Patents

Literature

68results about How to "Guaranteed movement speed" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

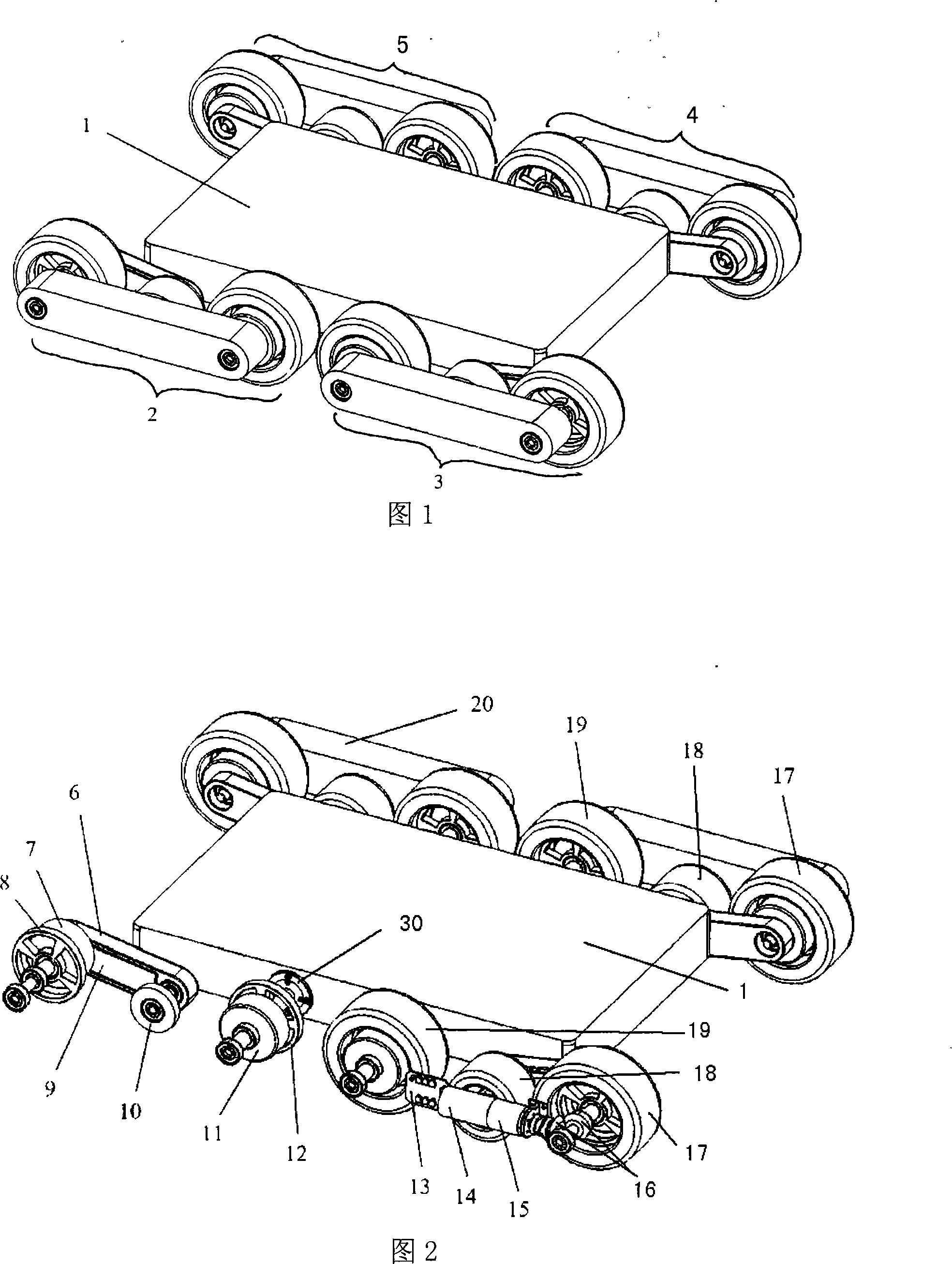

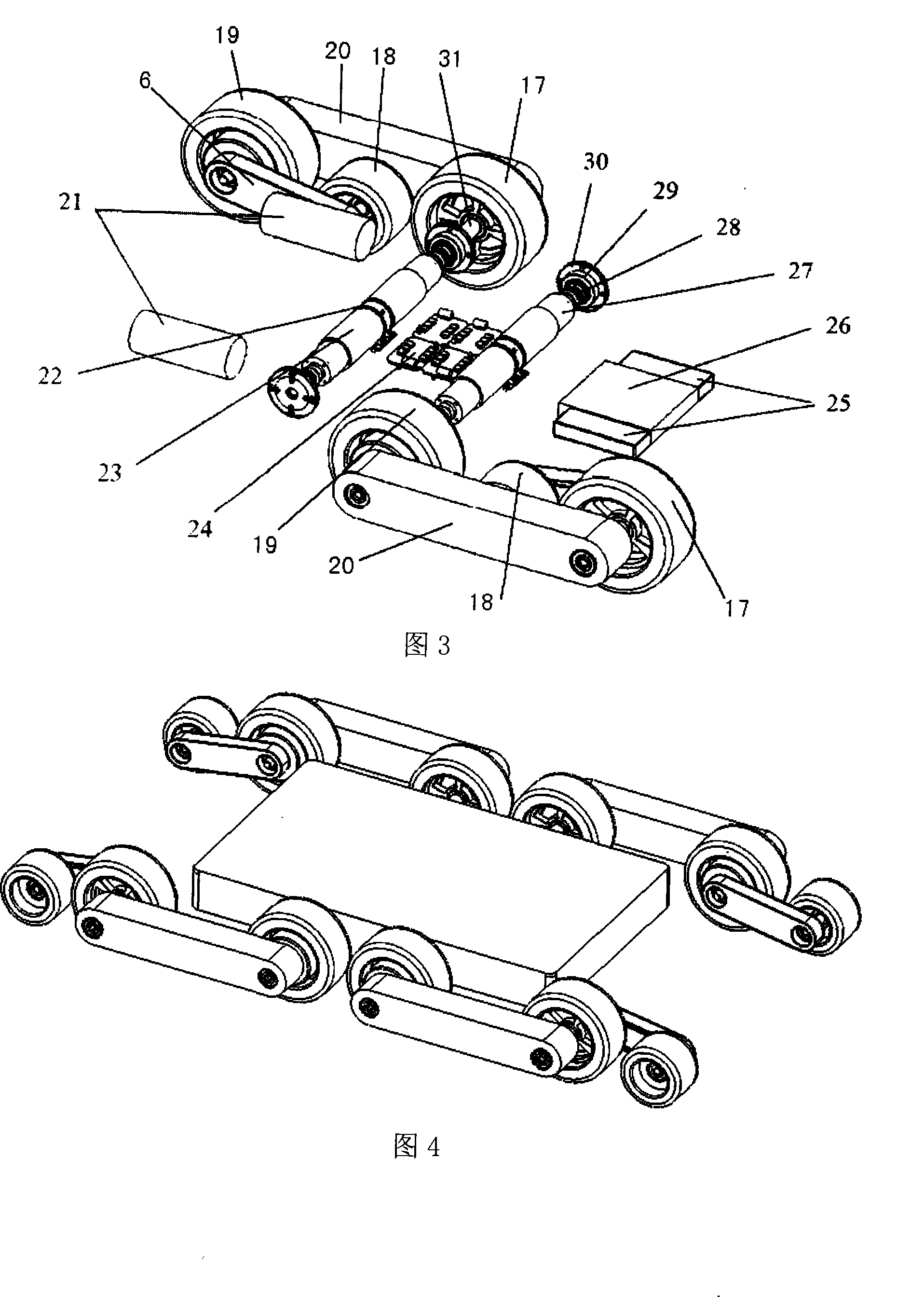

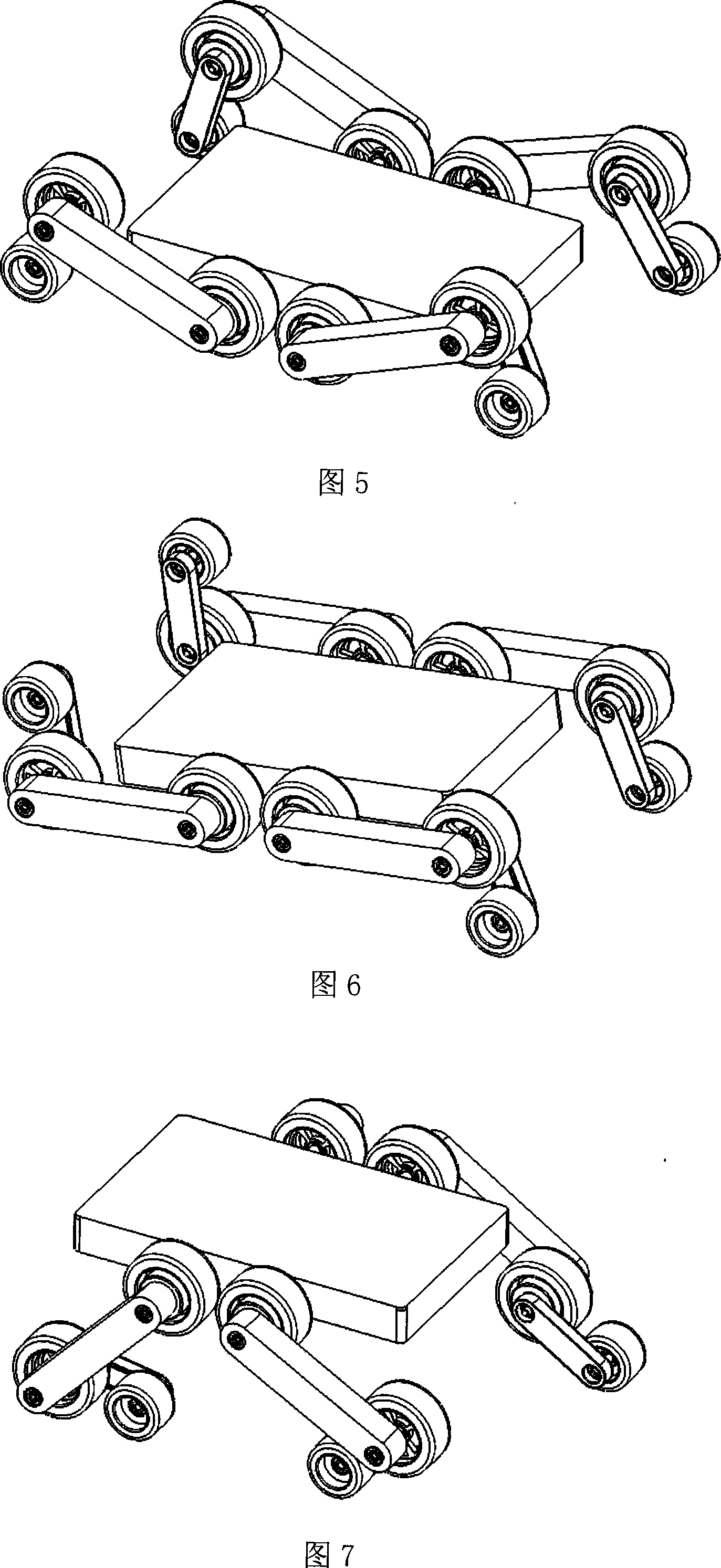

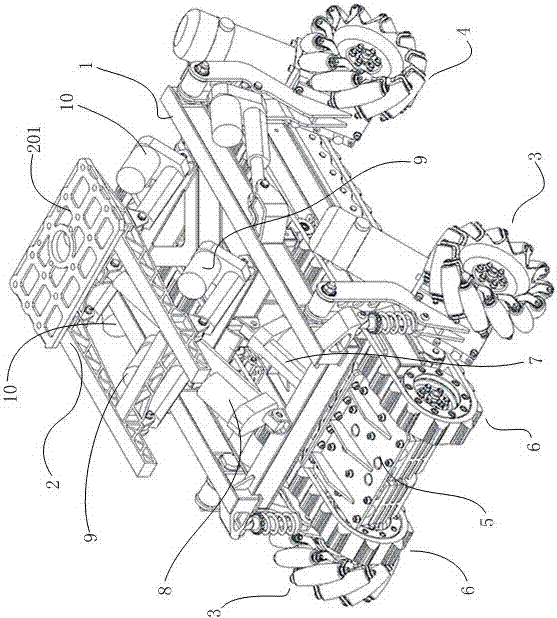

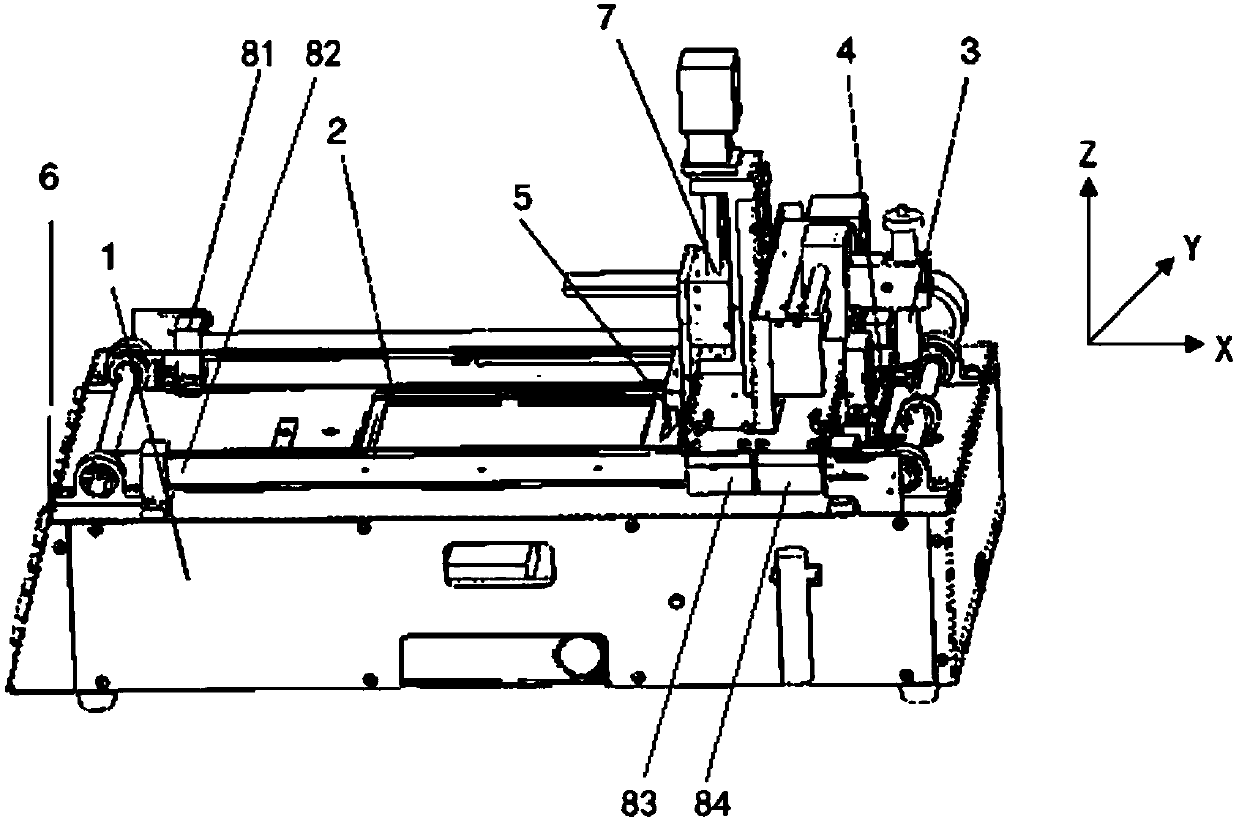

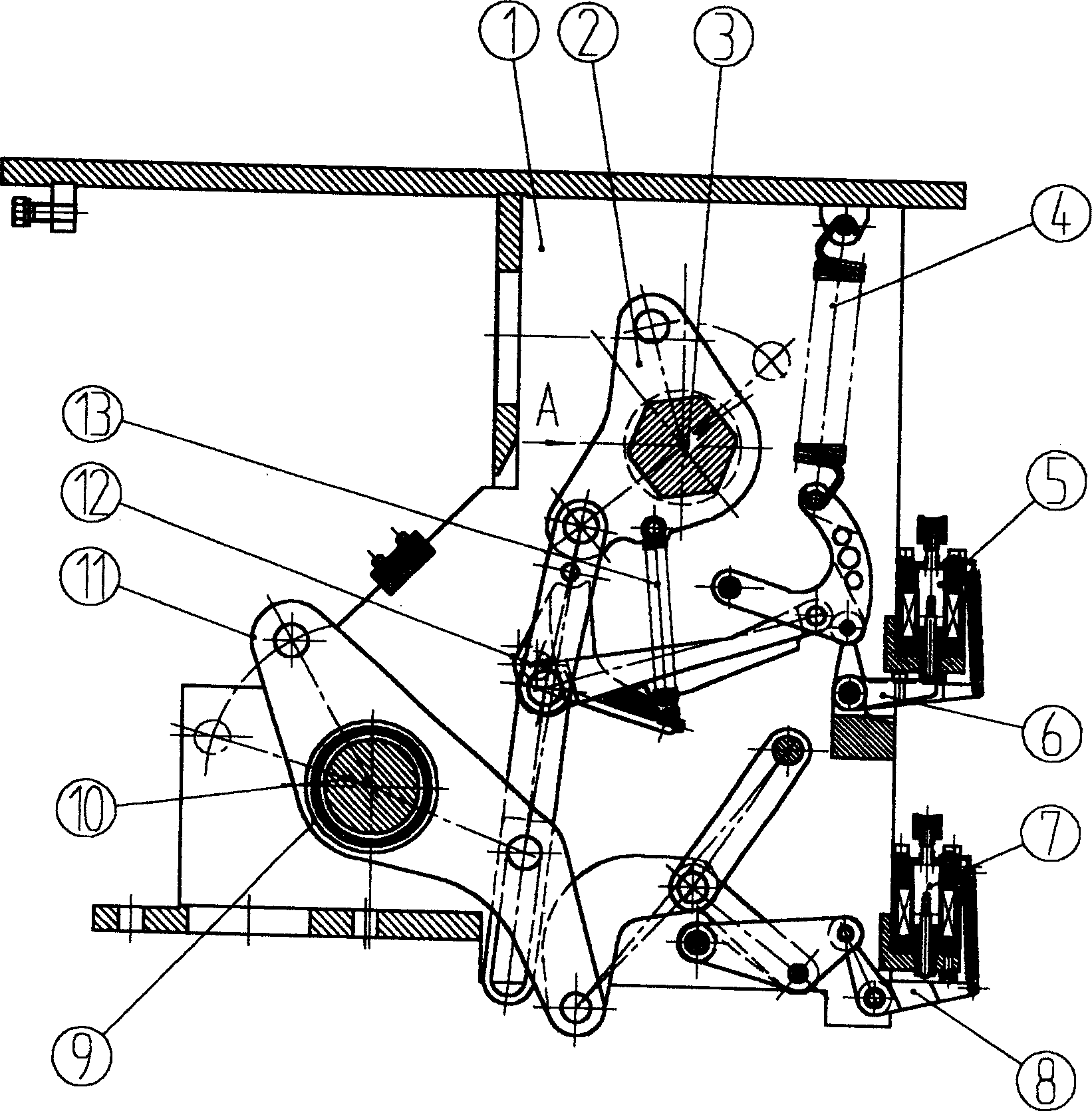

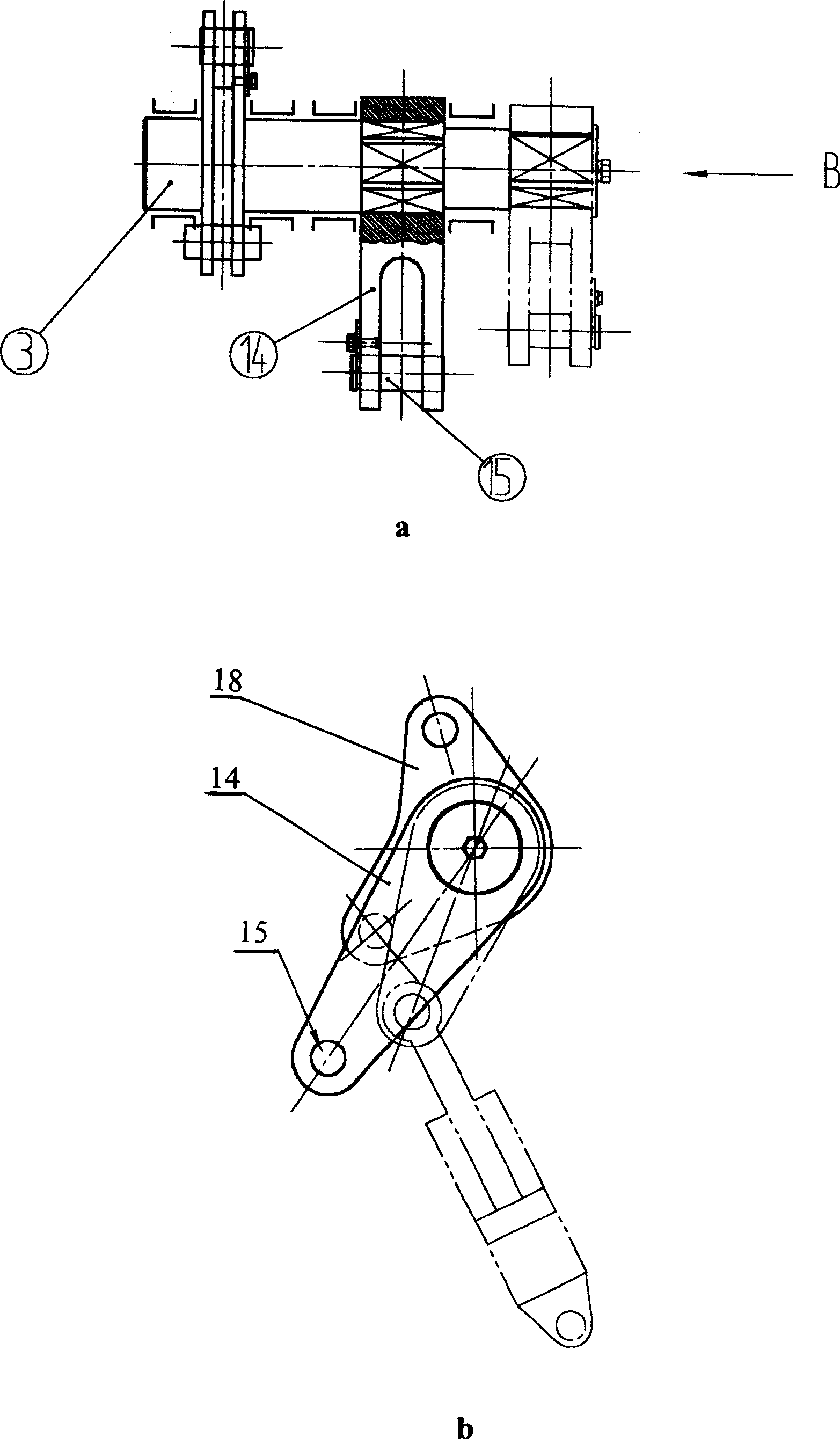

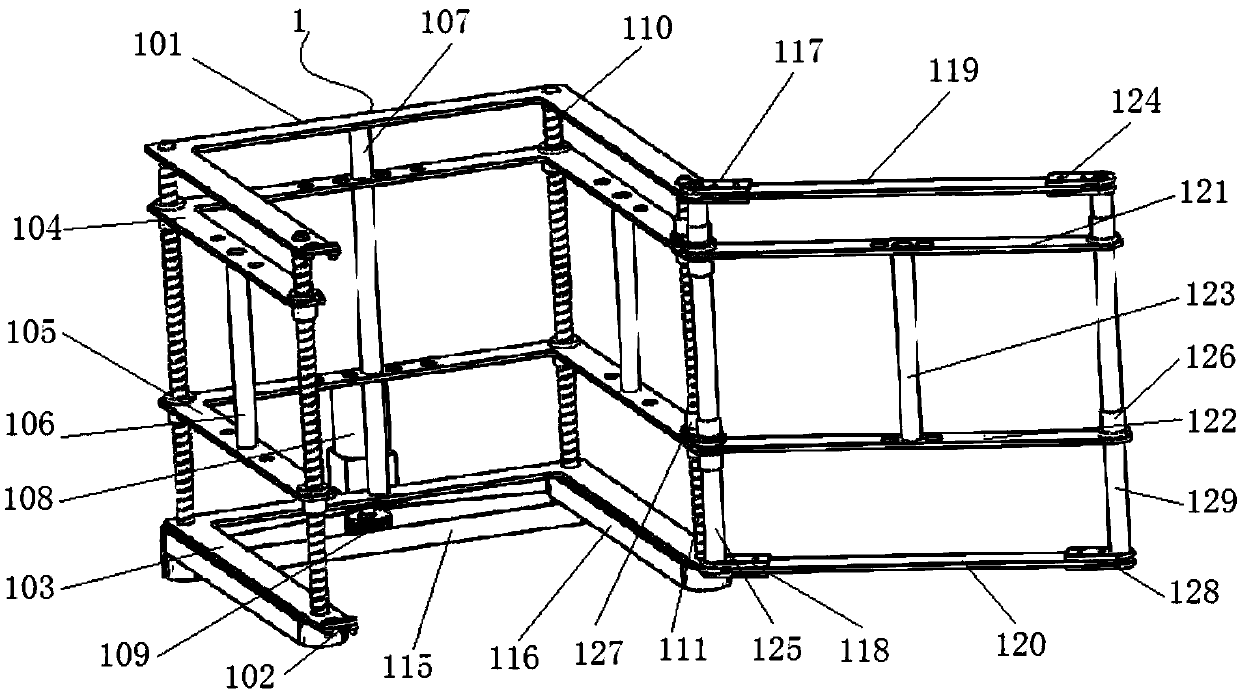

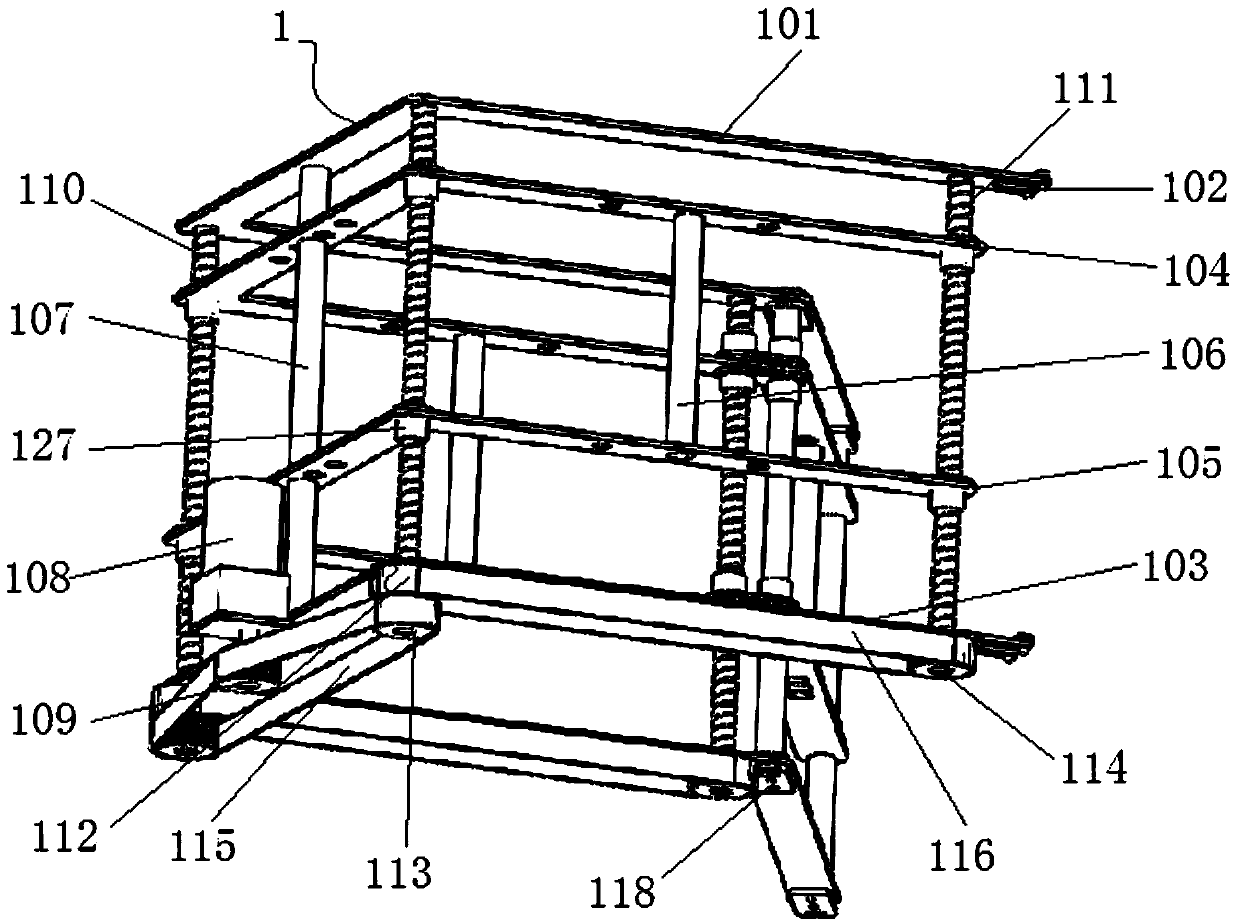

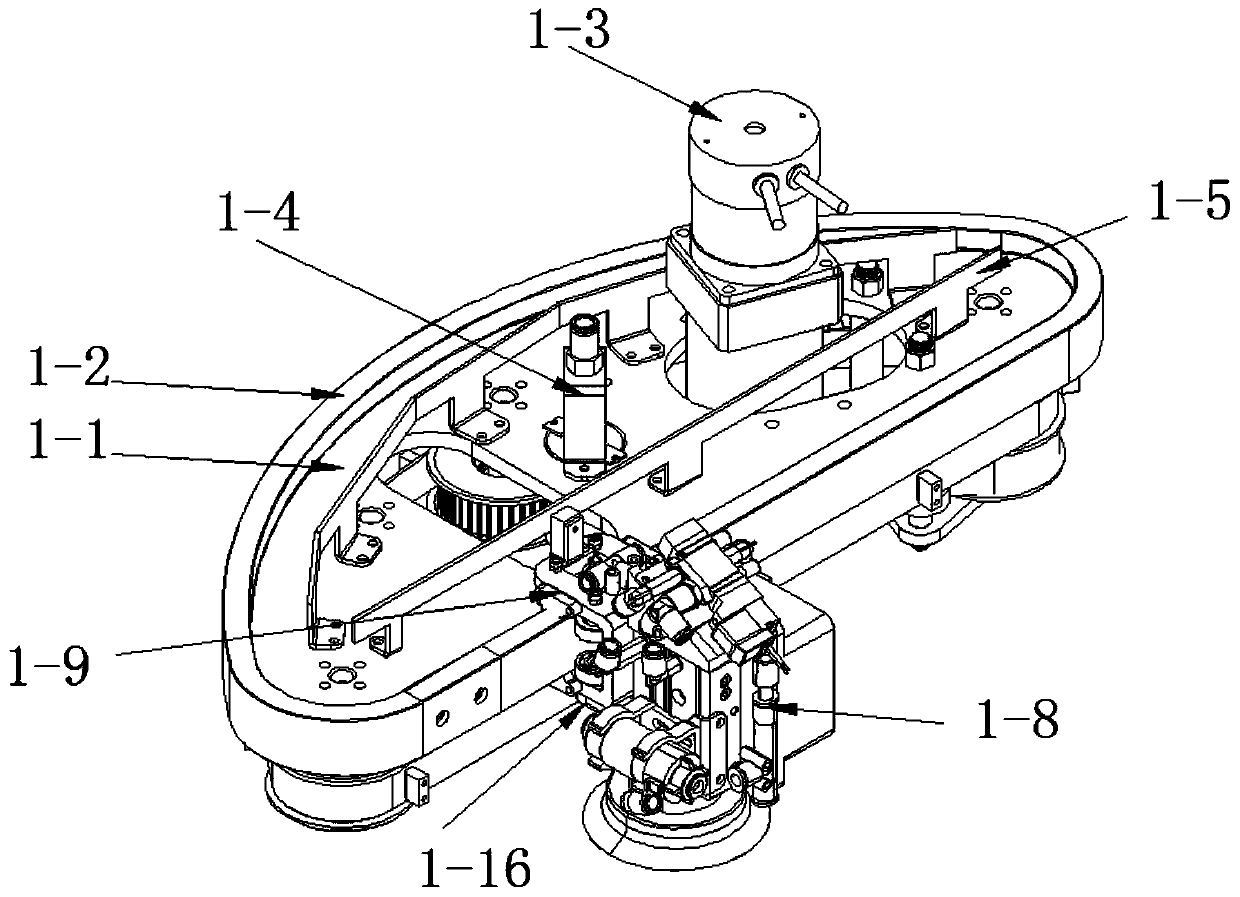

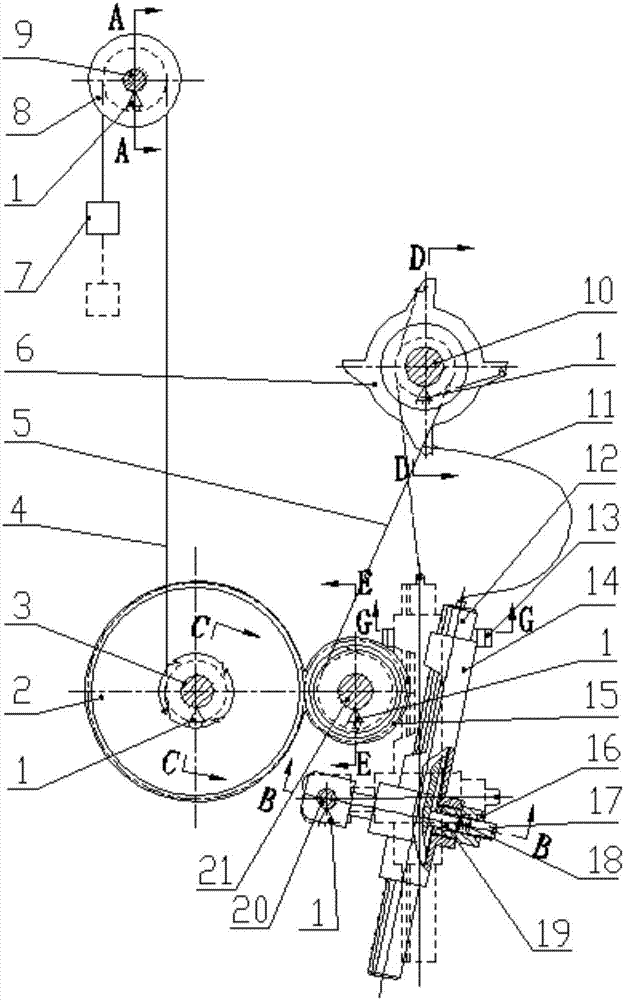

Dual-purpose mobile robot of wheel and foot

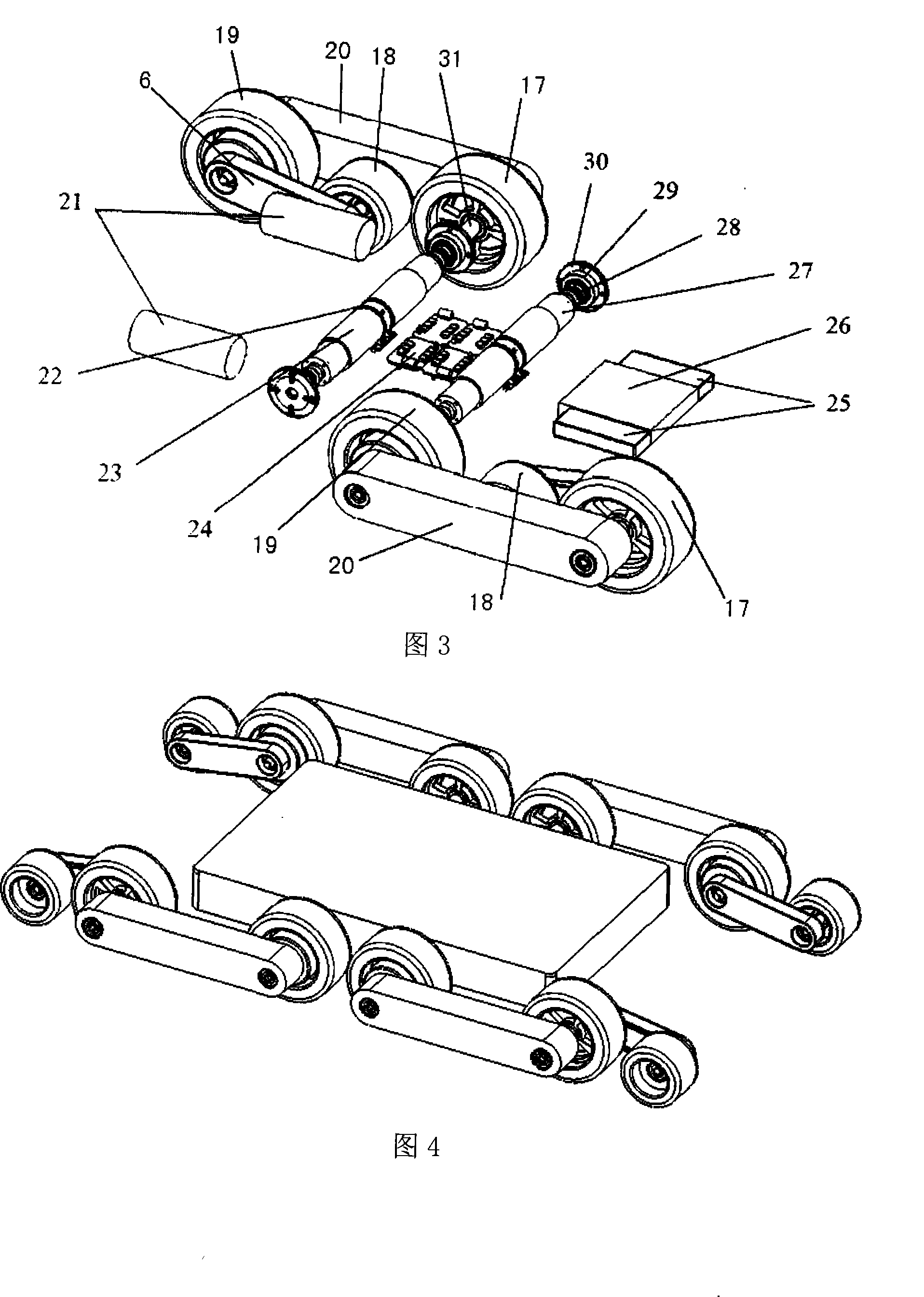

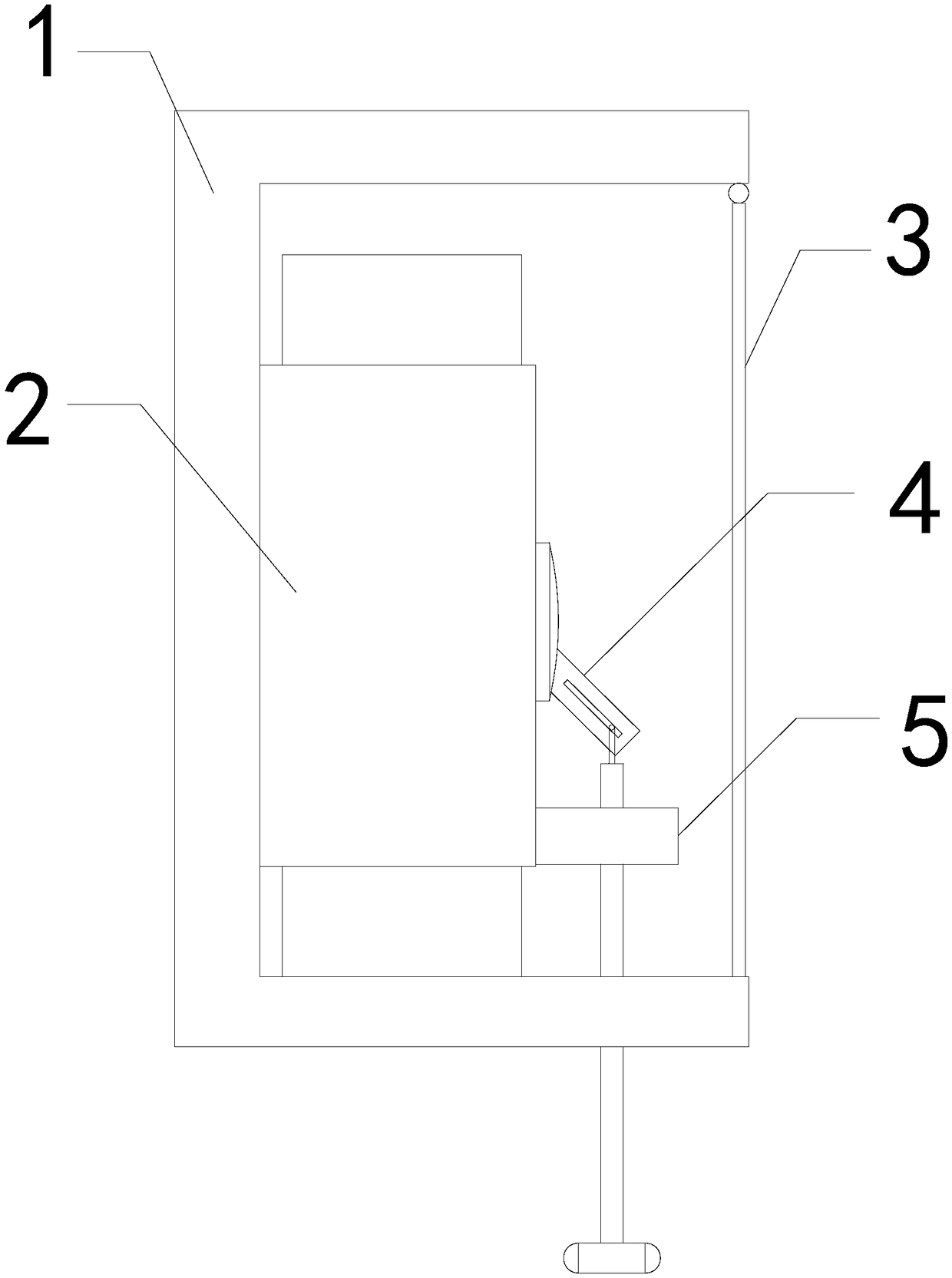

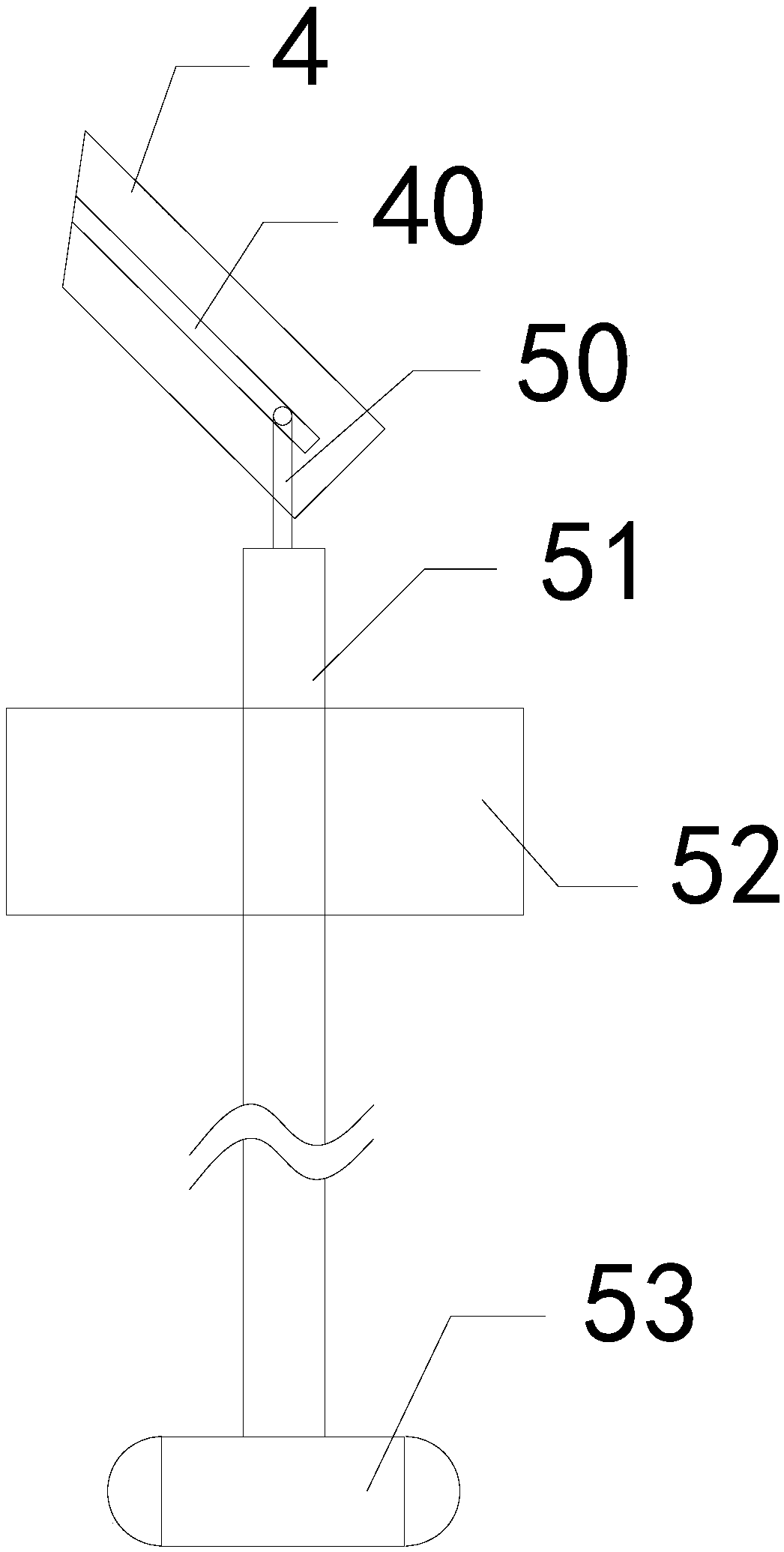

The invention belongs to a wheels and feet dual-purpose mobile robot in a robot technical field. The invention adopts a movement mode of combined wheels and feet; two long sides of a bodywork are respectively provided with four legs of the same structure with the duel-purpose of wheels and feet; the inside of the bodywork is provided with two batteries which provide energy for an on-board computer, an interior camera and an extended plug-in. Each leg comprises a thigh and a lower leg, with a power input unit of two levels; and the wheel mode and the foot mode are switched through a clutch. A first motor is fixed on a bottom plate of the bodywork through an insulation seat; a first shaft is fixed on a side of the bodywork by a seat, and the interior camera is equipped inside the bodywork as eyes of the robot; the on-board computer is taken as a planning and controlling center of movement of the entire robot; a plurality pony wheels are taken as driven