Patents

Literature

138results about How to "Lower floor height" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

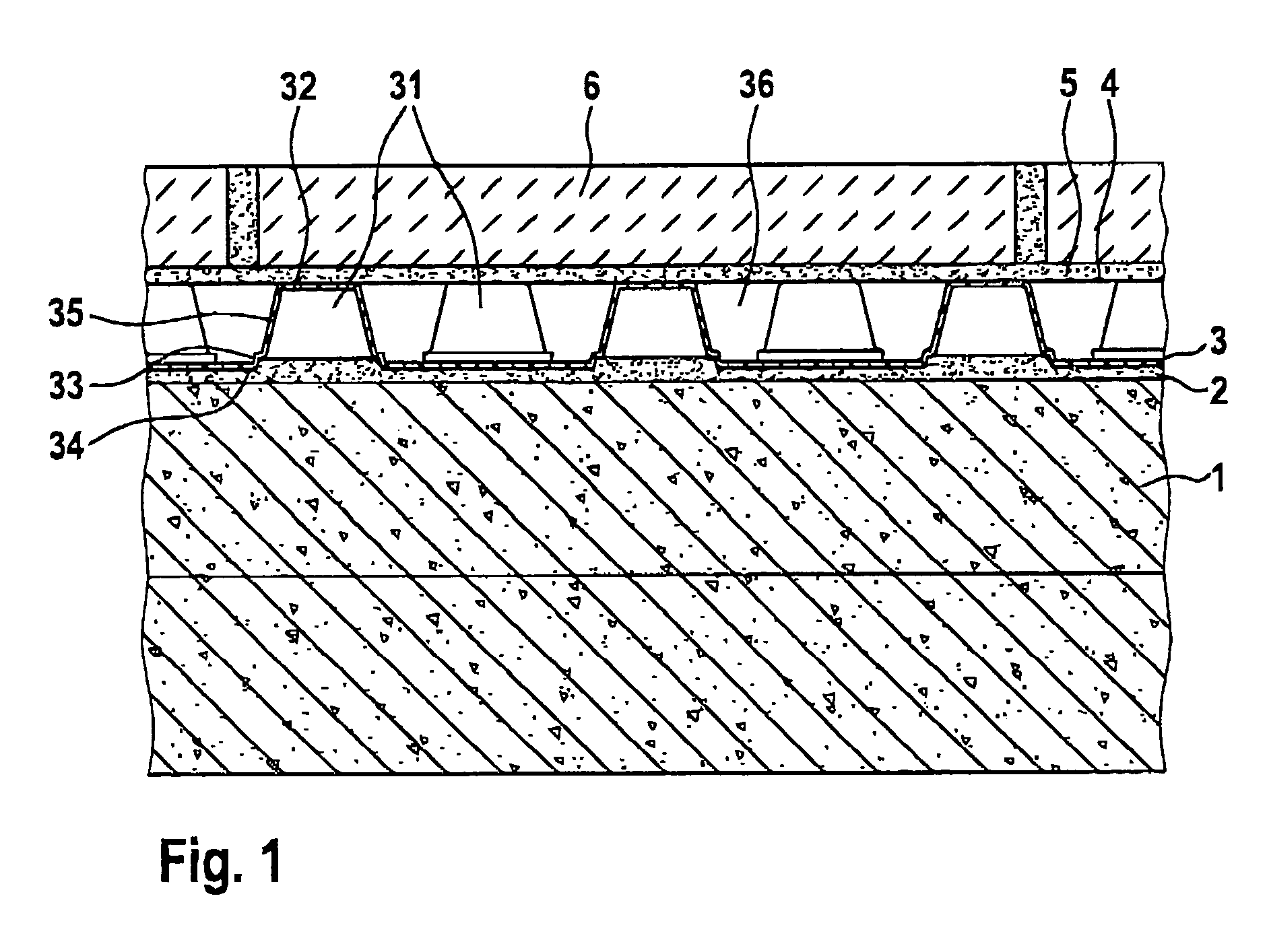

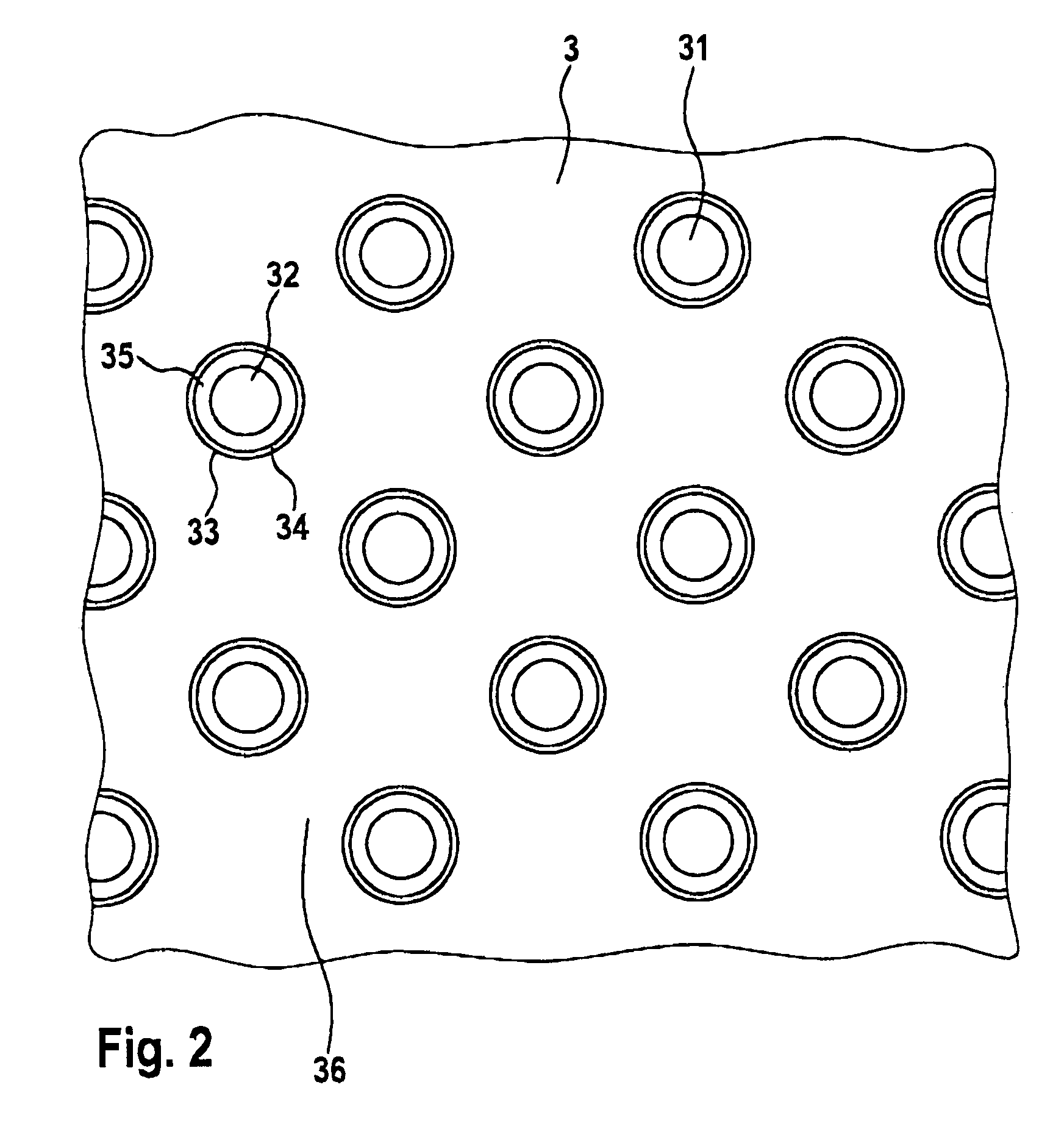

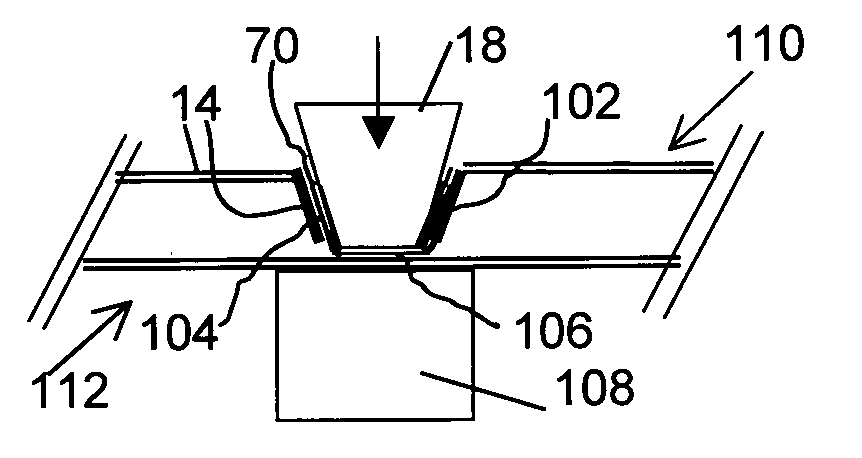

