Patents

Literature

39results about How to "Guaranteed speed requirements" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

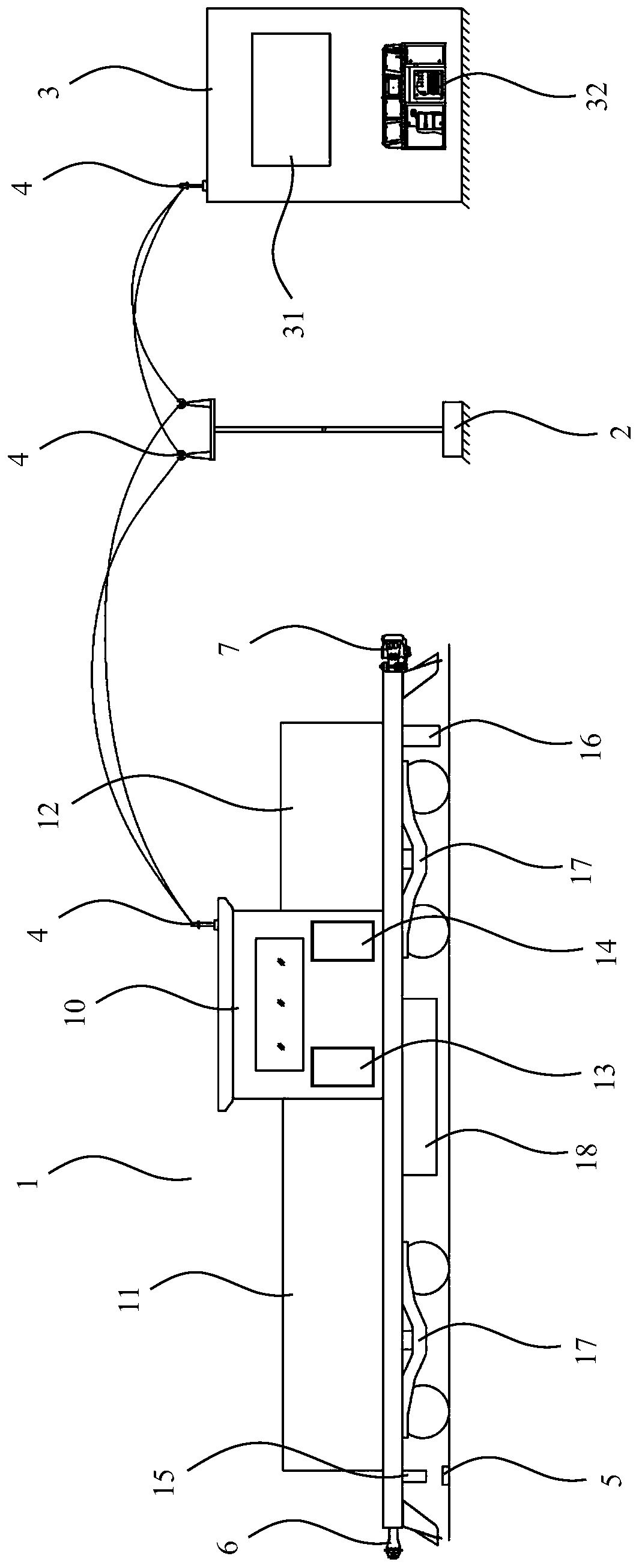

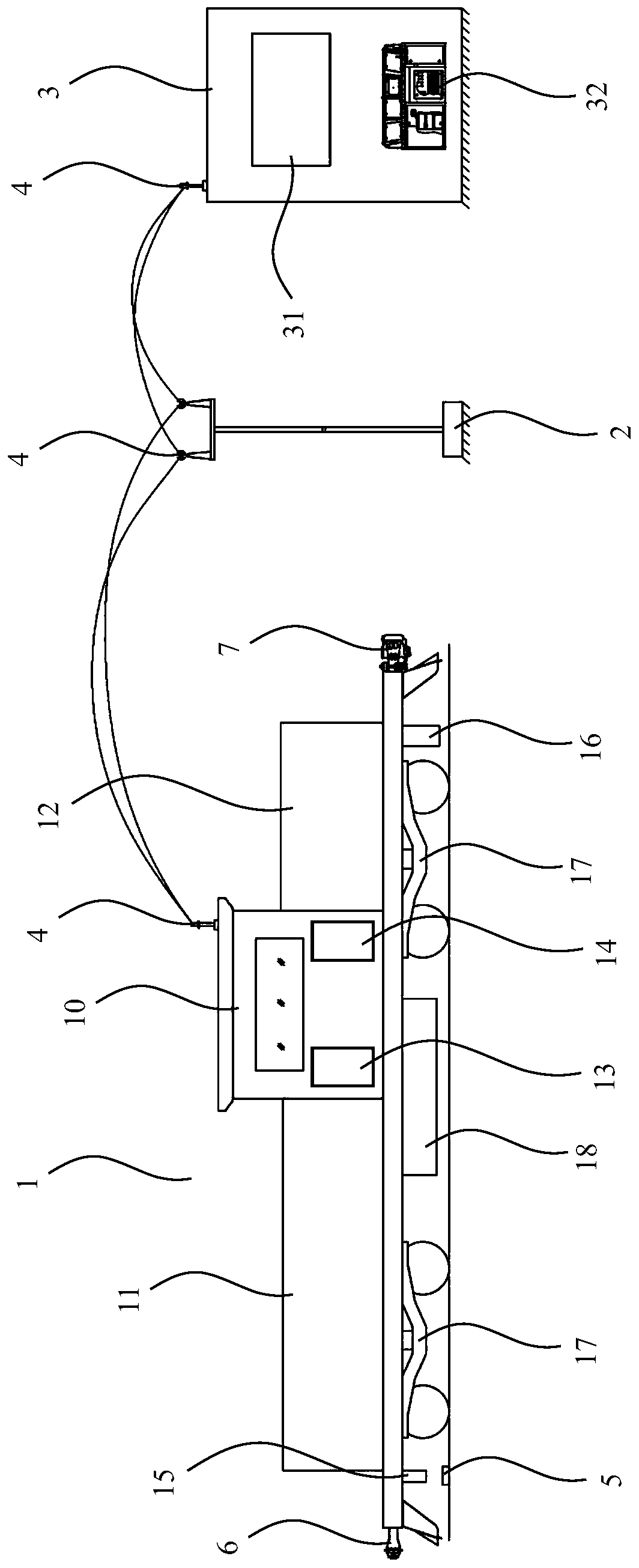

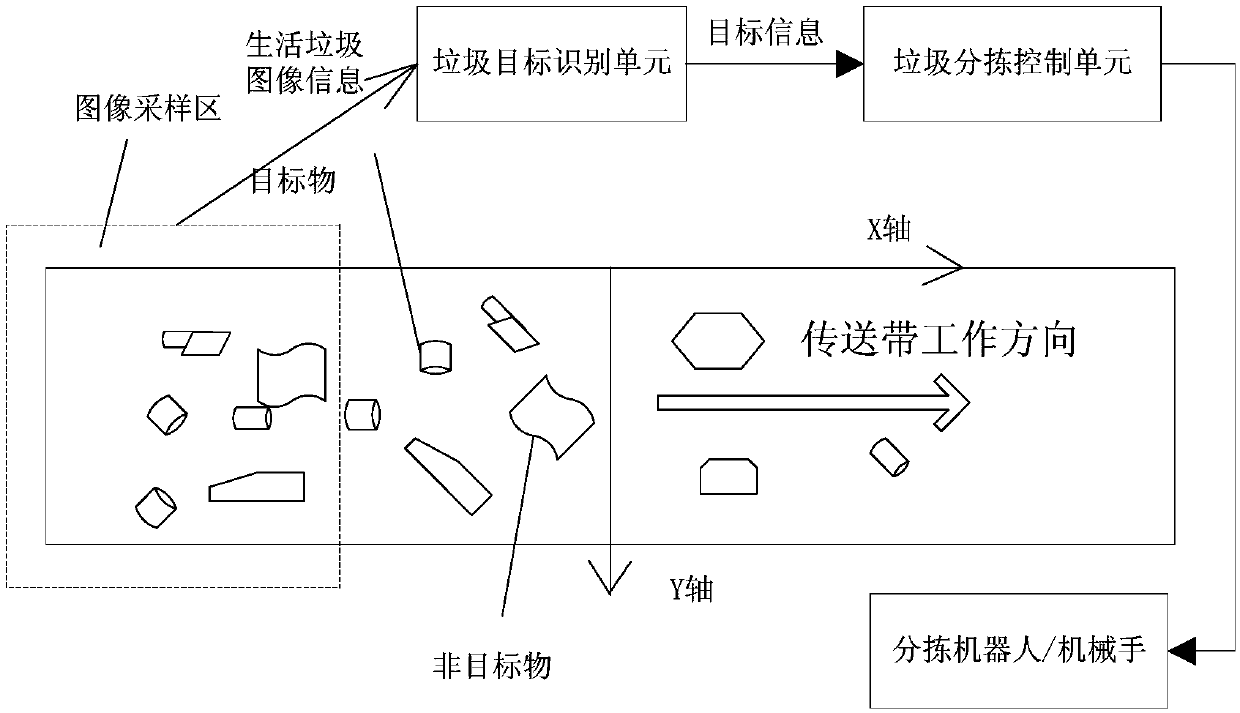

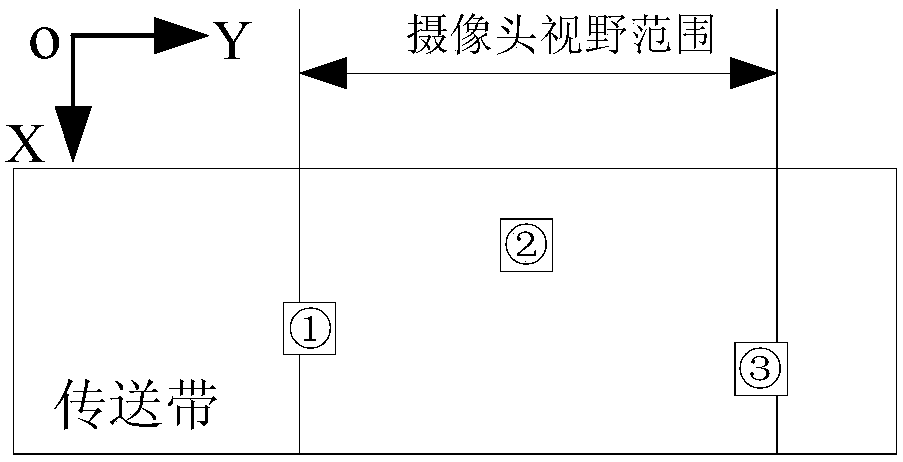

Automatic sorting system for household refuse

Disclosed is an automatic sorting system for household refuse. The system comprises a refuse target identification unit, a refuse sorting control unit, a mechanical arm and a sampling camera which is mounted at the fixed position of a conveying belt for conveying household refuse; the sampling camera shoots the household refuse on the conveying belt in real time and transmits obtained optical images to the refuse target identification unit; the refuse target identification unit receives the optical images in real time and displays the images, according to the characteristics of presorted target refuse, the optical images are treated, targets in the images are identified, and target posture information frames are obtained, and are input into the refuse sorting control unit; and the refuse sorting control unit judges whether a target enters the working section of the leisure mechanical arm or not according to the input target posture information frames and the opposite position of the mechanical arm and the conveying belt, the posture information of the target entering the working section of the mechanical arm is converted into a mechanical arm coordinate system and sent to the corresponding mechanical arm, and the corresponding mechanical arm is controlled to grab the corresponding target.