wheels of which the driven movement or rotating termination is controlled by an electromagnetic contracting brake. By carrying out modularization design, the invention guarantees the rapid and flexible movement of the robot, multiple movement manners, strong ground adaptability and changes of movement gesture aimed at special landforms, which is favorable to reduce energy consumption.

Owner:TSINGHUA UNIV +1

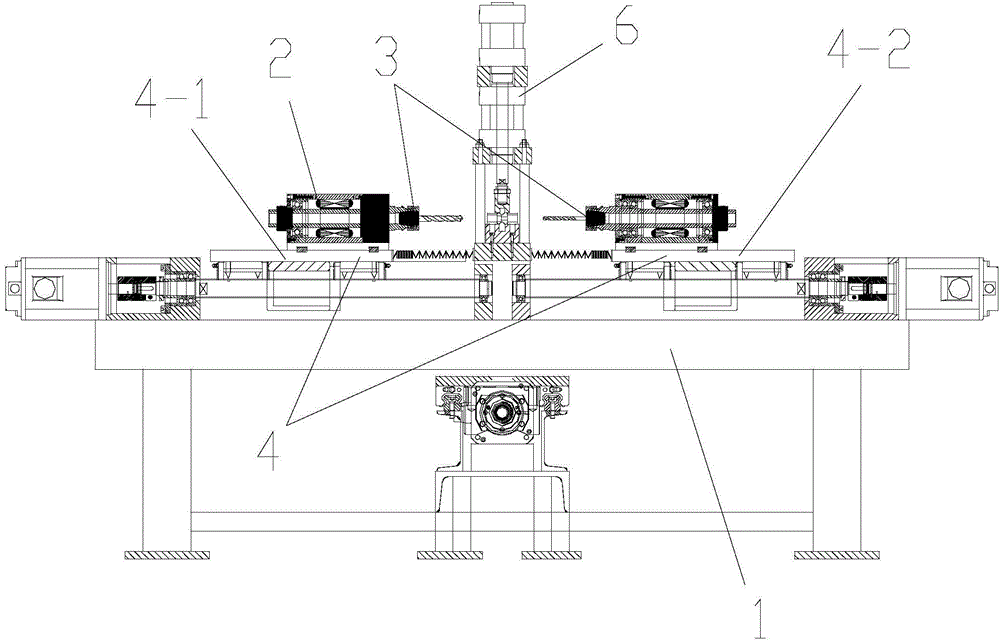

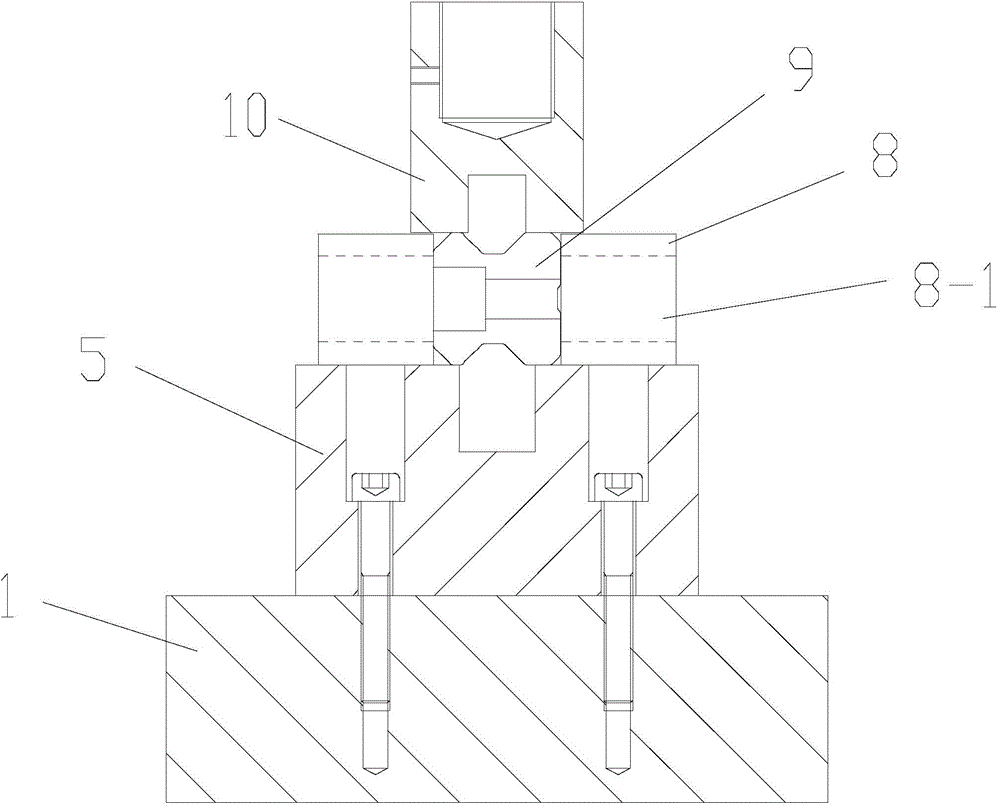

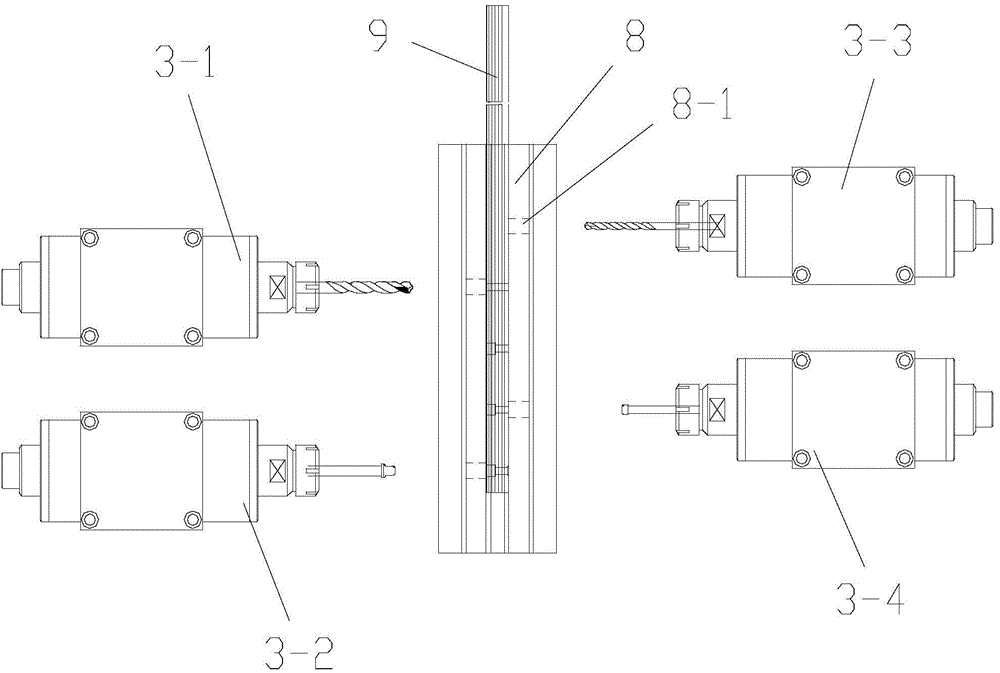

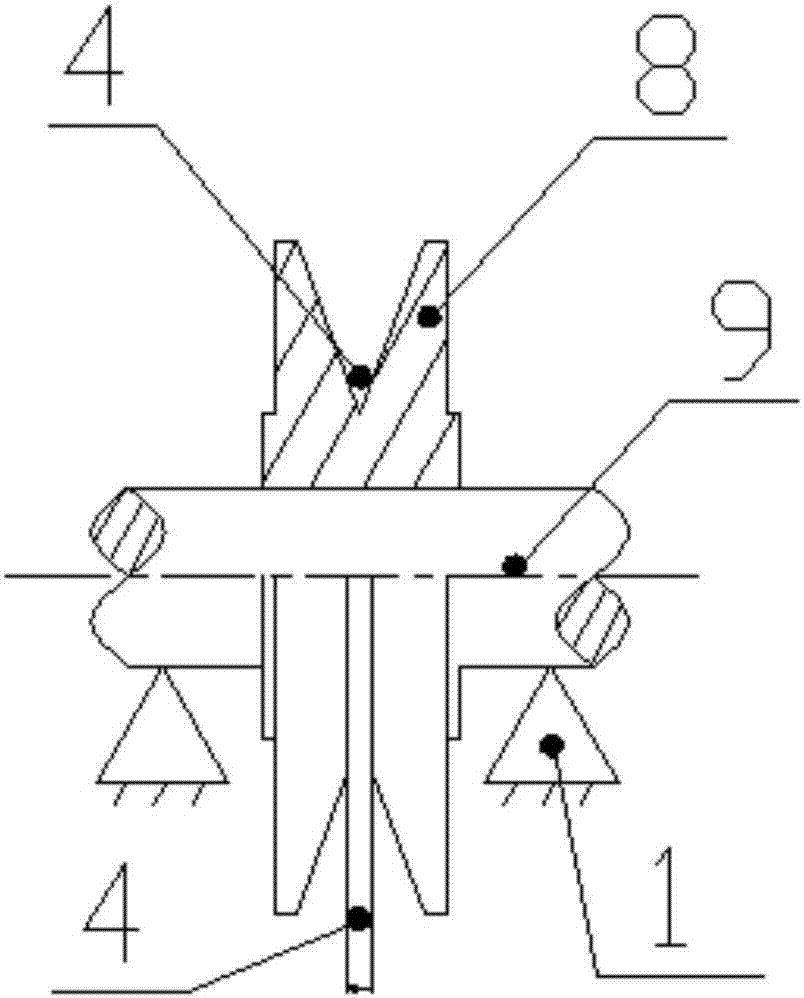

Guide rail machining device

ActiveCN104924080AImprove rigidityHigh strengthOther manufacturing equipments/toolsSynchronous motorMotor drive

A guide rail machining device comprises a working table. A drilling tool main shaft driven by a DC synchronous motor is arranged on the working table, arranged on a transverse guide rail and connected with a lead screw and nut mechanism driven by a motor. A supporting table for supporting a workpiece and a pressing cylinder for fixing the workpiece are installed on the working table. A pull rod for pulling the workpiece is arranged at the front end of the working table. By means of the structure, the guide rail is moved through the pull rod and fixed through the pressing cylinder, the drilling tool main shaft is only moved transversely without being moved longitudinally, and therefore the hopping of the drilling tool main shaft is reduced, and the machining quality of the guide rail is improved. The lead screw and nut mechanism driven by the motor mainly comprises a motor, a lead screw and a nut pair, wherein the motor drives the lead screw to rotate and drives the nut pair to move as well.

