Patents

Literature

51results about How to "Avoid speed fluctuations" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

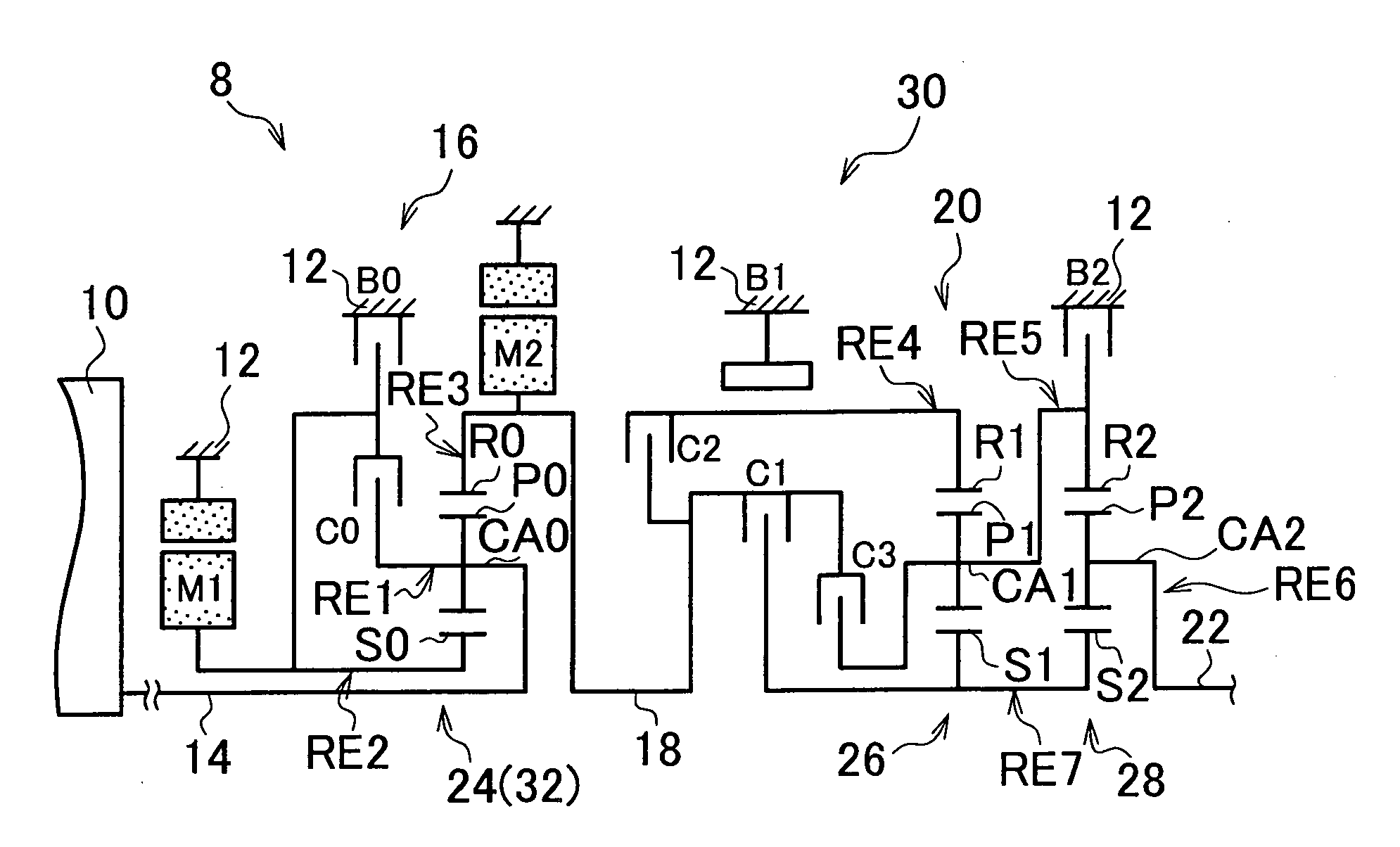

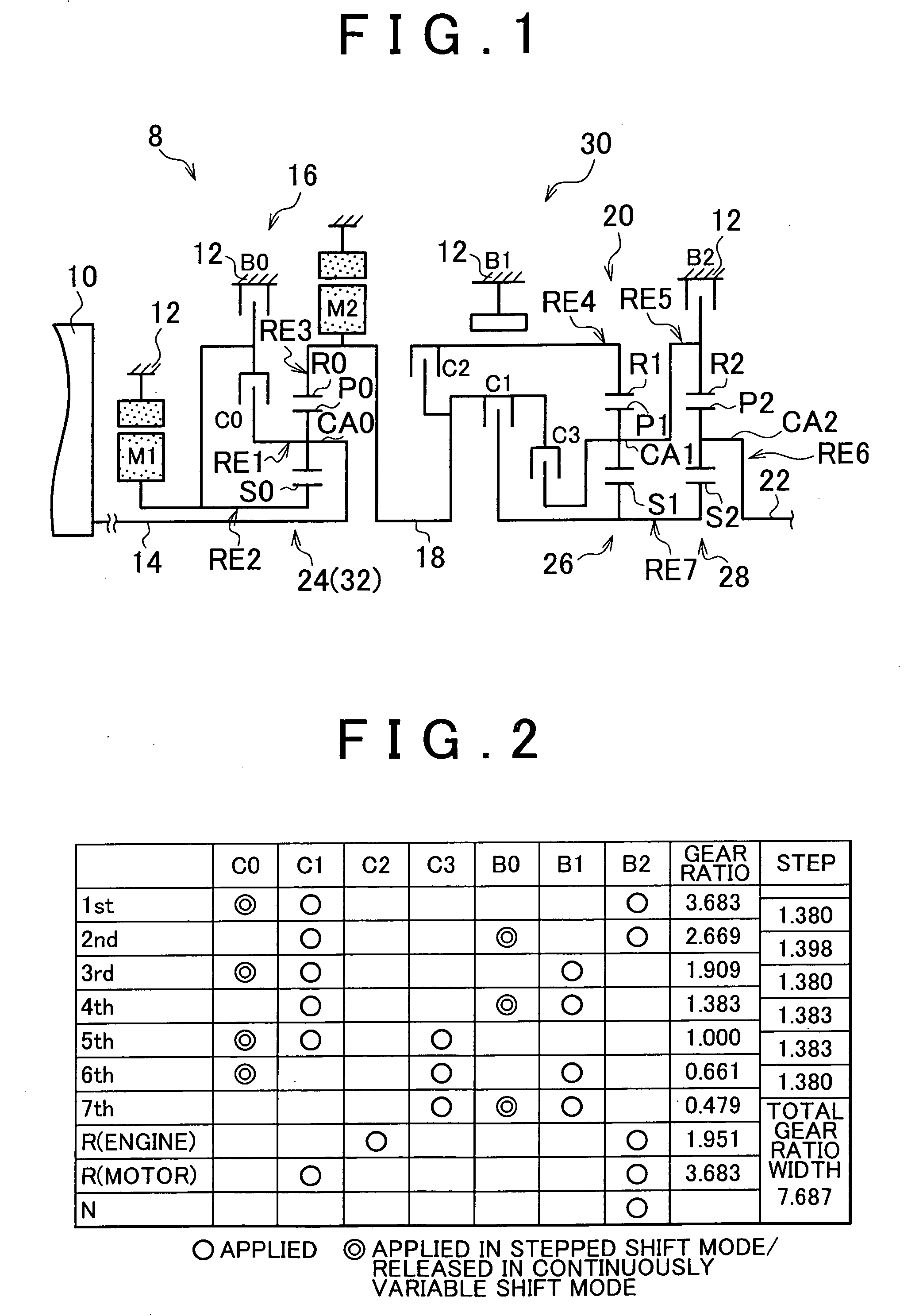

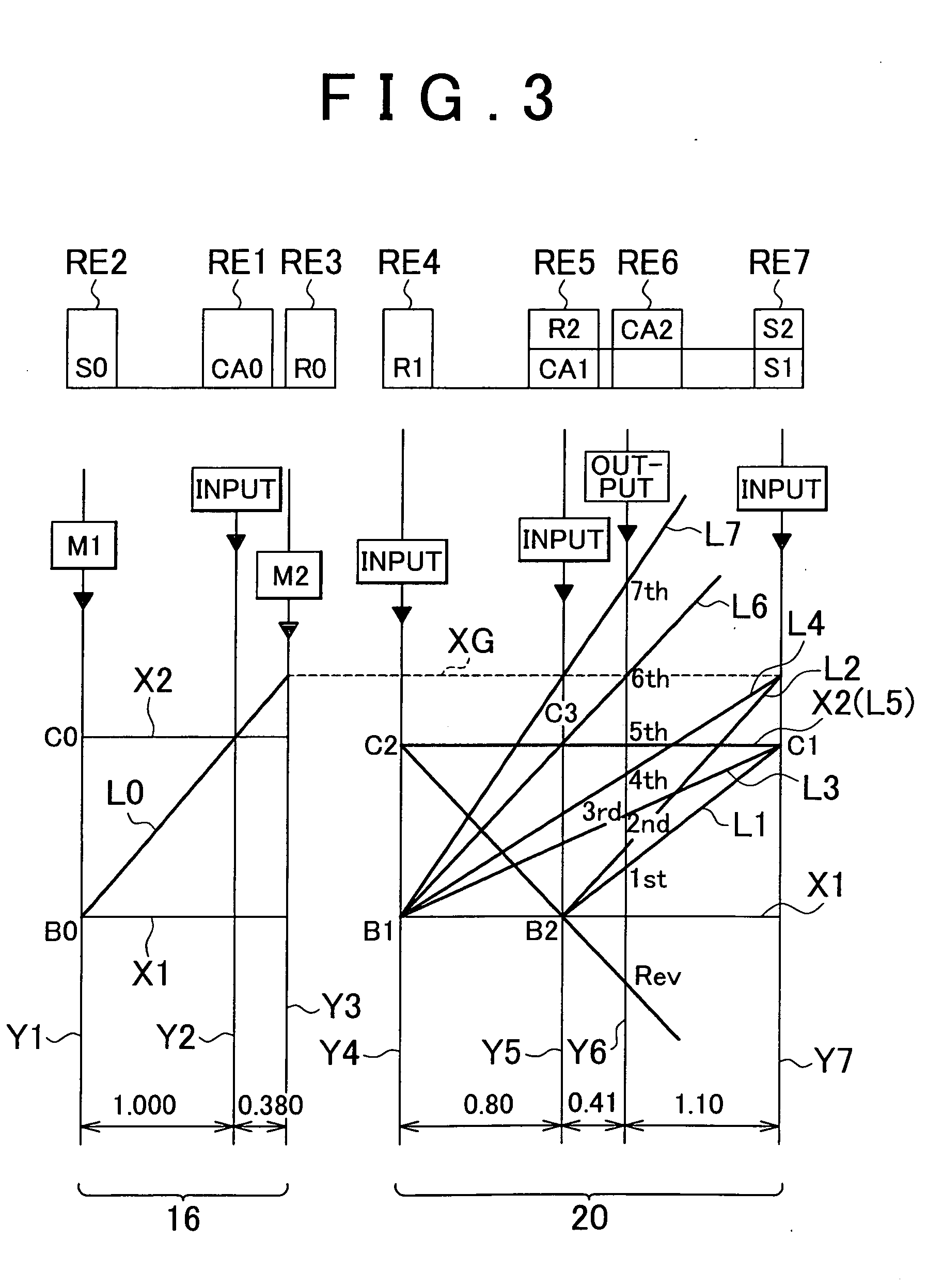

Power transmission apparatus for vehicle

InactiveUS20090156359A1Avoid speed fluctuationsShifting gears smoothlyHybrid vehiclesPropulsion using engine-driven generatorsGear ratioControl unit

A power transmission apparatus for a vehicle includes a main drive power source; a first shift unit that has an input shaft connected to the main drive power source; a second shift unit; at least one electric motor connected to a rotating element of the first shift unit or a rotating element of the second shift unit so that the rotational speed of the electric motor is changed in accordance with a gear-shift of the first shift unit or the second shift unit, and that is able to control the rotational speed of the main drive power source by changing its rotation; and a control unit that executes control so that the direction in which the rotational speed of the main drive power source is changed is maintained constant throughout a gear-shift, when the gear-shift is a simultaneous gear-shift in which the gear-shift of the first shift unit and the gear-shift of the second shift unit are performed simultaneously and a gear ratio of the first shift unit and a gear ratio of the second shift unit are changed in opposite directions. With the control executed by the control unit, it is possible to effectively suppress occurrence of shift shock.

Owner:TOYOTA JIDOSHA KK

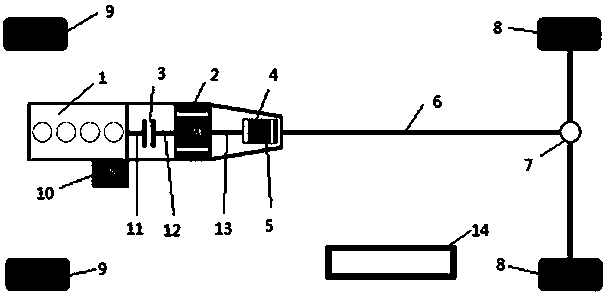

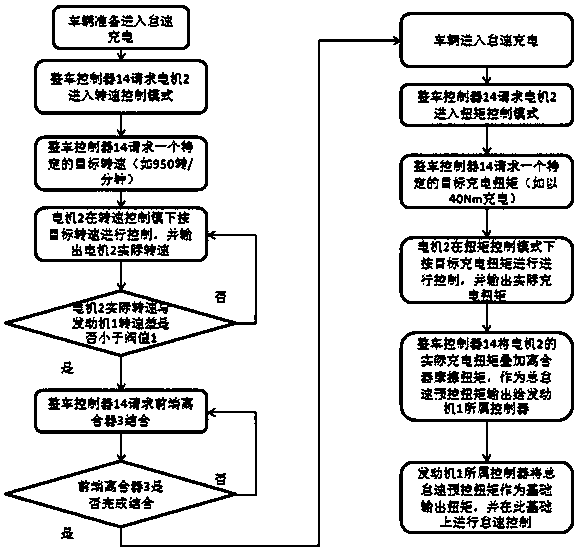

Hybrid electric vehicle power assembly control method used for series structure

ActiveCN108622072AAvoid speed fluctuationsImprove fuel economyHybrid vehiclesInternal combustion piston enginesElectric machineryIdle speed

The invention discloses a hybrid electric vehicle power assembly control method used for a series structure. When a vehicle is static, in the process that an engine enters in an idle speed charging working condition from a no-load idle speed working condition, a motor can quickly work to the rotation speed close to that of the engine in a rotation speed control mode, then in combination with a front-end clutch, rotation speed fluctuation of the engine can be greatly avoided, and the fuel economy of the engine is improved. When the vehicle is static, in the process that the engine enters in a vehicle starting working condition from the idle speed charging working condition, the charging torque of the motor is reduced to 0 firstly, then the front-end clutch is disengaged, the motor quickly works to the 0 rotation speed in the rotation speed control mode, then a gearbox is combined with a gear-shifting clutch, power output delay generated in the starting process can be greatly reduced, and the driving feeling is improved. The problems of engine rotation speed impact generated when the front-end clutch of the hybrid electric vehicle of the series structure is engaged and power transmission delay generated when the front-end clutch of the hybrid electric vehicle of the series structure is disengaged are solved.

Owner:SAIC MOTOR

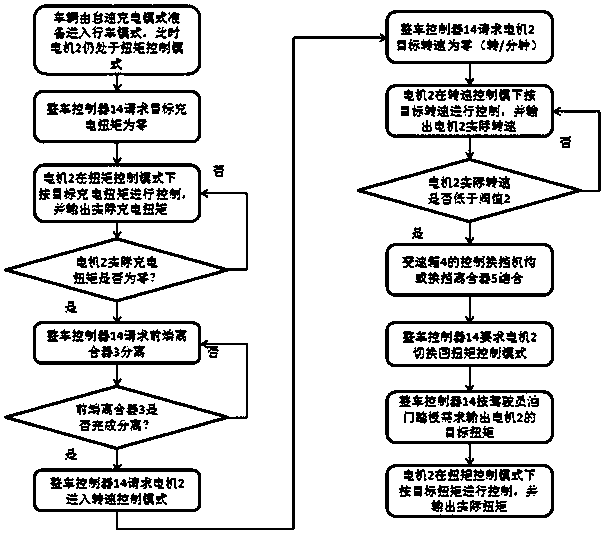

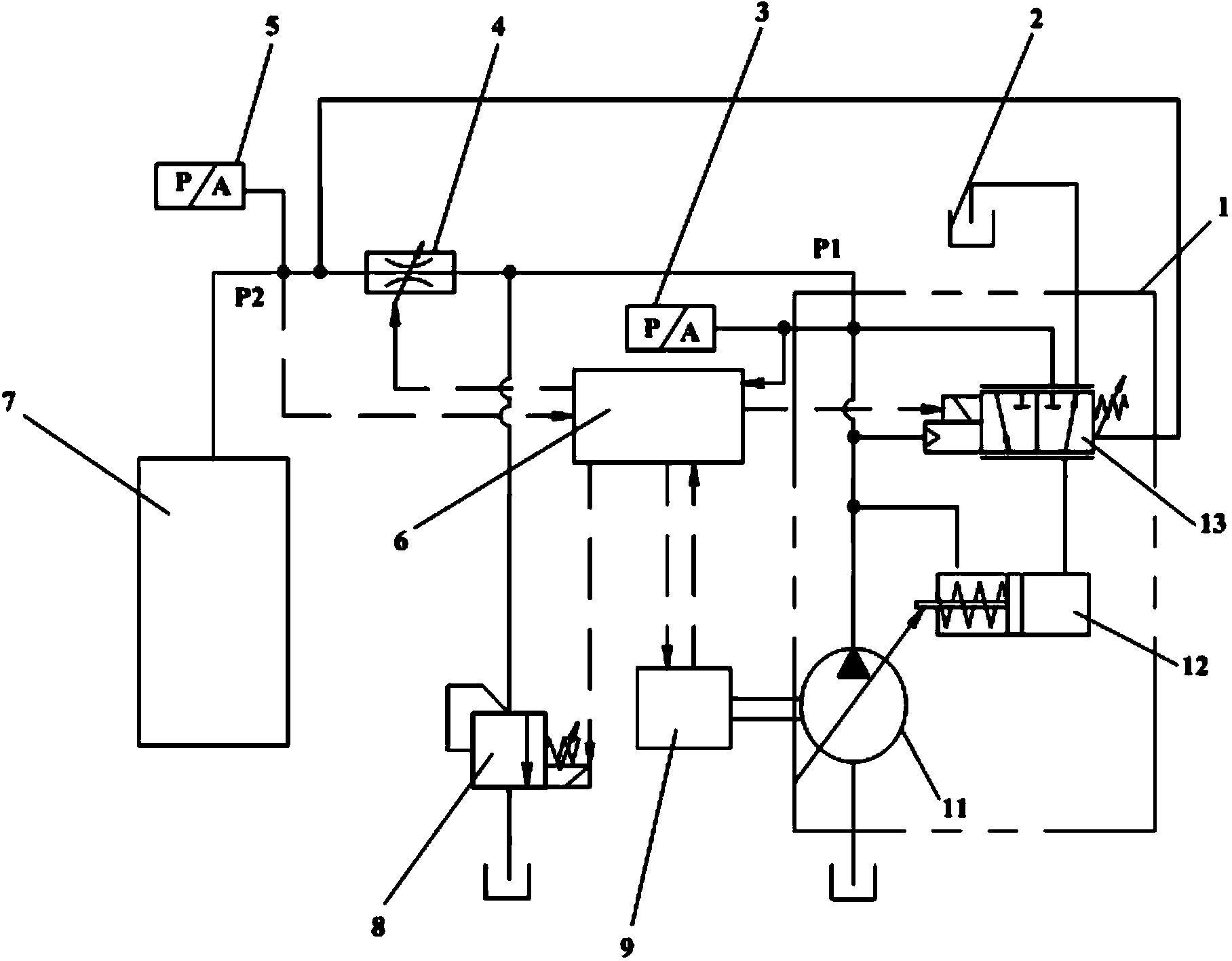

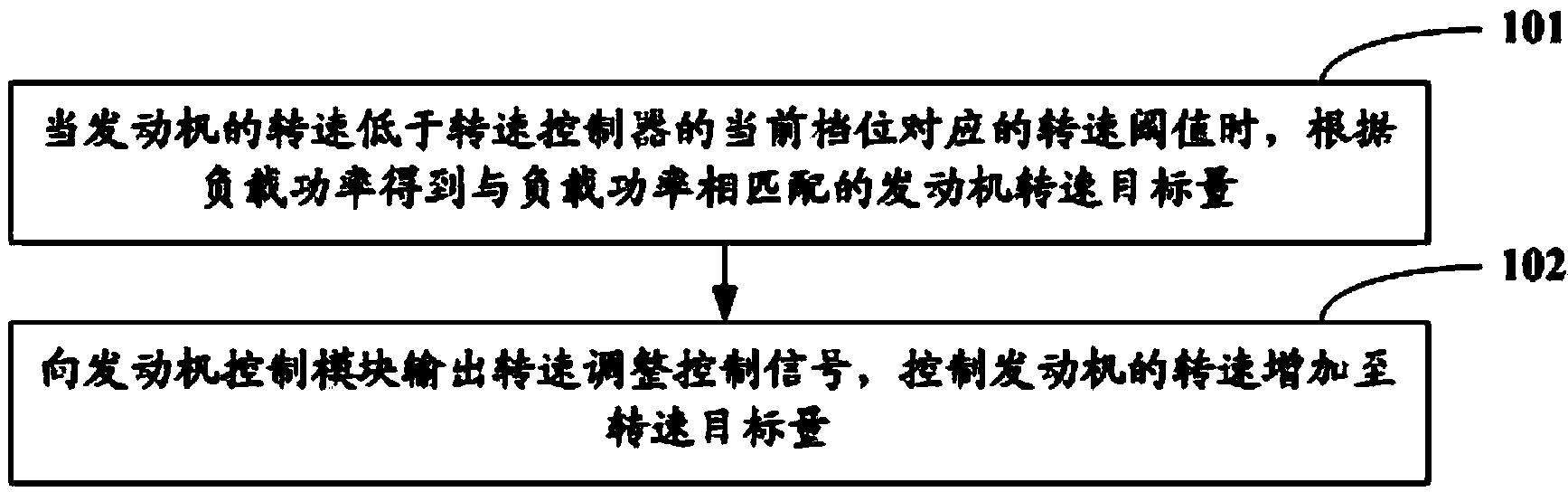

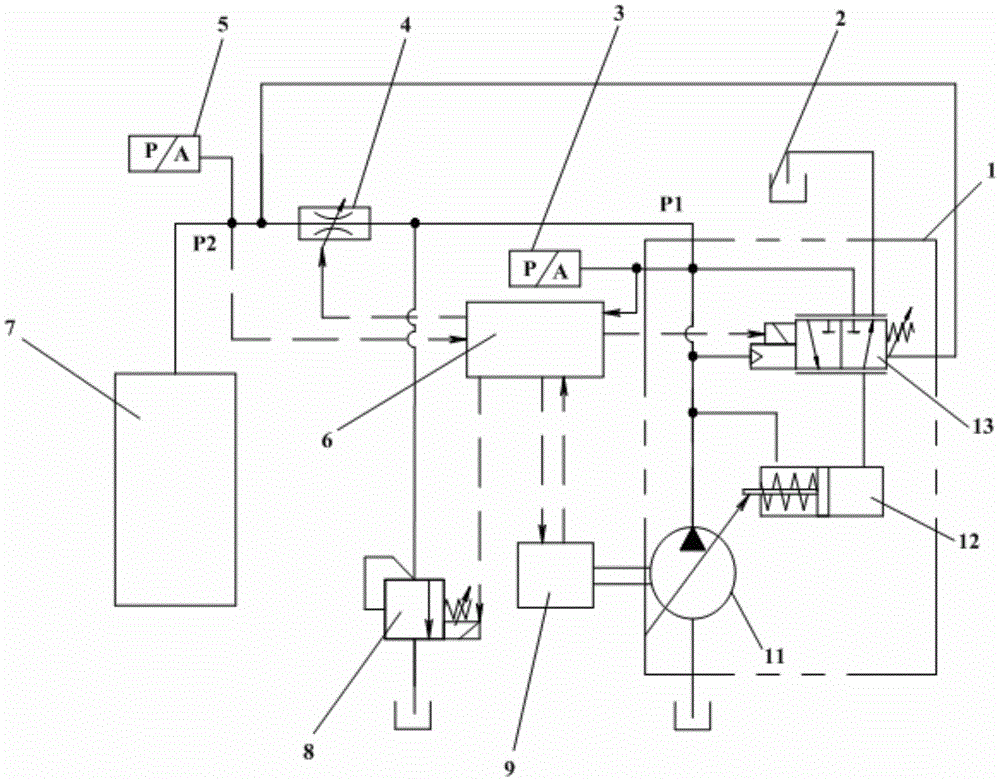

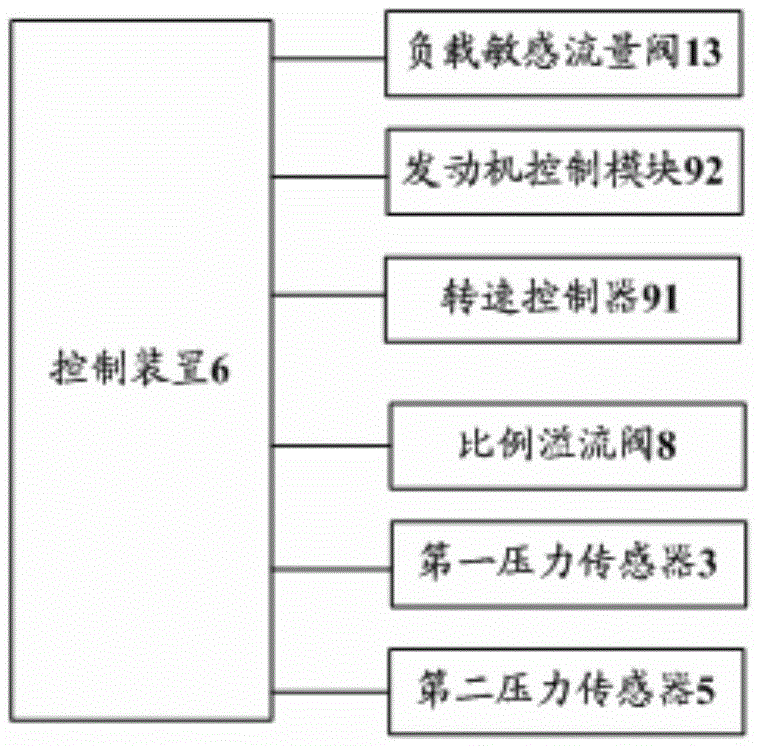

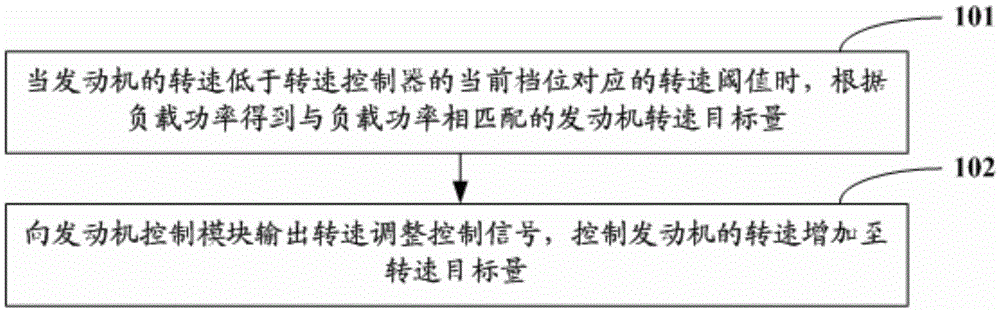

Power limit matching control system, method and device and engineering machine

ActiveCN103670750AImprove flameout phenomenonImproved handling and reliabilityElectrical controlMachines/enginesEngineeringControllability

The invention relates to the technical field of engineering machinery and discloses a power limit matching control system, method and device and an engineering machine. The power limit matching control system, method and device and the engineering machine are used for effectively reducing the flameout phenomenon caused when the power of an engine is not matched, thereby improving the controllability and the reliability of products. The control system comprises an engine control module and a rotation speed controller. The control device is connected with the engine control module and the rotation speed controller through signals and used for obtaining a target engine rotation speed value which is matched with a load power according to the load power when the rotation speed of the engine is smaller than a rotation speed threshold value, corresponding to a current gear, of the rotation speed controller. The control device also outputs a rotation speed adjustment control signal to the engine control module so as to control the rotation speed of the engine to be increased to the target rotation speed value.