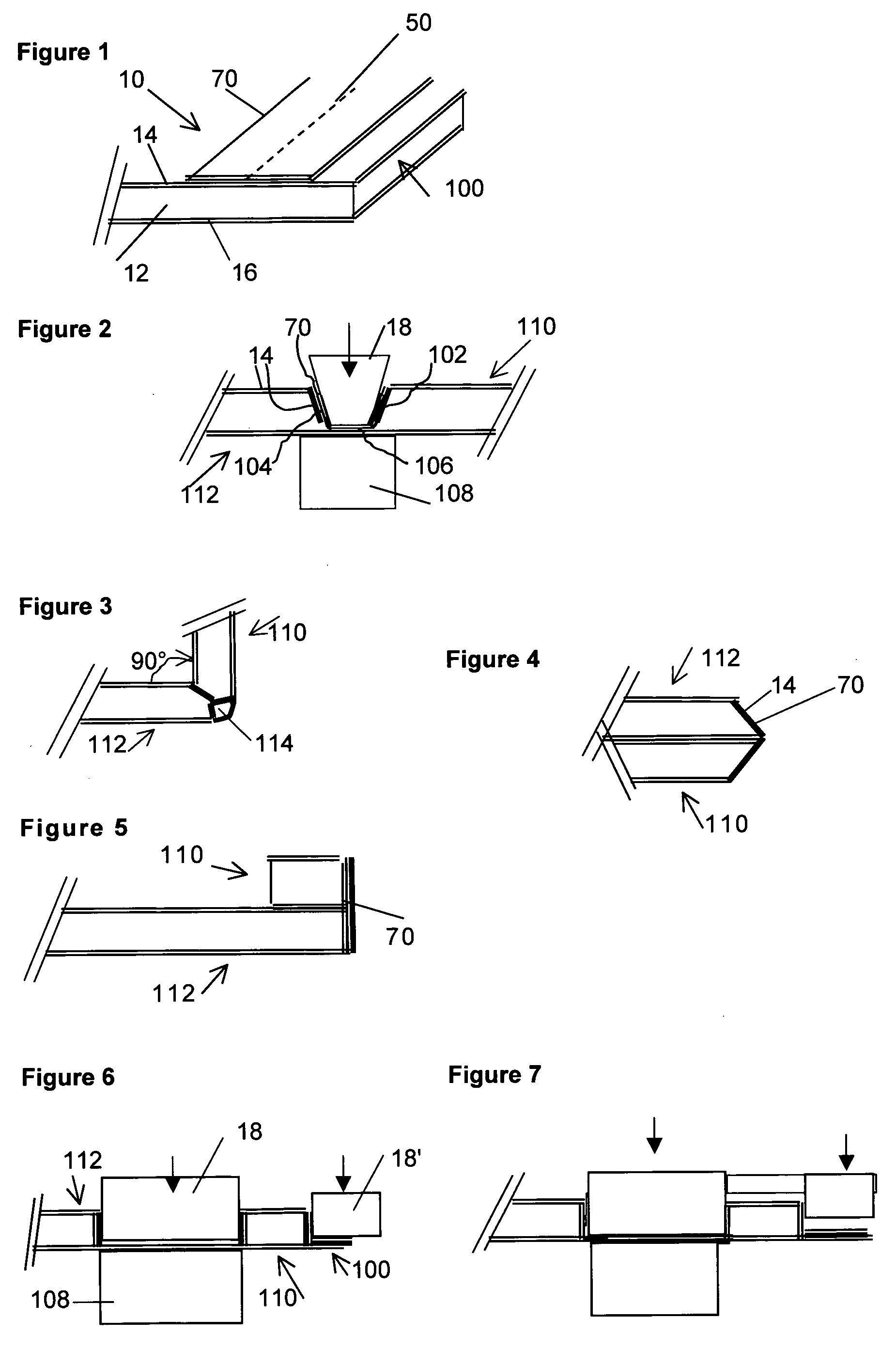

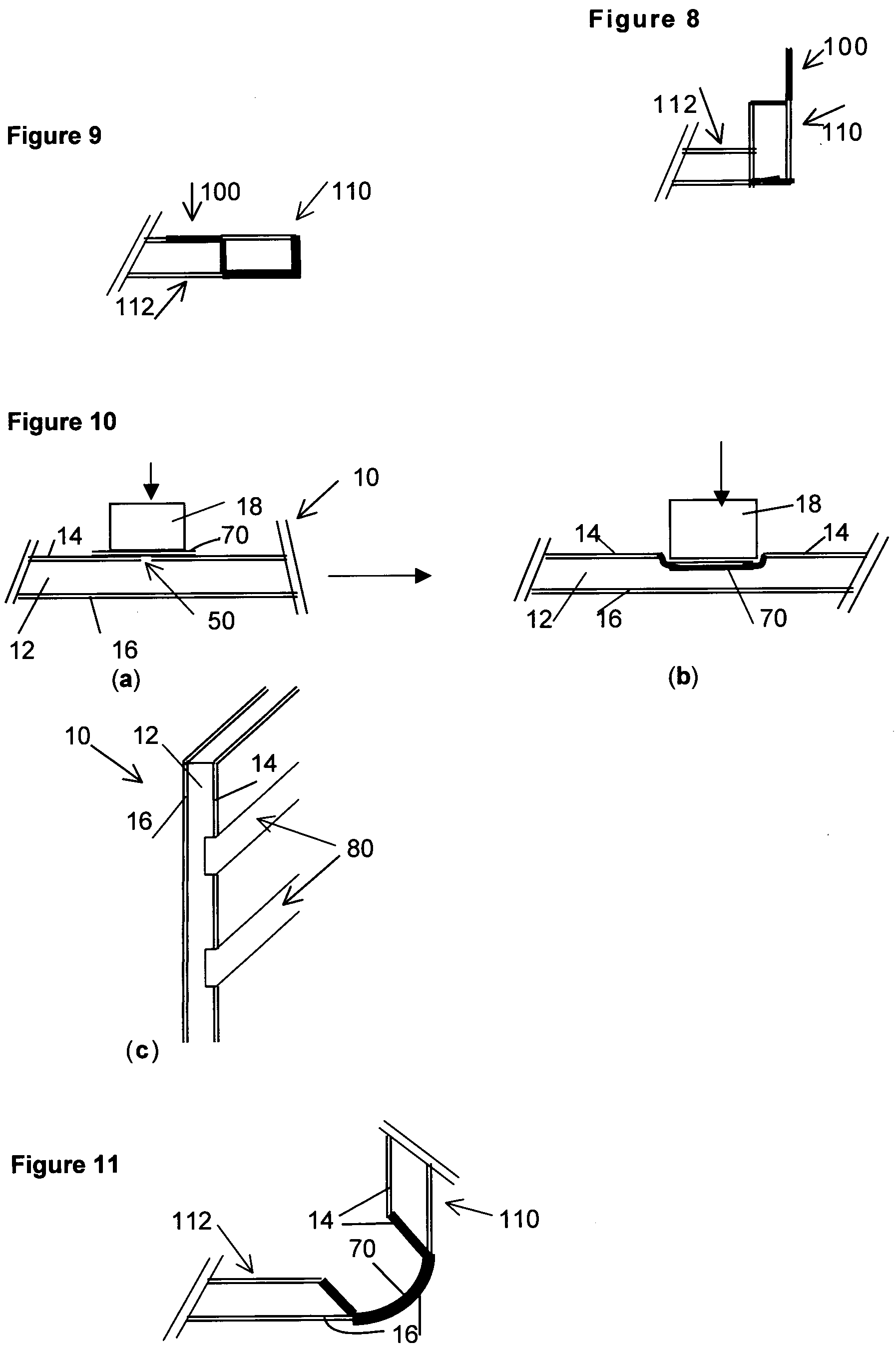

Floor construction covered with ceramic tiles

ActiveUS20060260233A1Reduce the overall heightSufficient load distributionCovering/liningsFloorsOpen waterBrick