Owner:LISHUI UNIV

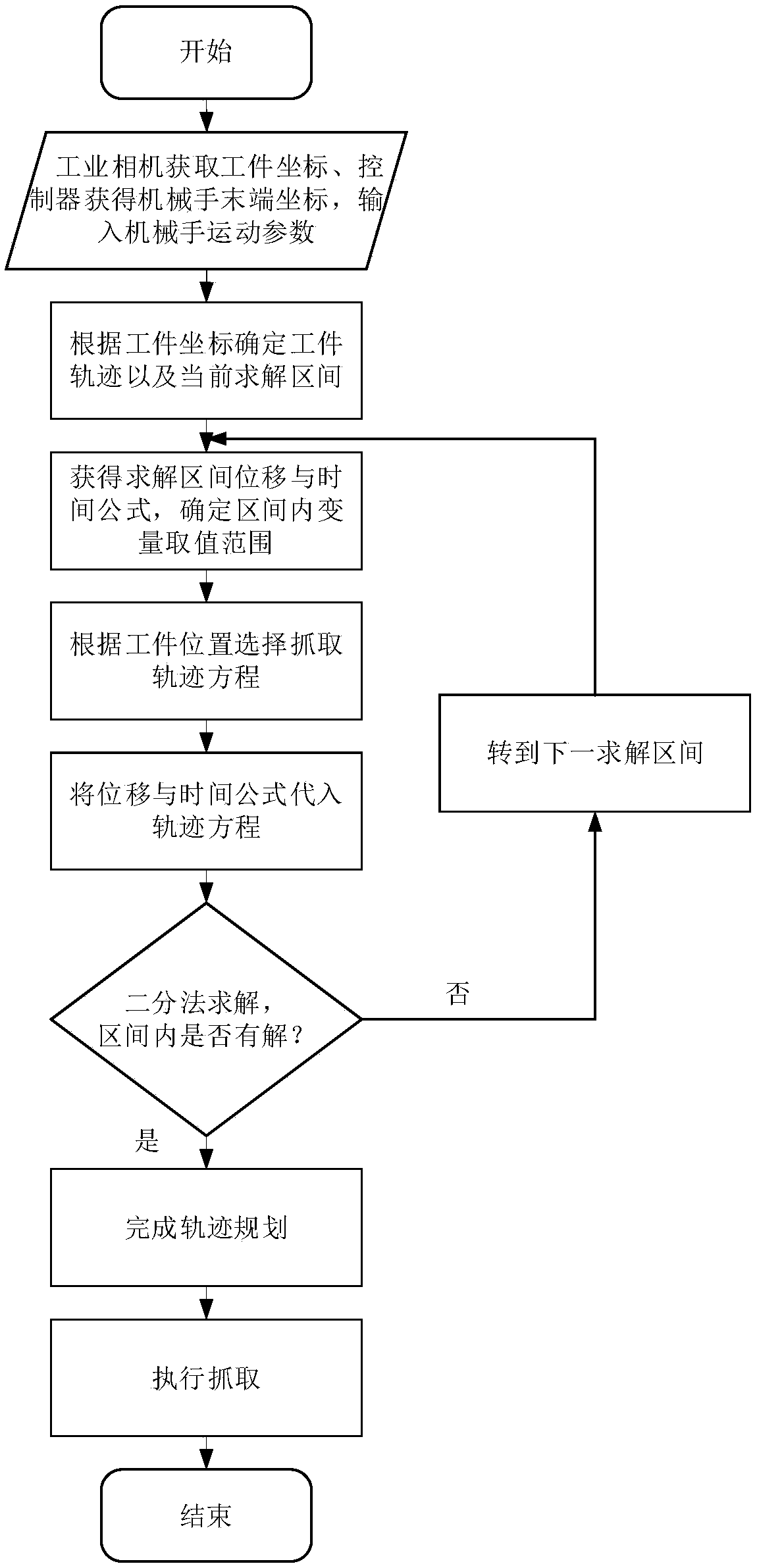

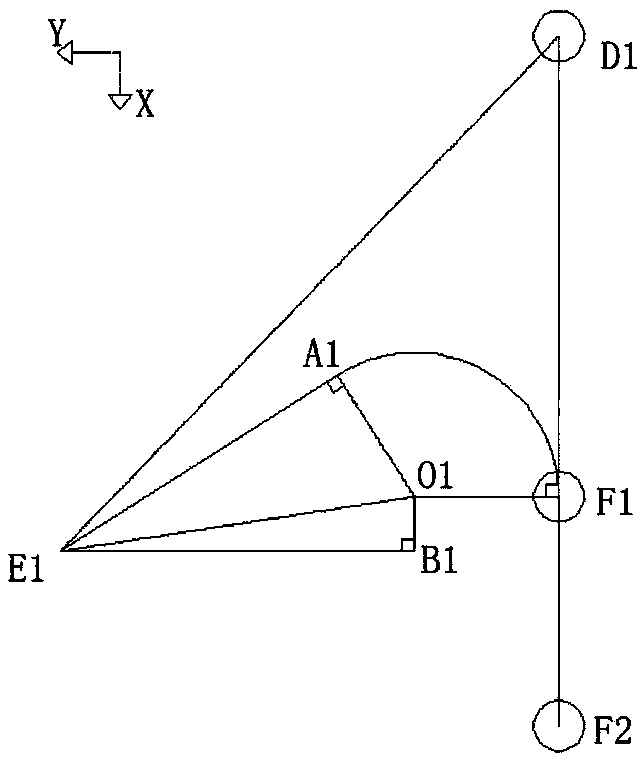

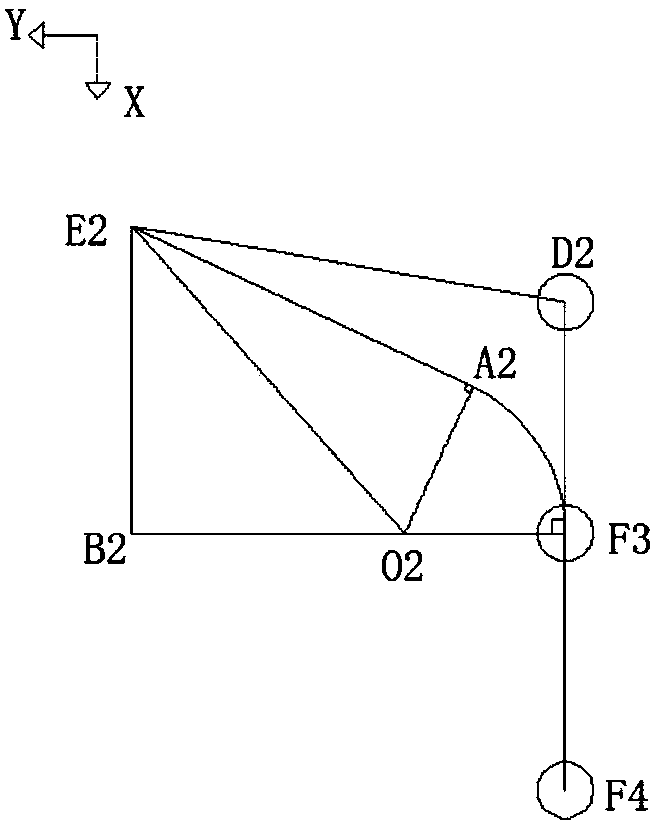

Workpiece following grabbing locus planning method and system used for high-speed sorting system

ActiveCN108549324AImprove crawling efficiencyImproved gripping accuracyProgramme controlComputer controlManipulatorWorking range

The invention discloses a workpiece following grabbing locus planning method and system used for a high-speed sorting system. The method comprises steps of establishing a following grabbing locus model, acquiring workpiece coordinates, manipulator end coordinates and manipulator movement parameters; according to the workpiece coordinates, determining conditions of workpiece loci and determining acurrent solving interval; according to the current solving interval, determining the interval displacement and a time formula, and determining the value range of a single variable in the interval; according to upper and lower half regions of the working range where the workpiece is arranged, determining a grabbing equation of locus; substituting the displacement and the time formula into the equation of locus; using the bisection method to solve the solution of the equation of the locus in the value range, if there is a solution, according to the equation solution, planning a grabbing locus and executing the grabbing; and if there is no solution, turning to the next solving interval and repeating the solving processes. The beneficial effects are that the working range of the manipulator are fully used; the characteristics of the S curve speed increasing and decreasing algorithm are fully used; grabbing efficiency is improved; and grabbing precision is improved.

Owner:SHANDONG UNIV

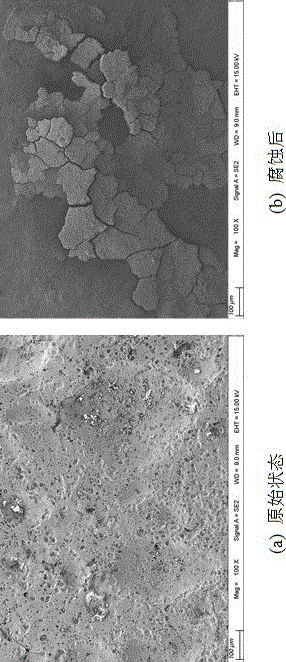

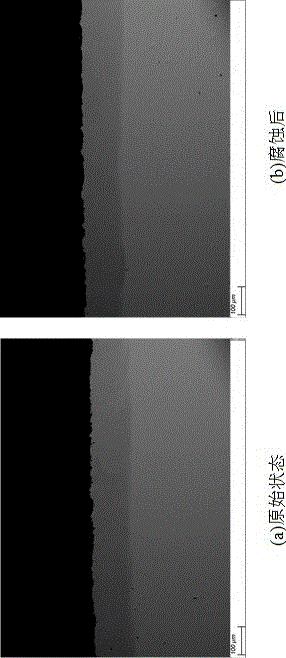

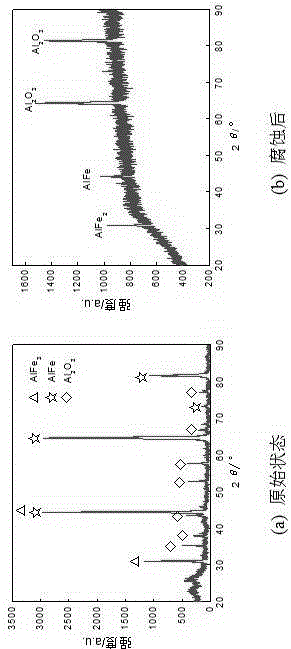

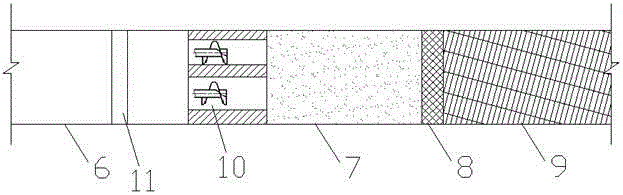

Laser remelting method for steel electric arc spraying aluminum coating layer used for ocean platform

ActiveCN104928617AGuaranteed movement speedGood mechanical bondMolten spray coatingCoated surfaceStructure property

The invention relates to the technical field of steel surface modification processing, in particular to a laser remelting method for a steel electric arc spraying aluminum coating layer used for an ocean platform, in order to solve the problem that the seawater corrosion resistant capacity of the coating layer is improved without increasing the thickness of the coating layer, and belongs to a material surface modification composite processing technology. By means of a electric arc spraying technology, a layer of the aluminum coating layer is prepared by using the surface of a steel base material on the ocean platform, then a laser remelting technology is used to iron melt the aluminum coating layer and the surface of a substrate, and after cooling is conducted, a Fe-Al alloy layer is formed; the surface of the coating layer is flat, the structure property can be improved, alloy combination is formed between the coating layer and the base material, a few amorphous state aluminum is generated in the coating layer, and the corrosion resistant performance of the coating layer can be improved.

Owner:CHANGZHOU UNIV

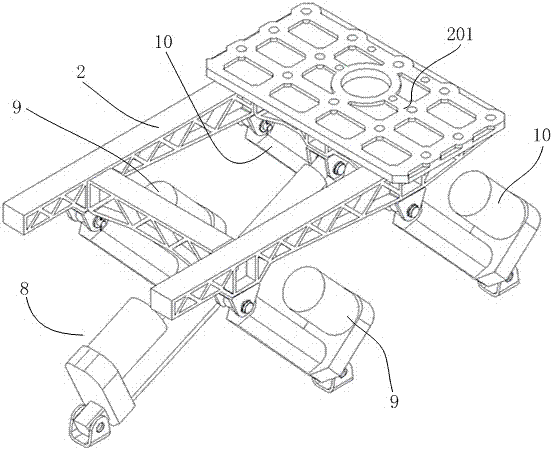

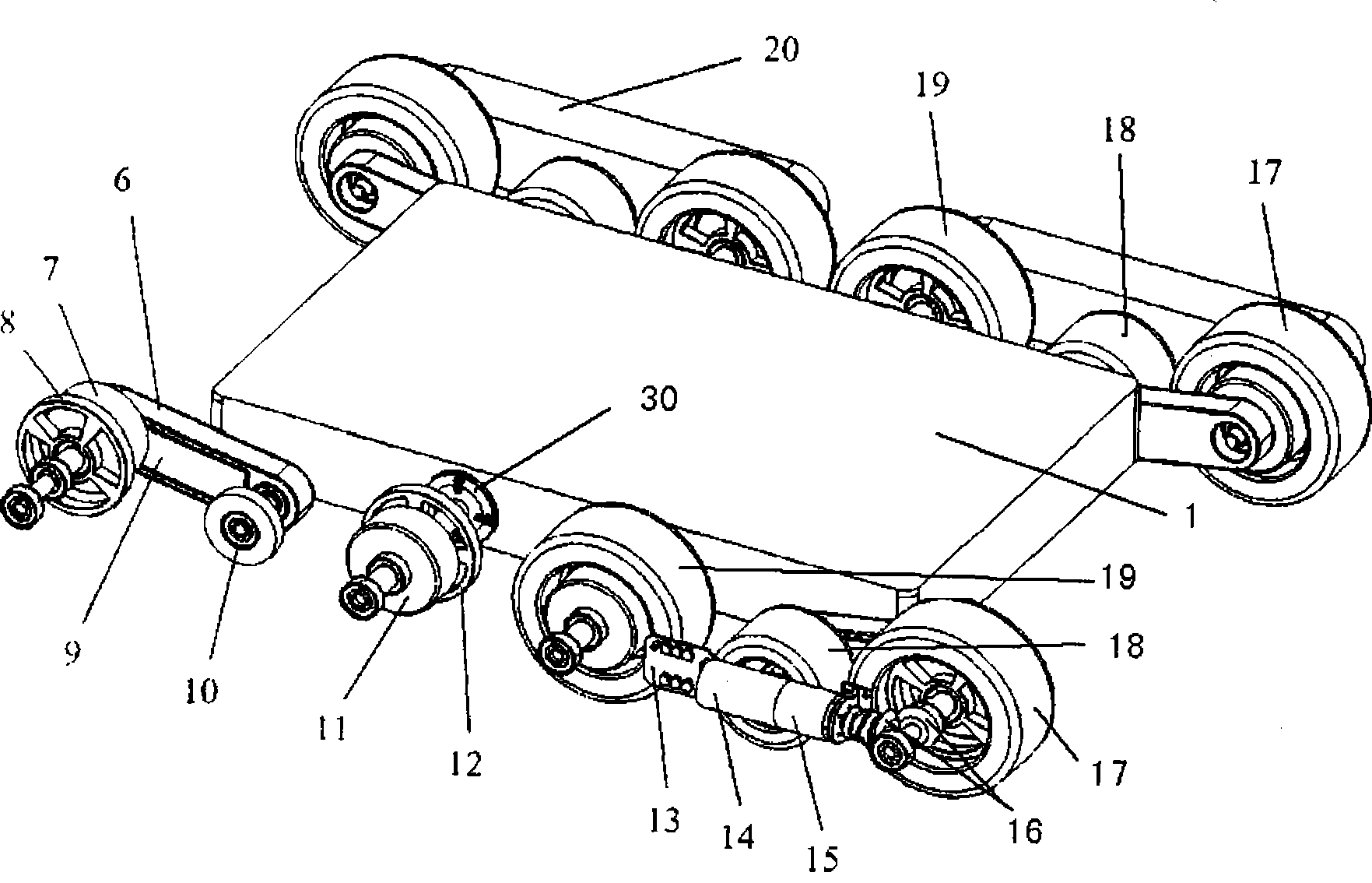

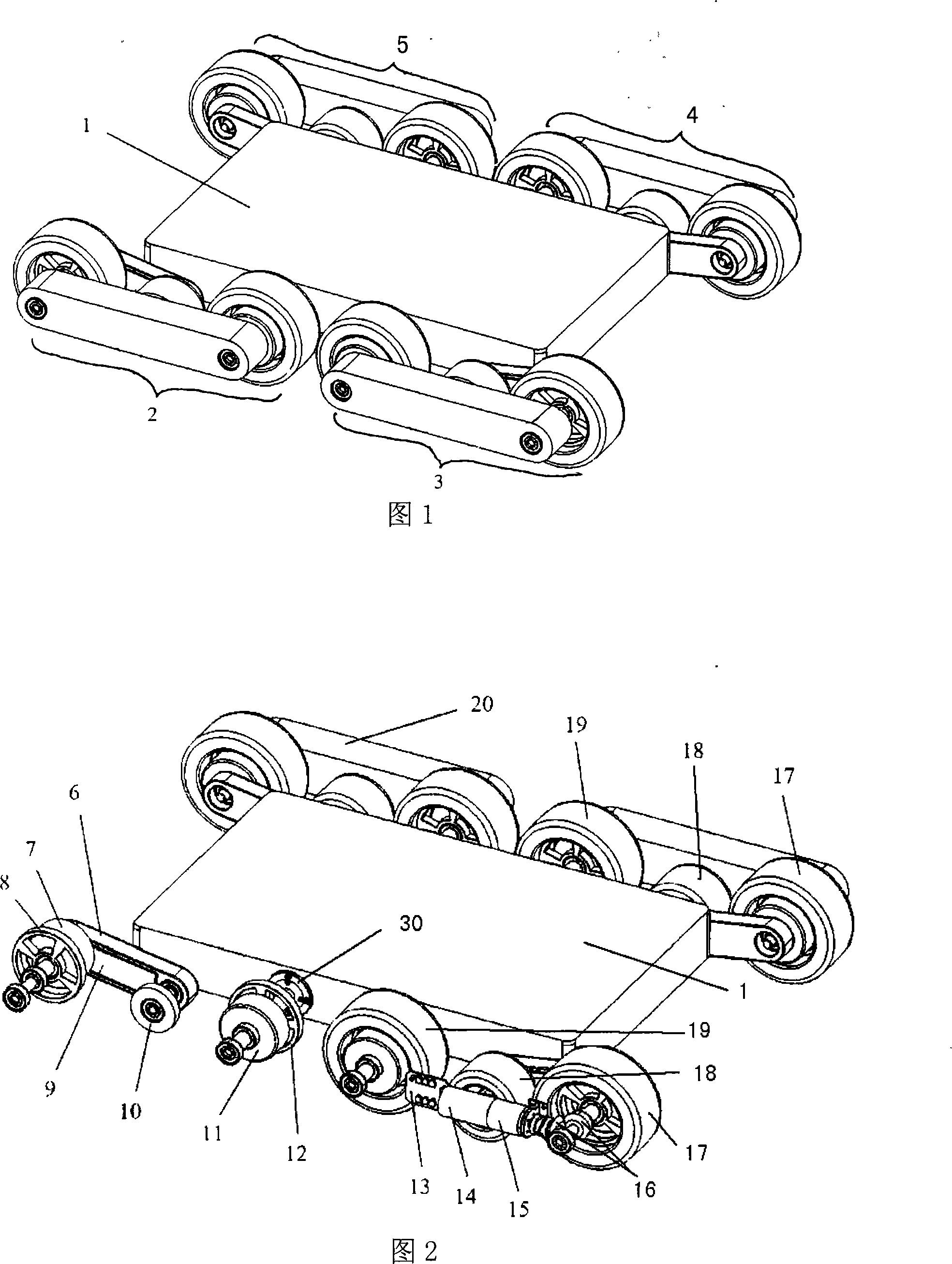

Wheel and caterpillar band switchable mobile chassis

ActiveCN107128375AImprove passabilityGuaranteed movement speedEndless track vehiclesCaterpillarRolling chassis

The invention relates to the field of mobile robots, in particular to a wheel and caterpillar band switchable mobile chassis. The wheel and caterpillar band switchable mobile chassis is characterized by comprising a connecting seat, a mounting platform, two wheel type moving pieces and a caterpillar band moving piece, wherein the mounting platform is arranged at the upper end of the connecting seat; the two wheel type moving pieces are symmetrically arranged on two sides of the connecting seat; each wheel type moving piece comprises a front wheel assembly close to the front end of the connecting seat and a rear wheel assembly close to the rear end of the connecting seat; a damping part is further connected between each front wheel assembly and the connecting seat; each rear wheel assembly can be folded or unfolded relative to the connecting seat; the caterpillar band moving piece is arranged below the connecting seat and comprises a supporting body and two caterpillar band assemblies arranged on two sides of the supporting body; the front end of the supporting body is connected with the front end of the connecting seat through a first folding and unfolding driving part; the rear end of the supporting body is hinged to the rear end of the connecting seat; and under the driving effect of the first folding and unfolding driving part, the supporting body can rotate relative to the connecting seat. The wheel and caterpillar band switchable mobile chassis not only is suitable for a flat ground environment, but also is suitable for climbing steps, and is high in movement speed.

