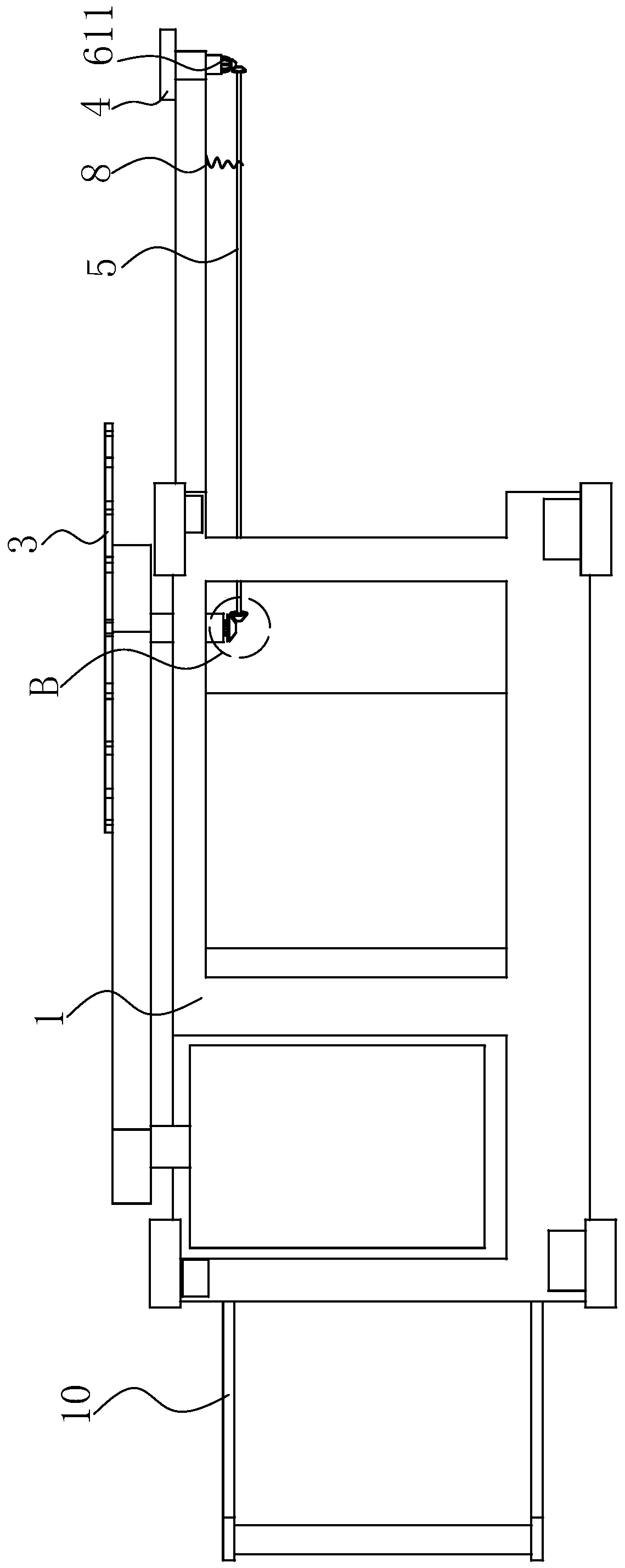

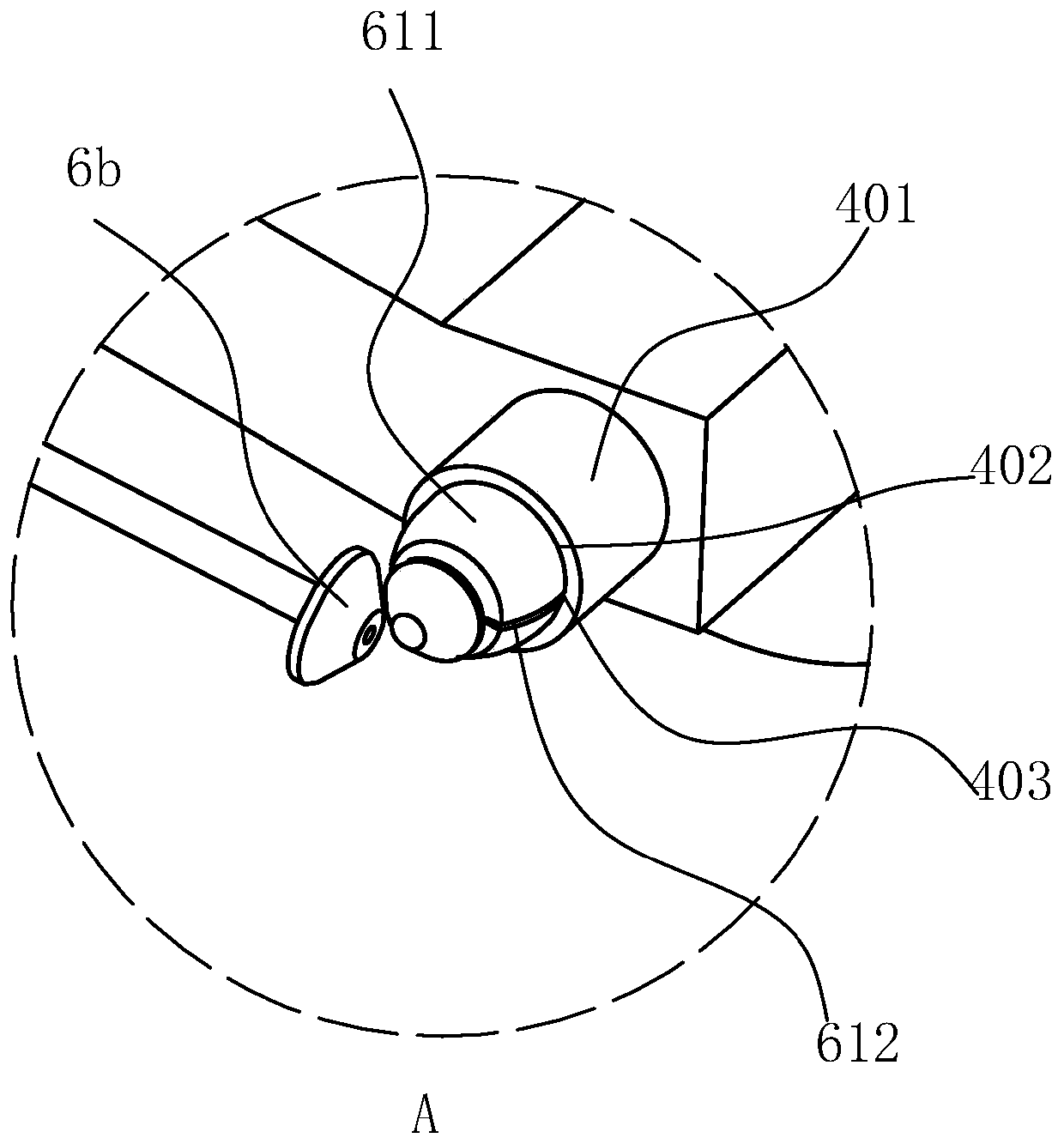

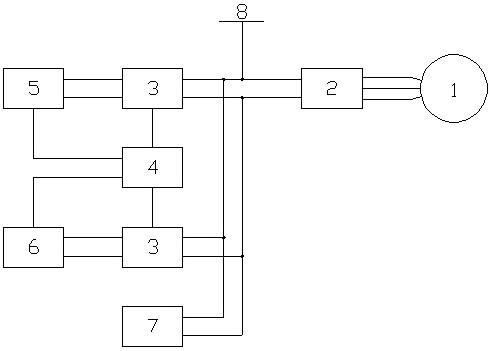

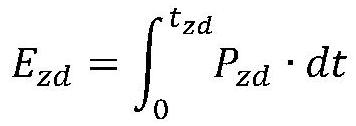

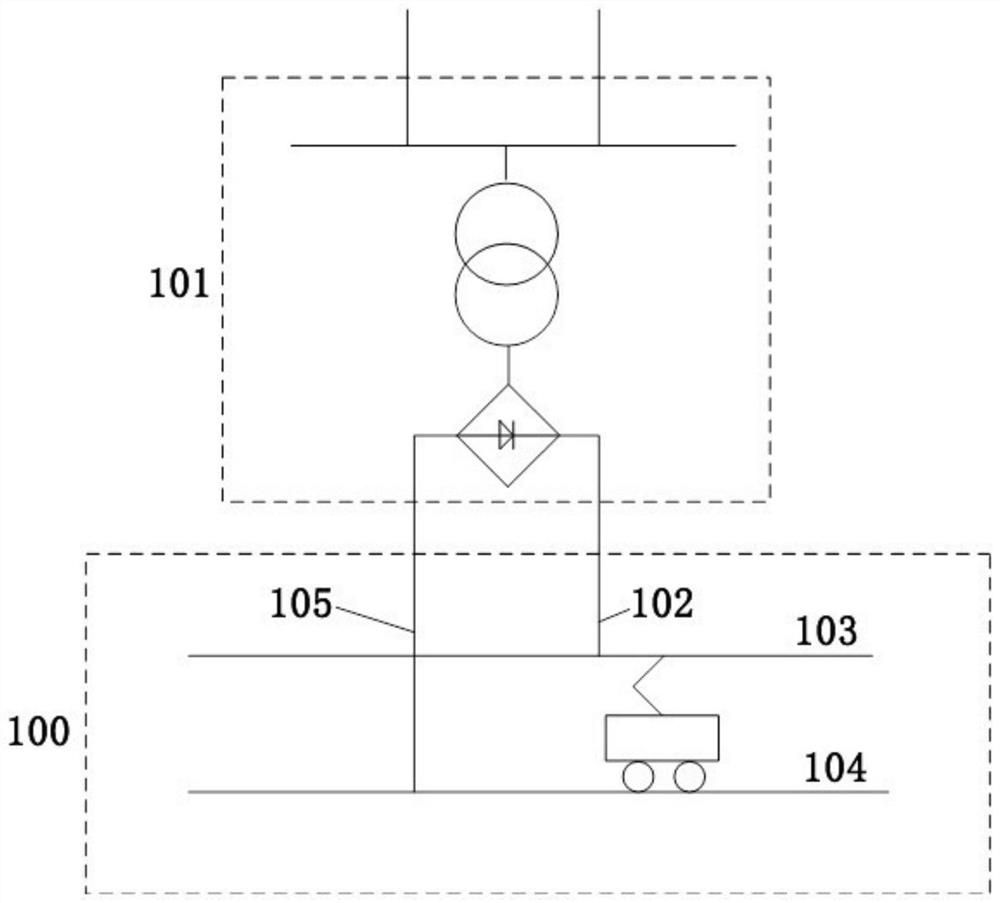

Urban rail train vehicle-mounted energy storage system control method based on power-time curve

ActiveCN110588358ABrief introductionImprove absorption efficiencyElectrodynamic brake systemsRailway transportCapacitanceCatenary

The invention provides an urban rail train vehicle-mounted energy storage system control method based on power-time curve. The urban rail train vehicle-mounted energy storage system comprises a traction motor, a four-quadrant inverter, two bidirectional DC-DC converters, a control module, a storage battery, a super capacitor, a resistance energy dissipation device and a catenary; in the control method, the double-cut-off frequency is adopted to control the charging action of the storage battery and the super capacitor. The urban rail train vehicle-mounted energy storage system control method has the beneficial technical effects that the urban rail train vehicle-mounted energy storage system control method based on the power-time curve is proposed, according to the scheme, the control method can fully play the advantages of high super capacitor absorption efficiency and large absorption power, reduce the power impact to the storage battery, improve the performance of the hybrid energy storage system, and reduce unnecessary heat dissipation.

Owner:SHENZHEN LOTUT INNOVATION DESIGN CO LTD

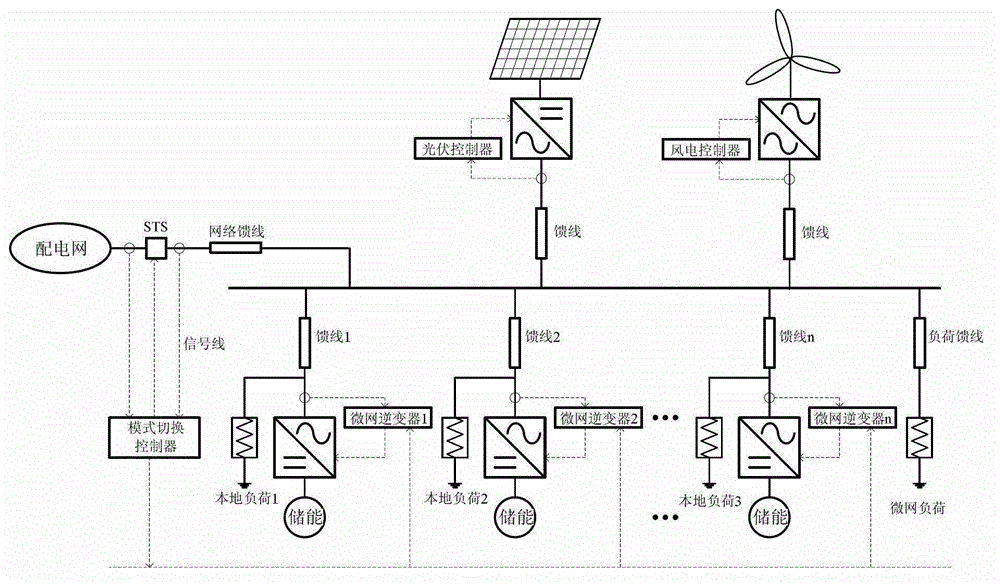

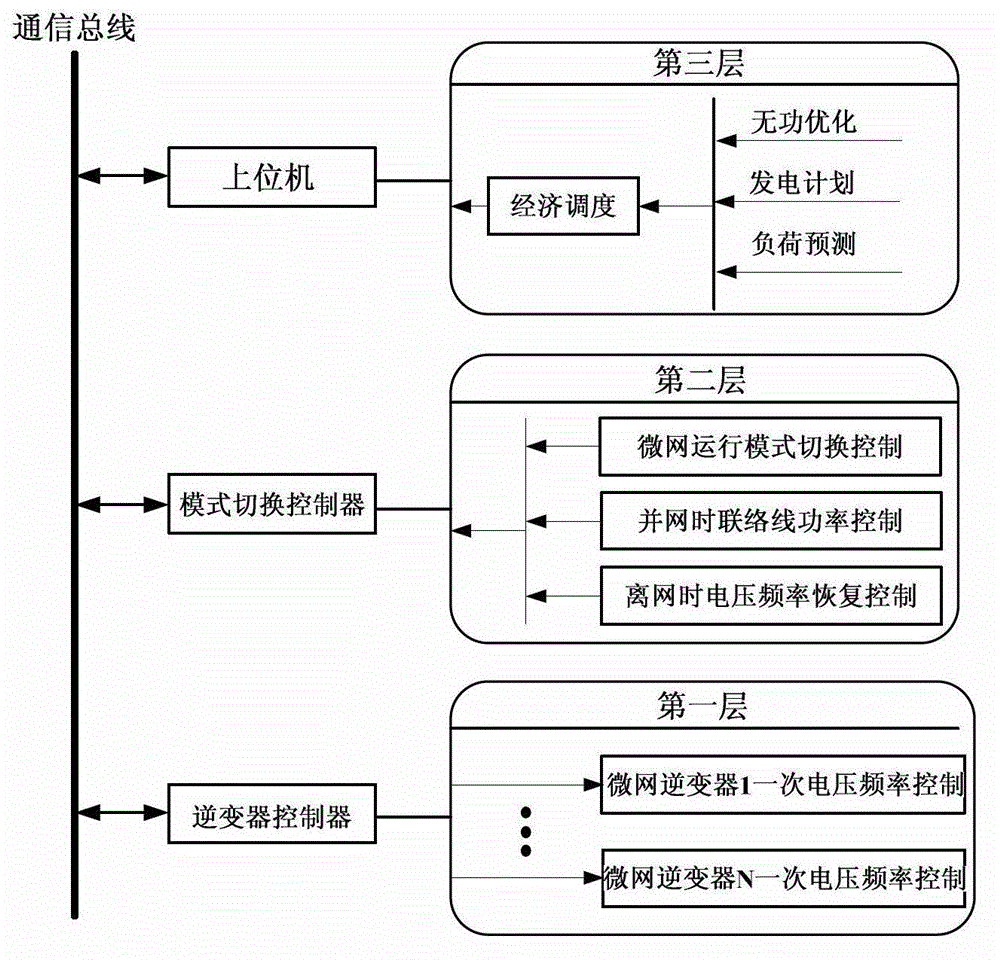

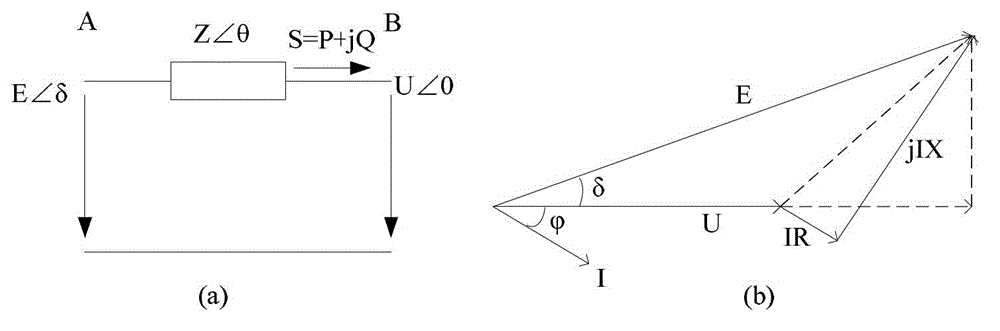

Microgrid seamless switching control method based on improving phase control under peer mode

ActiveCN103138290BFlexible accessRealize the function of plug and playSingle network parallel feeding arrangementsHandoff controlMicrogrid

The invention discloses a microgrid seamless switching control method based on improving phase control under a peer mode, and belongs to the technical field of a distributed power generation microgrid. According to the method, through utilization of a characteristic that a distributed power supply is always controlled by voltage under the grid-connected operation mode and the independent operation mode, the switch from the microgrid grid-connected operation mode to an off-grid operation mode is achieved conveniently, meanwhile, power rush at the moment of switching the off-grid operation to the grid-connected operation is reduced by the voltage\frequency restorative control of a second layer and the improved phase angle control. Not only is flexible access of the distributed power supply in the microgrid achieved, but also the function of plug and play of the whole microgrid is achieved.