Owner:BEIJING XINCHANGZHENG TIANGAO INTELLIGENT MACHINE TECH CO LTD

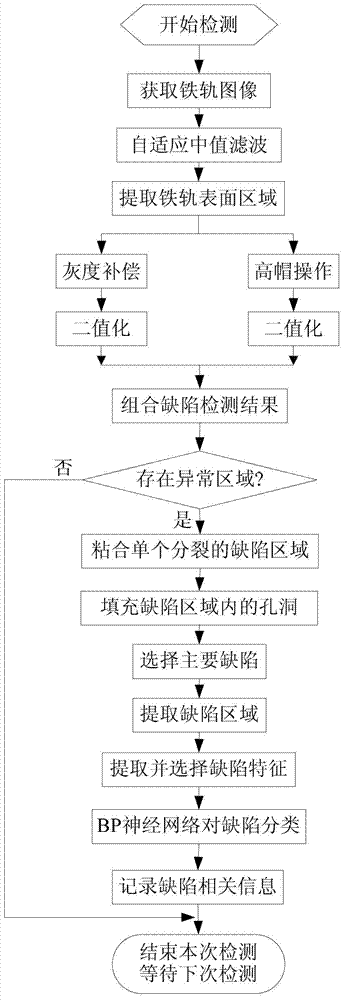

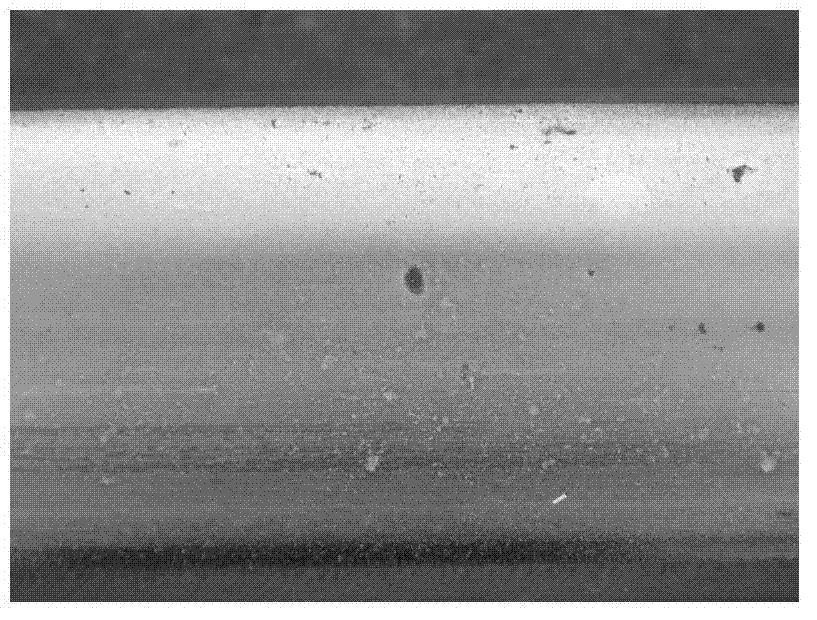

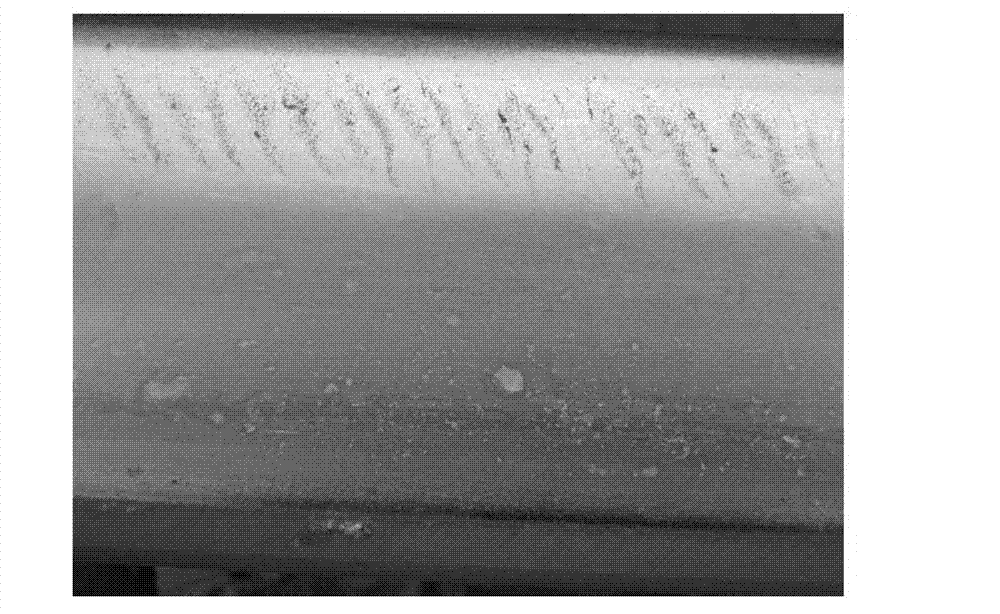

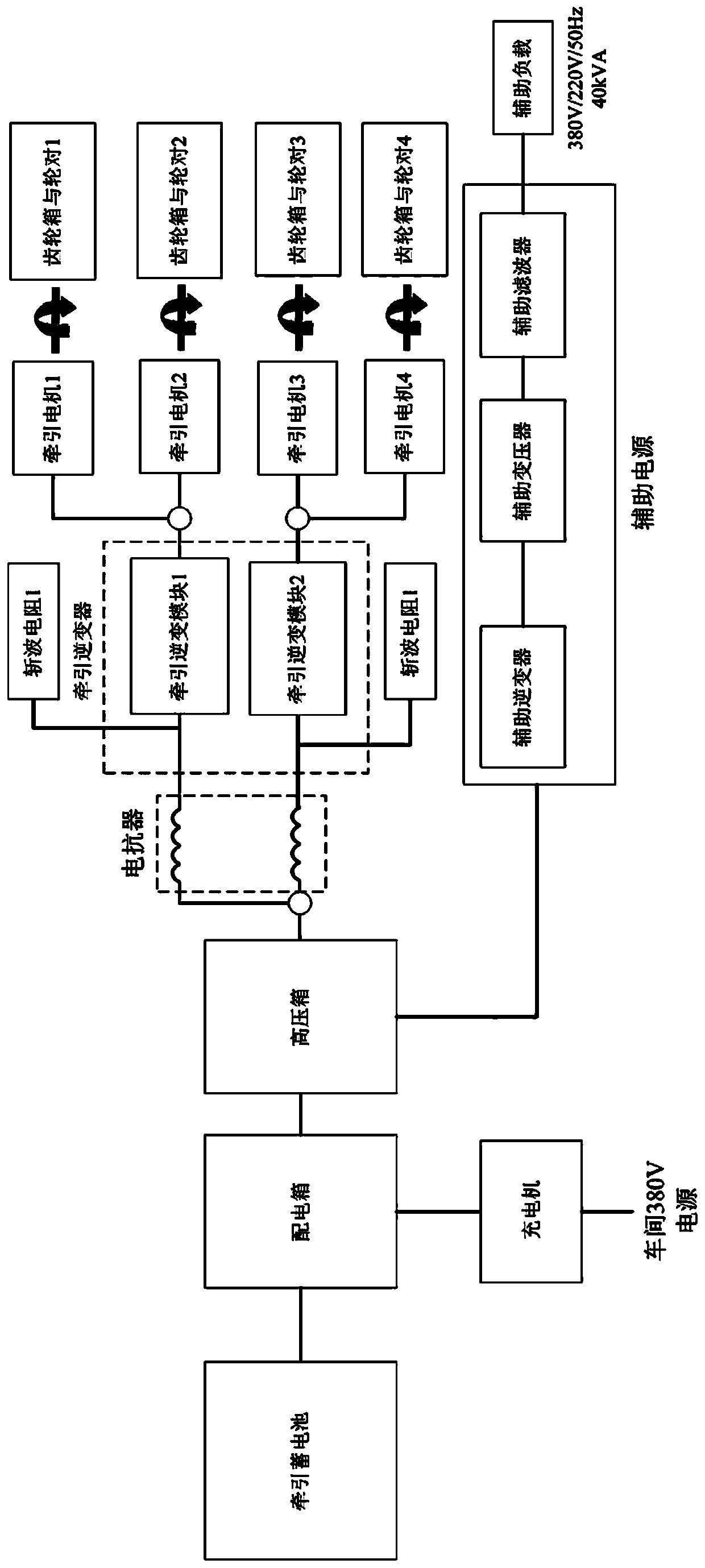

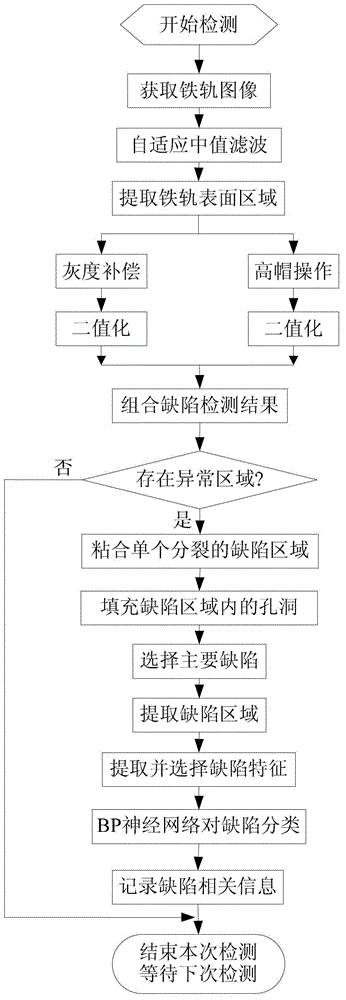

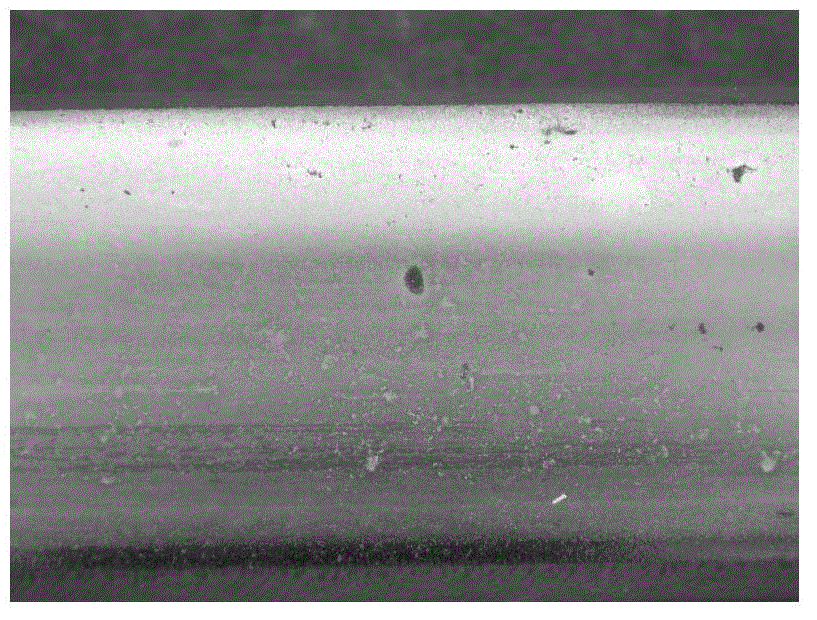

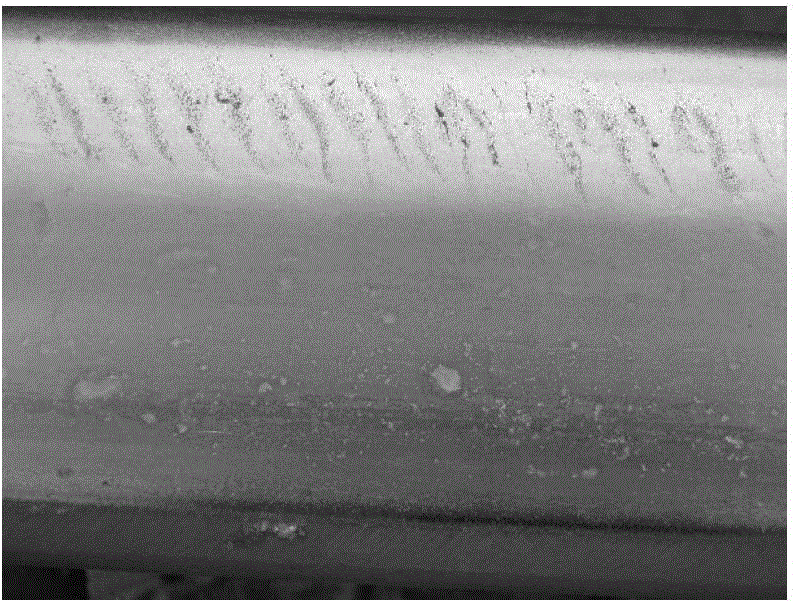

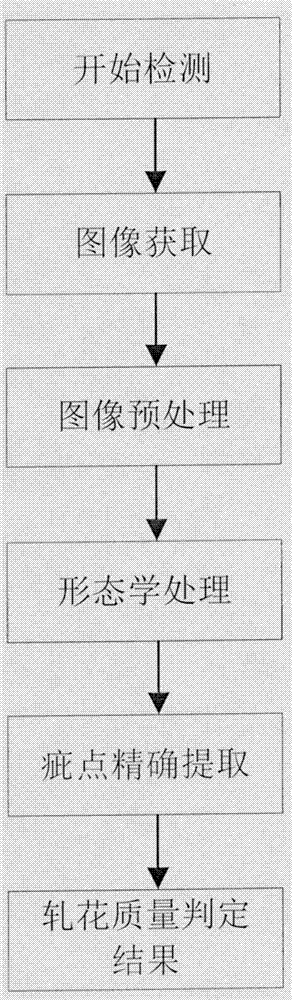

Real-time visual detection and identification method for high speed rail surface defect

ActiveCN102854191AGuaranteed Speed RequirementsShorten the timeCharacter and pattern recognitionOptically investigating flaws/contaminationPrinciple of orthogonal designAutonomation

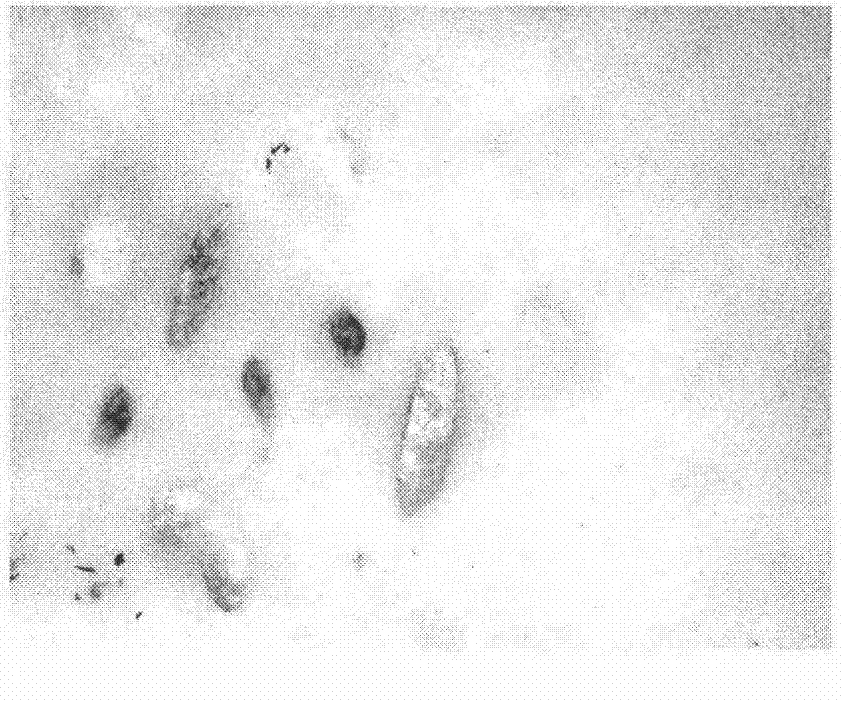

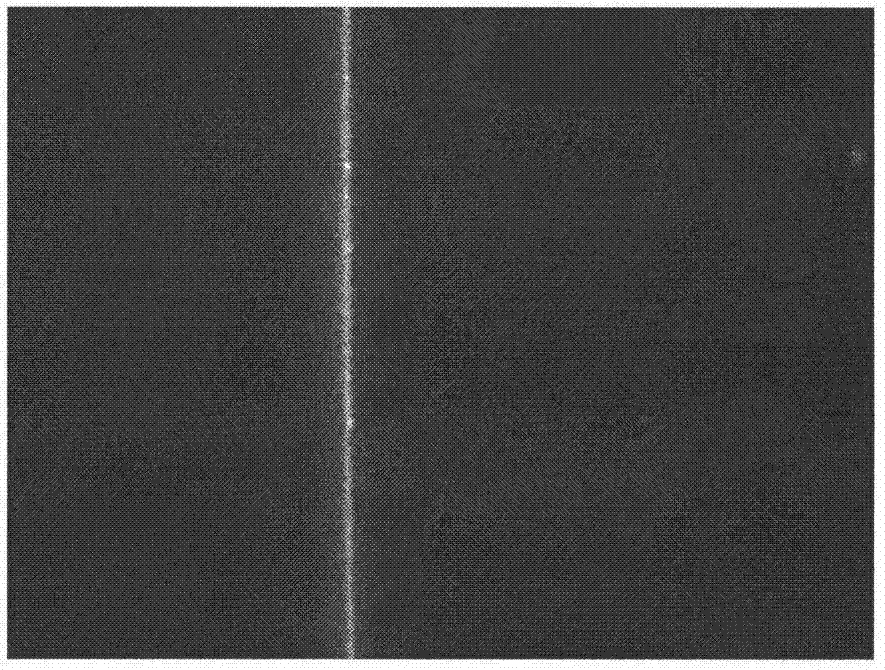

A real-time visual detection and identification method for high speed rail surface defects comprises the following steps of: (1) image acquisition; (2) image preprocessing; (3) defect preliminary detection, that is, performing logic or operation combination of detection results based on gray scale compensation with detection results based on top-hat operation, and detecting whether an abnormal area exists in an image, if not, finishing the detection, or else continuing the processing; (4) defect accurate positioning, that is, accurately positioning the defect by an algorithm of bonding single defect, an algorithm of filling holes in the defect area, and an algorithm of selecting the main defect, and extracting the defect area through marks; (5) defect classification, that is, extracting and selecting characteristics of the defect area, designing and training a BP neural network, and classifying the defects by the BP neural network. The invention has the advantages of simple principle, high automation degree, high detection speed, and high detection precision.

Owner:HUNAN UNIV

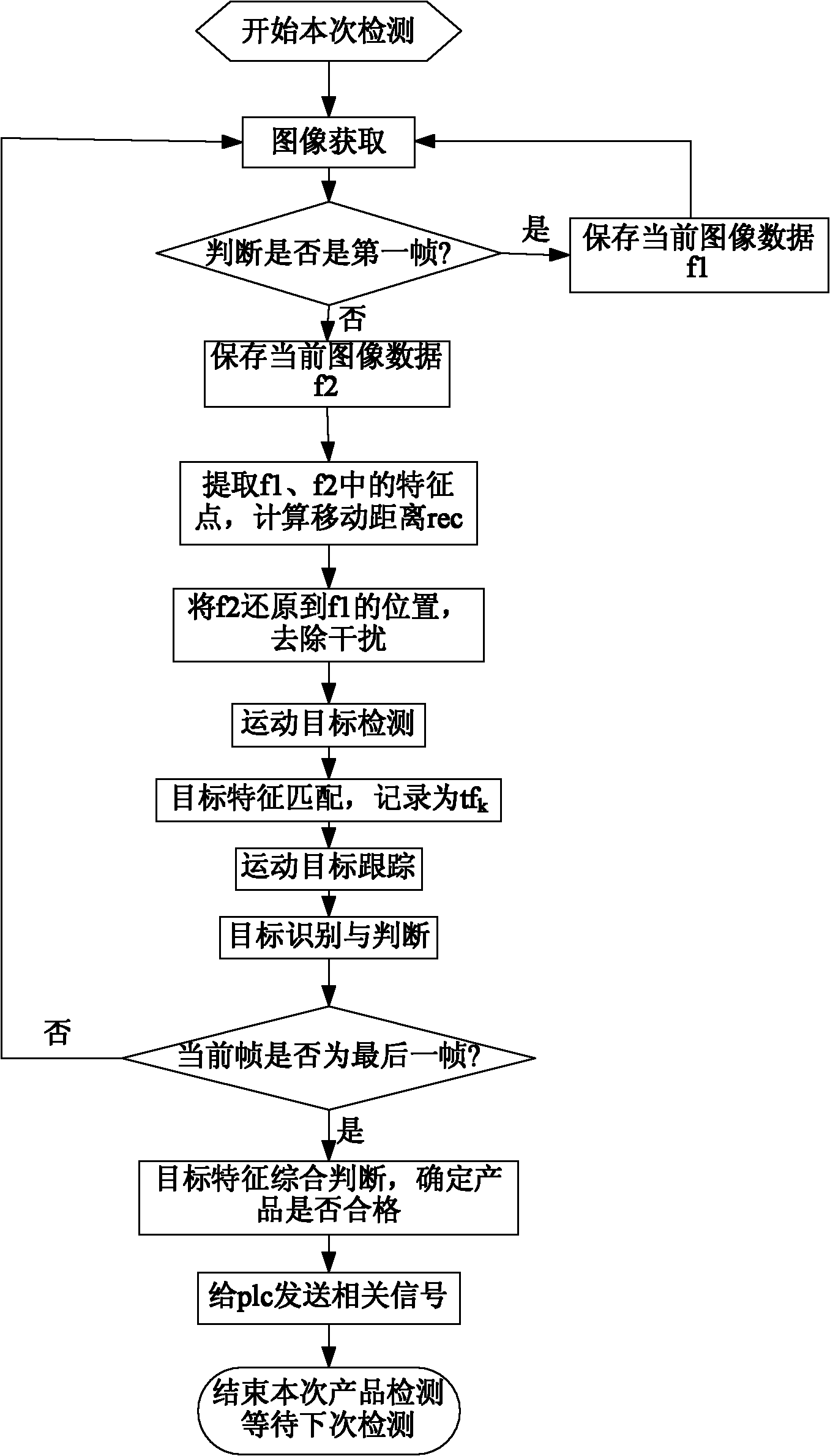

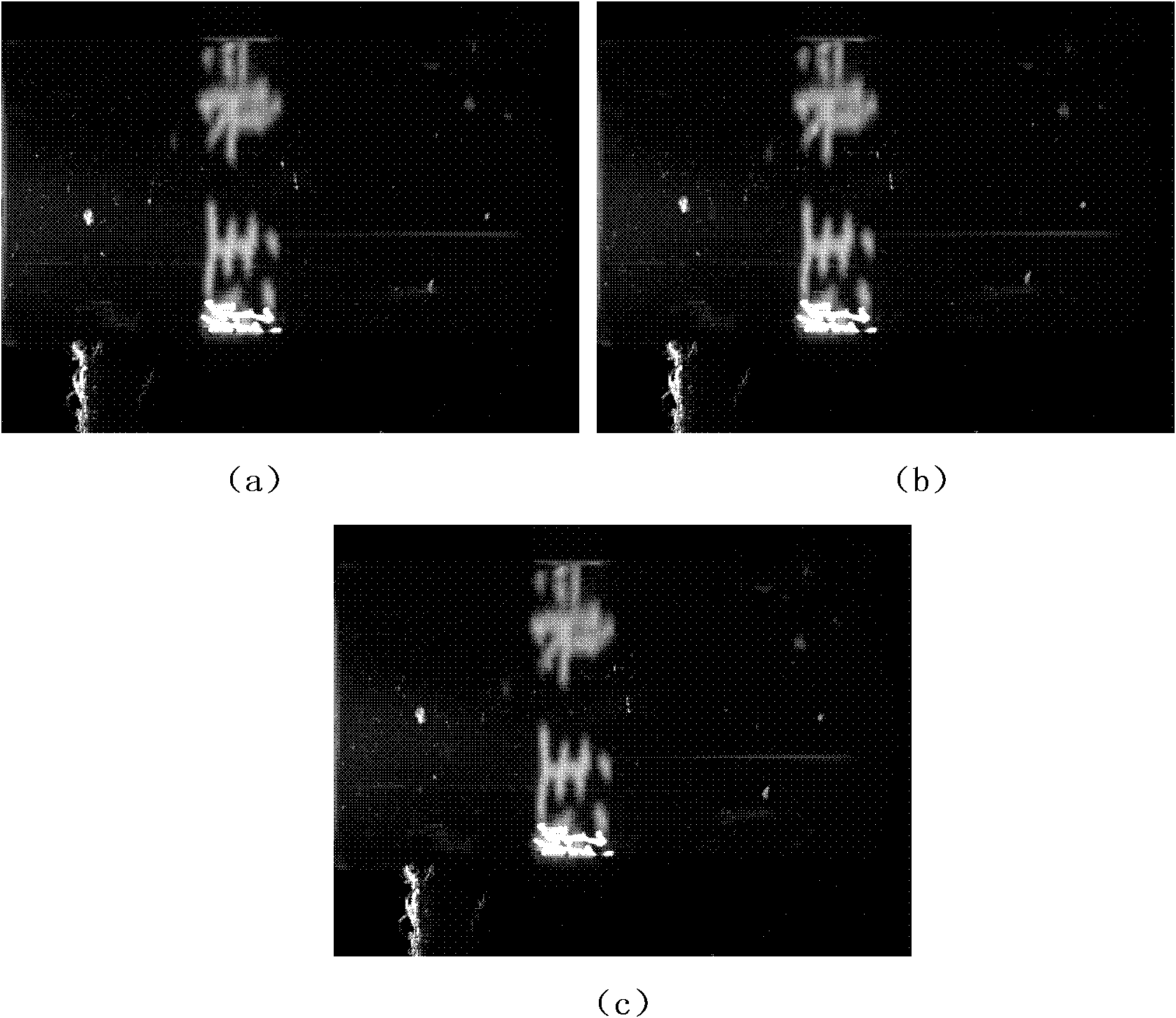

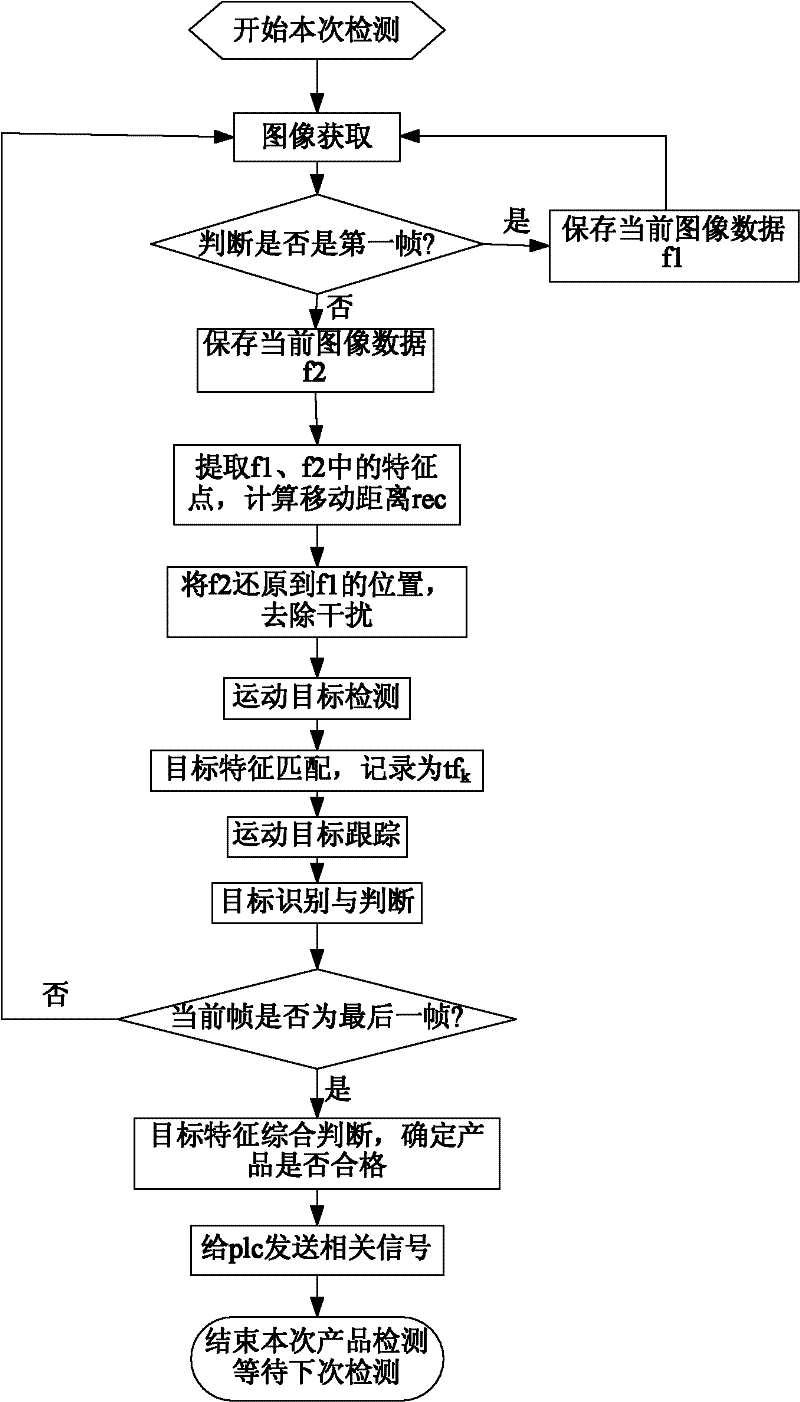

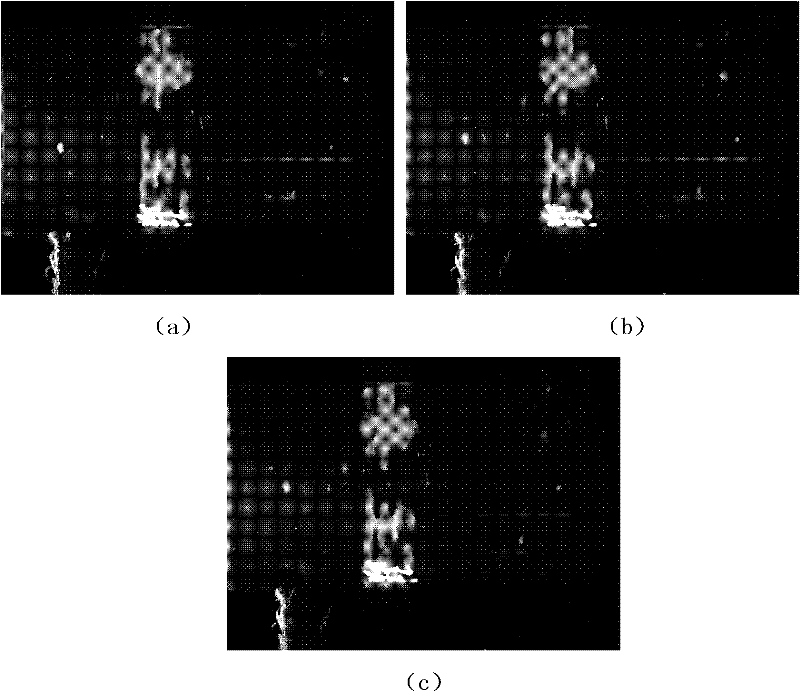

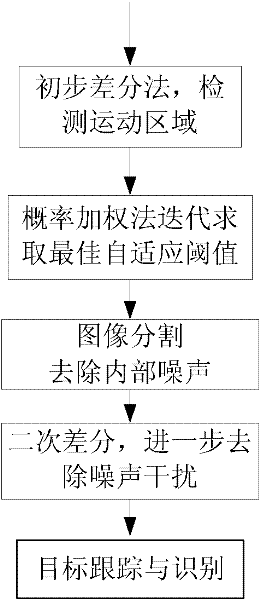

Visual detection method for quality of liquid medicine on high-speed pharmaceutical production line

InactiveCN101859378AGuaranteed Speed RequirementsThe detection process is fastImage enhancementImage analysisForeign matterGray level

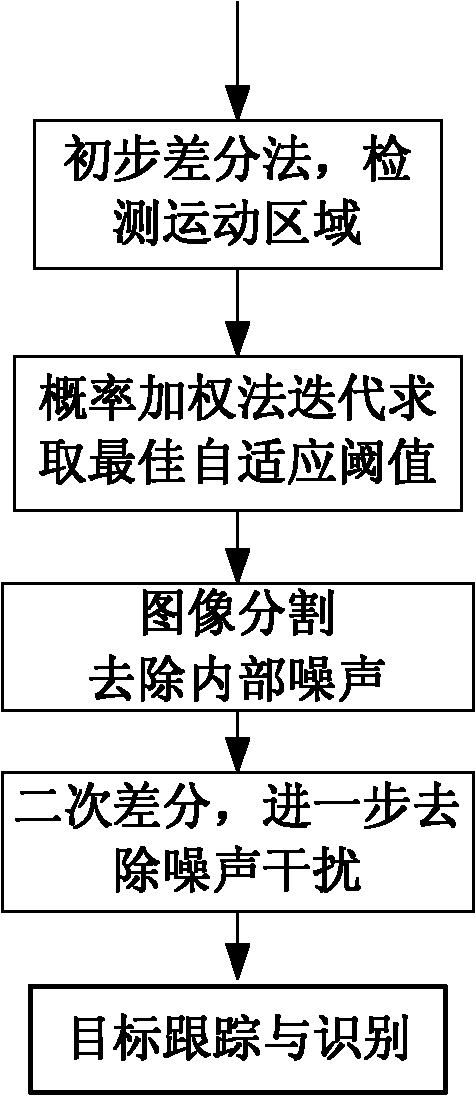

The invention discloses a visual detection method for the quality of liquid medicine on a high-speed pharmaceutical production line. The visual detection method is characterized by comprising the following steps of: firstly, acquiring images, i.e., acquiring five continuous sequence images of liquid medicine under a halted state of a bottle after revolution at a high speed, wherein the shot images are the gray-level images; secondly, initially denoising the images, i.e., removing the dynamic interference of the bottle wall by an offset background reduction method based on a characteristic point; thirdly, detecting a target, i.e., removing the static interference by a difference method and a threshold-based division method; fourthly, recognizing the target, i.e., judging whether the target is a foreign body or not according to the continuation of the motion trail of the target, and recording the foreign body; and fifthly, judging the target, i.e., judging whether the foreign body is the visible foreign body or not according to whether the size of the recorded foreign body exceeds the specified range or not. The method has the advantages of high detection precision and high detection speed.