Owner:壹利特机器人科技(常州)有限公司

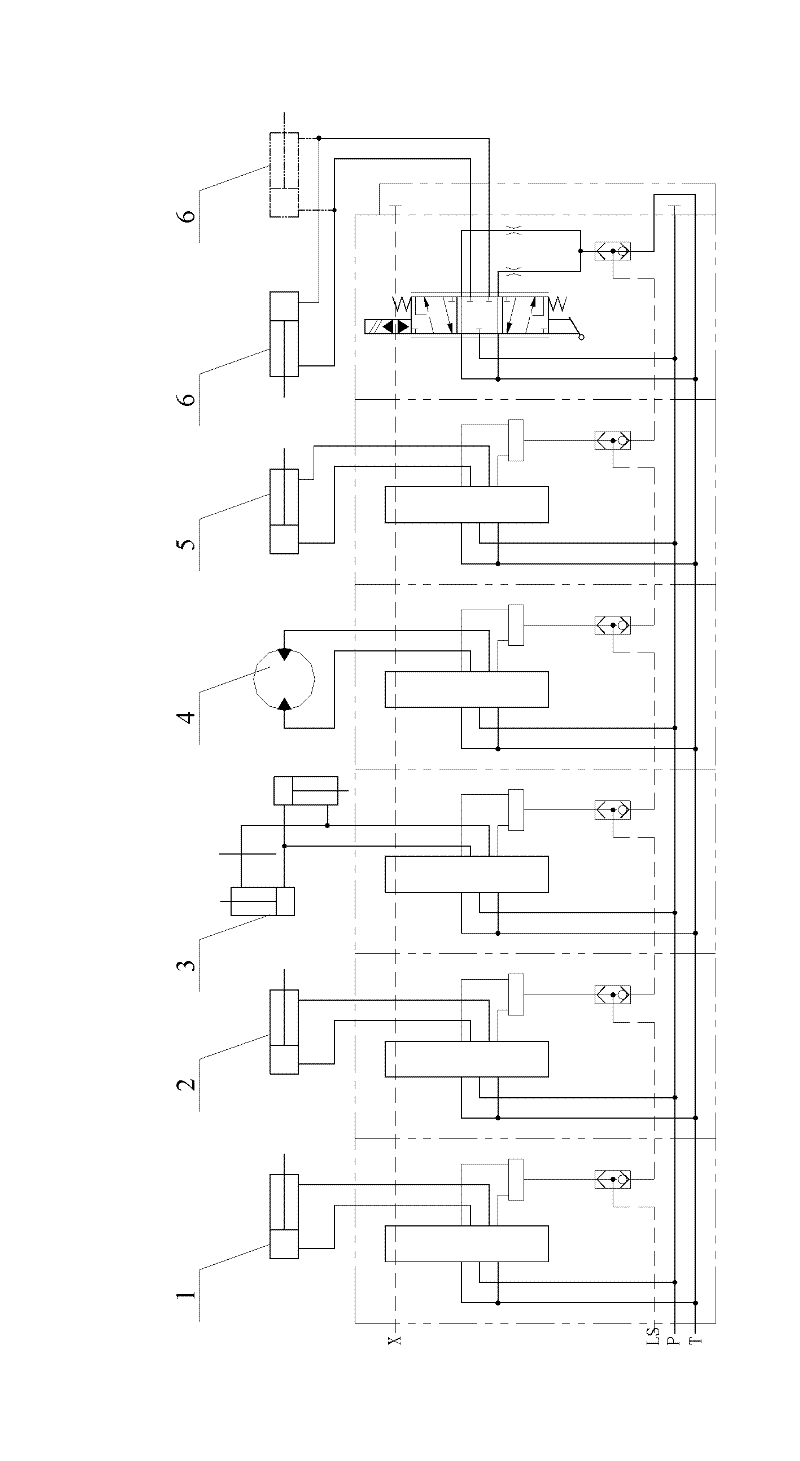

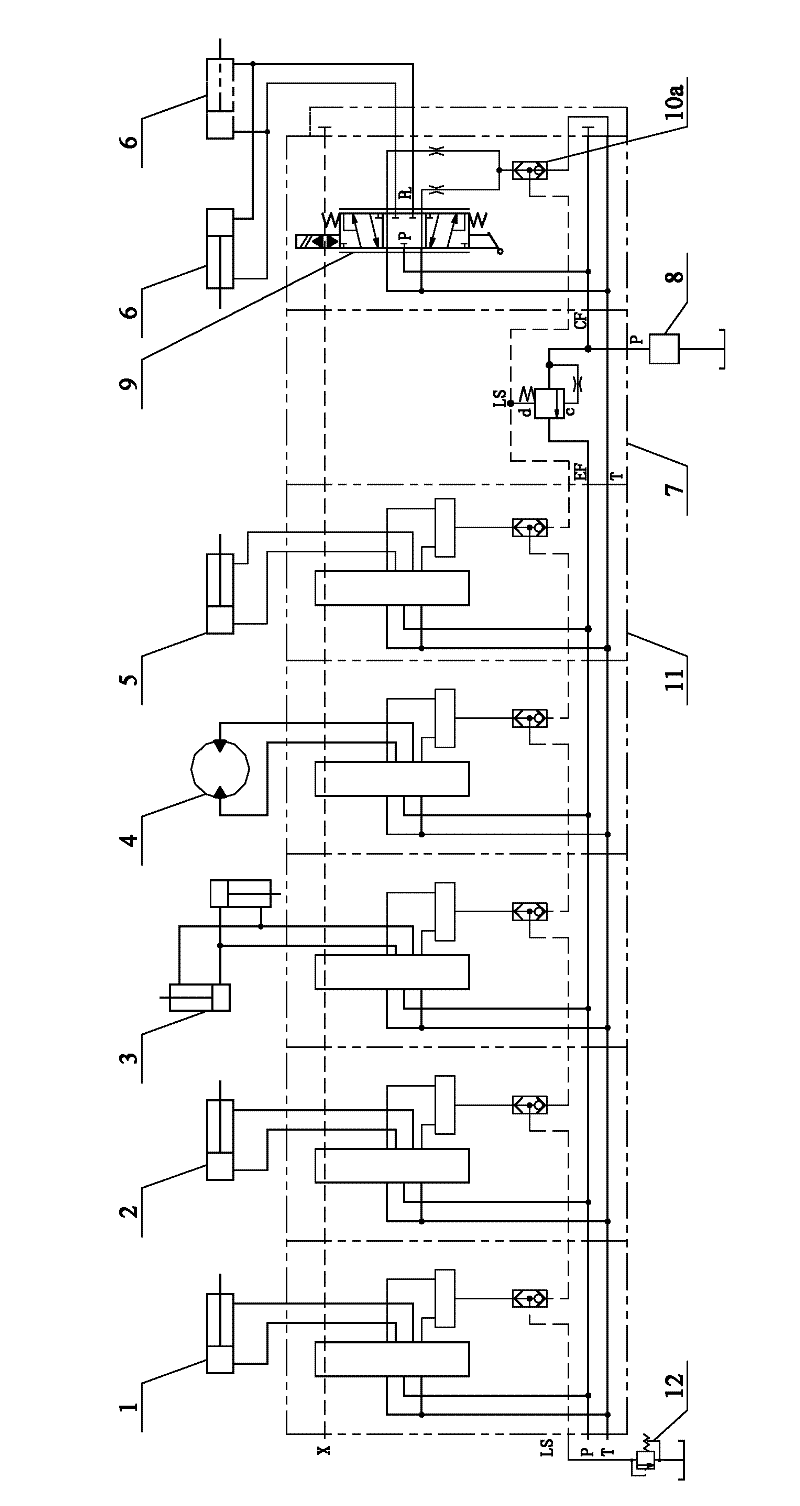

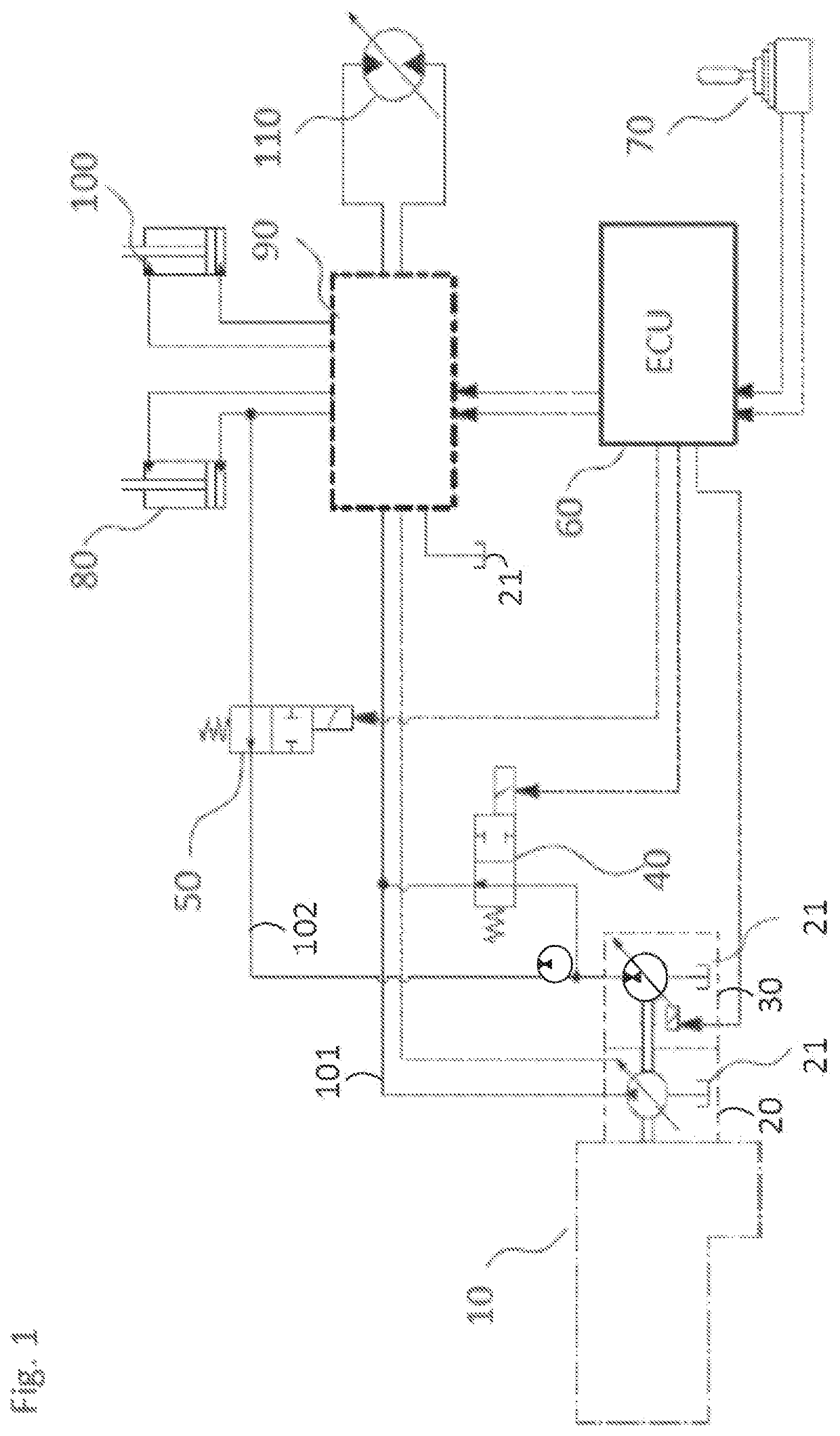

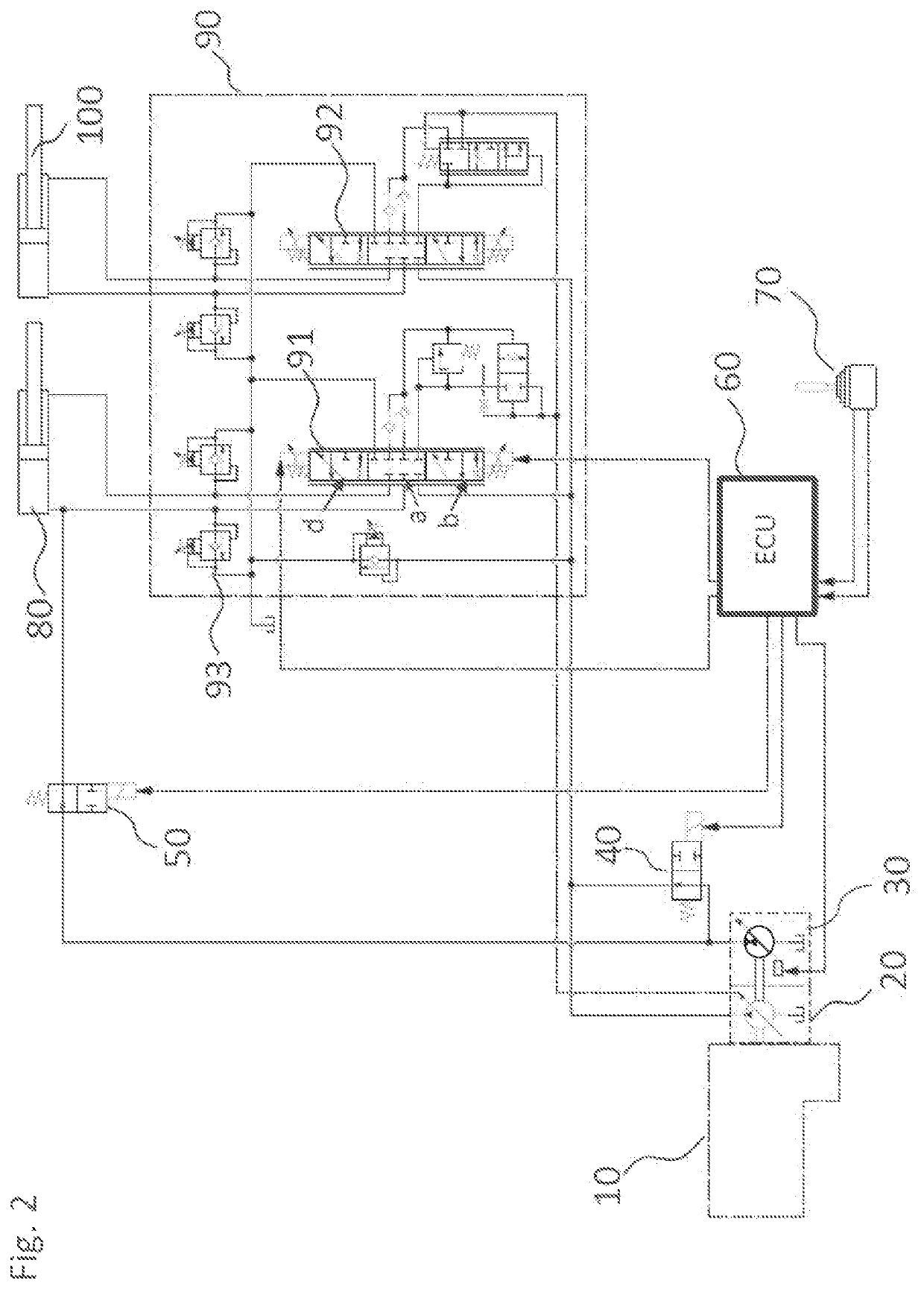

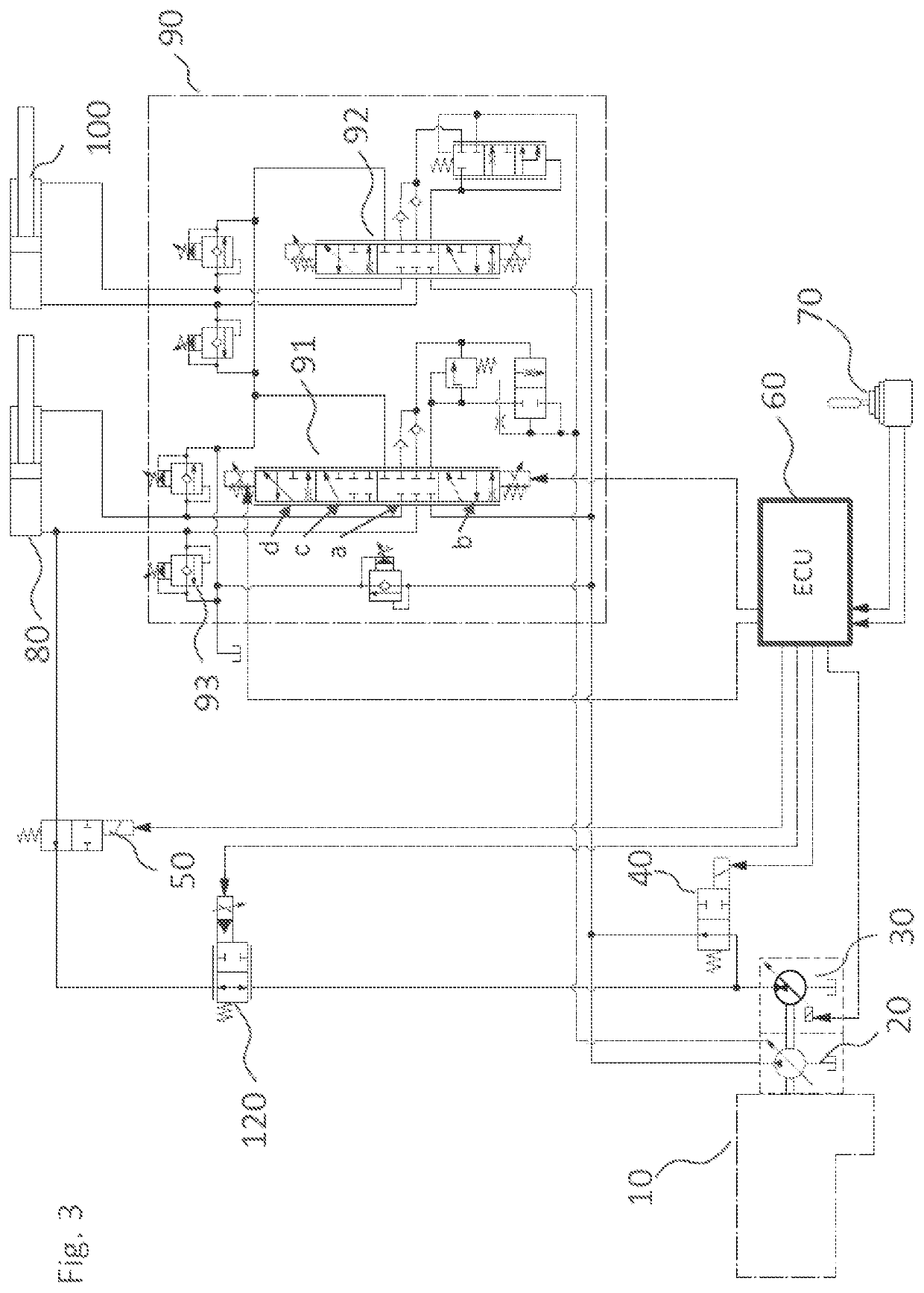

Compound action hydraulic control system and wheeled construction machinery applying same

ActiveCN102371956AFlexible steeringGuaranteed movement speedServomotorsLifting devicesSystem pressureDirectional Valve

The invention discloses a compound action hydraulic control system. A liquid inlet pipeline of each operation loop is connected in parallel with a system pressure oil circuit. A hydraulic-control direction control valve is arranged between the system pressure oil circuit and a plurality of get-on operation circuits. A valve body of the hydraulic-control direction control valve is provided with four oil ports, wherein a first oil port is communicated with a second oil port; the first oil port is communicated with the system pressure oil circuit; the second oil port is communicated with the liquid inlet pipeline of a steering operation circuit; a third oil port is communicated with the liquid inlet pipelines of a plurality of get-on operation circuits; a fourth oil port is communicated witha working port of an executive component of the steering operation circuit; under the action of pressure oil of the fourth oil port, a valve core of the hydraulic-control direction control valve has the trend of displacement from a first working position to a second working position; when the valve core is positioned at the first working position, the first oil port is communicated with the thirdoil port; and the valve core is positioned at the second working position, the first oil port is not communicated with the third oil port. The invention also provides a wheeled construction machineryapplying the compound action hydraulic control system.

Owner:XCMG FIRE FIGHTING SAFETY EQUIP CO LTD

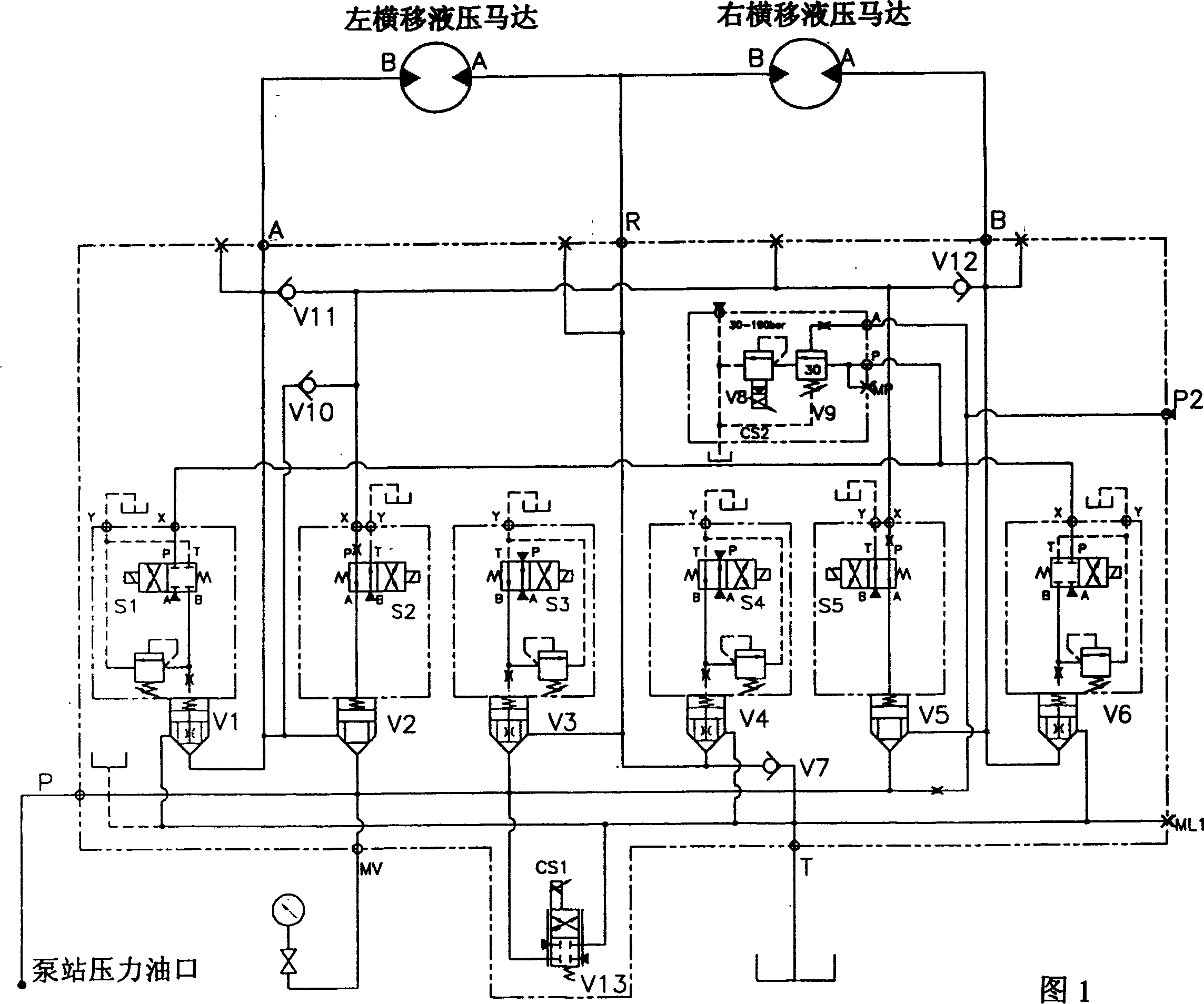

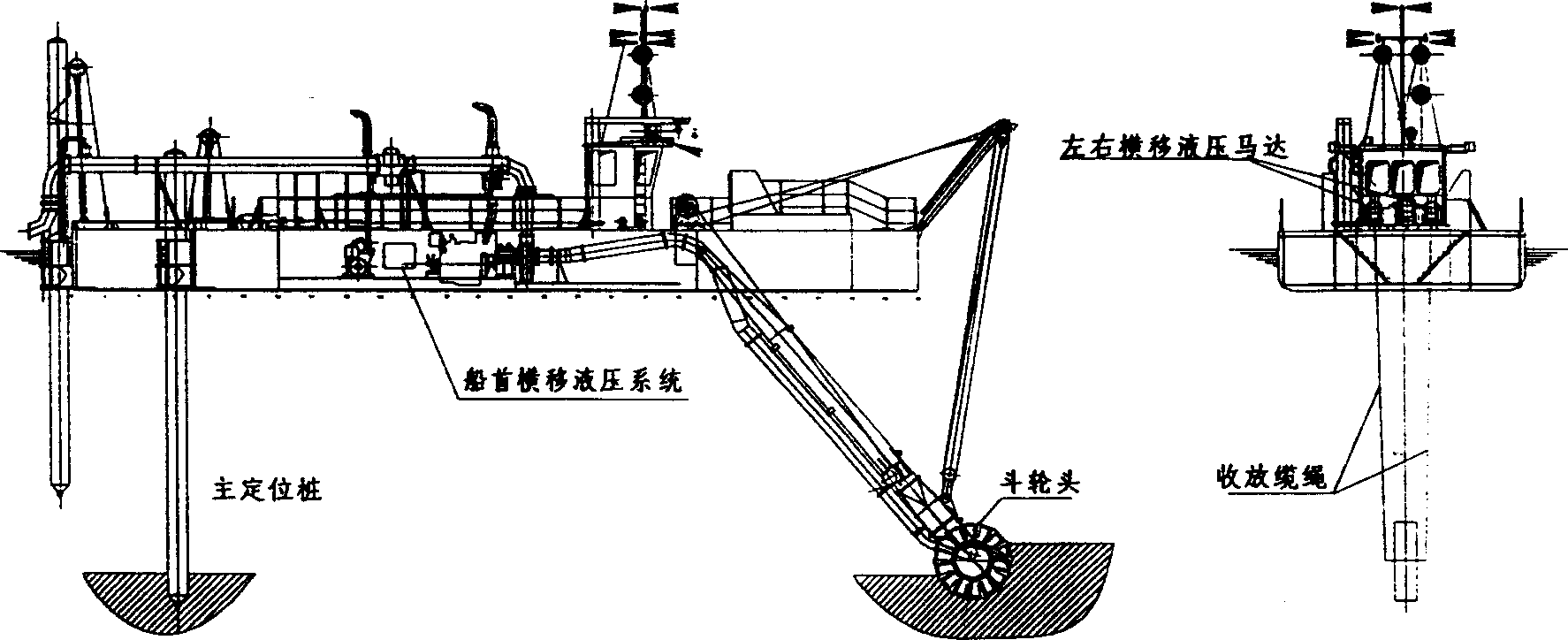

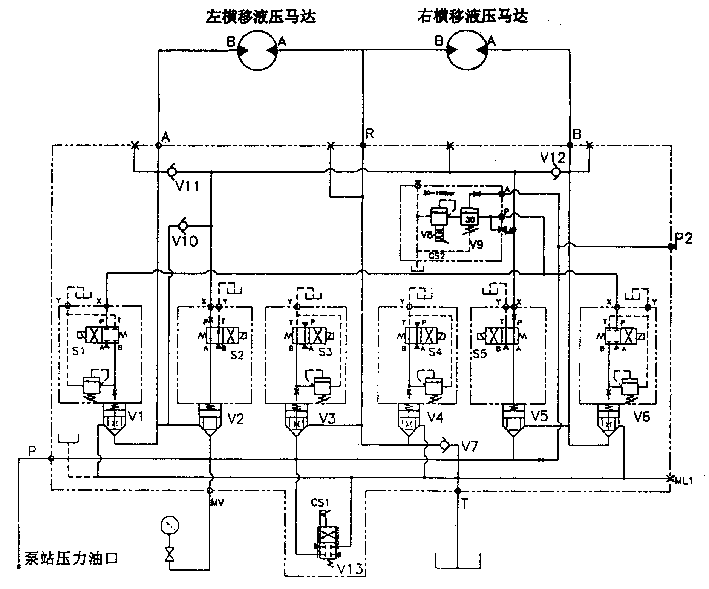

Transverse hydraulic control system on dredge boat stem

InactiveCN1456818ACompact structureGuaranteed movement speedAuxillariesServomotor componentsHydraulic motorControl system

A hydraulic control system for moving the bow of dredger transversely is composed of two one-way valves, four overflow valves, one sequence valve, one proportional overflow valve, one proportional throttle valve and four check valves. Its different oil ports are respectively connected to the oil ports of hydraulic motor according to invented logic. Its advantages are adjustable accurate speed, high safety and high anti-interference power.

Owner:杭州德泰电液系统工程有限公司

Automatic gluing device

InactiveCN109604113AGuaranteed movement speedConsistent amount of glueLiquid surface applicatorsCoatingsEngineeringCoating

The invention discloses an automatic gluing device. A vacuum adsorption table, a glue discharging needle tube, a glue scraping scraper plate and a control device are included. The upper end face of the vacuum adsorption table serves as a work plane for adsorbing a to-be-glued workpiece. The glue discharging needle tube horizontally moves along a horizontal control guide rail arranged on the work plane and is used for spot coating of an adhesion agent to the to-be-glued workpiece adsorbed to the work plane. The glue scraping scraper plate horizontally moves along the horizontal control guide rail and is used for scraping the adhesion agent arranged on the surface of the to-be-glued workpiece in a spot coating manner to be even and flat. The control device is connected with the vacuum adsorption table, the glue discharging needle tube, the glue scraping scraper plate and the horizontal control guide rail and controls the motions of the vacuum adsorption table, the glue discharging needletube, the glue scraping scraper plate and the horizontal control guide rail. According to the device, adsorption is utilized for achieving to-be-glued workpiece fixing, the to-be-glued surface is completely in the flat work plane, a machine is used for replacing manual work to finish spot coating and slicking, the position and the glue amount of each-time spot coating can be guaranteed, it can beguaranteed that the pressure and the speed of the glue scraping scraper plate relative to the to-be-glued workpiece are fixed, uniform gluing is finally achieved, and the gluing quality is improved.

Owner:CHANGCHUN INST OF OPTICS FINE MECHANICS & PHYSICS CHINESE ACAD OF SCI

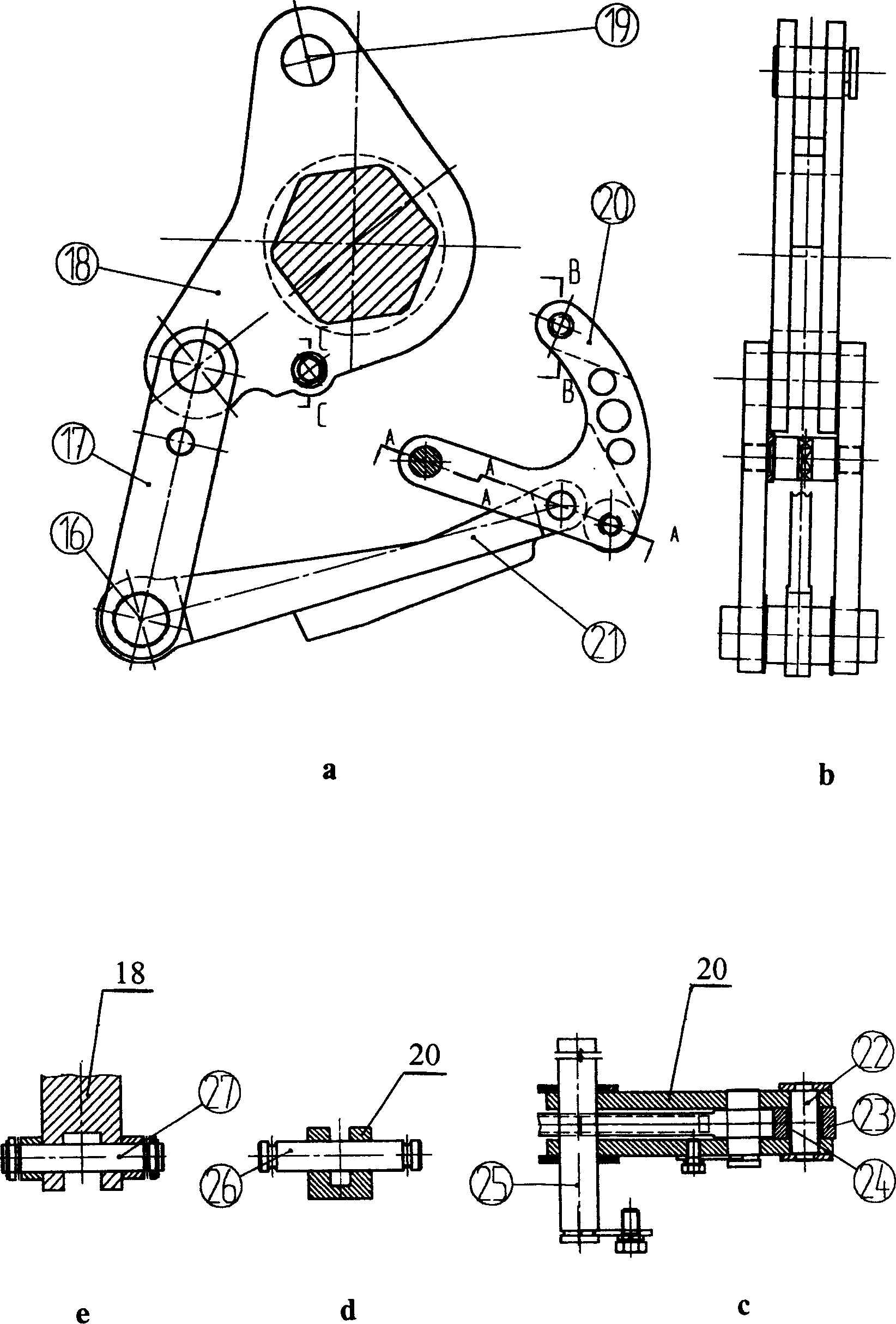

Transmission equipment and releasing arrangement

InactiveCN1480970AGuaranteed movement speedSlow downHigh-tension/heavy-dress switchesAir-break switchesDetentEngineering

The equipment is composed of a set of planar linkage mechanism including two pieces of switch off detent and switch on detent supported on a releasing arrangement and controlled by electromagnet. The advantages of the invention are: simple mechanism, reasonable arrangement, and small vibration in operation process. The equipment can be applied to SF6 high voltage breaker with large power and good working performances and high reliability.

Owner:沈阳亚泰高压电力设备制造有限公司

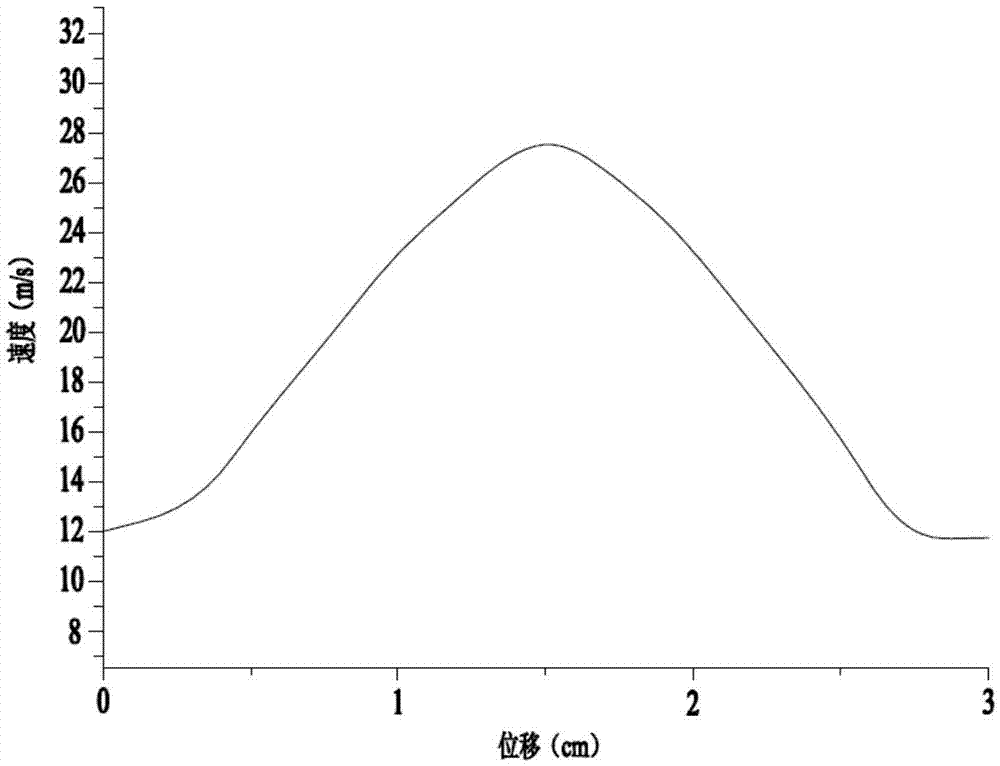

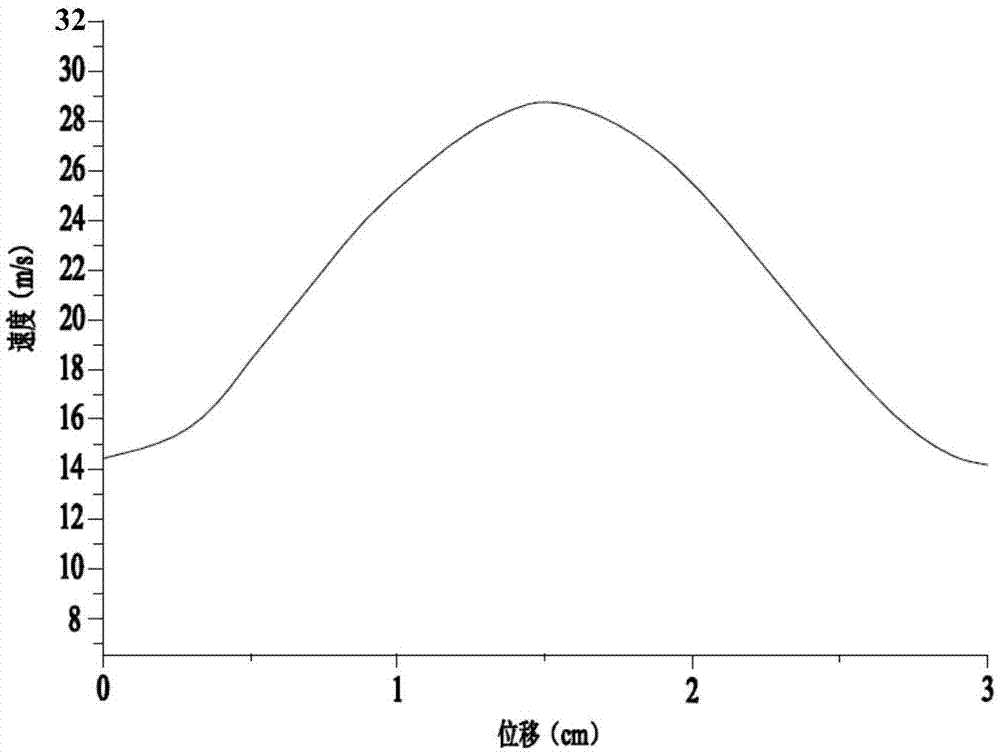

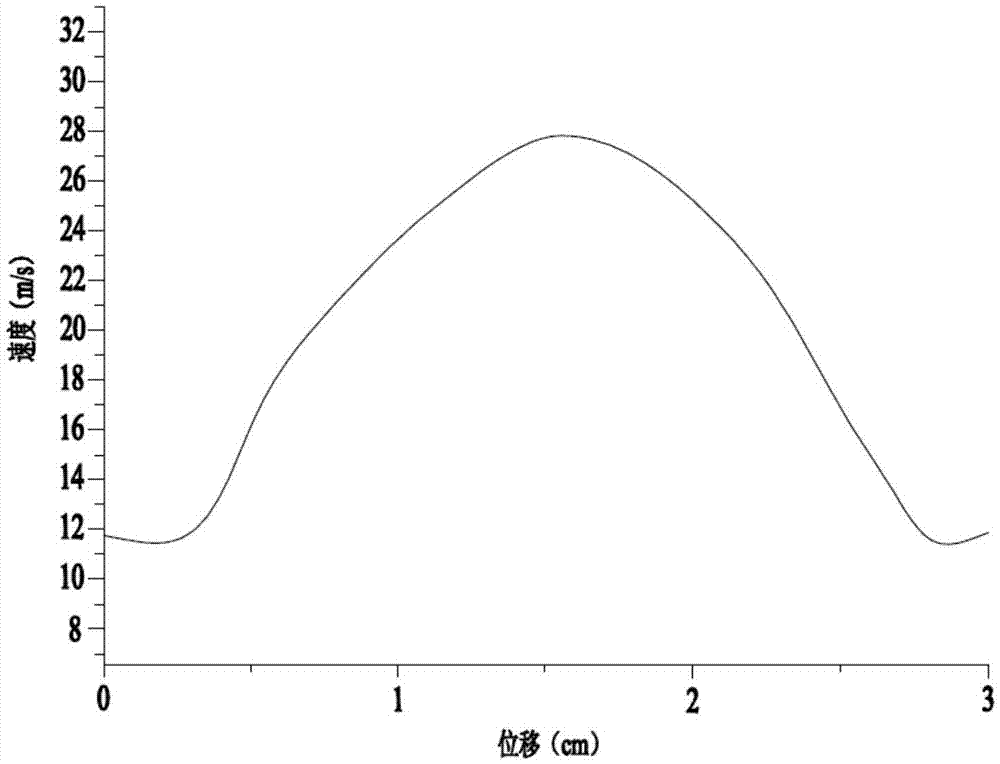

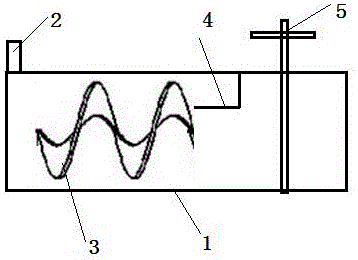

Auxiliary nozzle for air-jet loom

The invention discloses an auxiliary nozzle for an air-jet loom. The auxiliary nozzle for the air-jet loom comprises a nozzle body with an air flow chamber and a sprayer which is arranged on the nozzle body, wherein the sprayer comprises a first sprayer and a second sprayer which are arranged in parallel, a first air flow channel which is communicated with the air flow chamber is arranged in the first sprayer, a second air flow channel which is communicated with the air flow chamber is arranged in the second sprayer, rectangular blowholes are arranged on the first and the second sprayers, and the directions of the blowholes which are arranged on the first and the second sprayers are consistent. The auxiliary nozzle for the air-jet loom has strong injection capacity, specific performance in that the auxiliary nozzle for the air-jet loom is excellent in air flow stability on a flow channel section which is 250mm away from the blowholes, and can achieve 32m / s maximum speed of gas flow rate. Simultaneously, the first and the second sprayers respectively spray air from the upper and the lower sides of weft yarns, and enable the two sides of the weft yarns to evenly bear force, thereby being capable of perfectly maintaining kinematic velocity of the weft yarns, reducing fluctuation of the weft yarns, and guaranteeing stability of the weft yarns.

