Determination method for inherent frequency of rotor-blade coupled system

A technology for coupling systems and determining methods, applied in special data processing applications, instruments, electrical digital data processing, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0143] An embodiment of the present invention will be further described below in conjunction with the accompanying drawings.

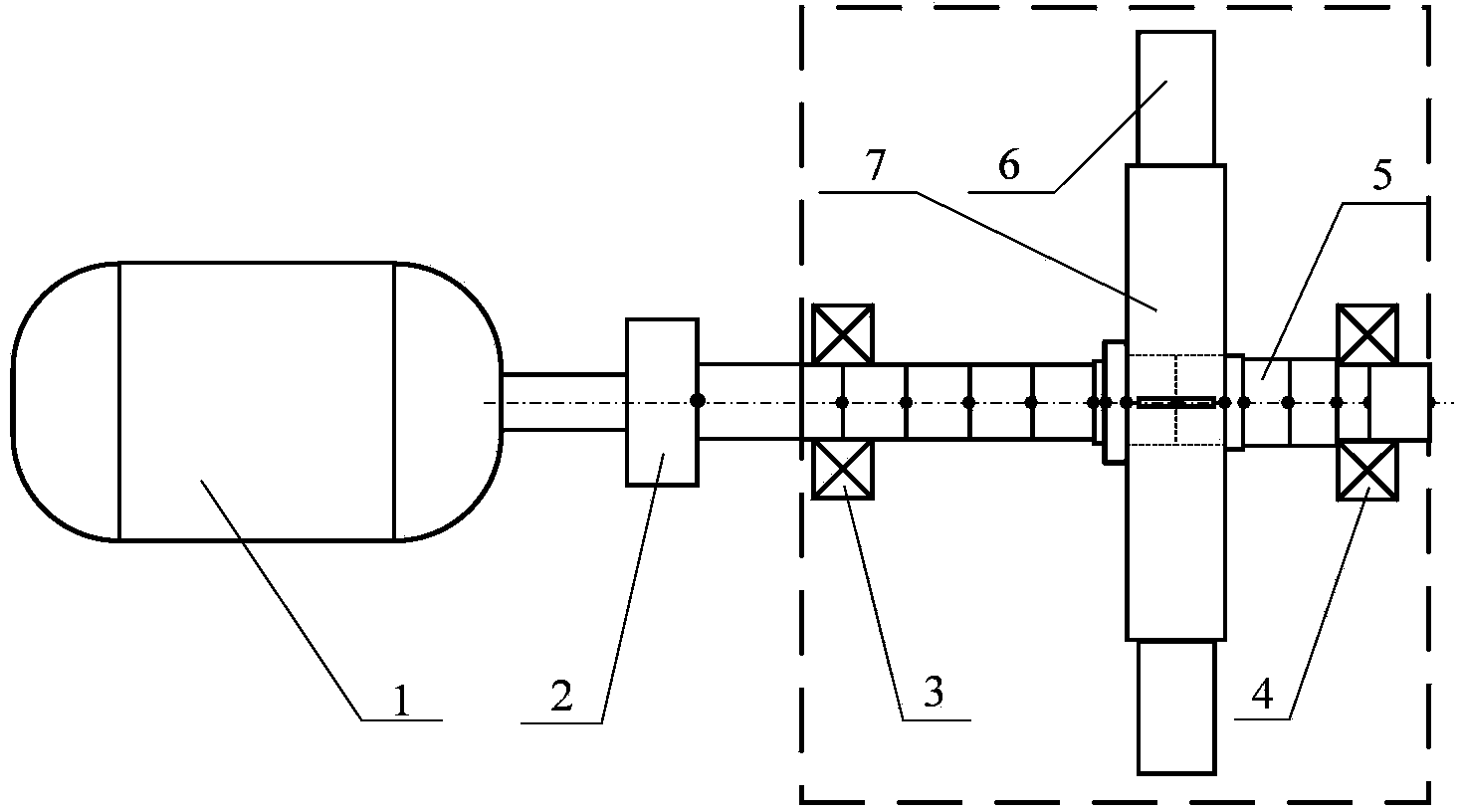

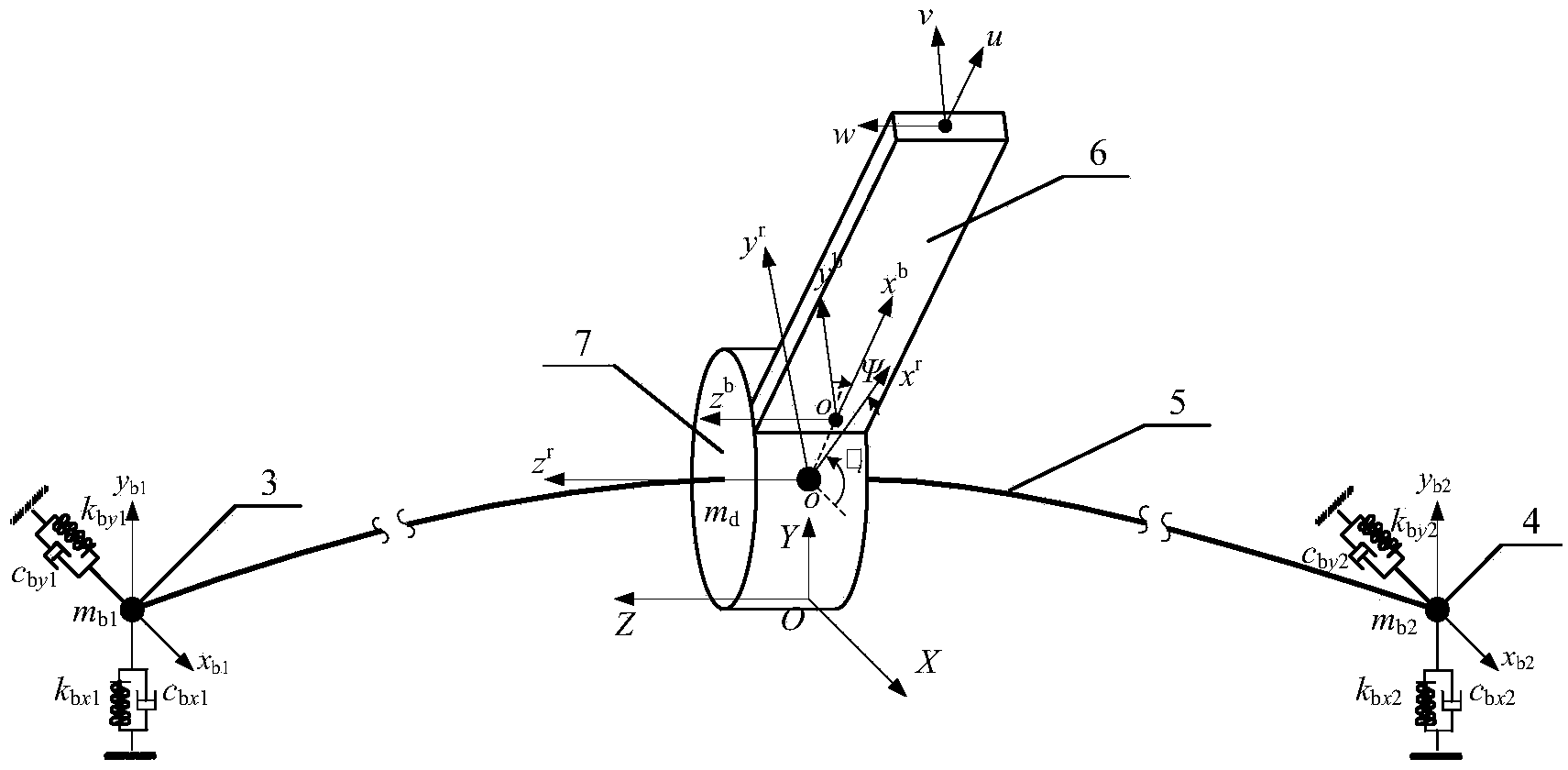

[0144] In the embodiment of the present invention, the system test bench such as figure 1 As shown, 1 indicates the motor (model YVP100L2-3), 2 indicates the elastic coupling (model YLD7), 3 indicates the left bearing, 4 indicates the right bearing, 5 indicates the stepped shaft, 6 indicates the disc and 7 indicates the blade. The geometric parameters of the shaft are shown in Table 1. The radius and thickness of the disk are 140mm and 58mm, respectively. The length, width and thickness of the blades are 82mm, 44mm and 3mm, respectively. The material parameters of rotor and blade are: Young's modulus E=200GPa, density ρ=7800kg / m 3 and Poisson's ratio υ = 0.3. The two ball bearings are identical, both simulated by linear springs and dampers, ignoring cross-coupling terms, and the horizontal and vertical rigidities are assumed to be k bx1 =k by1 =k...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com