Radially-adjustable heavy-duty cutting layer milling cutter

An adjustable and heavy-duty technology, applied in the direction of milling cutting blades, milling cutters, milling machine equipment, etc., can solve the problems of affecting processing efficiency, long processing cycle, and cutting teeth cannot all participate in cutting, so as to improve surface processing quality and improve cutting Edge strength and the effect of improving the metal removal rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

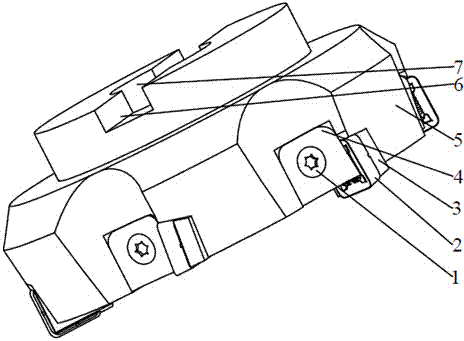

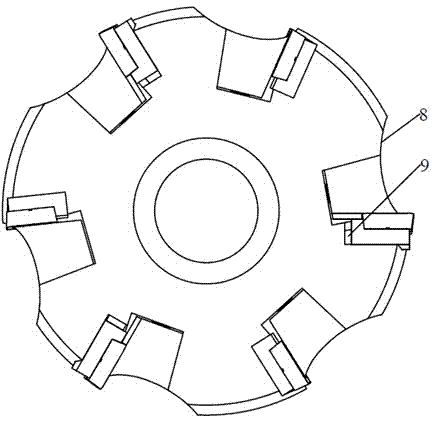

[0035] Specific implementation mode one: as Figure 1-Figure 7 As shown, a radially adjustable heavy-duty layer cutting milling cutter, the unequal-angle cutter body 5 of the cutter is connected with the main shaft of the machine tool through the center hole 7, and the keyway 6 is used to connect with the main shaft of the machine tool and transmit torque. The blade mounting grooves 11 of the cutter are arranged at different distances on the outer wall of the cutter body to increase the natural frequency of the cutter body, change the period of the milling force, suppress the vibration during milling, reduce the probability of cutter damage and improve the surface processing quality. The teeth of the milling cutter adopt a stepped distribution design, and a 3mm-high step block 12 is provided in the blade installation groove 11 of the unequal angle cutter body 5, and 6 blades 2 are installed on the unequal angle cutter body 5, and the blades 2 become Unequal angle distribution,...

specific Embodiment approach 2

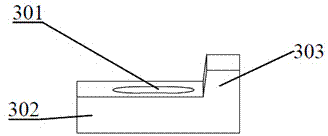

[0036] Specific implementation mode two: combination figure 1 , Image 6 Explain that in this embodiment, the main and secondary cutting edges of the blade 2 have a structural design to strengthen the strength of the cutting edge, improve the strength of the cutting edge, and can shunt chips at the same time, and a spherical shape is provided near the main and negative cutting edges. The protrusion reduces the wear of the tip and improves the service life of the blade.

specific Embodiment approach 3

[0037] Specific implementation mode three: combination figure 1 , Figure 4Note that when the layer cutting milling cutter in this embodiment cuts the head of the water chamber, the diameter of the layer cutting milling cutter is 125 mm, the cutter adopts 75° and 90° entering angles, and the layer cutting milling cutter adopts 90° entering angle, During milling, the main and auxiliary cutting edges of the tool participate in the cutting at the same time, which improves the utilization rate of the tool and thus improves the processing efficiency. If a machine tool with a smaller power is used, a 75° lead angle can be used to reduce the axial force. The undisclosed technical features in this embodiment are the same as those in the first embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com