Owner:ZHEJIANG SCI-TECH UNIV

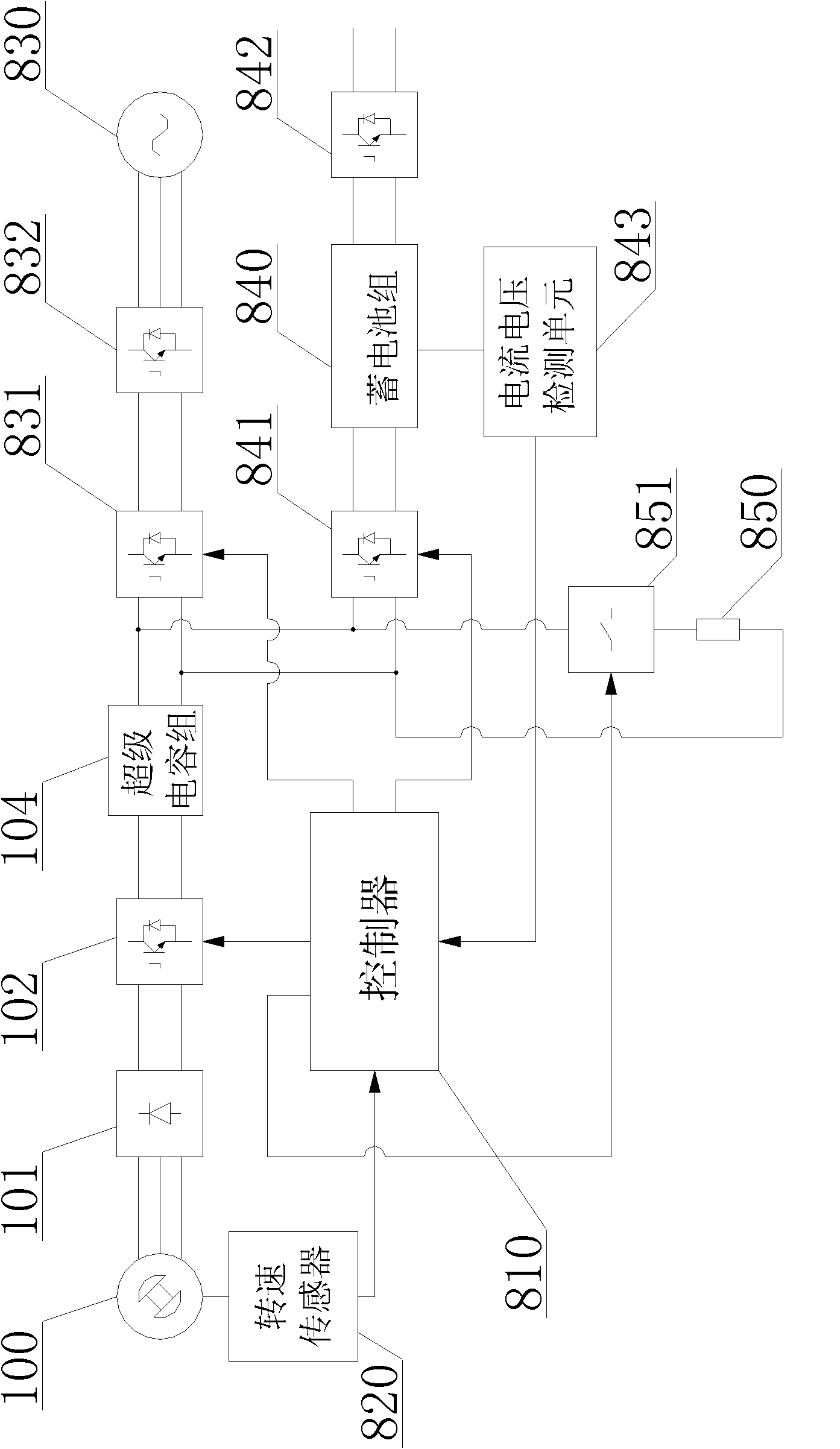

Carrying device and carrying system

InactiveCN102485627AEnough current adjustment spaceControl movement speedElevatorsBuilding liftsAutomotive engineeringLoad bearing

The invention discloses a carrying device and a carrying system comprising the same. The carrying device disclosed by the invention comprises a lift car, a counter weight, a load-bearing rope, a traction sheave and a generator, wherein the traction sheave is connected with the input shaft of the generator; the load-bearing rope is coiled on the traction sheave; two ends of the load-bearing rope downwards extend and are respectively connected with the lift car and the counter weight; and the weight of the counter weight is more than the weight of the lift car. When the carrying device provided by the invention is used, the lift car can be firstly put on a preset position with a preset height, and then preset load is formed; when the weight of the lift car and the weight of the preset load are more than the weight of the counter weight and when the lift car is under no load, because the weight of the counter weight is more than the weight of the lift car, the lift car can lift under the action of the counter weight and stops when reaching the preset-height position; the above processes are carried out repeatedly, and therefore people or cargoes can be conveyed to a lower position; and thus, a conveying function can be realized under the situation of consuming no energy.

Owner:傅涛 +3

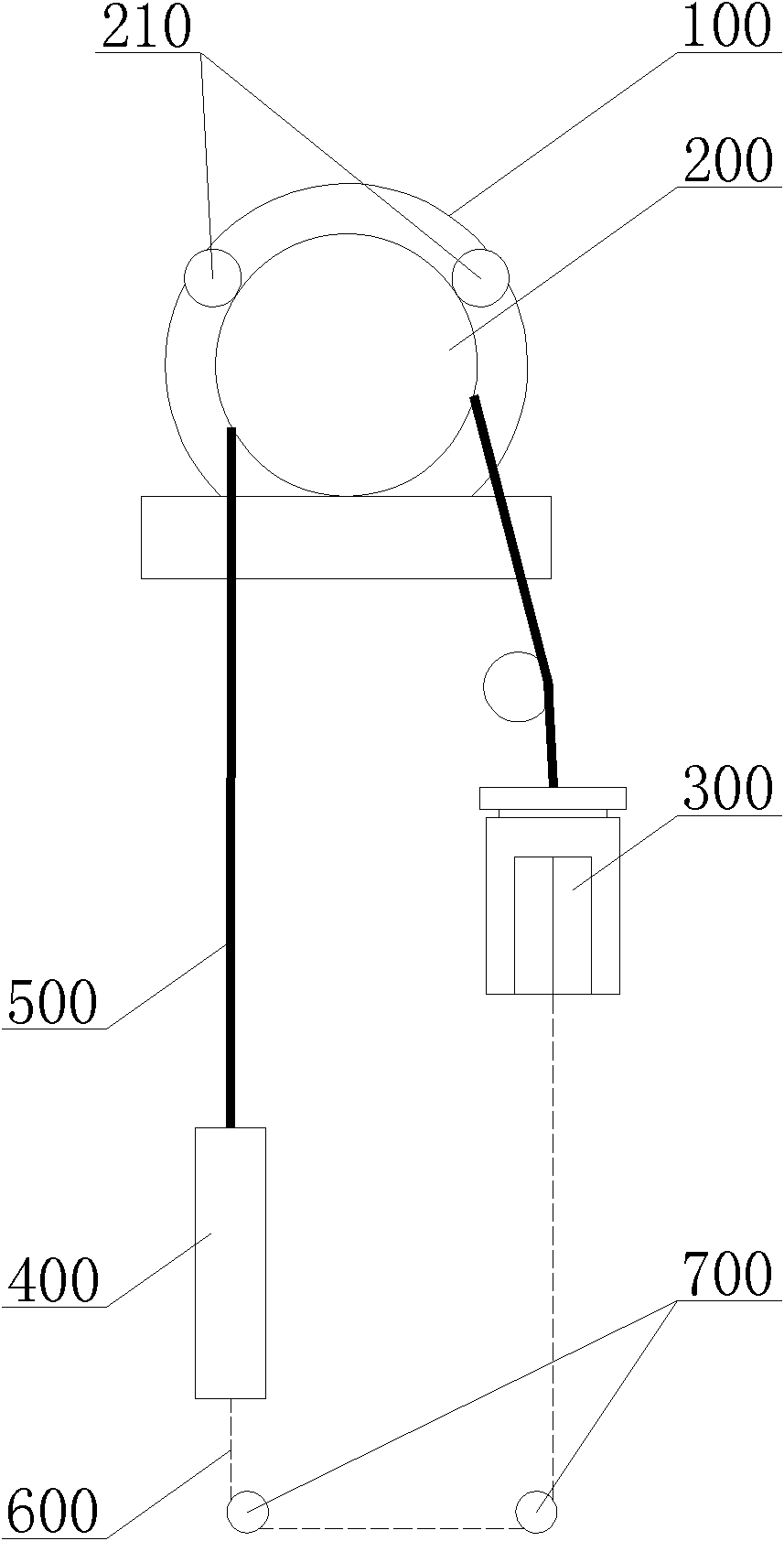

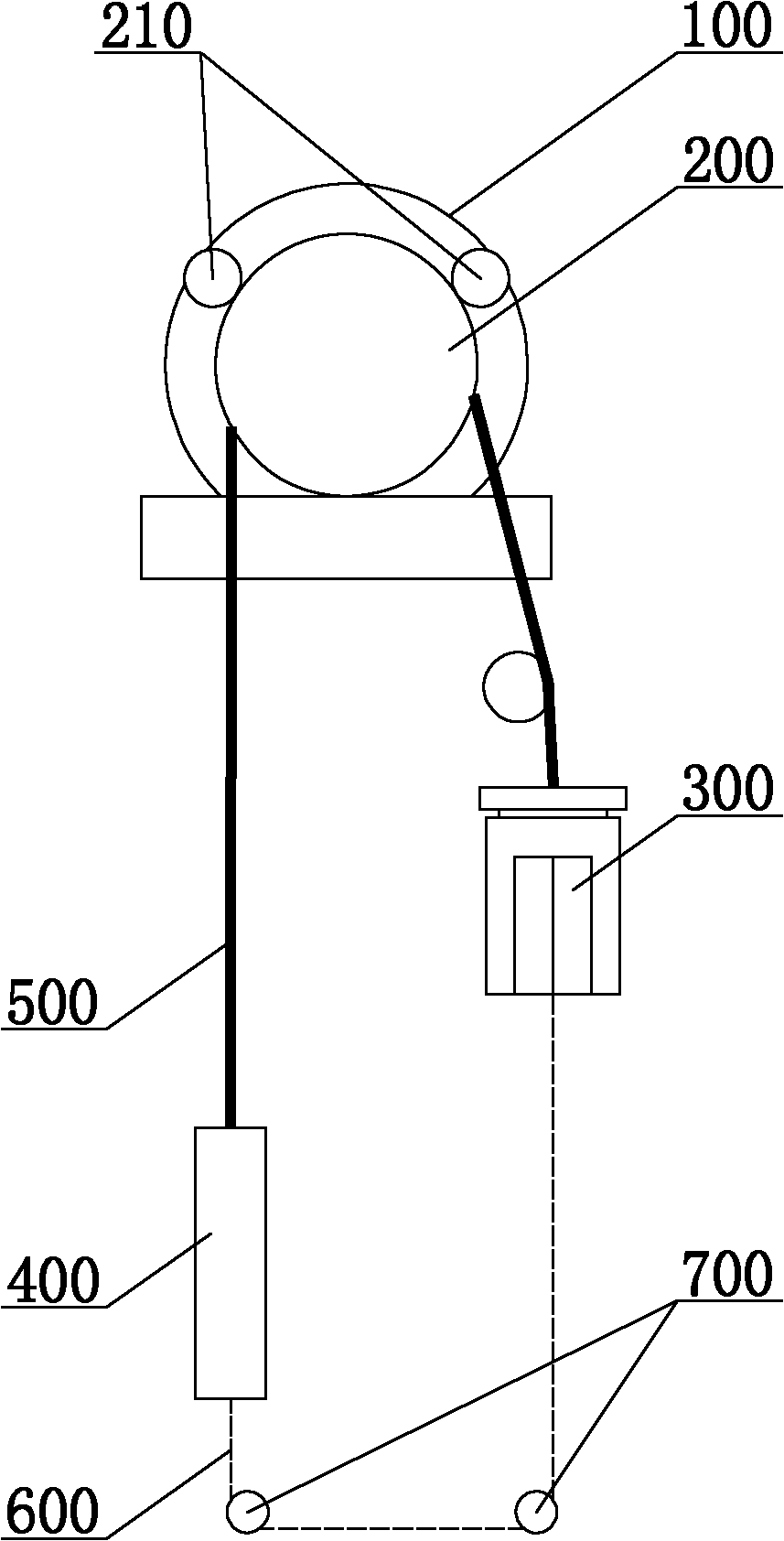

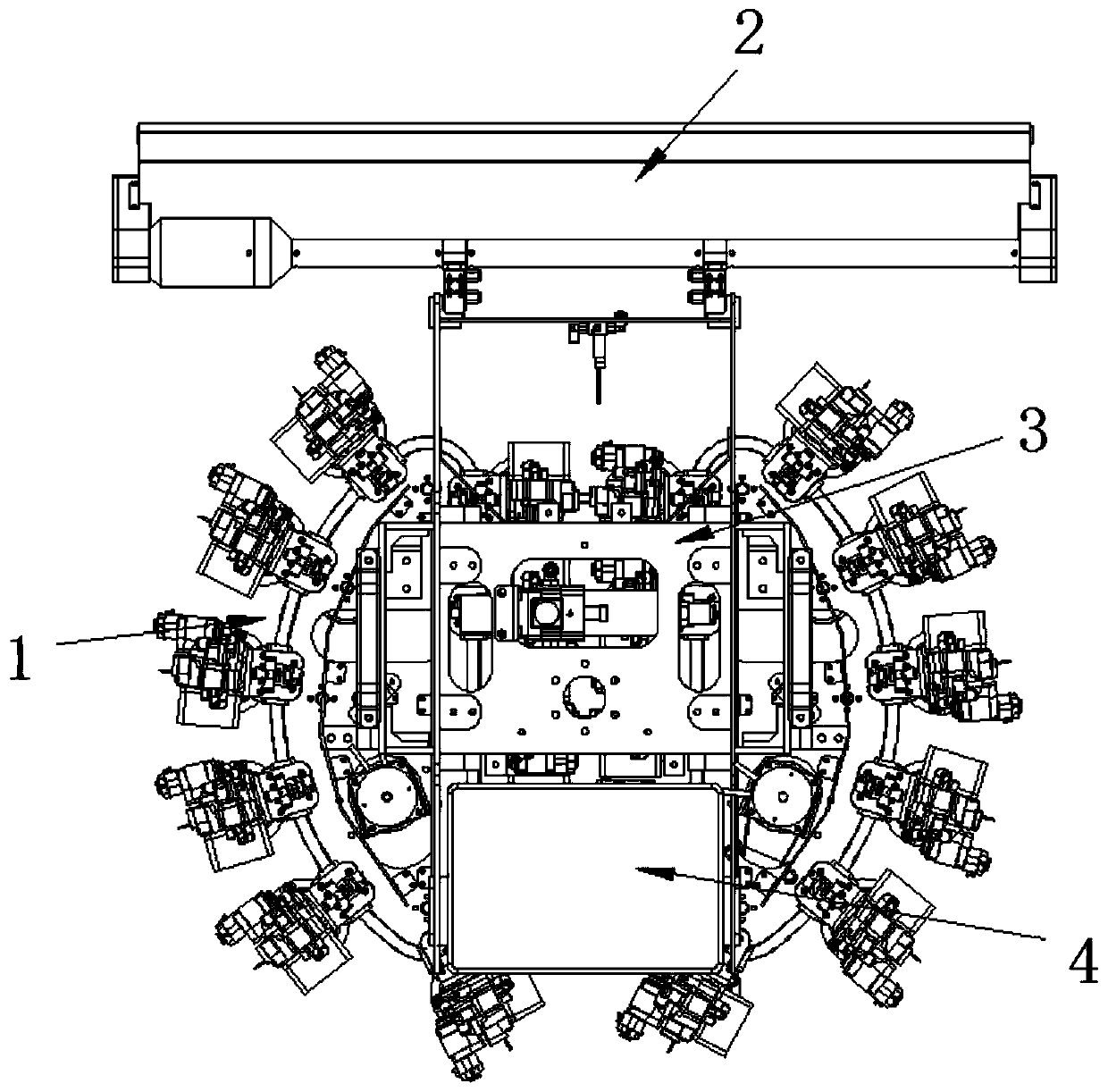

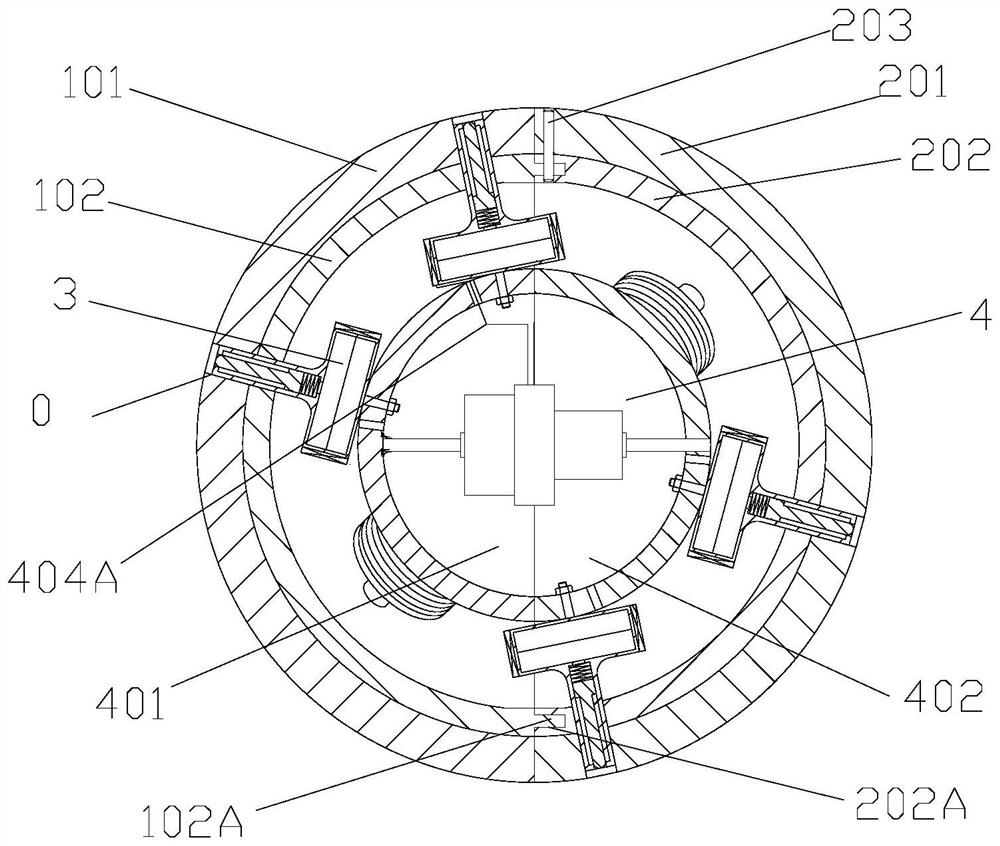

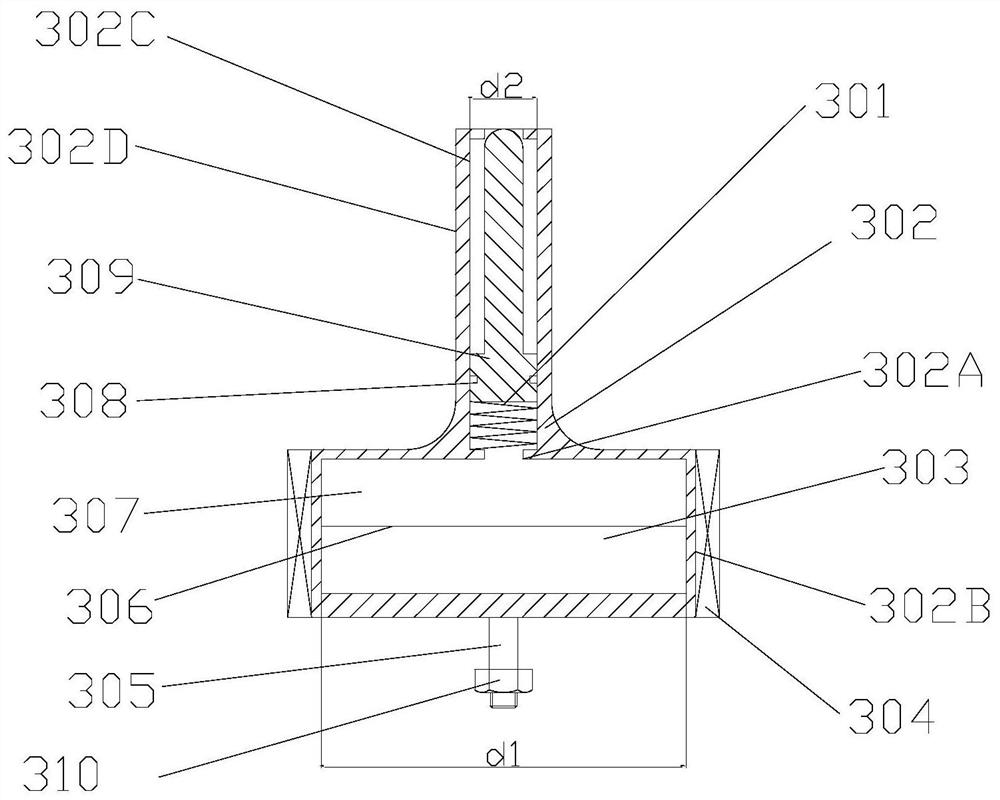

Omni-directional wheel type moving device and using method thereof

The invention relates to an omni-directional wheel type moving device and a using method thereof. The omni-directional wheel type moving device comprises an adjusting mechanism, tensioning mechanisms,an arc shell and moving mechanisms, four tensioning mechanisms are arranged on the adjusting mechanism, arc shell bodies are welded around the outside of the adjusting mechanism, the moving mechanisms are arranged on the tensioning mechanisms, and every two adjacent moving mechanisms are arranged upside down. The tensioning mechanisms of the device can change the posture inside the moving device,realizes the adaptation of variable diameter rods, in the movement process of the moving device, eight alternately orthogonally arranged double-row continuous switching wheels are driven by a motor,to provide uniform driving torque and uniform rotary inertia relative to the rods for the moving device, the straight climbing function is achieved, and the obstacle avoidance function is added on thebasis of the traditional climbing rod function, the mechanical automation degree is high, the operation is simple, the accuracy is high, the movement speed is ensured, flexibility is improved, and the work efficiency is improved.

Owner:四平维申科技有限公司

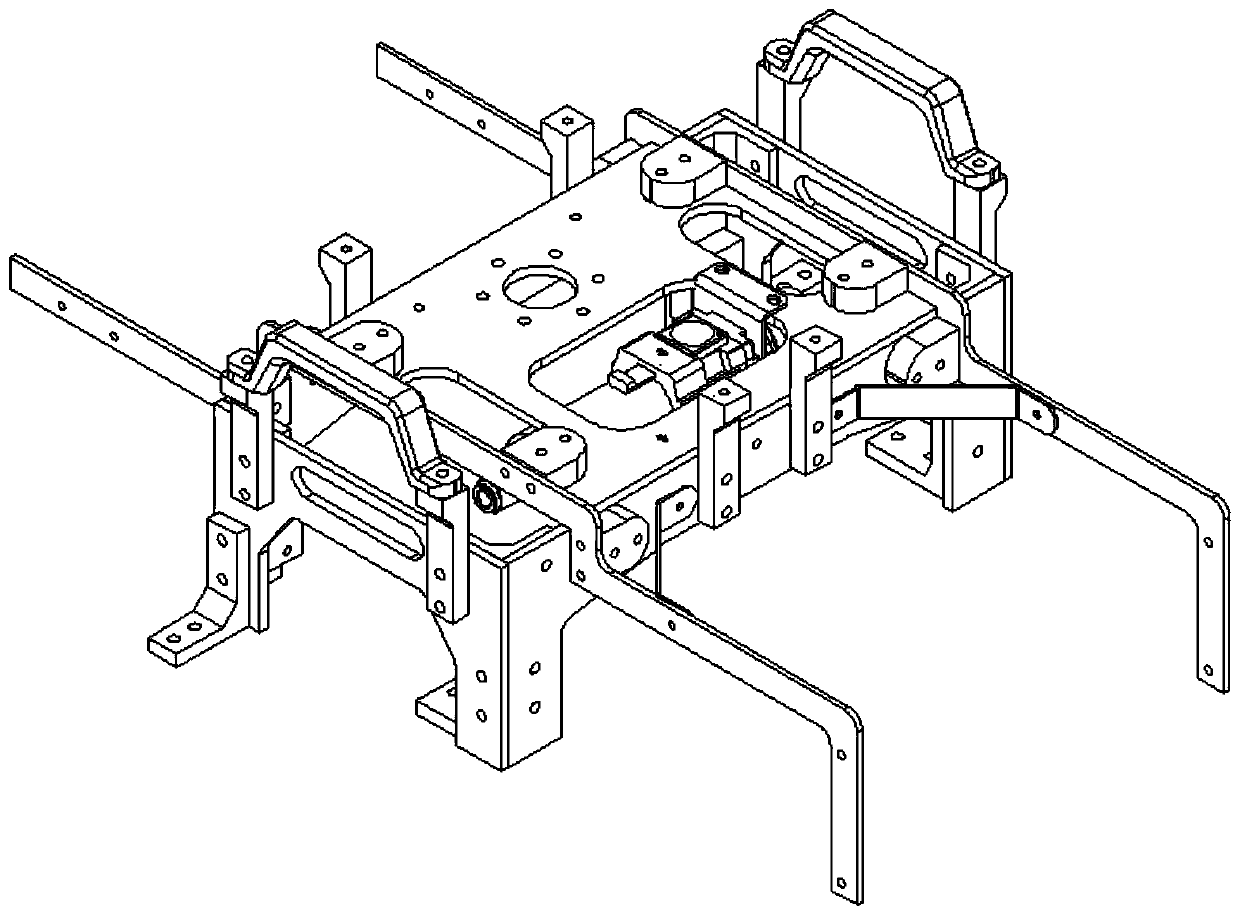

Planar motion curtain wall cleaning robot

ActiveCN110089972AChieve progressTo switch backAutomatic obstacle detectionTravelling automatic controlElectrical controlEngineering

The invention discloses a planar motion curtain wall cleaning robot and relates to the technical field of robots. The robot comprises a planar motion mechanism, a cleaning mechanism, a connecting bracket structure and an electrical control box, wherein the planar motion mechanism is composed of two semi-circular air cylinder-sucker combined mechanisms which are concentric and arranged in an axialsymmetry mode, and the two air cylinder-sucker combined mechanisms are fixed to the left side and the right side of the connecting bracket structure; the cleaning mechanism is fixed to the front end of the connecting bracket structure, and the electrical control box is fixed to the rear end of the connecting bracket structure. The planar motion curtain wall cleaning robot based on the air cylindervacuum suction cup assemblies has the advantages that the motion speed is guaranteed, the robot does not need to be moved through a mooring rope by means of manpower, and the robot has the capacity of being sucked to the working surface; the weight of the robot is greatly reduced through the two concentric and axisymmetric single-layer plate structures, and the portability is improved.