Owner:HUNAN UNIV

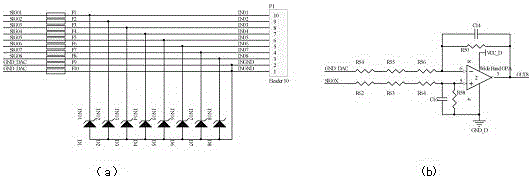

Cotton fault detecting and identifying method based on multi-spectrum technology

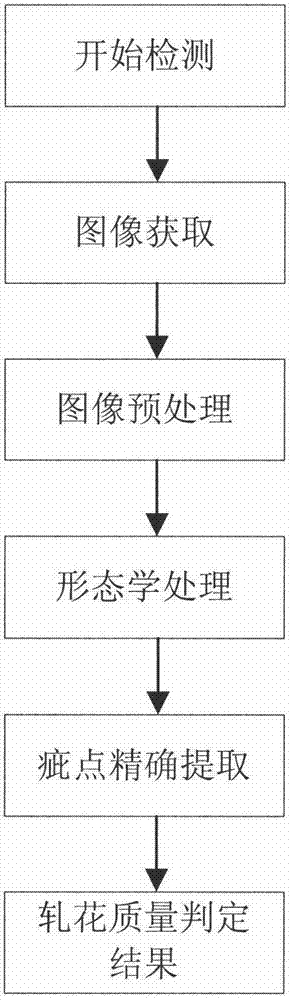

InactiveCN104751443AShorten the timeThe detection process is fastImage analysisPattern recognitionContrast enhancement

The invention discloses a cotton fault detecting and identifying method based on a multi-spectrum technology. The method comprises the steps: (1) image acquiring; (2) image pre-processing; (3) the preliminary detection of faults; carrying out edge detection on an improved morphological gradient algorithm to obtain the comprehensive edge detection intensities of all faults to obtain an image with contrast enhancement of all faults; (4) precise location of faults: converting the image into a connected domain image through an improved iterative threshold and morphological processing, precisely locating the faults by selecting a main fault algorithm, and extracting fault areas by marking; (5) cotton ginning quality judgment: carrying out statistics on the amount of all faults, and calculating the total cotton faults to obtain a cotton ginning quality grade. The cotton fault detecting and identifying method provided by the invention has the advantages of being simple in theory, fast in detection speed and high in detection precision.

Owner:ZHENGZHOU UNIVERSITY OF LIGHT INDUSTRY

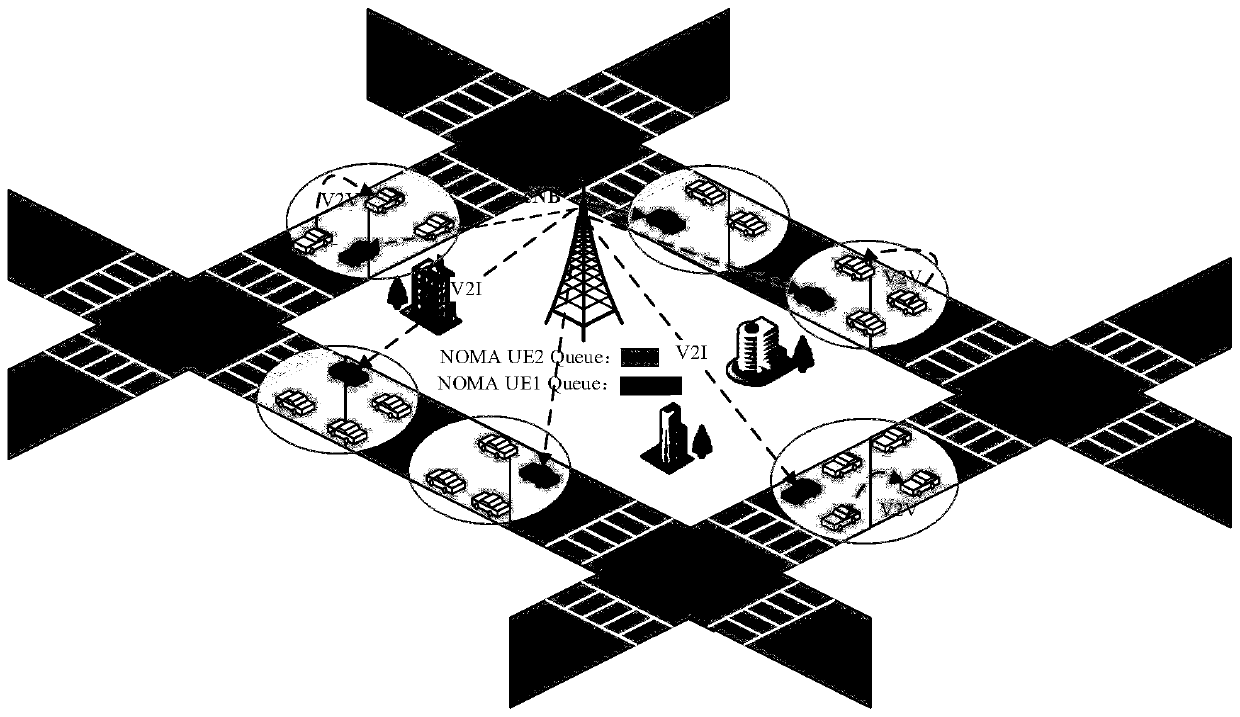

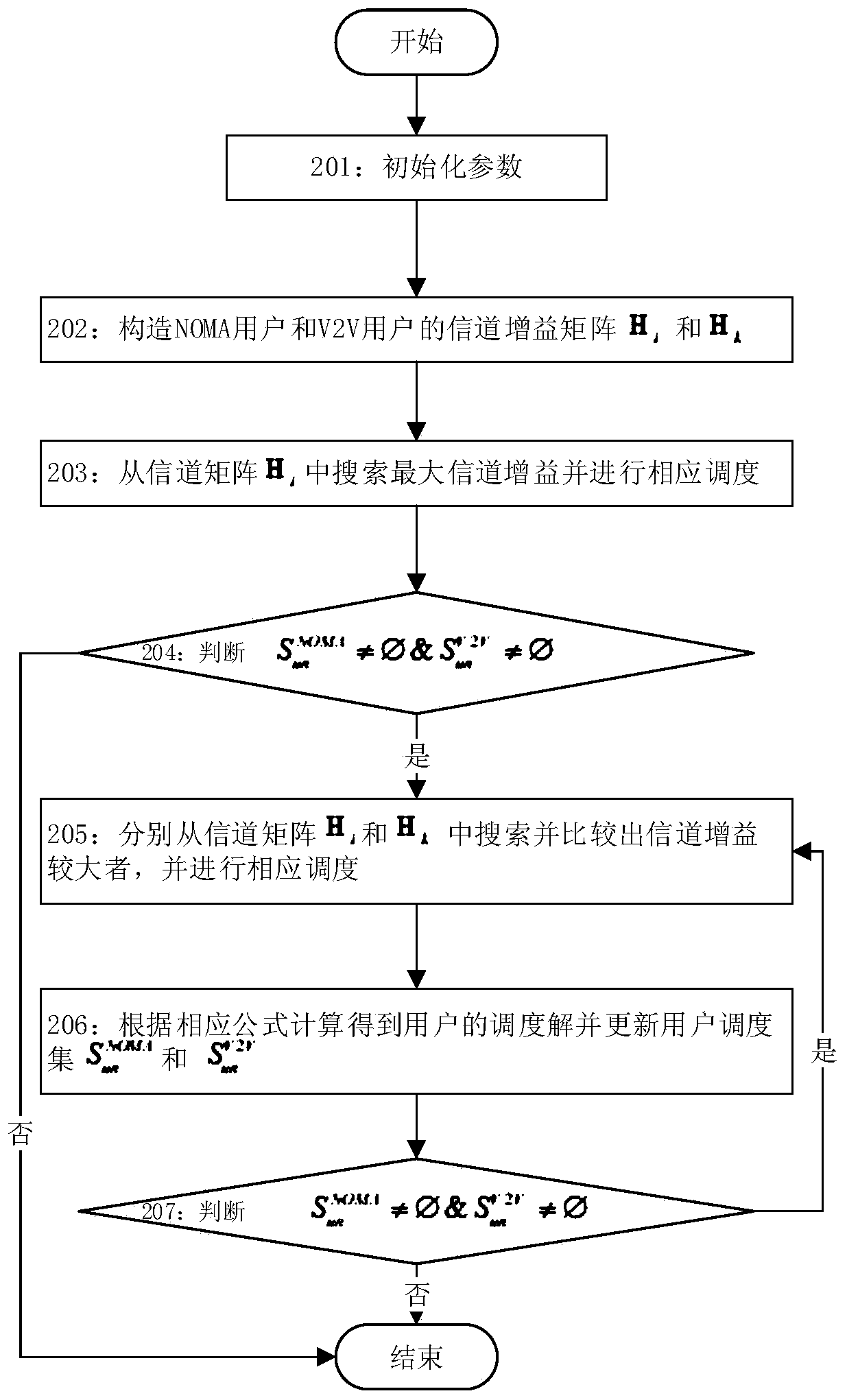

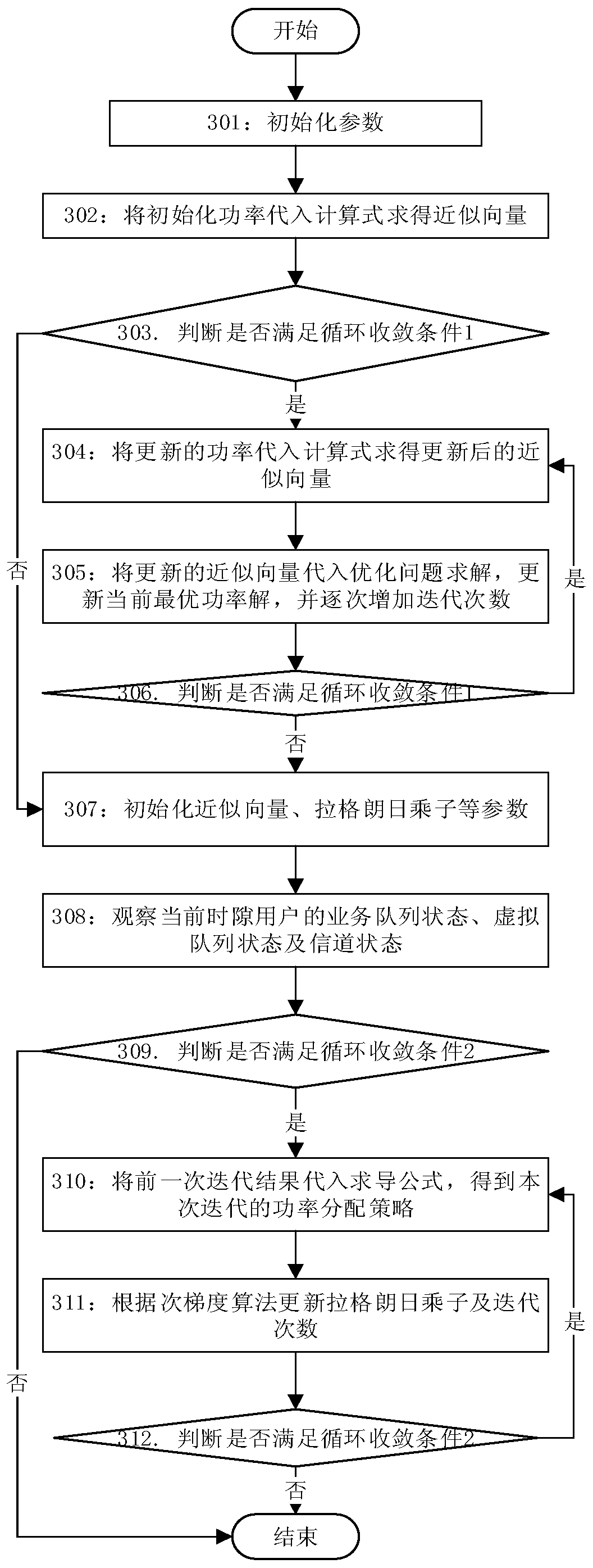

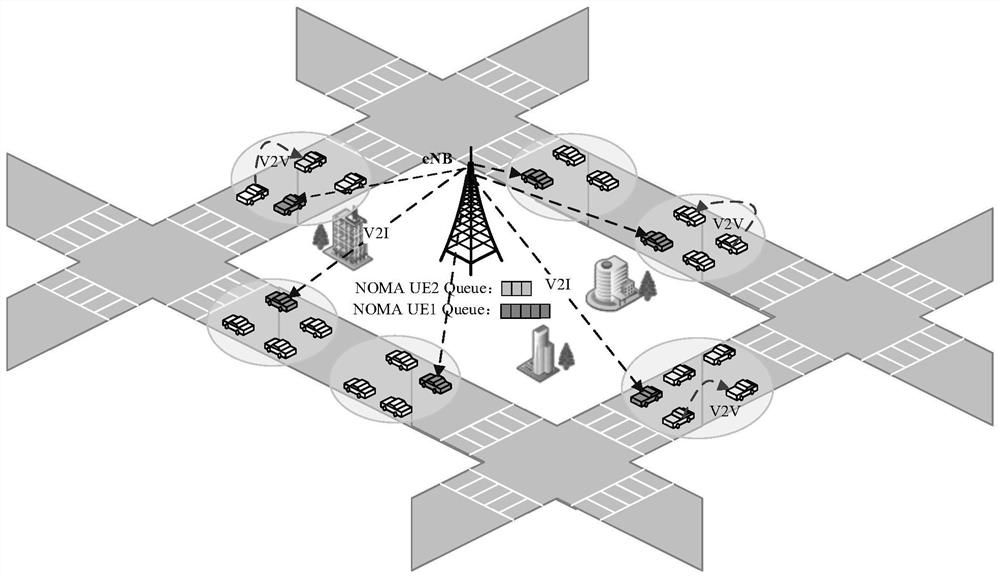

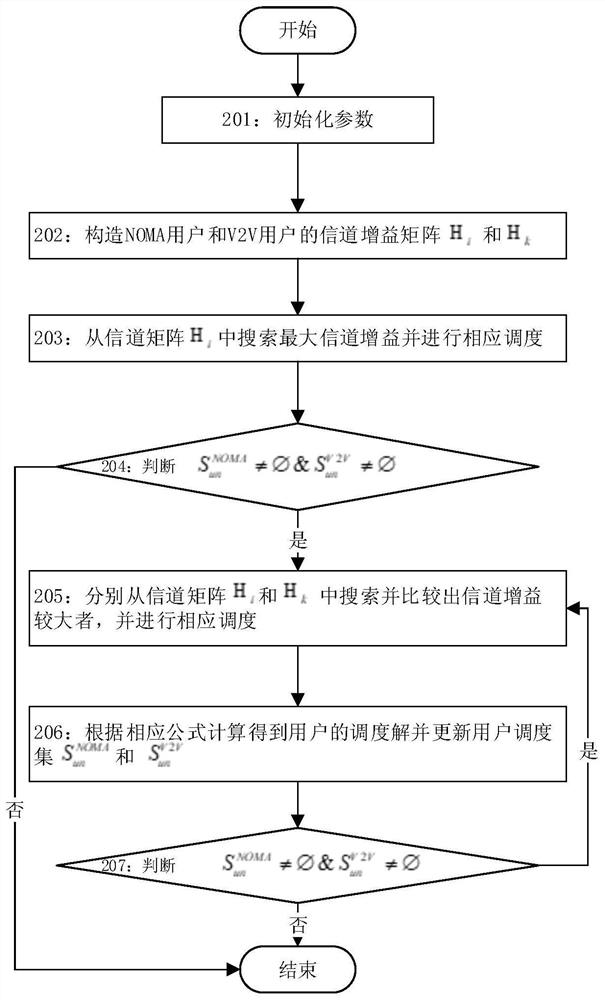

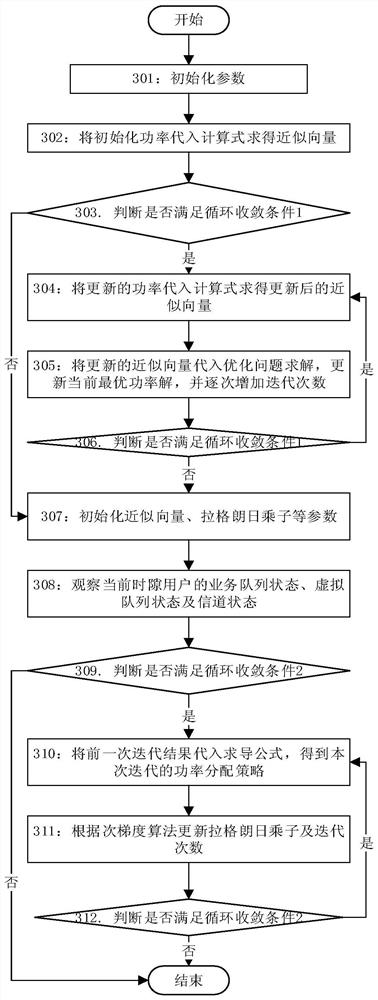

NOMA cellular Internet of Vehicles dynamic resource scheduling method based on energy efficiency

ActiveCN109905918AMaximize system energy efficiencyGuarantee queue stabilityPower managementInternal combustion piston enginesDynamic resourceNetwork congestion

The invention relates to a NOMA cellular Internet of Vehicles dynamic resource scheduling method based on energy efficiency, and belongs to the field of mobile communication. The method is: in the scenario of a NOMA cellular network supporting V2V communication, according to the reliability of the V2V user, the V2V user delay, the NOMA user rate requirement, and the power limit of the user as constraint conditions, adopting the goal of maximizing long-term average efficiency; creating a random optimization model in combination of subchannel distribution of NOMA users, spectrum distribution ofV2V users and subchannel adjusting strategies. According to the method, the system energy efficiency can be maximized on the premise of ensuring the system stability, and the requirements of V2V usertime delay, reliability and NOMA user rate can be met at the same time.