Owner:ZOOMLION HEAVY IND CO LTD

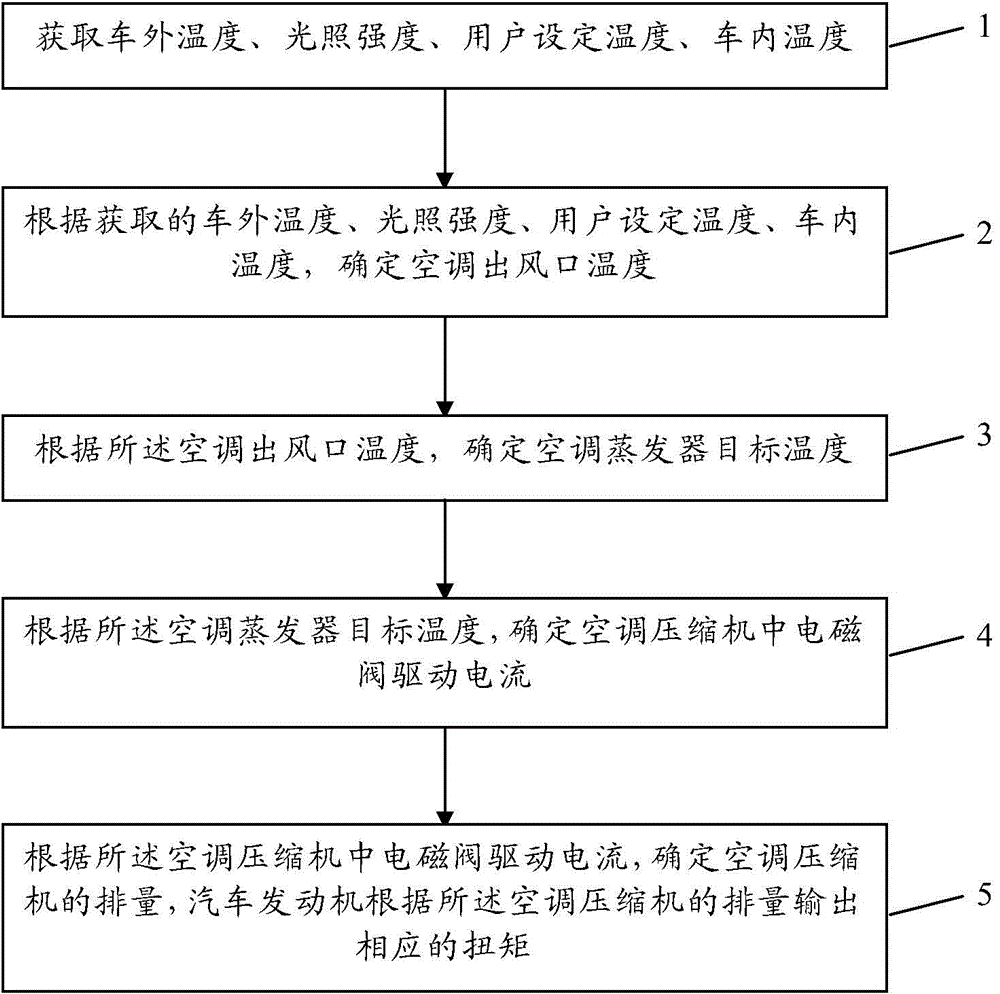

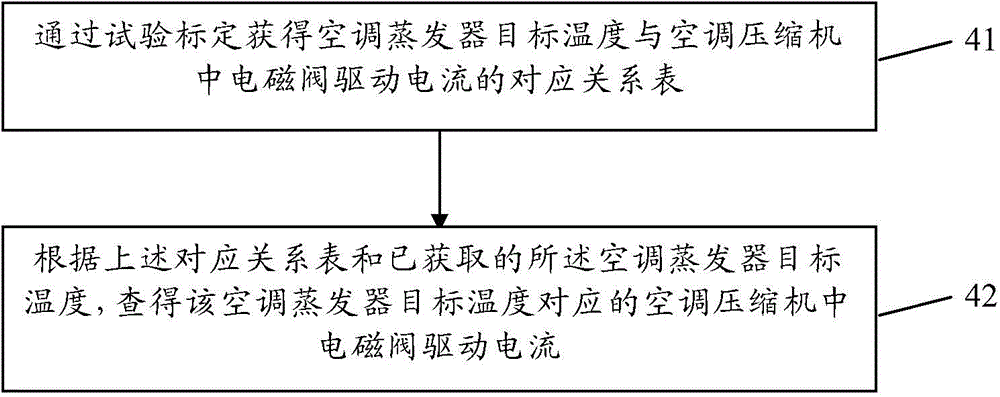

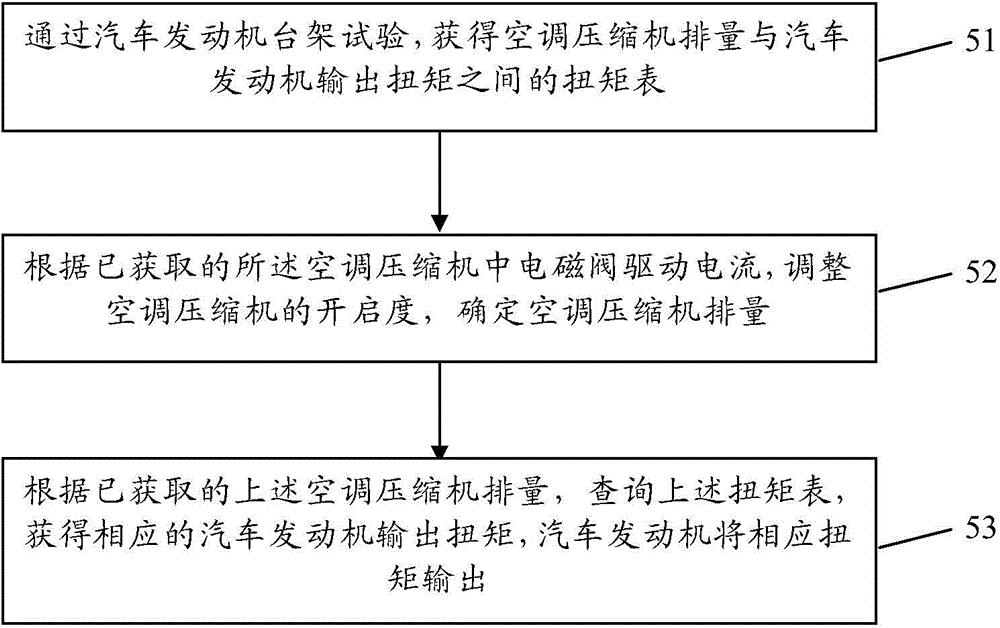

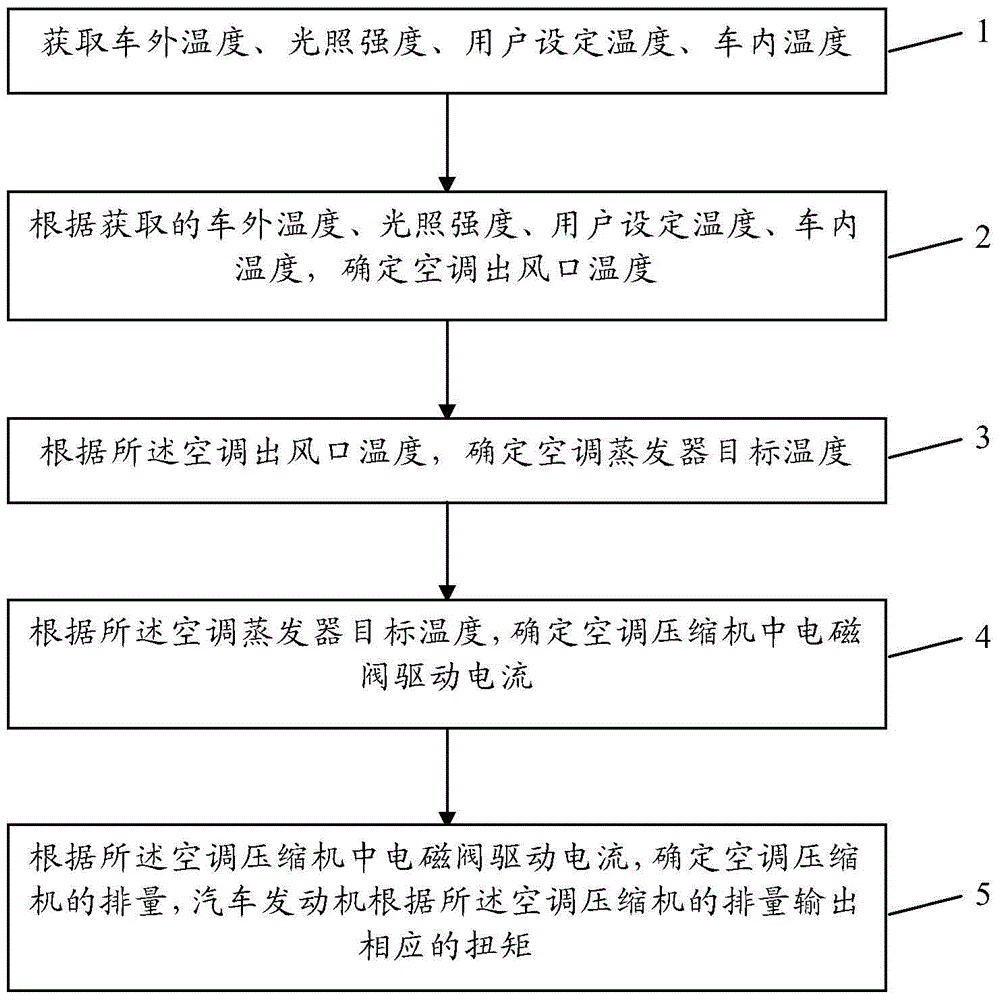

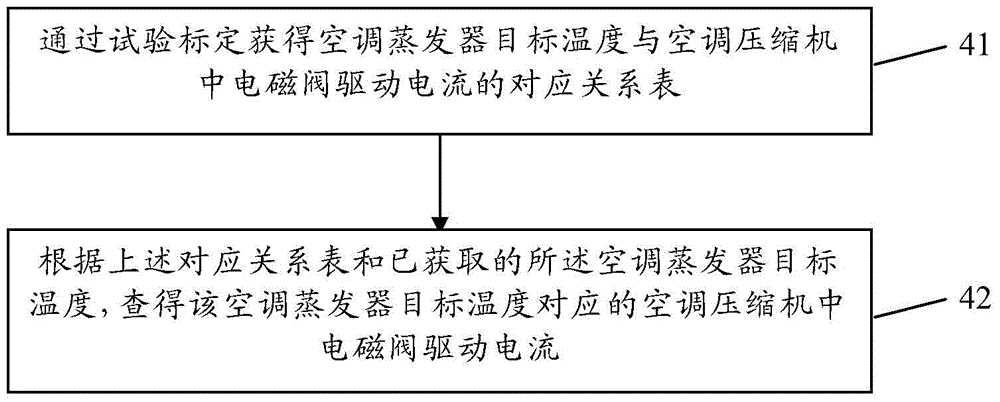

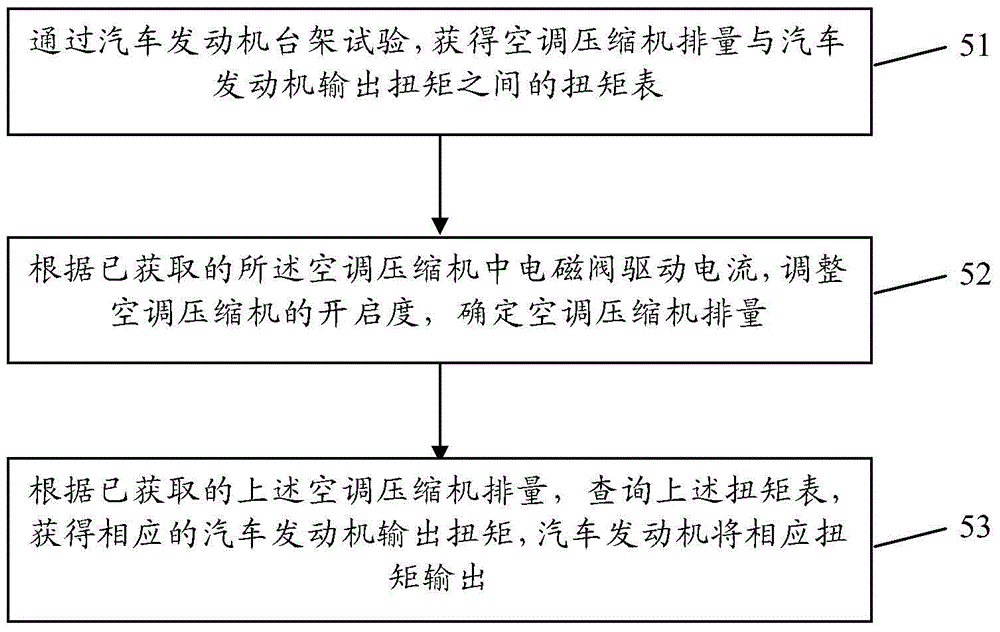

Control method and device for automobile air conditioner compressor

ActiveCN104807269AAvoid speed fluctuationsAvoid undermotivationAir-treating devicesElectrical controlEvaporatorElectromagnetic valve

The invention discloses a control method and a control device for an automobile air conditioner compressor. The method comprises the following steps: determining target temperature of an air conditioner evaporator according to temperature outside an automobile, light intensity, temperature set by a user and temperature in the automobile, acquiring the driving current of an electromagnetic valve in the air conditioner compressor according to the determined target temperature of the air conditioner evaporator, and finally determining the output torque of an engine of the automobile by virtue of the acquired driving current of the electromagnetic valve in the air conditioner compressor. According to the control method and the control device, the driving current of the electromagnetic valve in the air conditioner compressor is slowly regulated to fulfill the air of slowly regulating the output torque of the engine of the automobile according to the acquired target temperature of the air conditioner evaporator, so that the rotating speed fluctuation of the engine of the automobile is effectively avoided, the phenomenon of insufficient power of the automobile is also avoided, and the safety performance of the whole automobile is further improved.

Owner:ANHUI JIANGHUAI AUTOMOBILE GRP CORP LTD

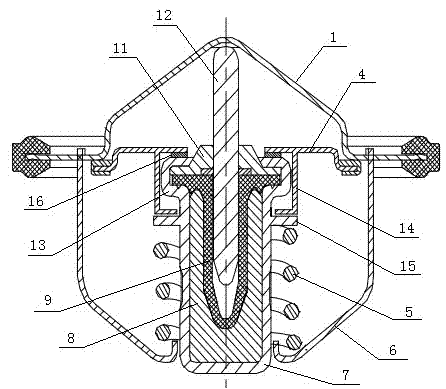

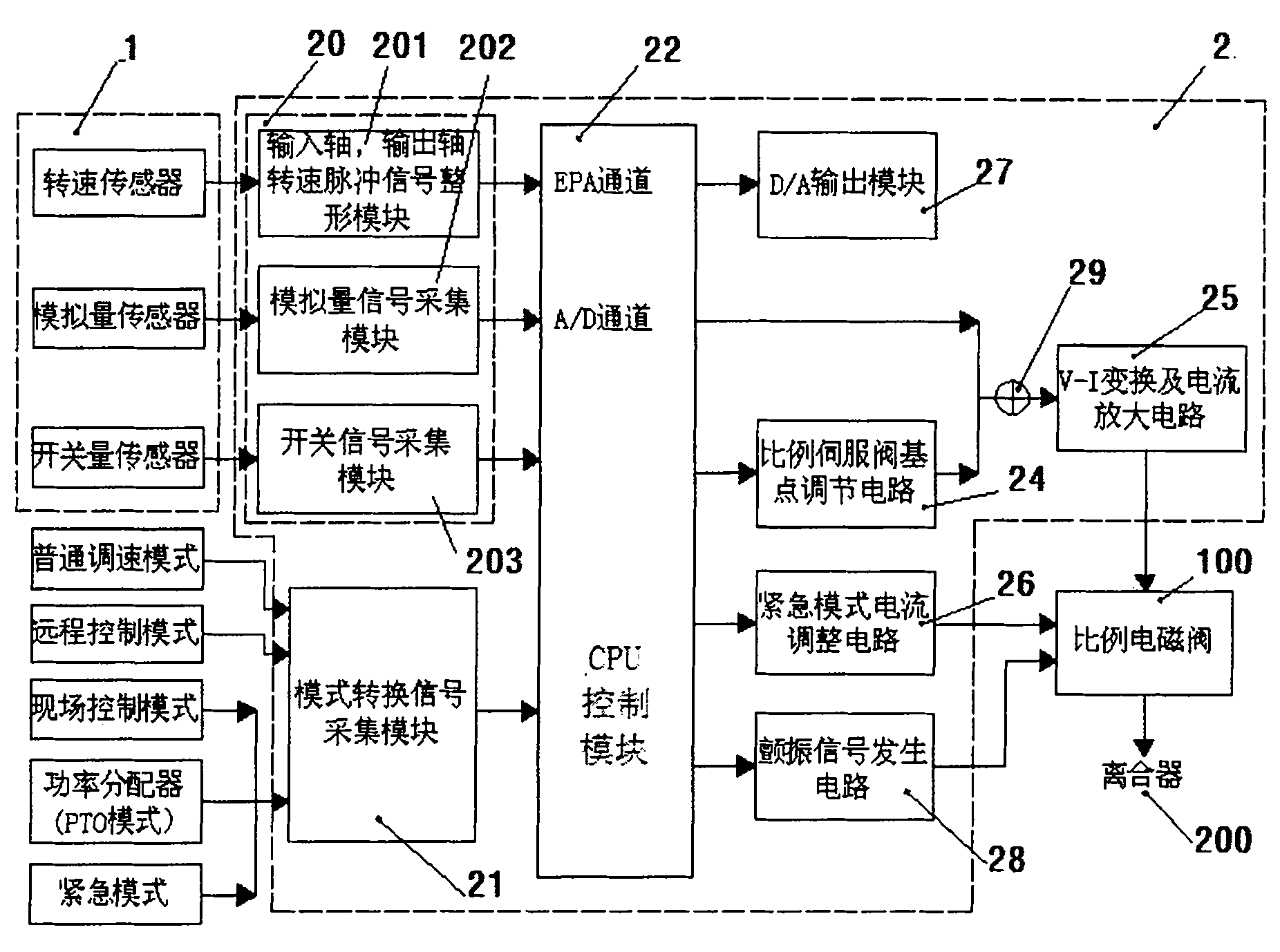

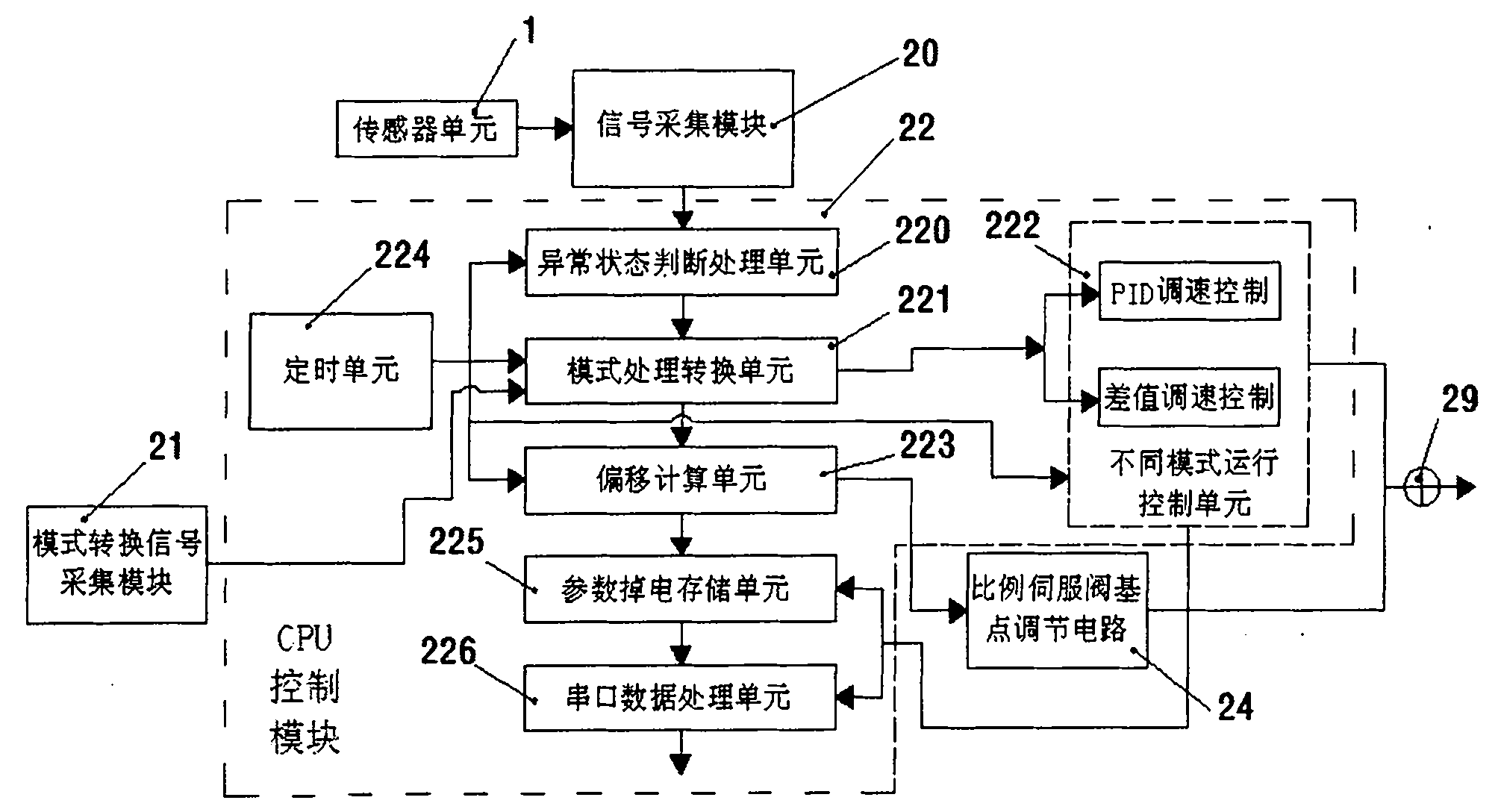

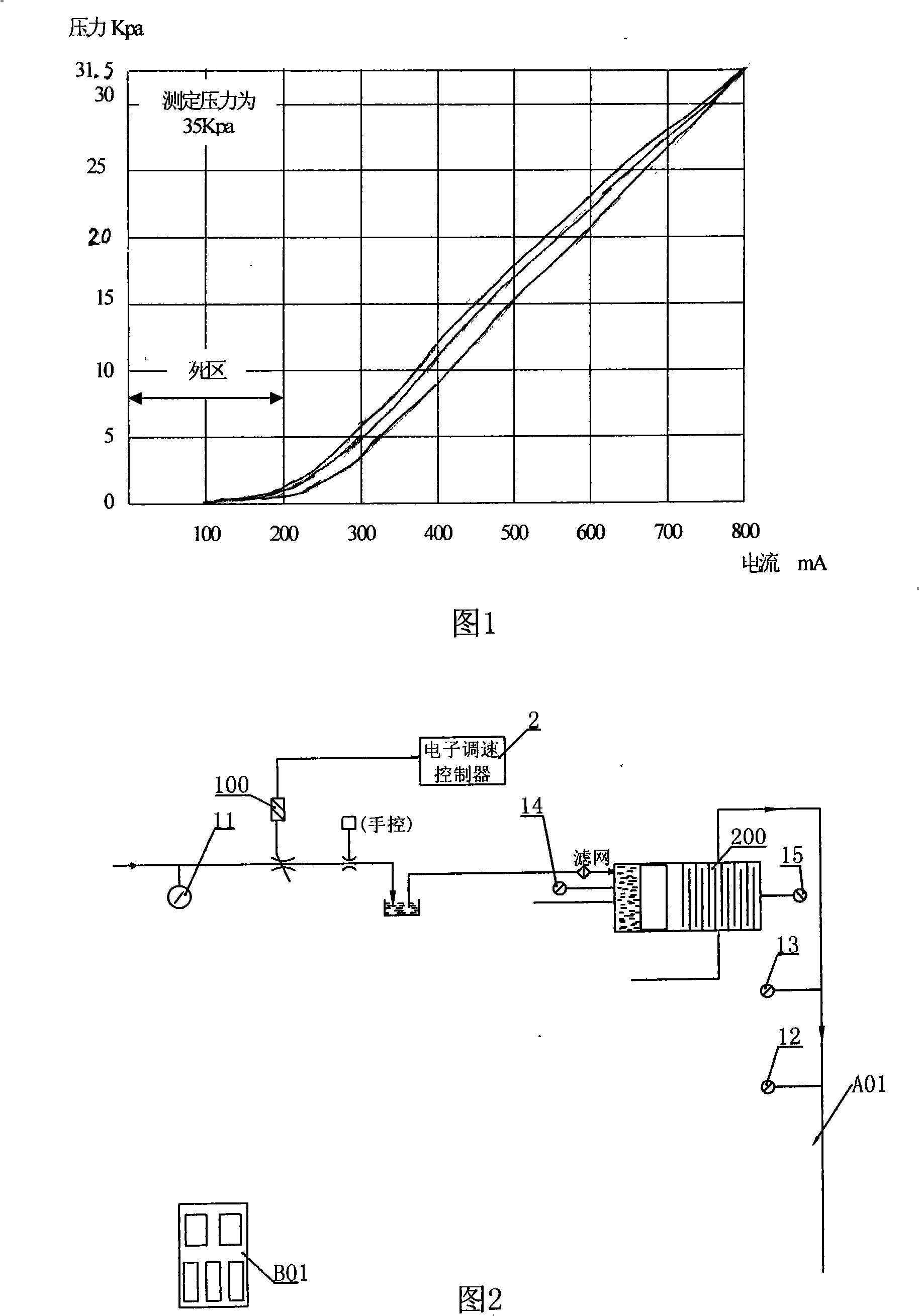

Applications-oriented control device of speed-regulating clutch and control method thereof