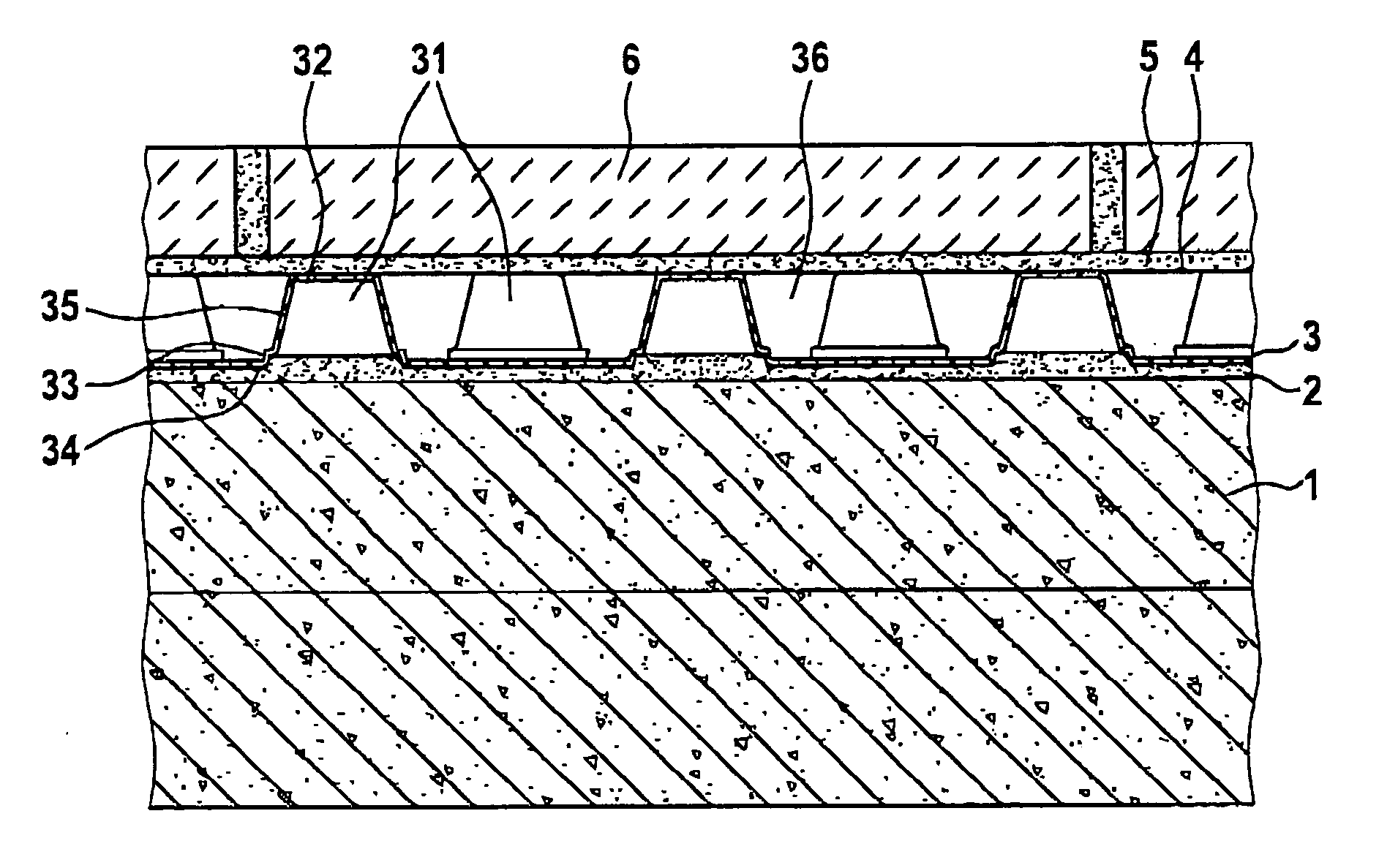

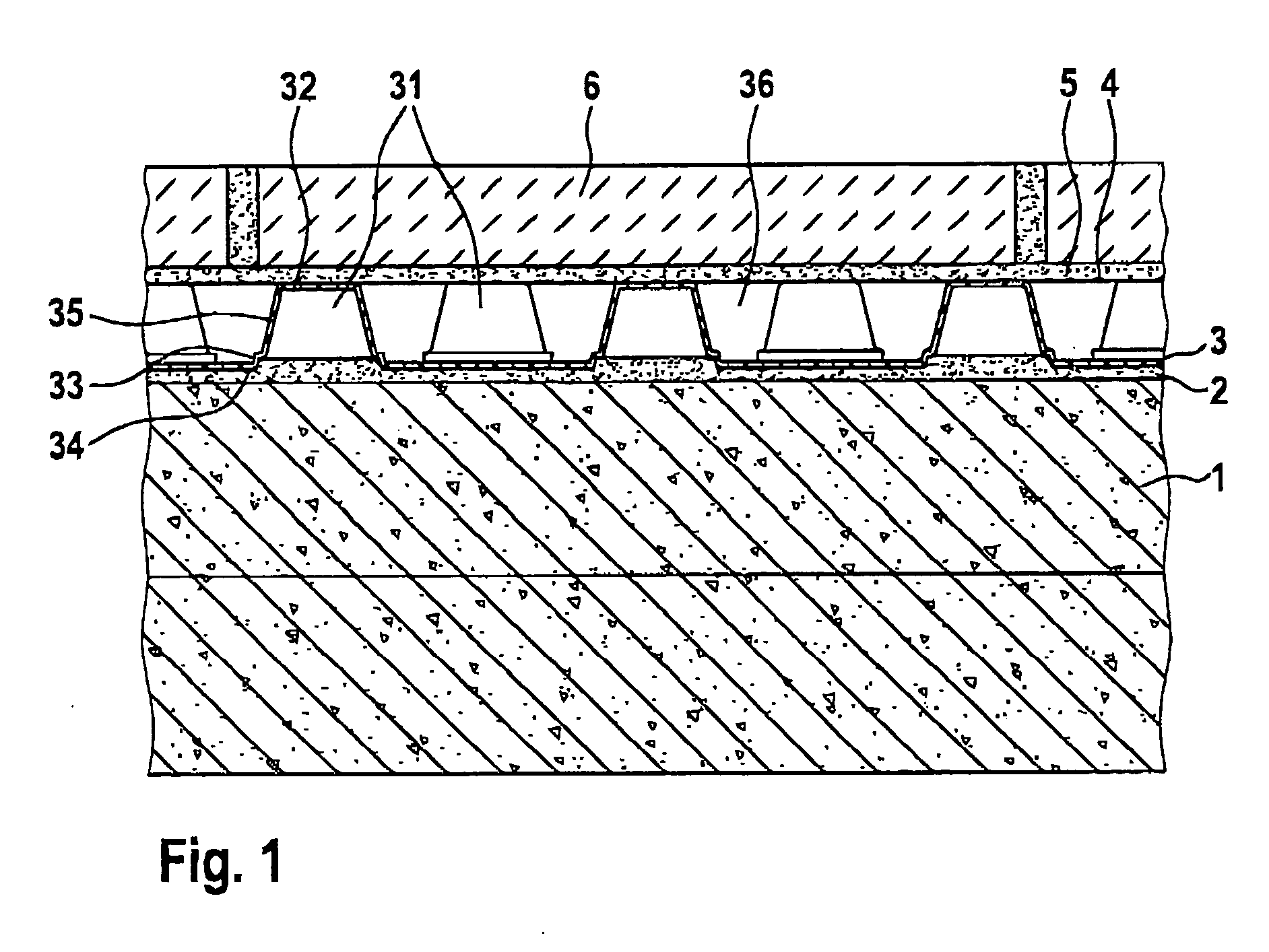

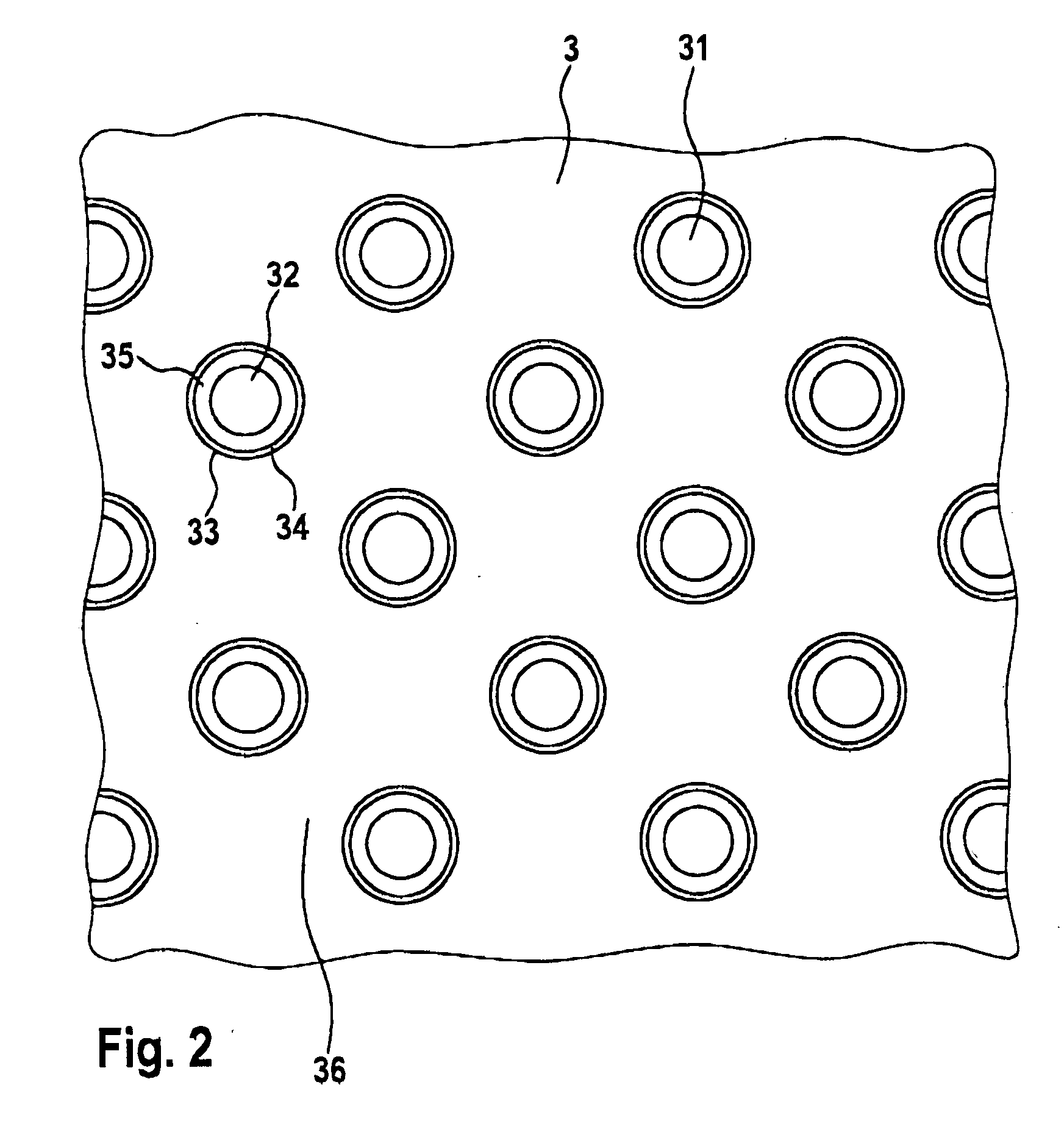

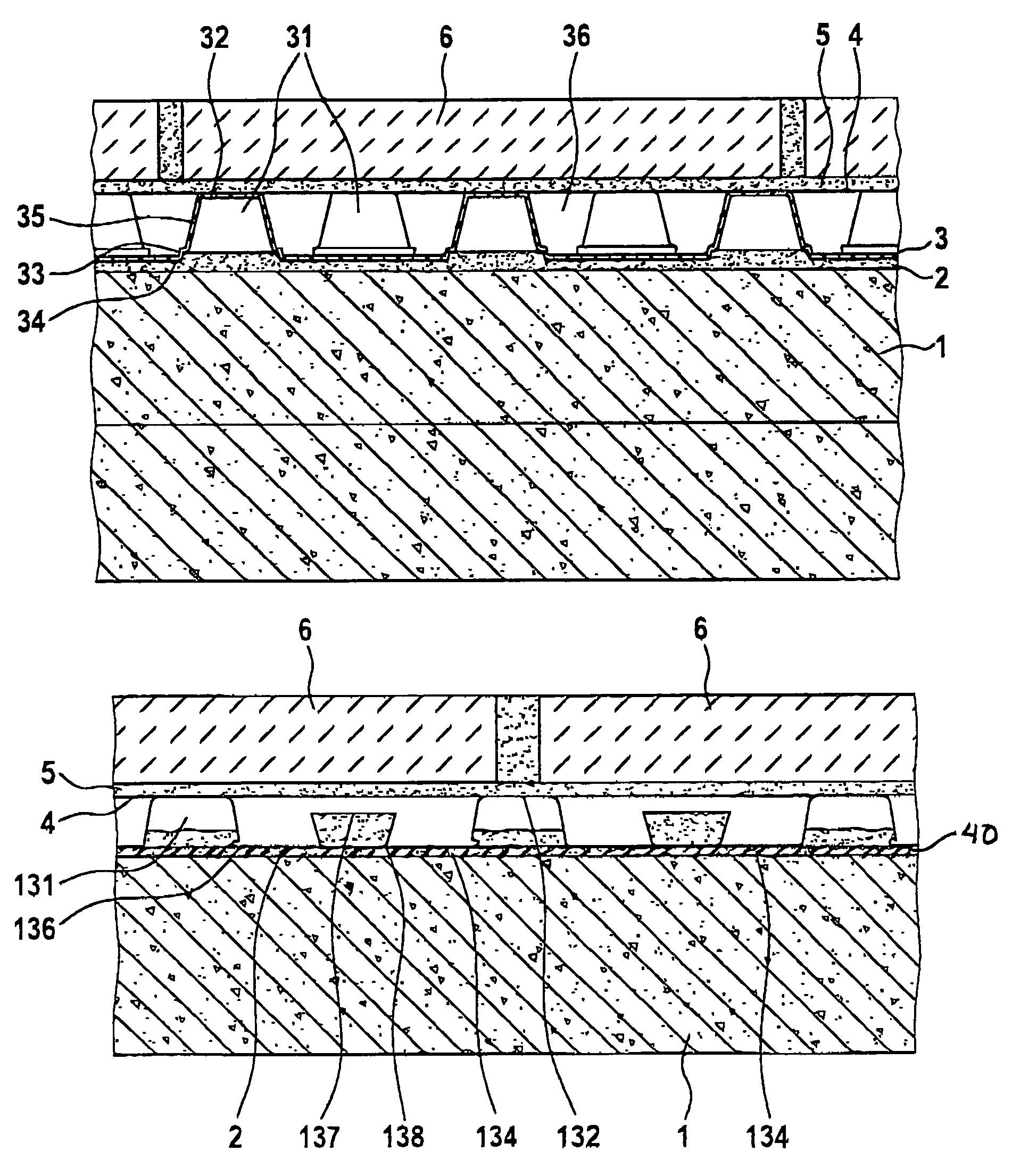

A floor construction covered with ceramic tiles, in which a film-like plastic mat having support elements disposed in a uniform area distribution, hollow towards the underside, capable of support, projecting out beyond the top of the mat, is applied on the sub-floor. Channels carrying open water are formed between the support elements, and a water-permeable or vapor-permeable covering in the manner of a non-woven fabric or woven fabric is disposed on the support elements. The plastic mat is embedded and attached, supported in a still soft, hardening thin-bed mortar layer on the sub-floor, over its full area, in the region of its lower contact surfaces. The ceramic tiles are laid and attached on the covering in the manner of a non-woven fabric, directly, with a thin-bed mortar layer.

Owner:SCHLUTER SYST LP

Floor construction covered with ceramic tiles

A floor construction covered with ceramic tiles, in which a film-like plastic mat having support elements disposed in a uniform area distribution, hollow towards the underside, capable of support, projecting out beyond the top of the mat, is applied on the sub-floor. Channels carrying open water are formed between the support elements, and a water-permeable or vapor-permeable covering in the manner of a non-woven fabric or woven fabric is disposed on the support elements. The plastic mat is embedded and attached, supported in a still soft, hardening thin-bed mortar layer on the sub-floor, over its full area, in the region of its lower contact surfaces. The ceramic tiles are laid and attached on the covering in the manner of a non-woven fabric, directly, with a thin-bed mortar layer.