Owner:CHONGQING UNIV OF POSTS & TELECOMM

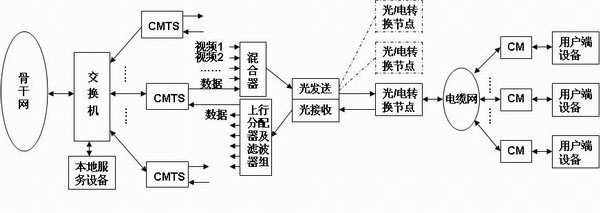

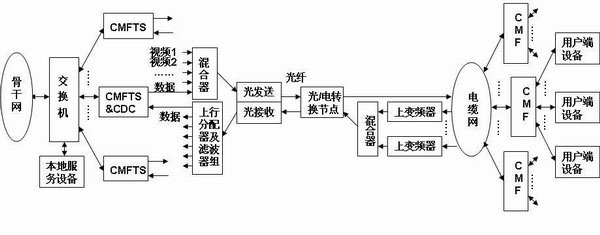

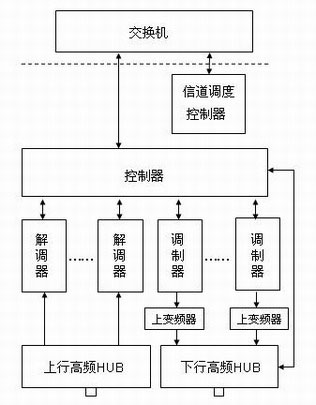

Wideband access system based on HFC (Hybrid Fiber Coaxial) network

The invention discloses a wideband access system based on an HFC (Hybrid Fiber Coaxial) network, comprising a front-end access system, the HFC network and a terminal access system. The wideband access system is characterized in that the front-end system is provided with a cable forwarder modem termination system (CFMTS) and a channel dispatch controller (CDC); the terminal access system is provided with a cable forwarder modem (CFM) and a transmission multimedia to a user terminal, wherein the CFMTS is connected with an IP (Internet Protocol) backbone network; a mixer, an optical transmitter, a photoelectric converting node, an upper frequency converter, an optical receiver and an uplink allocator are arranged between the CFMTS and the CMF. By improving a network structure, network equipment and the network wideband allocation of the traditional structure, the wideband of an uplink channel is enlarged, the uplink noise brought by an access cable can be blocked off and the transmission capability of the network can be enhanced. The wideband access system provides the function of multiplexing and de-multiplexing video streams of the uplink channel and the downlink channel, ensures the mixed transmission of uplink data, voice and video and meets the requirement of three-network integration while the traditional simulation television, an edge quadrature amplitude modulator (EQAM), a set top box and other equipment are ensured to normally work.

Owner:甘静 +1

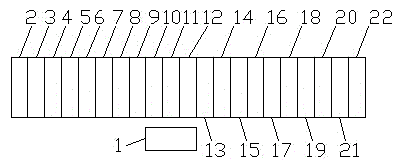

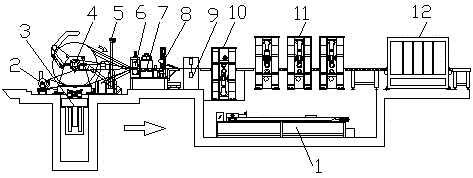

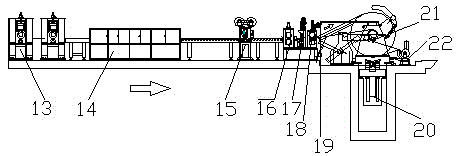

Combined machining center for stainless steel coiled materials

InactiveCN106271665ASolve troublesome problemsSimple structureOther manufacturing equipments/toolsEngineeringSpot welding

The invention discloses a combined machining center for stainless steel coiled materials. The combined machining center comprises a paper tape filtering machine and a paper collecting machine. A feeding trolley, an uncoiler, a centering device, a front pinch conveyor, a leveling machine, a hydraulic shear, a gantry spot welding machine, a back grinder, three front grinders, a five-axis straight-grain machine, a non-woven cloth polisher, a cleaning and drying machine, a film pasting machine, a rear pinch conveyor, a hydraulic shear, guide rollers, an edge aligning device, a discharging trolley, a coiler and a paper releasing machine are sequentially mounted behind the paper collecting machine. The combined machining center for stainless steel coiled materials is simple in structure, ingenious and reasonable in design, stable and reliable in quality, and high in machining speed and precision.

Owner:佛山市吉力佳机械有限公司

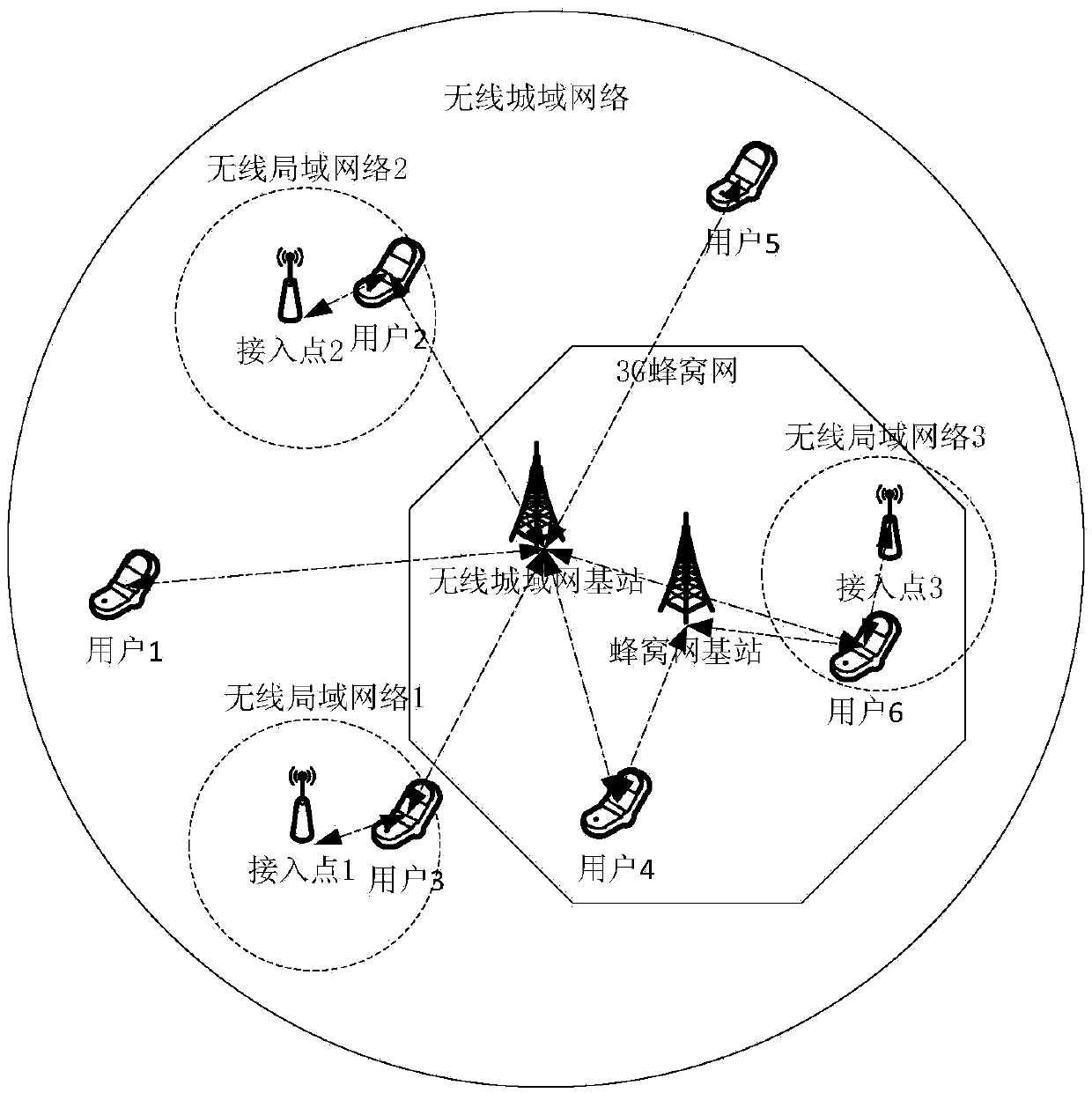

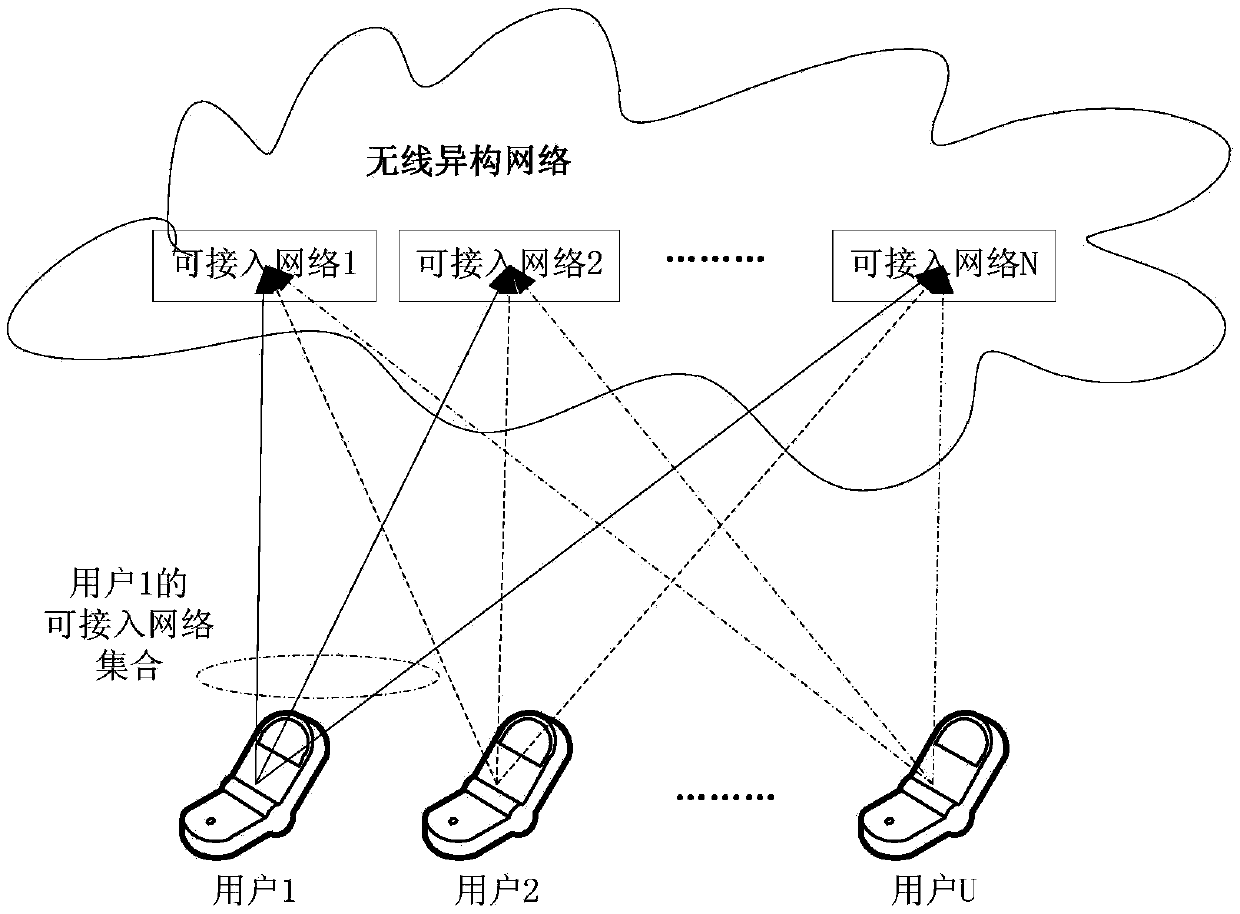

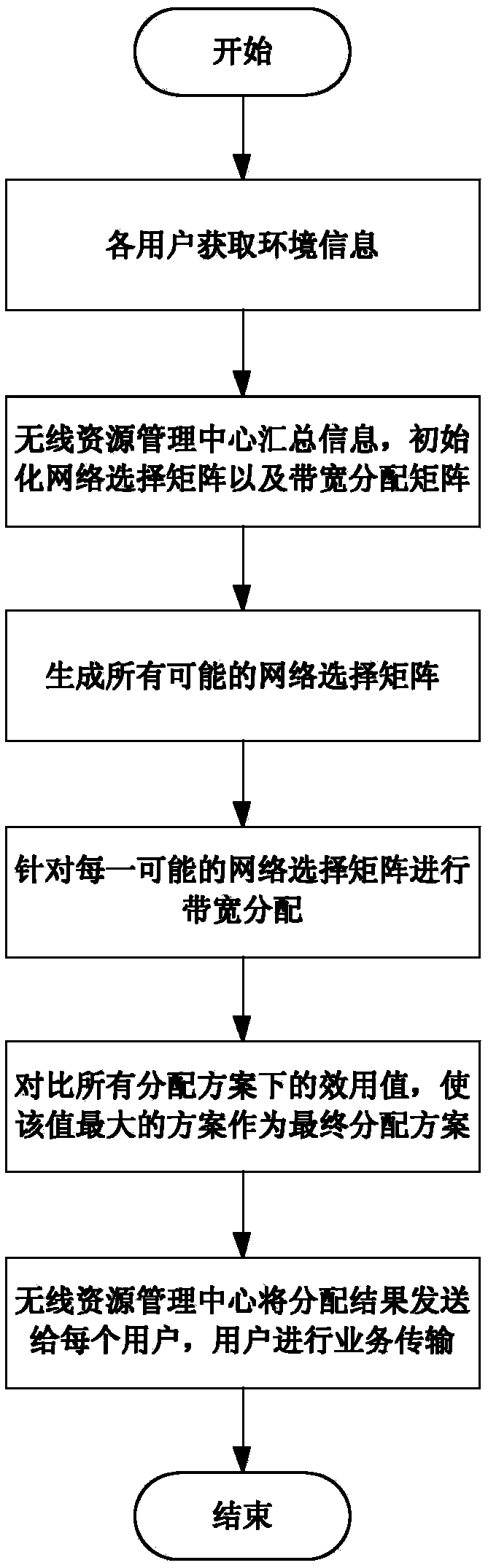

Network selection combined bandwidth allocation method in heterogeneous network

ActiveCN105376809AImprove effective utilizationAllocation coordinationNetwork traffic/resource managementLimited resourcesWireless resource management

The invention discloses a network selection combined bandwidth allocation method in heterogeneous network, and mainly aims at solving problems in coordinated resource allocation among networks of multiple users, and enables a user terminal to obtain higher service rate with lowest network access power. The method comprises the steps that 1) a wireless resource management center gathers environment information sensed by different users; 2) all possible network selection schemes are generated according to the obtained information; 3) the bandwidth is allocated for each scheme, and under the condition of limited resource, the service quality of users is ensured maximally; 4) a scheme which enables the highest total utility function value of the system is selected from all the schemes and serves as a final allocation result; and 5) the wireless resource management center sends the allocation result, and the users, as multi-mode terminals, access the network in a parallel manner and transmit data. The method has the advantages that the utilization rate of system resources is high, the service quality of users can be improved, and stable transmission of services is realized.

Owner:XIDIAN UNIV

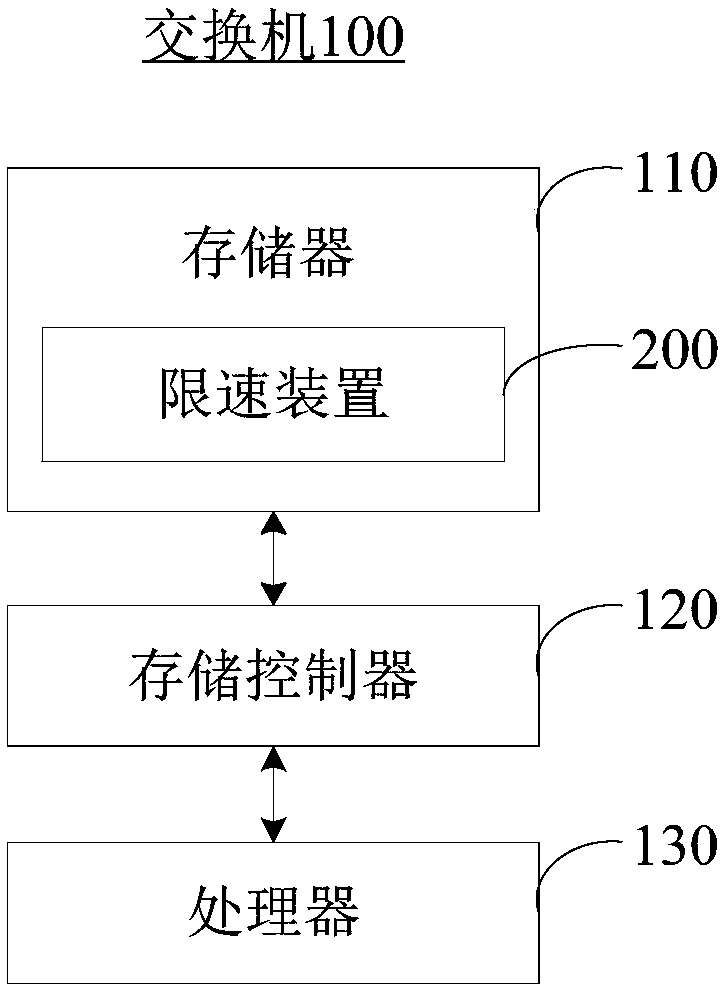

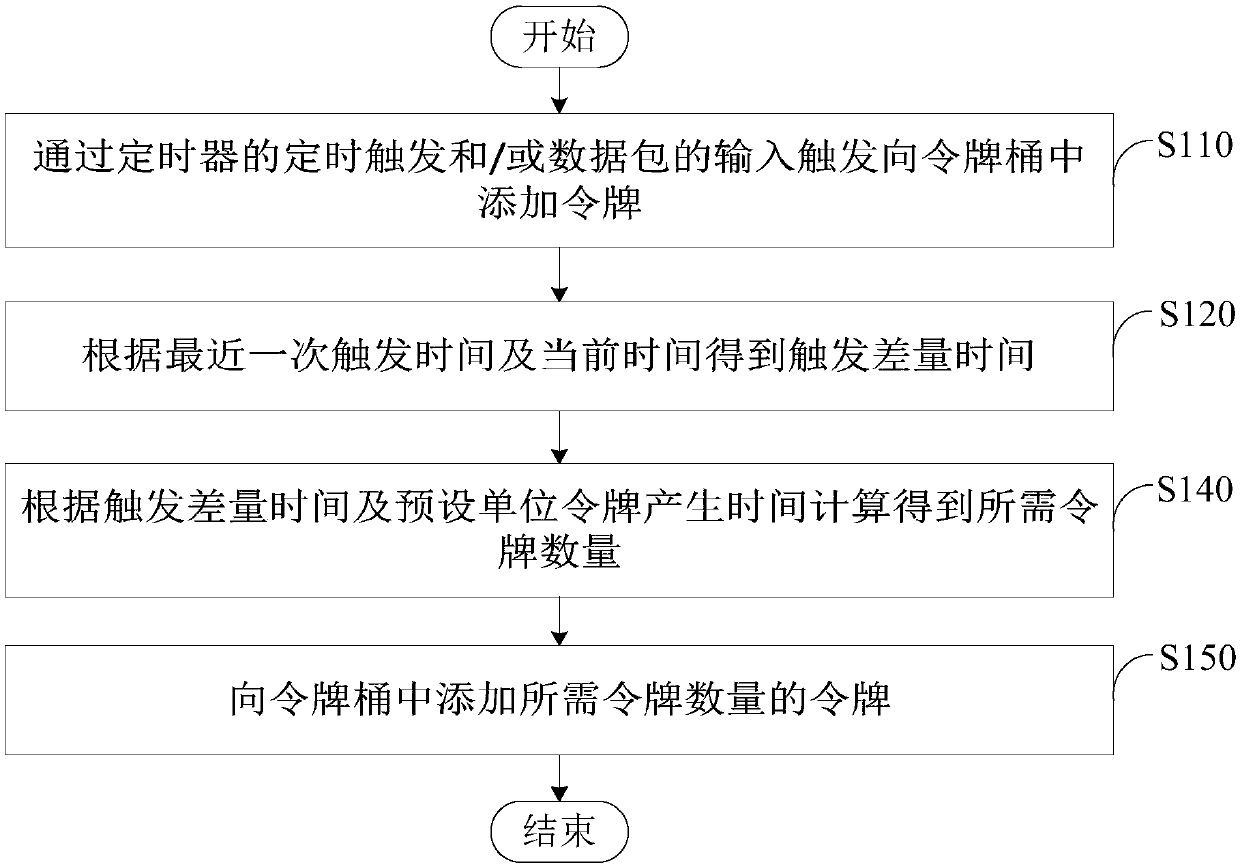

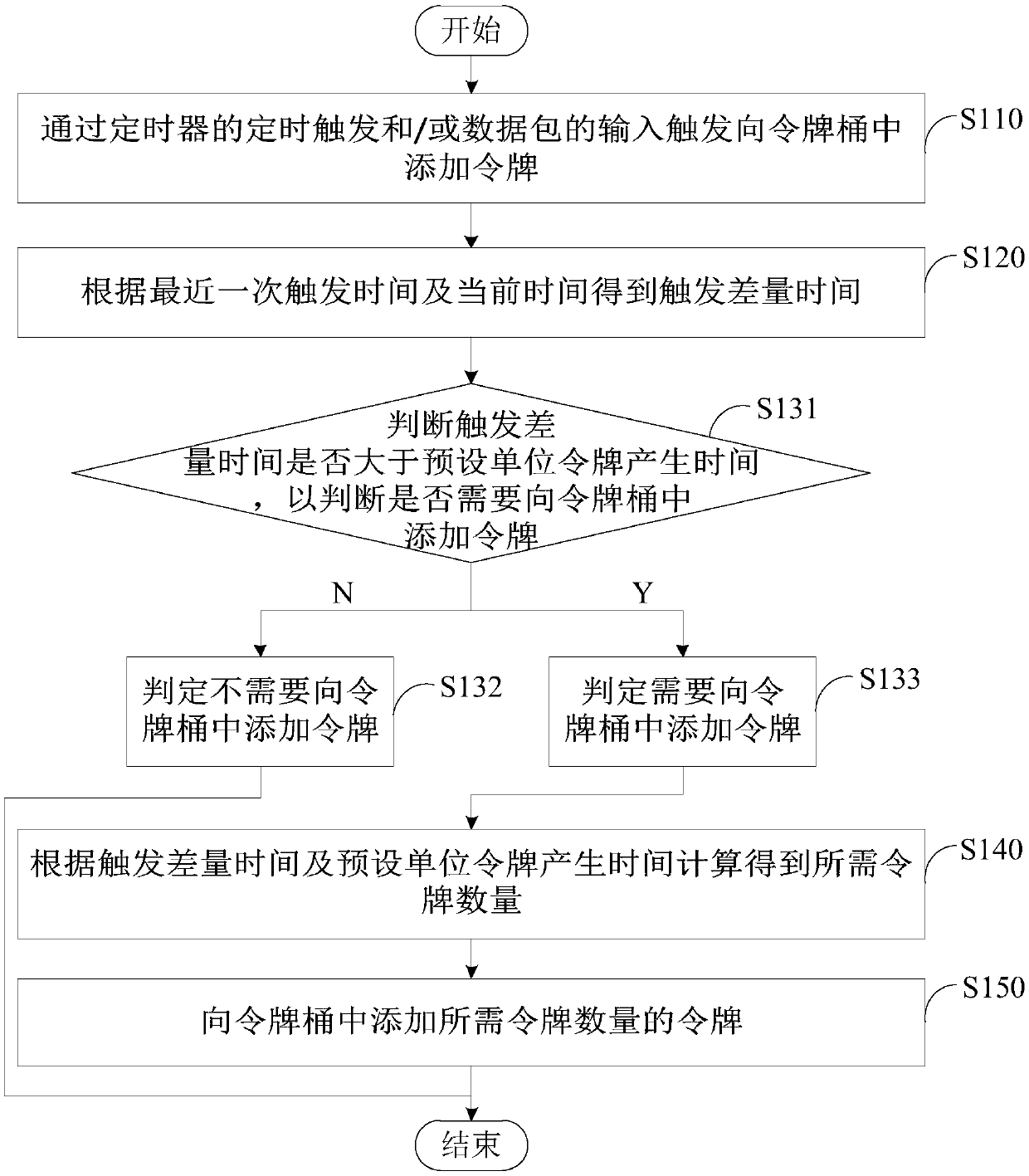

Speed-limiting method and device

ActiveCN107623641AGuaranteed Speed RequirementsImprove experienceData switching networksCommitted information rateTimer

The present invention provides a speed-limiting method and a device. The method is applied to a switch. The switch includes a timer. The method comprises the steps of adding a token into a token bucket through the timing triggering condition of the timer or the input triggering condition of data packets; obtaining the trigger delta time according to the latest triggering time and the current time;according to the trigger delta time and a preset unit token generation time, calculating to obtain the number of required tokens; and adding tokens of the required number into the token bucket. Therefore, tokens are added into the token bucket through the timing triggering condition of the timer or the input triggering condition of data packets. As a result, the switch cannot only meet the committed information rate requirements, but also the periodic network speed fluctuation condition can be avoided.