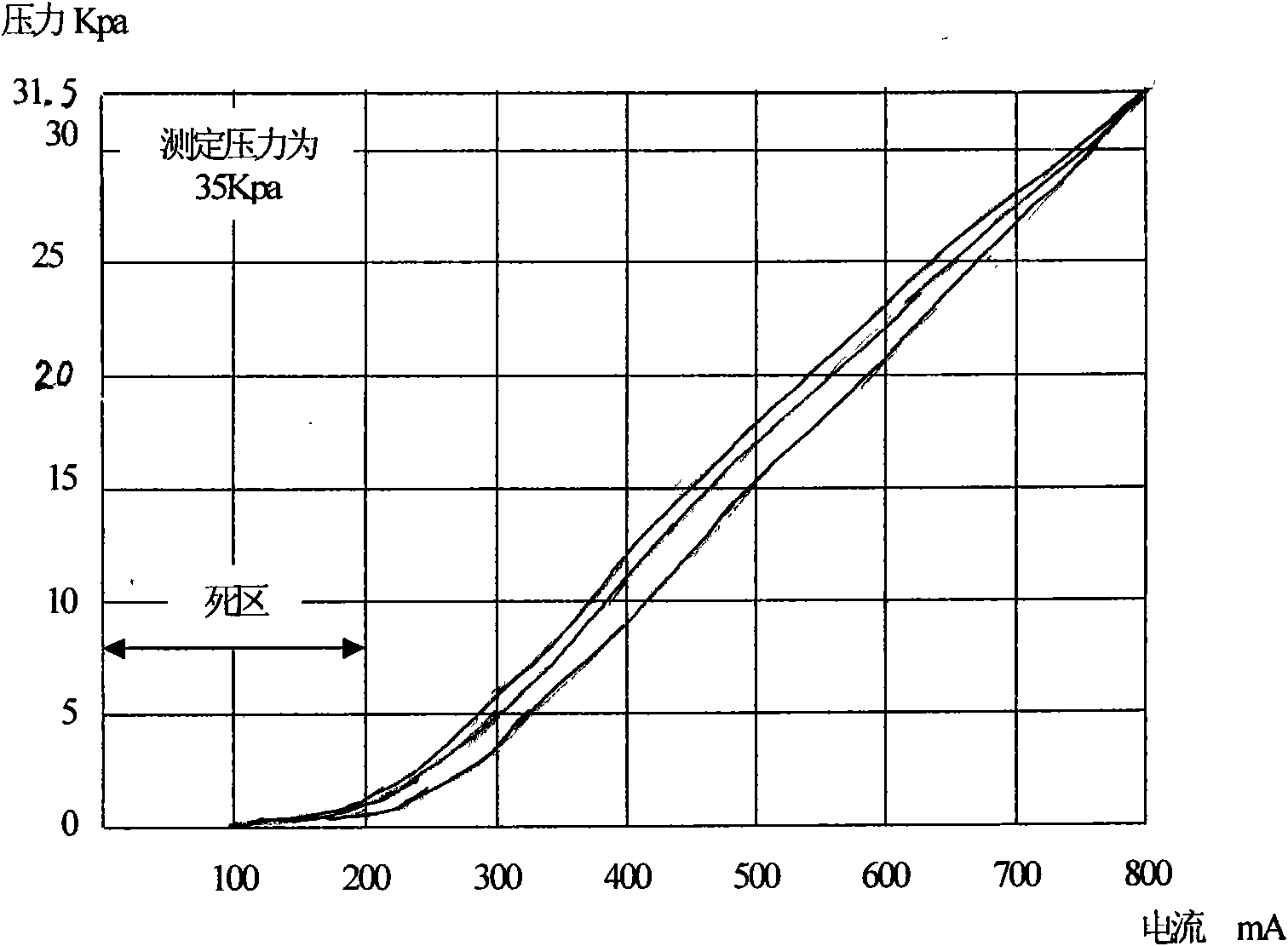

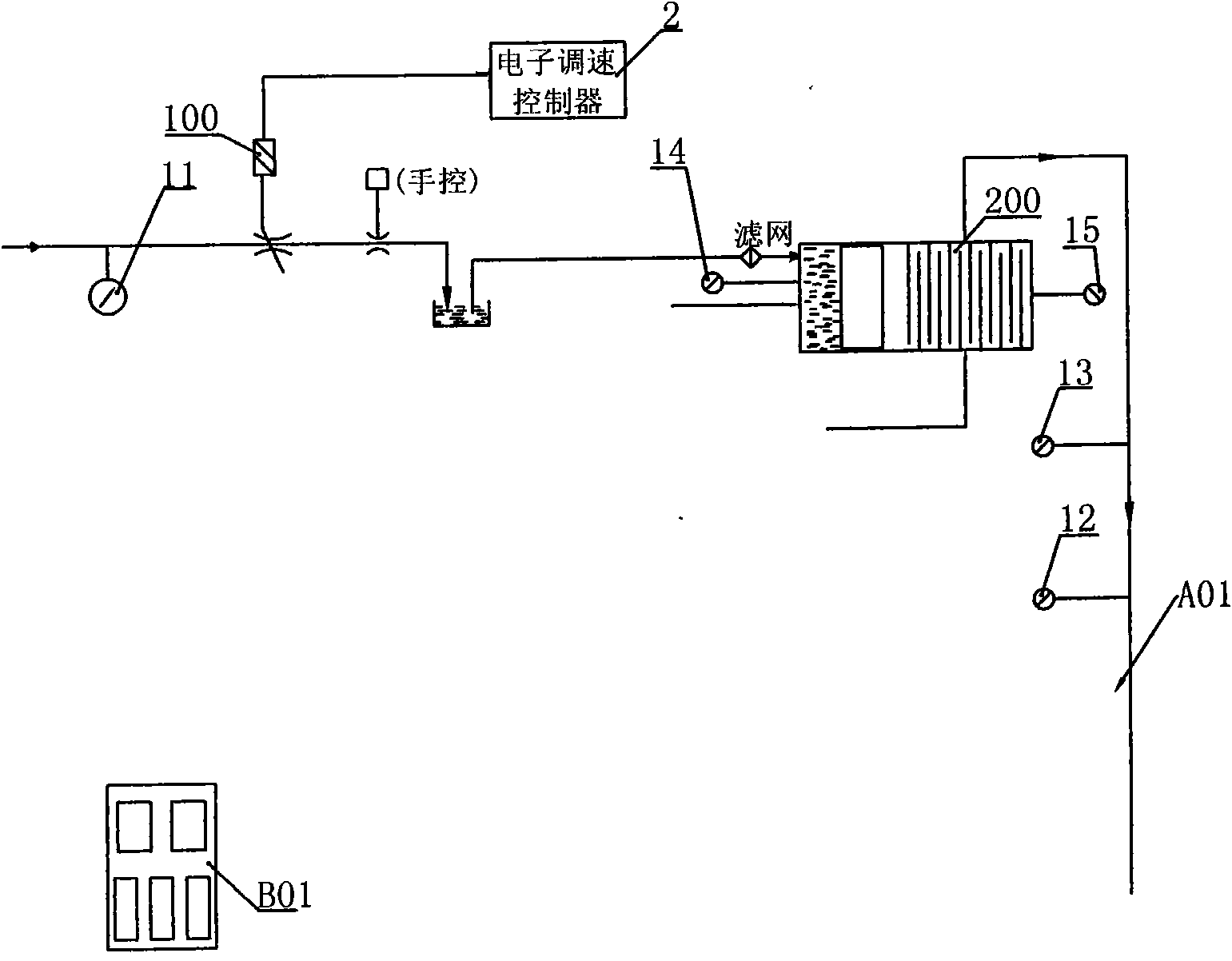

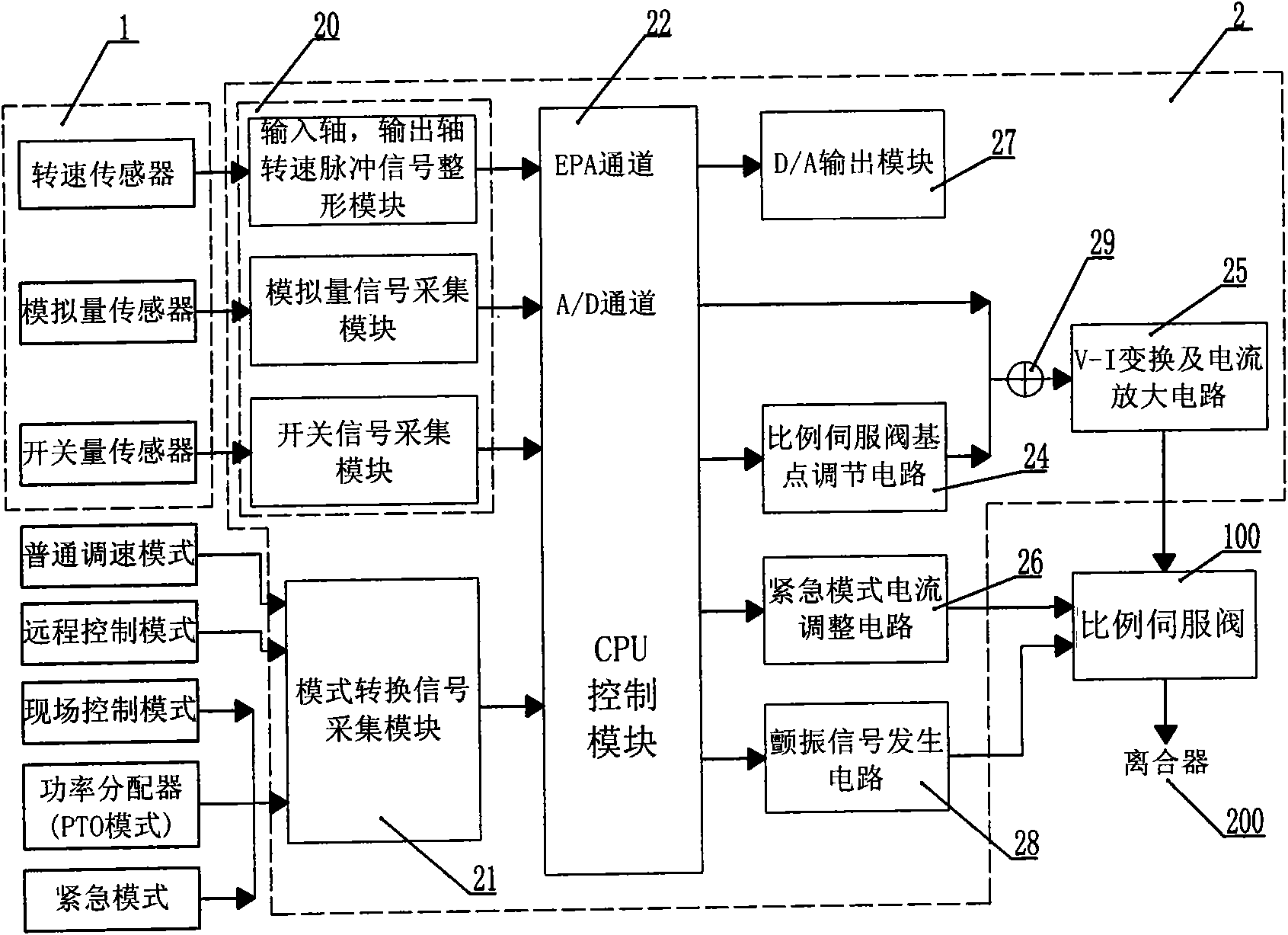

ActiveCN101561021AGuaranteed SensitivityAvoid speed fluctuations and oscillationsClutchesClutchElectricity

The invention relates to an applications-oriented control device of speed-regulating clutch and a control method thereof. The device comprises a sensor unit and an electronic speed-regulating controller electrically connected with the sensor unit. The electronic speed-regulating controller comprises a signal collecting module electrically connected with the output end of the sensor unit; a mode switching signal collecting module connected with a plurality of running modes; a CPU control module electrically connected with the output ends of the signal collecting module and the mode switching signal collecting module; a ratio servo valve base point regulating circuit electrically connected to the output end of the CPU control module; and a V-I converting and current amplifying circuit electrically connected with the output end accumulating the output end of the CPU control module and the output signal of the ratio servo valve base point regulating circuit. The output end of the V-I converting and current amplifying circuit drives a ratio servo valve and controls the actions of a clutch. By using a PID control policy, the invention has the advantages of adaptation to dead zone characteristics of different ratio servo valves and wide application range.

Owner:SHANGHAI QIYAO HEAVY IND CO LTD

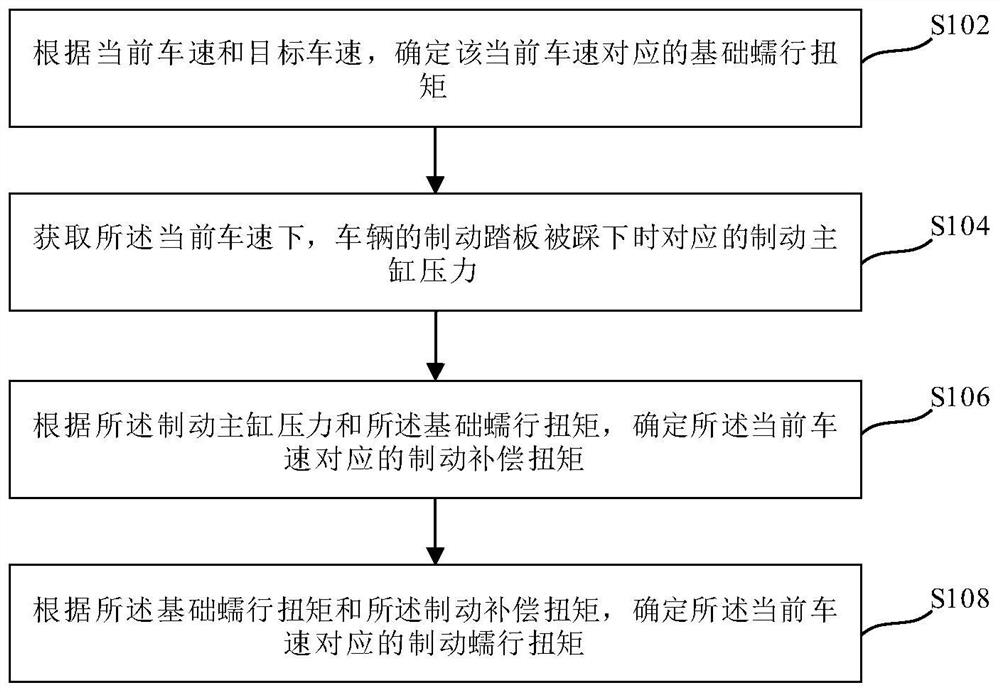

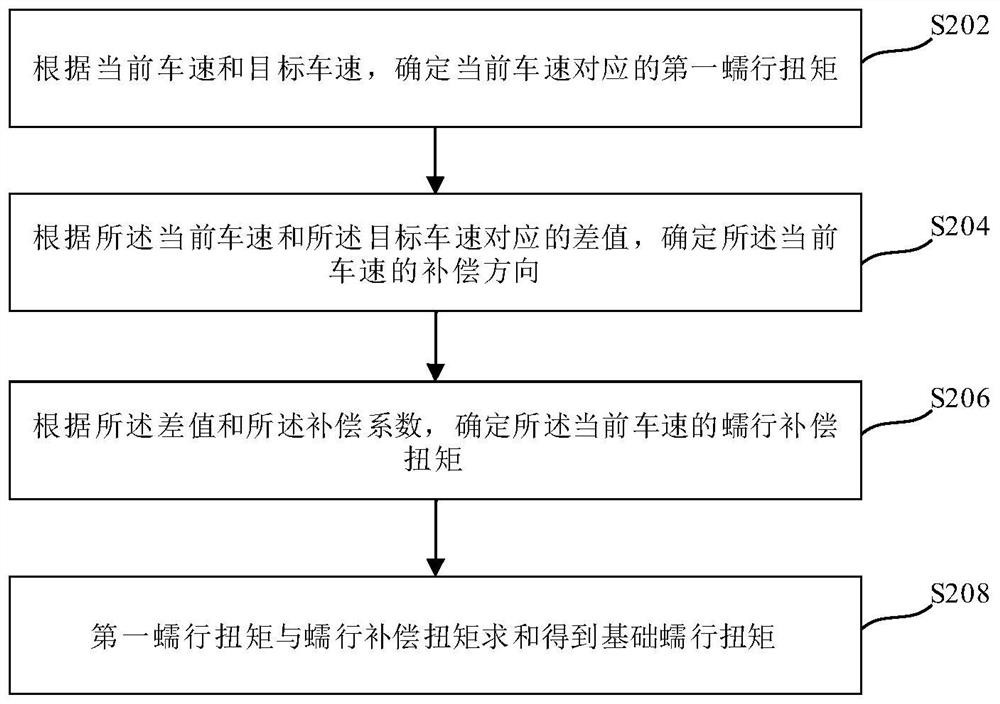

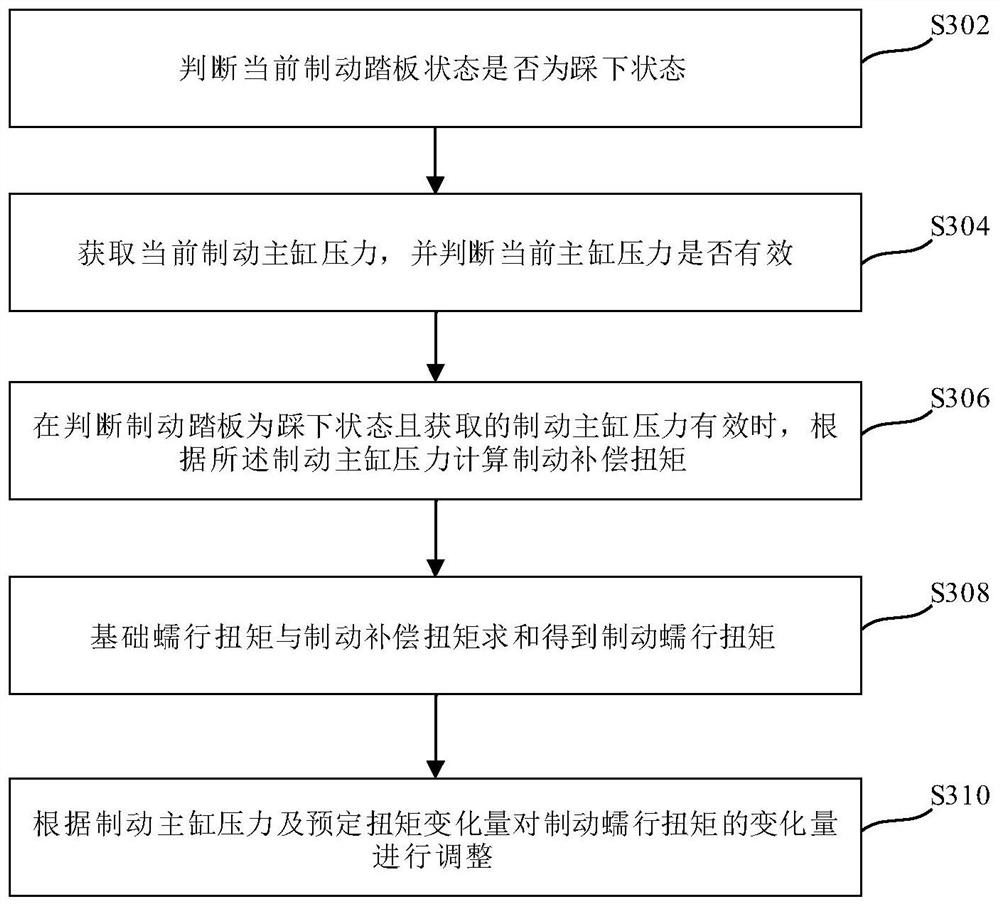

Vehicle crawling control method and device, electronic equipment, and storage medium

ActiveCN112109711AAvoid speed fluctuationsGood driving stabilityAutomotive engineeringMaster cylinder

The embodiments of the invention disclose a vehicle crawling control method and device, electronic equipment, and a computer storage medium. The method includes the steps that a basic crawling torquecorresponding to a current vehicle speed is determined according to the current vehicle speed and a target vehicle speed; a corresponding brake master cylinder pressure is acquired when a brake pedalof a vehicle is pressed at the current vehicle speed; a brake compensation torque corresponding to the current vehicle speed is determined according to the brake master cylinder pressure and the basiccrawling torque; and according to the basic crawling torque and the brake compensation torque, the brake crawling torque corresponding to the current vehicle speed is determined. According to the embodiment of the vehicle crawling control method and device, the electronic equipment, and the storage medium, the stability of low-speed running of the vehicle can be improved under the condition thatthe vehicle crawls during low-speed braking.

Owner:EVERGRANDE NEW ENERGY AUTOMOTIVE INVESTMENT HLDG GRP CO LTD

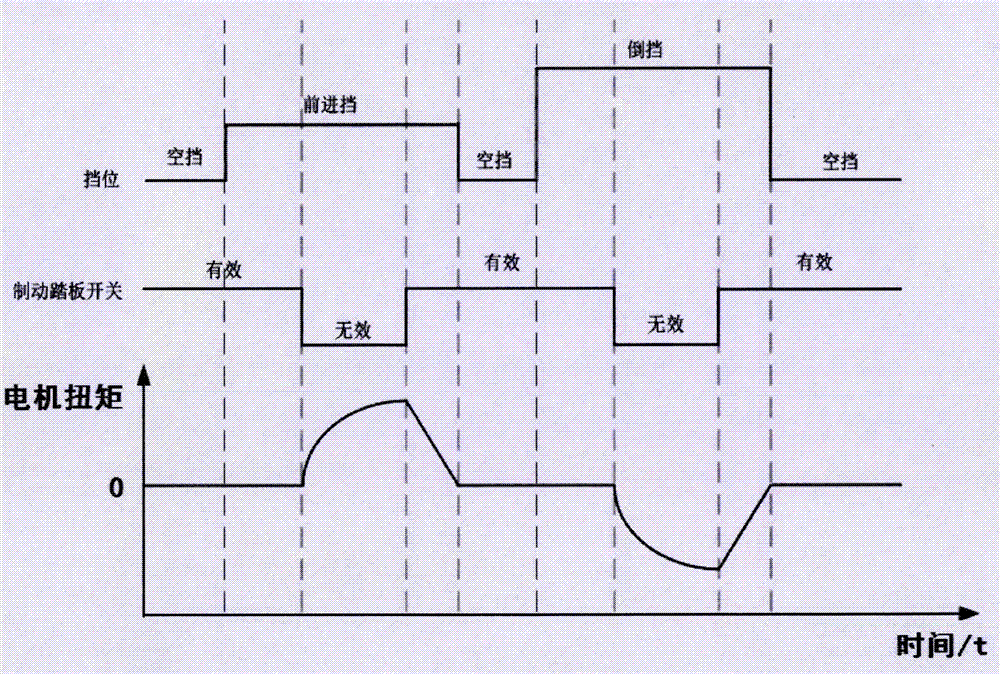

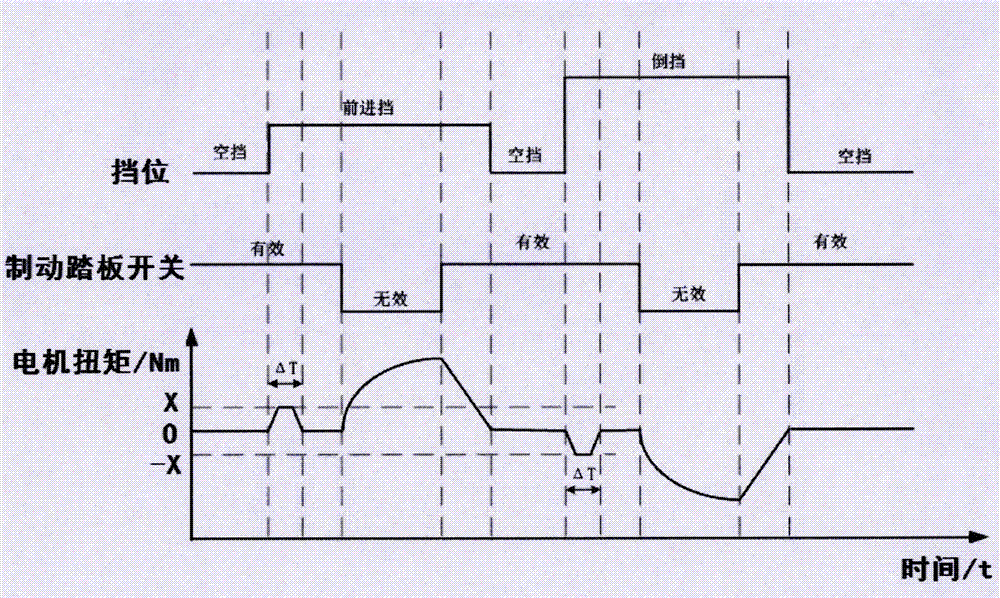

Electric vehicle starting pretension force control method

InactiveCN107117070AEliminate Driveline BacklashAvoid vibrations and vibrationsSpeed controllerElectric energy managementElectric vehicleTransmission system

The invention relates to an electric vehicle starting pretension force control method and belongs to the technical field of electric vehicles. The electric vehicle starting pretension force control method comprises the steps that when a gear signal transmitted by a gear sensor is a forward gear and an on-off signal of a brake pedal is effective, a vehicle controller generates torque X, maintains the torque X for delta T and sends the torque X to a motor controller, a motor is controlled by the motor controller, and then the brake pedal is loosened; and when the gear signal transmitted by the gear sensor is a reverse gear and the on-off signal of the brake pedal is effective, the vehicle controller generates torque -X, maintains the torque -X for delta T and sends the torque -X to the motor controller, the motor is controlled by the motor controller, and then the brake pedal is loosened. By adopting the starting pretension force control method, an vehicle transmission system gap after gear engaging can be effectively eliminated, rotating speed fluctuation and vibration sound of the motor at the starting moment due to the transmission system gap are avoided, and the starting smoothness of a vehicle is improved.

Owner:IAT AUTOMOBILE TECH

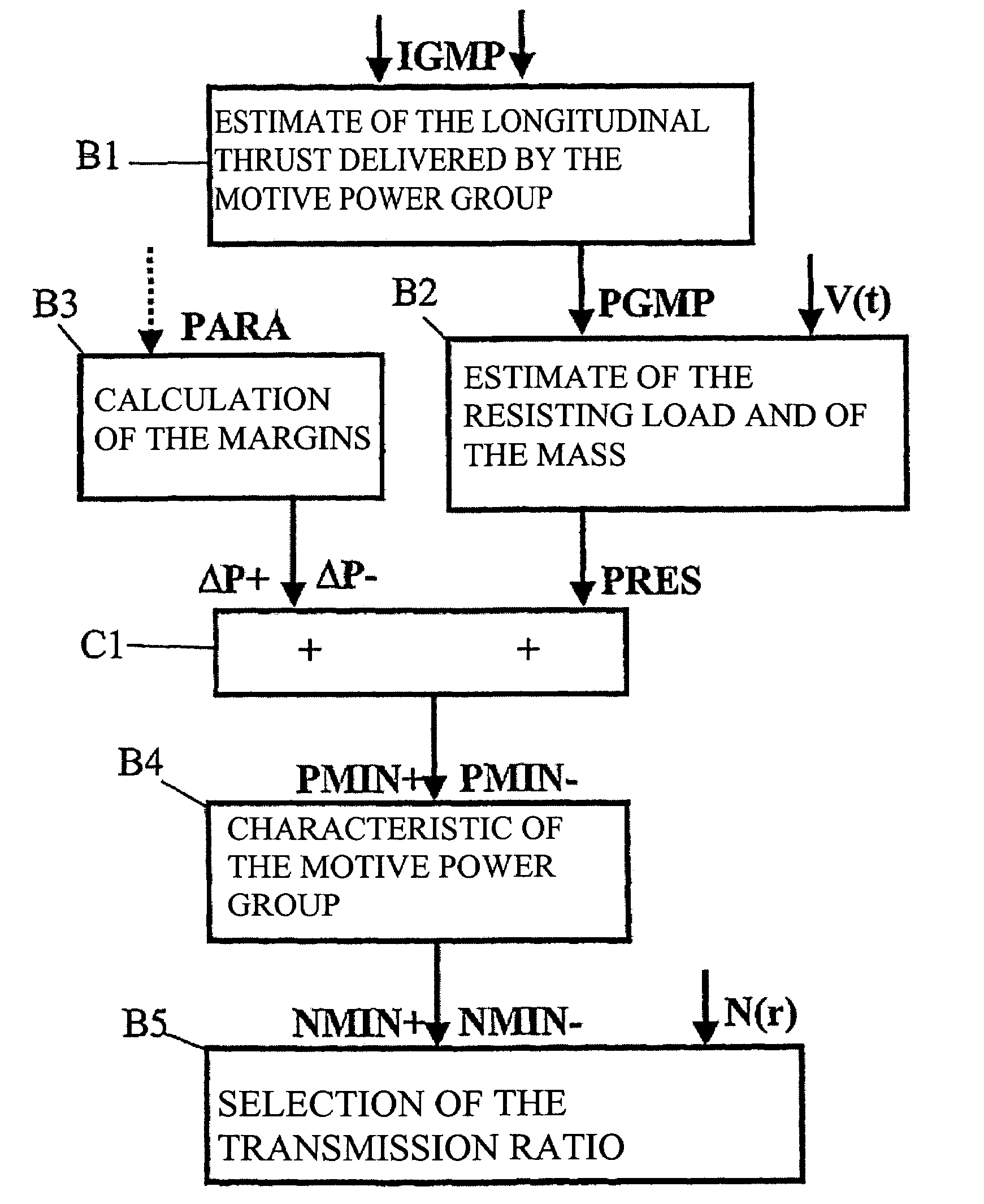

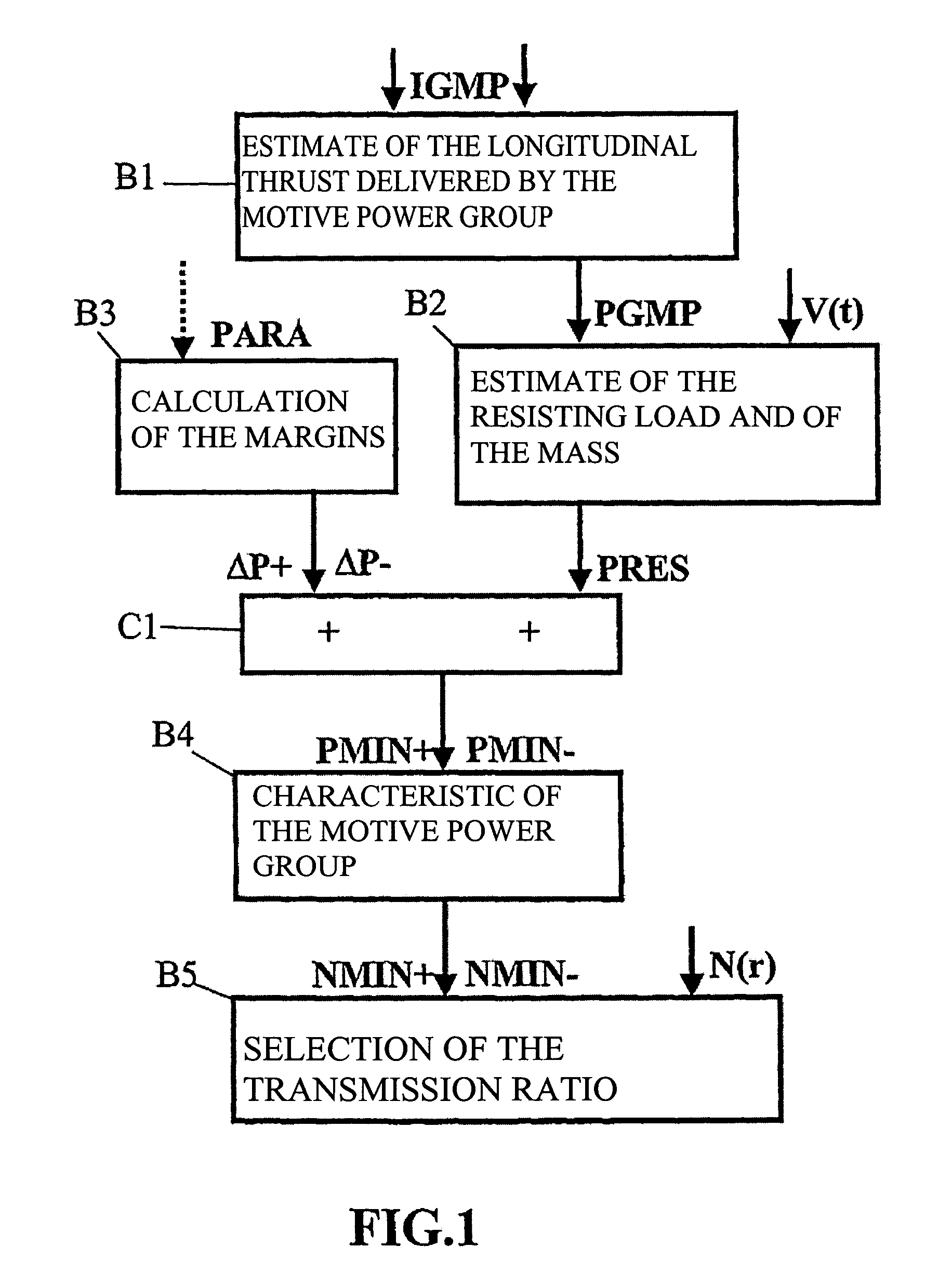

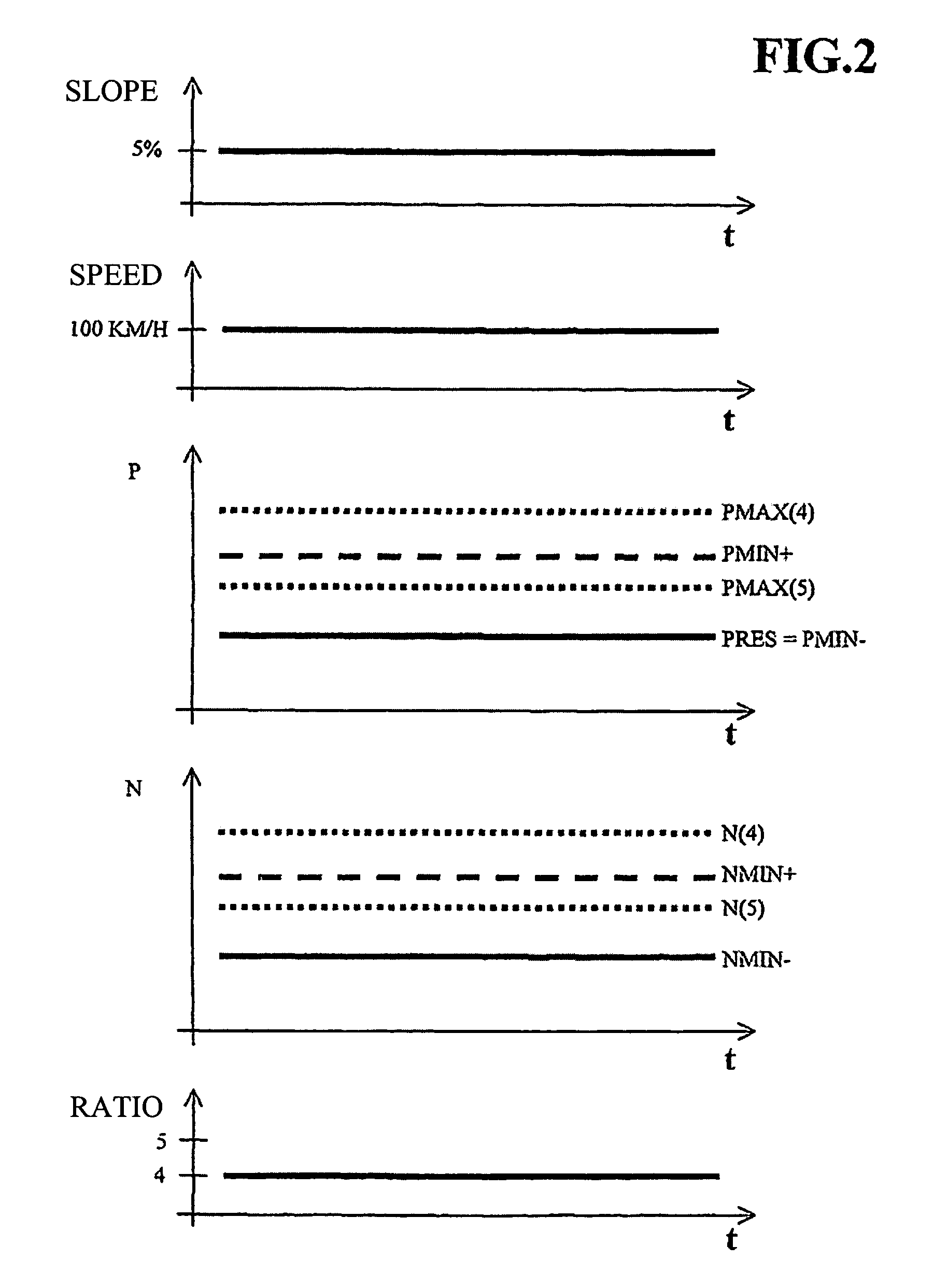

Method for controlling selection of an automatic transmission gear ratio

InactiveUS7529607B2Eliminate riskAnticipate the downshift sufficientlyHybrid vehiclesVehicle fittingsAutomatic transmissionControl selection