Owner:GUANGXI POWER GRID CORP +1

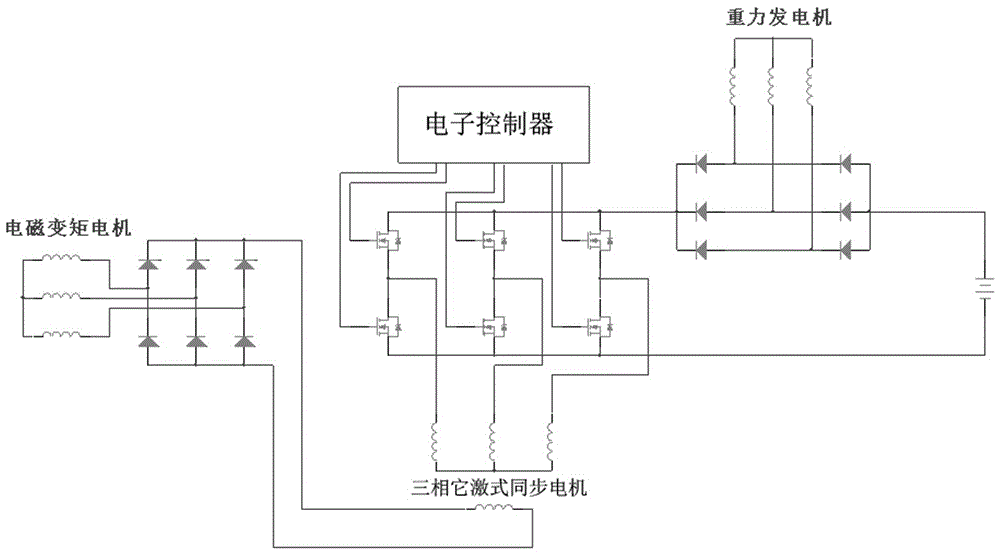

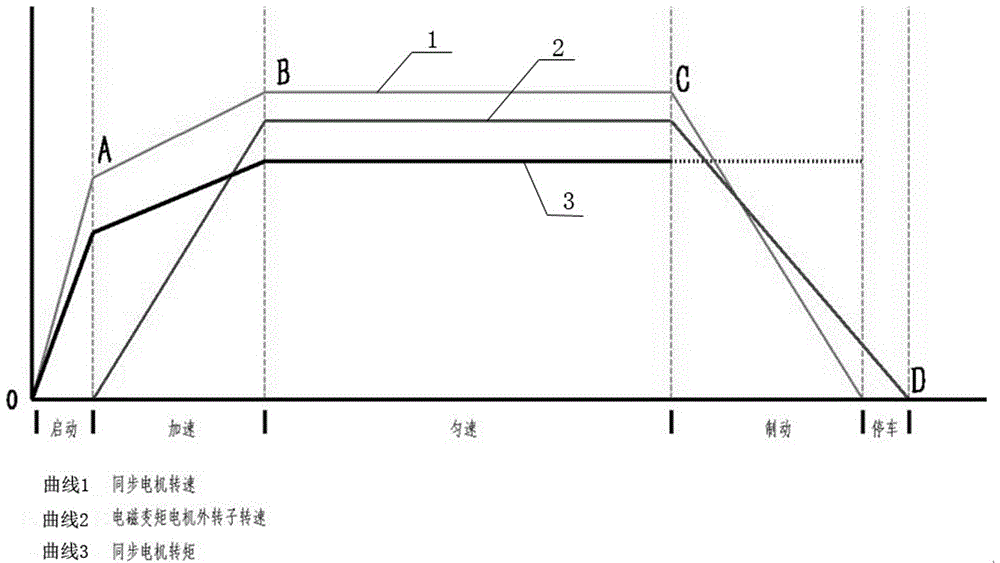

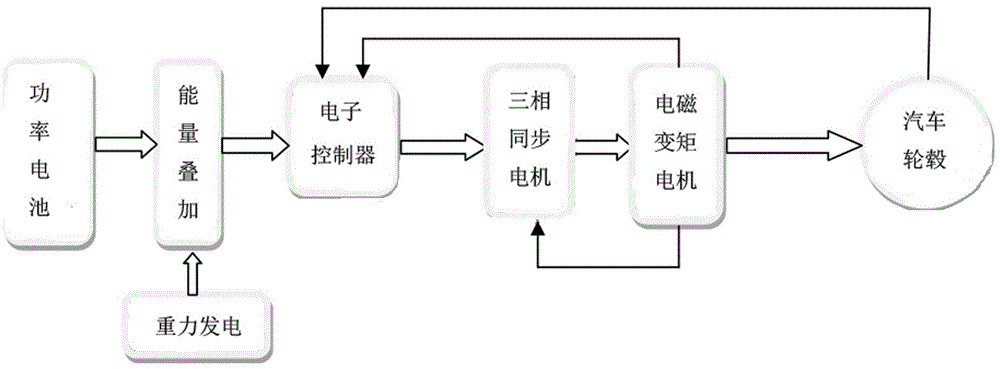

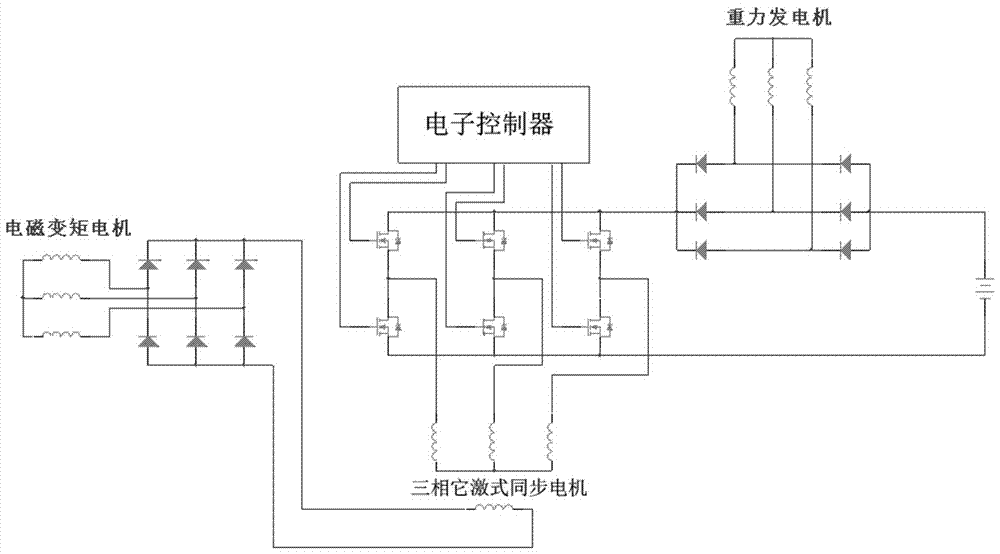

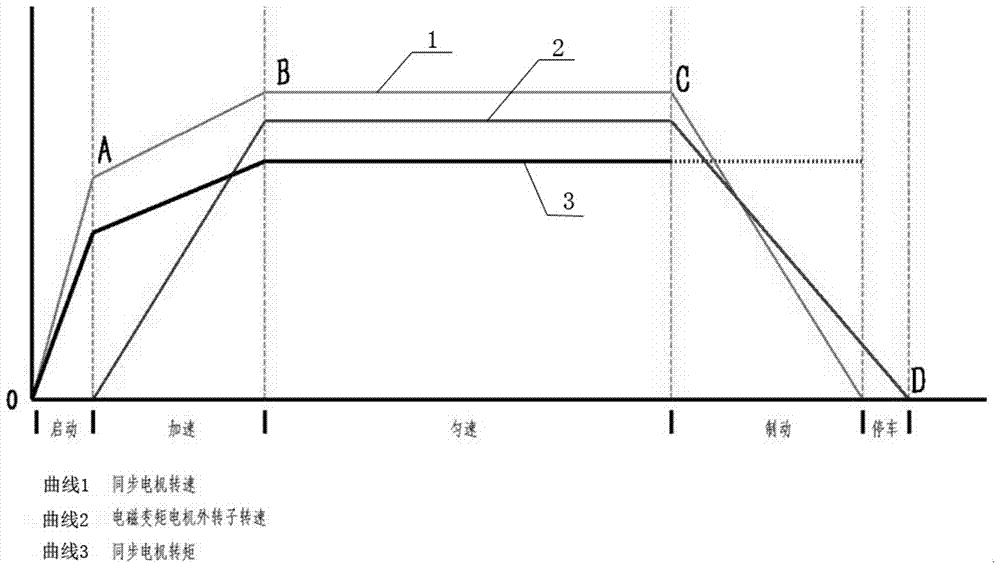

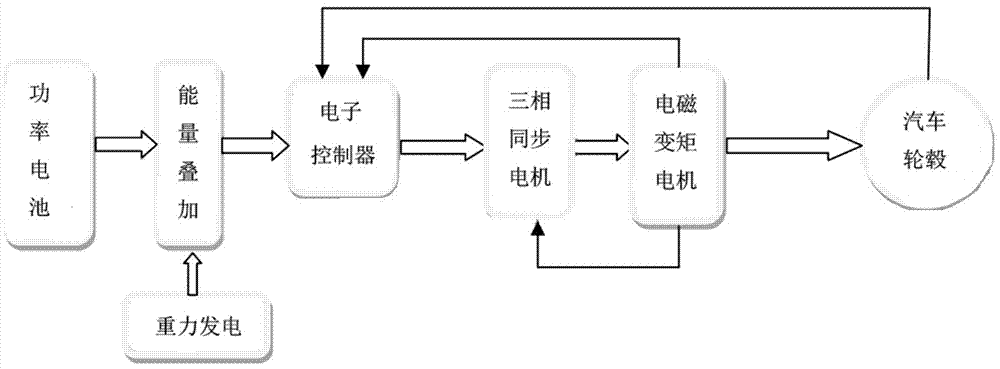

Electromagnetic variable-torque driving system of electric vehicle

ActiveCN105730217AReduce power shockExtended service lifeElectric devicesPropulsion by batteries/cellsSynchronous motorElectric vehicle

The invention relates to a driving system of an electric vehicle, in particular to an electromagnetic variable-torque driving system of an electric vehicle. The electromagnetic variable-torque driving system comprises an electromagnetic variable-torque driving device, a power cell, an electronic controller, a three-phase bridge type full control inverter circuit and a three-phase rectification circuit, wherein the electromagnetic variable-torque driving device comprises a three-phase separate excitation type synchronous motor and an electromagnetic variable-torque motor, and a rotor of the three-phase separate excitation type synchronous motor is connected with an inner rotor of the electromagnetic variable-torque motor; the power cell is connected with an input end of the three-phase bridge type full control inverter circuit, and an output end of the three-phase bridge type full control inverter circuit is connected with an armature winding of the three-phase separate excitation type synchronous motor; a magnetic pole winding of the inner rotor of the electromagnetic variable-torque motor is connected with an excitation winding of the three-phase separate excitation type synchronous motor through the three-phase rectification circuit, and an outer rotor of the electromagnetic variable-torque motor is connected with a hub. According to the electromagnetic variable-torque driving system disclosed by the invention, a completely new concept of electromagnetic variable-torque drive is provided, the electromagnetic variable-torque drive is realized through a specific structure, and an electric wheel of the electromagnetic variable-toque drive can have a great market application prospect.

Owner:DATONG YULONG ENVIRONMENTAL PROTECTION

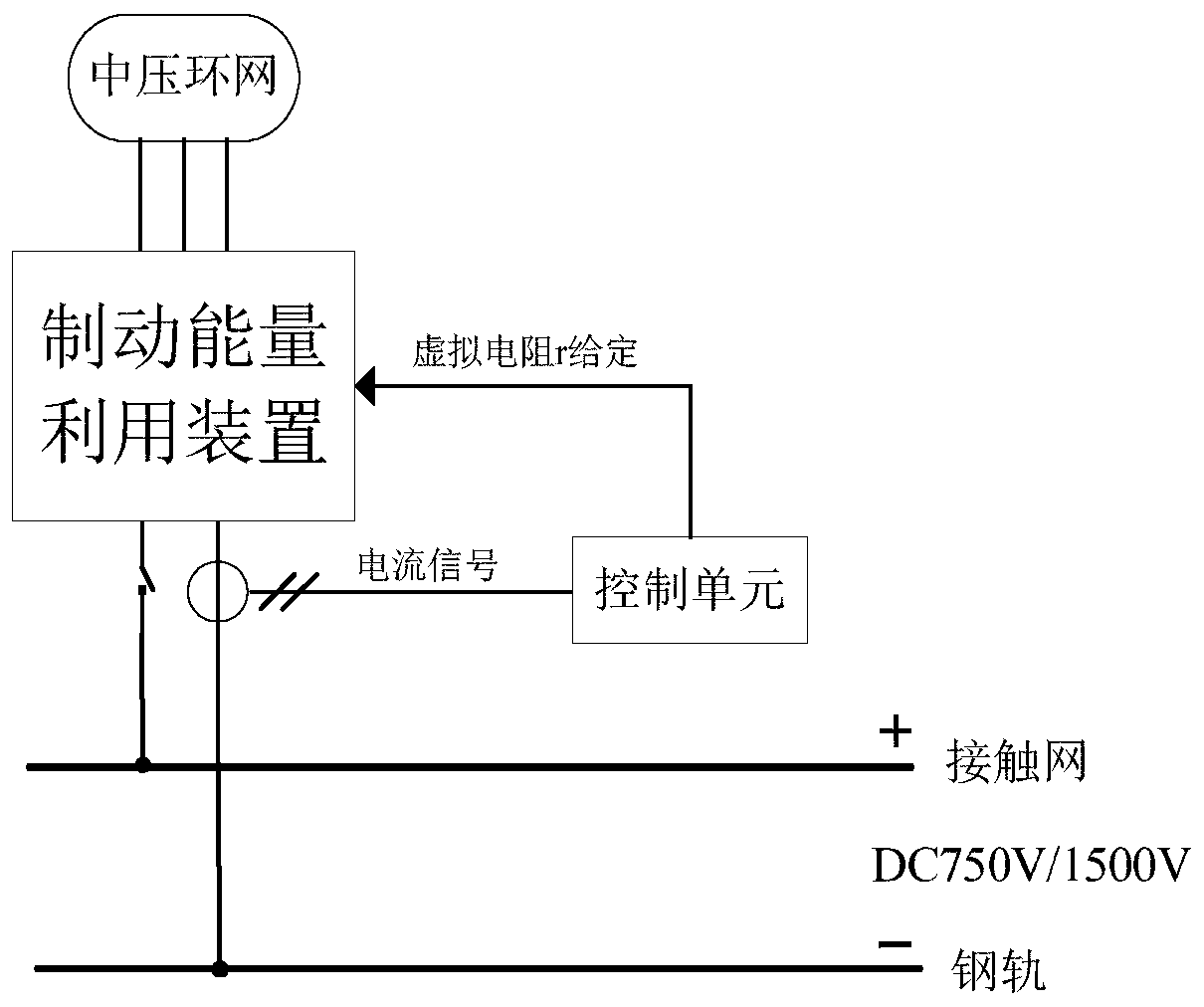

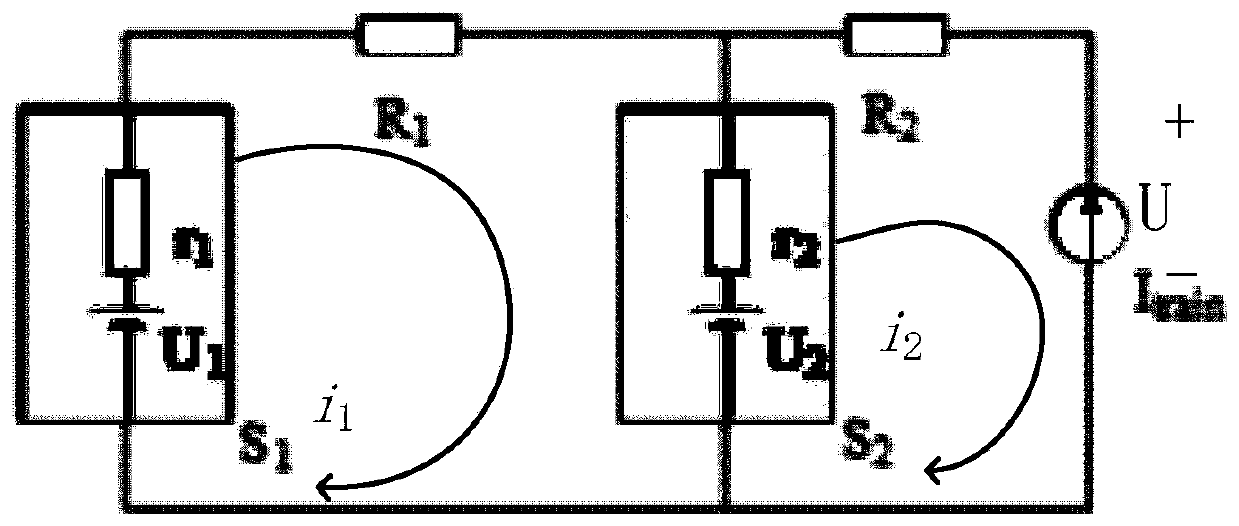

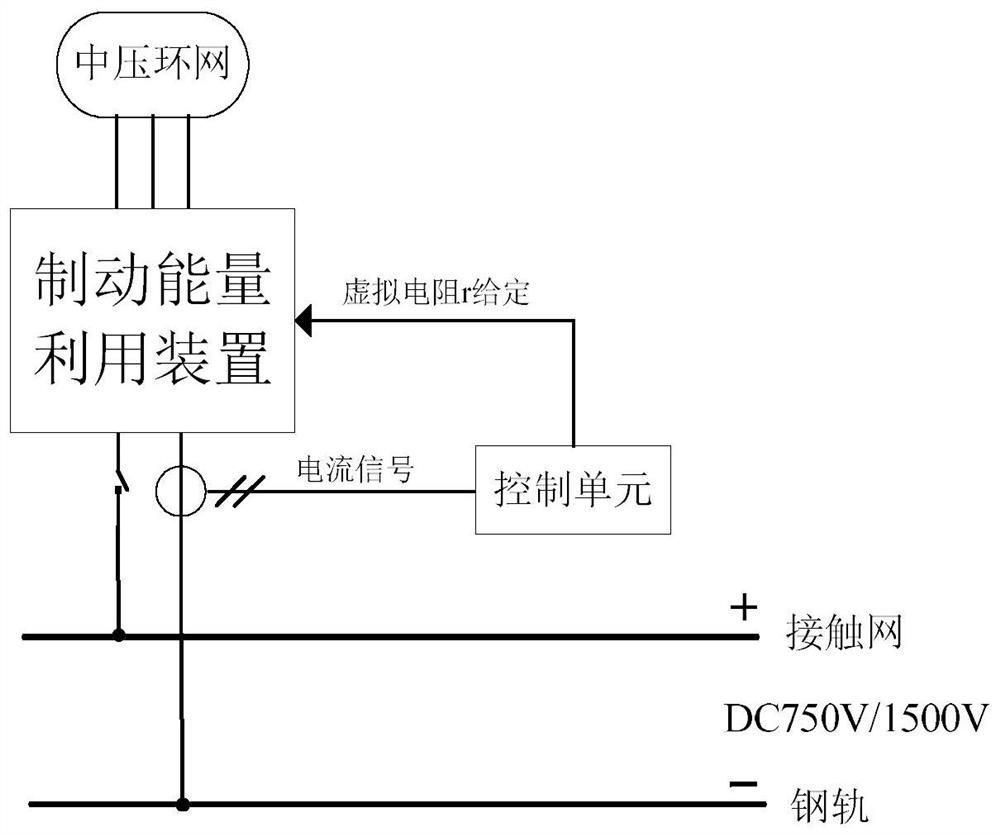

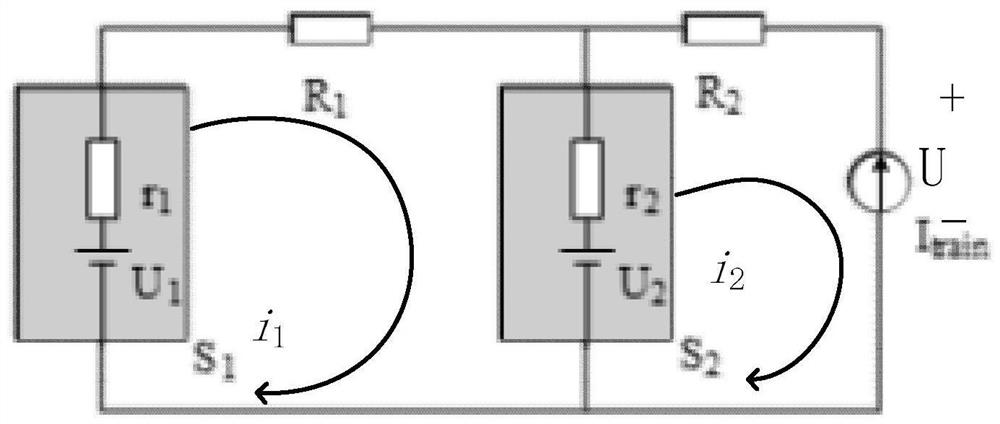

Distributed cooperative absorption method for urban rail transit braking energy

ActiveCN110816367AReduce power shockEfficient use ofPower supply linesTelecommunicationsRegenerative brake

The invention discloses a distributed cooperative absorption method for urban rail transit braking energy. Braking energy utilization devices of adjacent stations are triggered to be put into operation by controlling the absorption voltage of a traction substation braking energy utilization device, so that the regenerative braking peak power of a train which enters a station can be jointly absorbed by the energy utilization devices of the multiple adjacent stations, the power impact on a single station is reduced, better utilization of the regenerative braking energy in a subway system is facilitated, and the probability of transmitting electric energy back to an urban power grid is reduced.