Owner:HUNAN TIANGUAN ELECTRONICS INFORMATION TECH

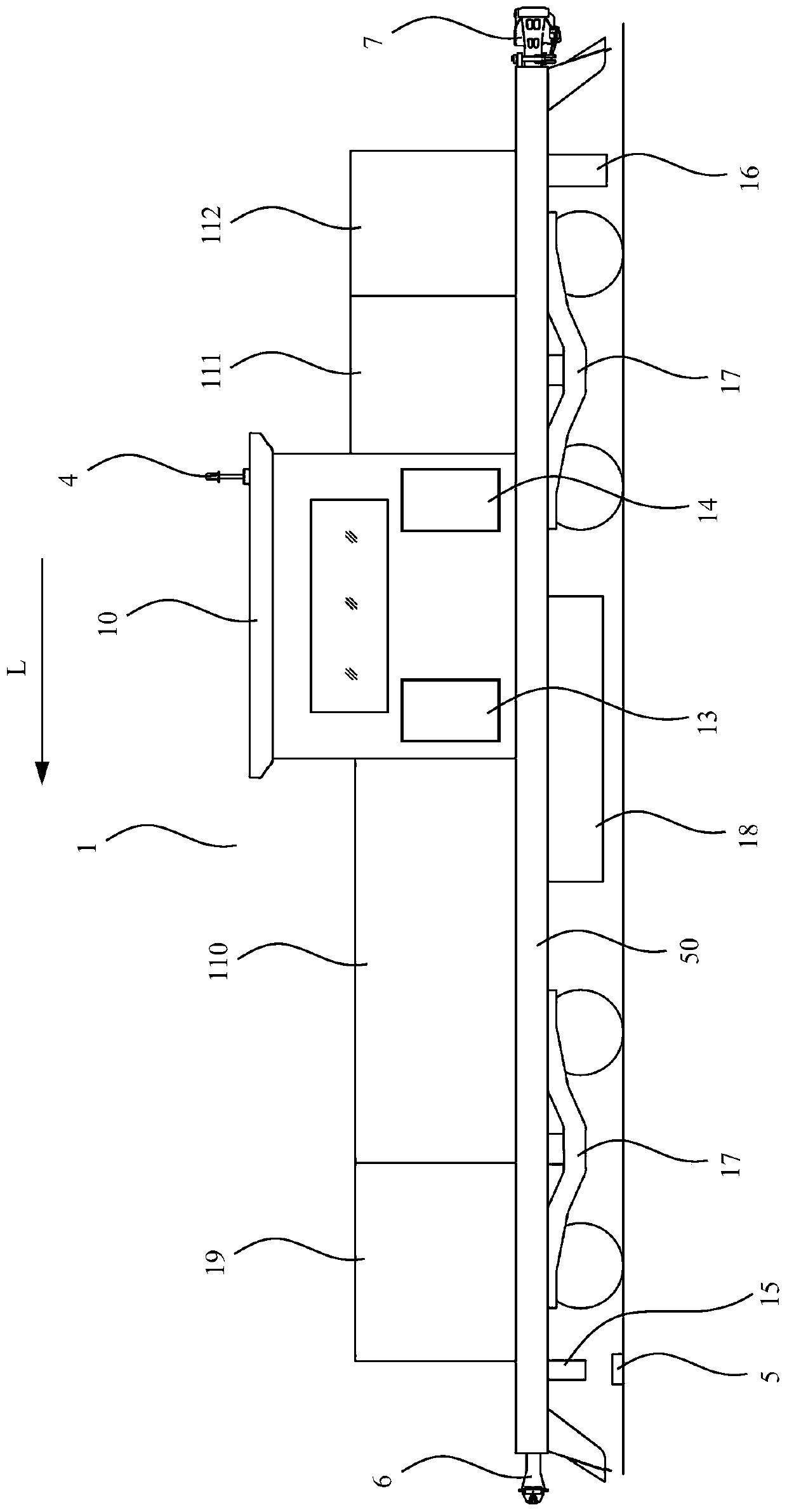

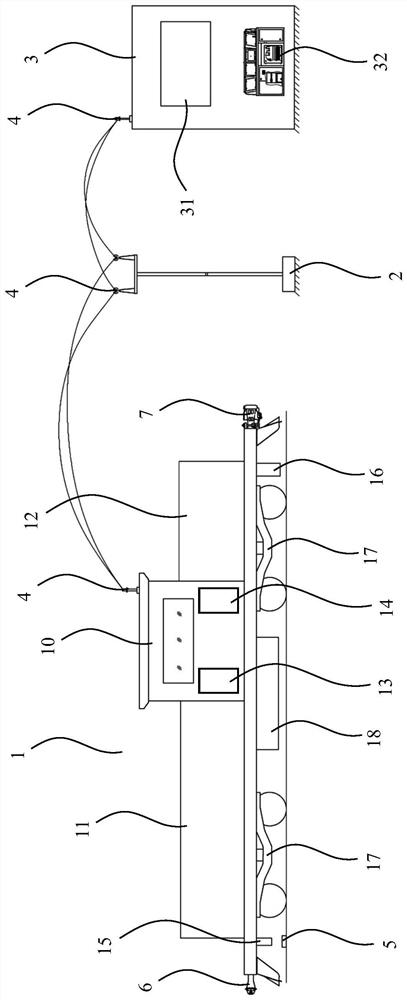

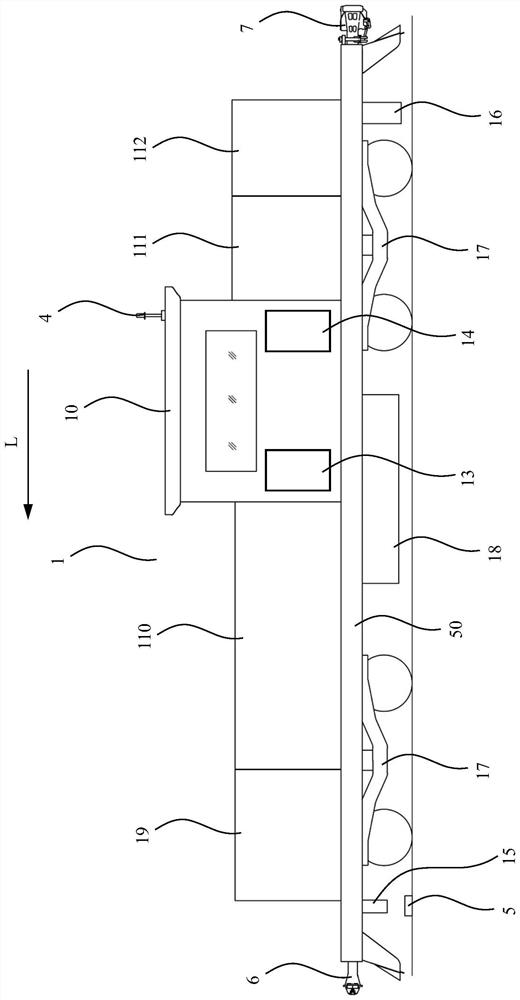

Railway vehicle line collision test method

ActiveCN110285987ARealize automatic decouplingAvoid harmRailway vehicle testingRoute devices for controlling vehiclesRemote controlCollision test

The invention discloses a railway vehicle line collision test method. When a vehicle under test starts to carry out a collision test, a test driving vehicle is connected with the vehicle under test through a first coupler; the test driving vehicle pushes the vehicle under test to start and accelerate; when the running speed of the test driving vehicle and the running speed of the vehicle under test reach a specified speed, the test driving vehicle and the vehicle under test operate at a constant speed for a period; when the vehicle under test arrives at the position of an unhooking point, a beacon reading device detects the position of a ground beacon, and sends a fixed-point signal to a ground control station; after receiving the fixed-point signal, the ground control station sends an unhooking instruction to the test driving vehicle, and the first coupler is opened; the test driving vehicle starts braking, and the test driving vehicle is separated from the vehicle under test, the vehicle under test performs idle running until arriving at a collision point, and the test driving vehicle gradually decelerates until stopping. With the railway vehicle line collision test method adopted, the technical problems of failure to realize the remote control of an experimental process, low test safety and low stability of an existing line collision test method can be solved.

Owner:ZHUZHOU TIMES ELECTRONICS TECH CO LTD +1

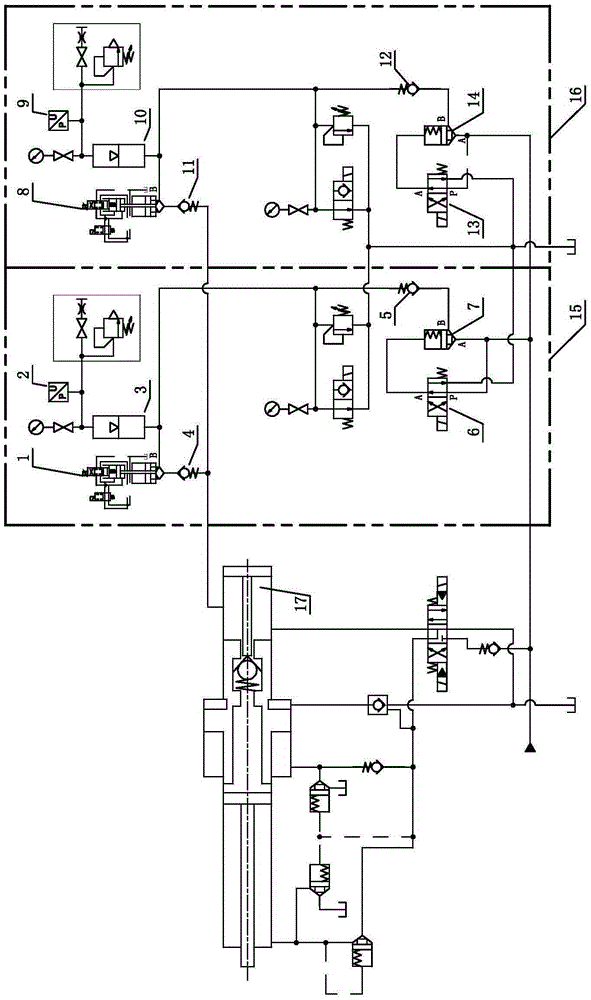

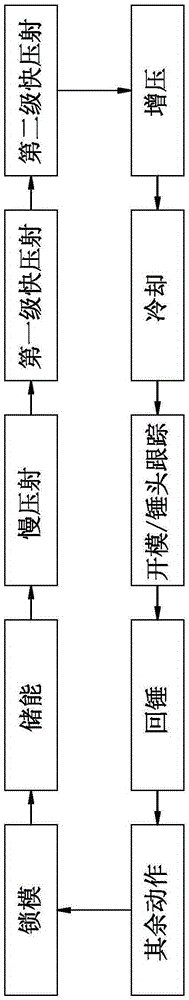

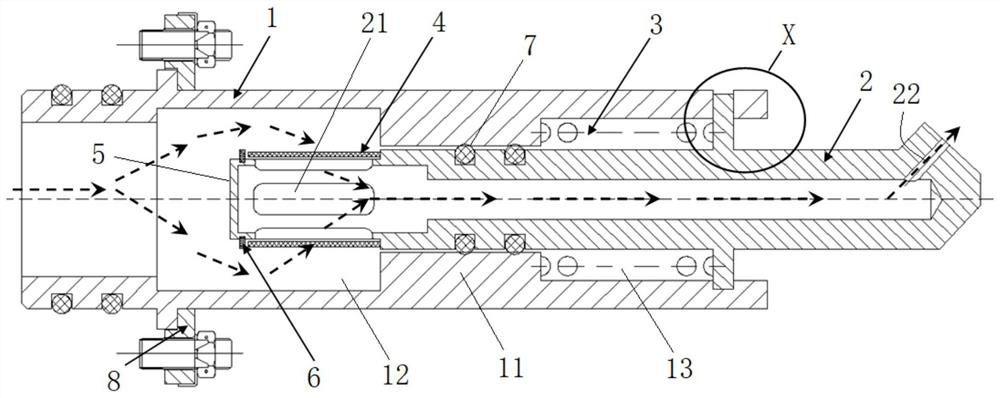

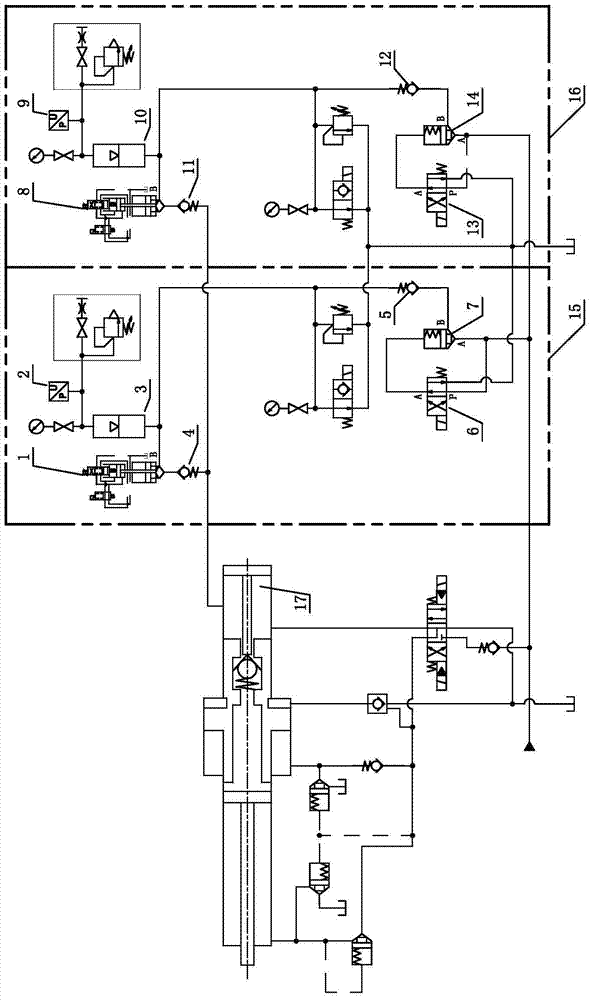

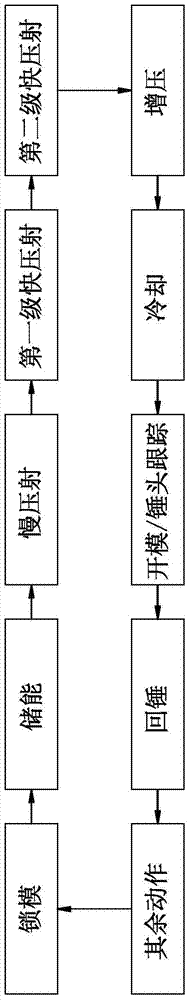

Hydraulic system with fast injection loops of die casting machine

The invention relates to a hydraulic system with fast injection loops of a die casting machine. The hydraulic system comprises an injection oil cylinder, a first stage of fast injection loop and a second stage of fast injection loop, wherein the first stage of fast injection loop and the second stage of fast injection loop are mutually independent and connected with each other in parallel, and the connected two ends of the first stage of fast injection loop and the second stage of fast injection loop are respectively connected with the rear chambers of the injection oil cylinder. Each of the first stage of fast injection loop and the second stage of fast injection loop uses an independent accumulator, and the first stage of fast injection loop and the second stage of fast injection loop are not interfere with each other in the working process. The pressure loss of the first stage of fast injection is reduced, and energy is saved. The first stage of fast injection does not consume the pressure oil of the second stage of fast injection accumulator, so that the pressure of the second stage of fast injection accumulator is not reduced, and therefore the speed demand of the second stage of fast injection can be beneficially ensured. The hydraulic system has the characteristics of being simple and reasonable in structure and energy-saving and being beneficial to ensuring the speed demand of the second stage of fast injection.

Owner:广东联升精密机械制造有限公司

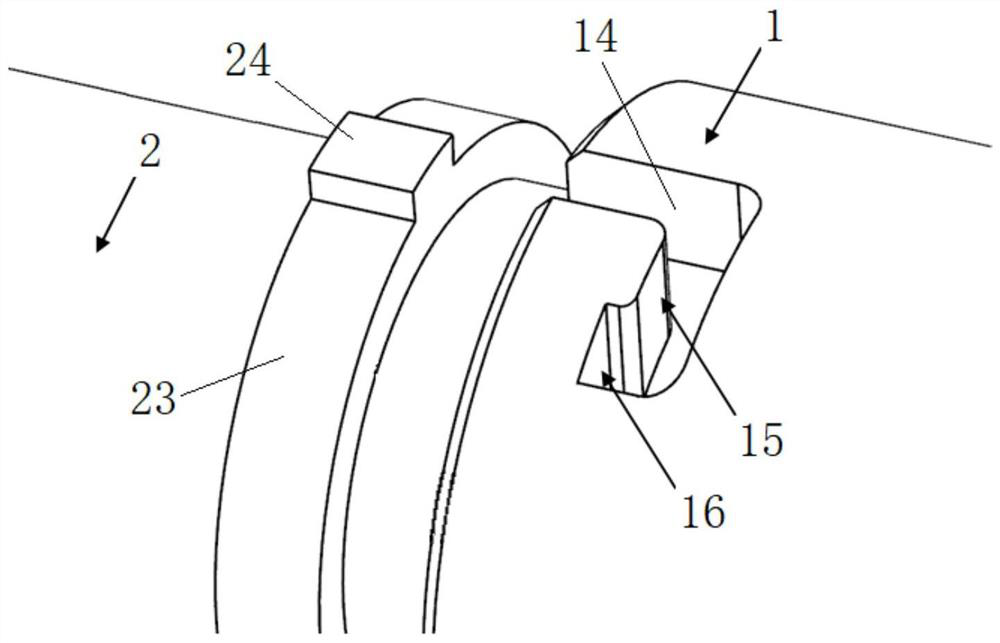

Lubricating oil nozzle with filtering function

ActiveCN112177779AGuaranteed Speed RequirementsGuaranteed traffic requirementsConduits/junctionsTurbine/propulsion lubricationForeign matterEngineering

The invention provides a lubricating oil nozzle with a filtering function. The lubricating oil nozzle with the filtering function comprises a nozzle shell, a nozzle, a spring and a filter screen, wherein the nozzle is at least partially arranged in the nozzle shell, one end of the nozzle is a spray hole, the other end of the nozzle is provided with a plurality of filter holes formed in the radialdirection, and the filter holes communicate with the nozzle; the spring is arranged between the nozzle shell and the nozzle; and the filter screen covers the filter holes, and lubricating oil flowinginto the spray hole is filtered through the filter screen. According to the lubricating oil nozzle with the filtering function, simple filtering before injection can be achieved, foreign matters possibly blocking the nozzle are intercepted, the requirements on the lubricating oil injection speed and flow are effectively met, and safe work of an engine is guaranteed.