A method for controlling selection of an automatic transmission gear ratio with staged ratios or constant variation for a vehicle including a control for preventing / allowing extension of the gear ratio or for controlling a shortening the transmission gear ratio if, at a current engine speed, the power is insufficient for maintaining the vehicle speed. The method prevents extension of the transmission gear ratio if the power available after the extension is insufficient for maintaining the vehicle speed; otherwise allowing extension of the transmission gear ratio.

Owner:RENAULT SA

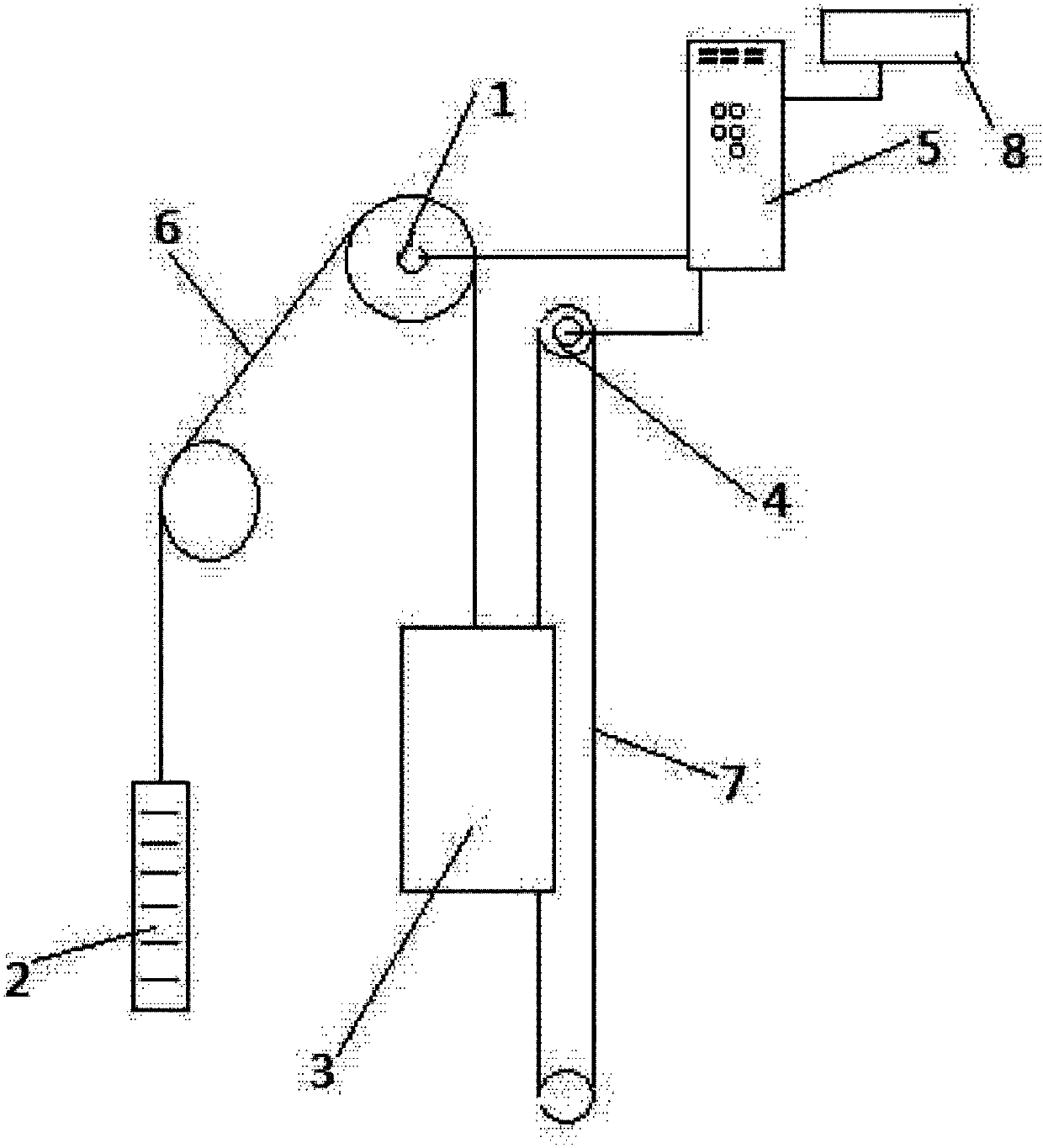

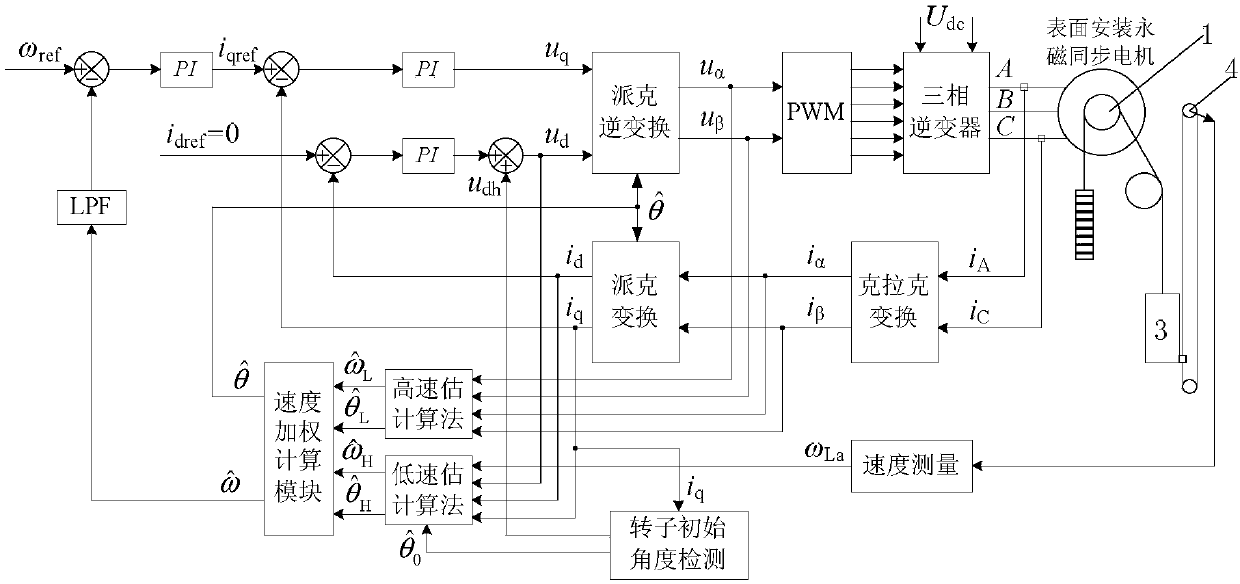

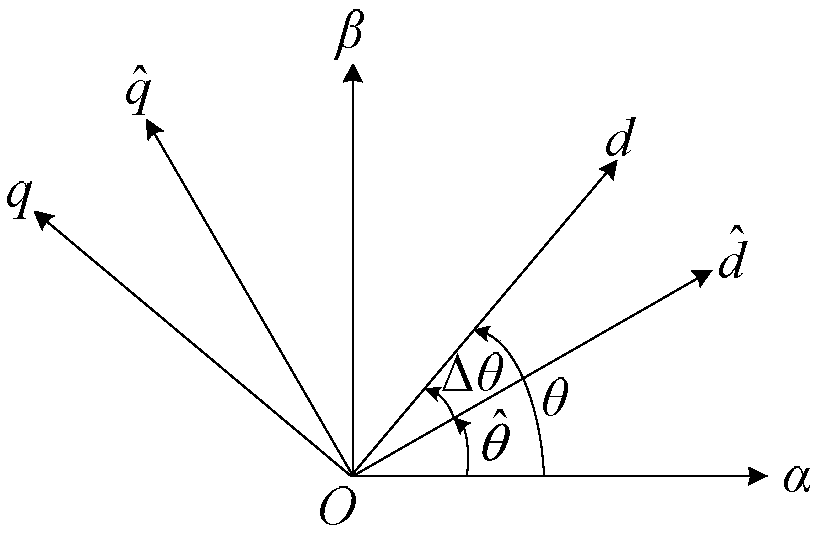

Method for controlling elevator tractor

ActiveCN108574428AStable controlAvoid speed fluctuationsSingle motor speed/torque controlElevatorsElevator systemLow speed

The invention discloses a method for controlling an elevator tractor, which comprises the steps of obtaining an initial rotor angle of the elevator tractor; obtaining the rotor speed and rotor angle of the tractor at low speed running and the rotor speed and rotor angle of the tractor at medium and high speed running; obtaining a full speed range rotor speed estimated value and a full speed rangerotor angle estimated value of the tractor by adopting a smooth weighting factor method according to the rotor speed and the rotor angle of the tractor at low speed running and the rotor speed and rotor angle of the tractor at medium and high speed running, and performing closed-loop control on the speed of the tractor. The method for controlling the elevator tractor can realize motor encoder freecontrol for the tractor in an elevator system within the full speed range and reduce the cost of the system.

Owner:SHANGHAI MITSUBISHI ELEVATOR CO LTD

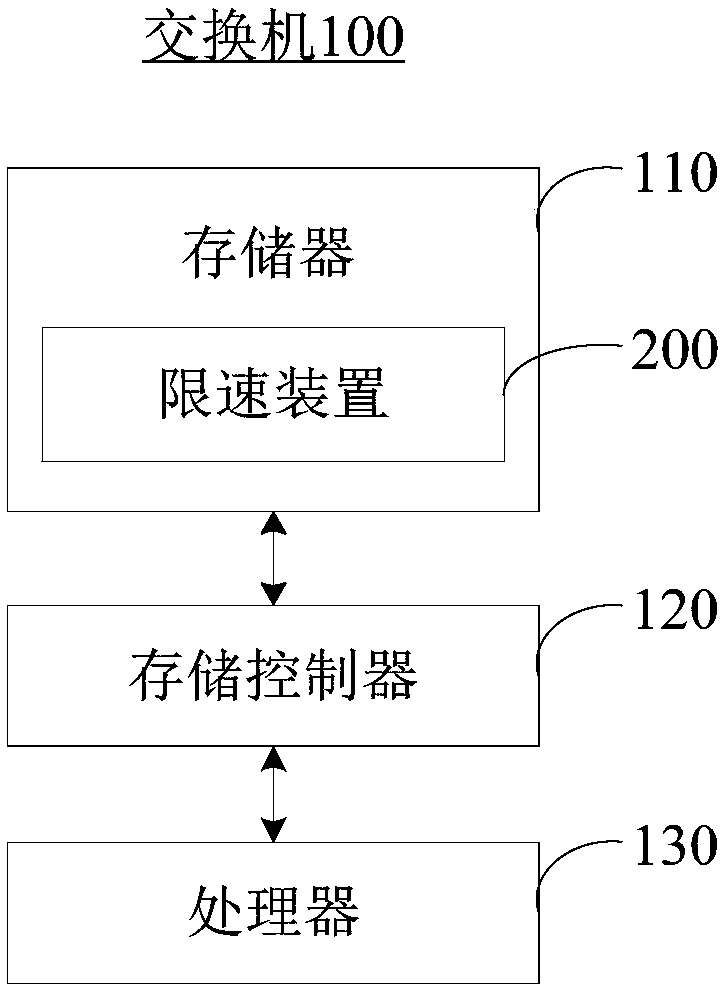

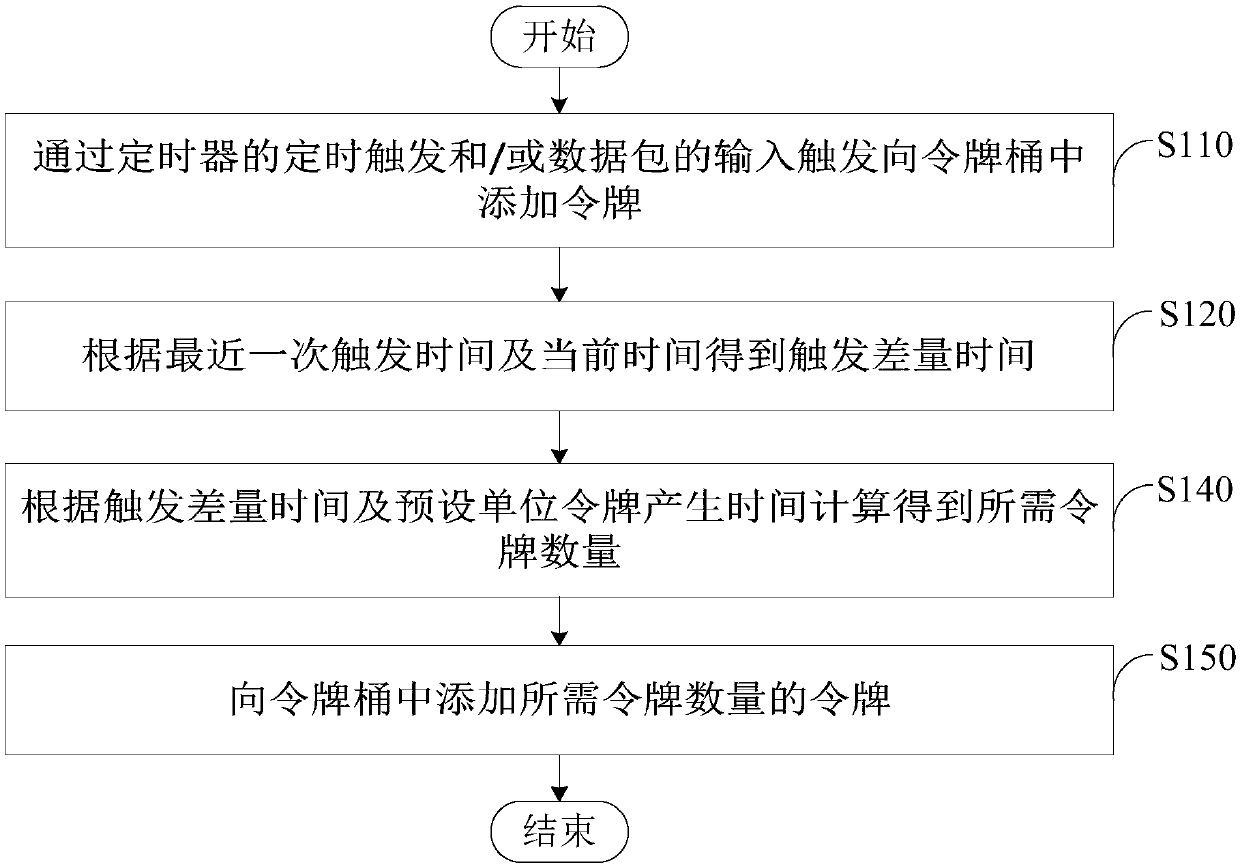

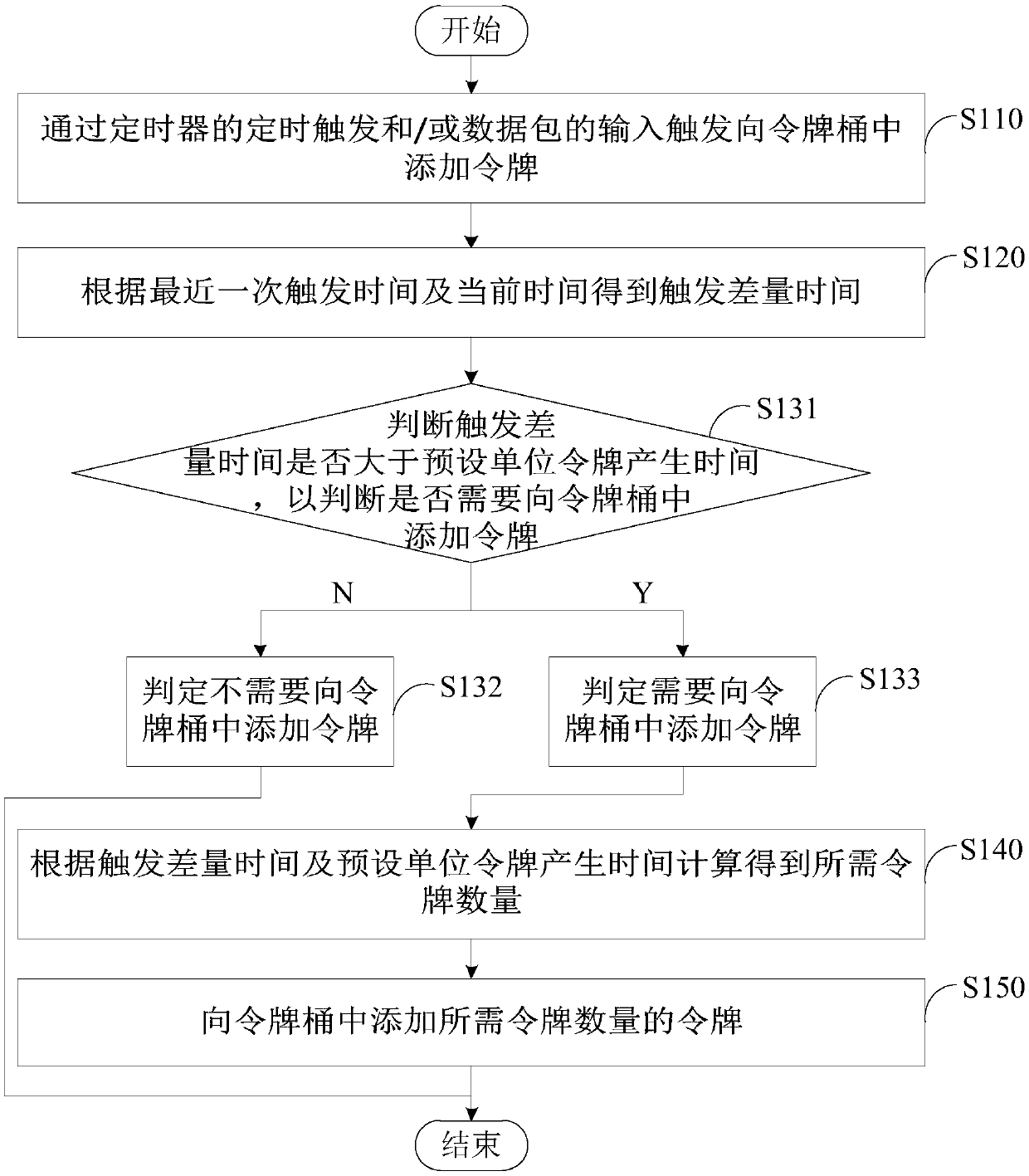

Speed-limiting method and device

ActiveCN107623641AGuaranteed Speed RequirementsImprove experienceData switching networksCommitted information rateTimer

The present invention provides a speed-limiting method and a device. The method is applied to a switch. The switch includes a timer. The method comprises the steps of adding a token into a token bucket through the timing triggering condition of the timer or the input triggering condition of data packets; obtaining the trigger delta time according to the latest triggering time and the current time;according to the trigger delta time and a preset unit token generation time, calculating to obtain the number of required tokens; and adding tokens of the required number into the token bucket. Therefore, tokens are added into the token bucket through the timing triggering condition of the timer or the input triggering condition of data packets. As a result, the switch cannot only meet the committed information rate requirements, but also the periodic network speed fluctuation condition can be avoided.