Owner:SCHLUTER SYST LP

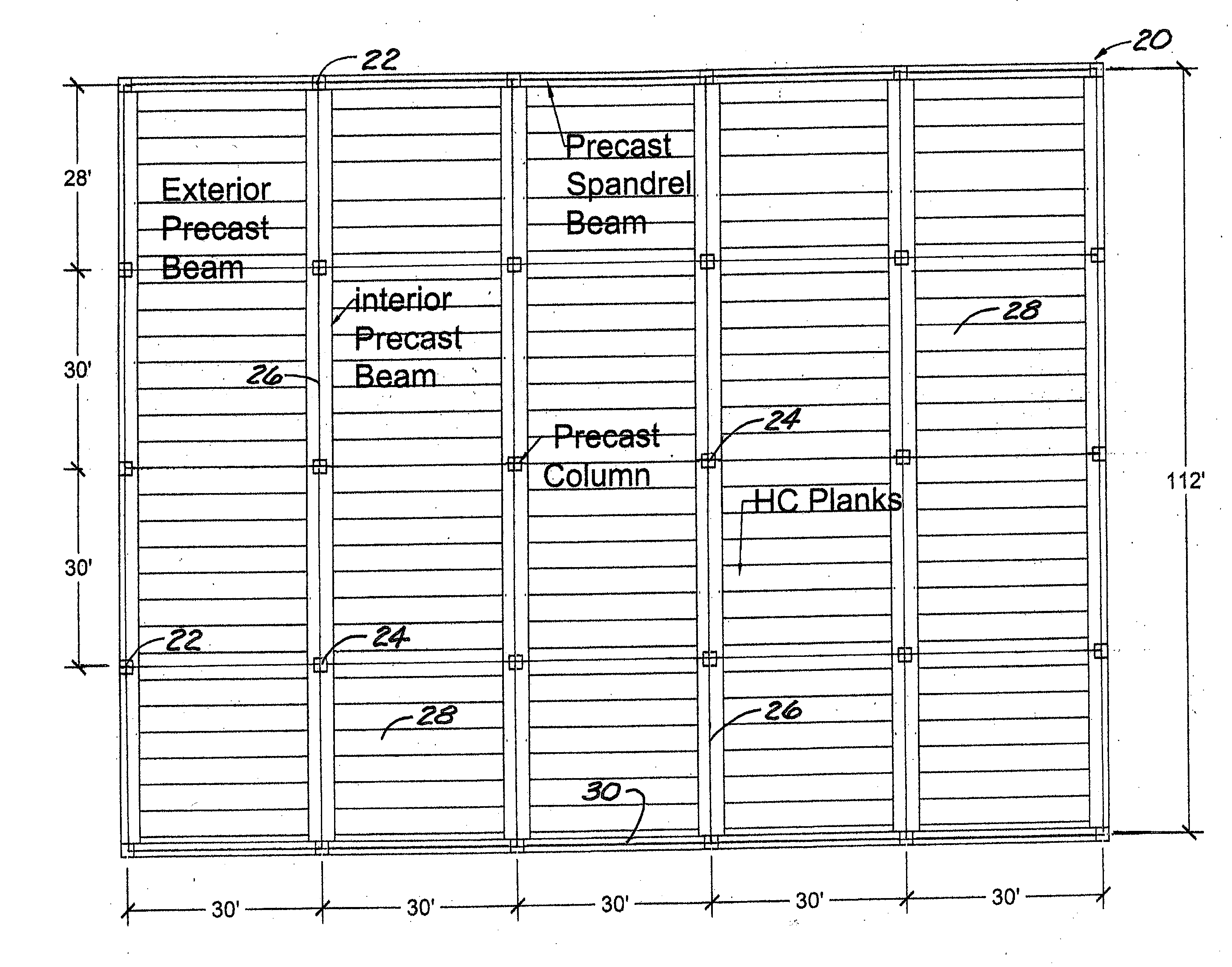

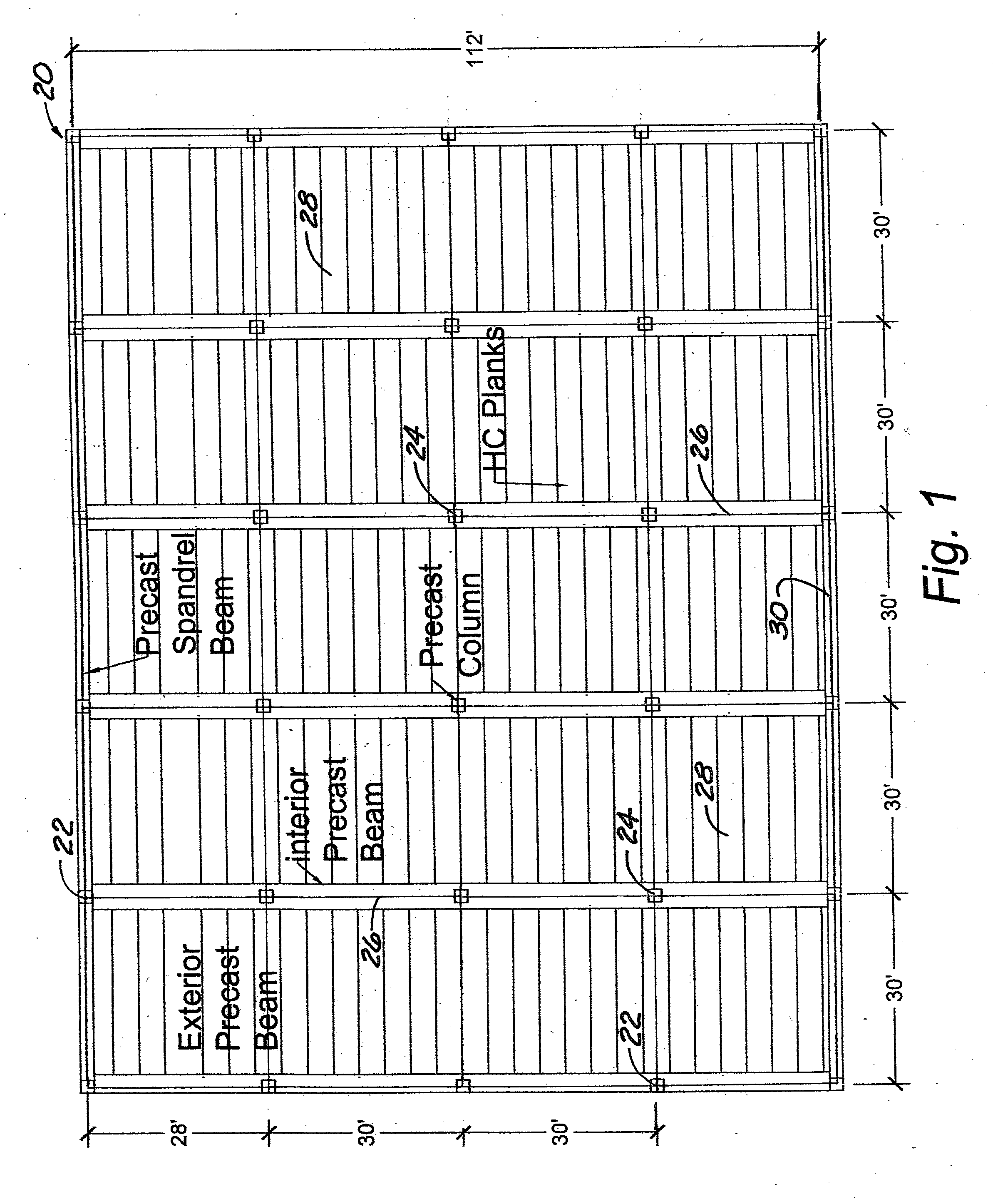

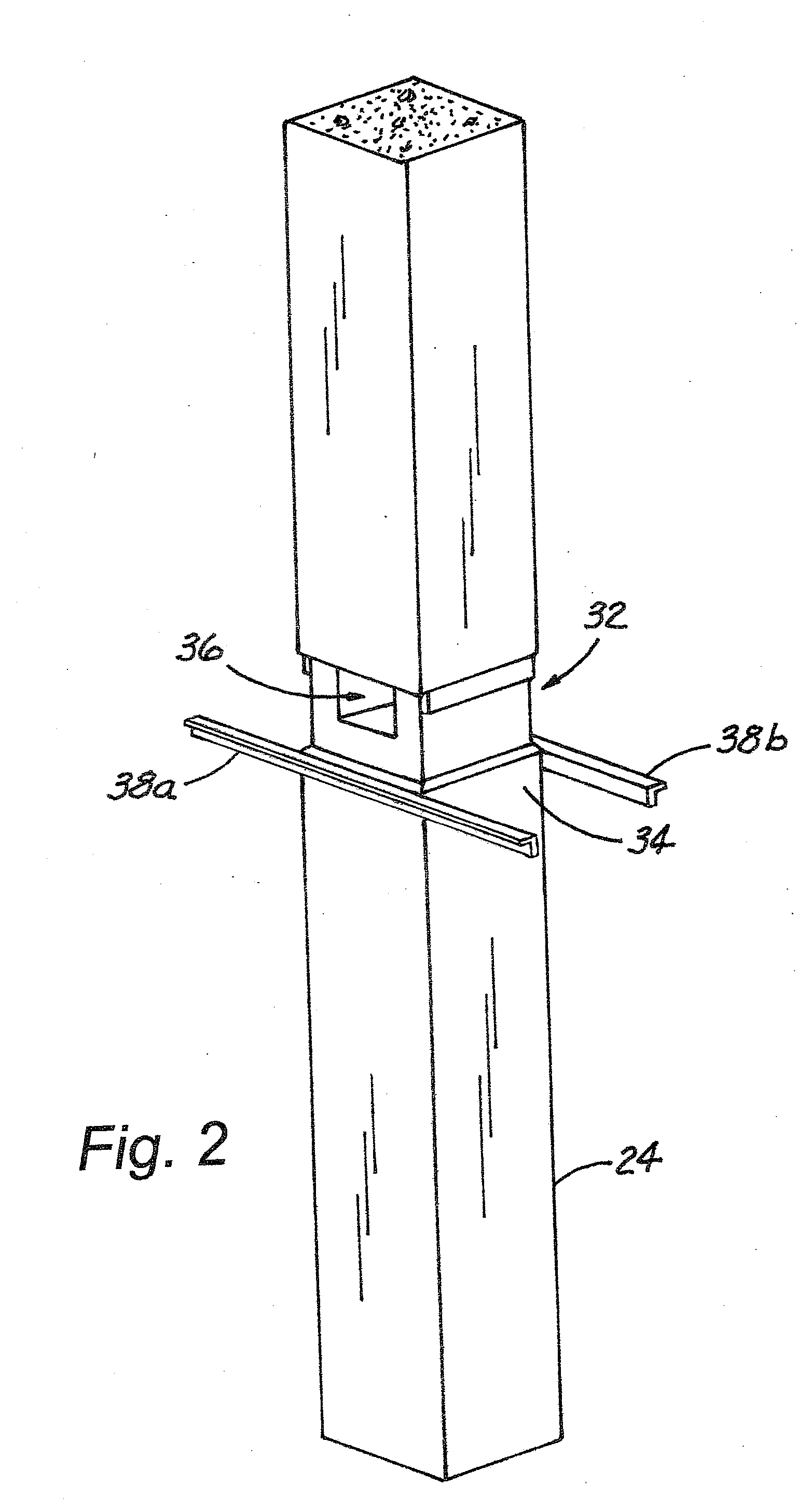

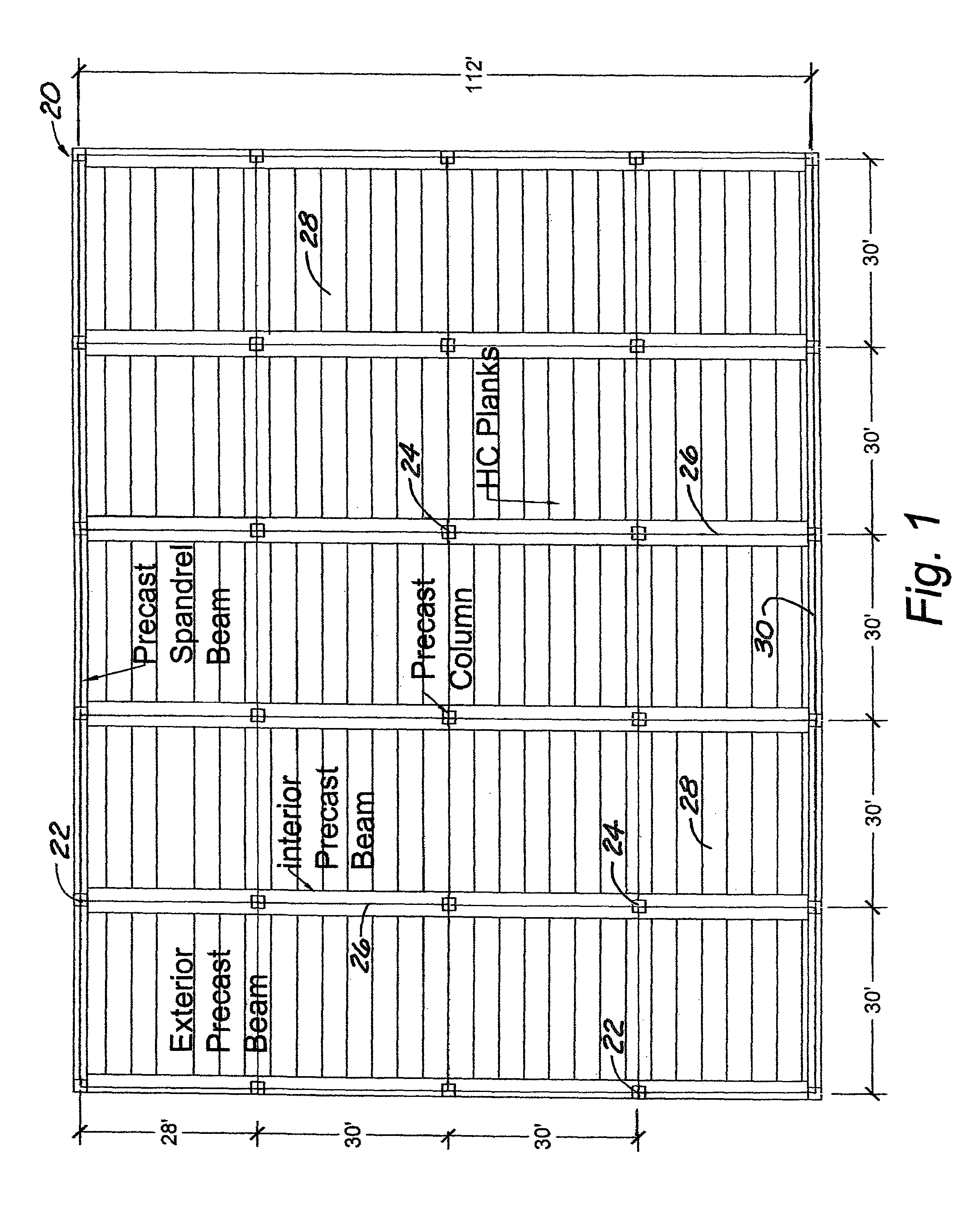

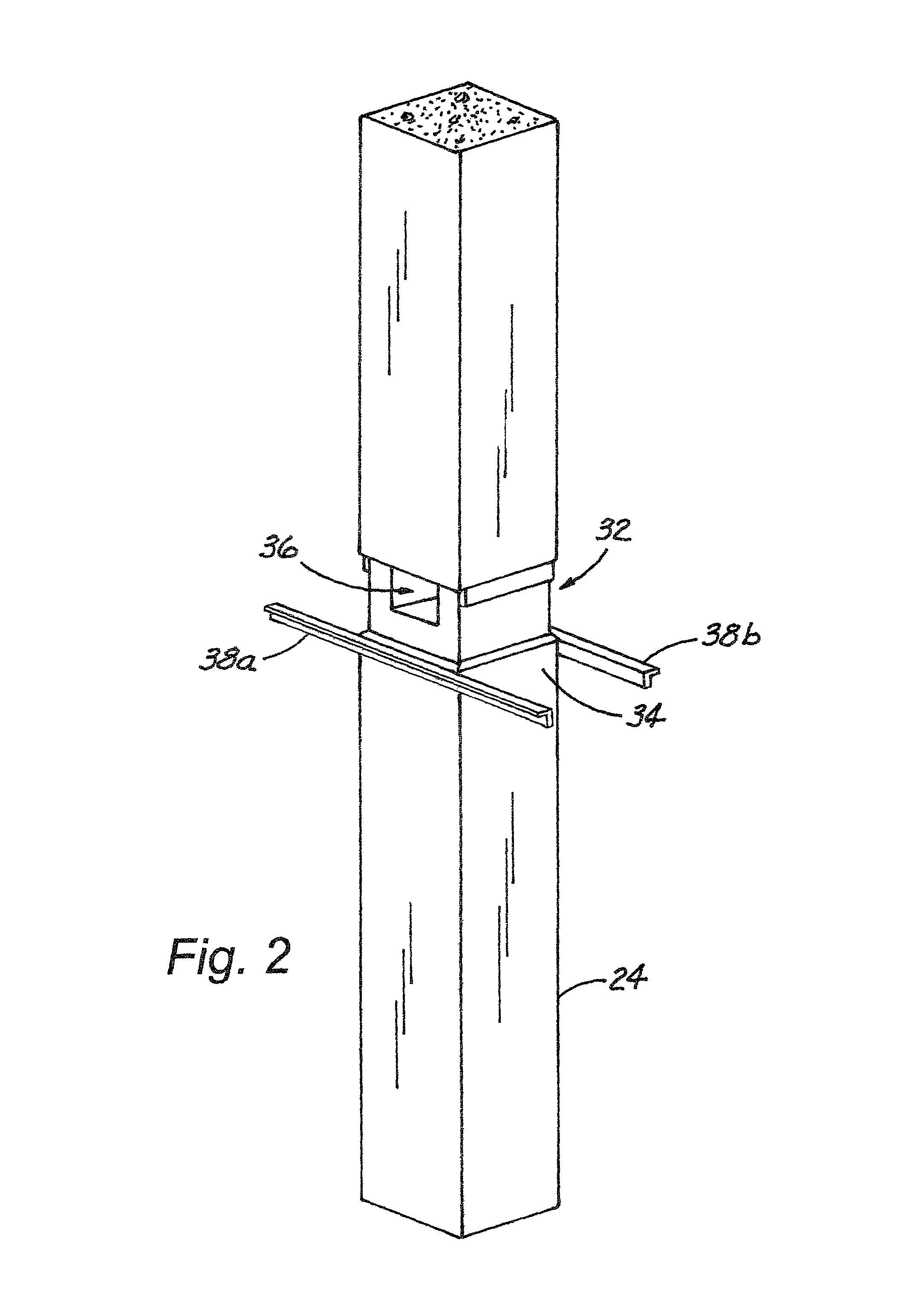

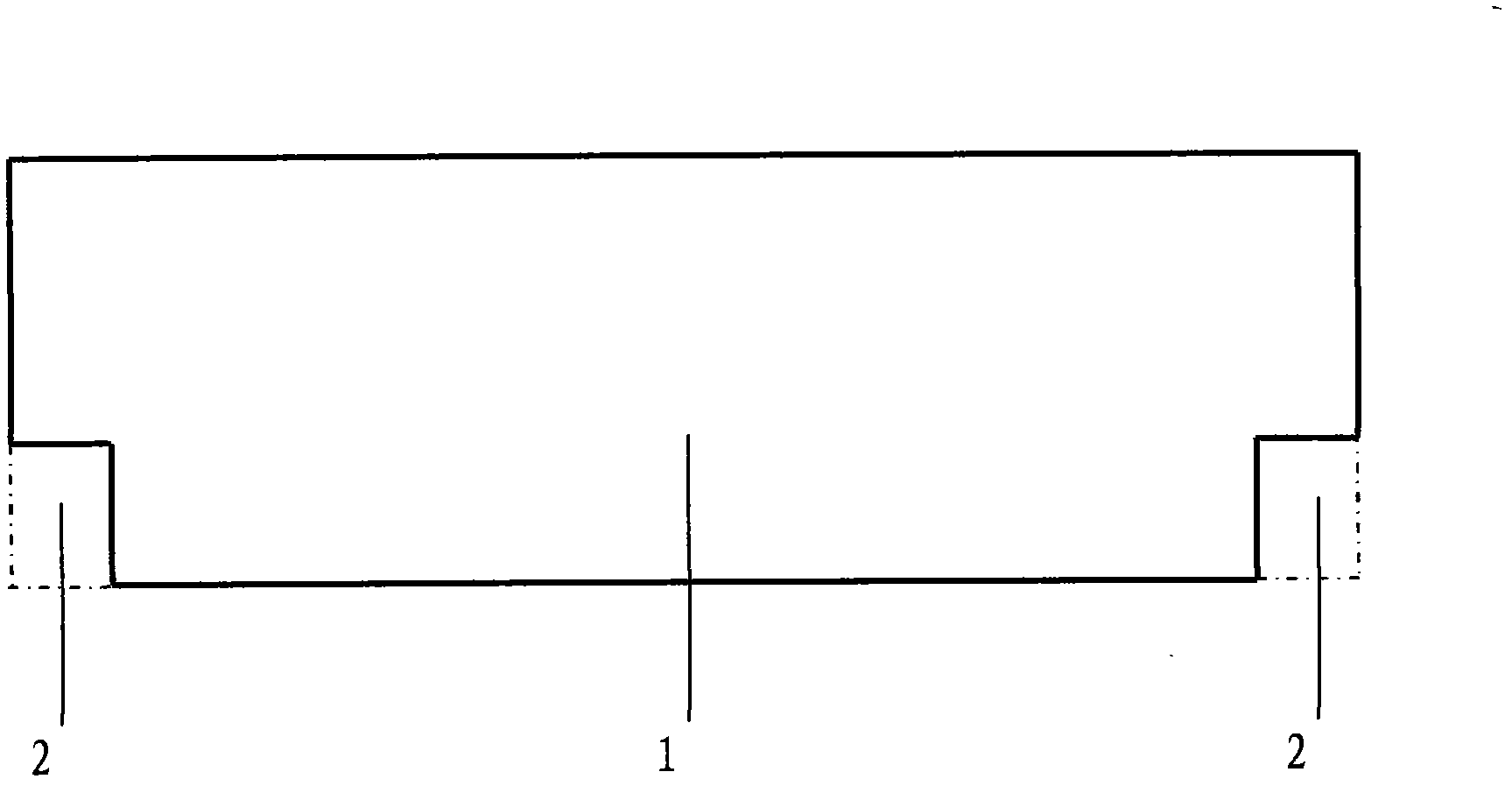

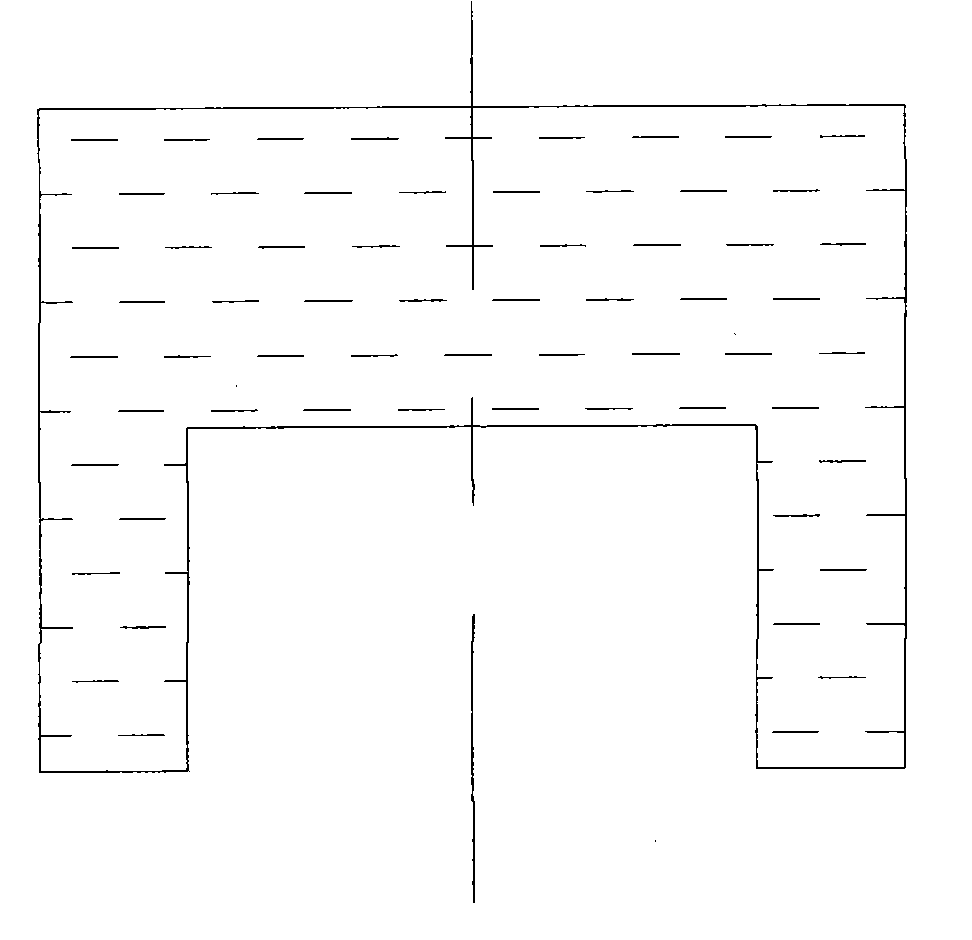

Shallow Flat Soffit Precast Concrete Floor System

A precast concrete floor system that eliminates the need for column corbels and beam ledges while being very shallow. The main advantages of the present system include a span-to-depth ratio of 30, a flat soffit, economy, consistency with prevailing erection