Owner:AECC SHENYANG ENGINE RES INST

Intelligent driving method for line collision test drive vehicle

ActiveCN110308001ARealize automatic decouplingAvoid harmRailway vehicle testingRoute devices for controlling vehiclesControl systemIn vehicle

The present invention discloses an intelligent driving method for a line collision test drive vehicle. A test drive vehicle is connected with a to-be-tested vehicle by using a first vehicle coupler, aclose-coupled coupler is used for the first vehicle coupler, and the test drive vehicle is used as a track tractor to drive the to-be-tested vehicle to run; during the test, a ground beacon arrangedon the sleeper is identified by a first in-vehicle network control system arranged on the test drive vehicle through a beacon reading device, so that the current position of the test drive vehicle canbe determined, and signals are transmitted through a vehicle wireless reconnection unit to a ground console of a ground control room; and a ground network control system arranged on the ground console transmits a traction, braking or decoupling operation instruction to the test drive vehicle through the ground wireless reconnection unit to remotely control the test drive vehicle to perform a collision test. According to the method provided by the present invention, technical problems that a series of train collision test control processes such as dynamic decoupling must be completed on the test vehicle in the existing line collision test mode with poor test safety and stability can be solved.

Owner:ZHUZHOU TIMES ELECTRONICS TECH CO LTD +1

Real-time visual detection and identification method for high speed rail surface defect

ActiveCN102854191BGuaranteed Speed RequirementsShorten the timeCharacter and pattern recognitionOptically investigating flaws/contaminationVisual perceptionImage pre processing

A real-time visual detection and identification method for high speed rail surface defects comprises the following steps of: (1) image acquisition; (2) image preprocessing; (3) defect preliminary detection, that is, performing logic or operation combination of detection results based on gray scale compensation with detection results based on top-hat operation, and detecting whether an abnormal area exists in an image, if not, finishing the detection, or else continuing the processing; (4) defect accurate positioning, that is, accurately positioning the defect by an algorithm of bonding single defect, an algorithm of filling holes in the defect area, and an algorithm of selecting the main defect, and extracting the defect area through marks; (5) defect classification, that is, extracting and selecting characteristics of the defect area, designing and training a BP neural network, and classifying the defects by the BP neural network. The invention has the advantages of simple principle, high automation degree, high detection speed, and high detection precision.

Owner:HUNAN UNIV

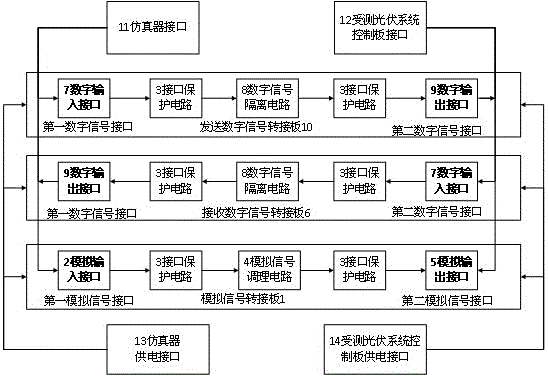

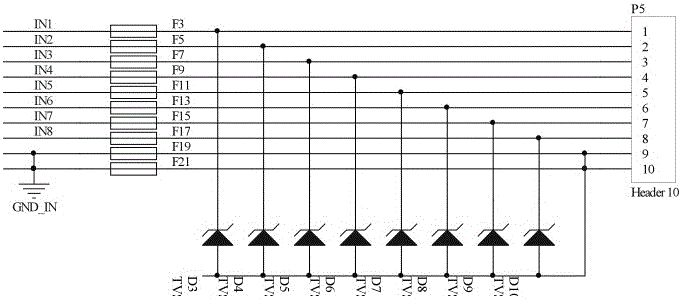

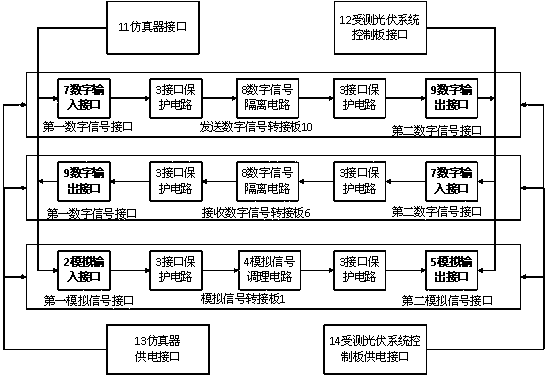

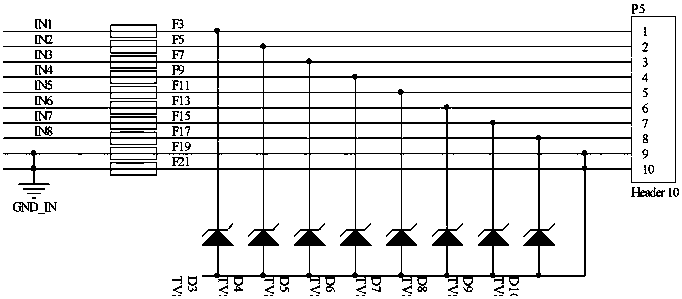

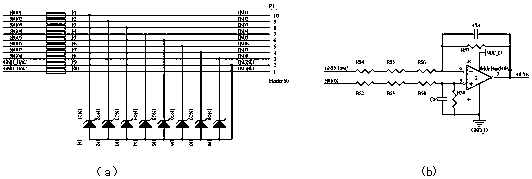

Safety interface device for semi-physical simulation, and design method

ActiveCN105068443AAvoid circulationReduce the impact of interferenceSimulator controlEngineeringRandom noise

The invention relates to a safety interface device for semi-physical simulation, and a design method. The device consists of a simulator interface, a tested photovoltaic system control board interface, a simulation signal adapter board, a digital signal receiving adapter board, a digital signal transmitting adapter board, and a peripheral interface power supply part. The device enables a simulator to be connected with a control board interface of a photovoltaic inversion system, can effectively reduce equipment damage risks caused by software and hardware design and connection errors, can make the most of analog precision of the simulator, provides an addition condition of random noise, provides electrical isolation, and reduces risks caused by external static. Meanwhile, aiming at the difference of simulation sampling of a photovoltaic control board, the characteristics of a digital signal and application voltage ranges of a control board and the simulator, the device especially employs a proper amplifier and a proper optical coupler. The device is quick and effect in application, greatly improves work efficiency, and reduces the possibility that misoperation causes loss. The invention provides a simple, convenient and reliable conversion device and design method for the field of semi-physical simulation.

Owner:FUDAN UNIV +1

Cotton defect detection and recognition method based on multi-spectral technology

InactiveCN104751443BShorten the timeThe detection process is fastImage analysisMorphological processingUltimate tensile strength

A cotton defect detection and recognition method based on multi-spectral technology, the steps of which are: (1) image acquisition; (2) image preprocessing; (3) preliminary detection of defects: using the improved morphology gradient algorithm for edge detection to obtain each defect Integrate the strength of edge detection to obtain the contrast-enhanced image of each defect; (4) Accurate defect positioning: convert the image into a connected domain image by improving the iterative threshold method and morphological processing, and accurately locate the defect by selecting the main defect algorithm, and extract it by marking Defect area; (5) Ginning quality judgment: Count the number of each defect, calculate the total number of cotton defects, and obtain the ginning quality grade. The invention has the advantages of simple principle, fast detection speed and high detection precision.

Owner:ZHENGZHOU UNIVERSITY OF LIGHT INDUSTRY

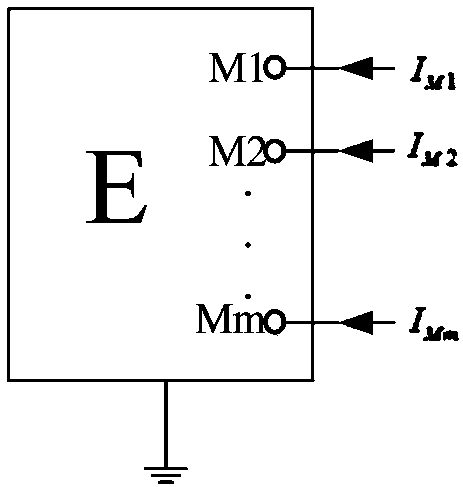

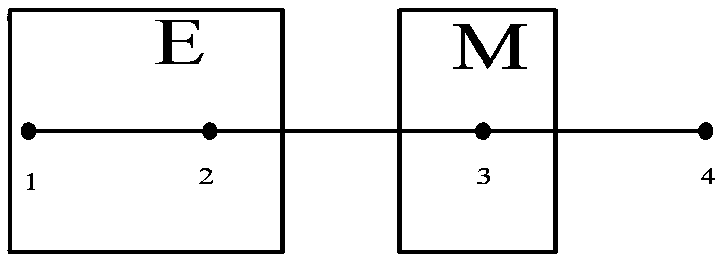

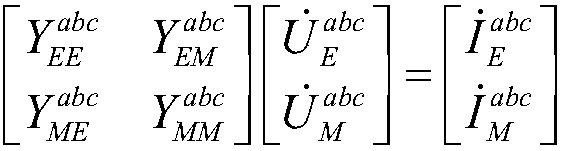

Node current injection based single three-phase hybrid tide calculation method

ActiveCN108134392AAchieve speed requirementsAchieving Accuracy RequirementsSpecial data processing applicationsAc networks with different sources same frequencyThree-phaseComputer science

The invention relates to a node current injection based single three-phase hybrid tide calculation method. The technical feature of the method is that the method includes steps of 1, constructing a single three-phase hybrid model used for power distribution network tide calculation; 2, performing power distribution network calculation by adopting a node current injection method based on the singlethree-phase hybrid model used for power distribution network tide calculation constructed in step 1. According to the invention, influence due to zero sequence and negative sequence components are taken into account, and calculation precision is ensured at the same time of ensuring the calculation speed.

Owner:ELECTRIC POWER SCI & RES INST OF STATE GRID TIANJIN ELECTRIC POWER CO +2

An automatic sorting system for domestic waste

Owner:BEIJING XINCHANGZHENG TIANGAO INTELLIGENT MACHINE TECH CO LTD

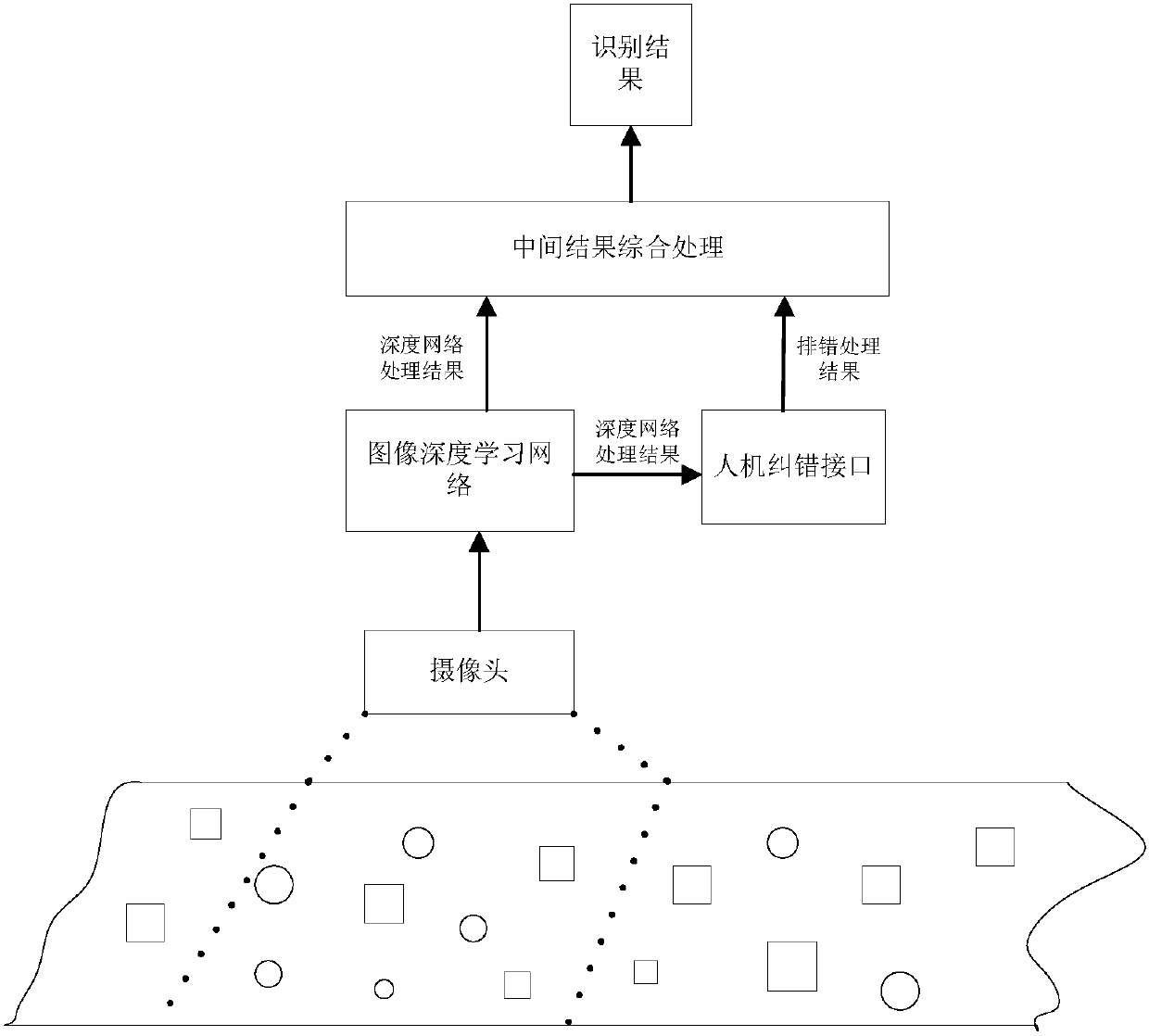

Machine vision recognition system based on artificial error correction mechanism and deep learning network collaboration

ActiveCN106067031BEfficient identificationMeet the use requirementsCharacter and pattern recognitionTime informationMachine vision

Based on the artificial error correction mechanism and the deep learning network collaborative machine vision recognition system, the deep learning network receives the captured visual feedback images in real time, performs deep learning processing on each frame of the received image, and converts the processed image and the coordinates of the detection target on the image, The angle and time information is sent to the intermediate result comprehensive processing unit; the processed image is sent to the man-machine error correction interface; the man-machine error correction interface continuously displays the processed image of each frame received, and the visual feedback image is manually captured According to the specific situation, remove the emphatic display of the obvious wrong target on the displayed image, and send the relevant information to the intermediate result comprehensive processing unit; the intermediate result comprehensive processing unit detects the target from the received frame of image The information of the wrong target is eliminated from the coordinates, angle and time information of the image coordinate system, and the coordinates, angle and time information of the recognized target are obtained. At the same time, the emphasis display of the wrong target is removed from the received visual feedback image, and the completion Visual Identity.

Owner:BEIJING XINCHANGZHENG TIANGAO INTELLIGENT MACHINE TECH CO LTD

A dynamic resource scheduling method for noma cellular Internet of Vehicles based on energy efficiency

ActiveCN109905918BAvoid congestionGuaranteed LatencyPower managementInternal combustion piston enginesDynamic resourceChannel scheduling

Owner:杭州拾毅网络科技有限公司

Hydraulic system of fast injection circuit of die casting machine

The invention relates to a hydraulic system with fast injection loops of a die casting machine. The hydraulic system comprises an injection oil cylinder, a first stage of fast injection loop and a second stage of fast injection loop, wherein the first stage of fast injection loop and the second stage of fast injection loop are mutually independent and connected with each other in parallel, and the connected two ends of the first stage of fast injection loop and the second stage of fast injection loop are respectively connected with the rear chambers of the injection oil cylinder. Each of the first stage of fast injection loop and the second stage of fast injection loop uses an independent accumulator, and the first stage of fast injection loop and the second stage of fast injection loop are not interfere with each other in the working process. The pressure loss of the first stage of fast injection is reduced, and energy is saved. The first stage of fast injection does not consume the pressure oil of the second stage of fast injection accumulator, so that the pressure of the second stage of fast injection accumulator is not reduced, and therefore the speed demand of the second stage of fast injection can be beneficially ensured. The hydraulic system has the characteristics of being simple and reasonable in structure and energy-saving and being beneficial to ensuring the speed demand of the second stage of fast injection.