Owner:HUNAN TIANGUAN ELECTRONICS INFORMATION TECH

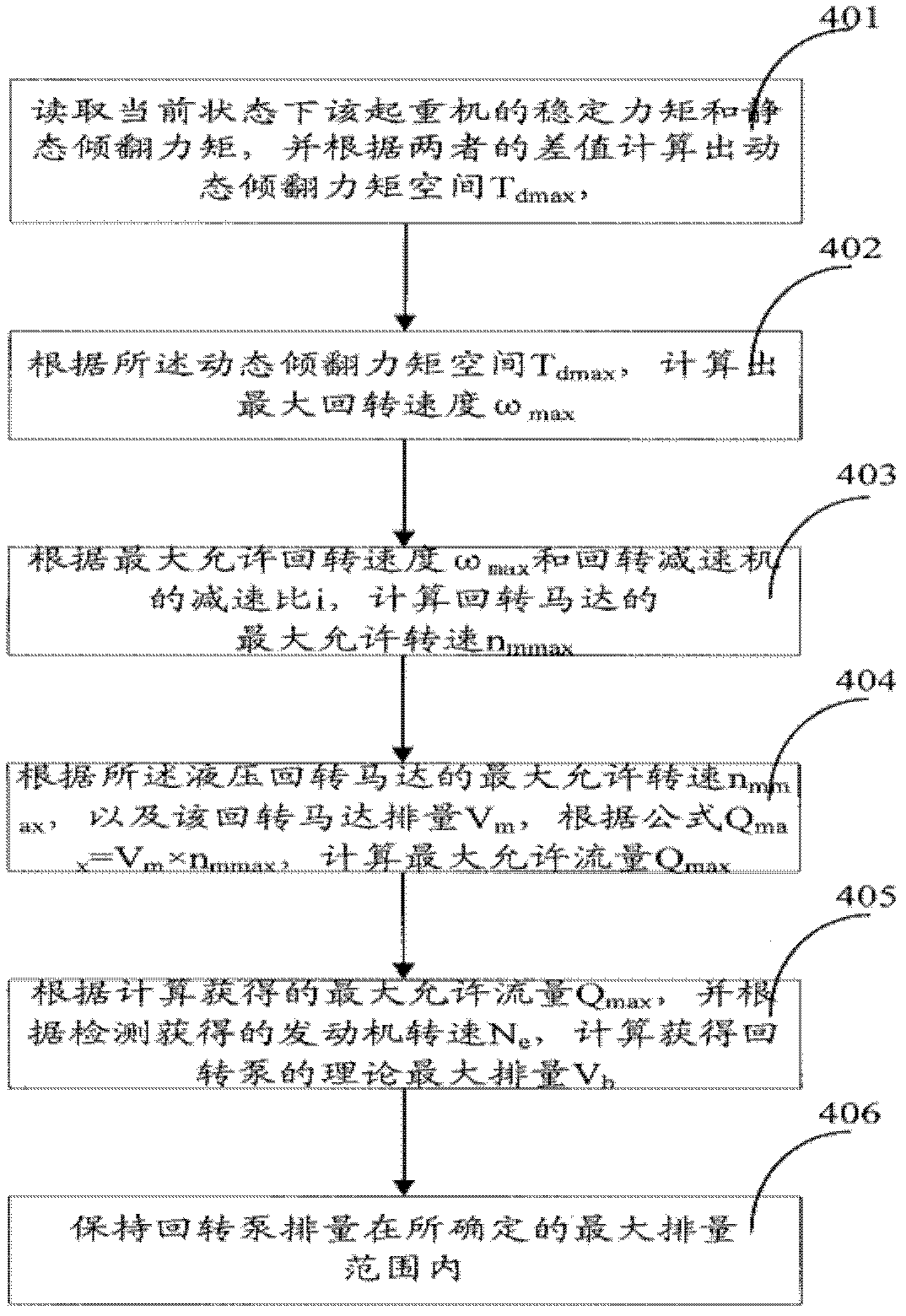

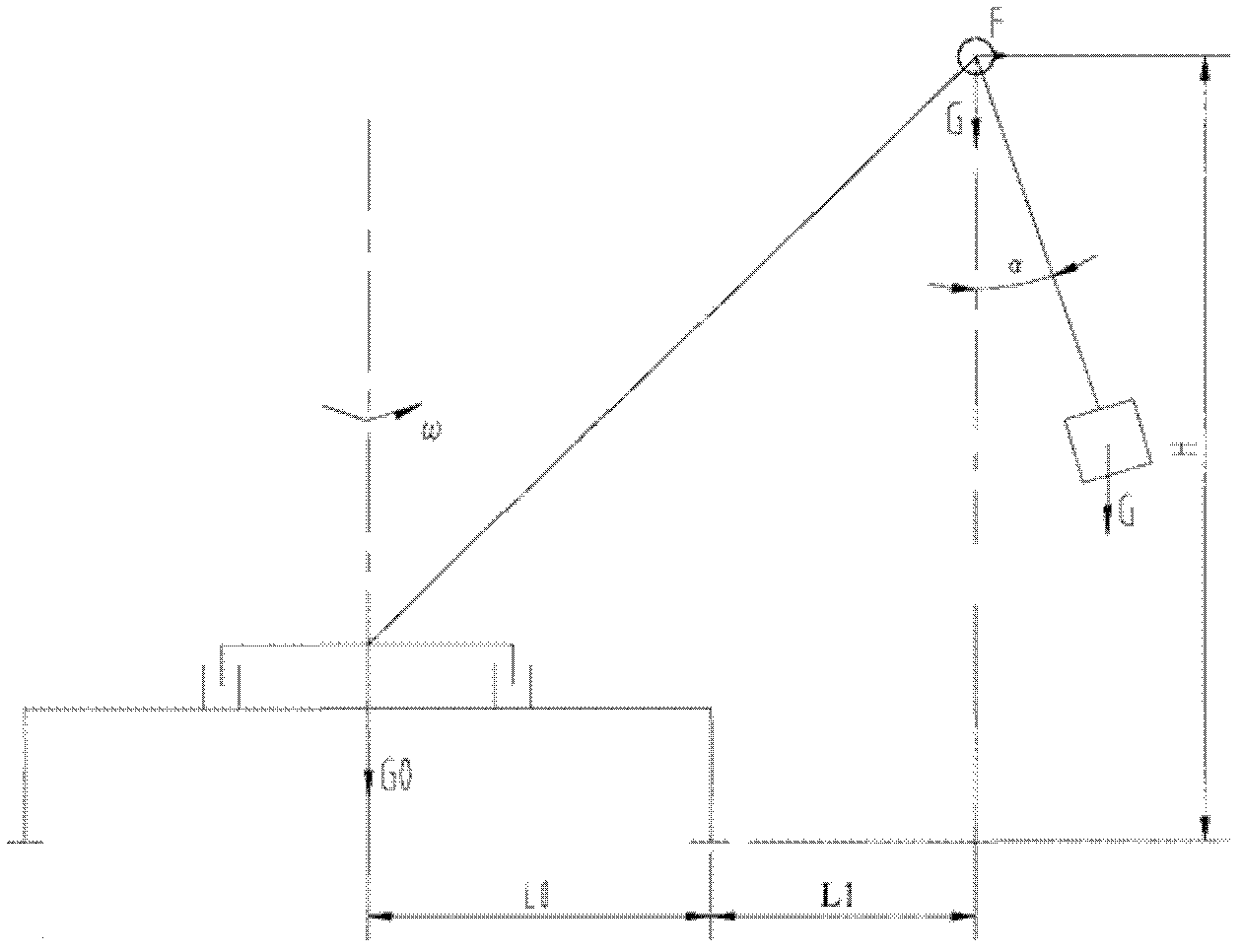

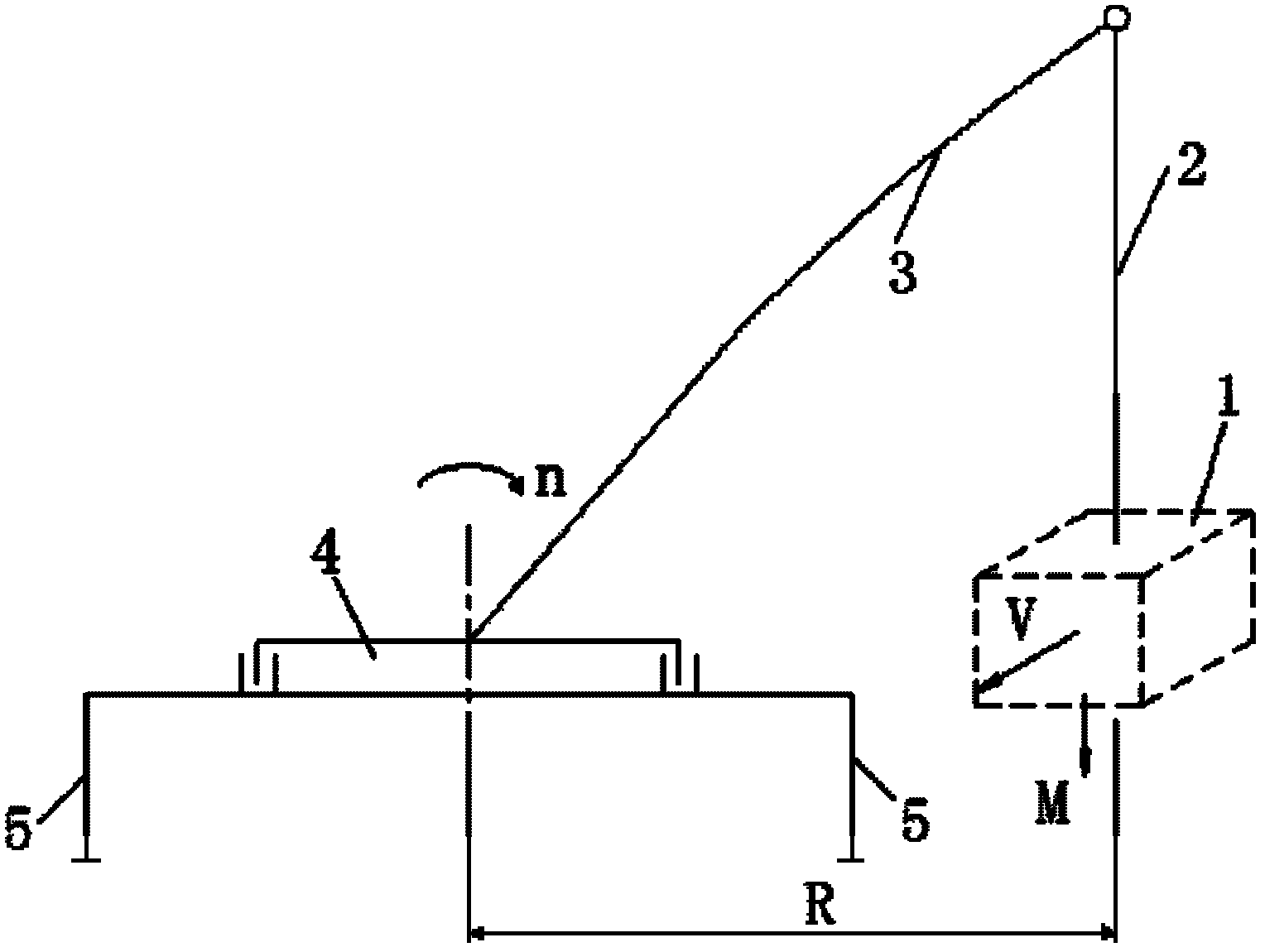

Rotatable engineering machinery rotation constant power control method, system and engineering machinery

ActiveCN102616687AAvoid volatilityEnsure safe workLoad-engaging elementsCranesRotation velocityPower control

A rotatable engineering machinery rotation constant power control method comprises step one (101) of calculating rotation reference power P=MxgxV, wherein the M is mass of lifted heavy objects, the g is a constant of the gravitational acceleration, and the V is rotation linear velocity of the heavy objects; step two (201) of calculating rotate velocity of a rotation platform n=Px9.549 / rated T, wherein the rated T is the rated output torque of a reduction box connected with a rotation driving device; and step three (301) of controlling actual rotation velocity of the rotation platform to be equal to the rotate velocity n of the rotation platform. In addition, the invention further provides a rotation constant power control system and rotatable engineering machinery used for achieving the control method. The control method and the control system can achieve control objectives of rotation operation velocity of the heavy objects of being fast in light or close objects and being slow in heavy or far objects according to different weight and working radius, and guarantee high efficiency of rotation operation and maximum utilization of structural strength of the whole machine.

Owner:ZOOMLION HEAVY IND CO LTD

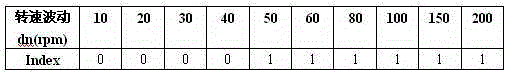

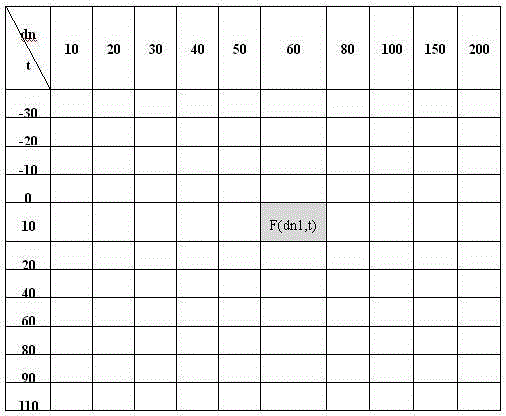

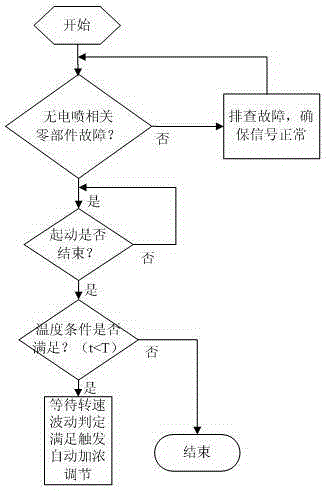

Gasoline engine gas mixture automatic enrichment control method based on characteristic MAP graph

ActiveCN105156218AAvoid pollutionAvoid speed fluctuationsElectrical controlMachines/enginesAutomatic Generation ControlAutomatic train control

The invention provides a gasoline engine gas mixture automatic enrichment control method based on a characteristic MAP graph, and the method eliminates fire chattering phenomenon caused by slight sparse of gas mixture concentration in a warm-up period after a vehicle is started, so as to ensure smooth operation of an engine in a later period, improve combustion, and optimize emission. The method comprises: determining whether components of an electronic fuel injection system have faults, determining parameters of engine operating states, required by entering automatic enrichment control, adjusting gas mixture automatic enrichment control, and determining to quit the automatic enrichment control. In the gasoline engine gas mixture automatic enrichment control method based on a characteristic MAP graph, an engine control unit (ECU) determines current speed fluctuation conditions through related signals of engine operating conditions, the signals being required by the ECU, implements automatic regulation on fuel injection pulse width, so as to realize rational control on gas mixture in the current working mode.

Owner:CHERY AUTOMOBILE CO LTD

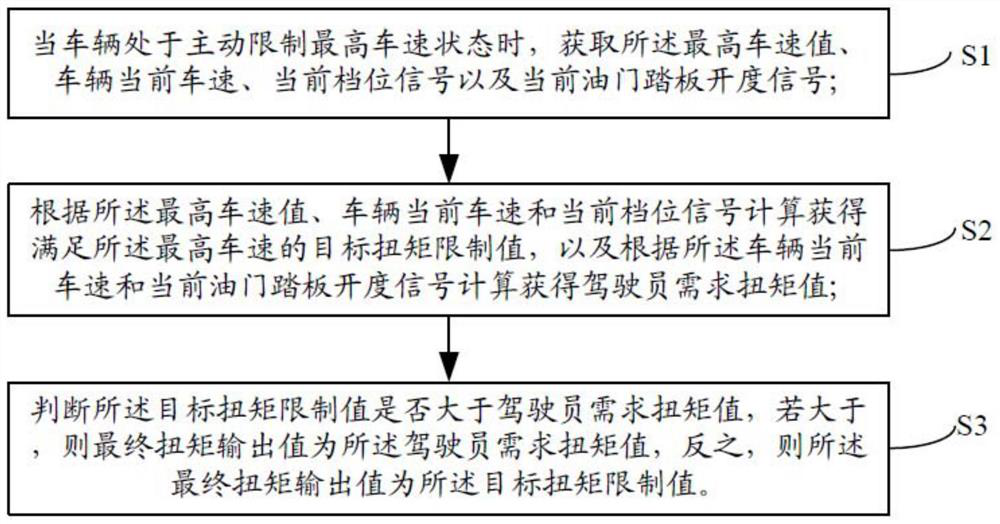

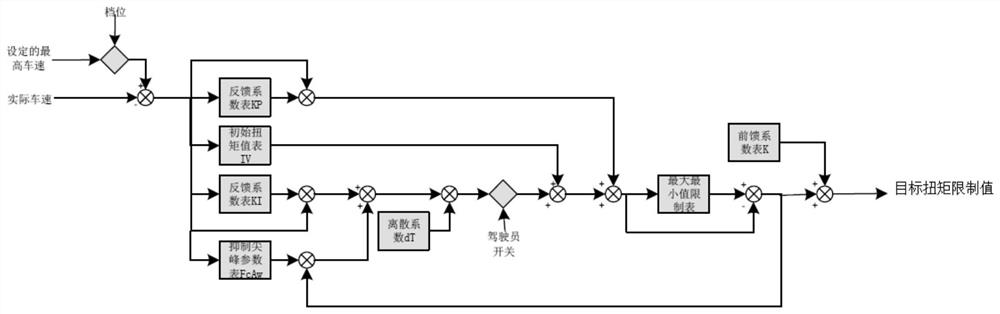

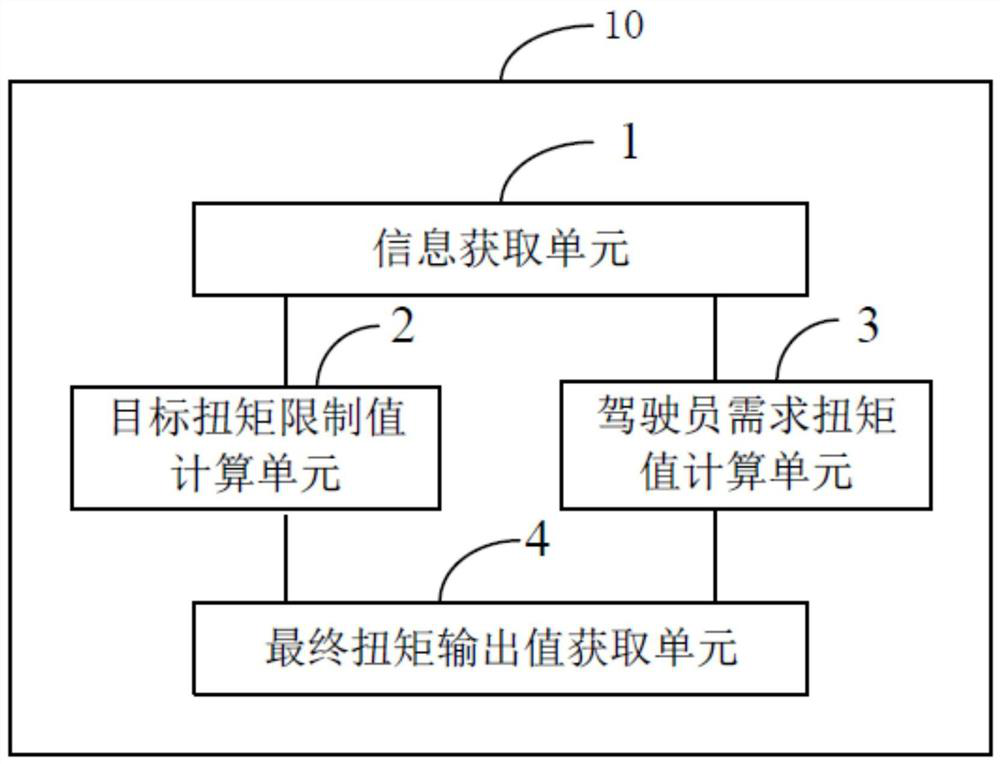

Vehicle speed control method and device, equipment and computer readable medium

ActiveCN112009242AImprove driving experienceStable speedVehicle fittingsSpeed/accelaration controlDriver/operatorControl theory

The invention provides a vehicle speed control method and device, equipment and a computer readable medium. The method comprises the following steps: S1, obtaining a maximum vehicle speed value, a current vehicle speed, a current gear signal and a current accelerator pedal opening signal when a vehicle is in a state of limiting the maximum vehicle speed; S2, obtaining a target torque limit value meeting the highest vehicle speed through calculation according to the highest vehicle speed value, the current vehicle speed and the current gear signal, and obtaining a torque value required by a driver through calculation according to the current vehicle speed and the current accelerator pedal opening degree signal; and S3, obtaining a final torque output value according to the target torque limit value and the driver demand torque value, and controlling to output the final torque output value. Compared with the prior art, the vehicle speed can be stabilized more quickly, obvious fluctuationof the vehicle speed is avoided when the vehicle has an over-temperature risk, and more excellent driving feeling can be brought to customers on the premise of ensuring safety.

Owner:GAC AION NEW ENERGY AUTOMOBILE CO LTD

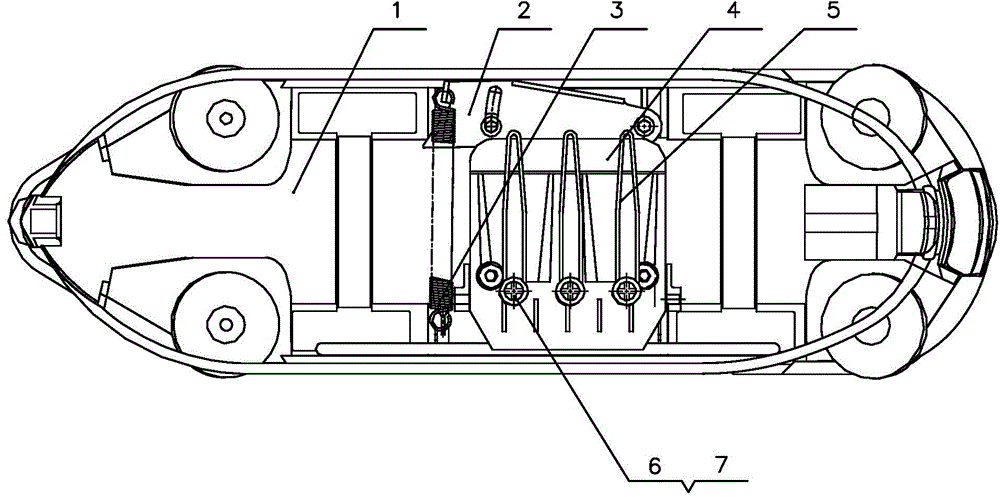

Yarn pressing device for plastic cylinder knitter shuttle

The invention relates to a yarn pressing device for a plastic cylinder knitter shuttle. The yarn pressing device is installed in the middle in a cylinder knitter shuttle body. The yarn pressing device comprises a yarn pressing plate, a tension spring base and a tension spring. The tension spring base is installed in the shuttle body, one end of the tension spring is hung on the tension spring base, and the other end of the tension spring tensions the yarn pressing plate. The yarn pressing plate is installed in the shuttle body, and wire brushes are installed on the upper surface of the yarn pressing plate and are each of a flat enclosed structure formed by winding steel wires. Compared with an original yarn pressing plate structure, surface contact or line contact between a weft bobbin and a yarn pressing plate is changed into line contact or point contact between a weft bobbin and the steel brushes, abrasion to yarn is weakened, the situation that the yarn is burned and broken due to large-area friction heating is avoided, the resistance applied by the yarn pressing late to the weft bobbin through the steel brushes can be stable, and the tension produced by weft in the process of knitting can be constant.