Owner:无锡轻捷智能科技有限公司

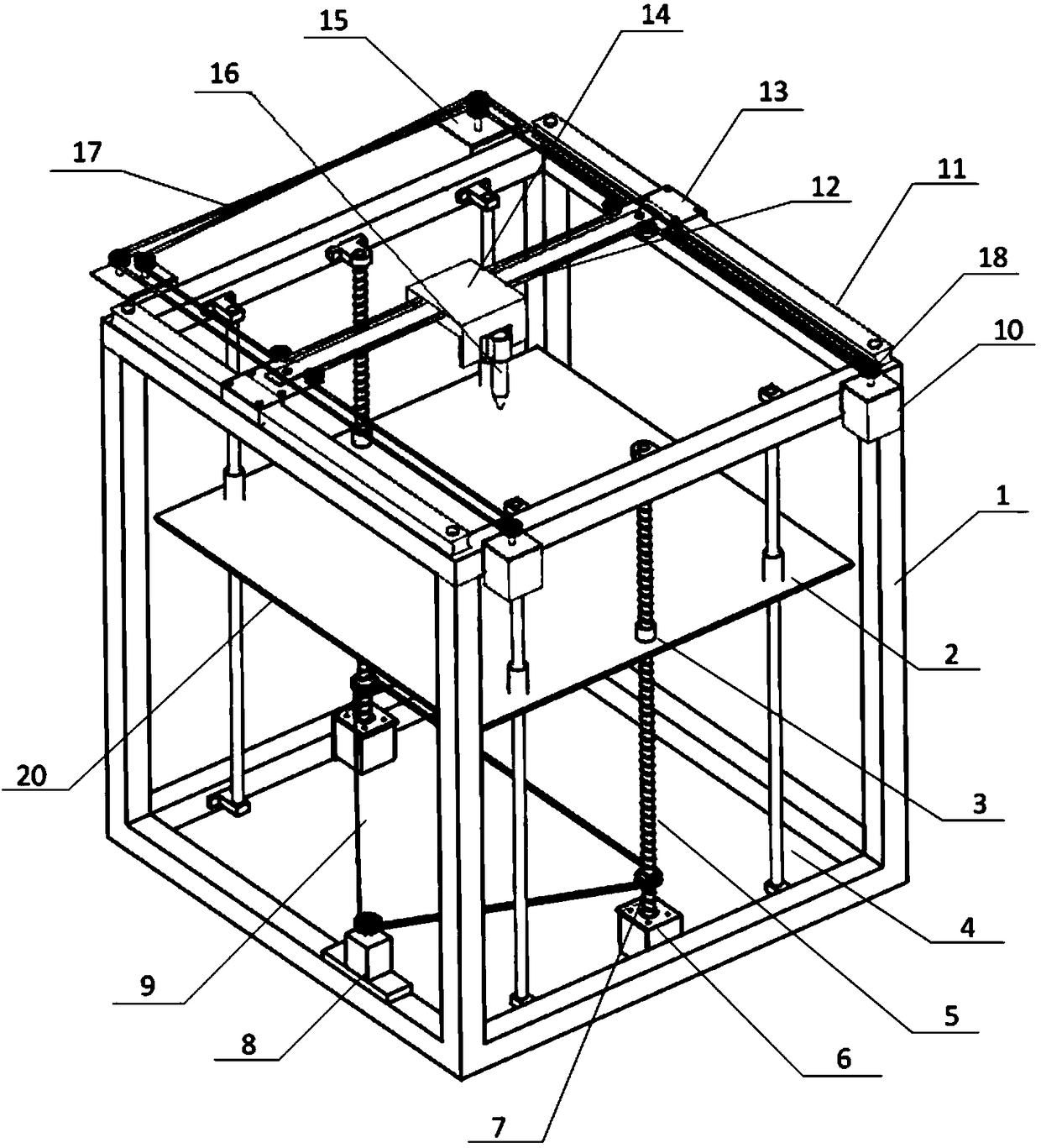

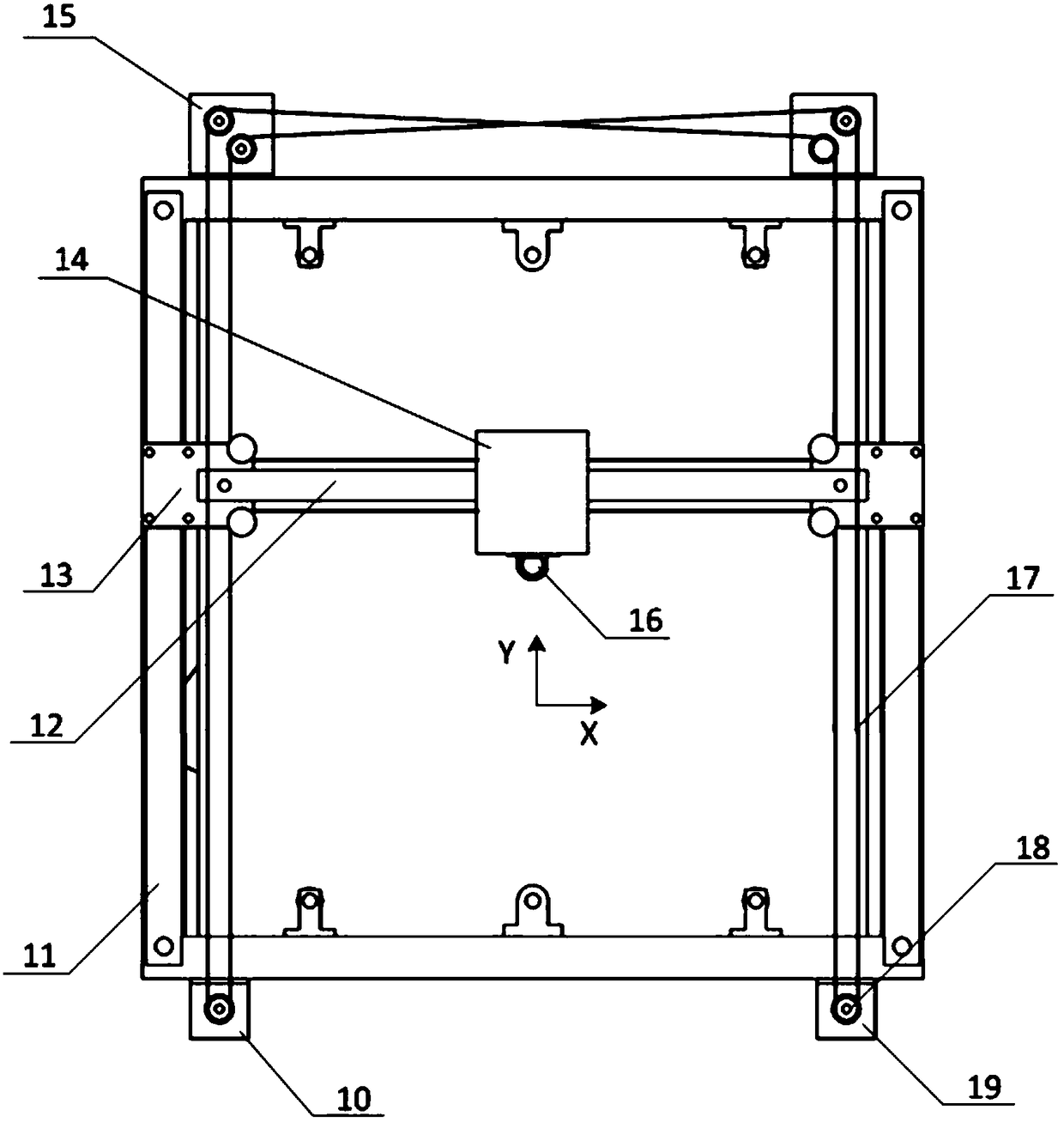

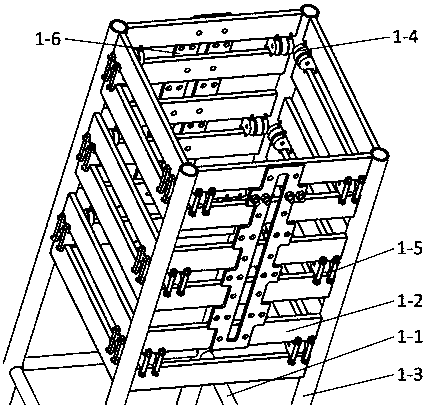

Low-cost high-efficiency 3D printer

InactiveCN108237688AAvoid uneven forceReduce deflectionAdditive manufacturing apparatus3D object support structuresAlloyEngineering

The invention discloses a low-cost high-efficiency 3D printer which comprises an aluminum alloy frame, a printing head, a printing head moving mechanism and a printing platform. The printing head moving mechanism comprises a stepping motor A, a stepping motor B, a Y-axis linear guide rail, an X-axis linear guide rail, a Y-axis sliding block, an X-axis sliding block and an uncoiling synchronous belt. The low-cost high-efficiency 3D printer is simple and reasonable in structural design, and the printing head is driven by the synchronous belt when moving in the XY direction. When a driving wheelis rotated, due to the winding way of the synchronous belt, the problem that the sliding blocks are uneven in stress in the moving process is solved, the moving speed is improved on the premise that the precision is ensured, and the printing efficiency is high. The Z axis is composed of two lead screws, deflection produced through the large span of the printing platform and shaking produced duringprinting work are reduced, and printing work is more stable and reliable.

Owner:TIANJIN UNIV OF SCI & TECH

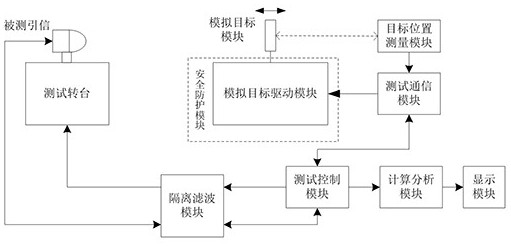

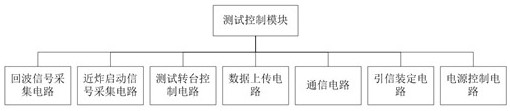

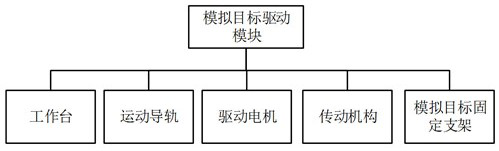

Dynamic simulation test device and method for ultra-wideband radio fuze

PendingCN113819818AThe testing process is simpleIncrease the range of motionAmmunition fuzesHigh level techniquesAutomotive engineeringDynamic simulation

The invention discloses a dynamic simulation test device and method for an ultra-wideband radio fuze. The device comprises a test control module, a simulation target driving module, a simulation target module, a target position measurement module, a test communication module, a calculation and analysis module, a safety protection module, an isolation filtering module, a fuse test turntable and a display module. The method comprises the following steps that a tested fuse is installed on a test turntable, and the simulation target driving module and a simulation target are placed in a detection interval of the tested fuse; the tested fuse is connected with the test control module, and the test turntable is connected with the test control module; the test control module sends a turntable angle instruction and sets a turntable test angle; the test control module automatically tests the tested fuse; the performance of the tested fuse is analyzed, and a test result is output; and a test cable is demounted to complete the test. The testing device is simple in deployment and low in manufacturing cost; and the test method is high in accuracy and high in efficiency.

Owner:BEIJING HONGDONG TECH CO LTD

Dual-purpose mobile robot of wheel and foot

Owner:TSINGHUA UNIV +1

Miniature circuit breaker breaking and closing mechanism capable of spirally controlling speed

ActiveCN109346383AWith self-locking functionReduce shockProtective switch operating/release mechanismsSelf lockingEngineering

The invention discloses a miniature circuit breaker breaking and closing mechanism capable of spirally controlling a speed. The miniature circuit breaker breaking and closing mechanism comprises a boxbody, an air switch, a cover plate, a knife switch and a speed control switch, wherein a front surface of the box body is hinged and connected with the cover plate, the air switch is arranged in thebox body, the knife switch is arranged on the air switch and is movably connected with the speed control switch, grooves are formed in a left side and a right side of the knife switch, the speed control switch comprises a sliding frame, a speed control rotation rod, a guide sleeve and a handle, the guide sleeve is connected with an outer side of the air switch and is arranged at a part below the knife switch, the speed control rotation rod penetrates through the guide sleeve and is in threaded connection with the guide sleeve, and the sliding frame is in a square shape. The miniature circuit breaker breaking and closing mechanism has the beneficial effects that a gate is moved by a self-locking effect of threaded connection, the moving speed is ensured, impact caused by automatic pop-out of the gate is prevented, the air switch is protected, the speed control rotation rod is controlled and loosen by combination and expansion of four threaded blocks, the control of the gate can be automatically loosen during trip, so that the circuit automatically trips and is protected.

Owner:安徽龙和电力集团有限公司

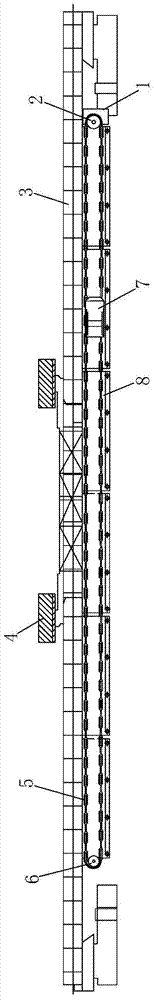

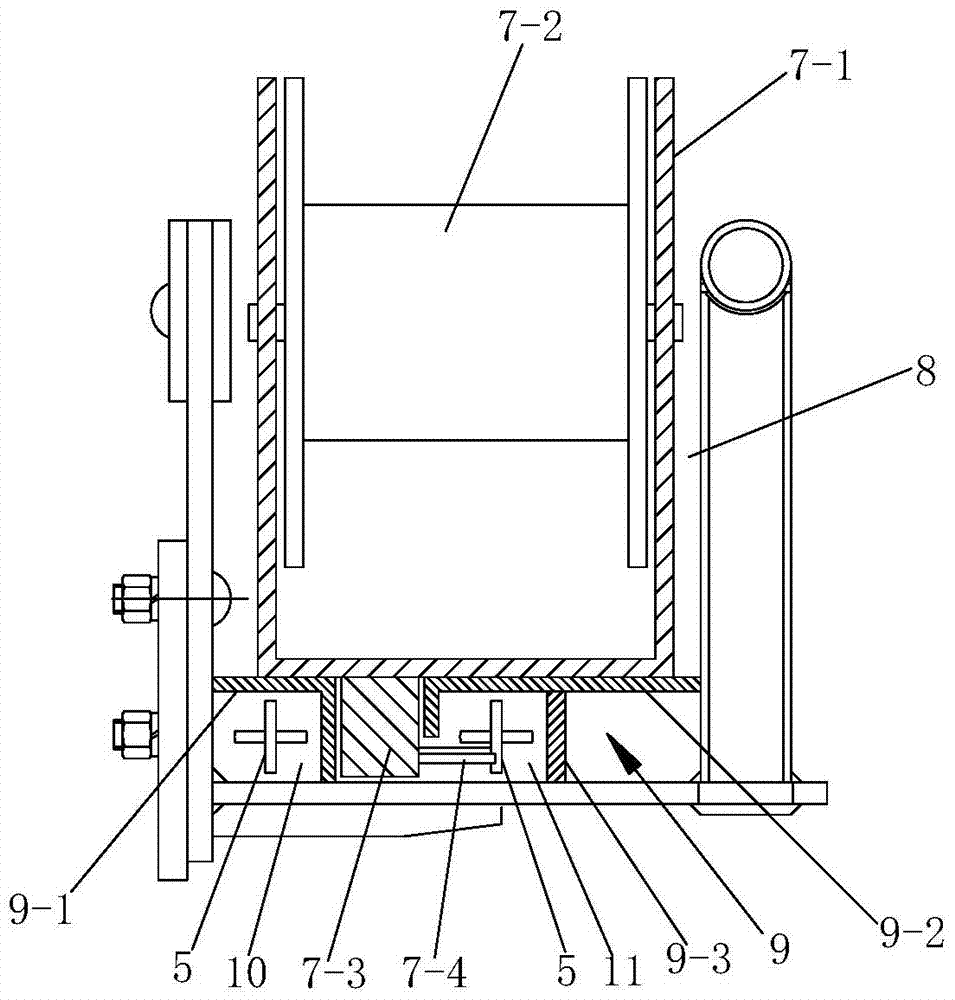

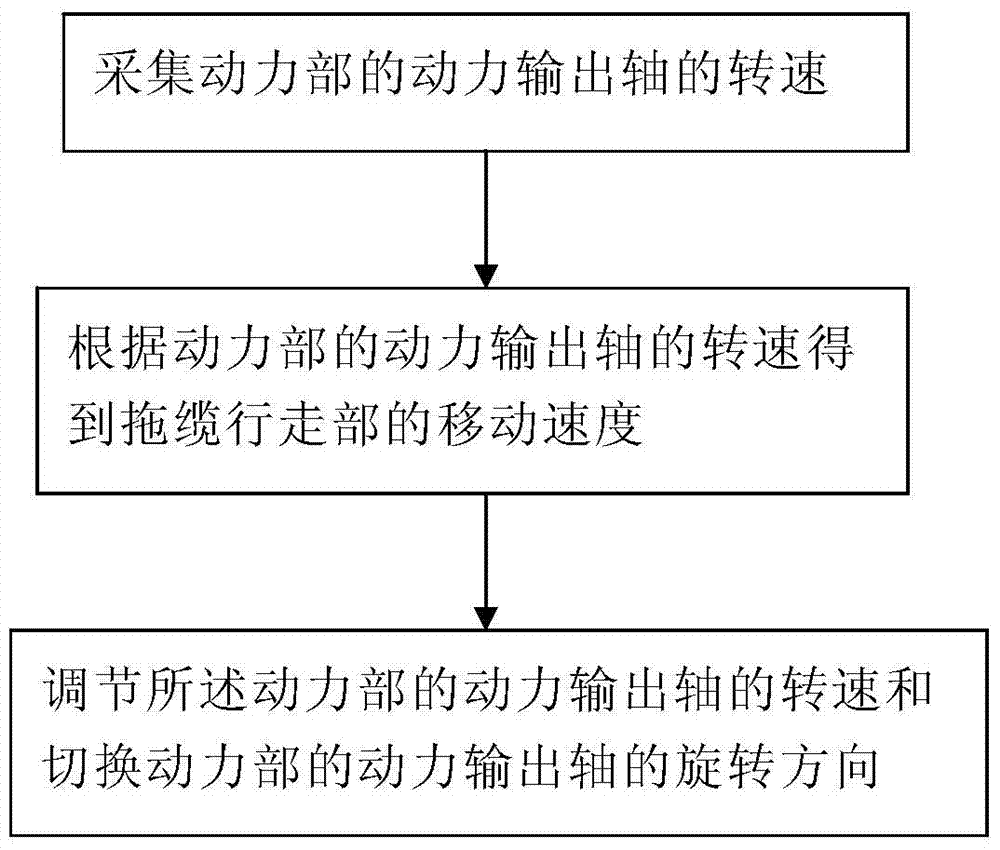

A control method and control device for an automatic towing cable system of a coal shearer

ActiveCN104953531BGuaranteed movement speedAvoid draggingCable arrangements between relatively-moving partsSlitting machinesElectric machineDrive motor

The invention discloses a control method and a control device for an automatic tow cable system of a coal shearer. The automatic tow cable system of a coal shearer includes an annular chain, a power part and a tow cable running part. A driving sprocket is installed on the output shaft, and the driving sprocket and the driven sprocket are connected by an endless chain. The automatic tow cable system can ensure that the cable splint of the shearer is always in a flat state during repeated walking of the shearer. The control method of the present invention ensures that the moving speed of the tow cable running part is half of the moving speed of the shearer by adjusting the rotating speed of the power output shaft of the power part. The control device of the invention includes a speed measuring encoder of the power part, a frequency converter and a tow cable controller, and can regulate the speed of the drive motor and control the commutation. The control method and the control device do not require workers to track and maintain the automatic towing cable system of the coal shearer, thereby improving the degree of automation and intelligence of the equipment.

Owner:XIAN COAL MINING MACHINERY

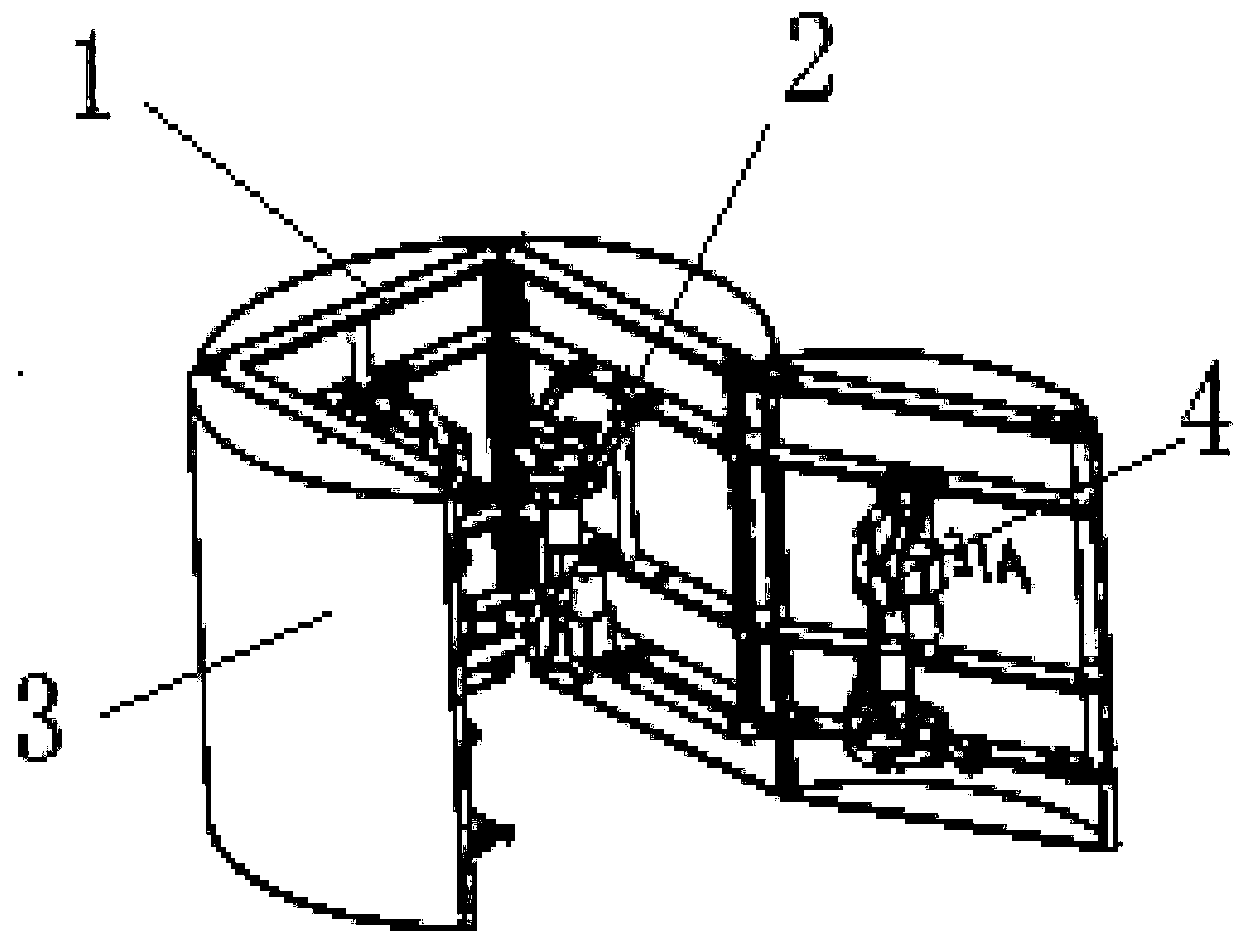

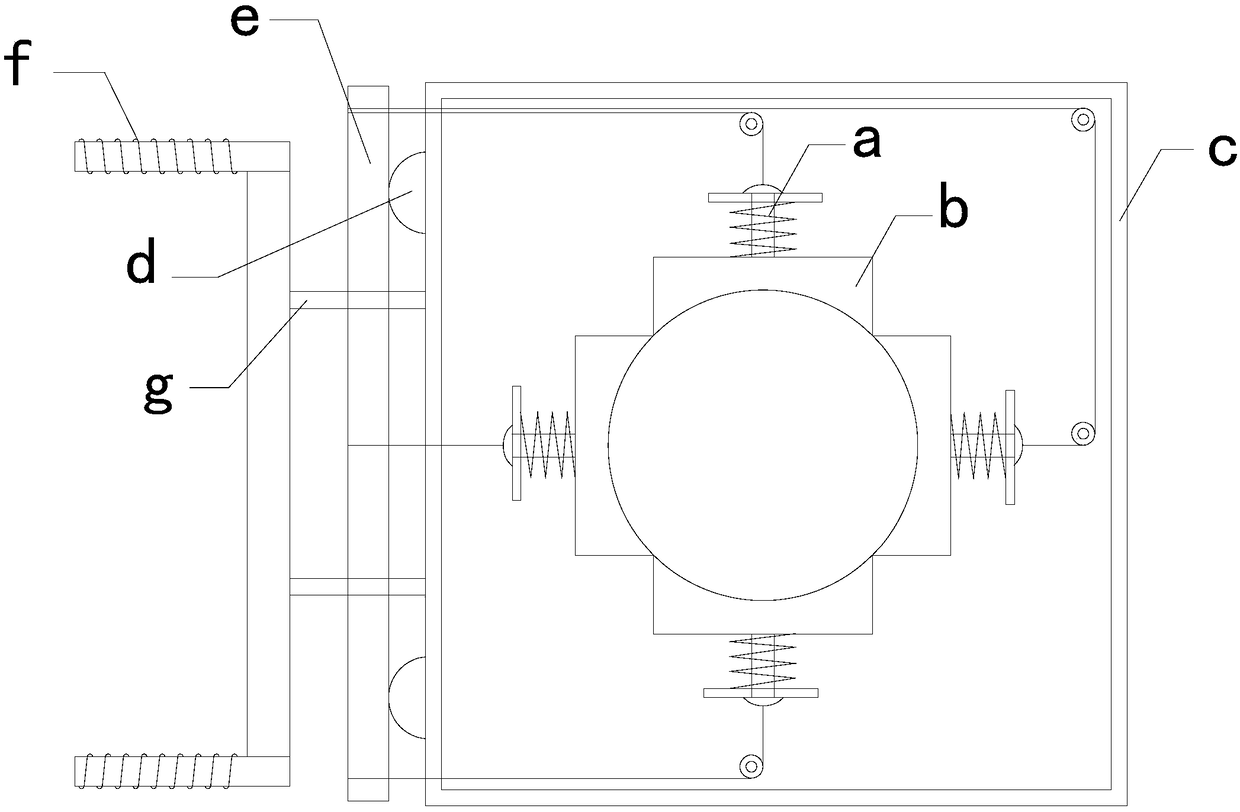

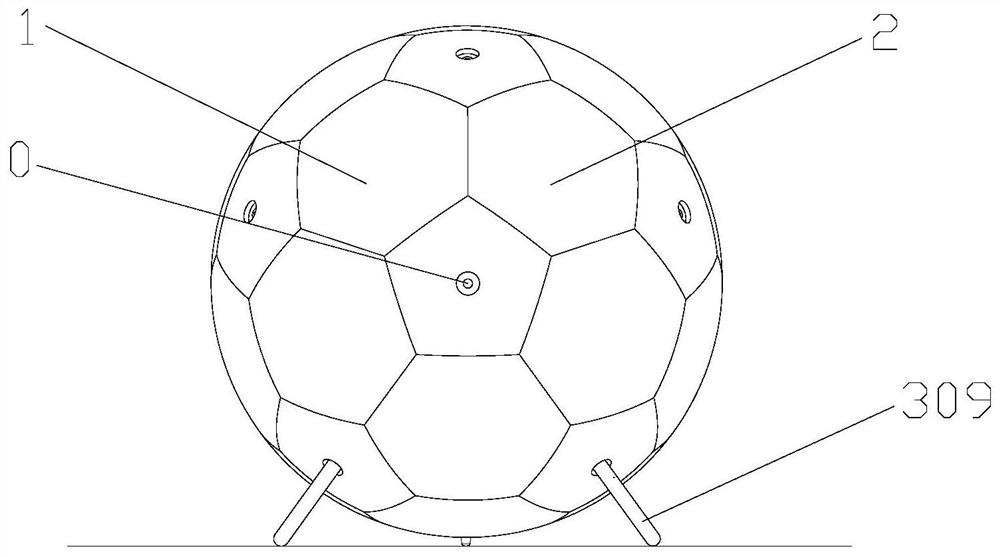

Spherical rescue robot with rolling-jumping function and control method

ActiveCN112849299ASolve the cooperative roll-jump drive problemGuaranteed movement speedVehiclesRescue robotClassical mechanics

The invention discloses a spherical rescue robot with a rolling-jumping function and a control method, belongs to the technical field of rescue robots, and relates to a spherical robot which is used for disaster search and rescue and has rolling and jumping functions and a control method. The robot is composed of a left hemispheroid, a right hemispheroid, a center control bin and a plurality of identical magneto-rheological thrust mechanisms. Each magneto-rheological thrust mechanism is composed of a reset spring, a thrust mechanism shell, a magneto-rheological material, an electromagnetic coil, a connecting bolt, a nut, a magneto-rheological material-water diaphragm, water, a sealing ring and a ground supporting rod. According to the control method, the center control bin is used for controlling, the IMU sensor measures the current pose and acceleration data of the spherical robot, the power-on state and the power-on time of each electromagnetic coil are controlled, the internal ground supporting rods are controlled to pop out to impact the ground, and power is provided for the spherical robot. The spherical robot is compact in structure, high in environment adaptability and low in movement energy consumption, and the problem of multi-group collaborative rolling-jumping driving in a small-size space of the spherical robot is effectively solved.

