Road surface cutting equipment and method for road construction

A cutting equipment and road surface technology, which is applied in the direction of roads, roads, road repairs, etc., can solve the problems of large diameter cutting blades, cutting and cleaning at the corners of difficult road surface depressions, and the guide wheels can not leave cutting marks, etc., so as to reduce vibration and Impact, reduction of consumables usage cost, and effect of simplifying equipment usage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

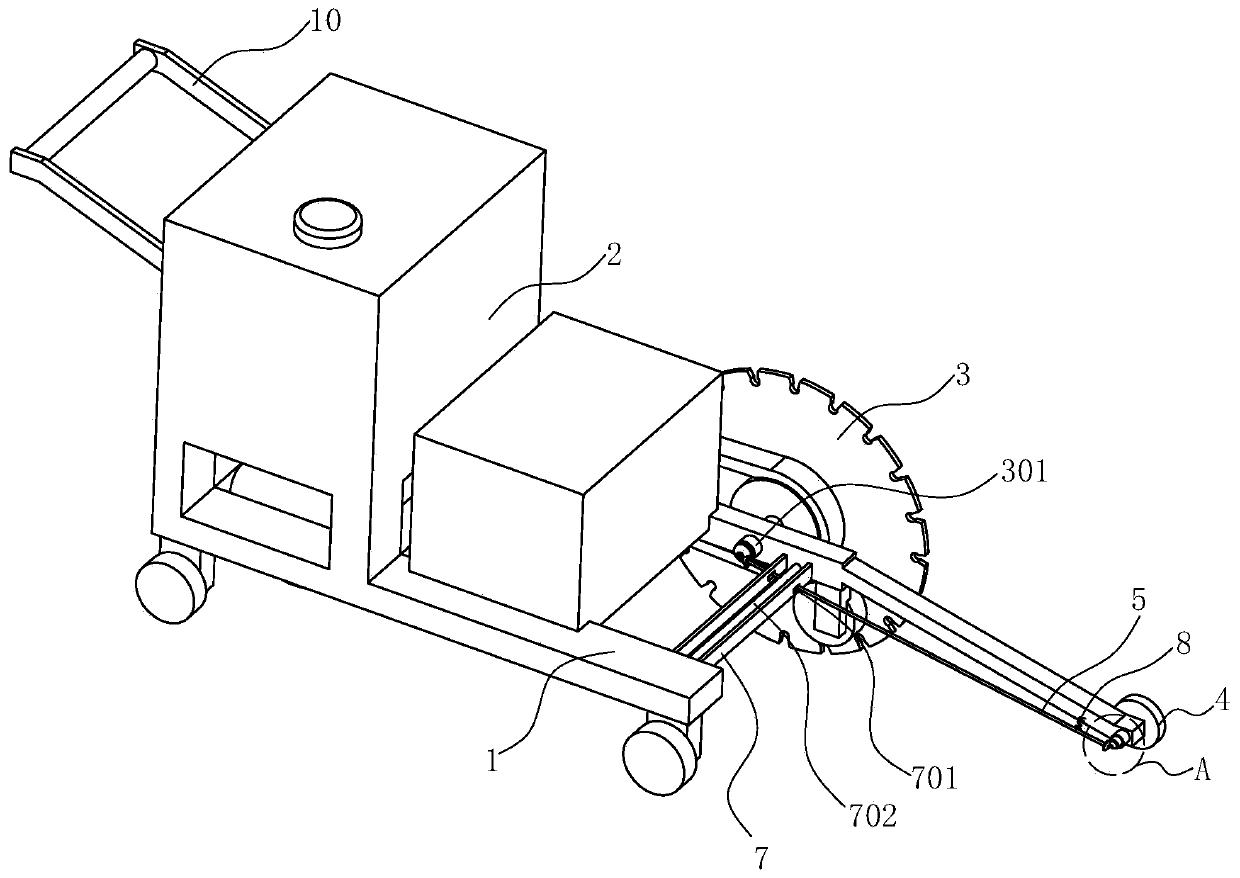

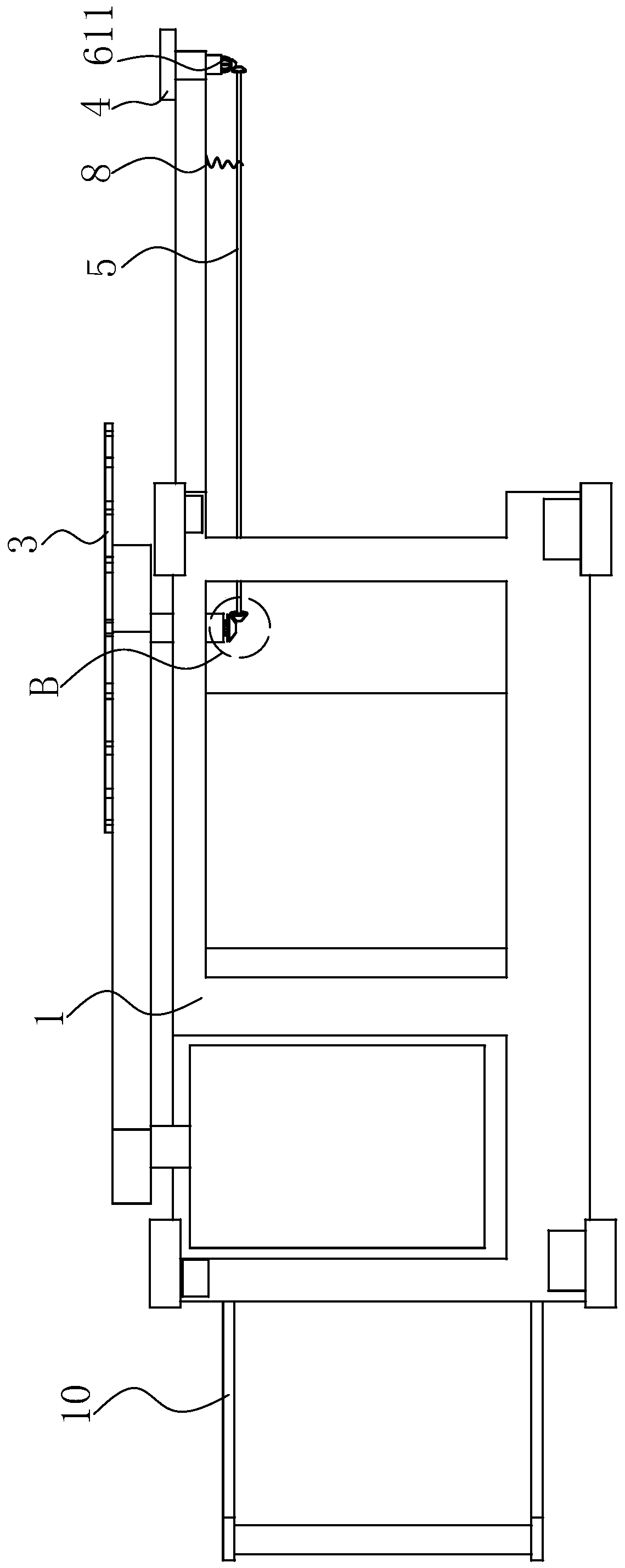

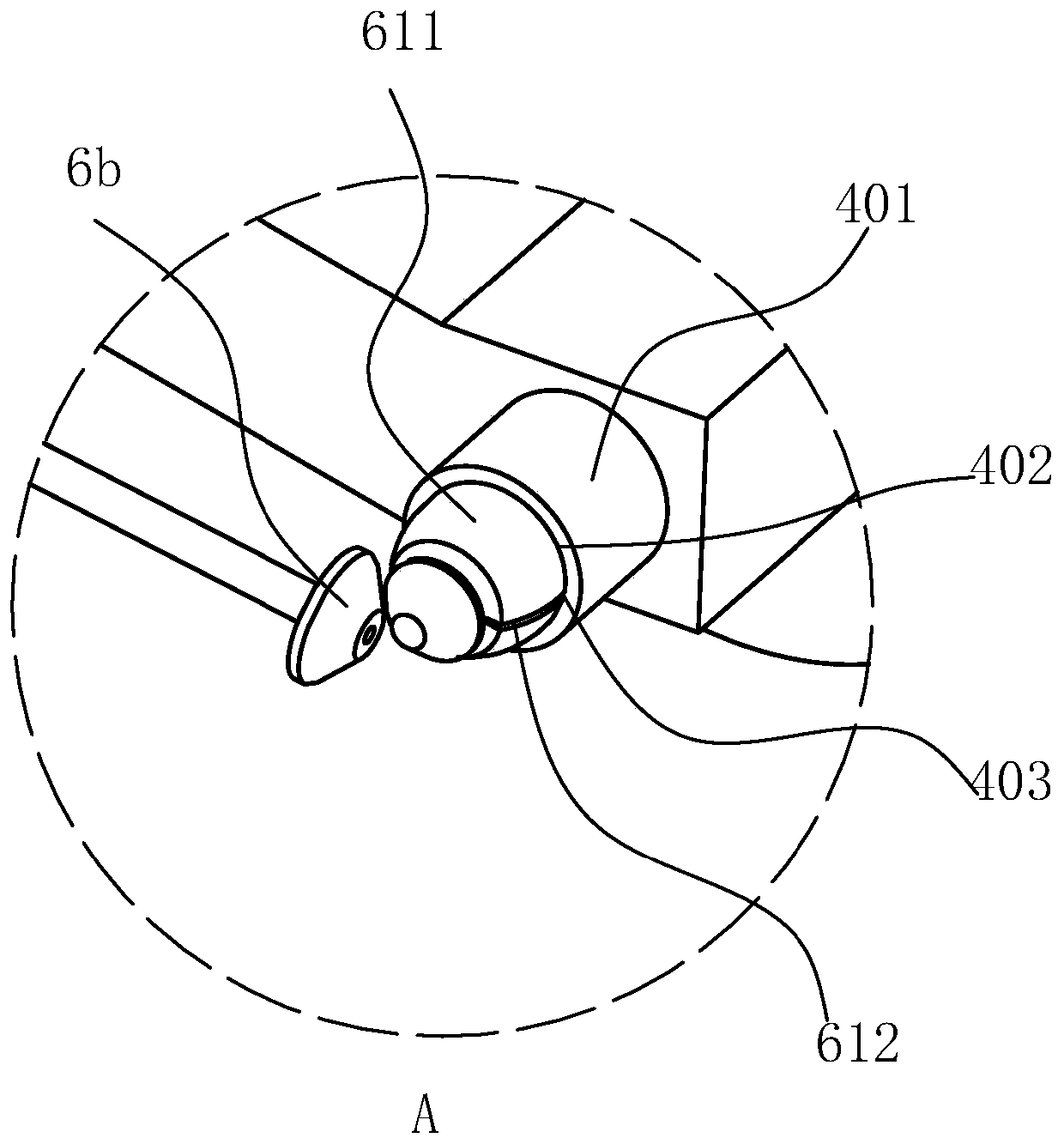