Owner:CHINA CREC RAILWAY ELECTRIFICATION BUREAU GRP

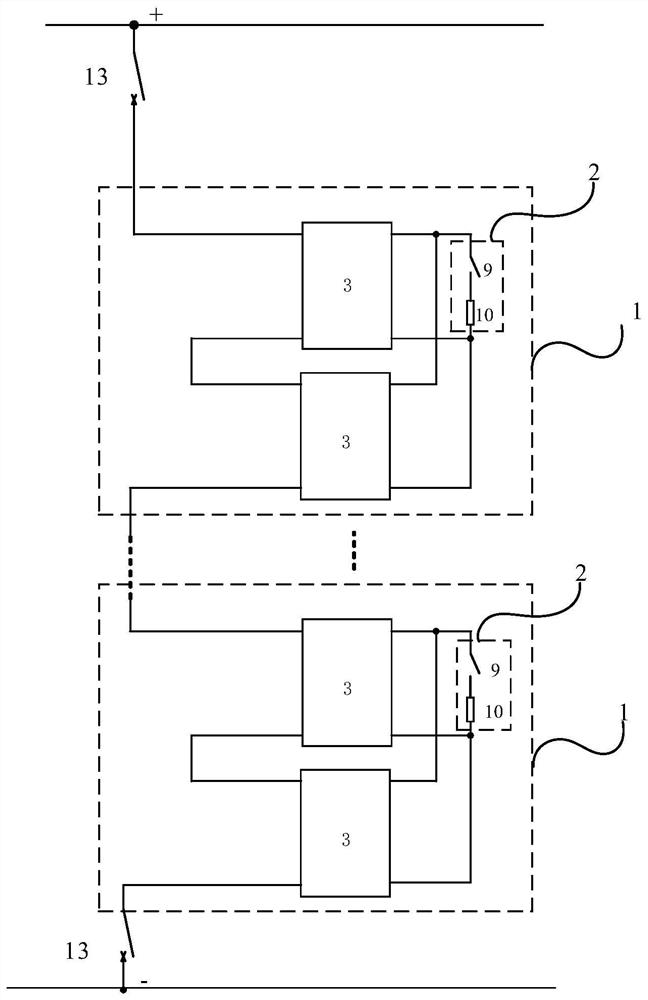

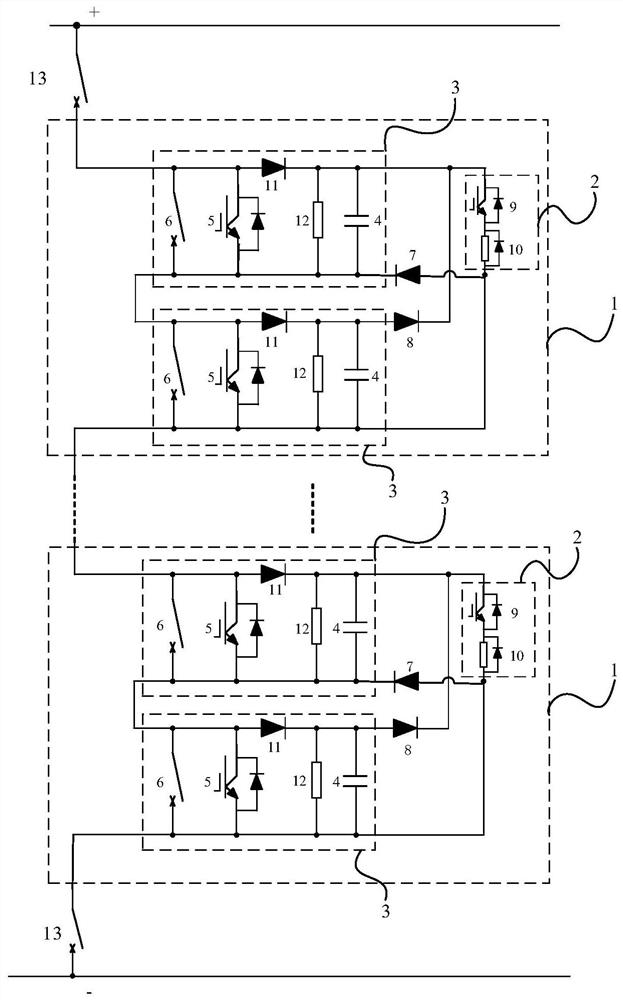

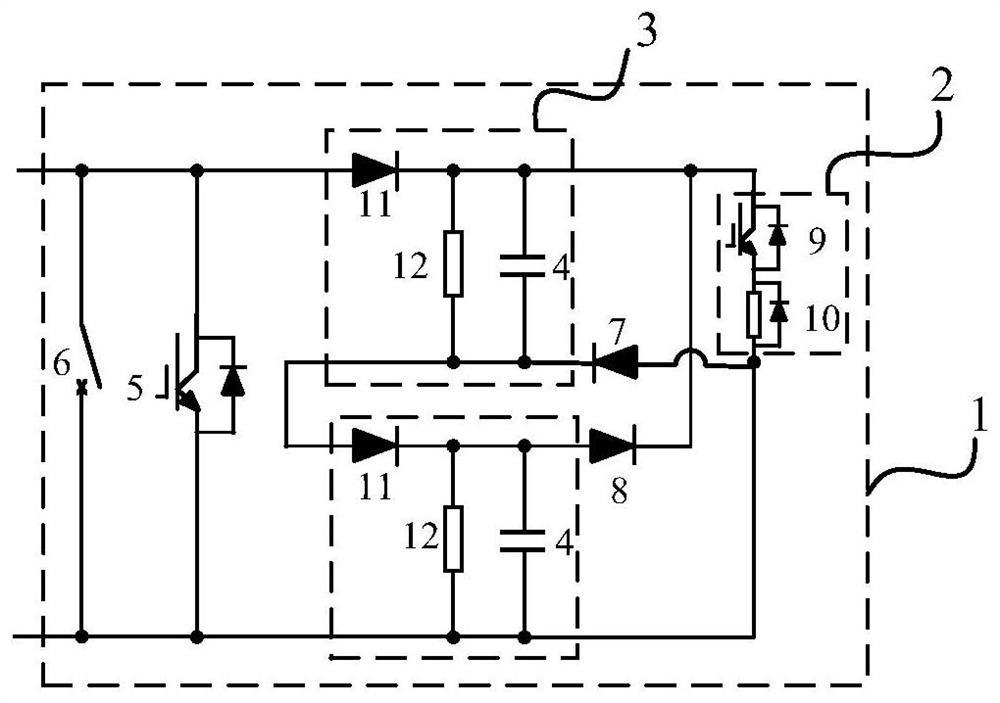

Direct-current energy consumption device

PendingCN112787317AAvoid risk of damageImprove stabilityEmergency protective arrangements for limiting excess voltage/currentCapacitancePower semiconductor device

The invention relates to a direct current energy consumption device, and the device comprises at least one energy consumption unit; the energy consumption units are connected in series, each energy consumption unit comprises an energy consumption branch and at least two energy consumption sub-modules, the energy consumption branch is formed by connecting a first switching device and an energy consumption resistor in series, and each energy consumption sub-module comprises an energy storage capacitor. The input ends of the energy consumption sub-modules are connected in series, and the output ends of the energy consumption sub-modules are connected in parallel and then connected with the energy consumption branch. According to the invention, the risk of device damage caused by inconsistent switching-on and switching-off in a direct series connection scheme of power semiconductor devices is avoided, the direct-current voltage stability in the power discharge period is good, the power impact in the discharge process can be reduced, a plurality of energy consumption sub-modules share one energy consumption branch, the device structure is greatly simplified, and the system cost is reduced.

Owner:XIAN XJ POWER ELECTRONICS TECH +3

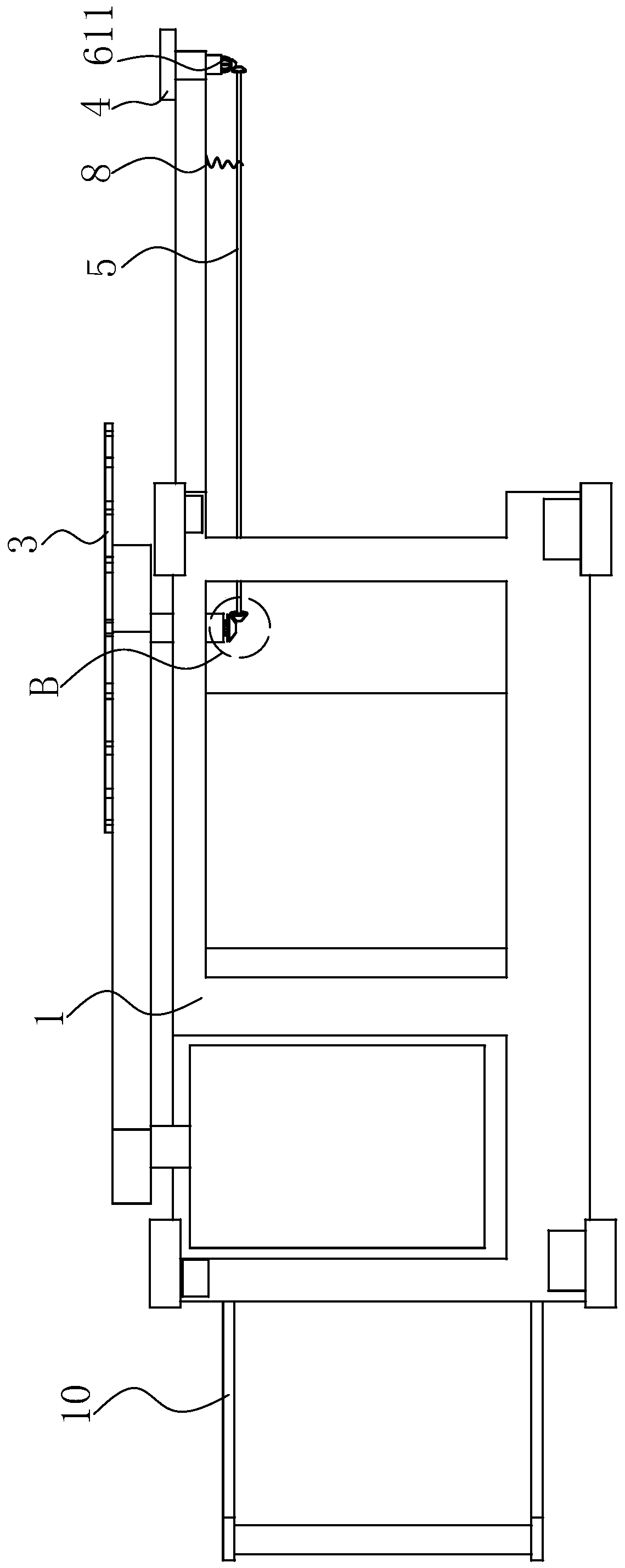

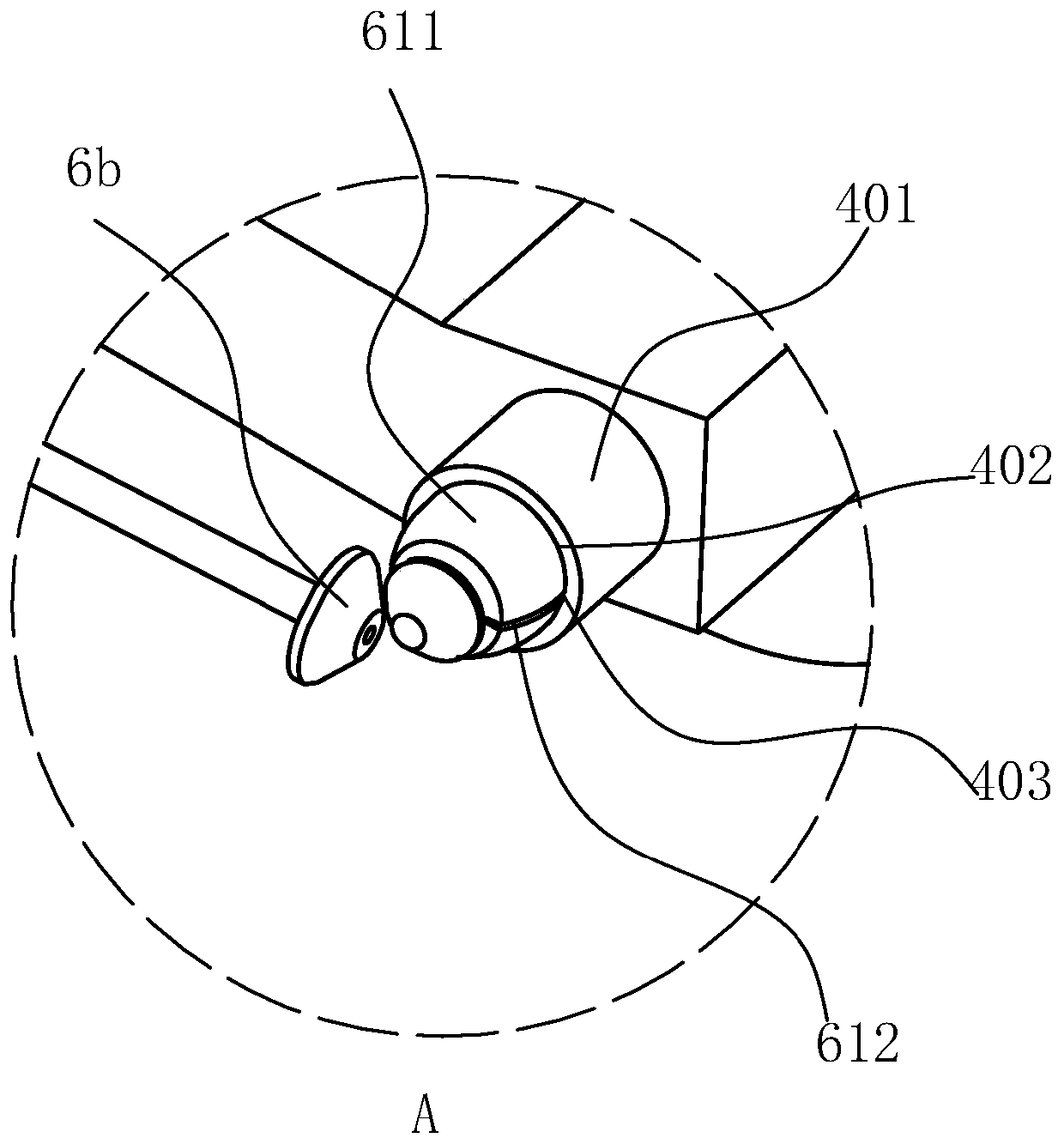

Road surface cutting equipment and method for road construction

InactiveCN109837828BAchieve cleanupImprove construction efficiencyRoads maintainenceDrive shaftElectric machinery

The invention relates to road surface cutting equipment and method for road construction, and belongs to the technical field of road surface construction equipment. The road surface cutting equipmentcomprises a frame body; a driving machine and a cutting blade driven by the driving machine are mounted on the frame body; a guide wheel is arranged at the front part of the frame body, the guide wheel and the cutting blade are coplanar, the guide wheel and the cutting blade are respectively and correspondingly supported by a guide shaft and a saw blade shaft which are movably arranged on the frame body; a transmission shaft for connecting the cutting blade and the guide wheel is arranged on the frame body, and two ends of the transmission shaft are respectively and correspondingly connected with the guide shaft and the saw blade shaft through a bevel gear transmission set; a supporting rod is arranged on the frame body, a strip-shaped hole is formed in the supporting rod, and the transmission shaft penetrates through the strip-shaped hole; a push rod is arranged in the supporting rod. A motor is adopted to drive the push rod to rotate, and the push rod is in threaded connection with asliding sleeve, so that the rotating push rod can push the sliding sleeve and the transmission shaft penetrating through the sliding sleeve to one side close to the cutting blade, the bevel gear transmission sets at two ends of the transmission shaft are correspondingly connected with the cutting blade and the guide wheel respectively, and power transmission is achieved.