Owner:DALIAN UNIV OF TECH

Explosion-proof heater

InactiveCN105485903AImprove heating efficiencyGuaranteed movement speedAir heatersMoving speedAirflow

The invention relates to an explosion-proof heater. The explosion-proof heater comprises a wiring base and a heating pipe body; and a wiring circuit is positioned in the wiring base. The explosion-proof heater further comprises an upper flange and a lower flange; the upper flange connects the wiring base with a control box of the explosion-proof heater; the lower flange connects the wiring base with the heating pipe body; the heating pipe body includes an air inlet near the lower end part of the heating pipe body, an air outlet near the upper end part of the heating pipe body, a heating pipe positioned in the heating pipe body, heating pipe fixed plates and a netty liner; the heating pipe fixed plates are flatly cylindrical, and are uniformly distributed in the axial direction of the heating pipe; two or more heating pipe fixed plates are provided; through holes are formed in the heating pipe fixed plates; the heating pipe penetrates through the through holes; the outer wall of the heating pipe is fixedly connected with the inner wall of the through holes; and the netty liner is uniformly distributed in the axial direction of the heating pipe. The explosion-proof heater is high in heating efficiency, and can guarantee the air flow moving speed in the heating pipe.

Owner:TIANJIN BSTEX EXPLOSION PROOF ELECTRICAL APPLIANCE

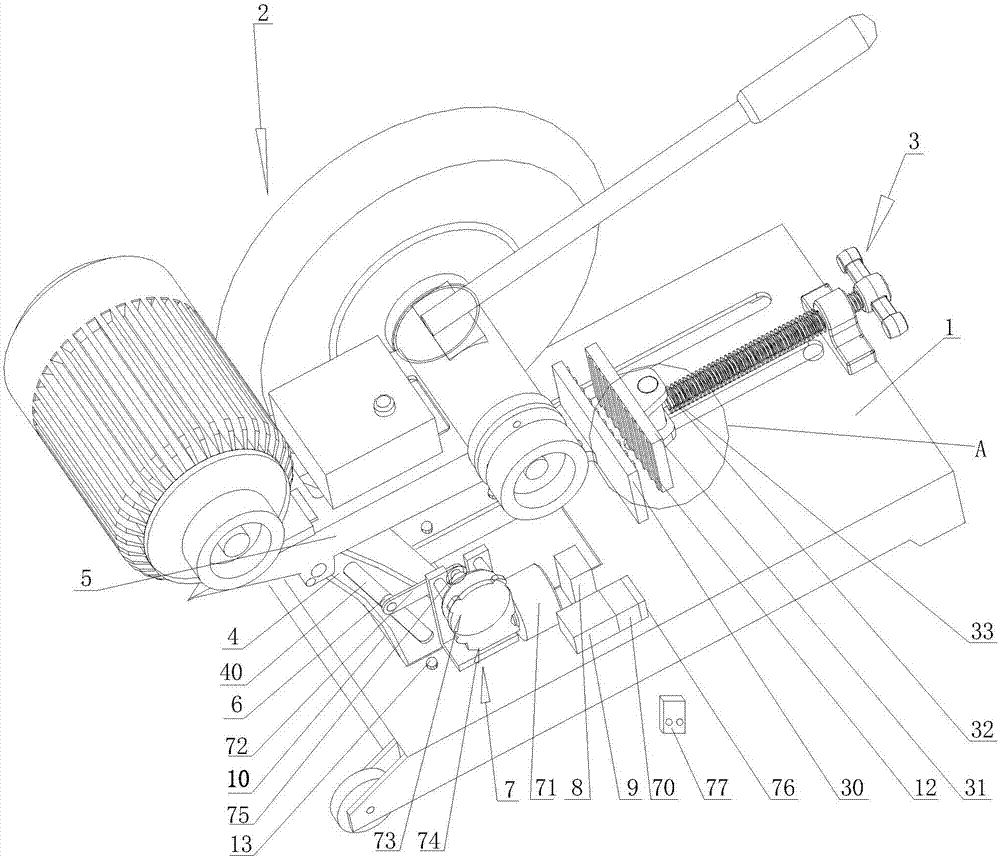

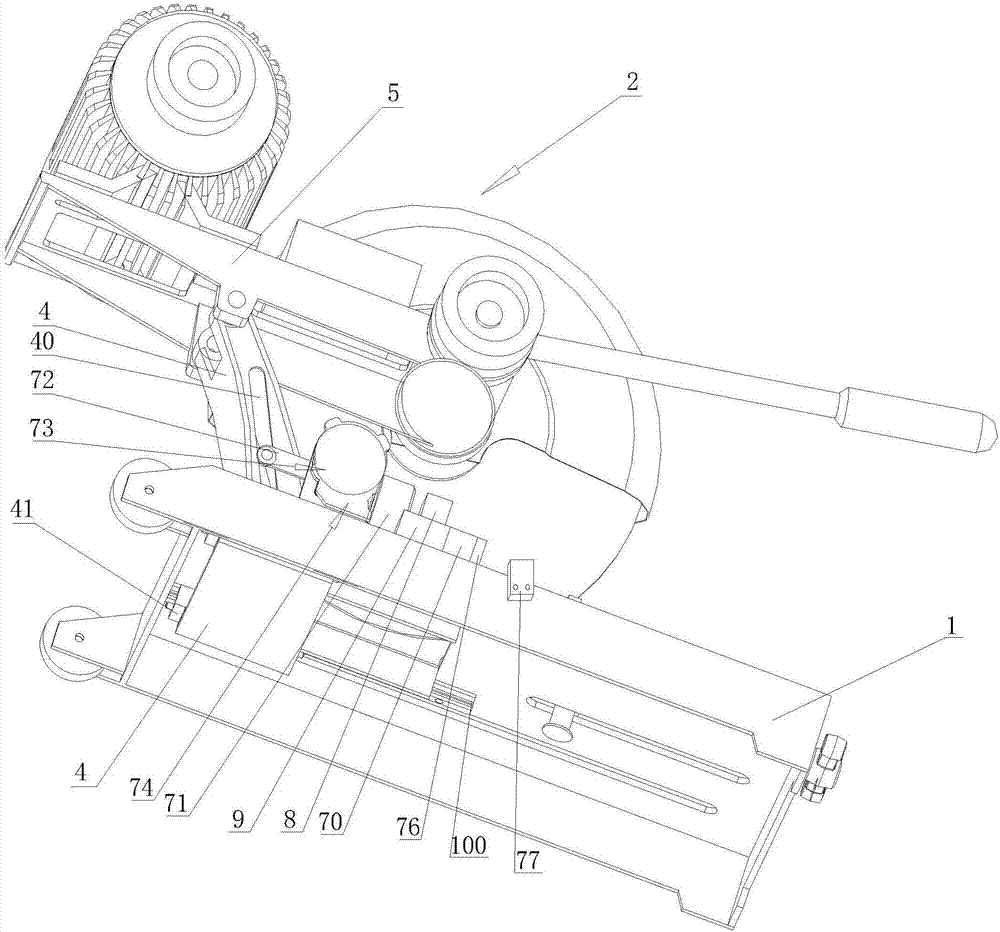

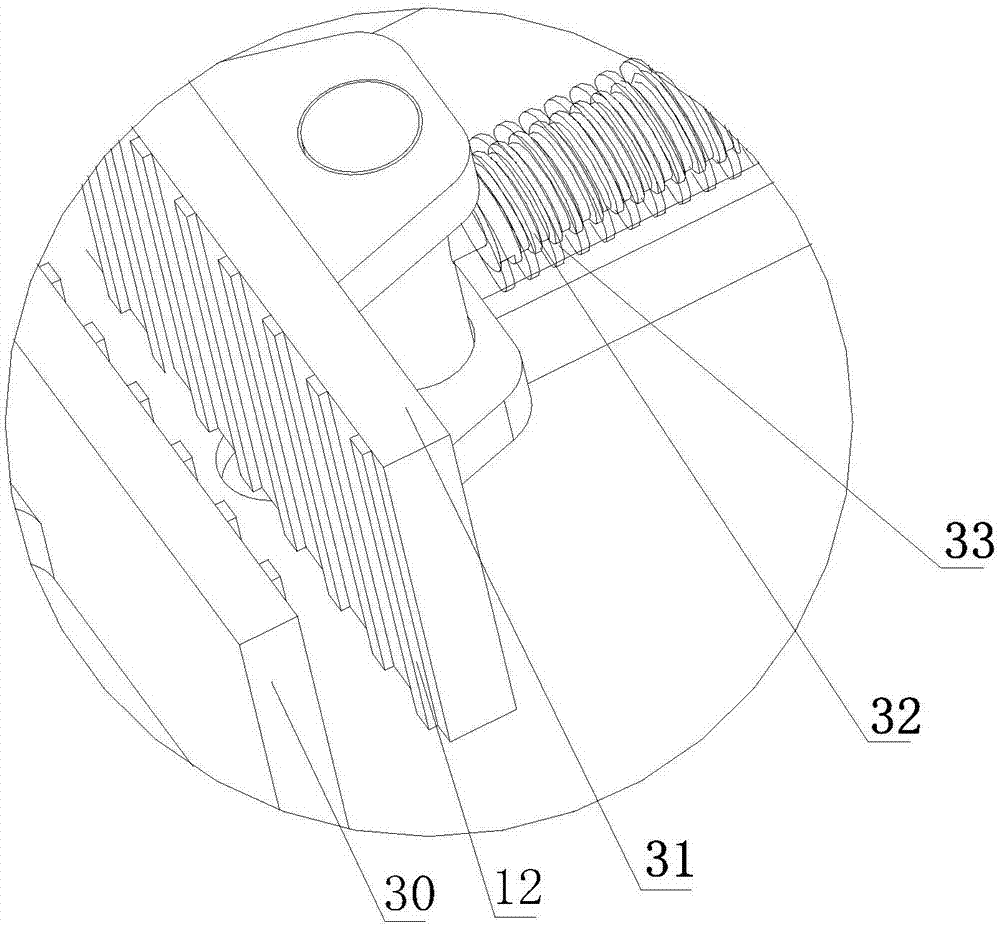

Automatic moving dovetail type grinding wheel cutting machine

InactiveCN107127668AEasy to moveControl movement speedGrinding carriagesGrinding feed controlTurbineGrinding wheel

The invention discloses an automatic moving dovetail type grinding wheel cutting machine. The machine comprises a base, a cutting assembly used for cutting workpieces and a fixture used for fixing the workpieces. A dovetail groove is formed in the base. The dovetail groove is internally provided with a dovetail support frame. The dovetail support frame is provided with a cutting bracket. The cutting assembly is connected with the cutting bracket. A sliding groove is formed in the dovetail support frame. The sliding groove is internally provided with a sliding block. The sliding block is connected with an automatic moving device. The automatic moving device drives the dovetail support frame to move in the dovetail groove. The automatic moving device comprises a controlling device, a motor, a connecting rod, a worm, a rotating shaft and a turbine. The controlling device is in circuit connection with the motor. The motor is connected with the worm. The turbine and the worm are connected with each other in a meshed mode. The turbine is connected with the connecting rod through the rotating shaft. The connecting rod is rotatably connected with the sliding block. According to the automatic moving dovetail type grinding wheel cutting machine, users can use the machine conveniently, time and labor are saved, the uniform moving speed is ensured, the cutting efficiency is improved, and the cutting quality is ensured.

Owner:安徽铸星机械制造有限公司

Vacuum adsorption hanging type crane

InactiveCN103964306AGuaranteed movement speedGuaranteed positioning accuracyTrolleysStructural engineeringMechanical engineering

The invention provides a vacuum adsorption hanging type crane which comprises a mounting rack, a motor holder, a motor, synchronous belt wheels, a synchronous belt, a trolley bottom plate, a linear bearing, a cylinder, a hollow guide post, a middle layer plate, standing arms, sucking disks and vacuum adsorption chambers, wherein the motor holder is fixedly mounted at one end of the mounting rack; the motor is fixedly mounted on the motor holder; the synchronous belt wheels are fixedly mounted on the motor; the synchronous belt is tightened between the synchronous belt wheels; the trolley bottom plate is mounted on the mounting rack; the linear bearing is fixedly mounted below the trolley bottom plate; the cylinder and the hollow guide post are mounted perpendicular to the trolley bottom plate; the middle layer plate is fixedly mounted on a telescopic link of the cylinder; the standing arms are mounted on both sides of the middle layer plate; one sucking disk is fixedly mounted at one end of the standing arm; and one vacuum adsorption chamber is fixedly mounted on the sucking disk. The vacuum adsorption hanging type crane is high in control accuracy and accurate in positioning; and meanwhile, a target product can be hung in an adsorption manner, so that the product can be transported and transferred, thereby greatly improving the working efficiency of the crane equipment.

Owner:XINXIELI PRESS PLATE

Automatic damping deceleration carbon-free trolley based on rack method

ActiveCN107261514AGuaranteed movement speedSolve driving direction driftGearingToy gearsRolloverElectric potential energy

The invention discloses an automatic damping deceleration carbon-free trolley based on a rack method. The trolley comprises a frame, a big gear and a small gear engaged with each other and installed on the frame, a potential energy transmission mechanism for driving the big gear to rotate and an automatic damping deceleration mechanism, wherein the automatic damping deceleration mechanism comprises a rack outer sleeve, a treaded sleeve component and a rack installed in the rack outer sleeve; a spring and a damping block are arranged in the threaded sleeve component, a convex surface is arranged at the left end of the damping block; teeth and a U-shaped concave surface are arranged on two opposite side surfaces of the rack, the teeth are engaged with the small gear, and the U-shaped con cave surface is in contact with the convex surface of the damping block in an arc surface contacting manner. According to the automatic damping deceleration carbon-free trolley provided by the invention, the condition that both the movement speed of the carbon-free trolley during downhill and the weight dropping speed are effectively controlled by damping, so that the damping deceleration effect is formed, and the purpose of automatic damping deceleration is achieved; and the problems of driving direction shifting and rollover caused by speed loss when the trolley avoids obstacles during downhill are effectively solved.

Owner:HUAIYIN INSTITUTE OF TECHNOLOGY

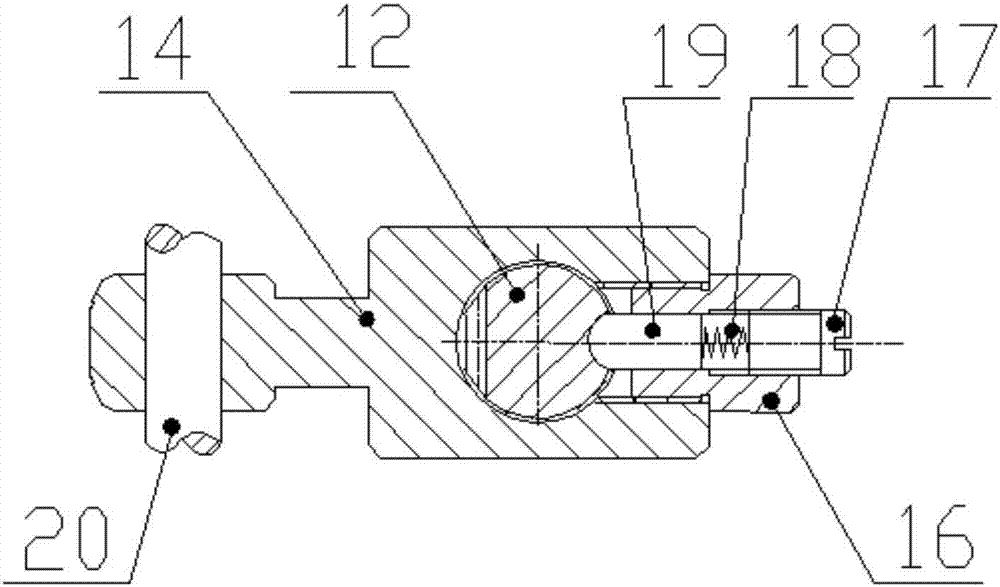

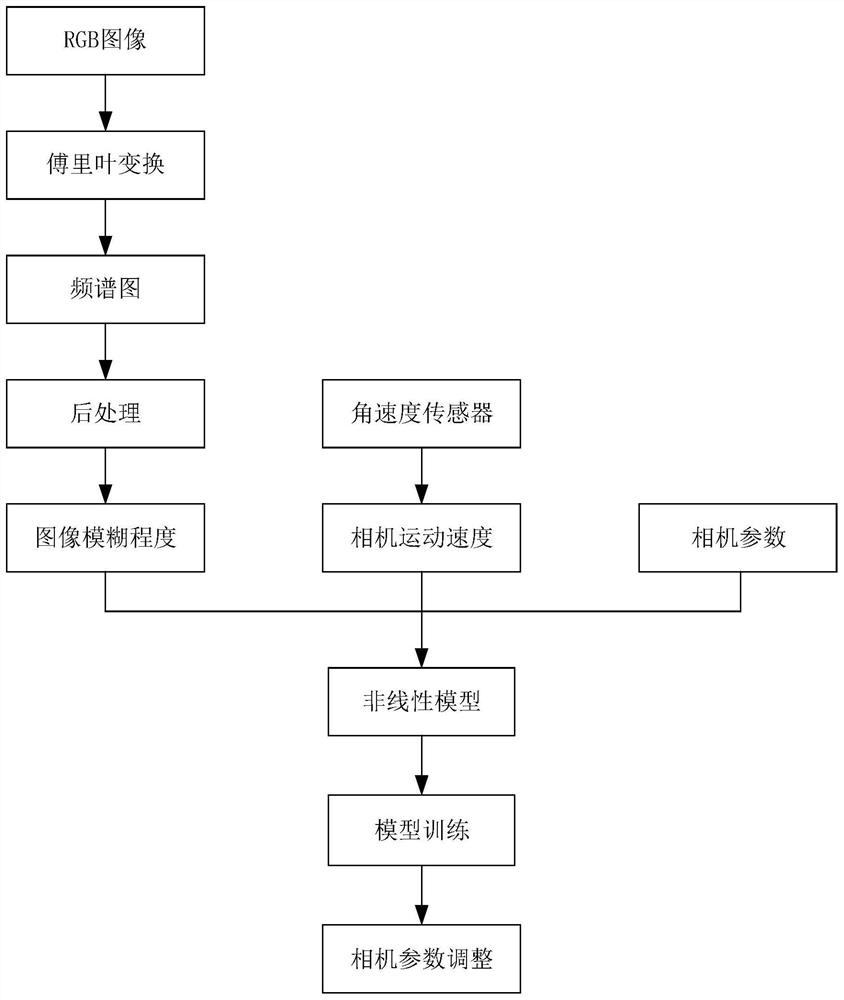

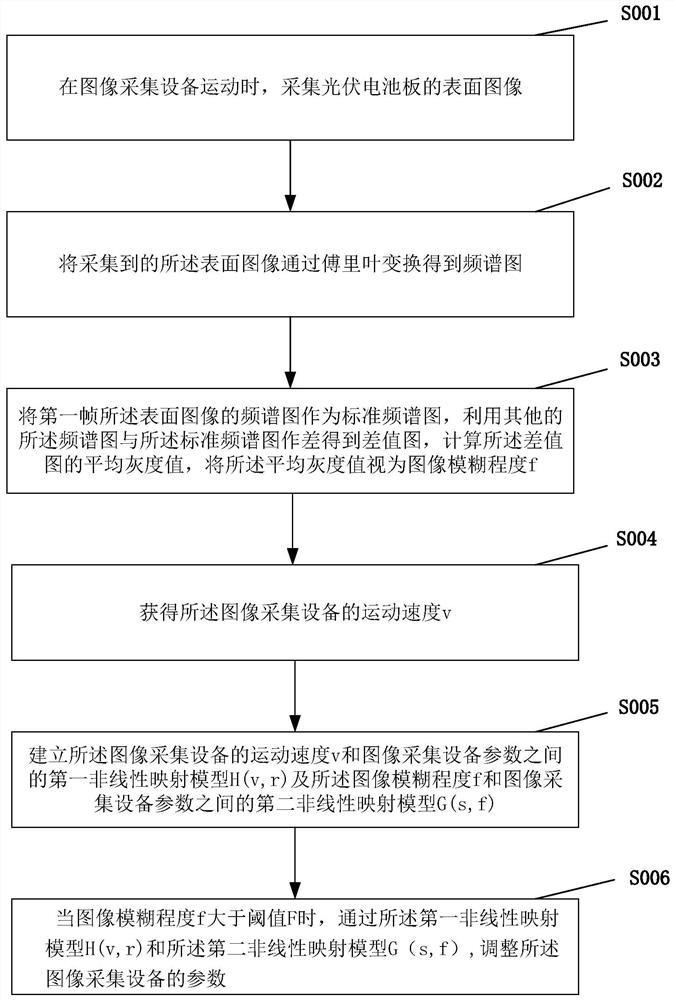

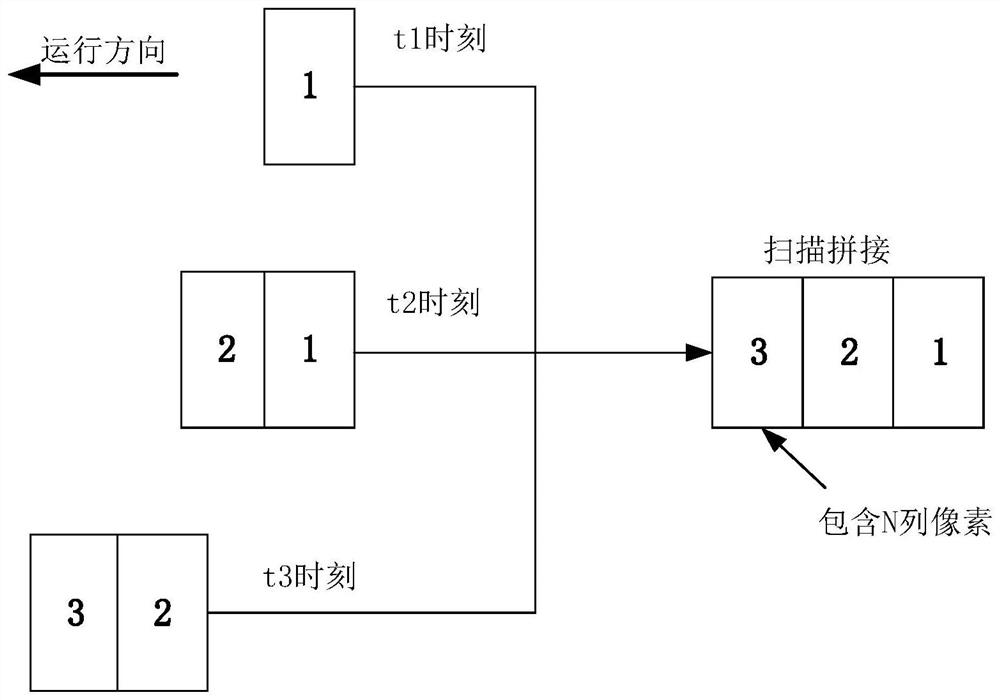

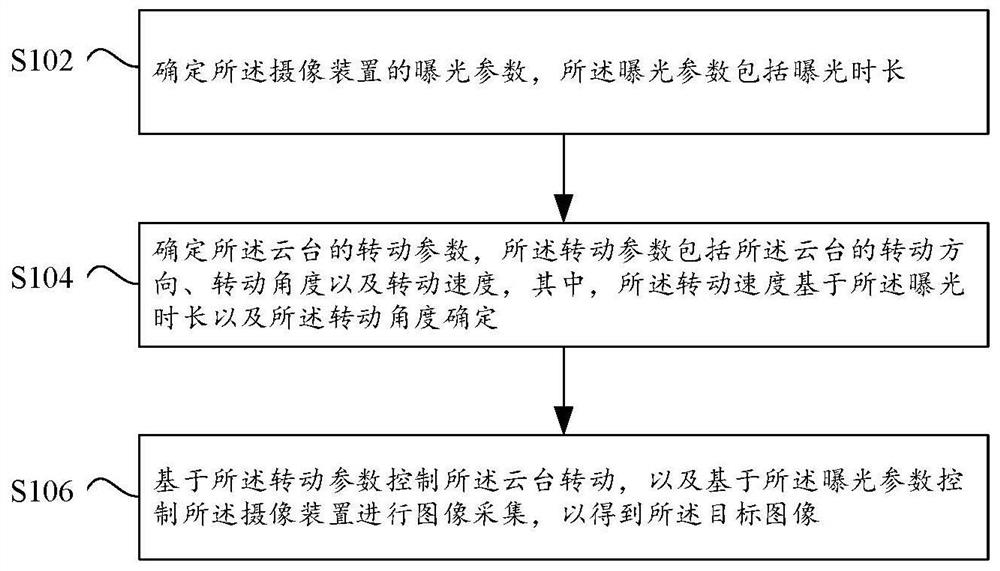

Photovoltaic camera motion blur adaptive adjustment method and system based on artificial intelligence

ActiveCN112217988AAccurate blurAccurate degree of blurring fTelevision system detailsColor television detailsCells panelAcquisition apparatus

The invention relates to the field of artificial intelligence, in particular to a photovoltaic camera motion blur self-adaptive adjustment method and system based on artificial intelligence. The method comprises the following steps of when image acquisition equipment moves, acquiring a surface image of a photovoltaic cell panel; performing Fourier transform on the acquired surface image to obtaina spectrogram; subtracting the other spectrograms from the standard spectrogram to obtain a difference diagram, and taking the average gray scale of the difference diagram as an image blurring degreef; obtaining the movement speed v of the image acquisition equipment; establishing a first nonlinear mapping model H (v, r) and a second nonlinear mapping model G (s, f) among the motion speed v of the image acquisition equipment, the image fuzzy degree f and the parameters of the image acquisition equipment; and when the image blurring degree f is greater than a threshold value F, adjusting parameters of the image acquisition equipment through the first nonlinear mapping model H (v, r) and the second nonlinear mapping model G (s, f). On the premise of ensuring the movement speed of the imageacquisition equipment, the parameters of the image acquisition equipment are adaptively adjusted to obtain a high-quality image.

Owner:深圳市美格智联信息技术有限公司

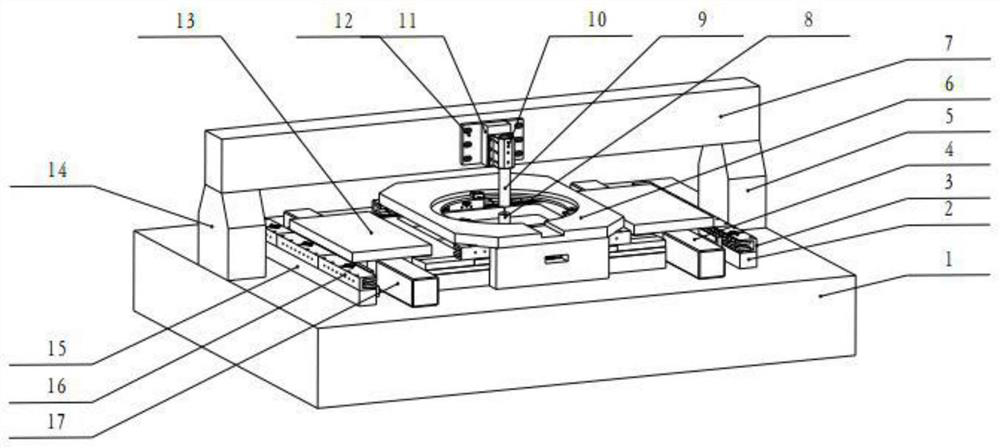

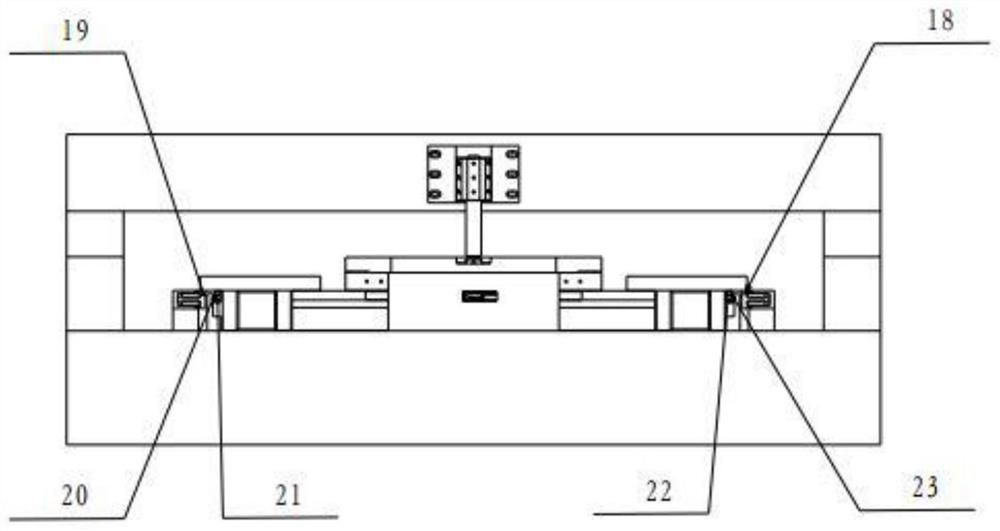

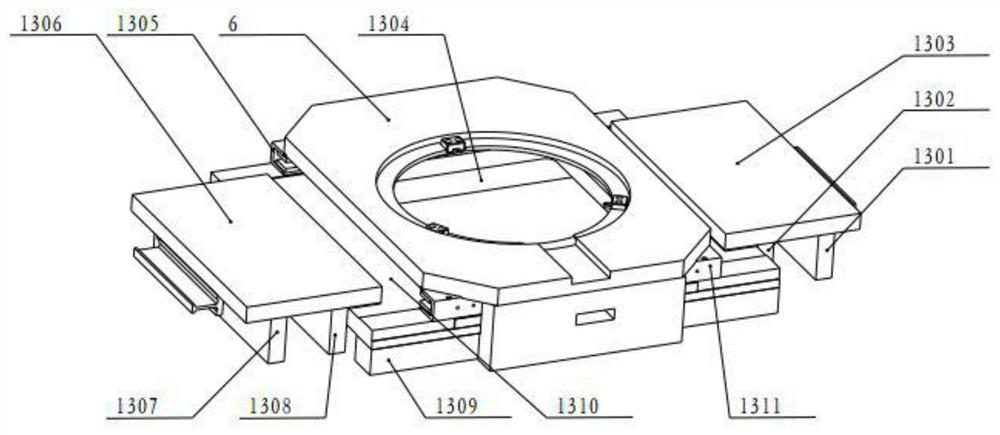

Platform for detecting thickness of large-size wafer

PendingCN112129234ARaise the natural frequencyReduce the difficulty of processing and debuggingOptically investigating flaws/contaminationUsing optical meansElectrical and Electronics engineeringMechanical engineering

The invention provides a platform for detecting the thickness of a large-size wafer. The platform comprises a marble base, wherein a pair of Y-direction marble guide rail and Y-direction marble guiderail which are arranged in parallel are arranged on the marble base; a Y-direction sliding block and a Y-direction sliding block are arranged on the Y-direction marble guide rail and the Y-direction marble guide rail respectively; a Y-direction motor stator connecting piece and a Y-direction motor stator connecting piece are arranged on the outer side surface of each of the Y-direction marble guide rail and the Y-direction marble guide rail; a Y-direction grating reading device is arranged on each of the Y-direction sliding block and the Y-direction sliding block; and the Y-direction sliding block are connected through a Y-direction cross beam piece to form a Y-direction integral sliding block. According to the platform, an objective table adopts a hollow design, and a Y axis adopts a Y1 / Y2 bidirectional n-shaped air floatation double-drive design, so that the overall inherent frequency of the platform can be improved, the processing and debugging difficulty can be reduced, and the X-direction precision and the movement speed can be guaranteed; the jump of an object carrying surface is within 1 micron, so that the detection requirements of the industry that the size is increased day by day and is stricter day by day can be met; and an air floatation platform is simple to maintain, and a clean room is not polluted.