[0049] like Figure 1 to Figure 6 As shown, a road surface cutting equipment for road construction includes a frame body 1, a driving machine 2 and a cutting blade 3 driven by the driving machine 2 are installed on the frame body 1, and guide wheels are installed on the front part of the frame body 1 4. The guide wheel 4 is coplanar with the cutting blade 3, and the guide wheel 4 and the cutting blade 3 are respectively supported by the guide shaft 401 and the saw blade shaft 301 that are movably installed on the frame body 1. The frame body 1 is provided with Connect the drive shaft 5 of the cutting piece 3 and the guide wheel 4, a tension spring 8 is arranged between the frame body 1 and the drive shaft 5, and the end of the drive shaft 5 close to the guide wheel 4 is always connected with the drive by the tension spring 8 The mechanism connection of the guide shaft 401 realizes the purpose of using only one set of driving equipment to control the power transmission process ...

Embodiment 2

[0061] like Figure 7 As shown, on the basis that the basic technical solution of Embodiment 1 remains unchanged, the spring groove 602 is arranged along the axial direction of the protruding part 601, and the groove bottom surface of the first groove 302 is provided with a The arc-shaped pit 304, using the arc-shaped pit 304 to increase the friction between the ball 9 and the first groove 302, prevent the ball 9 from completely eliminating the driving force between the two, and appropriately increase the protrusion of the saw blade shaft 301 Part 601 of the driving force.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com