Owner:郭二艳

Torque control method and device for mechanical throttle body, medium and vehicle

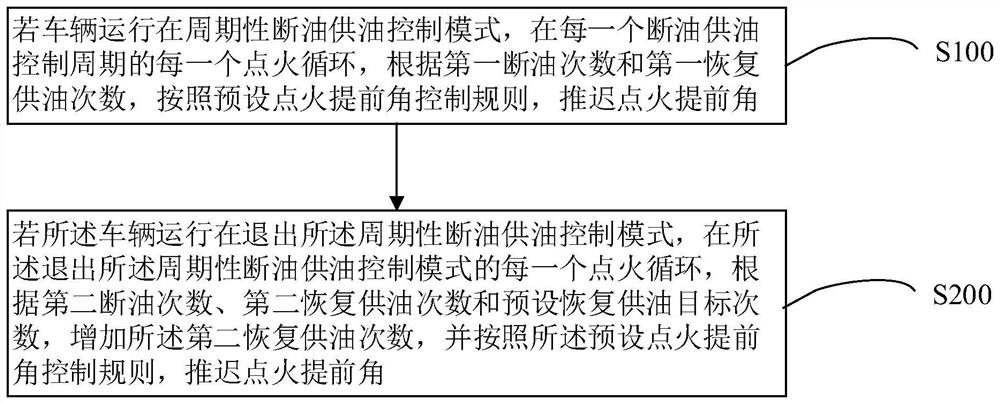

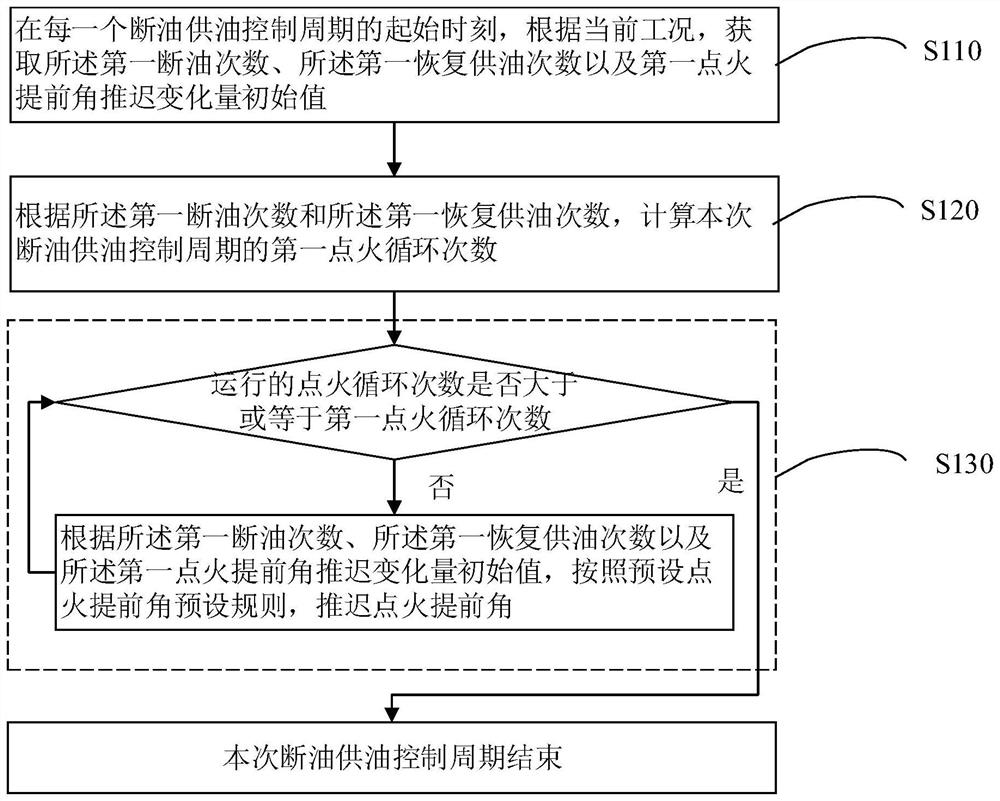

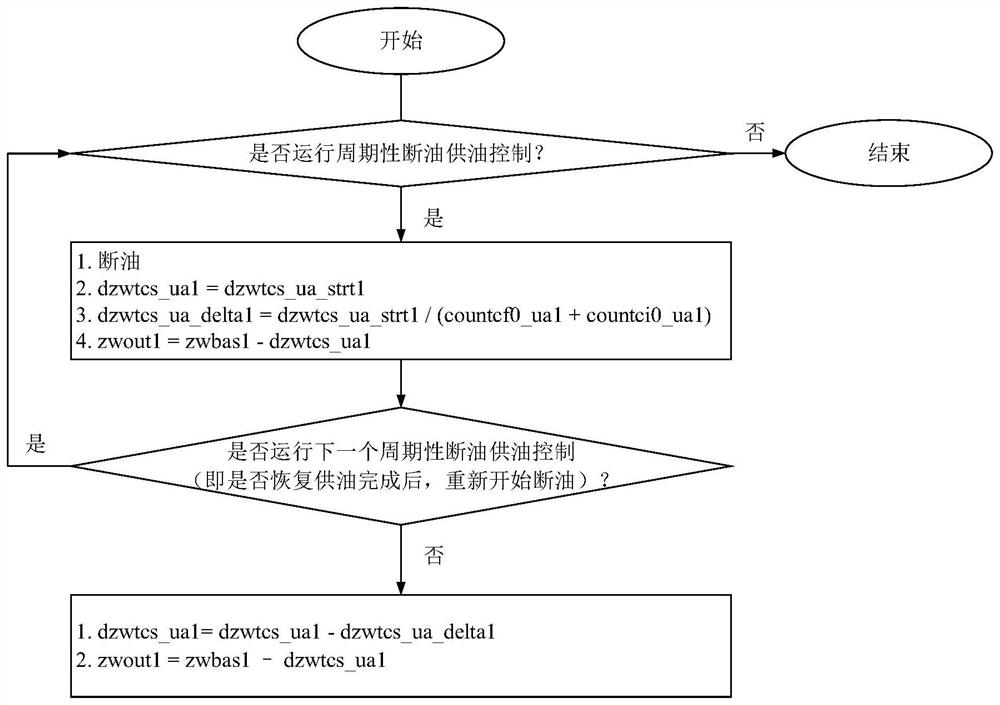

PendingCN114837870AReduce power shockImprove comfortInternal combustion piston enginesEngine controllersFuel supplyControl mode

The invention provides a torque control method and device for a mechanical throttle body, a medium and a vehicle. When torque response is achieved, when the vehicle runs in a periodic fuel cut-off and fuel supply control mode, in each ignition cycle of each fuel cut-off and fuel supply control period, the ignition advance angle is delayed according to the first fuel cut-off frequency, the first fuel supply recovery frequency and the preset ignition advance angle control rule. When the vehicle runs in each ignition cycle of quitting the periodic fuel cut-off and fuel supply control mode and quitting the periodic fuel cut-off and fuel supply control mode, the second fuel supply recovery times are increased according to the second fuel cut-off times, the second fuel supply recovery times and the preset fuel supply recovery target times, and the ignition advance angle of the vehicle is controlled according to the preset ignition advance angle control rule. And the ignition advance angle is delayed. When the torque reduction requirement is responded, power impact of a transmission system can be reduced, smooth transition of torque is achieved in the process of quitting the torque response mode, and therefore the driving comfort is improved.

Owner:UNITED AUTOMOTIVE ELECTRONICS SYST

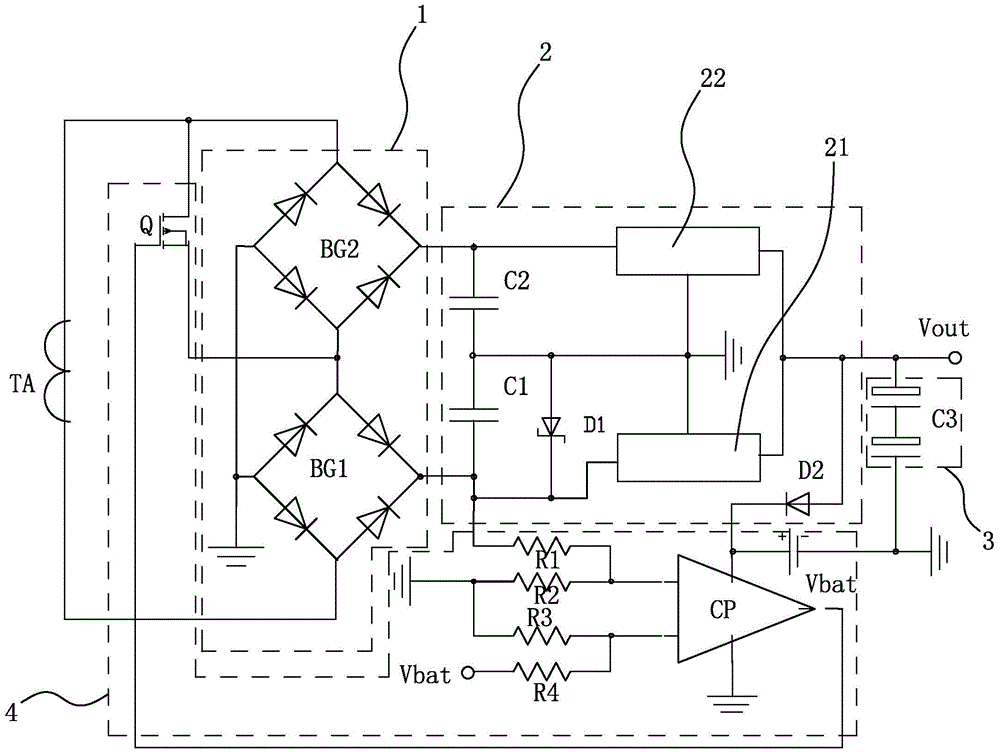

An automatic switching single-phase rectifier bridge series circuit

InactiveCN104052316BAvoid shockControlled full wave rectificationAc-dc conversionLow loadLow voltage

An automatic switching single-phase rectifier bridge series circuit comprises an electromagnetic coil TA, a rectifying circuit, an integrated voltage regulator circuit and a power supply circuit which are connected with each other. The automatic switching single-phase rectifier bridge series circuit is characterized by further comprising a switching circuit. The rectifying circuit comprises a low-voltage rectifier bridge BG1 and a high-voltage rectifier bridge BG2 which are connected in series, and the low-voltage rectifier bridge BG1 is in serial connection with the input end of the high-voltage rectifier bridge BG2 and in parallel connection with the output end of the high-voltage rectifier bridge BG2 in a land shared mode. The switching circuit switches full-wave rectification of the low-voltage rectifier bridge BG1 and half-wave rectification of the low-voltage rectifier bridge BG1 and the high-voltage rectifier bridge BG2 by means of the situation whether to short the high-voltage rectifier bridge BG2. The automatic switching single-phase rectifier bridge series circuit has the advantages that full-wave rectification of the low-voltage rectifier bridge is controlled by controlling conduction of an MOS switch Q through a constant voltage comparator, when an input voltage is lower than a current-limiting threshold, energy is collected to the maximum extent, energy loss is reduced, and power supplied to a sensor is ensured under the conditions that a high-voltage line has low load and even has no load.