Owner:广东联升精密智能装备科技有限公司

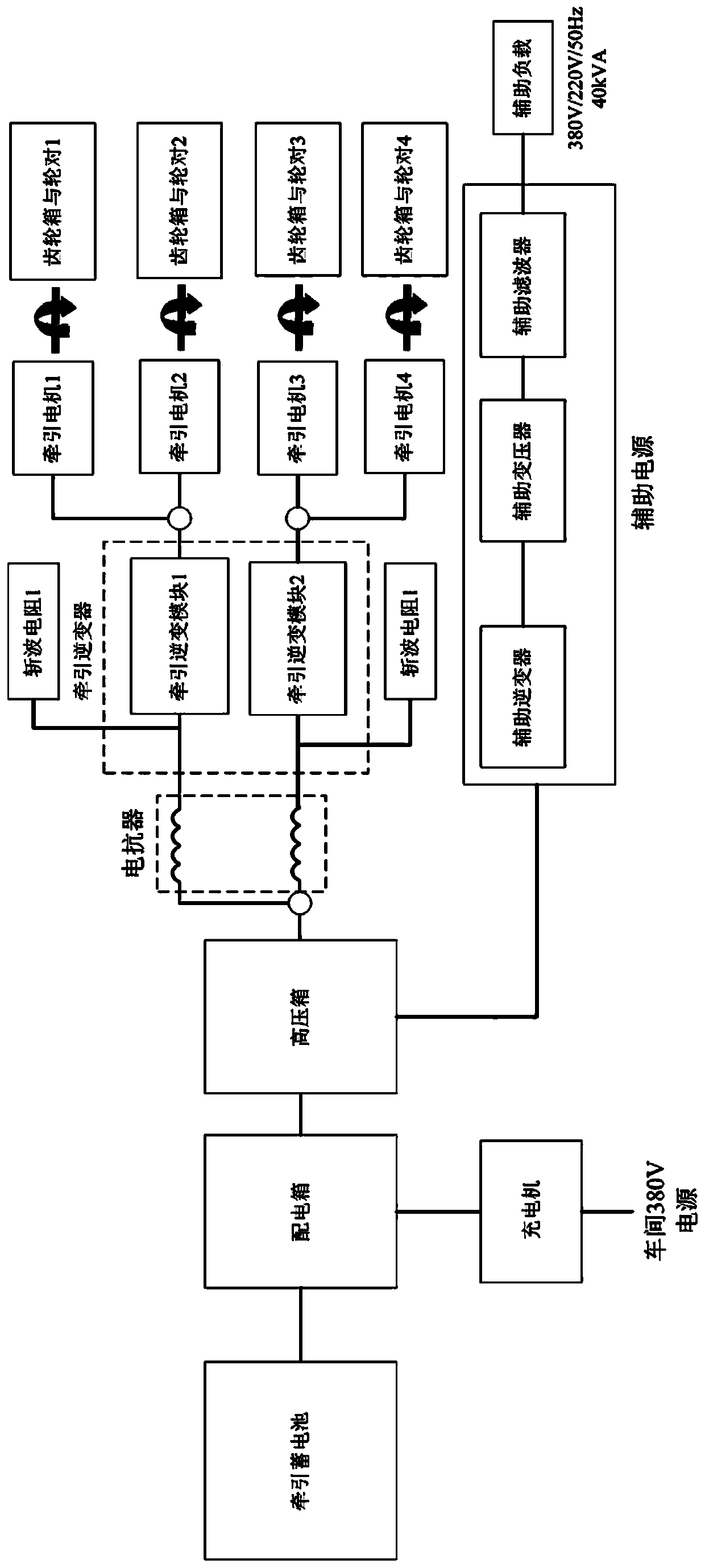

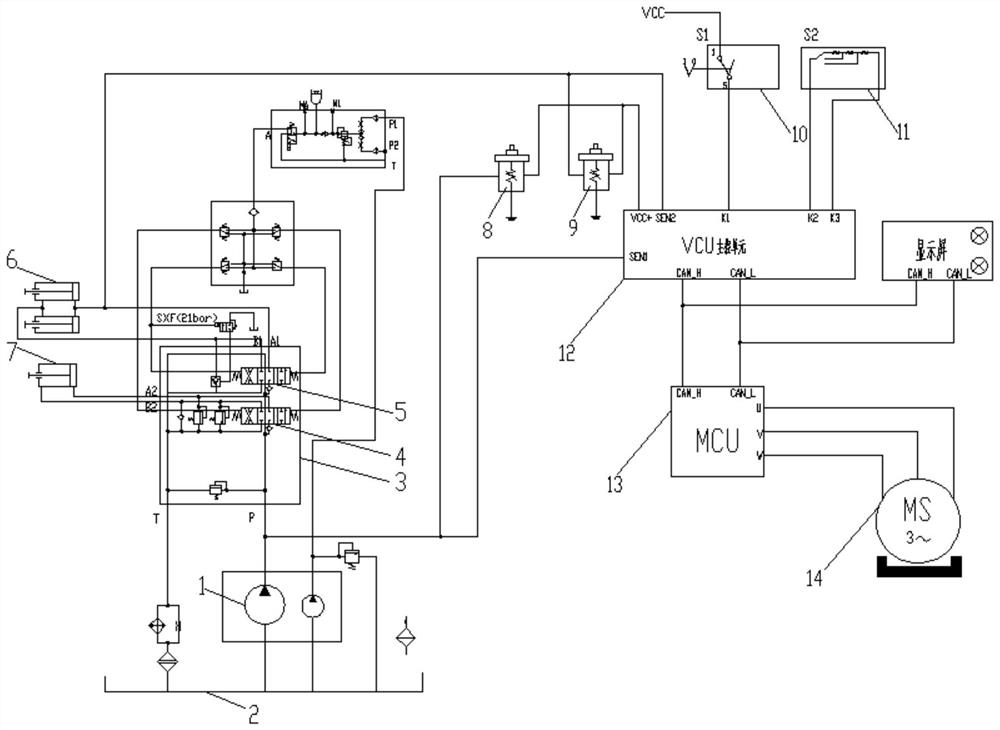

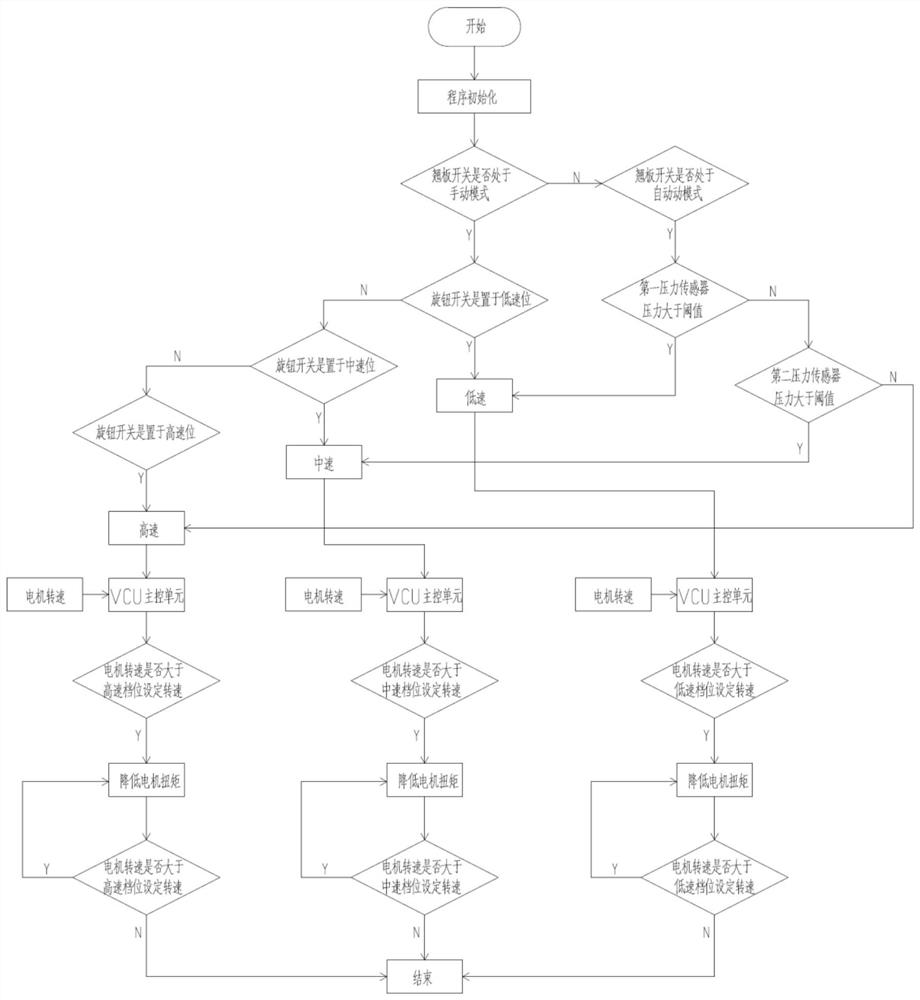

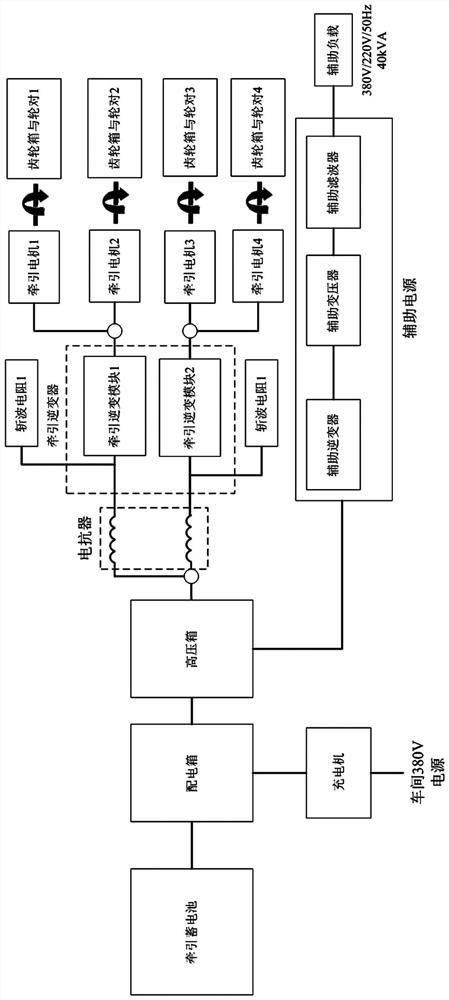

Multi-working-condition automatic speed regulation control system of electric loader

ActiveCN113910918AGuaranteed speed requirementsEnsure job safetySpeed controllerElectric energy managementControl cellMachine

The invention discloses a multi-working-condition automatic speed regulation control system of an electric loader, which comprises a detection module, the detection module comprises a first pressure sensor and a second pressure sensor, the first pressure sensor is arranged in a pump opening oil way of a working pump of a hydraulic system and used for detecting the pressure value of the working pump during shovel loading operation of the loader, the second pressure sensor is connected in an oil way of a large cavity of a movable arm oil cylinder of the hydraulic system and is used for detecting the pressure value of the large cavity of the movable arm oil cylinder when the working machine tool of the loading machine ascends or descends; a control module which comprises a VCU control unit which is used for controlling the motion state of the loading machine and electrically connected with the first pressure sensor and the second pressure sensor, and the VCU control unit is used for controlling the motion of the loading machine according to detection data of the first pressure sensor and the second pressure sensor. Speed requirements for different working conditions of shoveling operation and walking can be guaranteed, operation safety in the operation process is guaranteed, meanwhile, energy can be properly saved, consumption can be properly reduced, and the single-time charging interval is prolonged.

Owner:XCMG CONSTR MACHINERY

Visual detection method for quality of liquid medicine on high-speed pharmaceutical production line

InactiveCN101859378BGuaranteed Speed RequirementsThe detection process is fastImage enhancementImage analysisForeign matterGray level

The invention discloses a visual detection method for the quality of liquid medicine on a high-speed pharmaceutical production line. The visual detection method is characterized by comprising the following steps of: firstly, acquiring images, i.e., acquiring five continuous sequence images of liquid medicine under a halted state of a bottle after revolution at a high speed, wherein the shot images are the gray-level images; secondly, initially denoising the images, i.e., removing the dynamic interference of the bottle wall by an offset background reduction method based on a characteristic point; thirdly, detecting a target, i.e., removing the static interference by a difference method and a threshold-based division method; fourthly, recognizing the target, i.e., judging whether the targetis a foreign body or not according to the continuation of the motion trail of the target, and recording the foreign body; and fifthly, judging the target, i.e., judging whether the foreign body is the visible foreign body or not according to whether the size of the recorded foreign body exceeds the specified range or not. The method has the advantages of high detection precision and high detection speed.

Owner:HUNAN UNIV

A rail vehicle line crash test method

ActiveCN110285987BRealize automatic decouplingAvoid harmRailway vehicle testingRoute devices for controlling vehiclesRemote controlCrash test

The invention discloses a rail vehicle line collision test method. When the tested vehicle starts to carry out the collision test, the test driving vehicle is connected to the tested vehicle through a first coupler, and the test driving vehicle pushes the tested vehicle to start and accelerate operation; The test driving vehicle and the tested vehicle run at the specified speed, and the test driving vehicle and the tested vehicle keep running at a constant speed for a period of time; when the tested vehicle reaches the decoupling point, the beacon reading device detects the position of the ground beacon and sends the fixed point The signal is sent to the ground console; after receiving the fixed-point signal, the ground console sends a decoupling command to the test drive car to open the first coupler; the test drive car starts to brake, the test drive car and the tested vehicle are separated, and the tested vehicle Coasting until the collision point is reached, the test drive vehicle gradually decelerates until it stops. The invention can solve the technical problems that the existing line collision test method cannot realize the remote control of the test process, and the test safety and stability are not high.

Owner:ZHUZHOU TIMES ELECTRONICS TECH CO LTD +1

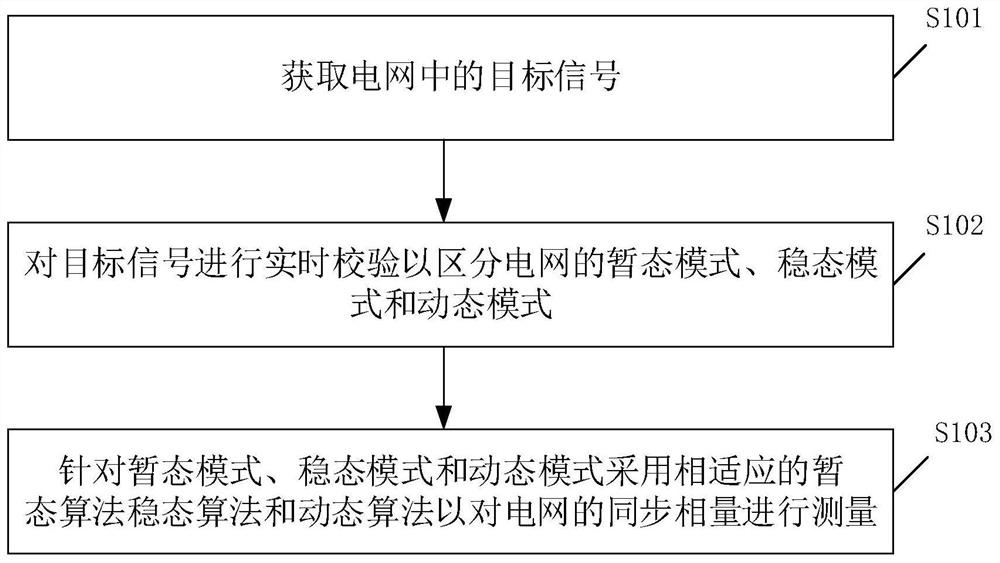

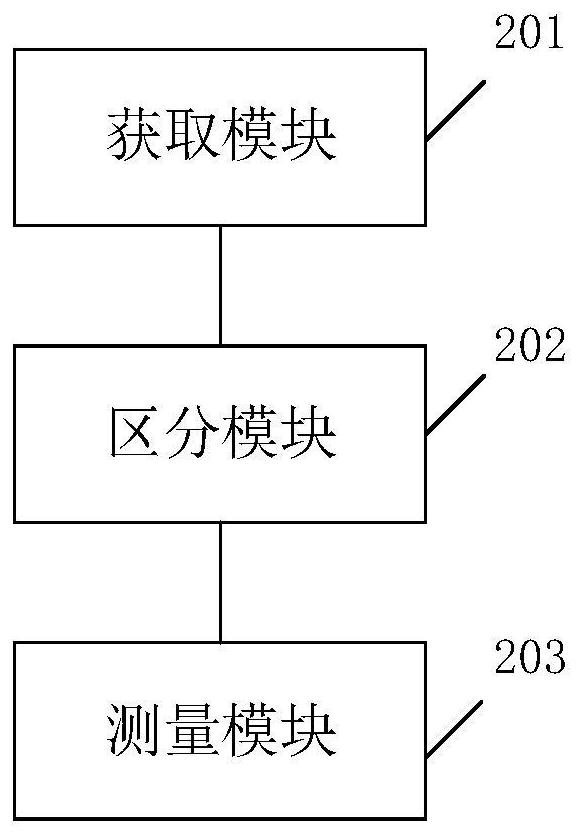

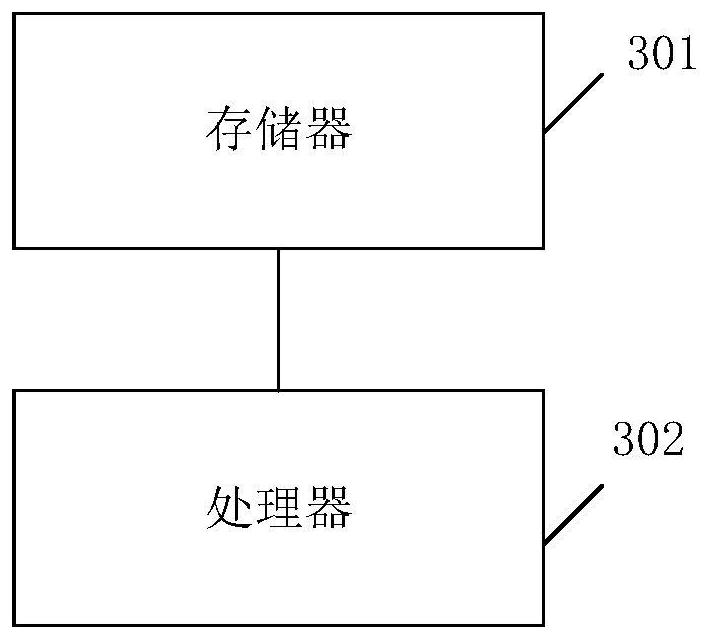

Synchronized phasor measurement method, device, equipment and storage medium for real-time calibration

ActiveCN109374970BGuaranteed Speed RequirementsGuaranteed measurement accuracy requirementsVoltage-current phase angleTransient stateMeasurement device

The invention discloses a synchronized phasor measurement method for multi-level real-time verification. Firstly, the target signal in the power grid is obtained, and then the target signal is verified in real time to distinguish the transient mode, steady-state mode and dynamic mode of the power grid. Transient mode, steady state mode and dynamic mode use adaptive transient algorithm, steady state algorithm and dynamic algorithm to measure the synchronized phasor of the power grid, and can adopt adaptive algorithm for three different modes in the power grid, because Each mode uses an appropriate algorithm, so it can meet the requirements of response speed and measurement accuracy when measuring the synchronized phasor of the power grid. Compared with using one measurement algorithm in three different modes in the prior art, when measuring synchronized phasors in three different modes of the power grid, both the measurement accuracy requirements and the response speed requirements can be guaranteed. The invention also provides a synchronized phasor measurement device, equipment and storage medium for multi-level real-time calibration, with the above effect.

Owner:ELECTRIC POWER RESEARCH INSTITUTE, CHINA SOUTHERN POWER GRID CO LTD +1

A design method of safety interface device for hardware-in-the-loop simulation

The invention relates to a safety interface device for semi-physical simulation, and a design method. The device consists of a simulator interface, a tested photovoltaic system control board interface, a simulation signal adapter board, a digital signal receiving adapter board, a digital signal transmitting adapter board, and a peripheral interface power supply part. The device enables a simulator to be connected with a control board interface of a photovoltaic inversion system, can effectively reduce equipment damage risks caused by software and hardware design and connection errors, can make the most of analog precision of the simulator, provides an addition condition of random noise, provides electrical isolation, and reduces risks caused by external static. Meanwhile, aiming at the difference of simulation sampling of a photovoltaic control board, the characteristics of a digital signal and application voltage ranges of a control board and the simulator, the device especially employs a proper amplifier and a proper optical coupler. The device is quick and effect in application, greatly improves work efficiency, and reduces the possibility that misoperation causes loss. The invention provides a simple, convenient and reliable conversion device and design method for the field of semi-physical simulation.