Owner:常州市永明机械制造有限公司

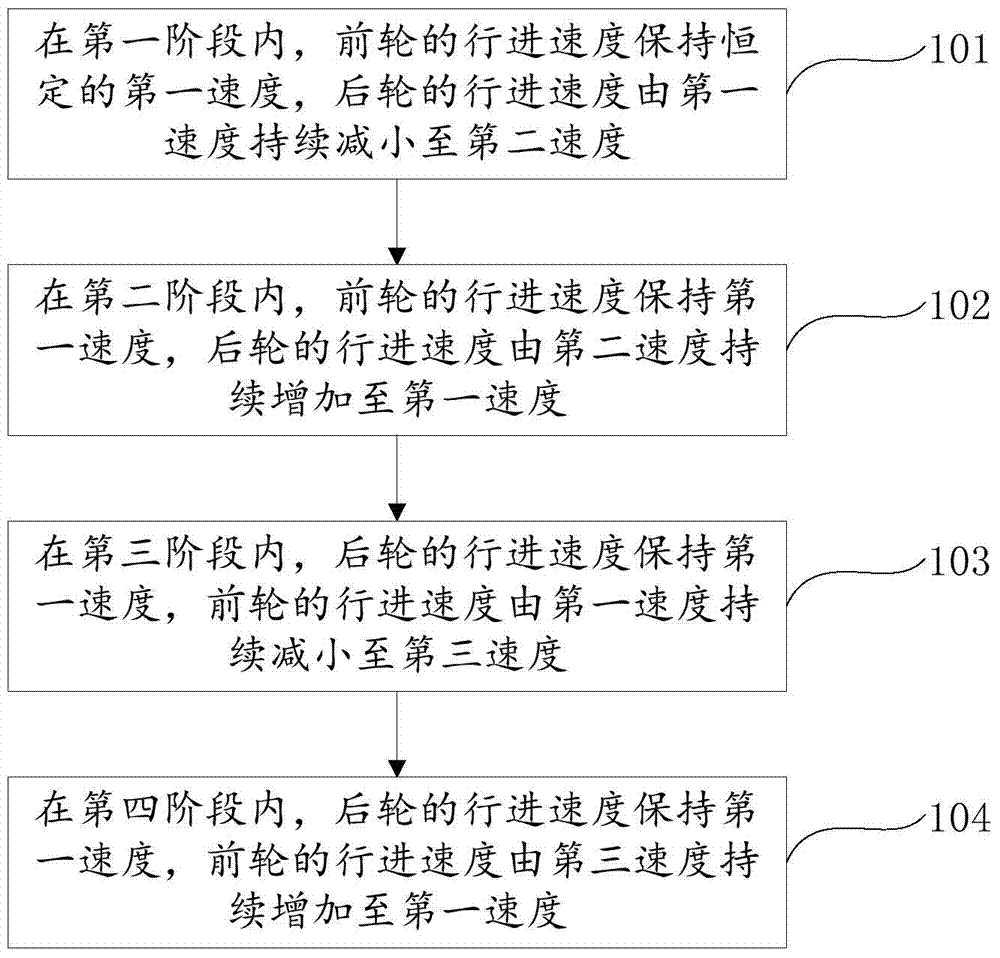

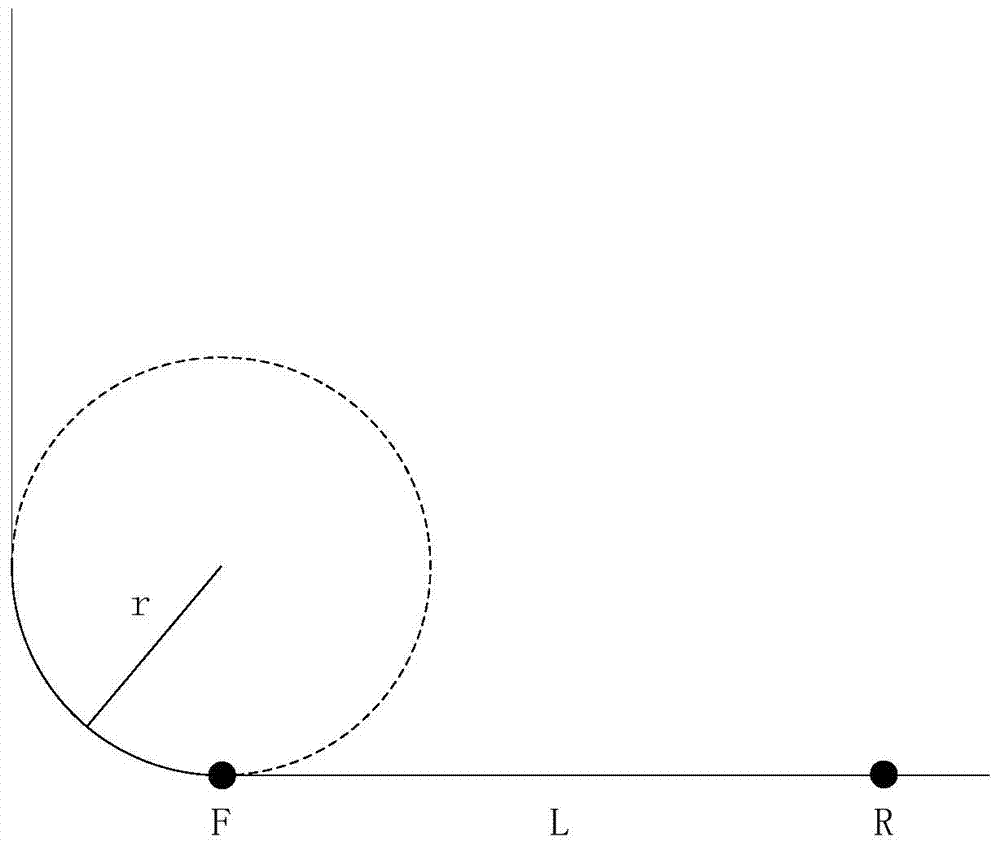

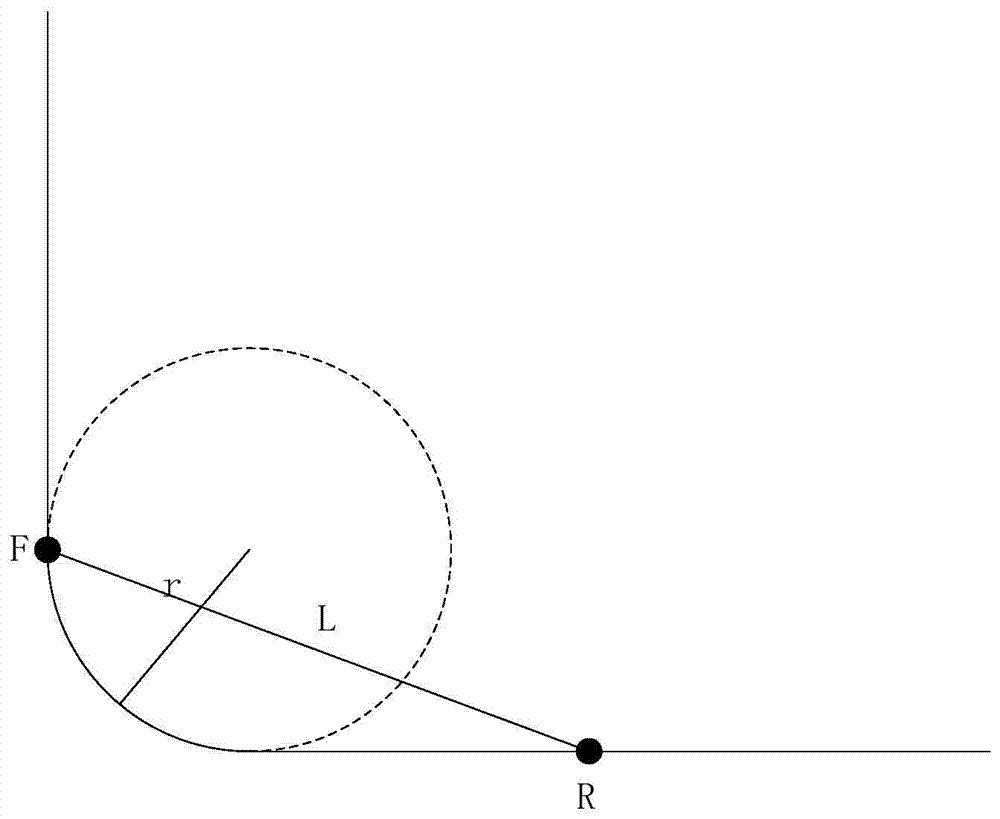

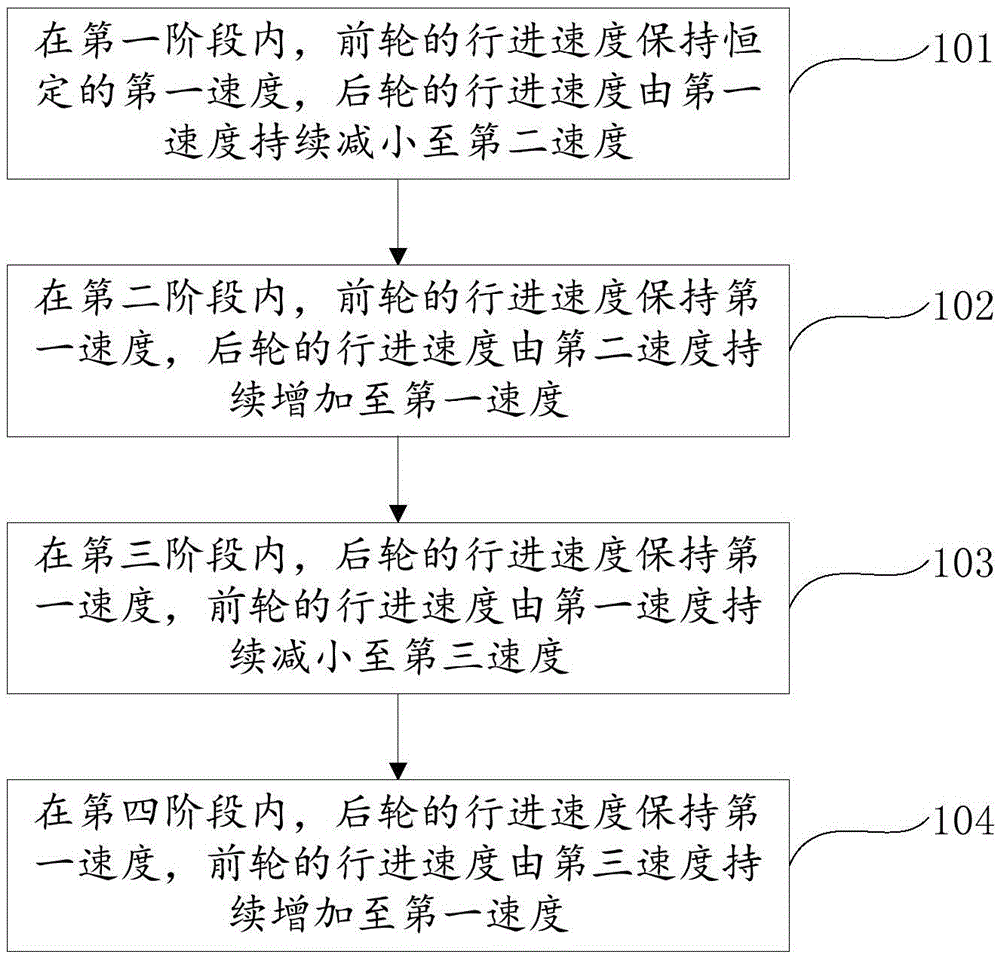

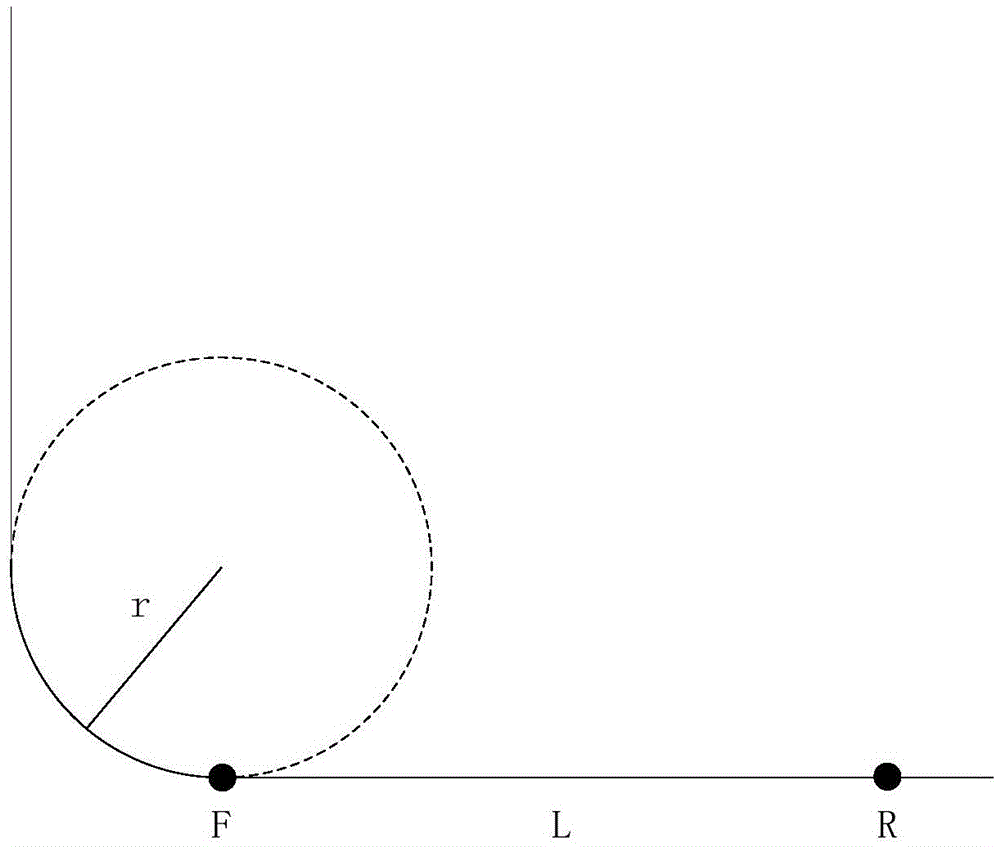

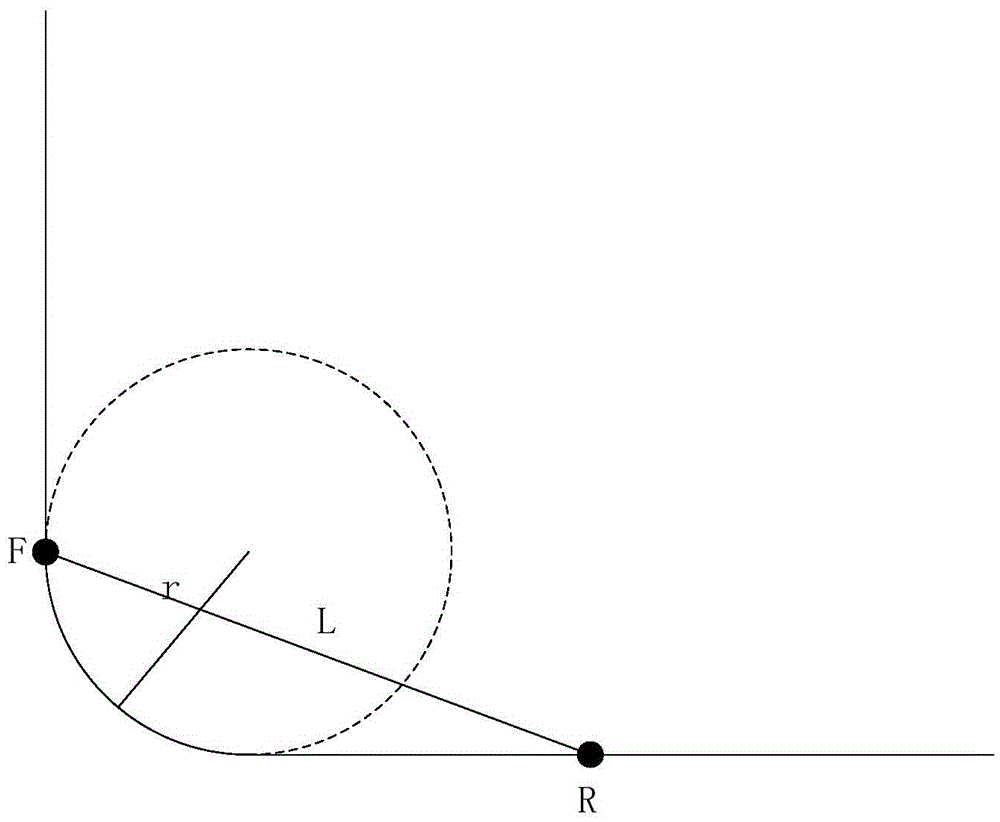

Double-wheel drive single-rail conveyor and over-bending control method thereof

ActiveCN104261086AWalking smoothlyAvoid speed fluctuationsControl devices for conveyorsWheel driveTurning radius

The invention discloses an over-bending control method of a double-wheel drive single-rail conveyor. The distance between a front wheel and a rear wheel of the single-rail conveyor is larger than the turning radius of a curve; according to the four continuous stages, when the front wheel passes through the curve, the approach speed of the front wheel is first speed kept constant in the first stage and the second stage, the first speed is continued to be reduced to the third speed in the third stage, and the third speed is continued to be increased to the first speed in the fourth stage; the approach speed of the rear wheel is continued to be reduced to the second speed from the first speed in the first stage, the second speed of the rear wheel is continued to be increased to the first speed in the second stage, and the first speed is kept in the third stage and the fourth stage. Compared with the prior art, the speed control over the front wheel and the rear wheel conforms to the actual speed change rule of the front wheel and the rear wheel of the single-rail conveyor, the speed fluctuation caused by mismatching of the actual speed and the output speed is avoided, and it is ensured that the conveyor smoothly and stably runs in the turning process.

Owner:XIKELIN CONTROL SYST SHANGHAI CO LTD

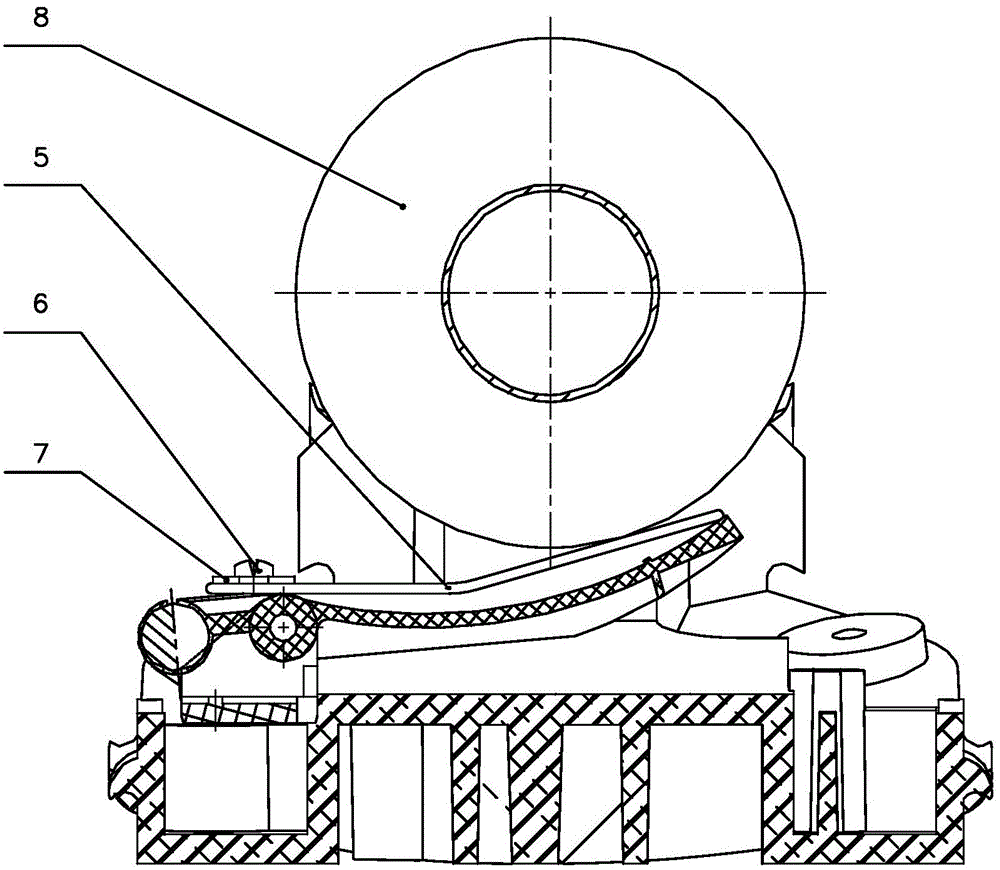

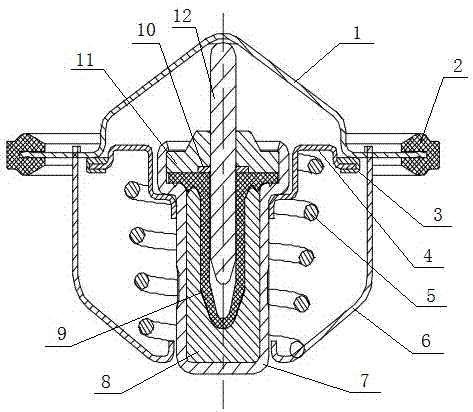

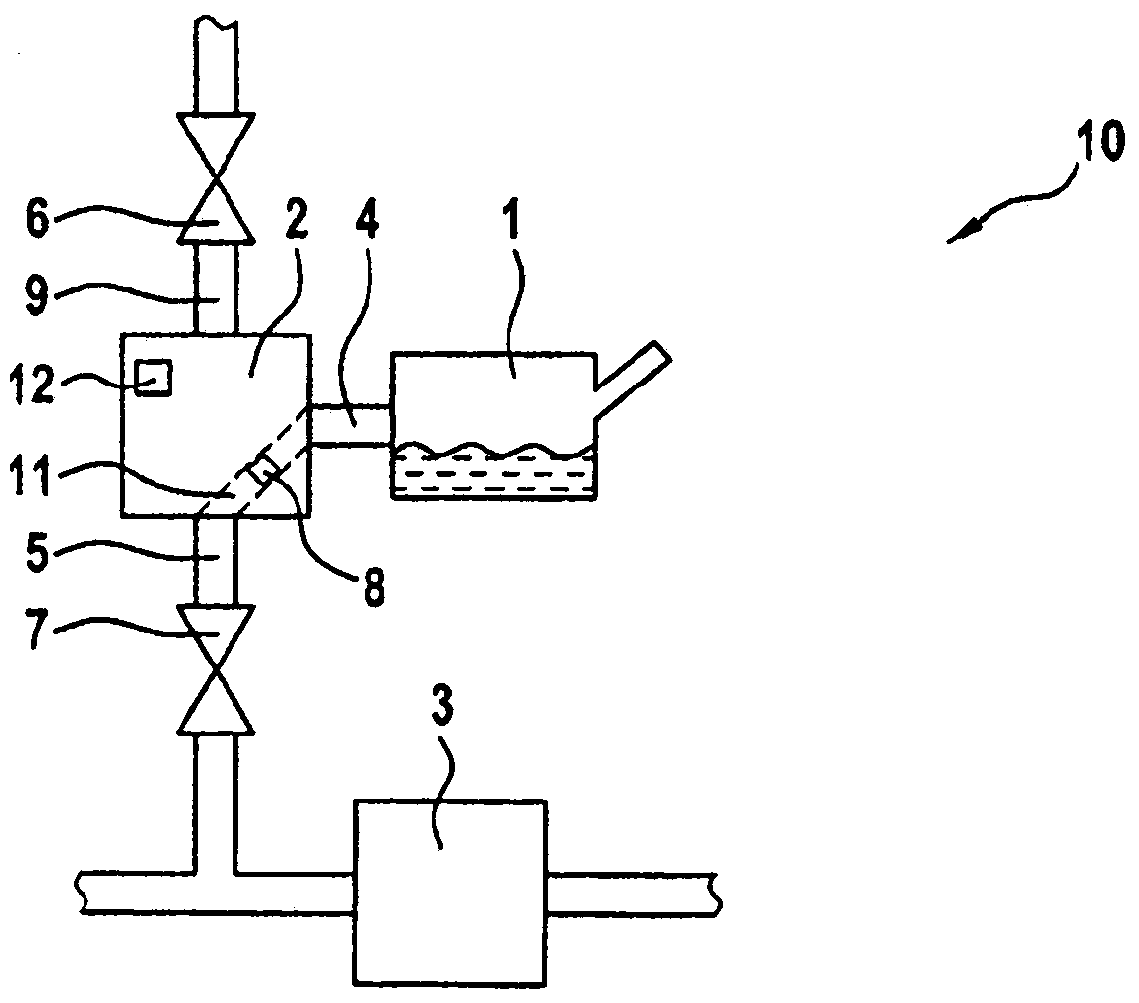

Engine thermolator assembly

InactiveCN104712413AAvoid speed fluctuationsReduce vibrationCoolant flow controlMachines/enginesEngineeringCoolant temperature

The invention discloses an engine thermolator assembly, which comprises a cover plate, a support, a jacking mechanism and a valve which is linked with the jacking mechanism, wherein the jacking mechanism comprises a sensing body, a sensing body cover, a rubber pipe, a push rod and a spring; a center hole is formed in the valve; a first shoulder of the upper end of the sensing body is located on the lower side of the valve; a limit shoulder is arranged on the lower surface of a main valve; a space in which the first shoulder can vertically move is reserved between the center hole and the limit shoulder; a stop block is arranged below the limit shoulder in the middle of the sensing body; the spring sleeves the sensing body; two ends of the spring abut against the stop block and the support; the upper end face of the first shoulder is closely attached to the lower surface of the valve; the upper surface of the valve is closely attached to the lower end of the cover plate. The condition that after the valve is opened, since the temperature fluctuation of cooling liquid is overlarge due to an overlarge flow area, the rotation speed fluctuation of an engine is caused is prevented, the vibration of the engine is reduced, and the oil consumption and the emission of the engine are reduced.

Owner:CHONGQING LEIWAN SCI & TECH

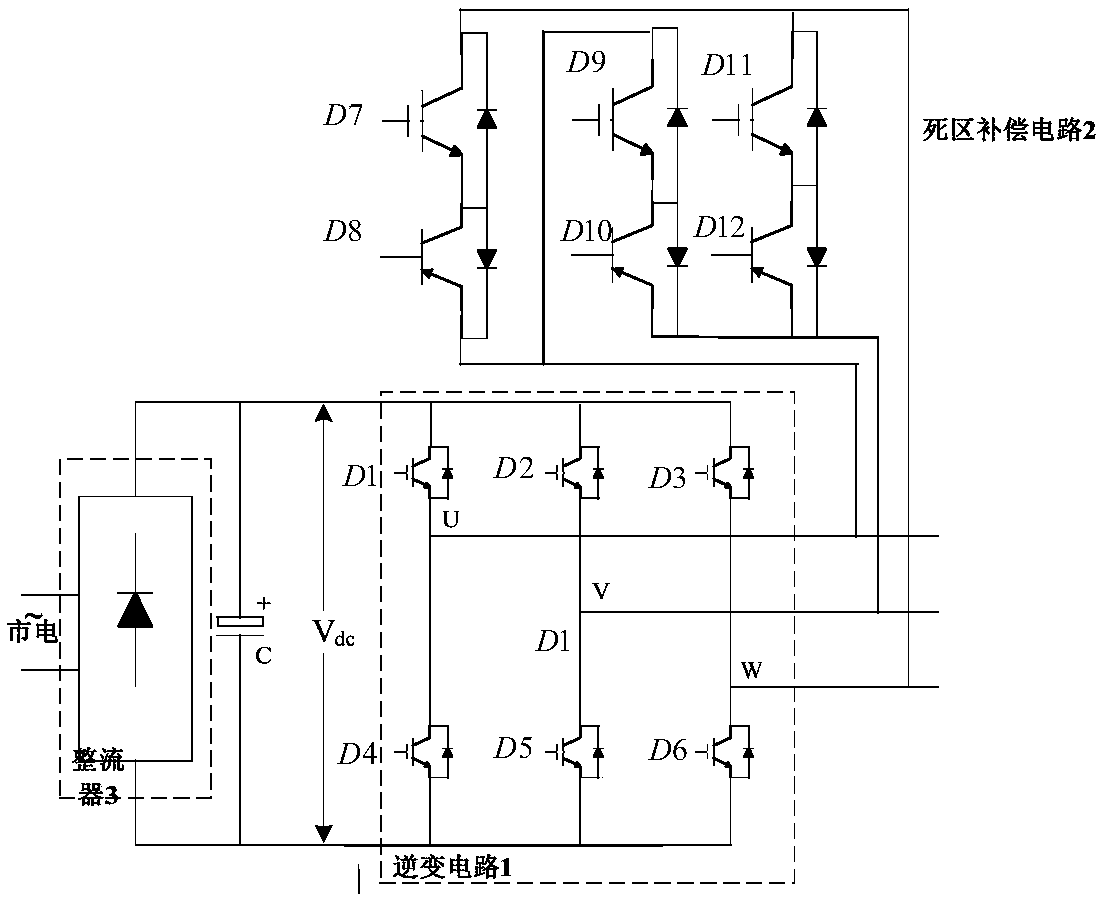

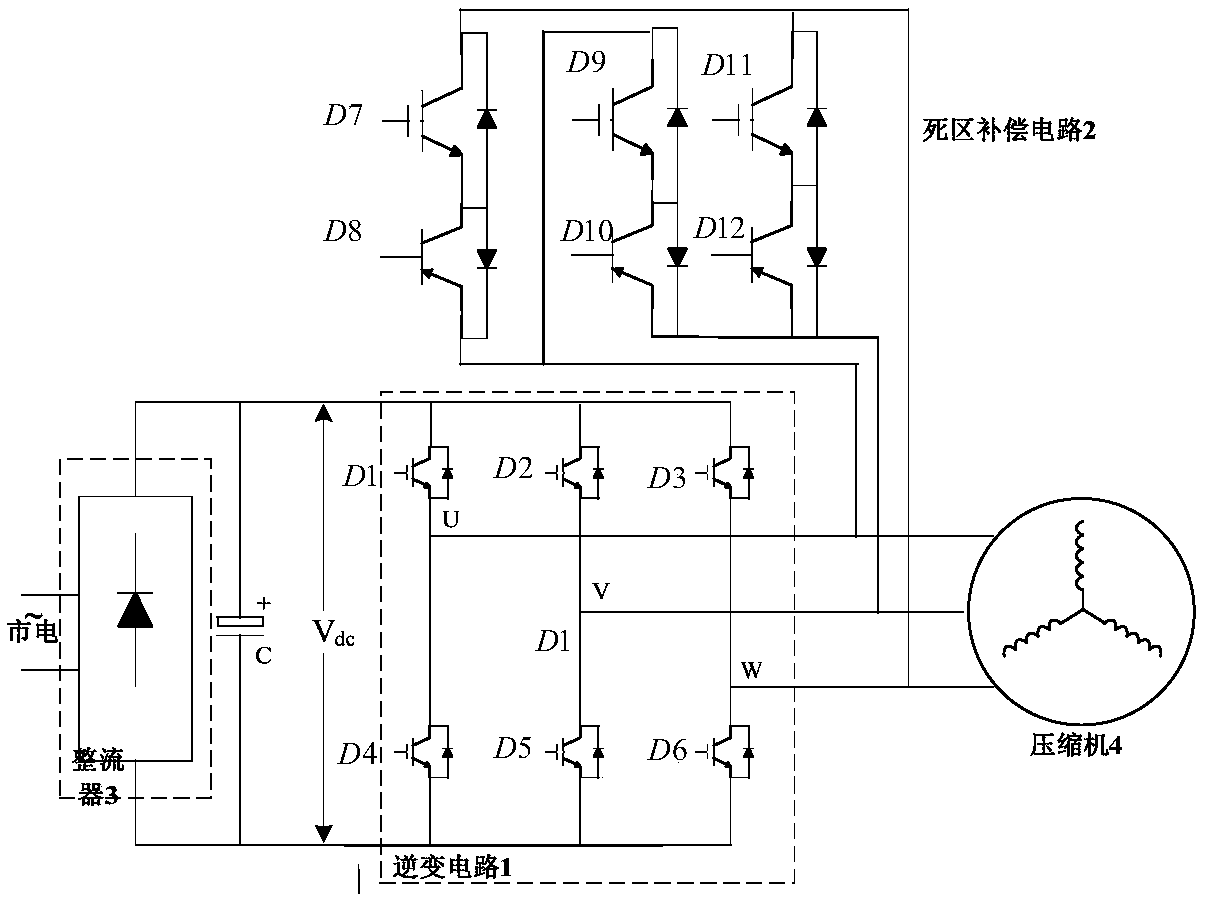

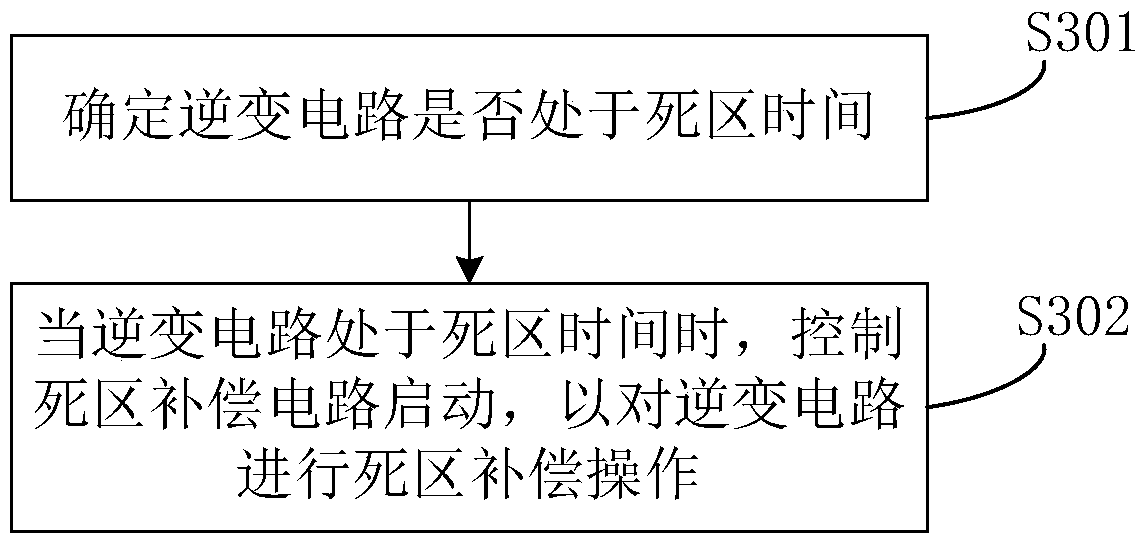

Dead zone compensation method, device, system, and drive controller

PendingCN108880392AGuaranteed uptimeReduce noiseAc-dc conversionMotor control for motor oscillations dampingMotor speedDead time

The invention discloses a dead zone compensation method, a device, a system and a drive controller. The system comprises a motor and a drive controller, wherein a dead zone compensation circuit is connected with the motor, the drive controller is used for determining whether a inverter circuit is in a dead time. When the inverter circuit is in the dead zone time, a starting signal is sent to the dead zone compensation circuit; the dead zone compensation circuit is used for receiving the starting signal, so as to perform a dead zone compensation operation on the inverter circuit. According to the dead zone compensation method, the device, the system, and the drive controller, the motor can be a compressor, the voltage output from the inverter circuit to the motor zero during the dead time can be zero, so as to ensure that the voltage output to the motor is consistent with the expected voltage value of PWM during modulation. The current distortion caused by waveform distortion and the fluctuation of the motor speed are avoided, so that the operation of the motor is more stable and reliable, and the noise is small.

Owner:GREE ELECTRIC APPLIANCES INC

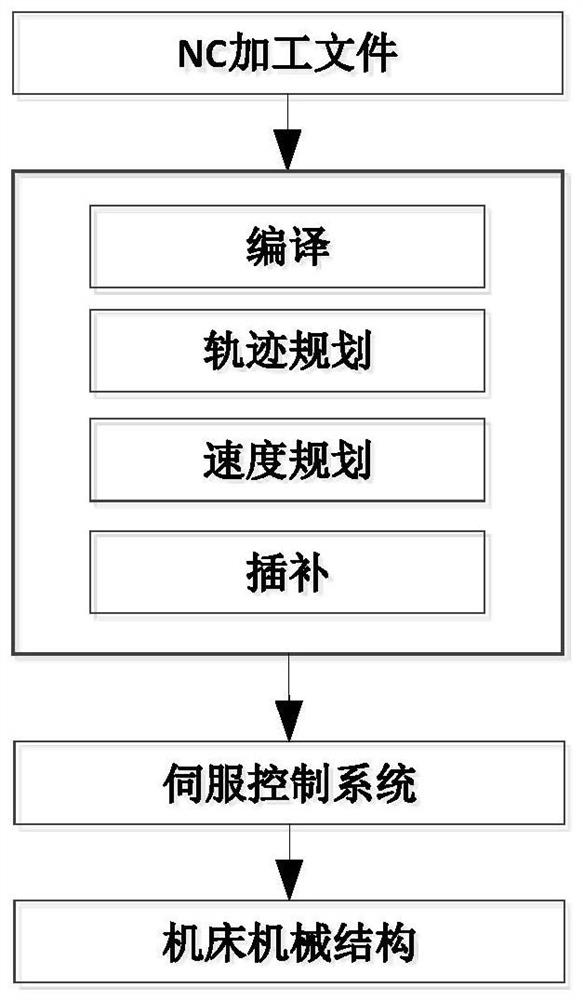

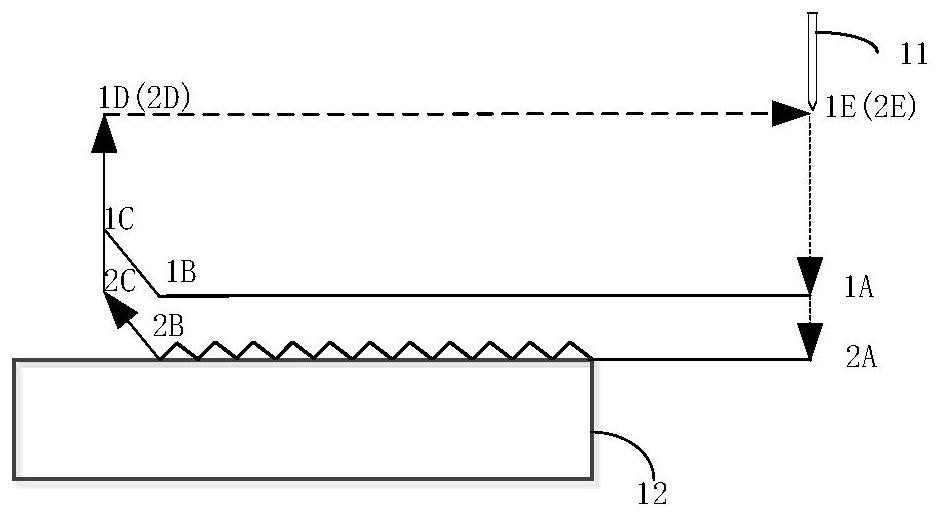

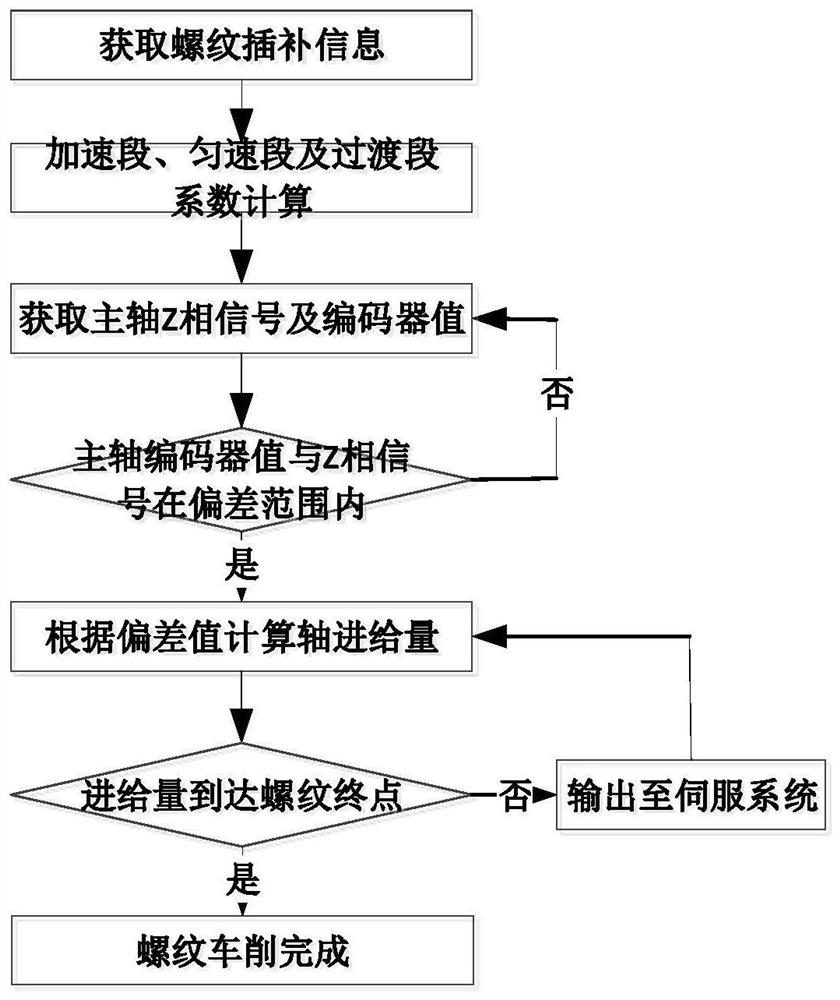

Main shaft following synchronous control method for improving thread turning precision

ActiveCN111857040AGuaranteed synchronicityConsistent positionNumerical controlNumerical controlSynchronous control

The invention provides a main shaft following synchronous control method for improving thread turning machining precision, and belongs to the technical field of numerical control machining thread turning, and the method comprises the following steps: obtaining thread interpolation information; respectively designing a function relationship between the rotating speed of the main shaft and the feedamount of the feed shaft for the acceleration section, the constant-speed section and the transition section between the acceleration section and the constant-speed section; the feeding shaft is synchronously controlled along with the main shaft; and calculating the feed amount of the feed shaft according to the number of turns of the main shaft encoder relative to the main shaft Z-phase signal reference so as to perform thread machining. According to the method, speed fluctuation of the main shaft in the actual process can be solved, the strong following relation between feeding displacementof the feeding shaft and feeding of the main shaft is adopted, and thread precision and surface machining quality can be achieved under the condition that threads are cut many times.