Owner:北京科锐云涌科技有限公司

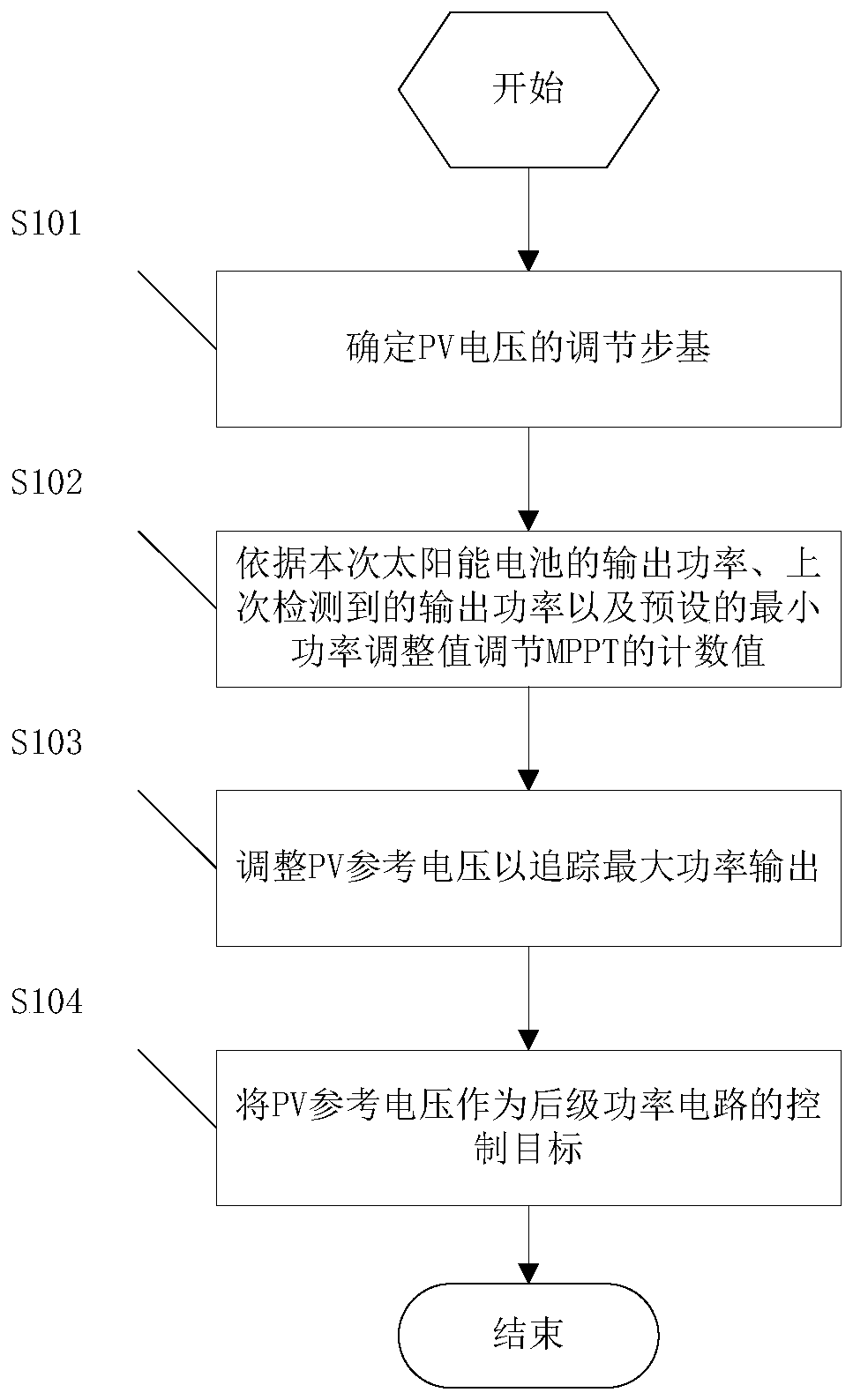

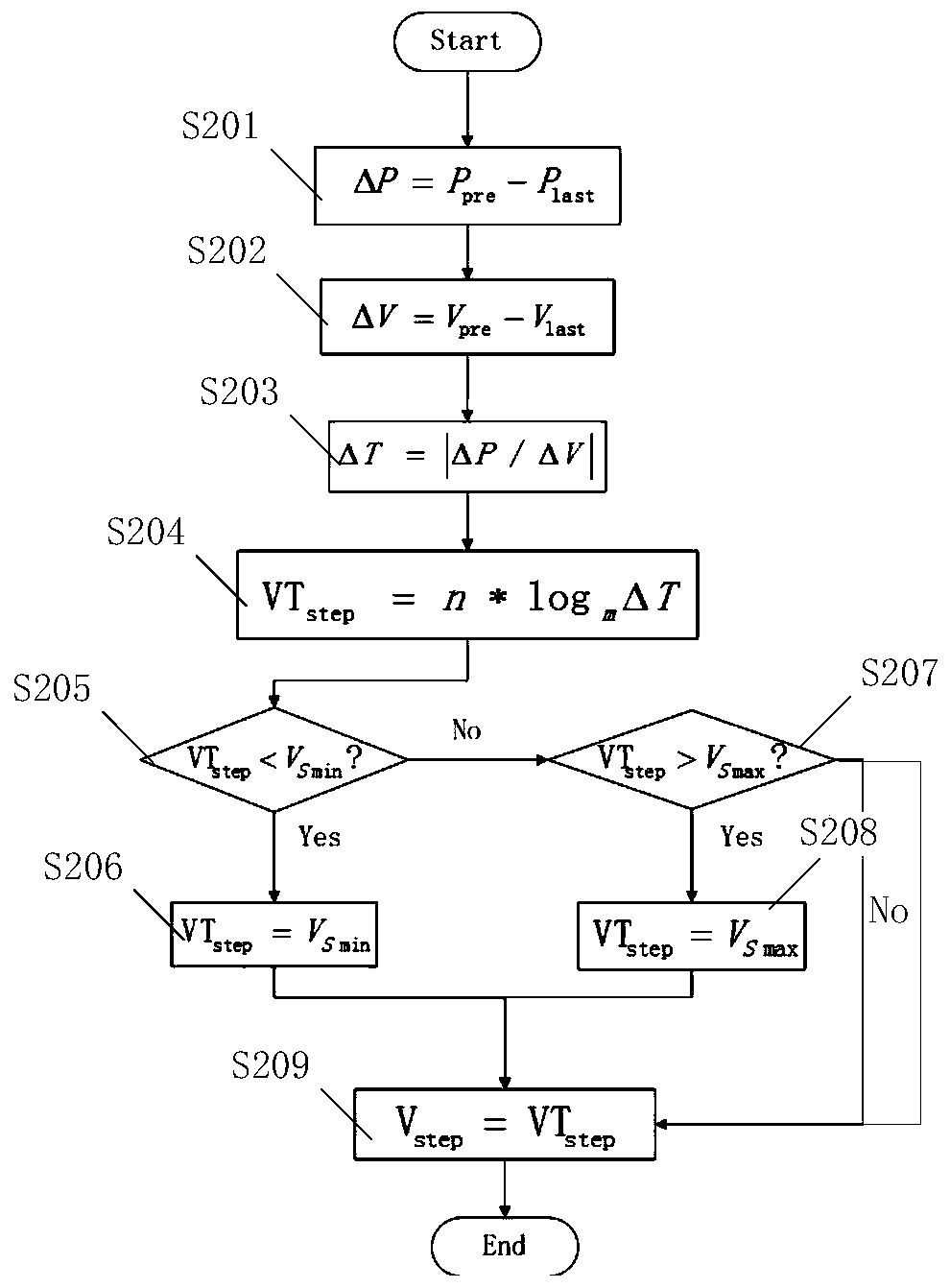

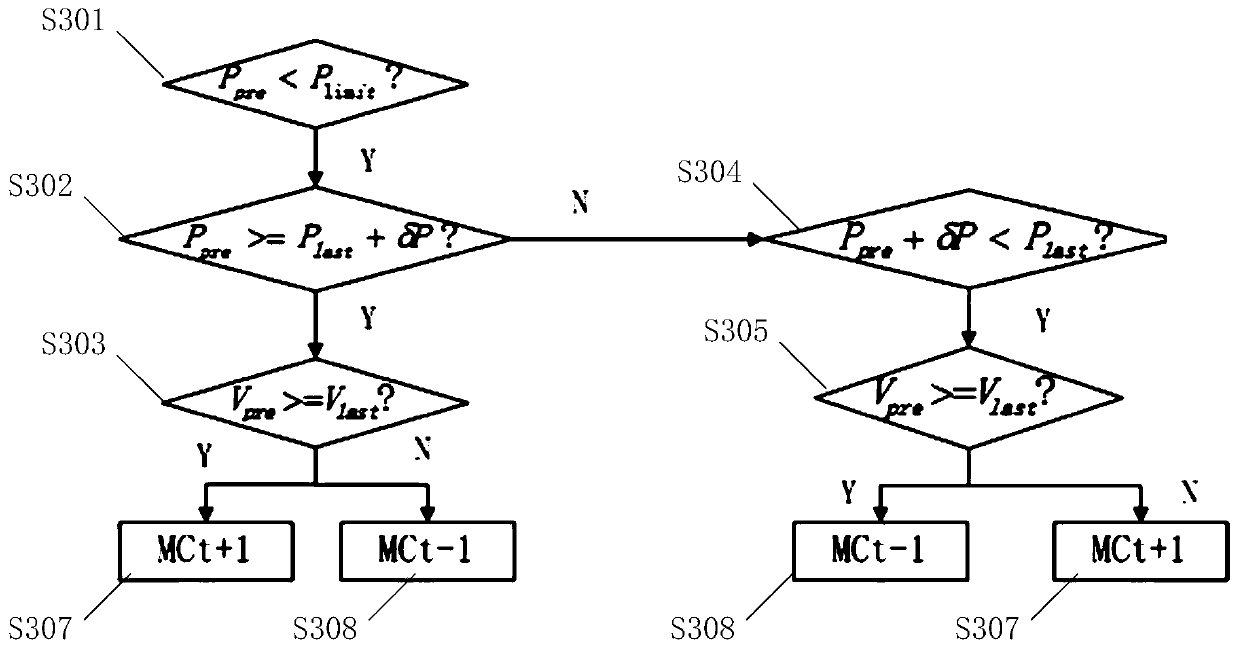

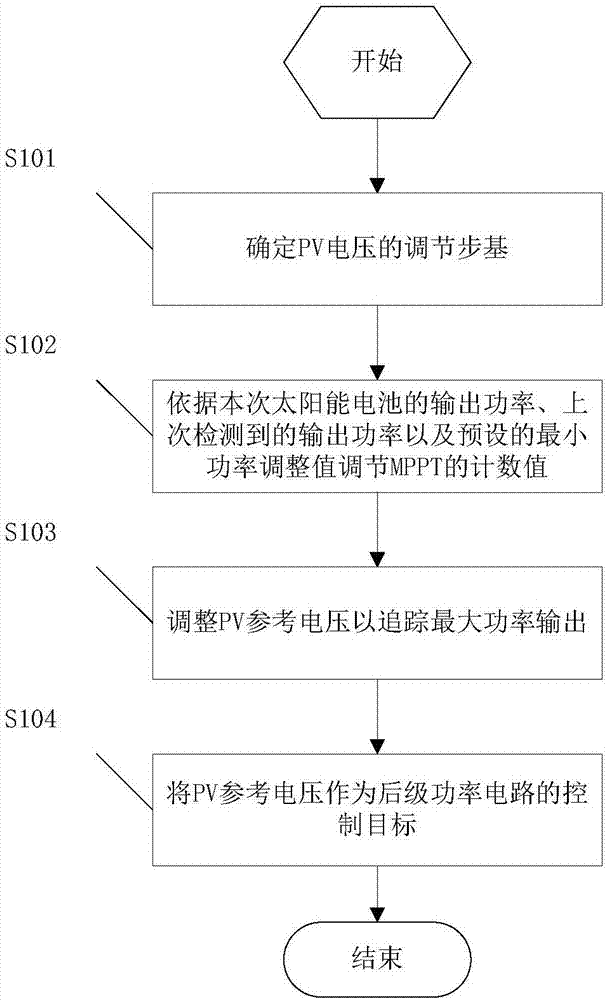

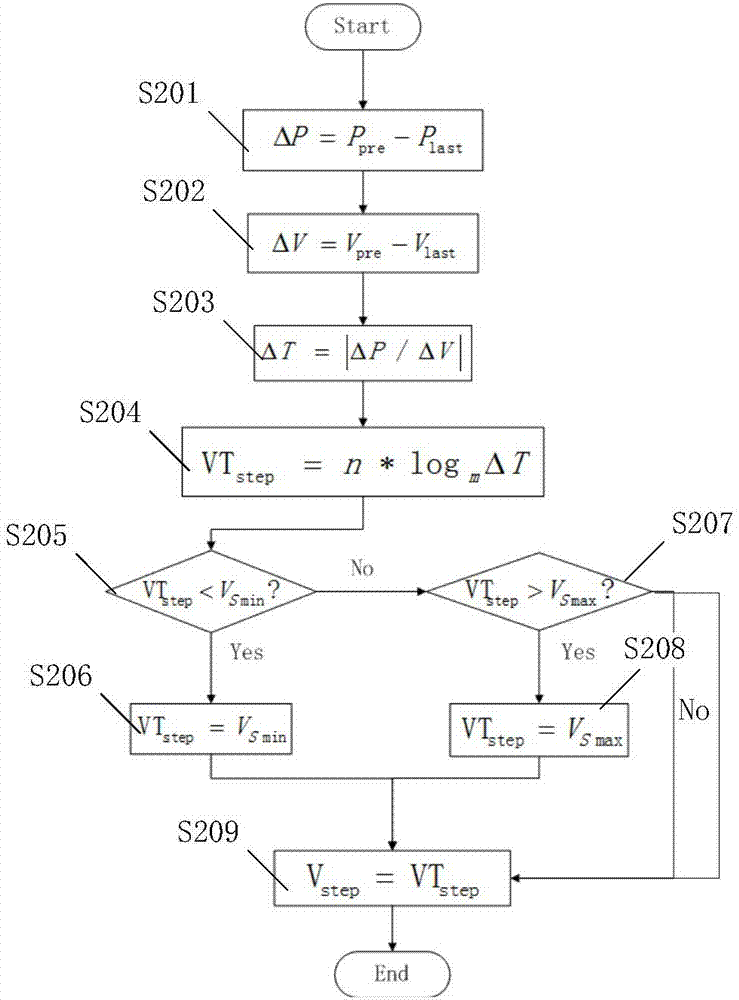

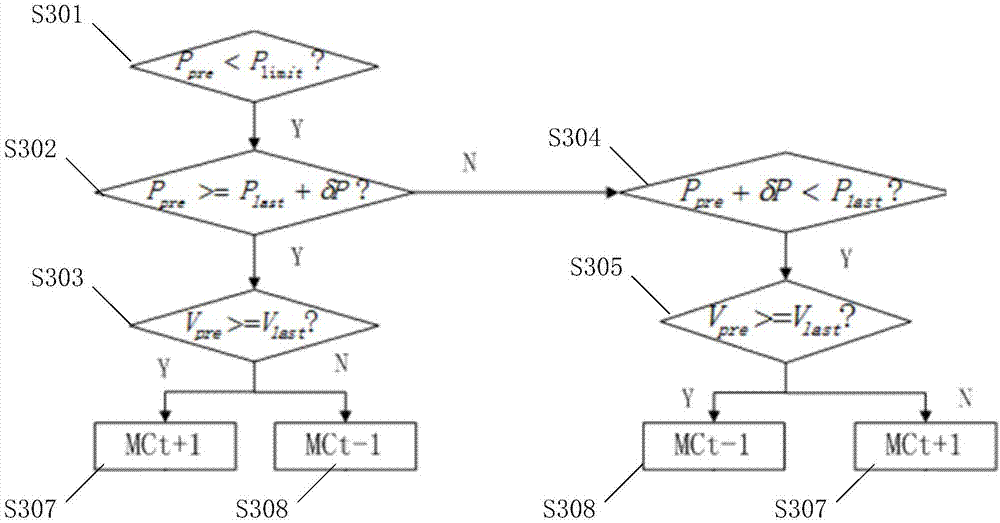

A method and device for maximum power tracking

ActiveCN107992154BReduce power shockPhotovoltaic energy generationElectric variable regulationElectrical batteryHemt circuits

The application provides a maximum power tracing method and a maximum power tracing device. The method includes steps of monitoring output power and PV voltage of a solar panel according to the setting frequency; calculating to obtain adjusting step base of the PV voltage according to the monitored output power and the PV voltage of the solar panel; adjusting the counting value of MPPT according to the output power of the solar battery this time, the output power detected last time and preset minimum power adjusting value; adjusting the PV reference voltage on the basis of the adjusting step base according to the comparison result of the adjusted counting value of MPPT and the set MPPT reference value; using the PV reference voltage as the control target of a past-grade power circuit. Themaximum power tracing method and device have the advantages of realizing the purpose of reducing the power oscillation of the MPPT maximum power tracing.

Owner:深圳市英威腾光伏科技有限公司

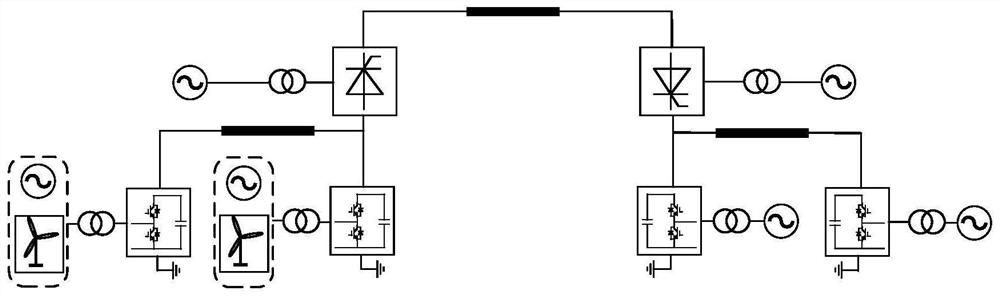

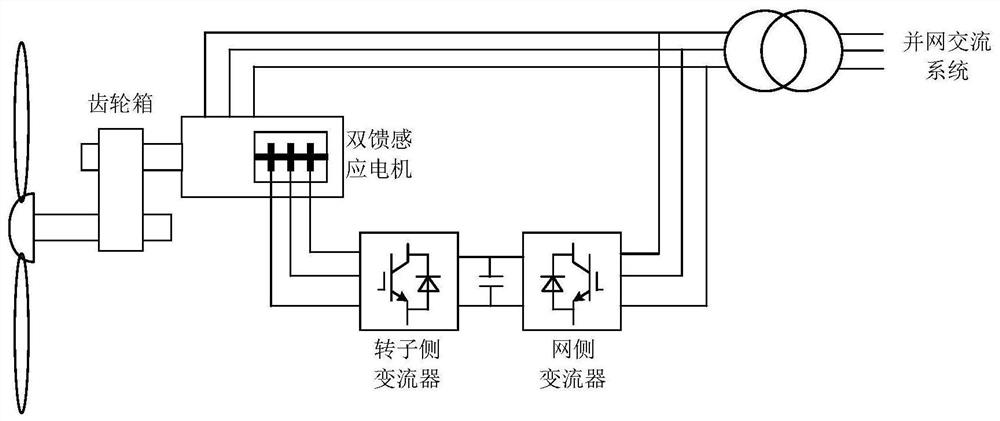

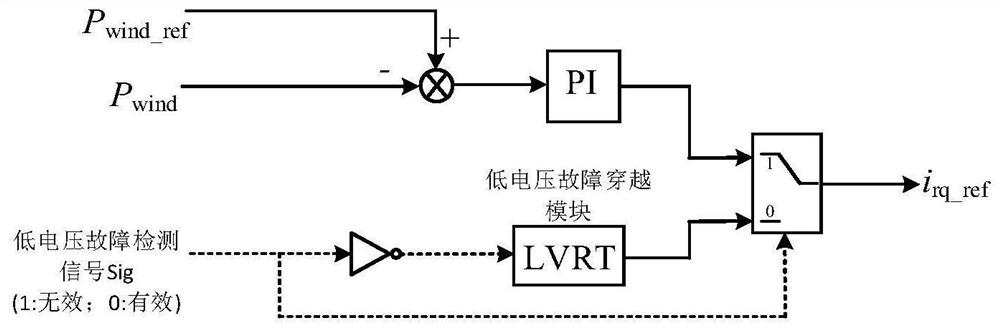

Alternating current fault control method and control system for doubly-fed wind power hybrid direct current sending-out system

PendingCN114530895ANo saturationReduce power shockElectric power transfer ac networkSingle network parallel feeding arrangementsOvervoltageControl system

The invention relates to a doubly-fed wind power hybrid direct current sending-out system alternating current fault control method and control system, an active power outer ring is transformed and optimized, when an alternating current fault occurs, an actual power instruction value of a wind generating set can quickly follow the grid-connected point output power of the wind generating set, and when the alternating current fault is cleared, the actual power instruction value of the wind generating set can quickly follow the grid-connected point output power of the wind generating set. The actual power instruction value of the wind generating set is gradually recovered to the power instruction value before the fault at a certain slope, and smooth processing is carried out on switching between a low-voltage fault ride-through link and a conventional active power control link, so that the wind generating set can stably and gradually recover output after the fault is cleared, and the power utilization rate of the wind generating set is improved. The power impact on the MMC is reduced, sufficient adjustment time is reserved for the MMC, and the phenomena that the voltage of the sub-module rises and serious overvoltage occurs on the direct current side and the alternating current side due to the fact that serious power surplus occurs in the MMC in the alternating current fault recovery period are avoided.

Owner:XUJI GRP +2

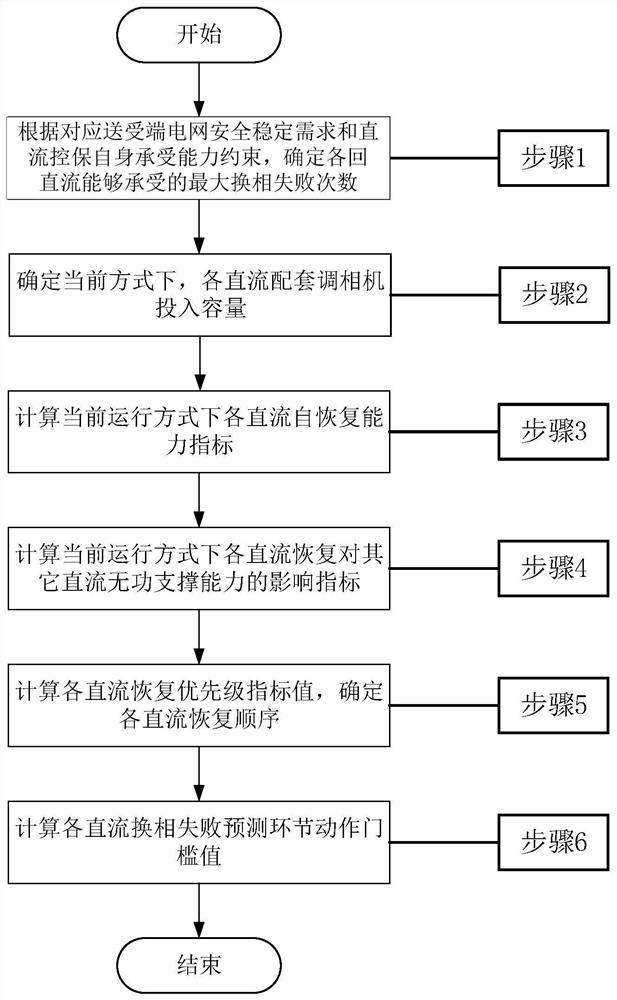

A Threshold Value Setting Method for Prediction Link of DC Commutation Failure

ActiveCN107658895BImprove recovery effectReduce power shockElectric power transfer ac networkElectric power systemControl engineering

Owner:NARI TECH CO LTD +3

Method for eliminating power shock waves generated by switching of single transformer and double transformers

InactiveCN108390548AEliminate Power BlastReduce power shockPower conversion systemsShock waveTransformer

The present invention discloses a method for eliminating power shock waves generated by switching of a single transformer and double transformers. The method allows a period value T and an open valueTon of a transformer to be consistent so as to eliminate power shock waves, reduce the power shock to the most extent and improve the product life. The method provided by the invention allows the system power to suddenly maximally reduce 1%, allows the maximum power to suddenly reduce 37.5% and allows the maximum power to maximally increase 100% compared to a current market, and has a substantialprogress, namely eliminates the power shock waves generated by switching of the single transformer and the double transformers.

Owner:HANGZHOU COMFIRMWARE TECH CO LTD

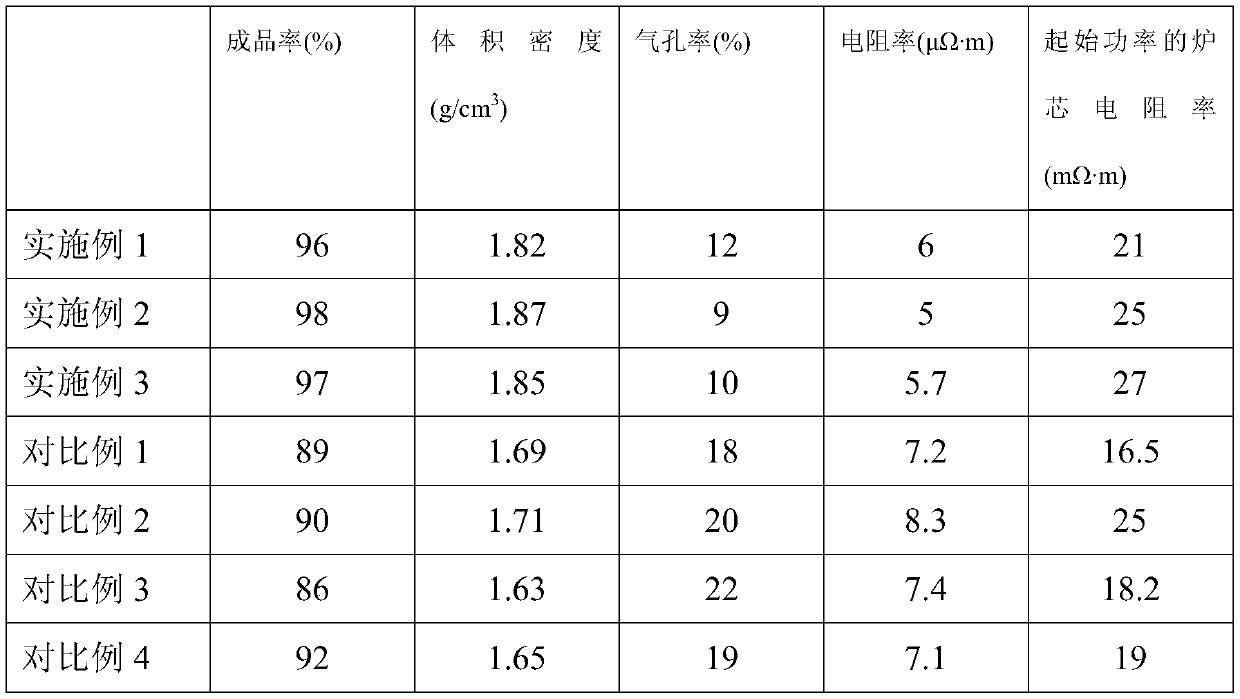

A super-sized graphite product and its graphitization method

ActiveCN108147404BImprove furnace resistanceHeat up faster and more evenlyCarbon compoundsPower transmissionGraphite

The invention relates to the technical field of graphite product processing, in particular to a large-scale graphite product and a graphitizing method thereof. The large-scale graphite product has thevolume density being 1.82 to 1.87g / cm<3>, the electrical resistivity being 5 to 6 mu omega. m, and the porosity being 9 to 12 percent; according to the graphitizing method, during power transmissioninitial power, the electrical resistivity of a furnace core is 21 to 27m omega. m, preferably 25m omega. m, and a fluctuation range of the electrical resistivity of the furnace core is 5 to 10 percentduring a graphitizing process. According to the large-scale graphite product and the graphitizing method thereof provided by the invention, through adjusting the initial furnace core electrical resistivity, changing a charging way of the large-scale graphite product, and adjusting a power increasing speed of a power transmission curve, the graphitized product has a favorable compact performance,and the yield is improved.