Owner:无锡星微科技有限公司

Work machine having hydraulics for energy recovery

ActiveUS10927867B2Easy to implementHigh degree of opennessMechanical machines/dredgersServomotorsEngineeringMachine

The present invention relates to a work machine having at least one hydraulic actuator for actuating a piece of working equipment and having a first displacement unit that is driven by a drive assembly of the work machine and that feeds the hydraulic actuator with hydraulic medium from a hydraulic tank, wherein at least one second displacement unit is provided that is driven by the drive assembly and that feeds the hydraulic actuator and / or further hydraulic consumers with hydraulic medium from a hydraulic tank in the working mode and that is drivable during a recovery mode by the hydraulic volume displaced by the at least one hydraulic actuator or by a hydraulic consumer to feed kinetic energy back to the drive assembly.

Owner:LEIBHERR HYDRAULIKBAGGER GMBH

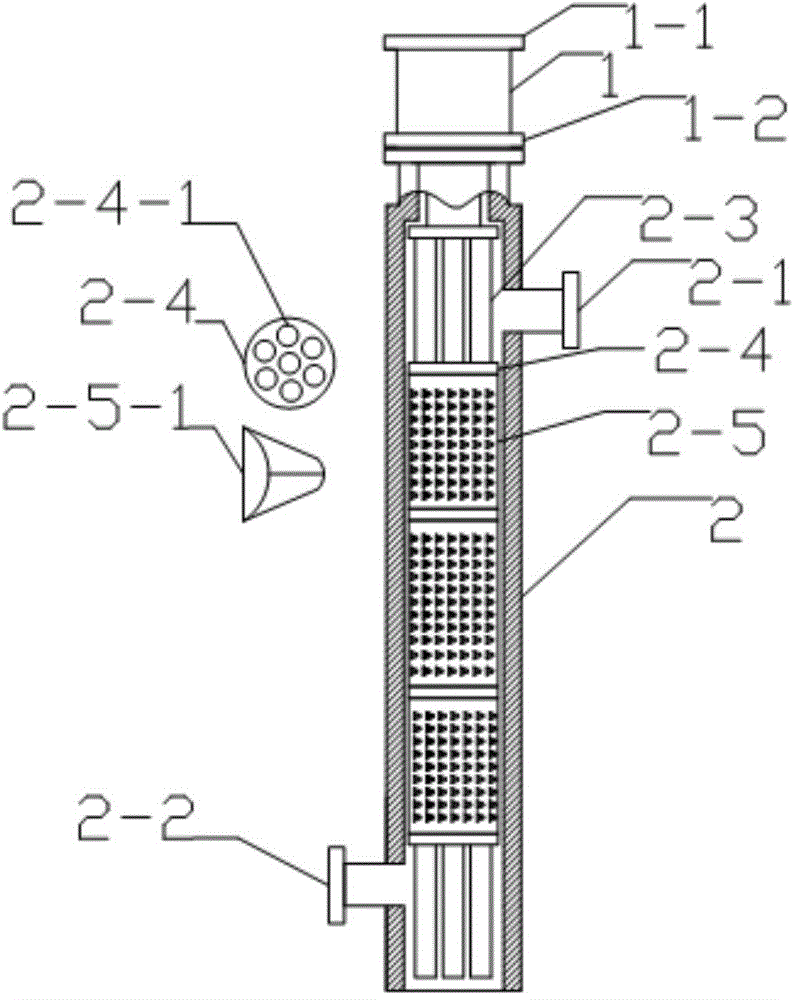

Method and structure for providing necessary preconditions for constructing river water body ecosystem

PendingCN106116061AIncrease responsivenessImprove oxidation effectWater/sewage treatment by irradiationMultistage water/sewage treatmentActivated carbonRiver water

The invention discloses a method and a structure for providing necessary preconditions for rapidly constructing a river water body ecosystem. According to the method, a rapid diffusing and mixing device capable of allowing one or a combination of more than one of soluble water and gas, flocculating agents or activated carbon to rapidly and uniformly diffuse to a specified flow section is arranged in a river in which water treatment needs to be performed; an air flotation area is formed in the rear of the river with the rapid diffusing and mixing device; a scum collection device is arranged at the tail end of the air flotation area; and a biological stuffing area is formed in the river behind the scum collection device. Therefore, the quality of river treated by the biological stuffing area is greatly improved, and preconditions can be provided for constructing the river water body ecosystem.

Owner:GUIZHOU LVCHUN ENVIRONMENT DEV CO LTD

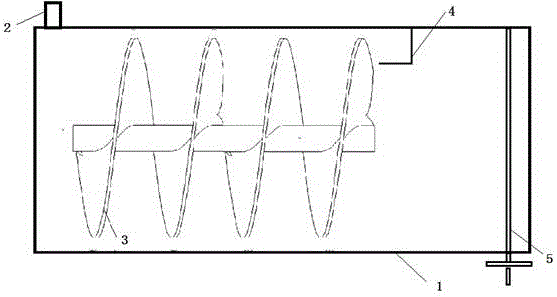

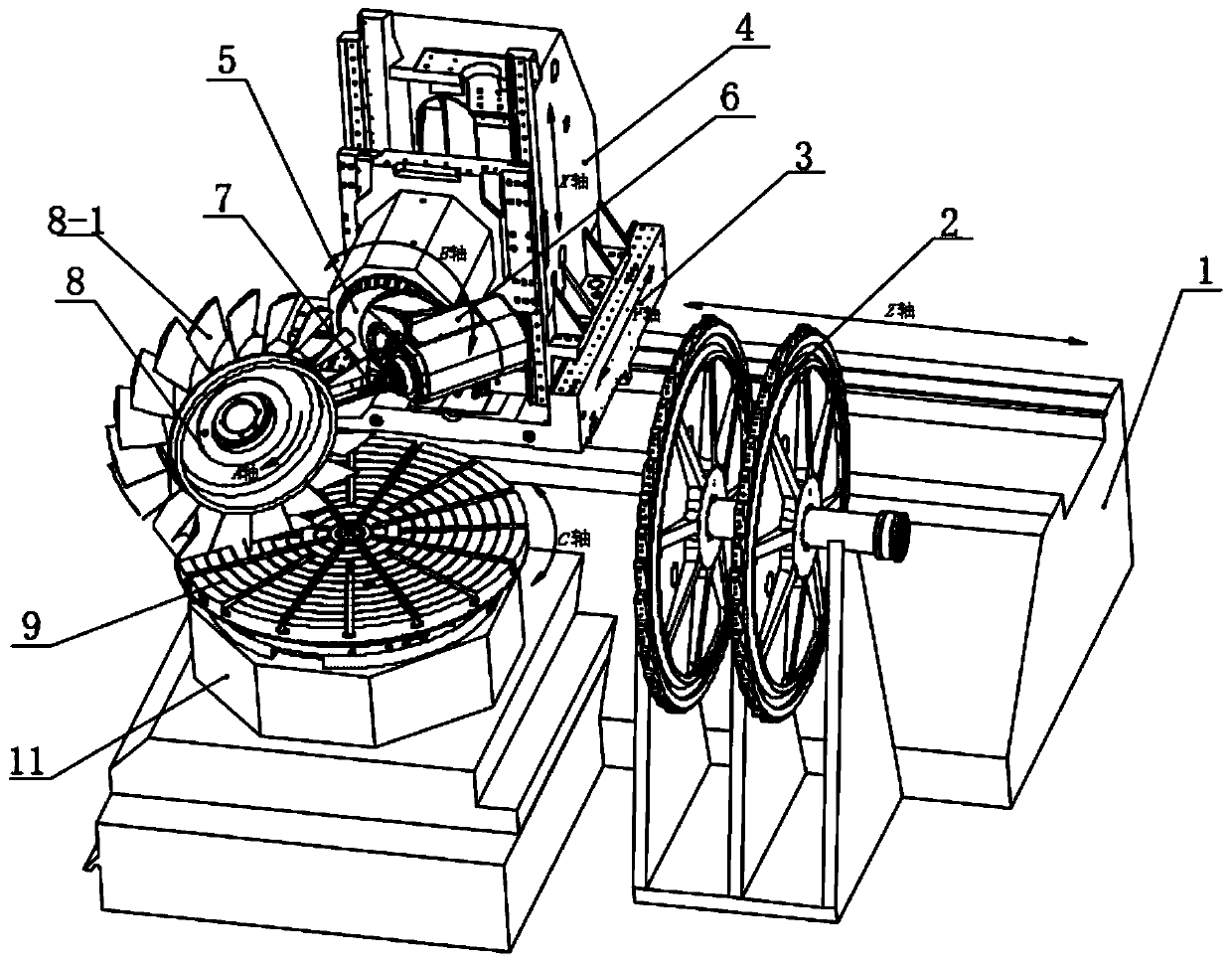

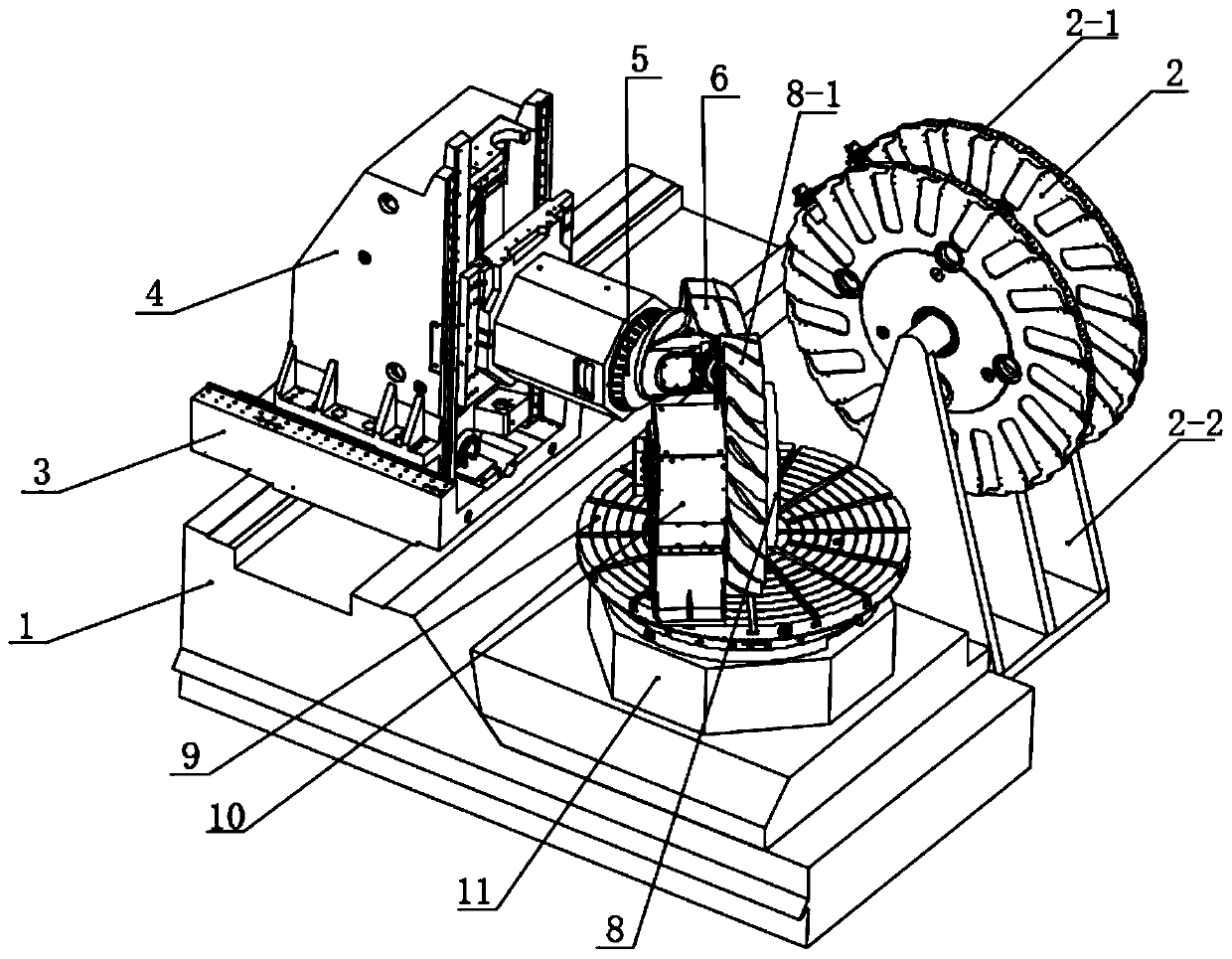

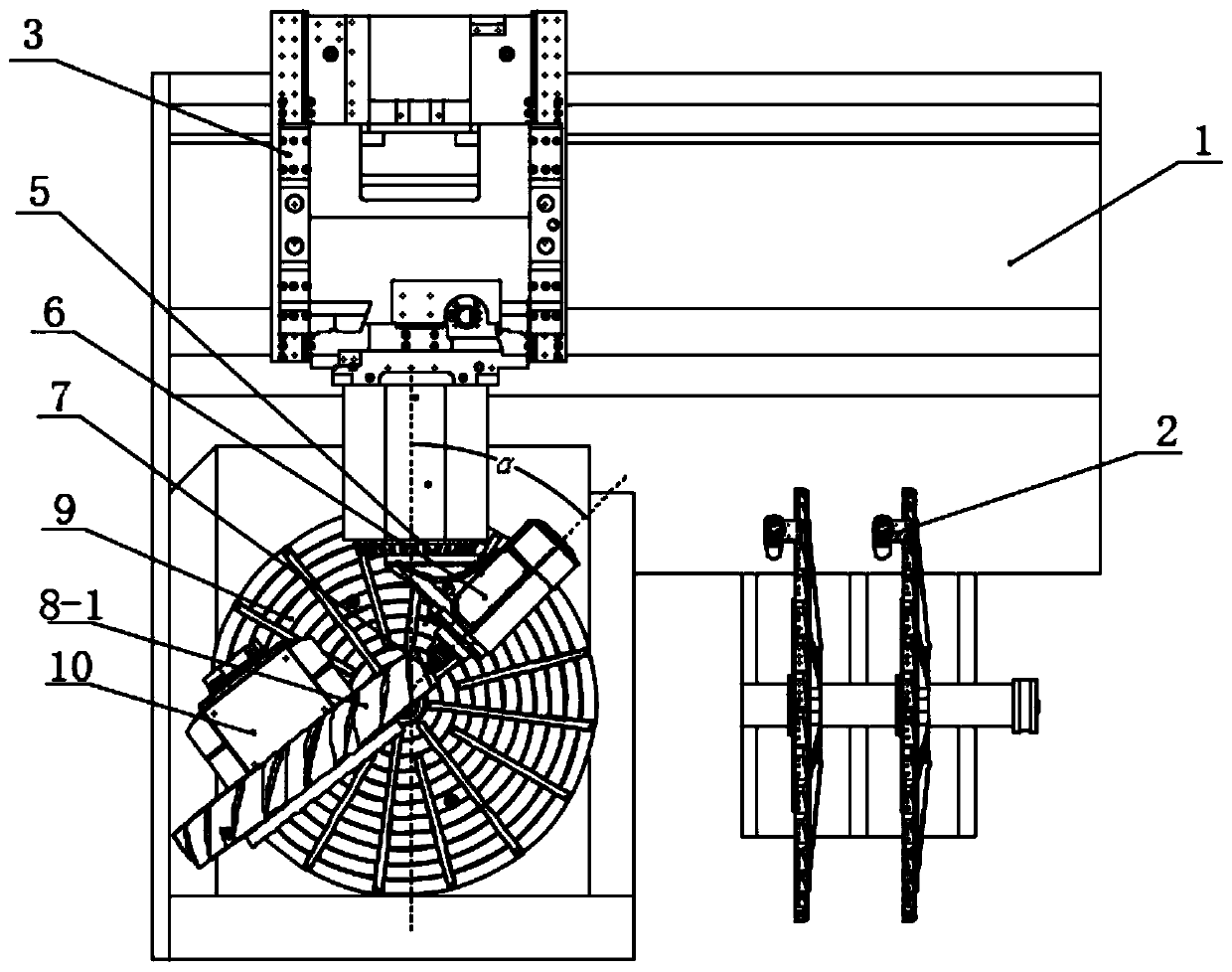

Bladed disc machining center

PendingCN111113122AGuaranteed movement speedMachine tool componentsBlade accessoriesPhysicsCentre of rotation

The invention provides a bladed disc machining center. The bladed disc machining center comprises an A-axis rotary assembly, a B-axis rotary assembly and a C-axis rotary assembly, wherein the A-axis rotary assembly drives a blade disc to do rotary motion; the B-axis rotary assembly drives an accessory head to do rotary motion, and the accessory head drives a tool to machine the bladed disc; the C-axis rotary assembly drives the A-axis rotary assembly to do rotary motion; the intersection point of the rotating axis of the B-axis rotary assembly and the rotating axis of the C-axis rotary assembly is the center of the machining area of the bladed disc; and the tool nose point of the tool is on the rotating axis of the B-axis rotary assembly. According to the bladed disc machining center, themachining area is close to the rotating center of a C-axis rotary table, and it can be guaranteed that when a machine tool conducts five-axis rotating tool center machining action, the movement speedand acceleration of all physical axes can be kept within a low range compared with those of a machine tool of a common structure.

Owner:KEDE NUMERICAL CONTROL CO LTD

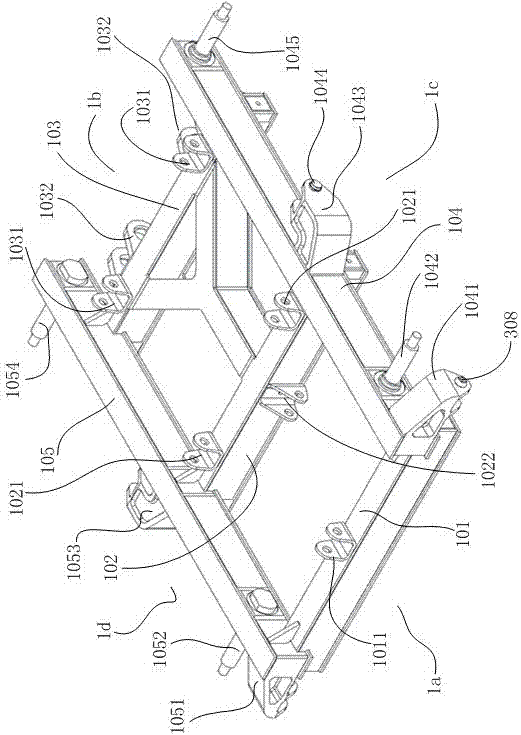

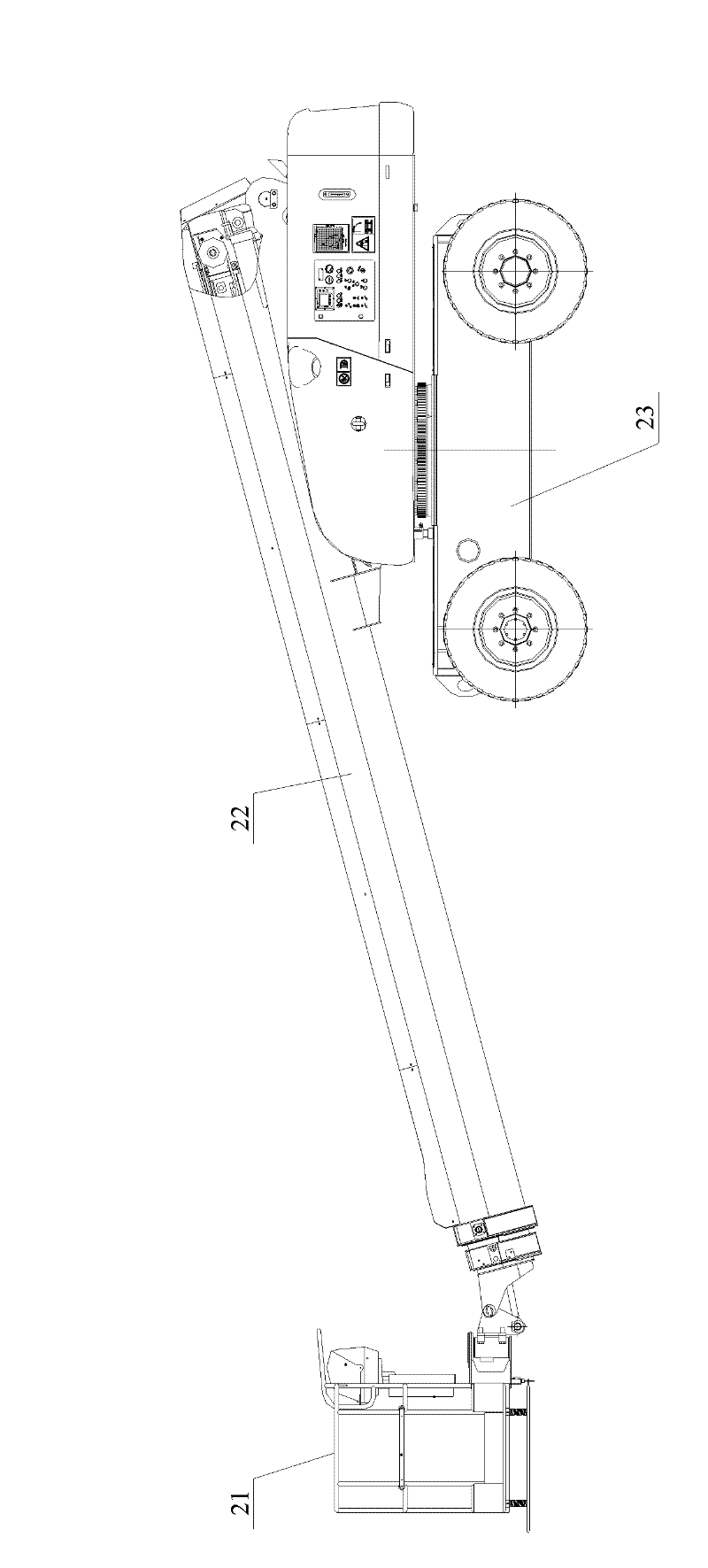

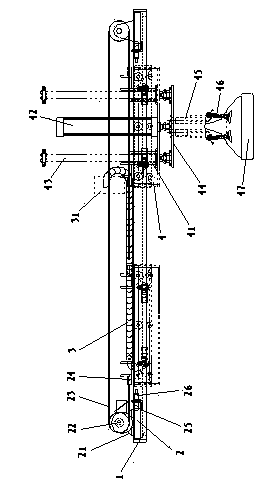

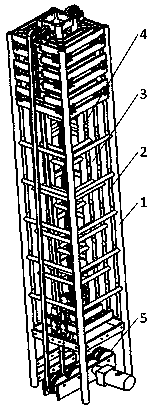

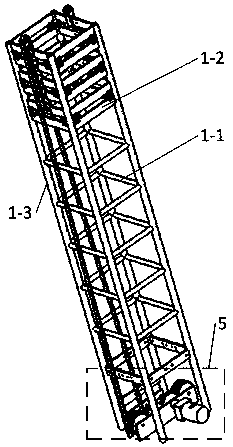

Aerial work conveying scaling ladder device

ActiveCN108910794AGuaranteed movement speedImprove efficiencyLifting devicesLinear motionComputer science

The invention discloses an aerial work conveying scaling ladder device. The aerial work conveying scaling ladder device comprises a scaling ladder mechanism and a scaling ladder driving mechanism. Thescaling ladder mechanism comprises a first-level scaling ladder, a second-level scaling ladder, a third-level scaling ladder and a fourth-level scaling ladder, wherein the first-level scaling ladder,the second-level scaling ladder, the third-level scaling ladder and the fourth-level scaling ladder are sequentially arranged in a sleeving manner. The scaling ladder driving mechanism is arranged onthe lower portion of the first-level scaling ladder. The scaling ladder mechanism is internally provided with multiple rolling wheel devices and scaling ladder hanging plates. The hanger plate hanging plates are provided with cover sleeves and rope steel rings. Transmission is achieved between the first-level scaling ladder and the second-level scaling ladder through a synchronous belt. Transmission is achieved between the second-level scaling ladder and the third-level scaling ladder as well as between the third-level scaling ladder and the fourth-level scaling ladder through flexible transmission ropes. According to the aerial work conveying scaling ladder device, the whole ascending and descending process of a scaling ladder is completed through the driving mechanism; the mechanical automation degree is high; the device is easy to operate and good in precision, the operation speed of the scaling ladder can be guaranteed, and the using efficiency of the scaling ladder is improved; amulti-level linkage ascending-and-descending structure is adopted, and the drive number and the space occupied by the scaling ladder are reduced; and long-distance linear motion is achieved so that the operation height requirement can be met.

Owner:ELECTRIC POWER RES INST OF GUANGXI POWER GRID CO LTD

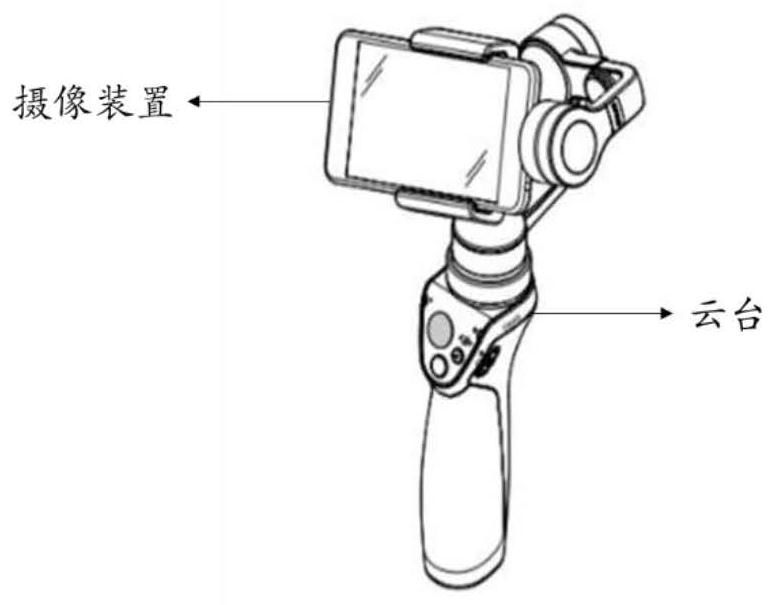

Image acquisition method, control device and movable platform

ActiveCN112514368AGuaranteed movement speedEasy to operateTelevision system detailsColor television detailsComputer graphics (images)Engineering

The invention discloses an image acquisition method, a control device and a movable platform. The method is used for collecting a target image through a camera device installed on a cradle head, and comprises the steps that exposure parameters of the camera device are determined, and the exposure parameters comprise exposure duration; determining rotation parameters of the cradle head, the rotation parameters including a rotation direction, a rotation angle and a rotation speed of the cradle head, the rotation speed being determined based on the exposure duration and the rotation angle; and controlling the holder to rotate based on the rotation parameters, and controlling the camera device to perform image acquisition based on the exposure parameters so as to obtain the target image. In the exposure process, the holder drives the camera device to have a certain motion speed, a target image with dynamic special effects such as ghost images can be automatically acquired, the operation issimple, and images with dynamic special effects such as ghost images can also be acquired for some static objects or objects with low motion speed.

Owner:SZ DJI TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com