Wheel and caterpillar band switchable mobile chassis

A mobile chassis and wheel shoe technology, which is applied in the field of mobile robots, can solve the problems of poor ground adaptability, scratches, and slow speed of wheeled chassis, and achieve the effects of ensuring movement speed and comfort, improving passing capacity, and facilitating switching

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The present invention will be further described in detail below through specific embodiments in conjunction with the accompanying drawings.

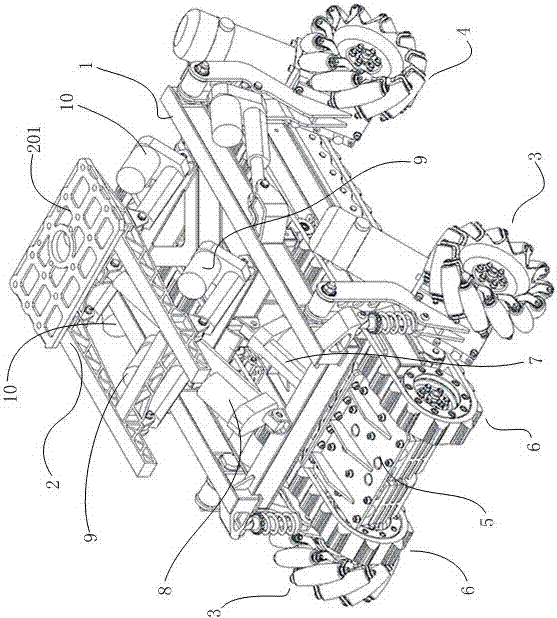

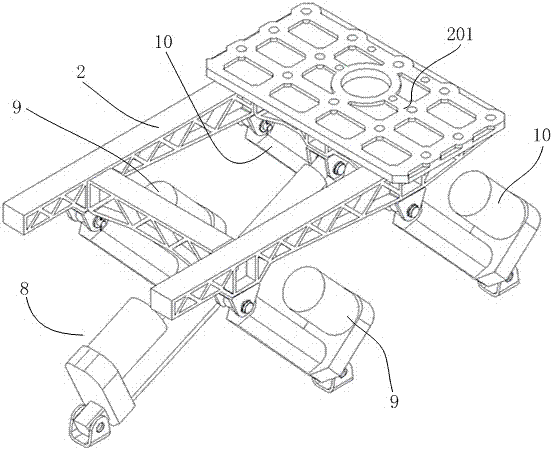

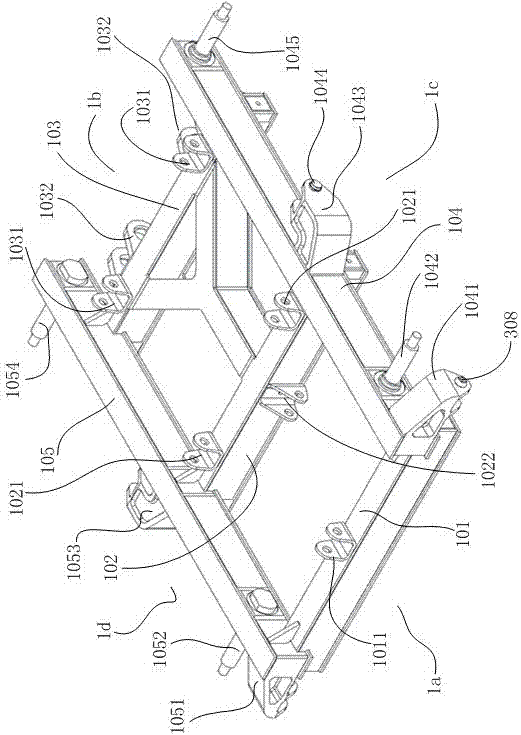

[0040] Please refer to Figure 1 to Figure 17 , the mobile chassis for wheel-shoe switching in the embodiment of the present invention, which includes a connecting seat 1; an installation platform 2 arranged on the upper end of the connecting seat 1; The set of wheeled moving parts includes a front wheel assembly 3 arranged near the front end 1a of the connecting seat, and a rear wheel assembly 4 arranged near the rear end 1b of the connecting seat. In order to weaken the vibration amplitude of the installation platform 2, the front wheel assembly 4 A shock absorber 301 is also connected between the wheel assembly 3 and the connecting seat 1, and the rear wheel assembly 4 can be stowed or lowered relative to the connecting seat 1; The crawler moving part includes a support body 5 and two crawler belt assemblies 6 arranged on both...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com