Owner:DATONG XINCHENG NEW MATERIAL CO LTD

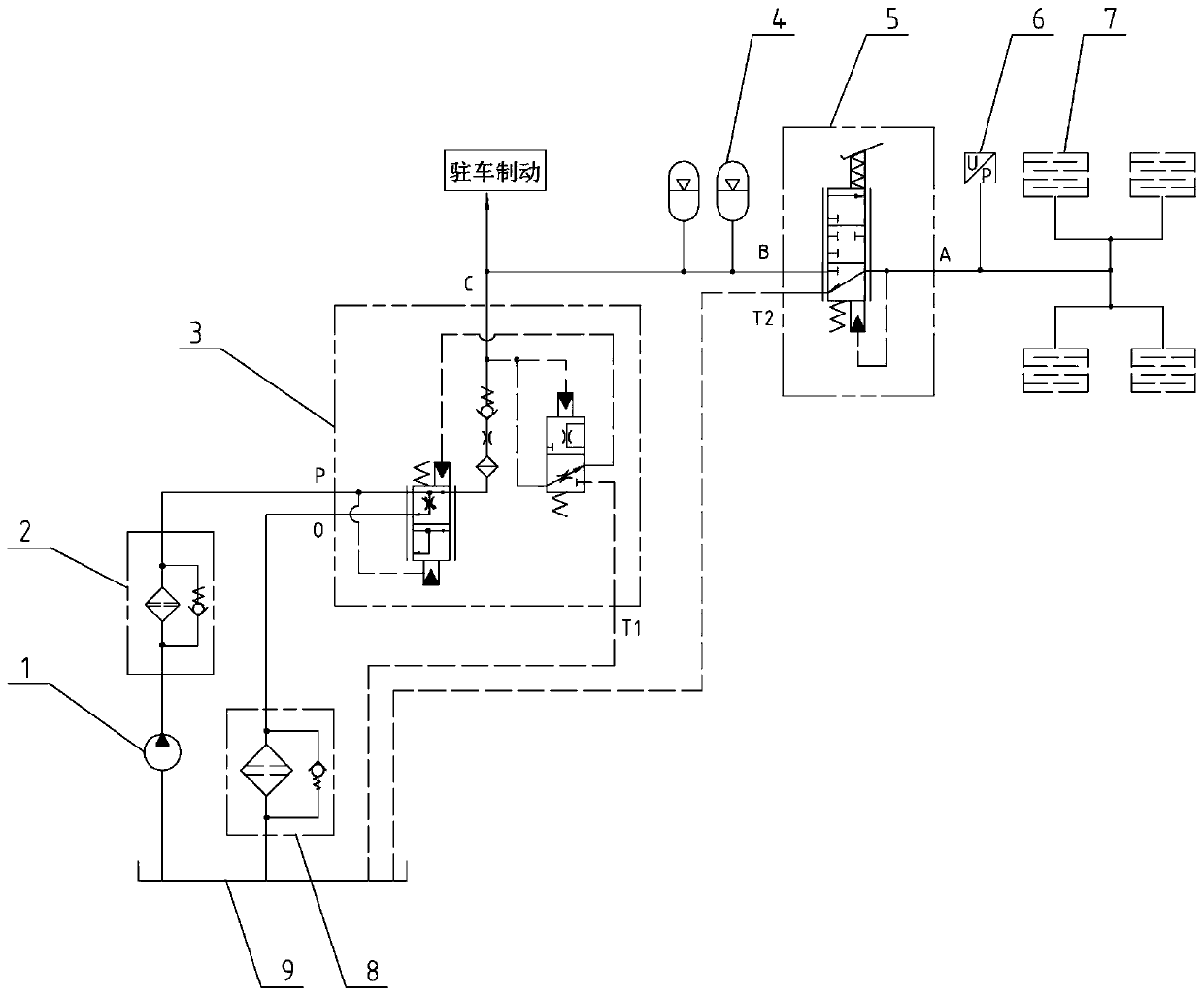

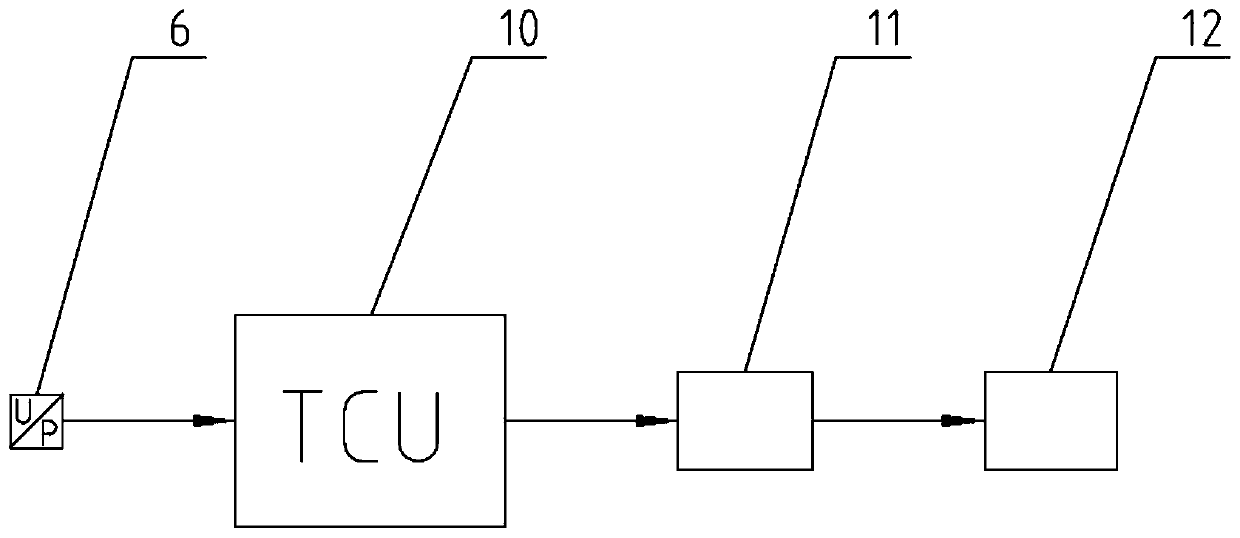

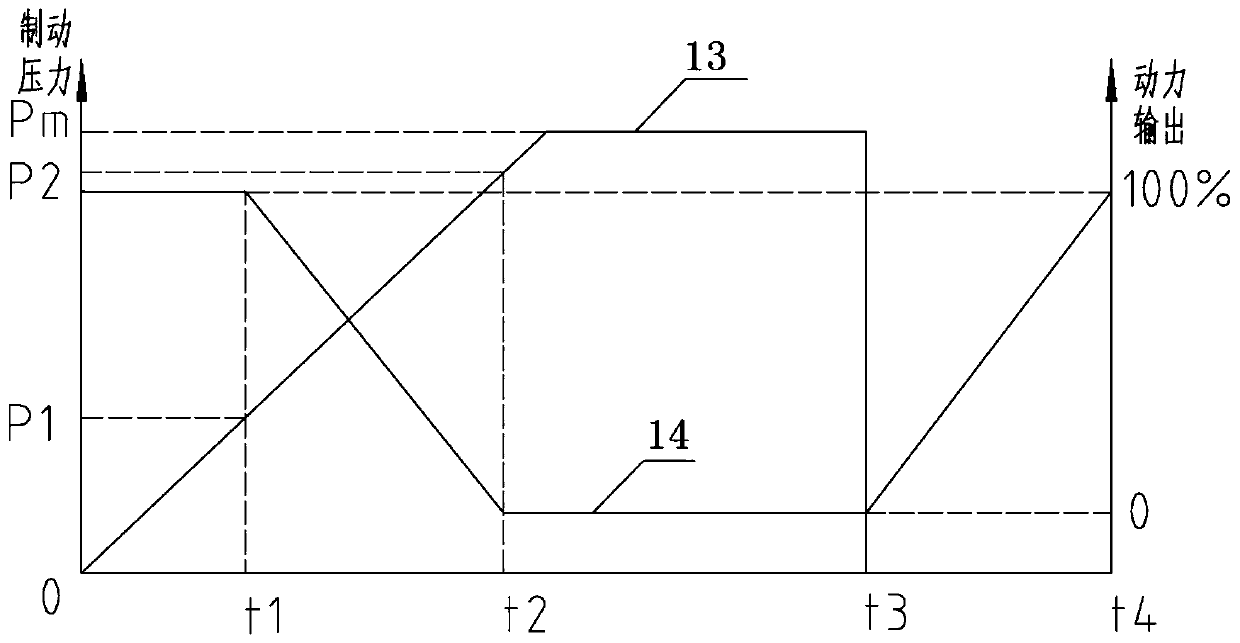

Output power cut-off control system and method of construction machinery gearbox

ActiveCN108662137BExtended service lifeReduce power shockClutchesGearing controlPower componentMotive power

The invention relates to engineering machine speed changing box power cut-off control, aims at overcoming the defect that when an existing speed changing box power output cut-off control system cuts off power output or recovers power output, impacts can be generated, and discloses an engineering machine speed changing box power output cut-off control system and method. According to the braking pressure, the joint degree of a power cut-off clutch in a speed changing box is controlled; when the braking pressure value is smaller than P1, the joint degree of the power cut-off clutch is 100%; whenthe braking pressure value ranges from P1 to P2, the joint degree of the power cut-off clutch ranges from 0% to 100% and is reduced along with increasing of the braking pressure value; and when the braking pressure value is larger than P2, the joint degree of the power cut-off clutch is 0%. The slope control principle is used in the engineering machine speed changing box power output cut-off control system and method for controlling the power output of the speed changing box, disengaging and engaging of the power cut-off clutch are gradually changed, power cut-off and recovery are stable, theimpacts are reduced, the service life of power components is prolonged, and the work comfort is improved.

Owner:GUANGXI LIUGONG MASCH CO LTD

Control method of on-board energy storage system of urban rail train based on power-time curve

ActiveCN110588358BBrief introductionImprove absorption efficiencyElectrodynamic brake systemsRailway transportConvertersElectric capacity

Owner:南方电网调峰调频发电有限公司储能科研院

Linear compressor

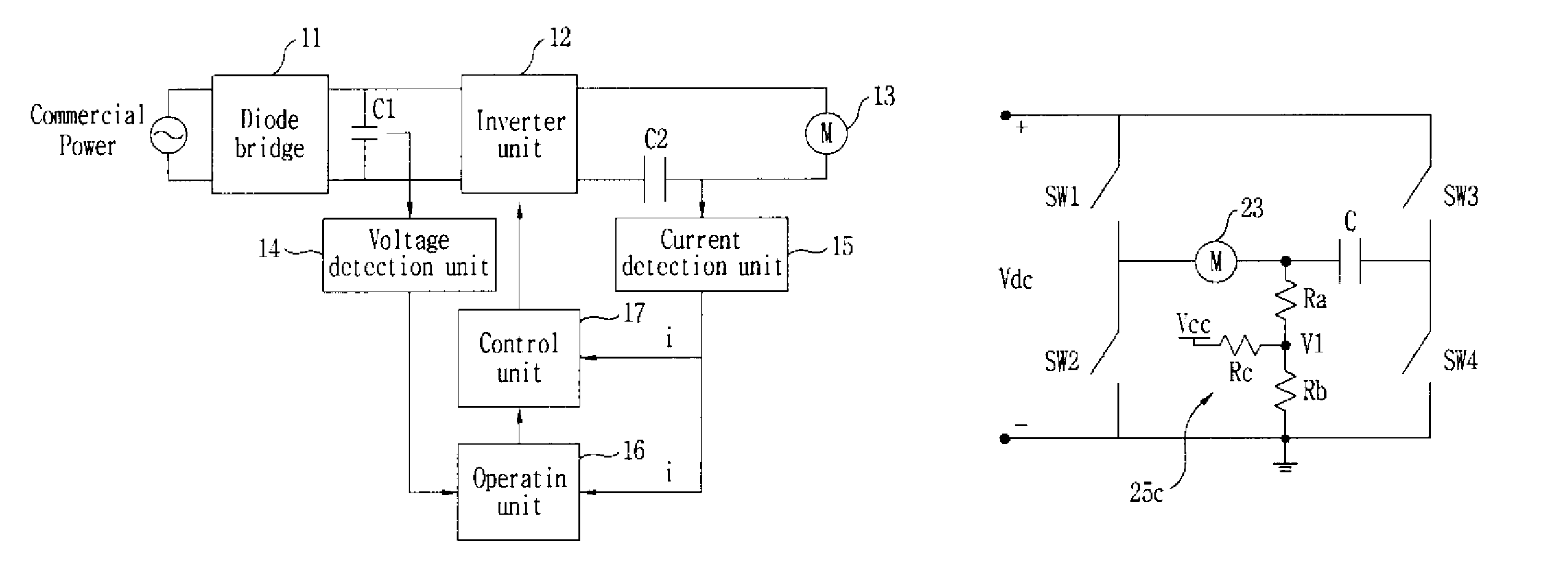

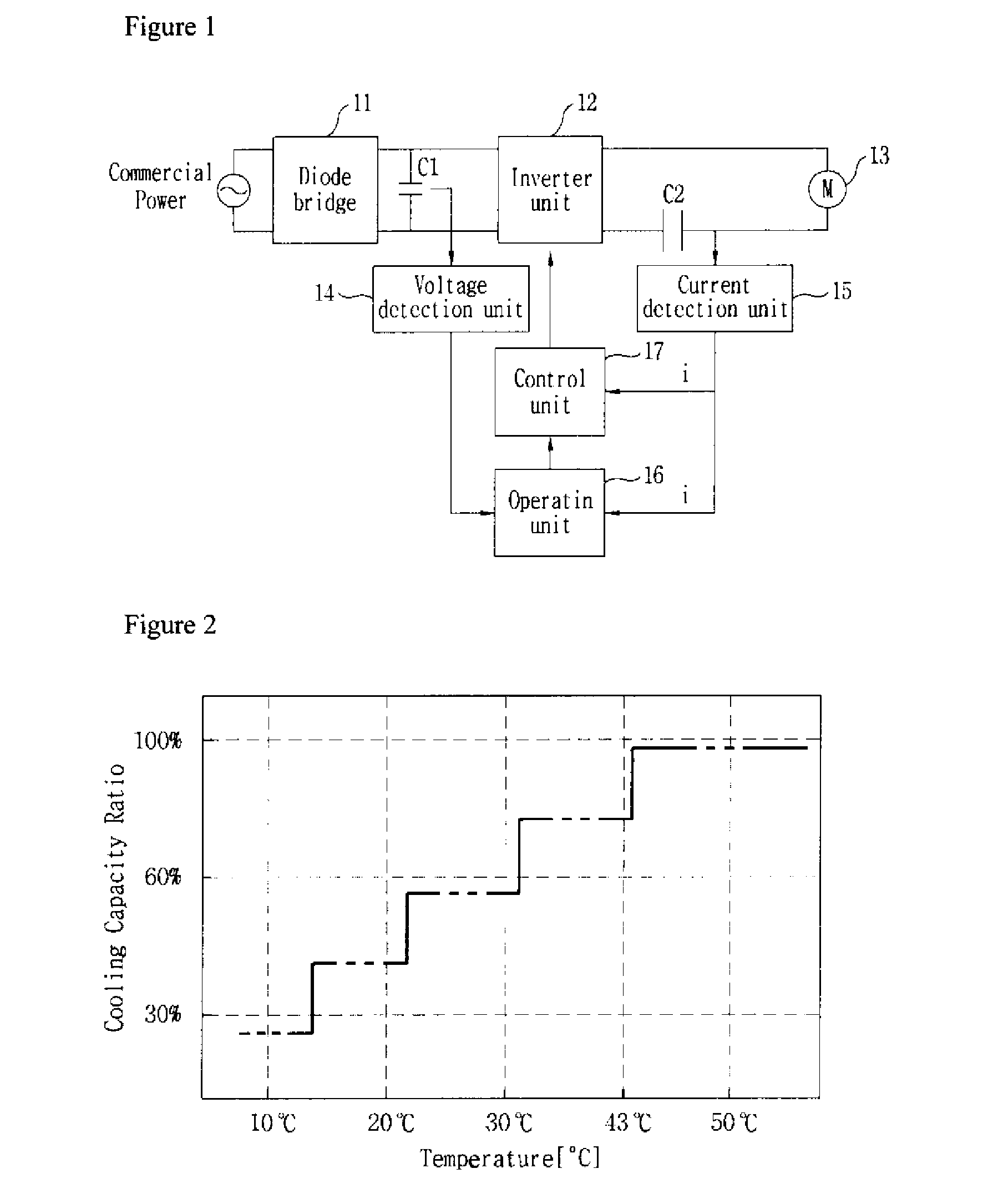

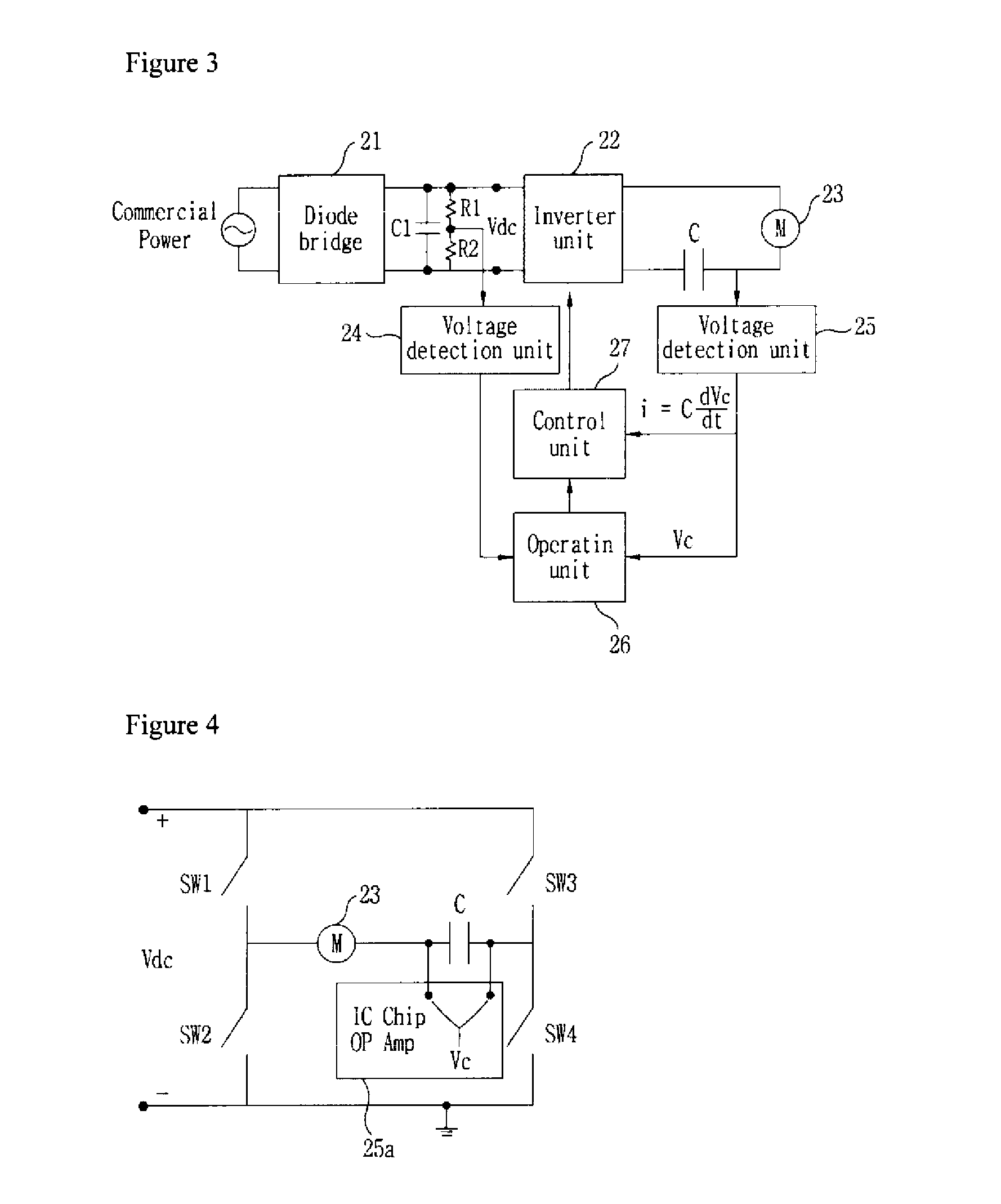

ActiveUS8858186B2Easy to controlReduce total powerPositive displacement pump componentsCompression machines with non-reversible cycleReciprocating motionLinear compressor

The present invention relates to a linear compressor, and more particularly, to a linear compressor which supplies a necessary cooling capacity through a natural cooling capacity modulation and a forcible cooling capacity modulation, and a cooling system using the same. The linear compressor according to the present invention includes a compression space into which refrigerant is sucked, a movable member which linearly reciprocates to compress the refrigerant sucked into the compression space, one or more springs which are installed to elastically support the movable member in a motion direction of the movable member, a motor unit which includes a motor and a capacitor connected in series to the motor so as to make the movable member linearly reciprocate, and a motor control unit which performs a natural cooling capacity modulation according to a load by reciprocation of the movable member.