Owner:FUDAN UNIV +1

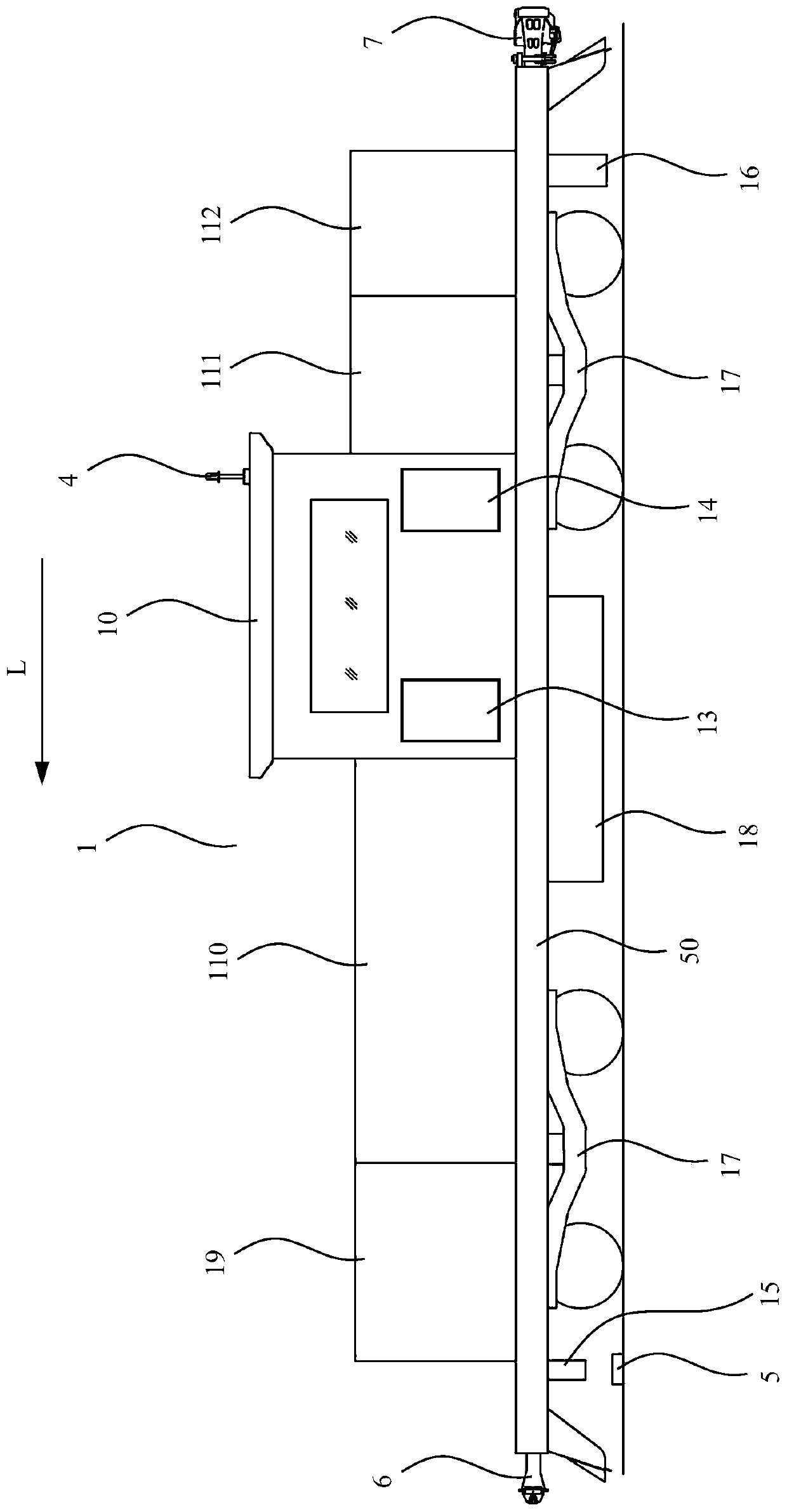

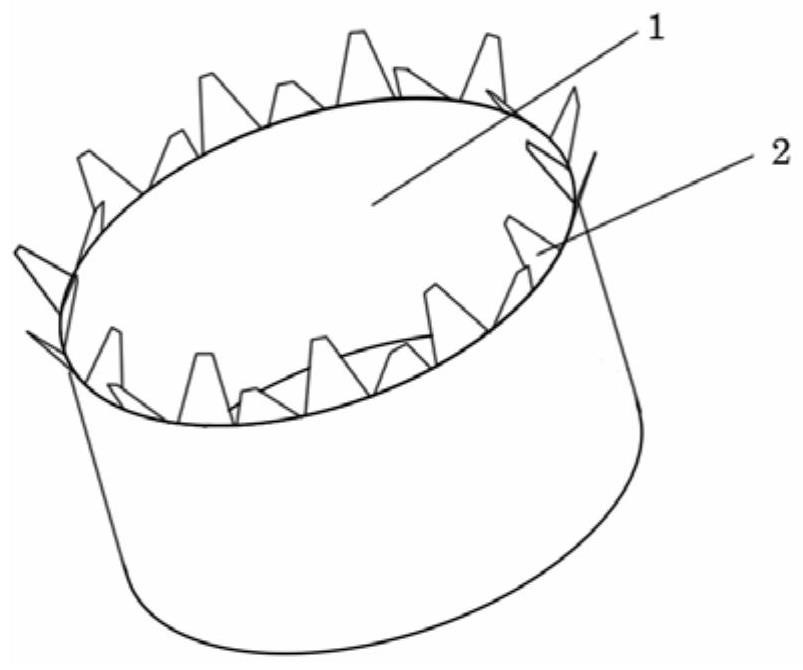

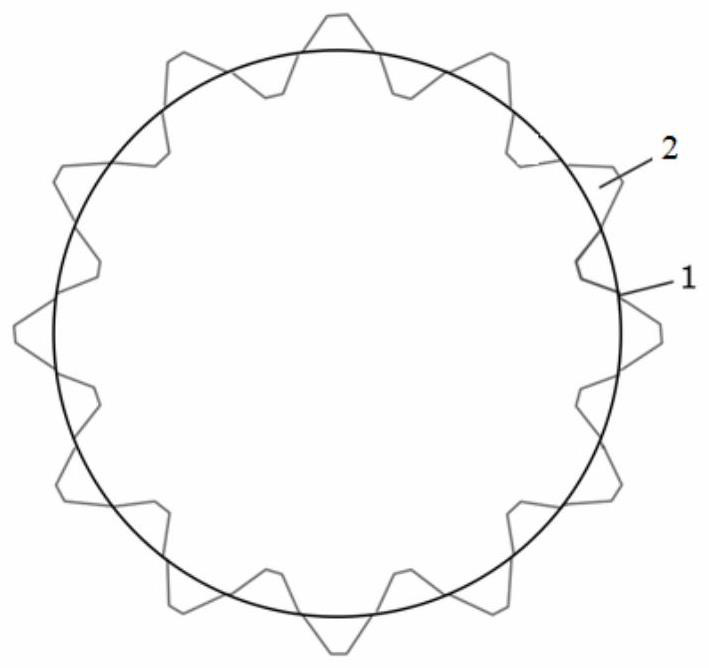

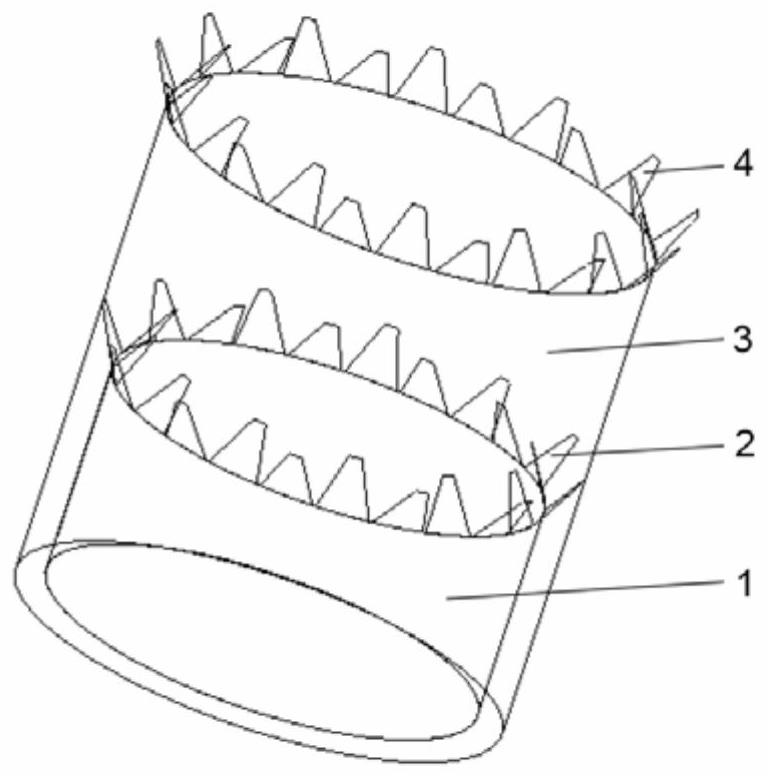

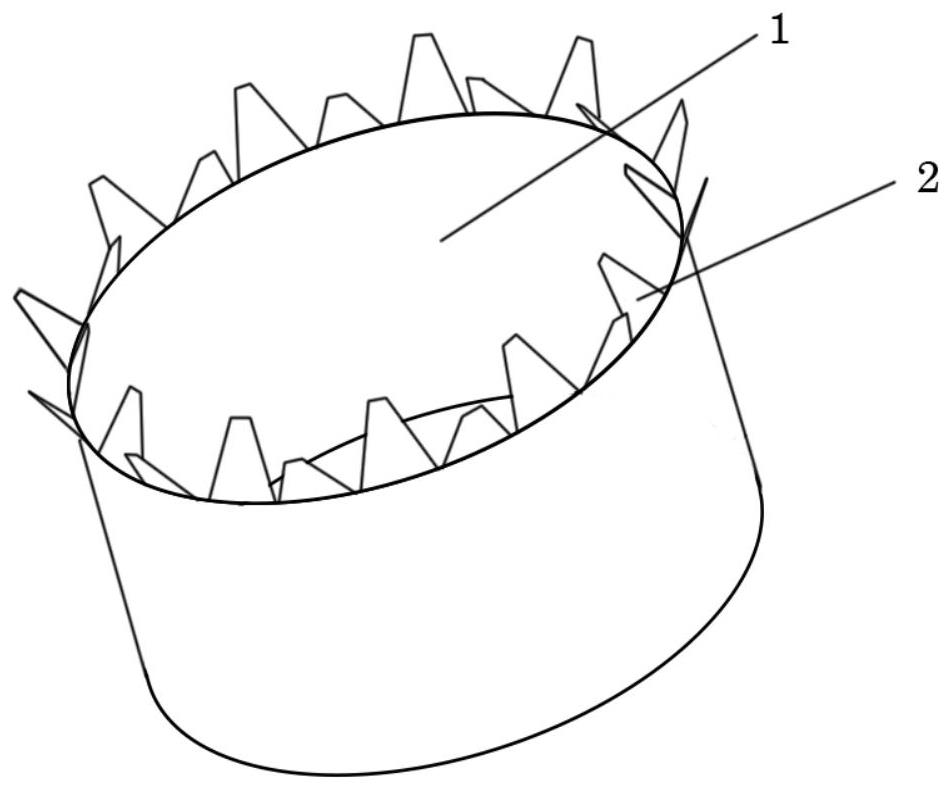

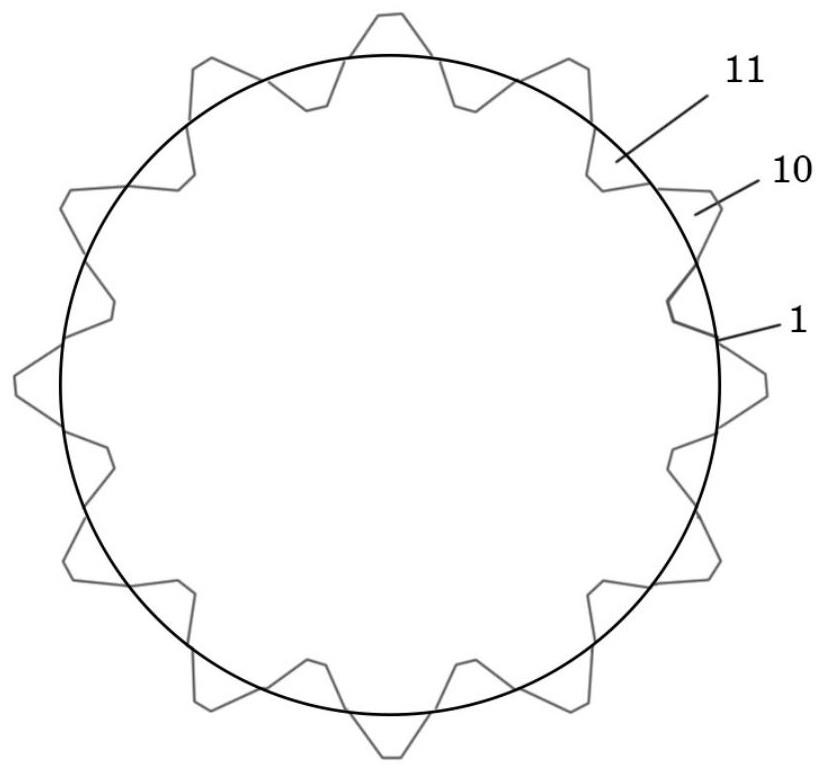

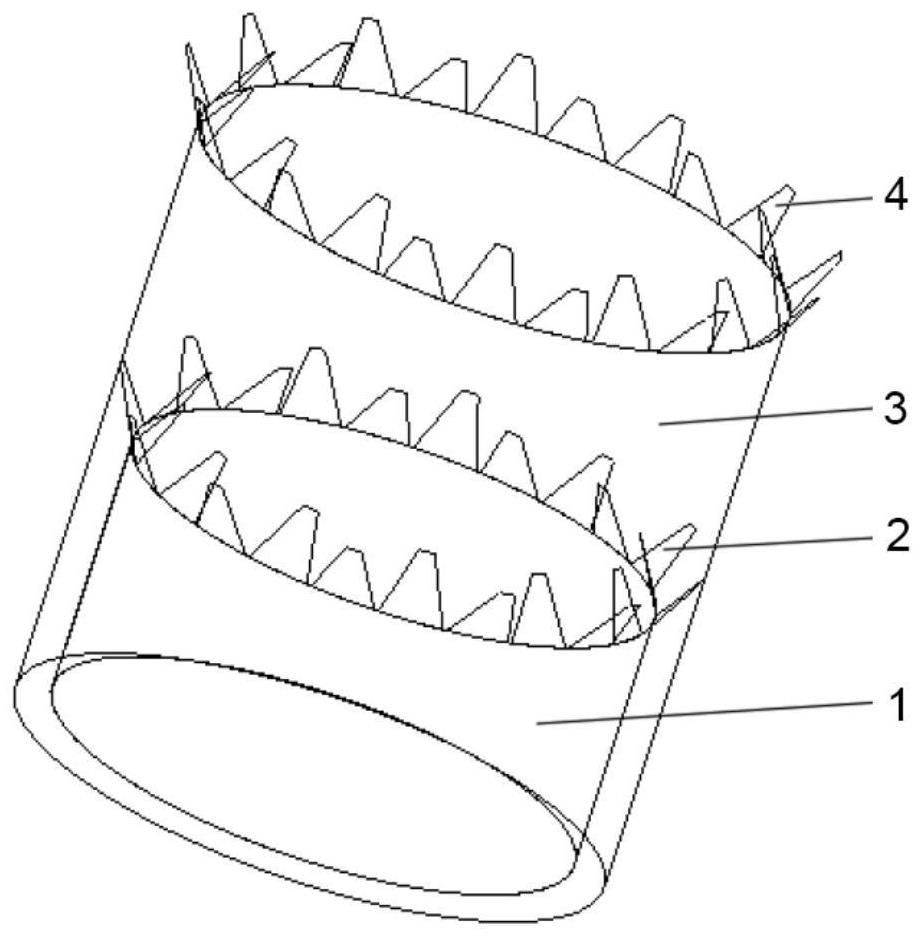

A multi-stage ladder-tooth type mixer for integrated afterburner

ActiveCN114060853BImprove thermal mixing efficiencyIncreased Thermal Mixing EfficiencyContinuous combustion chamberCombustion chamberEngineering

A multi-stage ladder-tooth type mixer for an integrated afterburner relates to an aeroengine afterburner. There are two-stage blending sections, each of which is composed of ladder-tooth crown mixers of different sizes, and the blending section is a ring structure. and a second-stage blending section, the first-stage blending section is set inside the second-stage blending section; each stage blending section is composed of an inner wall and a ladder-tooth crown mixer, and the ladder-tooth crown mixer is inwardly inclined with ladder teeth and outwardly inclined. The ladder teeth are alternately and evenly arranged on the outlet end face of the mixing section of each stage. When the gas flows through the inclining ladder teeth and the outward inclination ladder teeth, the staggered distribution of the ladder teeth induces a flow vortex, which forms a stable vortex at the rear end of the ladder-tooth crown mixer. And uniform mixing zone, strengthen the mixing of internal and external bypass airflow. It can effectively suppress the generation of noise, effectively enhance the mixing of the internal and external bypass airflow of the aero-engine, improve the mixing efficiency, reduce the total pressure loss, and thus improve the combustion efficiency of the afterburner.

Owner:XIAMEN UNIV

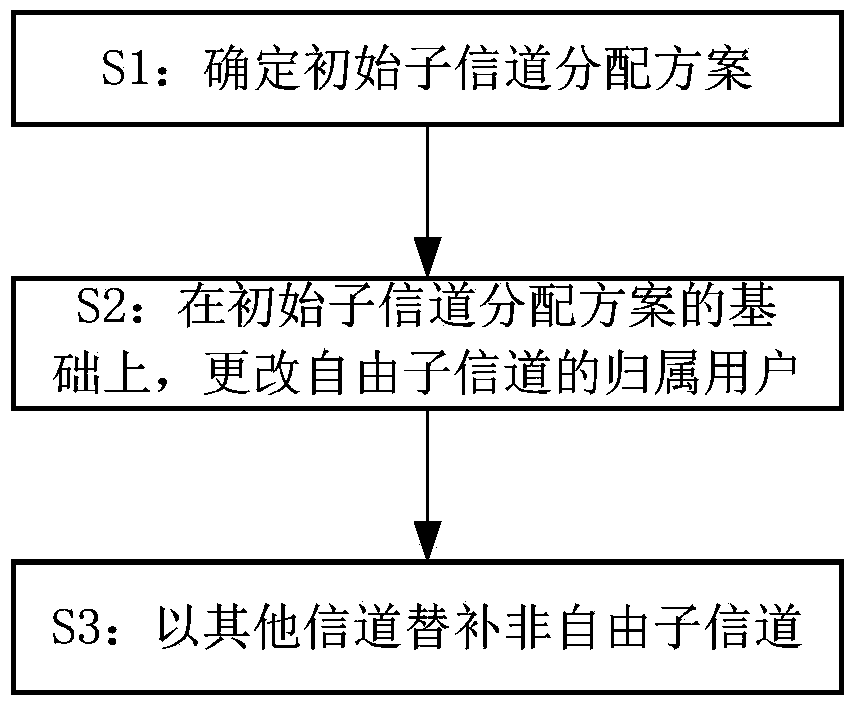

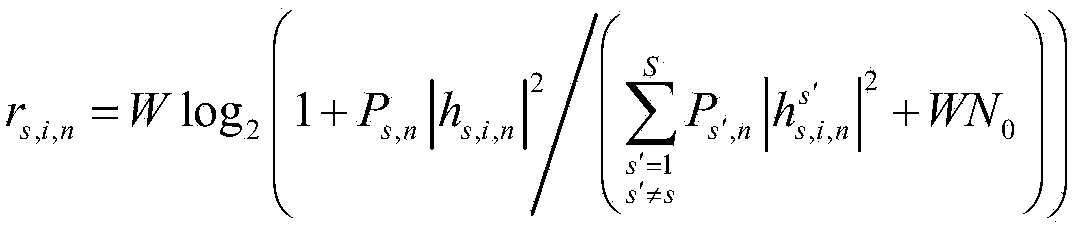

Sub-channel distribution method based on efficacy

InactiveCN103731922AMaximize energy efficiencyMaximize total energy efficiencyEnergy efficient ICTHigh level techniquesDistribution methodComputer science

The invention discloses a sub-channel distribution method based on efficacy, and belongs to the technical field of resource distribution in the wireless mobile communication network. The sub-channel distribution method based on efficacy particularly comprises the following steps: determining an initial sub-channel distribution plan, changing the user to which a free sub-channel belongs as the user with the largest rate in the sub-channel on the basis of the initial sub-channel distribution plan, selecting a non-free sub-channel according to the improvable space of the rate from big to small, and carrying out substitution operation on the non-free sub-channel. On the premise of ensuring the requirement of the rate of each user, the method can reasonably distribute sub-channels to the cell users, and enable the total efficacy of a cell to be maximum, thereby improving the energy efficiency.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

Multi-stage ladder tooth type mixer for integrated afterburner

ActiveCN114060853AImprove thermal mixing efficiencyIncreased Thermal Mixing EfficiencyContinuous combustion chamberNoise generationCombustion chamber

The invention discloses a multi-stage ladder tooth type mixer for an integrated afterburner, and relates to an aero-engine afterburner. Two stages of mixing sections are arranged, each stage of mixing section is composed of ladder tooth crown-shaped mixers of different sizes, the mixing sections are of an annular structure, the mixing sections are sequentially named as the first-stage mixing section and the second-stage mixing section according to the flowing sequence of outer culvert airflow, and the first-stage mixing section is arranged in the second-stage mixing section; and each stage of mixing section is composed of an inner wall and a ladder tooth crown-shaped mixer, inwards-inclined ladder teeth and outwards-inclined ladder teeth of the ladder tooth crown-shaped mixer are alternately and evenly arranged on the end face of an outlet of each stage of mixing section, when gas flows through the inwards-inclined ladder teeth and the outwards-inclined ladder teeth, the ladder teeth distributed in a staggered mode induce a flow direction vortex, a stable and uniform mixing area is formed at the rear end of the ladder tooth crown-shaped mixer, and mixing of airflow of the inner duct and the outer duct is enhanced. Noise generation is effectively restrained, air flow mixing of inner and outer ducts of an aero-engine is effectively enhanced, mixing efficiency is improved, total pressure loss is reduced, and therefore combustion efficiency of an afterburner is improved.

Owner:XIAMEN UNIV

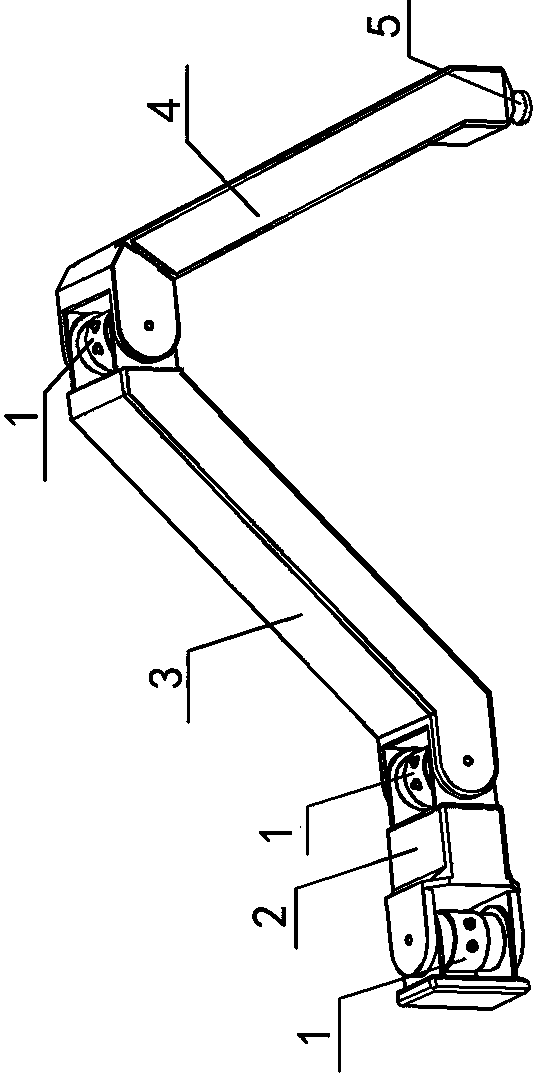

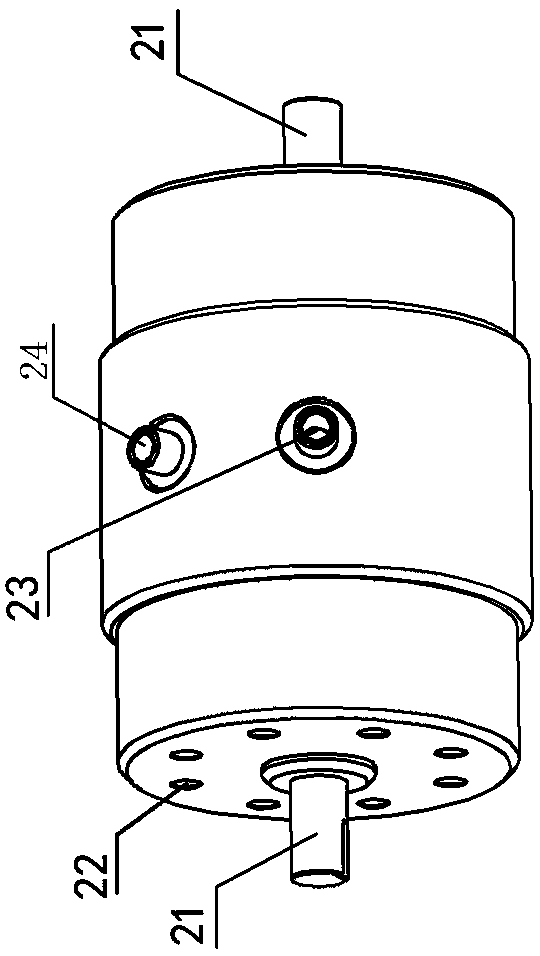

Robot leg

InactiveCN108749952AGuaranteed carrying capacityGuaranteed movement speedVehiclesThighHydraulic motor

The invention discloses a robot leg, which aims at solving the problems that the existing heavy-loaded large-scale six-foot robot generally uses a hydraulic cylinder for driving, and the obstacle passing capability of the six-foot robot is limited. The robot leg comprises a blade type swinging hydraulic motor, a robot calf, a robot thigh and a robot base section, wherein the blade type swinging hydraulic rotor comprises a motor casing, a first hydraulic oil inlet and outlet opening, a second hydraulic oil inlet and outlet opening, a flange installing hole and two output shafts. The leg structure is subjected to fire-new design; the bearing and obstacle passing requirements of the heavy-loading large-scale six-foot robot can be effectively met. In the robot leg, on the basis of the robot leg structure improvement, the blade type swinging hydraulic motor is introduced for leg joint driving, so that the defects of small rotating angle and low obstacle passing capability of the conventional hydraulic cylinder driving heavy-loading large-scale six-foot robot can be effectively overcome. The design is ingenious; the design is reasonable; the structure is simple; the use is convenient; high application values and good application prospects are realized.

Owner:SOUTHWEAT UNIV OF SCI & TECH +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com