Owner:TSINGHUA UNIV

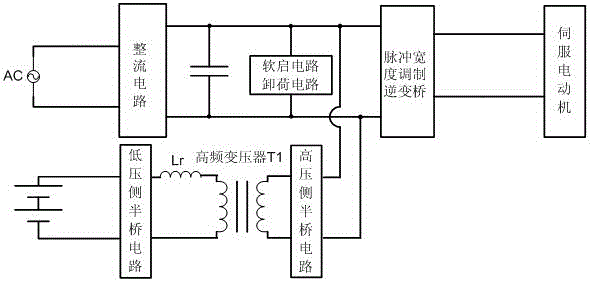

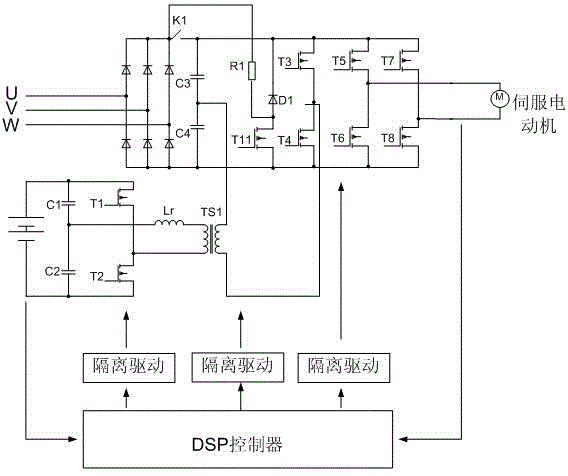

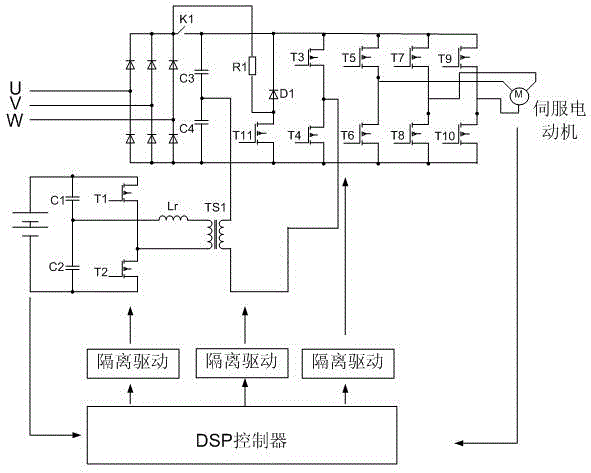

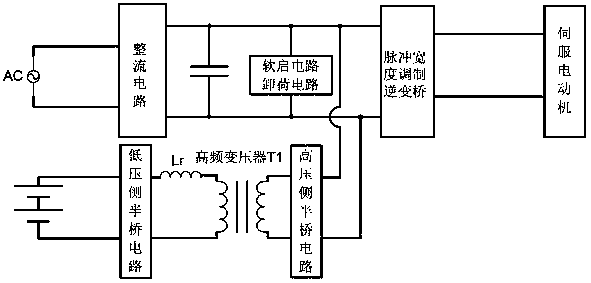

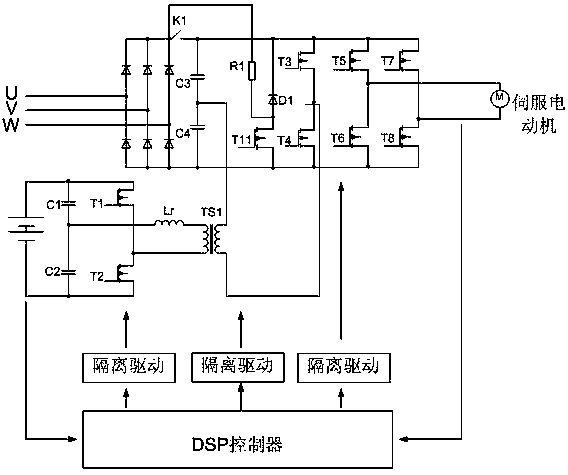

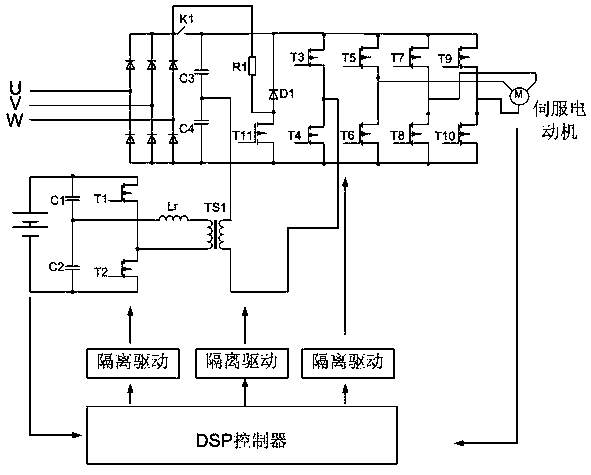

Motor servo controller and control method thereof

ActiveCN106788109ASolving Two-Way Flow ProblemsGuaranteed accuracyAC motor controlPower network operation systems integrationSoft switchingTransformer

The invention discloses a motor servo controller. The motor servo controller comprises a servo motor, a standby power source, a soft startup and unloading circuit, a controllable rectification circuit connected to an AC power, a PWM inverter bridge and a DC-DC half-bridge soft switching high-frequency circuit; the DC-DC half-bridge soft switching high-frequency circuit comprises a low-voltage side half-bridge circuit, a high-frequency transformer and a high-voltage side half-bridge circuit; the low-voltage side half-bridge circuit is connected with the high-voltage side half-bridge circuit through a high-frequency transformer; the standby power source is connected with the low-voltage side half-bridge circuit; the high-voltage side half-bridge circuit is connected with the DC end of the PWM inverter bridge; the AC end of the PWM inverter bridge is connected with the servo motor; and the rectification circuit is connected with the DC end of the PWM inverter bridge. According to the motor servo controller, the standby power source can provide sufficient electric energy to the servo motor when the voltage of a power grid fluctuates, so that precision requirement of rotating speed control of a blade motor is guaranteed, and the working stability of a whole system is enhanced.

Owner:DONGFANG ELECTRIC AUTOMATIC CONTROL ENG CO LTD

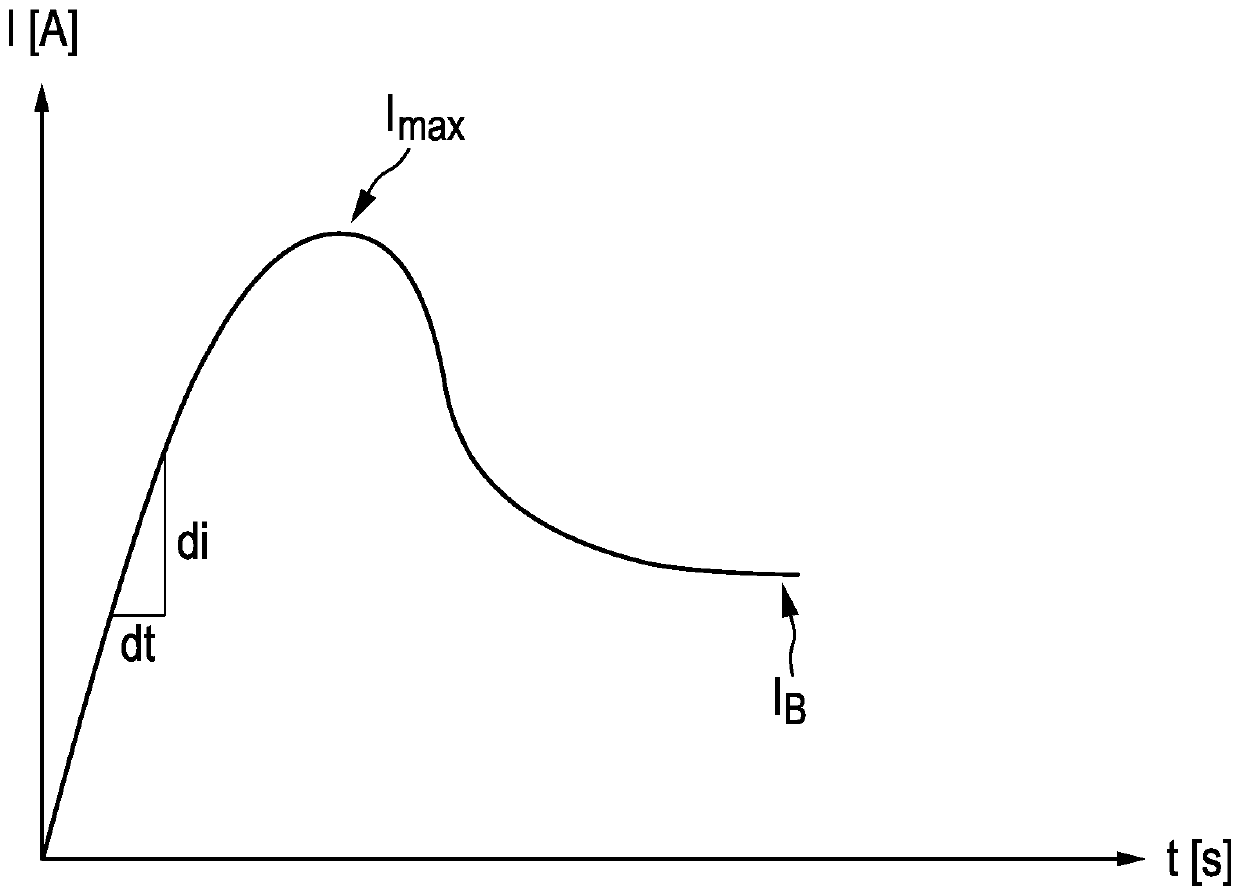

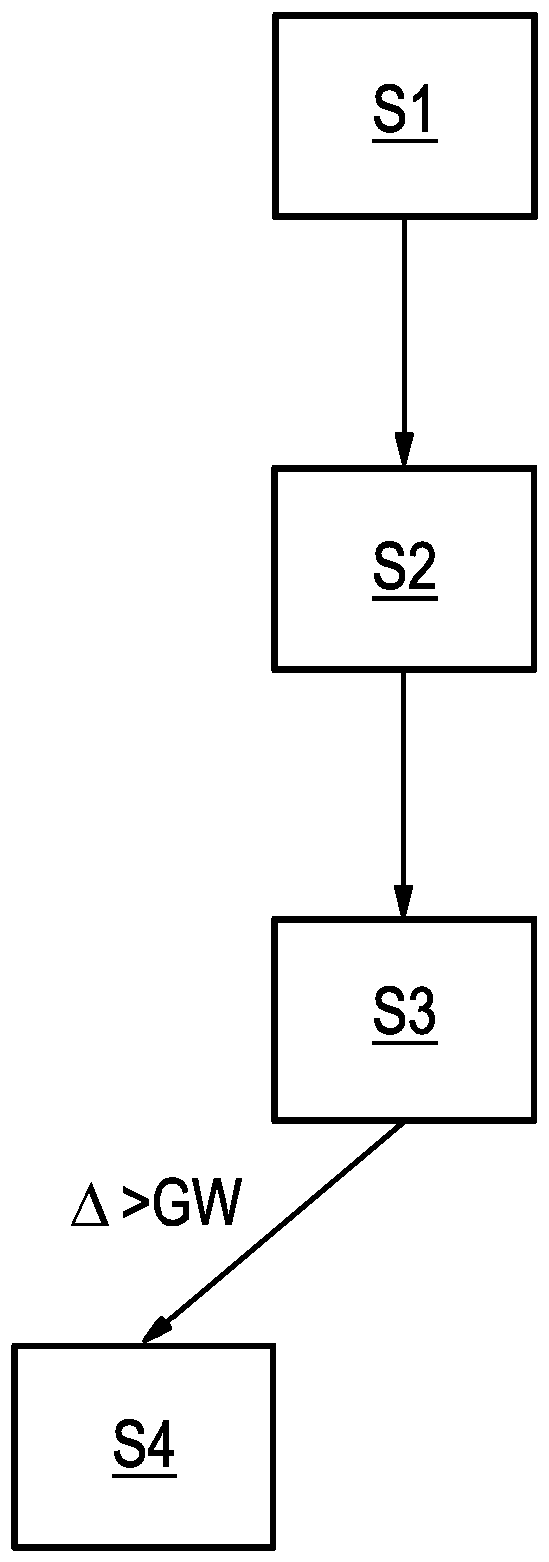

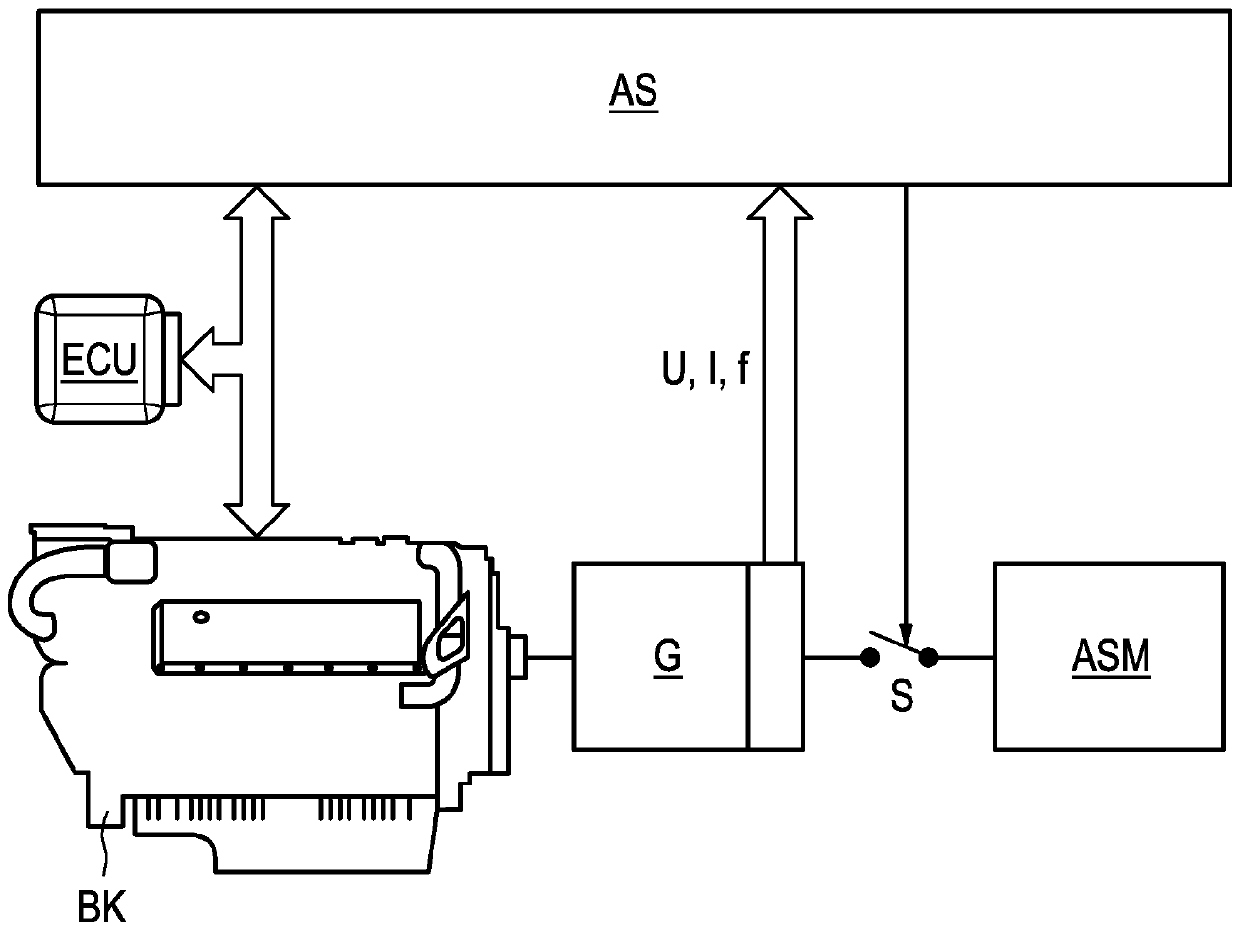

Method for the open-loop and closed-loop control of an internal combustion engine with a generator and asynchronous machine, open-loop and closed-loop control unit, and internal combustion engine

ActiveCN111556923AIncreased fuelImproved load switching capabilityElectrical controlSpeed sensing governorsLoop controlEngineering

The invention relates to a method for the open-loop and closed-loop control of an internal combustion engine (BK), in particular a diesel engine or gas engine, with a generator (G) and asynchronous machine (ASM), comprising the following steps: detecting at least one electrical characteristic variable of the generator, wherein the electrical characteristic variable is selected from current (I), voltage (U) or frequency (f); determining a characteristic variable change in the electrical characteristic variable of the generator in a predetermined time interval; comparing the change in characteristic variable with a first threshold value; and in the event that the change in characteristic variable is greater than the first threshold value, changing from a standard speed control of the internal combustion engine to a feed-forward control.

Owner:ROLLS ROYCE SOLUTIONS GMBH

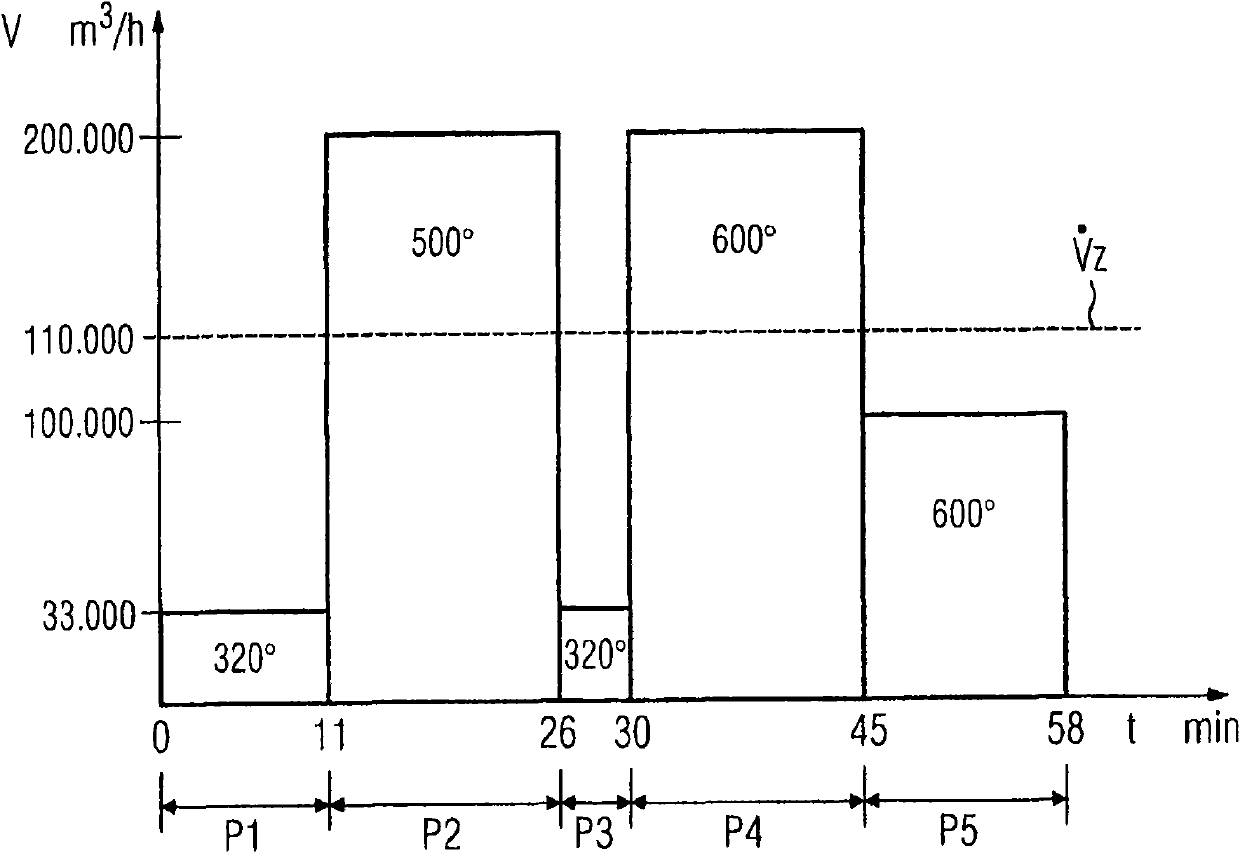

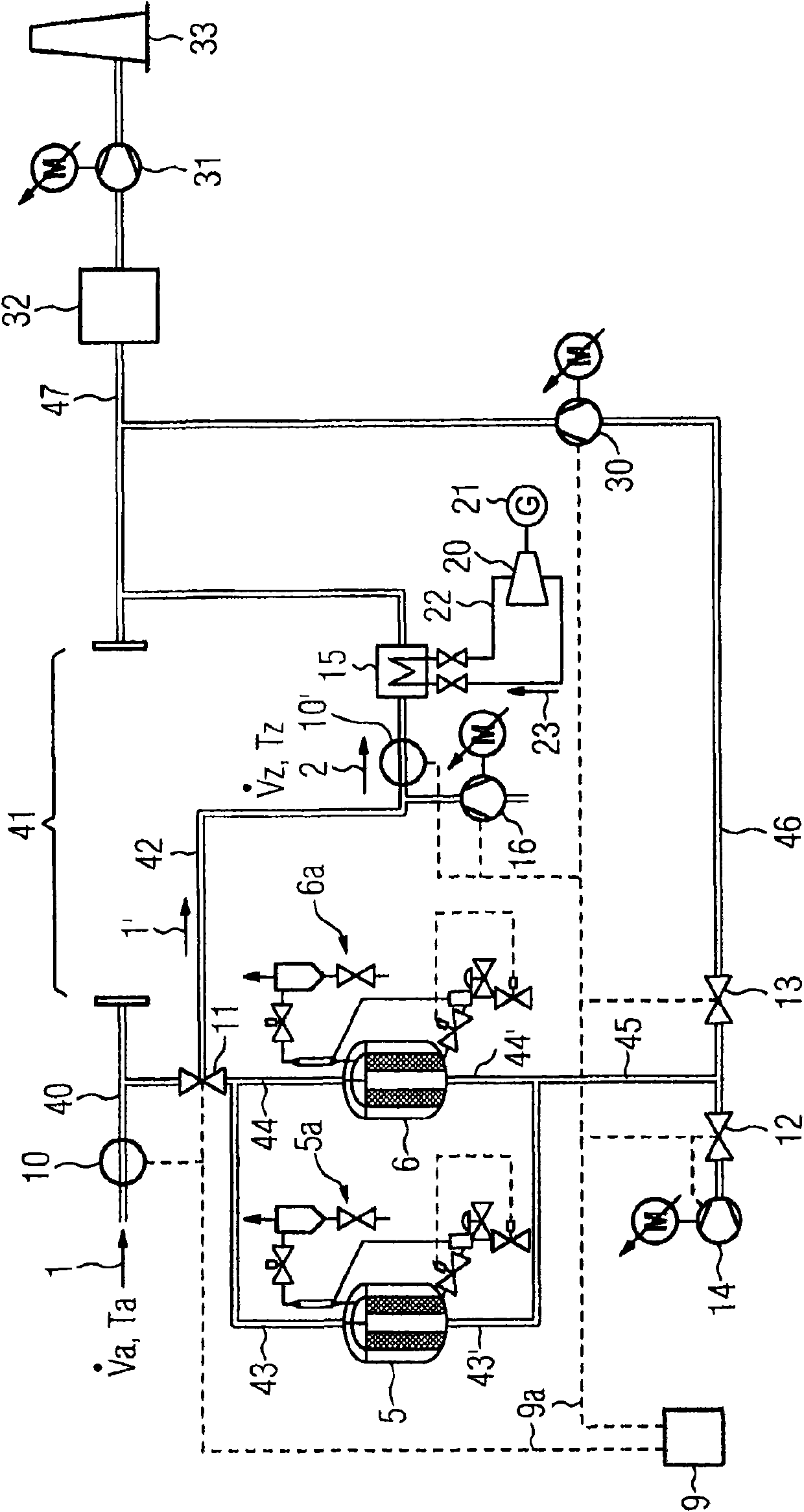

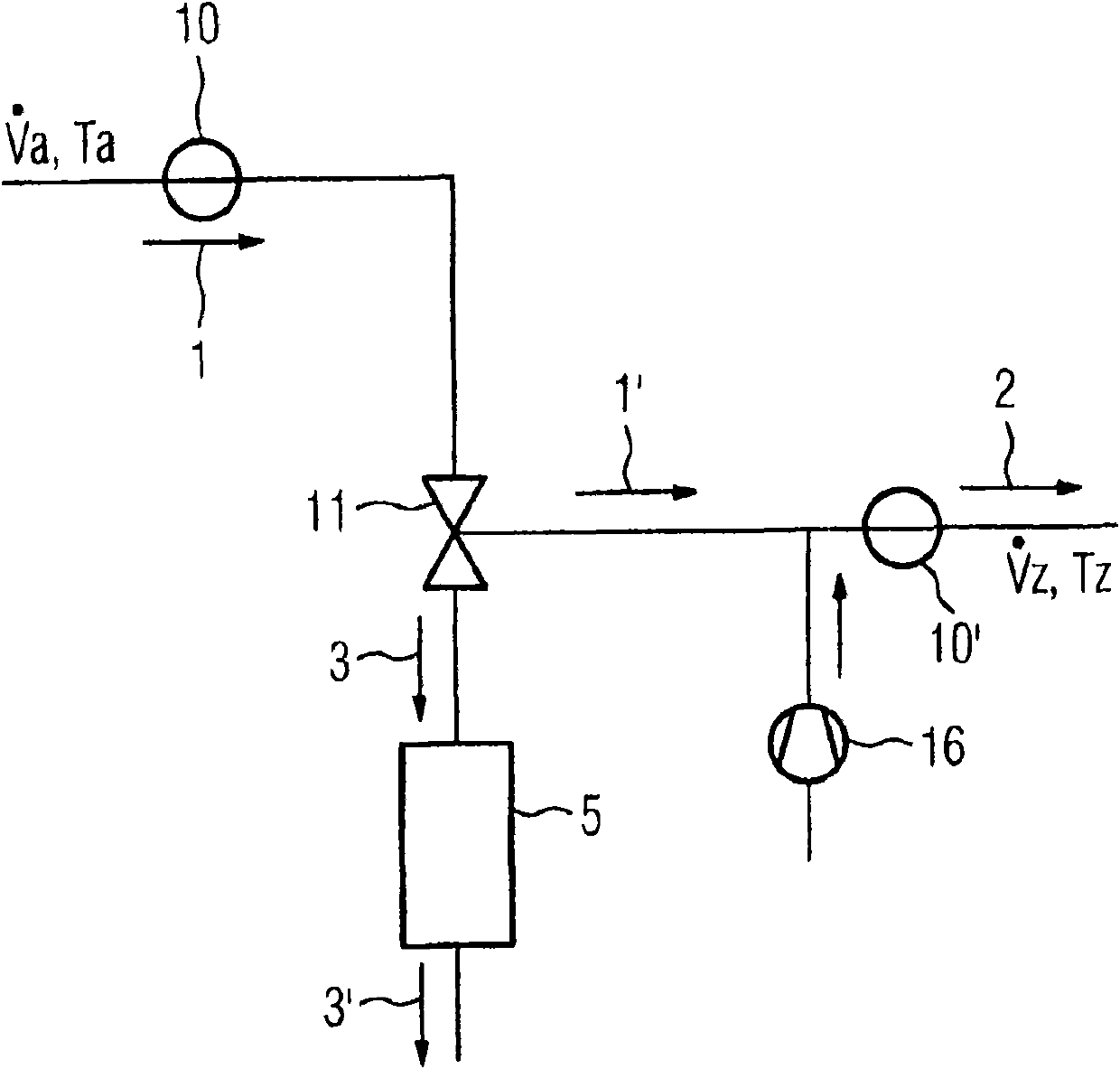

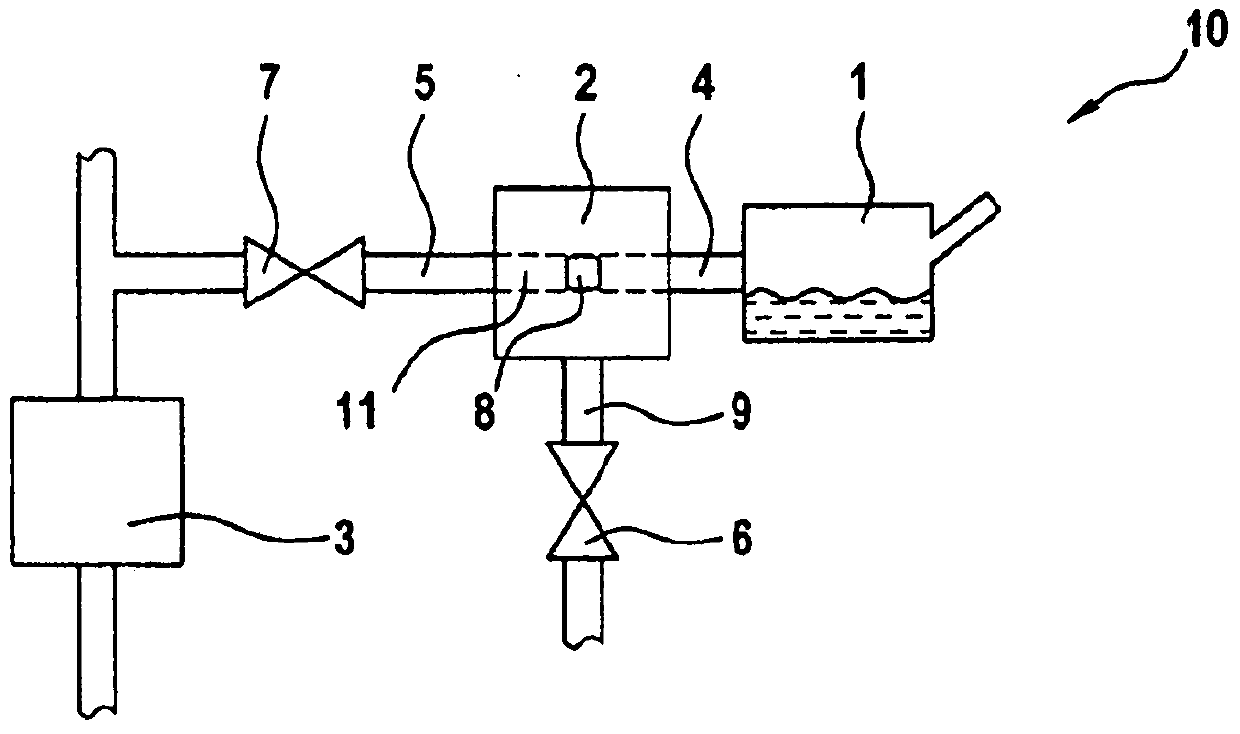

Method and device for utilizing heat transported by a discontinuous flow of exhaust gases

InactiveCN101680717AAchieve target temperatureSmall sizeHeat storage plantsHeat recoveryThermal energyProcess engineering

The invention relates to a method and a device for utilizing heat transported by a discontinuous flow of exhaust gases (1), wherein the discontinuous flow of exhaust gases (1) is emitted in phases (P1, P2, P3, P4, P5) with, in each case, constant output values for volume flowing (Va) and temperature (Ta)from an industrial installation, particularly an industrial furnace, wherein the discontinuousflow of exhaust gases (1) is converted into a continuous working flow (2) with adjustable, constant target values for the volume flowing (Vz) and the temperature (Tz). The continuous working flow (2),with the heat contained therein, is used for the conversion of thermal energy into useful energy.