Owner:LG ELECTRONICS INC

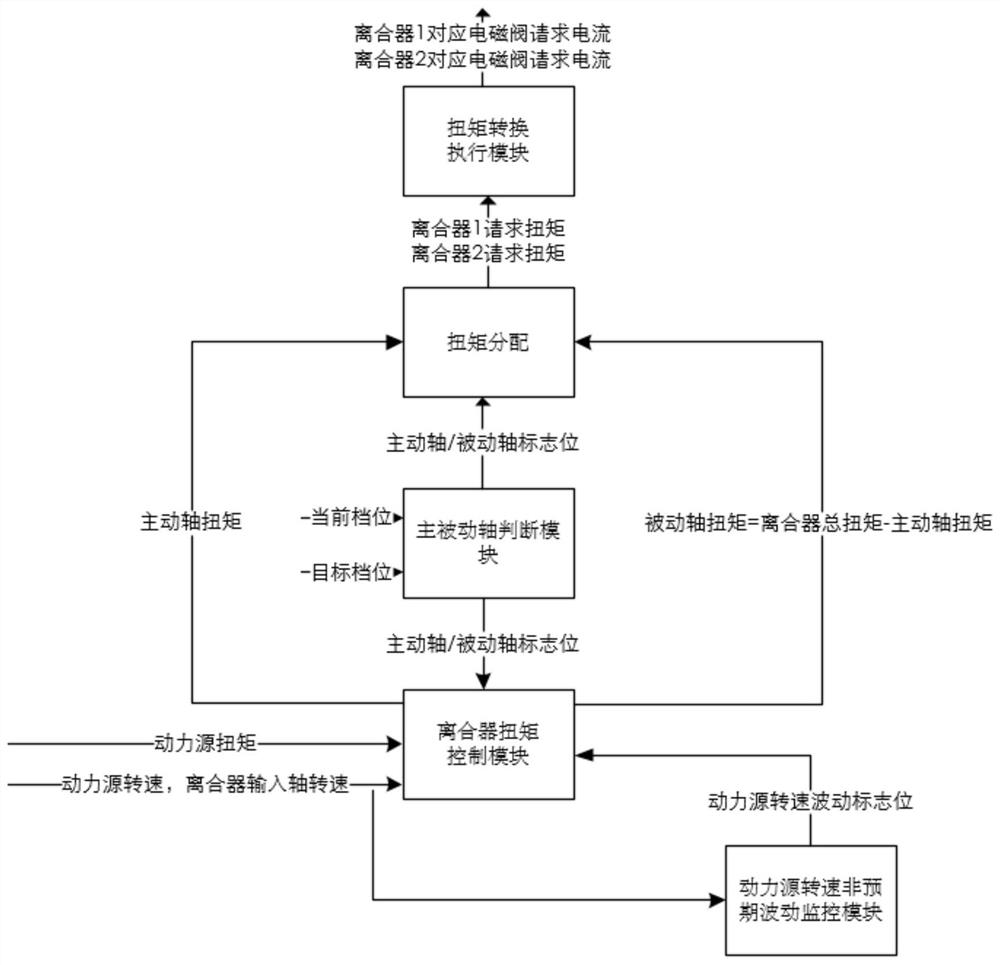

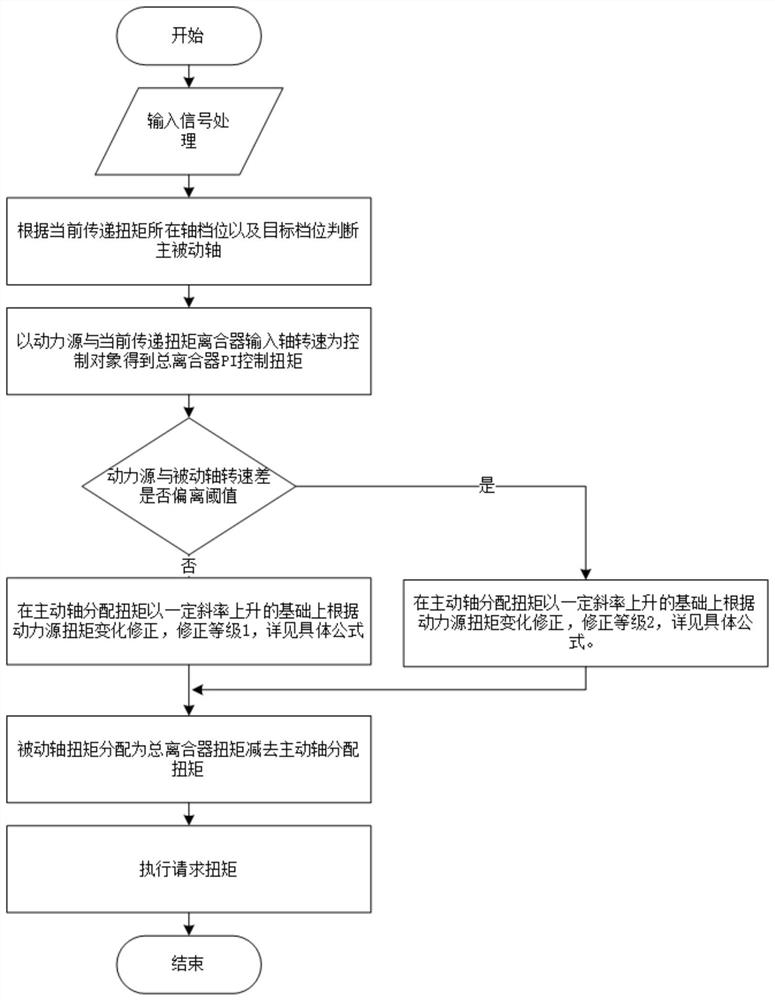

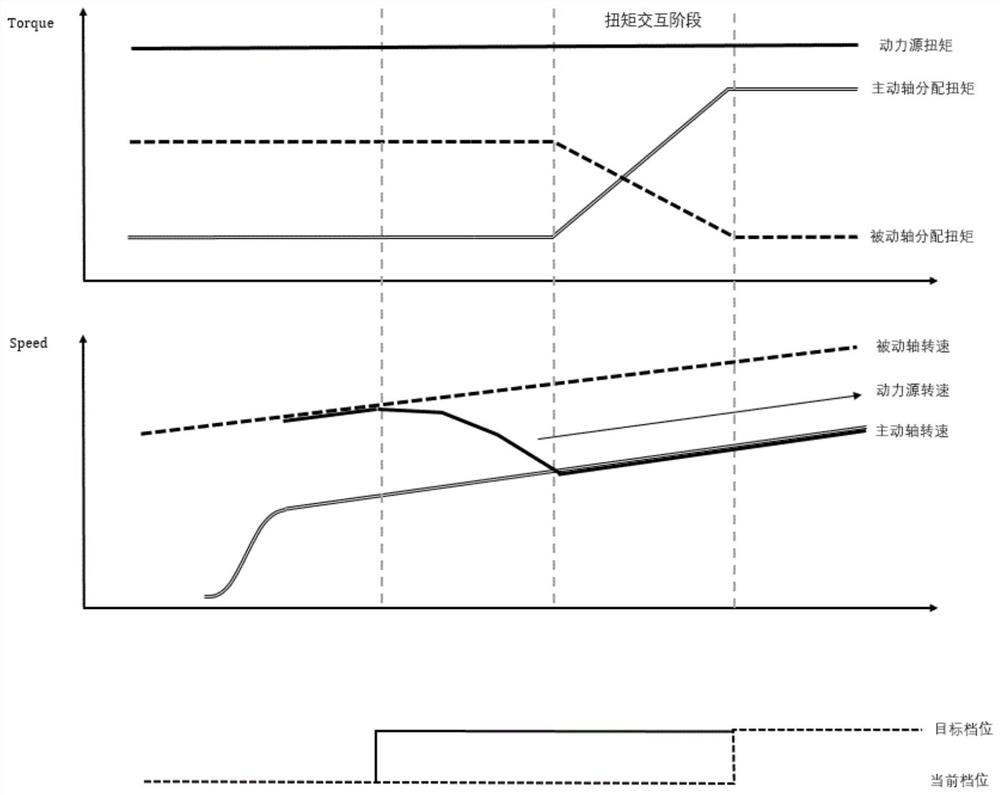

Double-clutch torque exchange control system and control method

ActiveCN113915246AAvoid speed fluctuationsReduce the frequency of power shocksClutchesGearing controlClutch controlDrive shaft

The invention discloses a double-clutch torque exchange control system and control method. The control system comprises a driving / driven shaft judgment module, a clutch torque control module, a torque conversion module and a power source monitoring module. The control method comprises the steps of processing an input signal and judging a driving shaft and a driven shaft; obtaining a main clutch control torque; according to the rotating speed difference between a power source and the driven shaft, determining different correction grades for driving shaft torque correction; obtaining torque distribution data of the driven shaft; and executing the request torque. According to the rotating speed difference between the power source and the driven shaft, different correction levels to correct the torque of the driving shaft is determined, the rotating speed of the power shaft and the rotating speed of the clutch driven shaft is monitored, whether the rotating speed difference between the rotating speed of a power shaft and the rotating speed of the clutch driven shaft exceeds a set threshold value or not is judged, the torque correction of the driving shaft is calculated by adopting different formulas, and meanwhile, the driven shaft torque is equal to total clutch torque minus driving shaft torque. According to the method, the Tie-Up or engine rotating speed fluctuation condition can be avoided.

Owner:江苏新能源汽车研究院有限公司

A method and device for on-off and off-grid switching of a microgrid battery energy storage system

ActiveCN108448607BEnsure power supply reliabilityImprove power qualityFlexible AC transmissionSingle network parallel feeding arrangementsPower qualityMicrogrid

The present invention provides a grid-connected and off-grid switching method and device for a battery energy storage system of a micro-grid, which includes, during grid-connected operation, according to the positive and negative sequence components of the grid-connected point voltage under the PQ control mode and the positive and negative sequence components of the inverter output current Sequence components are used to calculate the current and voltage values of the inner loop of the current to control the output power of the inverter; at the moment when the grid is connected to the grid, the VF control mode adopts the state-following method, and the grid output power is transferred through the added power compensation control link to the inverter; when running off-grid, the voltage outer loop under VF control mode provides voltage and frequency support for the system; the device includes a PQ control module and a VF control module. The technical solution provided by the invention realizes the control of the negative sequence voltage during off-grid switching, ensures the reliability of power supply, and improves the quality of electric energy.

Owner:CHINA ELECTRIC POWER RES INST +2

Electric Vehicle Electromagnetic Torque Drive System

ActiveCN105730217BAchieve self-adaptionReduce power shockElectric devicesPropulsion by batteries/cellsSynchronous motorElectronic controller

The invention relates to a driving system of an electric vehicle, in particular to an electromagnetic variable-torque driving system of an electric vehicle. The electromagnetic variable-torque driving system comprises an electromagnetic variable-torque driving device, a power cell, an electronic controller, a three-phase bridge type full control inverter circuit and a three-phase rectification circuit, wherein the electromagnetic variable-torque driving device comprises a three-phase separate excitation type synchronous motor and an electromagnetic variable-torque motor, and a rotor of the three-phase separate excitation type synchronous motor is connected with an inner rotor of the electromagnetic variable-torque motor; the power cell is connected with an input end of the three-phase bridge type full control inverter circuit, and an output end of the three-phase bridge type full control inverter circuit is connected with an armature winding of the three-phase separate excitation type synchronous motor; a magnetic pole winding of the inner rotor of the electromagnetic variable-torque motor is connected with an excitation winding of the three-phase separate excitation type synchronous motor through the three-phase rectification circuit, and an outer rotor of the electromagnetic variable-torque motor is connected with a hub. According to the electromagnetic variable-torque driving system disclosed by the invention, a completely new concept of electromagnetic variable-torque drive is provided, the electromagnetic variable-torque drive is realized through a specific structure, and an electric wheel of the electromagnetic variable-toque drive can have a great market application prospect.

