Platform for detecting thickness of large-size wafer

A technology of wafer thickness and detection platform, applied in measurement devices, optical devices, mechanical measurement devices, etc., can solve problems such as inconvenience and high cleanliness requirements, cumbersome installation, etc., to ensure X-direction accuracy and movement speed. , the effect of simple maintenance, reducing the difficulty of processing and debugging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

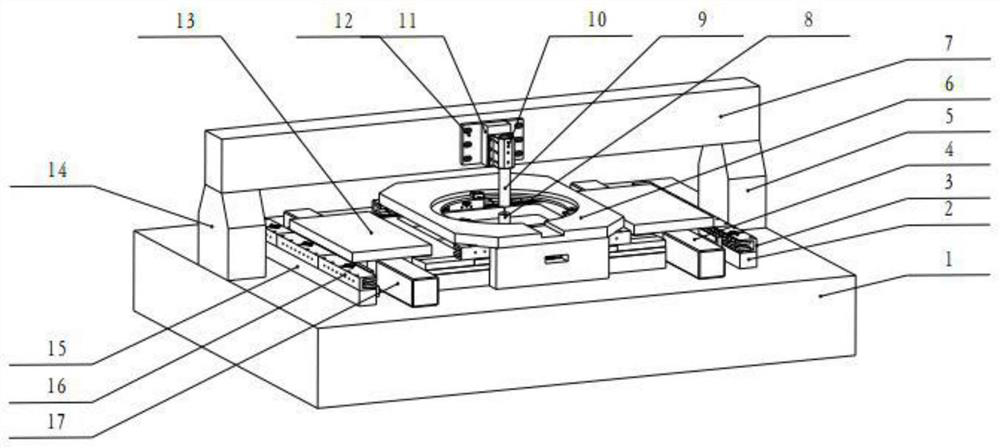

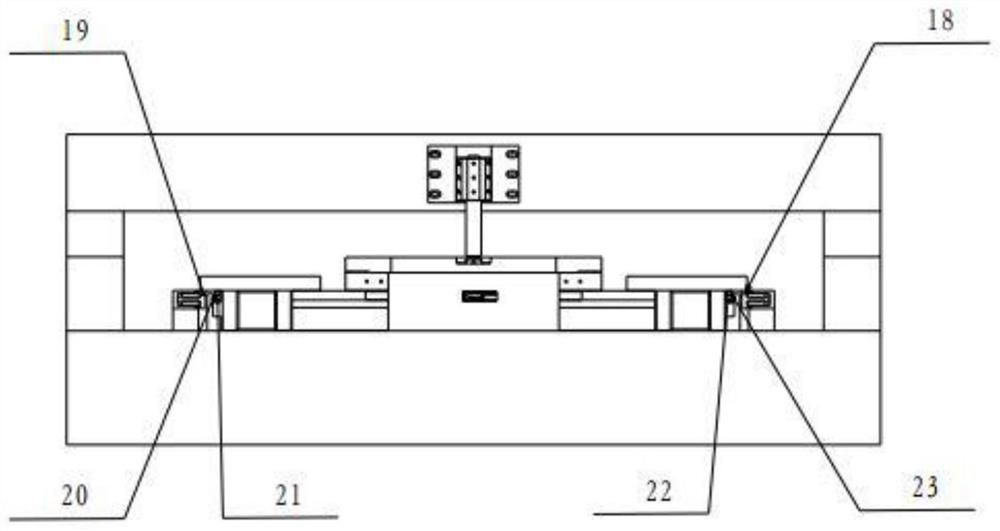

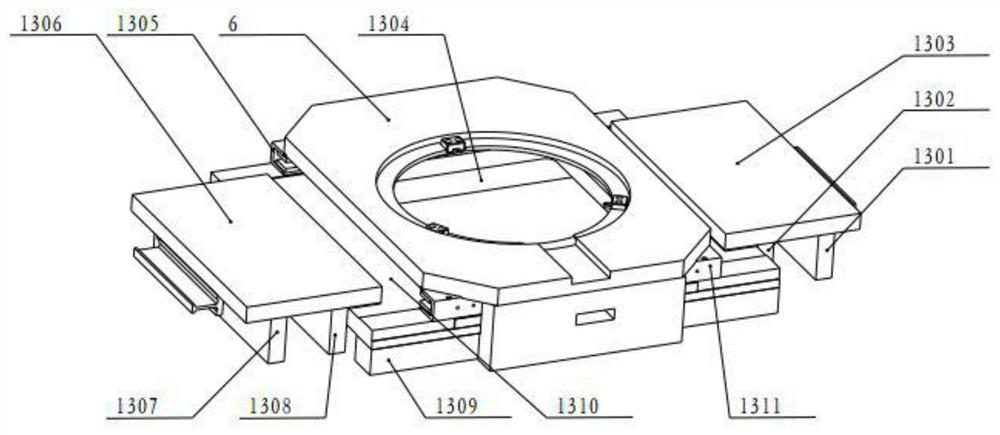

[0034] like Figure 1-5 It can be seen that the present invention includes: marble base (1), Y1 direction marble guide rail (4), Y2 direction marble guide rail (17), Y direction grating reading device and X direction grating reading device;

[0035] A pair of Y1 to marble guide rails (4) and Y2 to marble guide rails (17) arranged in parallel are installed on the marble base (1), and the Y1 to marble guide rails (4) and Y2 to marble guide rails (17) respectively A Y1-direction slider and a Y2-direction slider are provided, and a Y1-direction motor stator connector (2) and a Y2-direction motor stator connector (15) are provided on the outer surface, and the Y1-direction slider and the Y2-direction slider are both Equipped with a Y-direction grating reading device,

[0036] The Y1-direction slider and the Y2-direction slider are connected by a Y-direction beam (1310) to form a Y-direction overall slider, and the outer surfaces of the Y1-direction slider and the Y2-direction slid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com