Pretensioned prestressing composite girder and method for producing the same

A production method, pretensioning technology, applied in the processing of building materials, structural elements, building components, etc., can solve the problems of high cost, poor seismic performance, inability to pass through pipelines, etc., to reduce building height and vibration comfort Good, the effect of speeding up the construction progress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

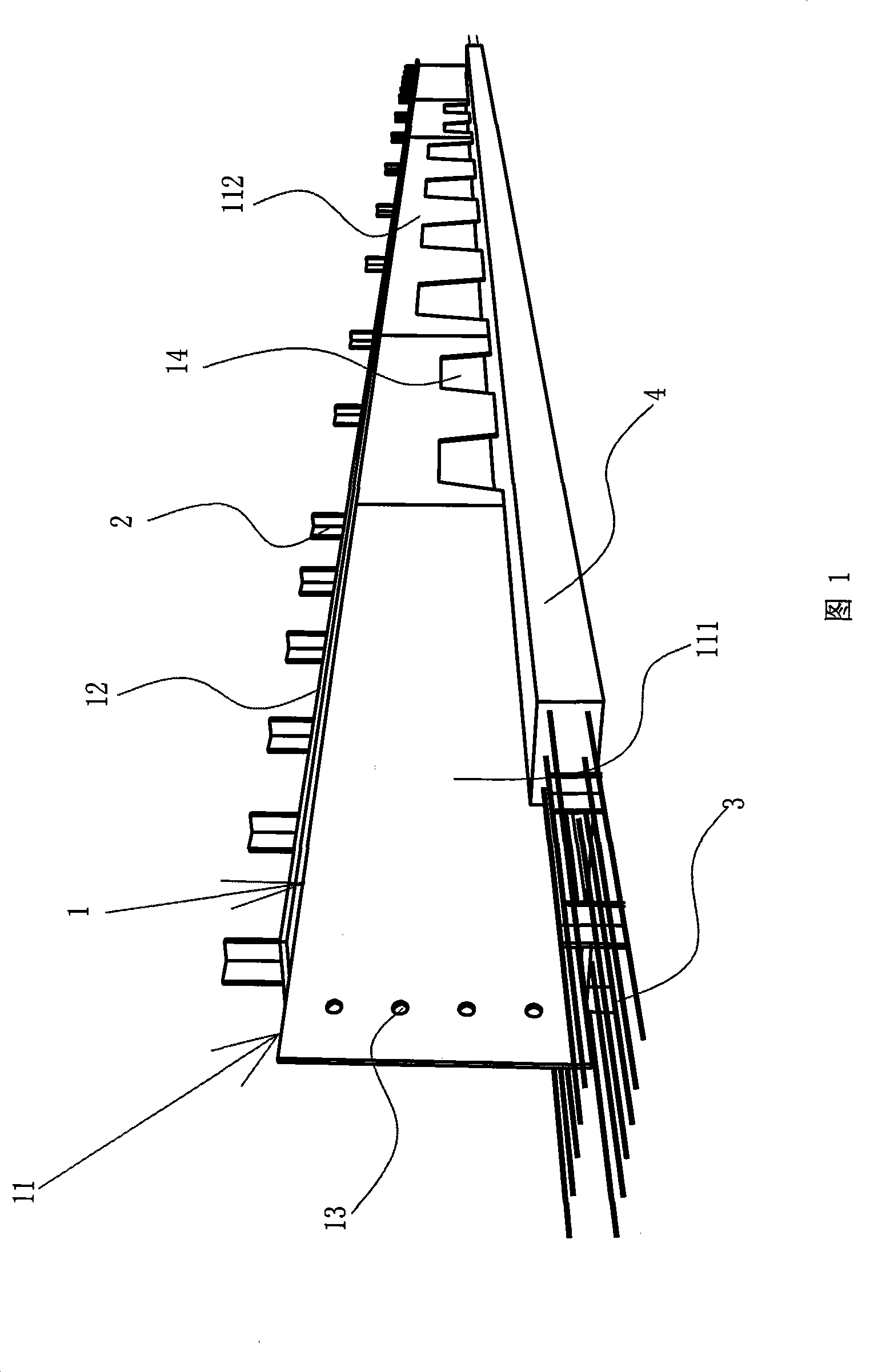

[0039] 1. Pretensioned prestressed composite beam

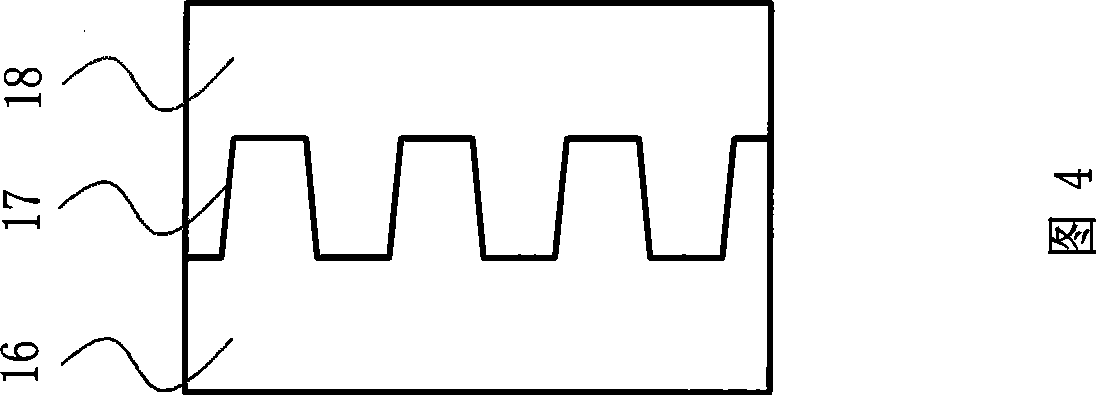

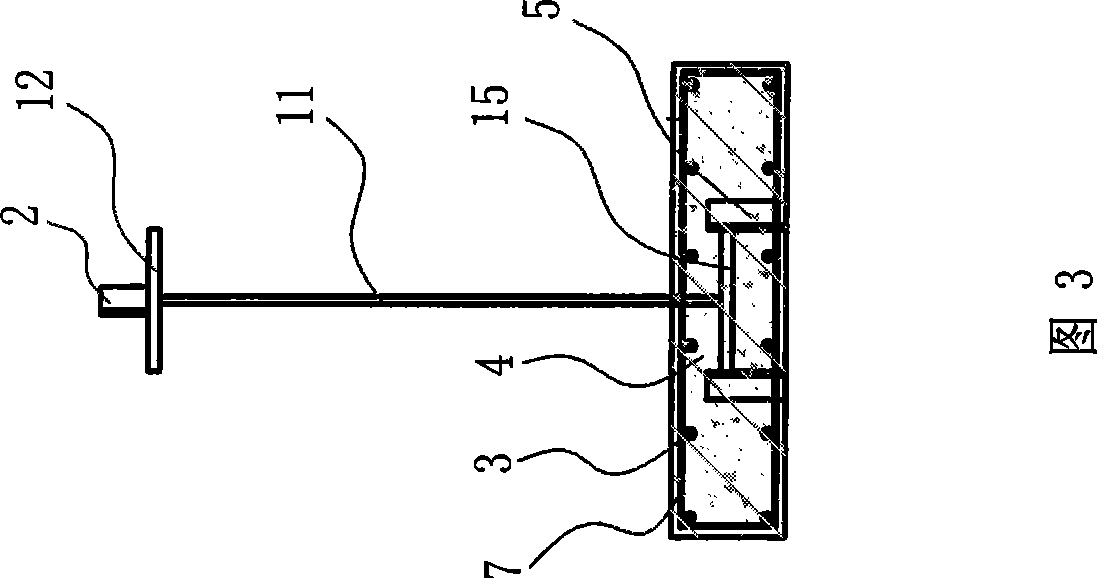

[0040] The pretensioned prestressed composite beam is an I-shaped beam composed of H-shaped steel 1 and concrete. The web 11 of the H-shaped steel is provided with trapezoidal holes 14 at intervals, and the size of several trapezoidal holes in the middle of the web is relatively large. Several trapezoidal holes on both sides of these trapezoidal holes are relatively small in size, bolt holes 13 are opened at both ends of the web, and shear nails are welded on the upper and lower flanges of the H-shaped steel. The shear nails are angle steel and channel steel. Or studs, the lower flange 15 of the H-shaped steel is surrounded by concrete to form a steel-concrete lower flange 4, the steel-concrete lower flange is a steel-concrete lower flange with a rectangular or polygonal cross section, and the steel-concrete lower flange Prestressed steel strands 3 are buried in the pretensioning method, and the two ends of the steel strands ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com