Owner:SIEMENS AG

Two-wheel drive monorail conveyor and its cornering control method

ActiveCN104261086BWalking smoothlyAvoid speed fluctuationsControl devices for conveyorsMonorailTurning radius

The invention discloses an over-bending control method of a double-wheel drive single-rail conveyor. The distance between a front wheel and a rear wheel of the single-rail conveyor is larger than the turning radius of a curve; according to the four continuous stages, when the front wheel passes through the curve, the approach speed of the front wheel is first speed kept constant in the first stage and the second stage, the first speed is continued to be reduced to the third speed in the third stage, and the third speed is continued to be increased to the first speed in the fourth stage; the approach speed of the rear wheel is continued to be reduced to the second speed from the first speed in the first stage, the second speed of the rear wheel is continued to be increased to the first speed in the second stage, and the first speed is kept in the third stage and the fourth stage. Compared with the prior art, the speed control over the front wheel and the rear wheel conforms to the actual speed change rule of the front wheel and the rear wheel of the single-rail conveyor, the speed fluctuation caused by mismatching of the actual speed and the output speed is avoided, and it is ensured that the conveyor smoothly and stably runs in the turning process.

Owner:XIKELIN CONTROL SYST SHANGHAI CO LTD

Method for controlling composition of combustible gas mixture and control device thereof

ActiveCN105408612BReliable emission limit valueReliable compliance with emission limit valuesNon-fuel substance addition to fuelFuel injection apparatusActivated carbonExhaust valve

The invention relates to a method for controlling the composition of a combustible mixture for an internal combustion engine by means of a fuel tank venting device when venting a fuel storage device, the venting device being introduced between the fuel tank and the internal combustion engine and comprising: with an activated carbon bed The fuel storage of the fuel storage; the air intake pipeline that inputs the scavenging gas into the storage, and the air intake pipeline includes an air intake valve; the fuel pipeline that sends the fuel from the fuel tank connected to the exhaust device to the storage; The gas is fed from the reservoir to the exhaust line of the internal combustion engine, in which there is an exhaust valve; and the heat is arranged in the accumulator in the direct flow path of the fuel between the fuel line and the exhaust line Sensitive element, this method comprises the steps: determine the temperature T0 of the activated carbon bed in the direct flow path at time 0 by means of a heat sensitive element before air intake; open the air intake valve if necessary; open the exhaust valve if necessary; The sensor determines the temperature T1 in the direct flow path at time 1; and closes the exhaust valve or increases the scavenging gas when T1>T0.

Owner:BAYERISCHE MOTOREN WERKE AG

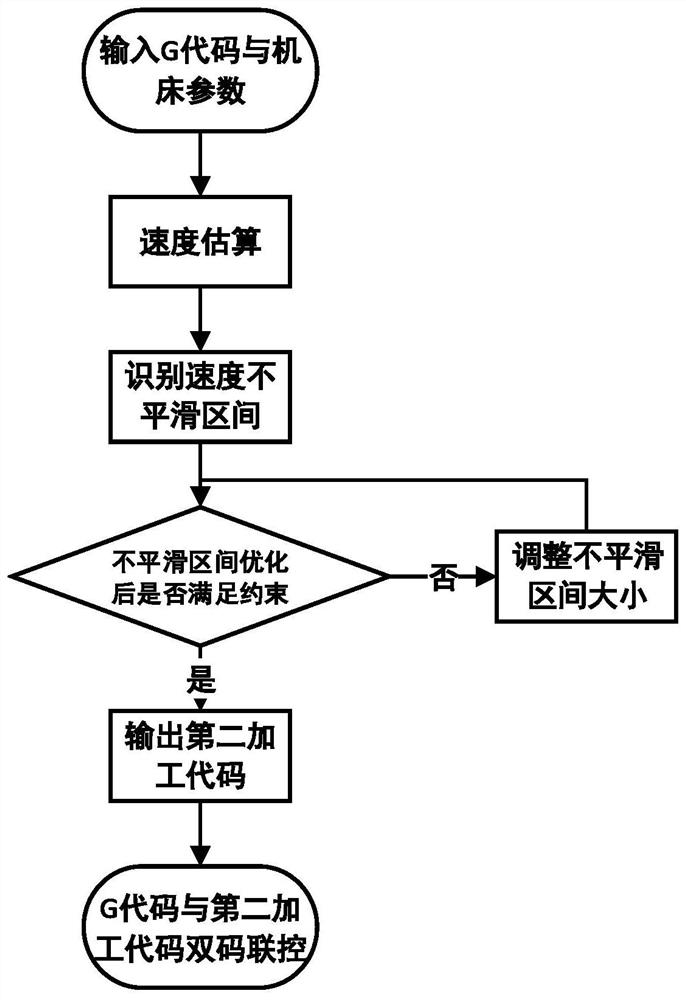

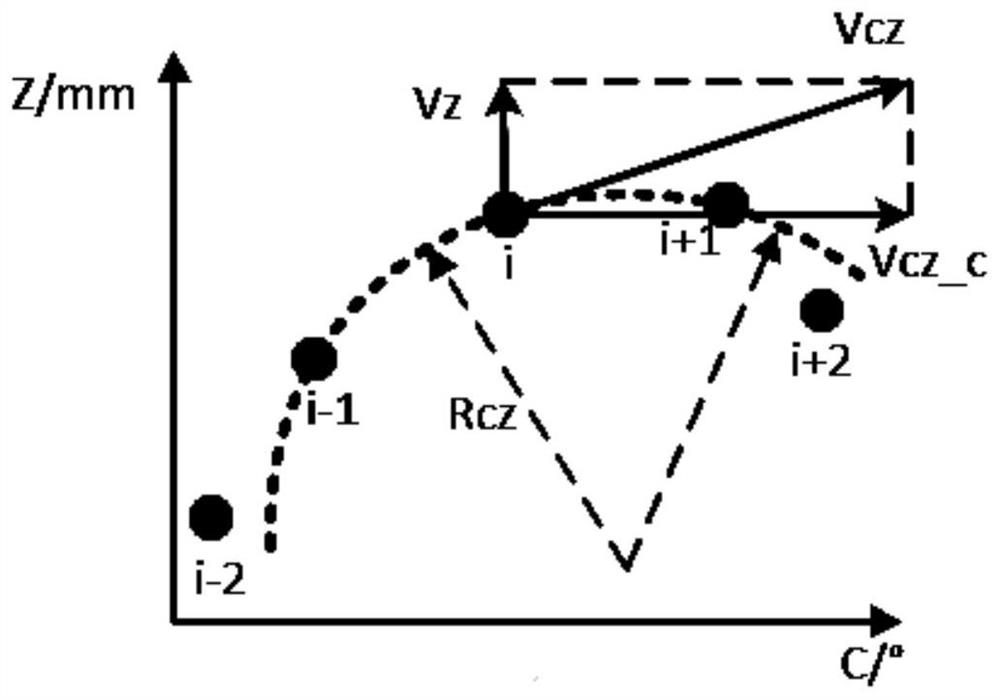

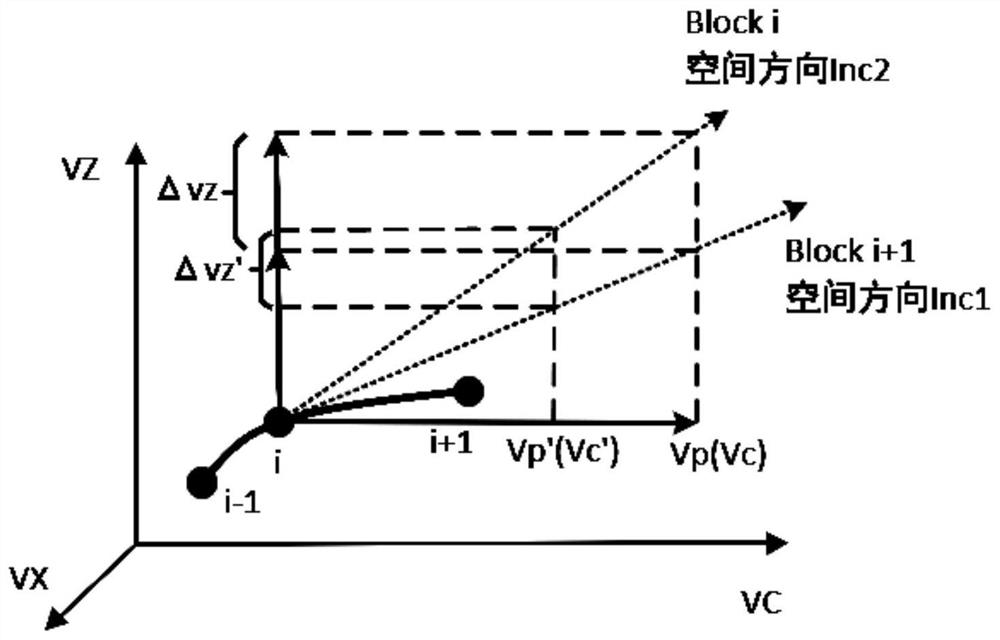

A winding machine process optimization method and winding machine based on dual-code joint control

ActiveCN113189953BImprove processing qualityAvoid speed fluctuationsTotal factory controlProgramme total factory controlWinding machineNumerical control

Owner:HUAZHONG UNIV OF SCI & TECH

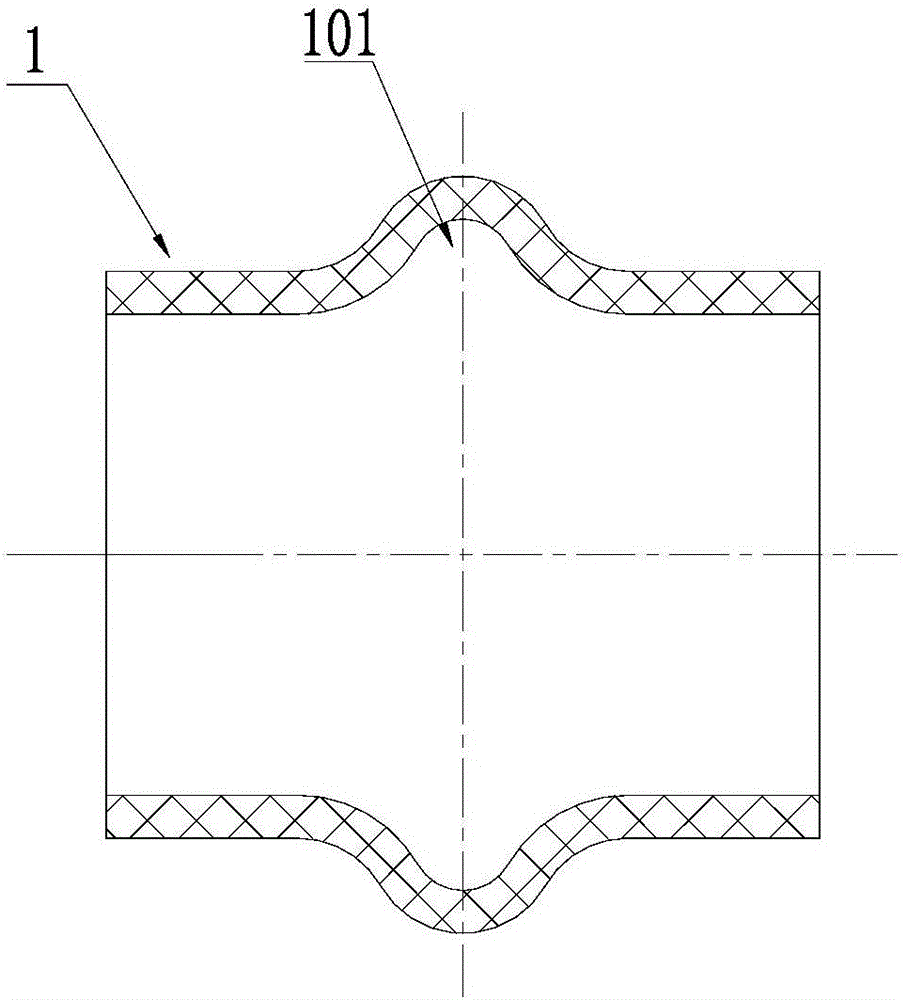

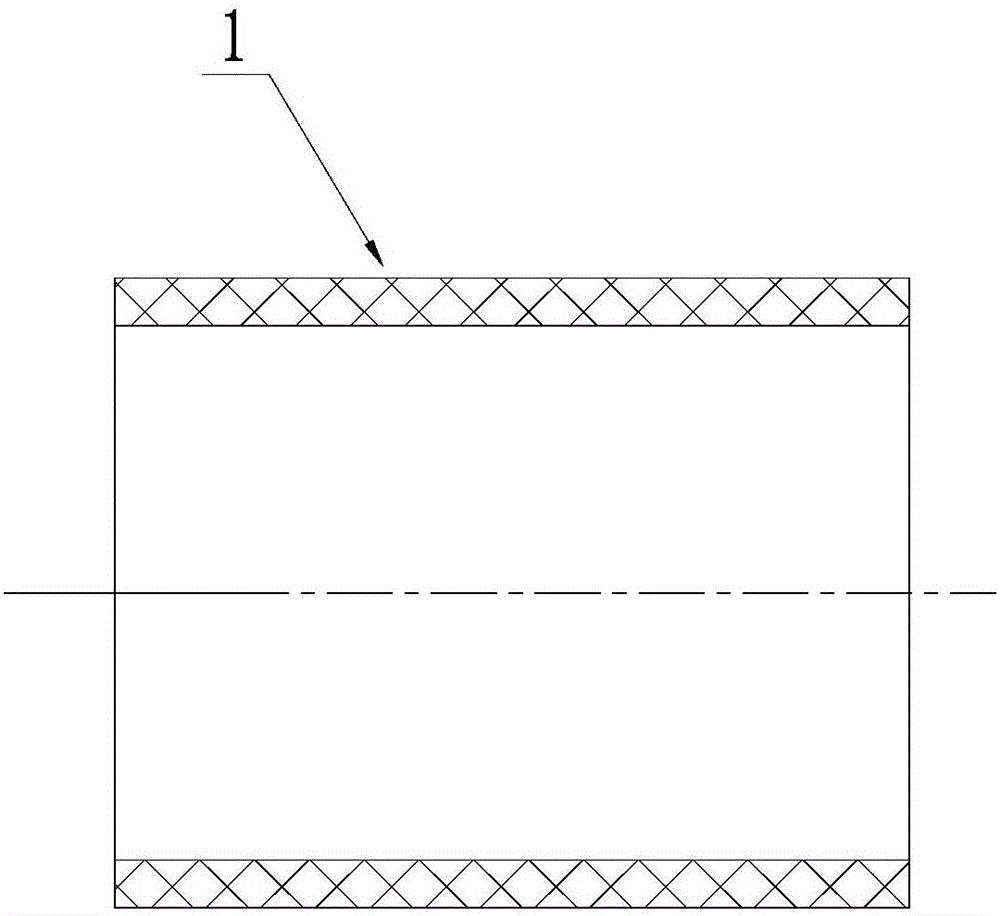

Vacuum air intake rubber hose for diesel engine

InactiveCN106014717AAvoid speed fluctuationsAvoid air intake fluctuationsCombustion-air/fuel-air treatmentMachines/enginesEngineeringIntake pressure

The invention relates to a vacuum intake rubber hose for a diesel engine, which comprises a rubber hose body. The rubber hose body is provided with at least one deformation cavity along the length direction of the rubber hose body. The inner diameter of the deformation cavity is larger than the inner diameter of the rubber hose body. The outer wall forms a bulge, and the two ends of the bulge make a smooth transition with the outer wall of the rubber hose body. The inner wall of the deformation chamber has a circular arc structure, and the inner wall of the deformation chamber and the inner wall of the rubber hose body have a circular arc transition. Adopting the above-mentioned technical solution, that is, a variable-diameter deformation chamber is set on the traditional equal-diameter rubber hose, which effectively prevents the rubber hose from being sucked and deflated when the turbocharger speed fluctuates and the intake pressure decreases; avoiding engine air intake Fluctuation, to ensure the stability of engine performance, to avoid the problem of causing the diesel engine to turn off and extinguish the car caused by the introduction of gas fluctuations. In addition, the vacuum intake hose can withstand greater vibration, especially the deformation of axial tension, which is superior to the traditional equal-diameter hose.

Owner:TIANJIN LOVOL ENGINES

A motor servo controller and its control method

ActiveCN106788109BSolving Two-Way Flow ProblemsGuaranteed accuracyAC motor controlPower network operation systems integrationSoft switchingTransformer

The invention discloses a motor servo controller. The motor servo controller comprises a servo motor, a standby power source, a soft startup and unloading circuit, a controllable rectification circuit connected to an AC power, a PWM inverter bridge and a DC-DC half-bridge soft switching high-frequency circuit; the DC-DC half-bridge soft switching high-frequency circuit comprises a low-voltage side half-bridge circuit, a high-frequency transformer and a high-voltage side half-bridge circuit; the low-voltage side half-bridge circuit is connected with the high-voltage side half-bridge circuit through a high-frequency transformer; the standby power source is connected with the low-voltage side half-bridge circuit; the high-voltage side half-bridge circuit is connected with the DC end of the PWM inverter bridge; the AC end of the PWM inverter bridge is connected with the servo motor; and the rectification circuit is connected with the DC end of the PWM inverter bridge. According to the motor servo controller, the standby power source can provide sufficient electric energy to the servo motor when the voltage of a power grid fluctuates, so that precision requirement of rotating speed control of a blade motor is guaranteed, and the working stability of a whole system is enhanced.

Owner:DONGFANG ELECTRIC AUTOMATIC CONTROL ENG CO LTD

Applications-oriented control device of speed-regulating clutch and control method thereof

Owner:SHANGHAI QIYAO HEAVY IND CO LTD

Ultimate power matching control system, method, device and construction machinery

ActiveCN103670750BImprove flameout phenomenonImprove handlingElectrical controlMachines/enginesControl signalControl system

The invention relates to the technical field of engineering machinery and discloses a power limit matching control system, method and device and an engineering machine. The power limit matching control system, method and device and the engineering machine are used for effectively reducing the flameout phenomenon caused when the power of an engine is not matched, thereby improving the controllability and the reliability of products. The control system comprises an engine control module and a rotation speed controller. The control device is connected with the engine control module and the rotation speed controller through signals and used for obtaining a target engine rotation speed value which is matched with a load power according to the load power when the rotation speed of the engine is smaller than a rotation speed threshold value, corresponding to a current gear, of the rotation speed controller. The control device also outputs a rotation speed adjustment control signal to the engine control module so as to control the rotation speed of the engine to be increased to the target rotation speed value.

Owner:ZOOMLION HEAVY IND CO LTD

Control method and device for automobile air-conditioning compressor

InactiveCN104807269BAvoid undermotivationImprove securityAir-treating devicesElectrical controlDriving currentControl theory

The invention discloses a control method and a control device for an automobile air conditioner compressor. The method comprises the following steps: determining target temperature of an air conditioner evaporator according to temperature outside an automobile, light intensity, temperature set by a user and temperature in the automobile, acquiring the driving current of an electromagnetic valve in the air conditioner compressor according to the determined target temperature of the air conditioner evaporator, and finally determining the output torque of an engine of the automobile by virtue of the acquired driving current of the electromagnetic valve in the air conditioner compressor. According to the control method and the control device, the driving current of the electromagnetic valve in the air conditioner compressor is slowly regulated to fulfill the air of slowly regulating the output torque of the engine of the automobile according to the acquired target temperature of the air conditioner evaporator, so that the rotating speed fluctuation of the engine of the automobile is effectively avoided, the phenomenon of insufficient power of the automobile is also avoided, and the safety performance of the whole automobile is further improved.

Owner:ANHUI JIANGHUAI AUTOMOBILE GRP CORP LTD

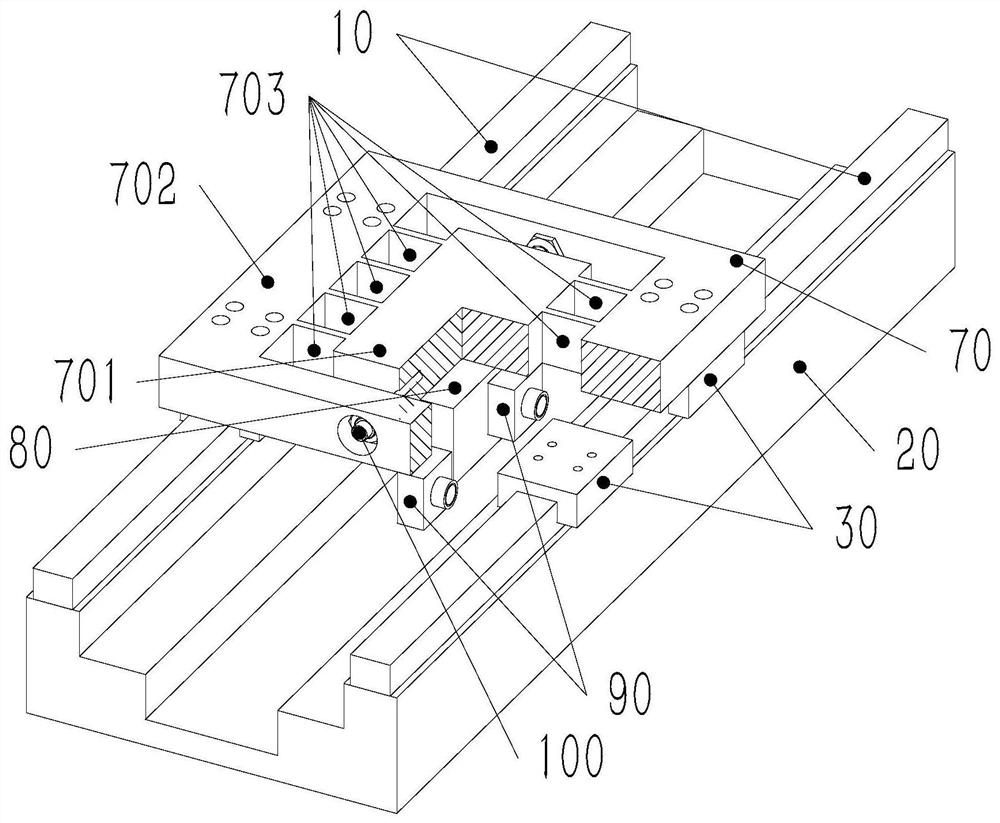

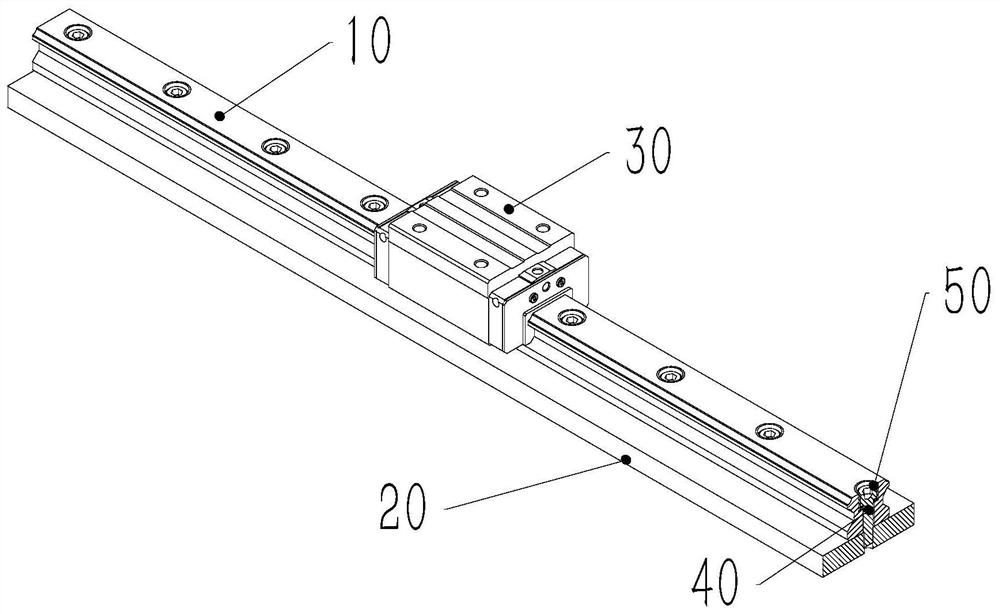

Novel guide rail rigid-flexible coupling platform

InactiveCN112081822AHigh precisionAvoid speed fluctuationsLinear bearingsNon-rotating vibration suppressionCouplingClassical mechanics

The invention provides a novel guide rail rigid-flexible coupling platform. The novel guide rail rigid-flexible coupling platform comprises a base, guide rails mounted on the base, sliding blocks arranged on the guide rails in a sliding mode, a rigid-flexible coupling platform fixedly arranged on the sliding blocks, a driving unit used for driving the rigid-flexible coupling platform to slide anddetection units used for detecting speed and displacement of the rigid-flexible coupling platform; each guide rail comprises a guide rail body and a bolt; each guide rail body comprises a first surface, a second surface, a third surface and a fourth surface; the first surfaces face to the sliding blocks; the second surfaces and the third surfaces are adjacent to the first surfaces; lug bosses arearranged at positions, away from the base, of the second surfaces and the third surfaces and are used for mounting rolling parts in the sliding blocks; the fourth surfaces are opposite to the first surfaces and are in contact with the base; through holes penetrating through the first surfaces and the fourth surfaces are formed in the guide rail bodies; the bolts are used for fixing the guide railbodies on the base through the through holes; and pore-free connection is formed between the bolts and the through holes.

Owner:FOSHAN HUADAO SUPER PRECISION TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com