Owner:DATONG YULONG ENVIRONMENTAL PROTECTION

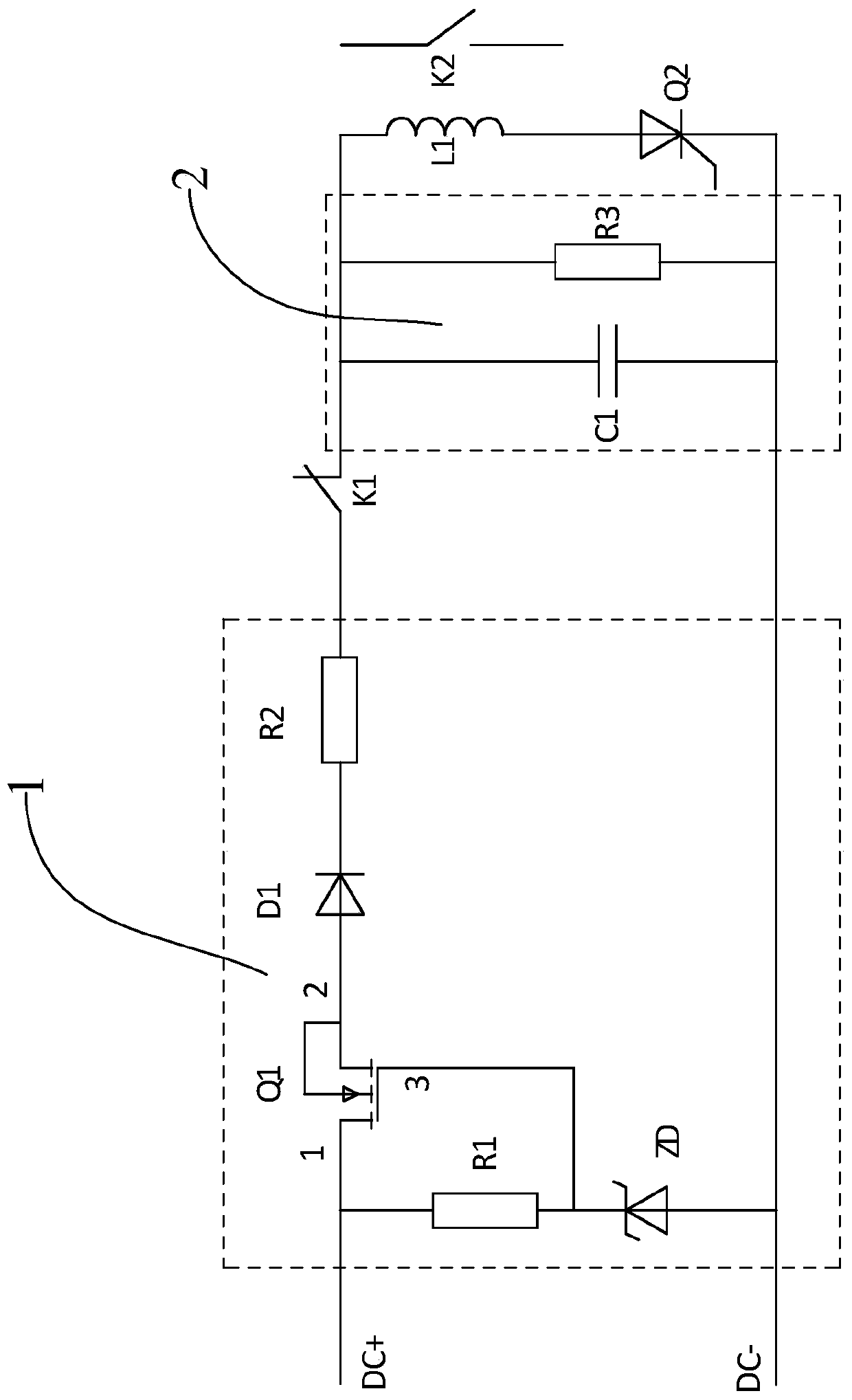

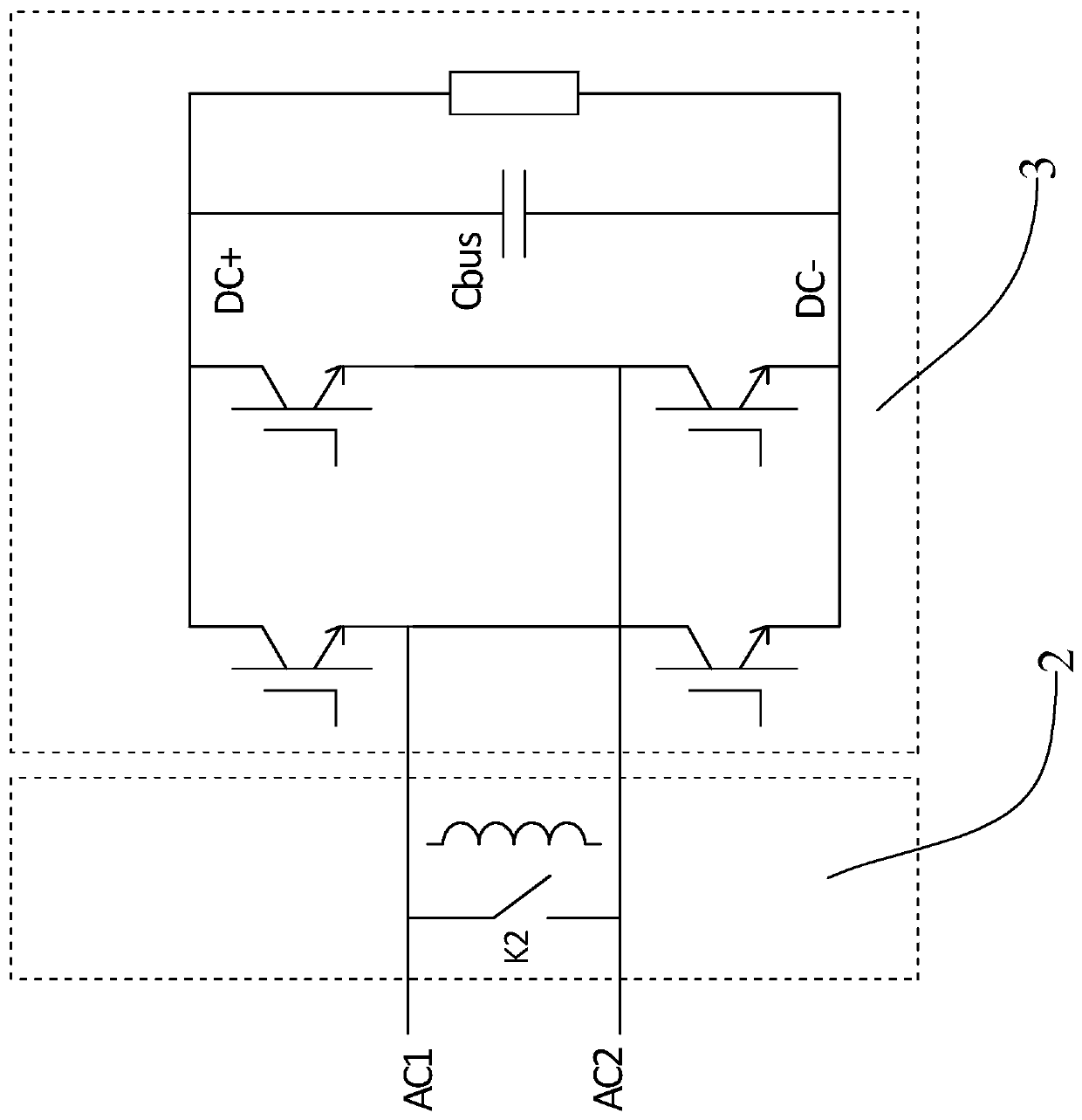

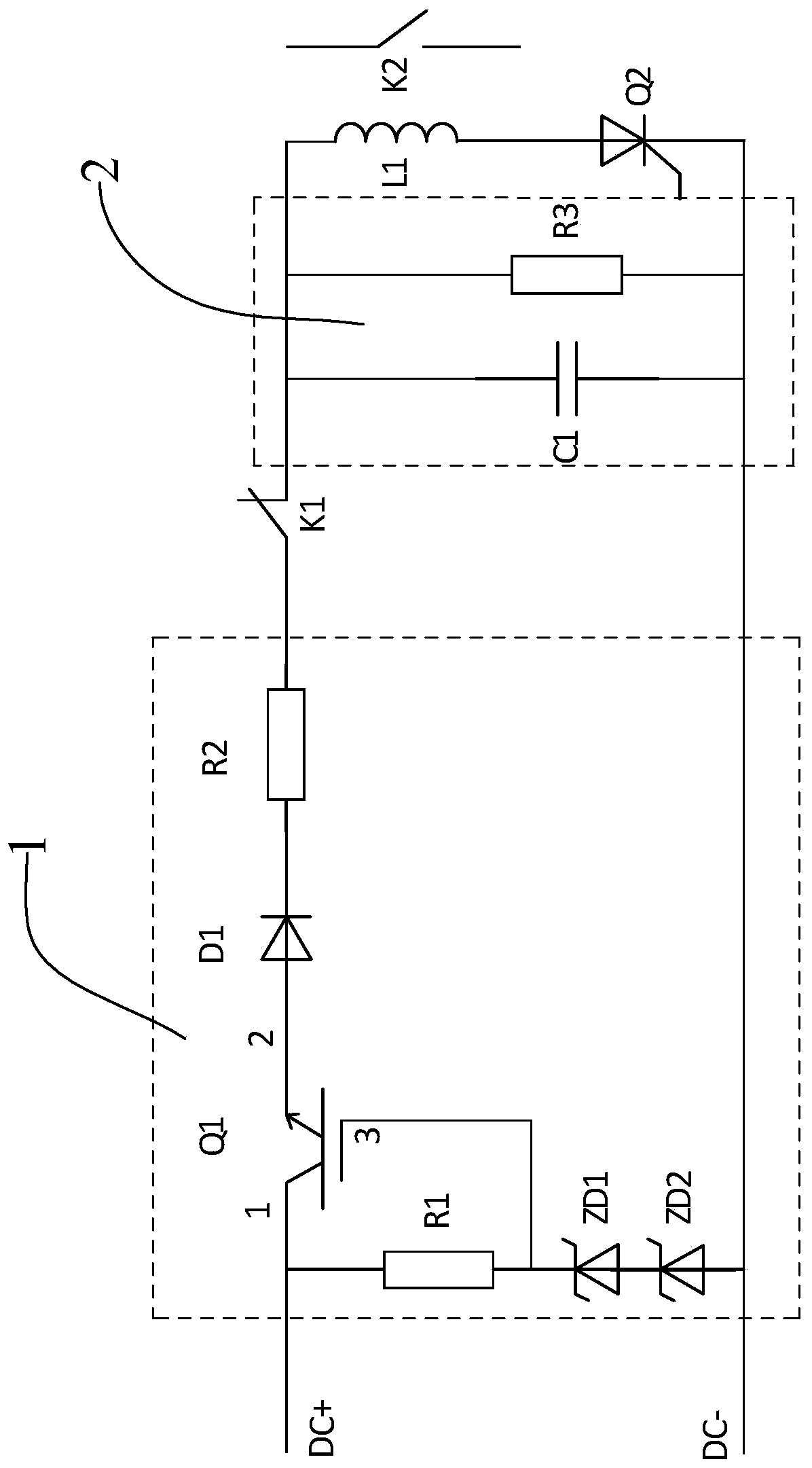

Switch driving circuit and multi-level cascaded power unit topology using same

PendingCN110707914AReduce power shockClose reliableAc-dc conversionDc-dc conversionControl signalControl engineering

The invention discloses a switch driving circuit and a multi-level cascaded power unit topology using the same. The switch driving circuit is characterized by comprising a charging switch K1, an energy storage linear discharging assembly, a driving coil L1 and a controllable switch Q2, wherein an external power supply is electrically connected with the energy storage linear discharging assembly through the charging switch K1 to form a charging loop, the driving coil L1 can drive an external bypass contact switch K2, and the controllable switch Q2 can be switched on and off according to an external control signal; the driving coil L1 and the controllable switch Q2 are connected in series to form a series branch, and the series branch is connected with the energy storage linear discharge assembly to form a power supply loop. By reasonably controlling the controllable switch Q2, the reliable switching-on of the bypass can be realized. Meanwhile, the design is simplified, the design cost is reduced, and the very high reliability and practicability are achieved.

Owner:GUANGDONG UNLIMITED POWER CO LTD

A motor torque zero-crossing anti-shake control method for new energy vehicles

ActiveCN111731111BSmooth torque changeReduce power shockSpeed controllerElectric energy managementVehicle dynamicsNew energy

The invention relates to a motor torque zero-crossing anti-shake control method for a new energy vehicle. Step 1: judging whether the motor torque is in a zero-crossing condition; step 2: limiting the torque output slope to reduce the torque zero-crossing shock; step 3: Judging whether the requested torque has a zero-crossing condition again within the time limit of the torque output slope; Step 4: Judging whether the time limit of the torque output slope has expired; Step 5: Judging whether the difference between the requested torque and the torque after passing the limit torque output slope is not is less than the first preset threshold; Step 6: use the follow-up control algorithm to obtain the output torque; Step 7: determine whether the difference between the current output torque and the requested torque is less than the second preset threshold; Step 8: complete the torque zero-crossing control, and return to the step 1. Wait for the next torque zero-crossing condition. Compared with the prior art, the present invention has the advantages of predictable torque zero-crossing conditions, faster torque response speed, improved driving experience and vehicle dynamics.

Owner:DELPHI TECH SUZHOU CO LTD

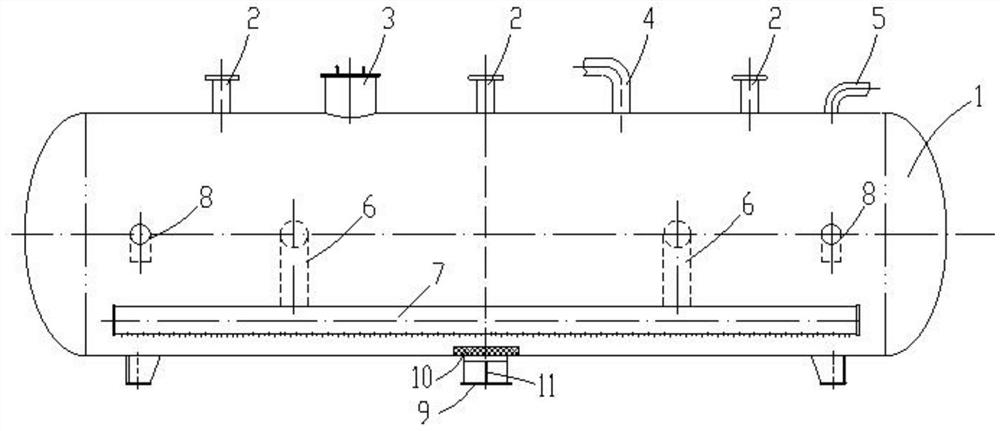

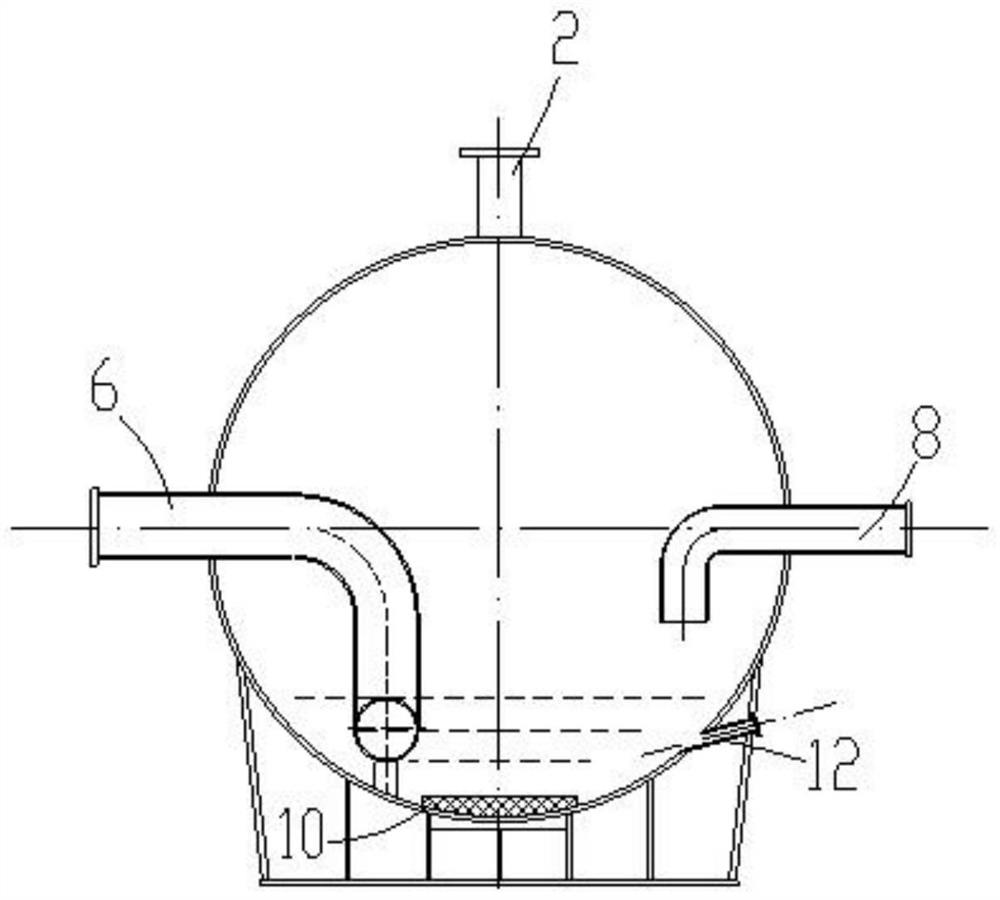

Outlet buffer tank of fused salt heat absorber

ActiveCN114111070ARun fastReduce power shockSolar heating energySolar heat collector controllersBuffer tankMolten salt

The invention discloses an outlet buffer tank of a fused salt heat absorber, which is connected with a heat absorber tube panel outlet pipeline through a tube panel outlet pipeline inlet pipe interface. The end portion, arranged in the outlet buffer tank, of the inlet pipe connector of the pipe panel outlet pipeline is connected with a distribution header which is arranged at the bottom in the outlet buffer tank and arranged in the axial direction of a tank body of the outlet buffer tank, and a plurality of nozzles are formed in the distribution header in the axial direction of the distribution header. Molten salt heated by the heat absorber enters the distribution header through a tube panel outlet pipeline introduction pipe connector and enters the outlet buffer tank through a plurality of nozzles in the distribution header. The outlet connecting pipe of the heat absorber is introduced into the tank body and connected with the distribution header, so that power impact of jet flow on the tank body can be reduced, sufficient disturbance and mixing of fluid of different loops of the heat absorber can be guaranteed, mixing of fused salt is enhanced, and on the premise that the operation requirement of a heat absorber system is met, the energy consumption is reduced. And the reliability and the safety of equipment operation are improved.

Owner:DONGFANG BOILER GROUP OF DONGFANG ELECTRIC CORP

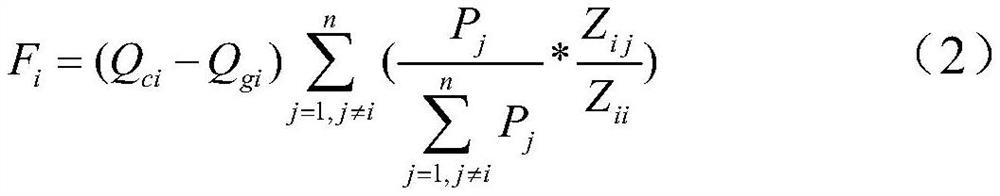

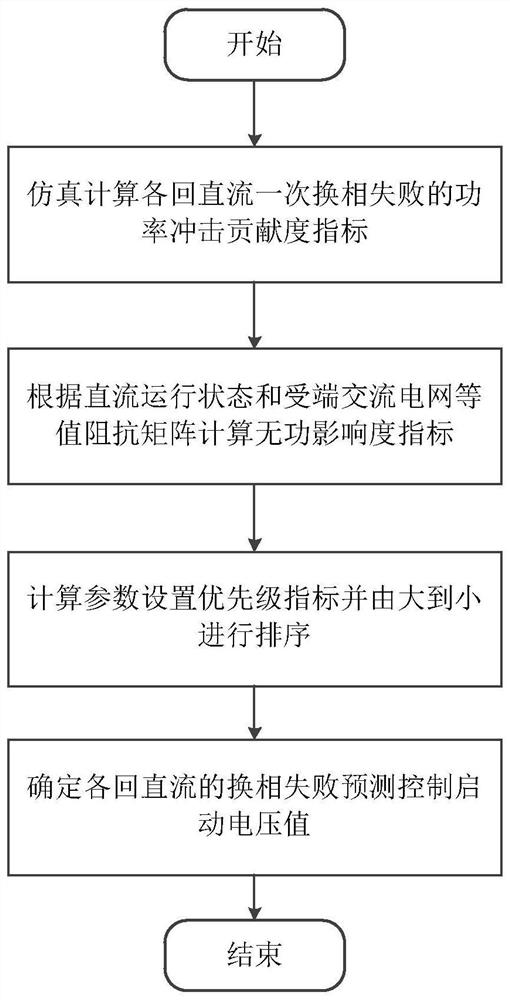

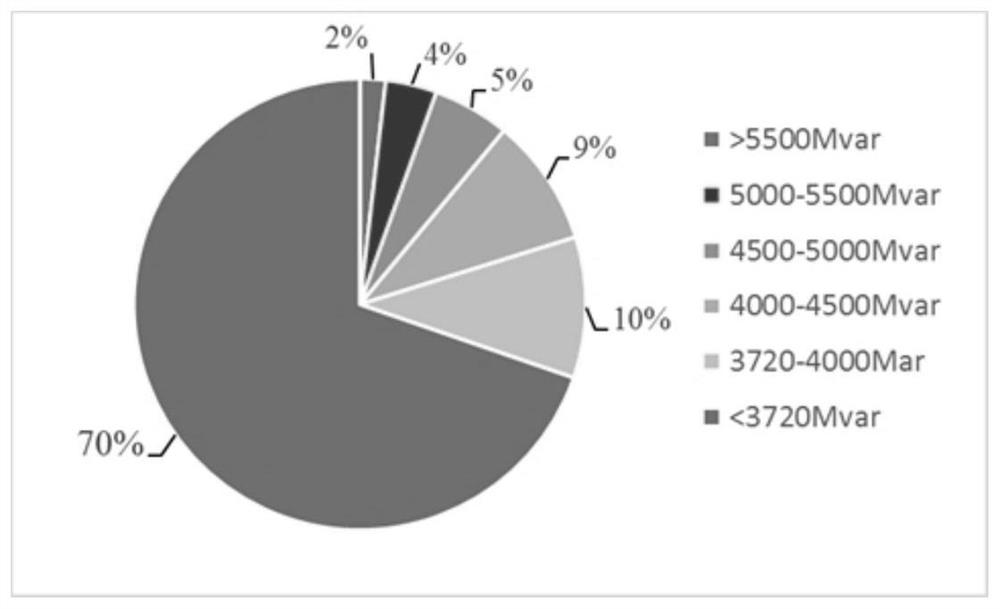

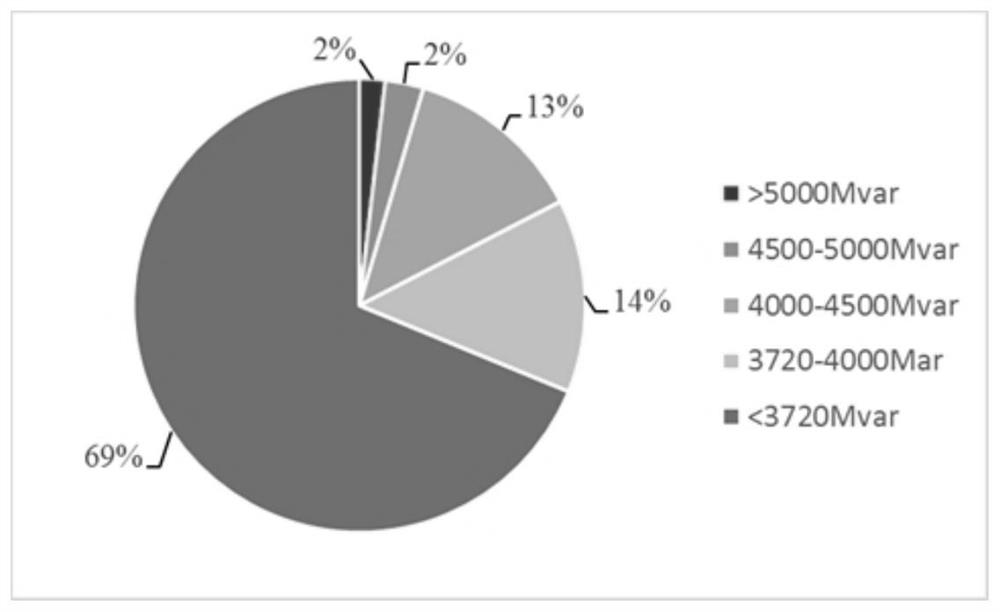

A start-up voltage value optimization method for commutation failure predictive control

InactiveCN110635503BReduce power shockElectric power transfer ac networkAc network voltage adjustmentAC - Alternating currentControl engineering

The invention discloses a commutation failure prediction control starting voltage value optimization method, which comprises the following steps of: simulating and calculating the power impact of primary commutation failure of each loop of direct current, and calculating a power impact contribution degree index, calculating a reactive influence degree index according to the direct-current operation state and the equivalent impedance matrix of the receiving-end alternating-current power grid, calculating parameter setting priority indexes, and sorting the indexes from large to small, and determining a commutation failure prediction control starting voltage value of each loop of direct current. The method provided by the invention can effectively reduce the overall power impact caused by commutation failure, and avoids adverse effects on the voltage stability of the receiving-end alternating-current power grid caused by overlarge multi-loop direct-current reactive power demand at the same time.

Owner:SOUTHEAST UNIV +1

A distributed collaborative absorption method for braking energy in urban rail transit

Owner:CHINA CREC RAILWAY ELECTRIFICATION BUREAU GRP

Maximum power tracing method and device

ActiveCN107992154AReduce power shockPhotovoltaic energy generationElectric variable regulationEngineeringSolar battery

The application provides a maximum power tracing method and a maximum power tracing device. The method includes steps of monitoring output power and PV voltage of a solar panel according to the setting frequency; calculating to obtain adjusting step base of the PV voltage according to the monitored output power and the PV voltage of the solar panel; adjusting the counting value of MPPT according to the output power of the solar battery this time, the output power detected last time and preset minimum power adjusting value; adjusting the PV reference voltage on the basis of the adjusting step base according to the comparison result of the adjusted counting value of MPPT and the set MPPT reference value; using the PV reference voltage as the control target of a past-grade power circuit. Themaximum power tracing method and device have the advantages of realizing the purpose of reducing the power oscillation of the MPPT maximum power tracing.

Owner:深圳市英威腾光伏科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com