techniques, and fire and corrosion protection. The present system consists of continuous precast columns, prestressed rectangular beams, hollow-core planks, and cast-in-place composite topping. Testing results have indicated that a 12 inch deep flat soffit precast floor system has adequate capacity to carry gravity loads (including 100 psf live load) in a 30 ft×30 ft bay size. Testing has also shown that shear capacity of the ledge-less hollow-core-beam connections can be accurately predicted using the shear friction theory.

Owner:BOARD OF RGT UNIV OF NEBRASKA

Method for casting in-situ composite lightweight wall by detaching-free template and equipment thereof

InactiveCN101550736AAvoid freezing and thawingImprove efficiencySolid waste managementWallsCement boardHigh intensity

The invention relates to a method for casting in-situ composite lightweight wall by a detaching-free template and equipment thereof, comprising: in position of lightweight wall installation at construction site, using pressure fibre cement boards as a external layer of wall and a detaching-free template, casting physical foaming concrete in a sandwich layer between the pressure fibre cement boards. After casting, the physical foaming concrete and the pressure fibre cement board become one to compose the lightweight wall, the circumference of the lightweight wall is cast for one with the construction structure. The wall external layer the composite lightweight wall obtained has high intensity, and interior has low volume weight, reaching excellent performance of lightweight, heat preservation, noise insulation and non-cracking. Besides, a special shunt buffer is collocated, a foaming, mixing and conveying integration foaming conveyor is employed as a filling machine, in-situ highly effective mechanization linkage automatization cast is implemented.

Owner:顾小林

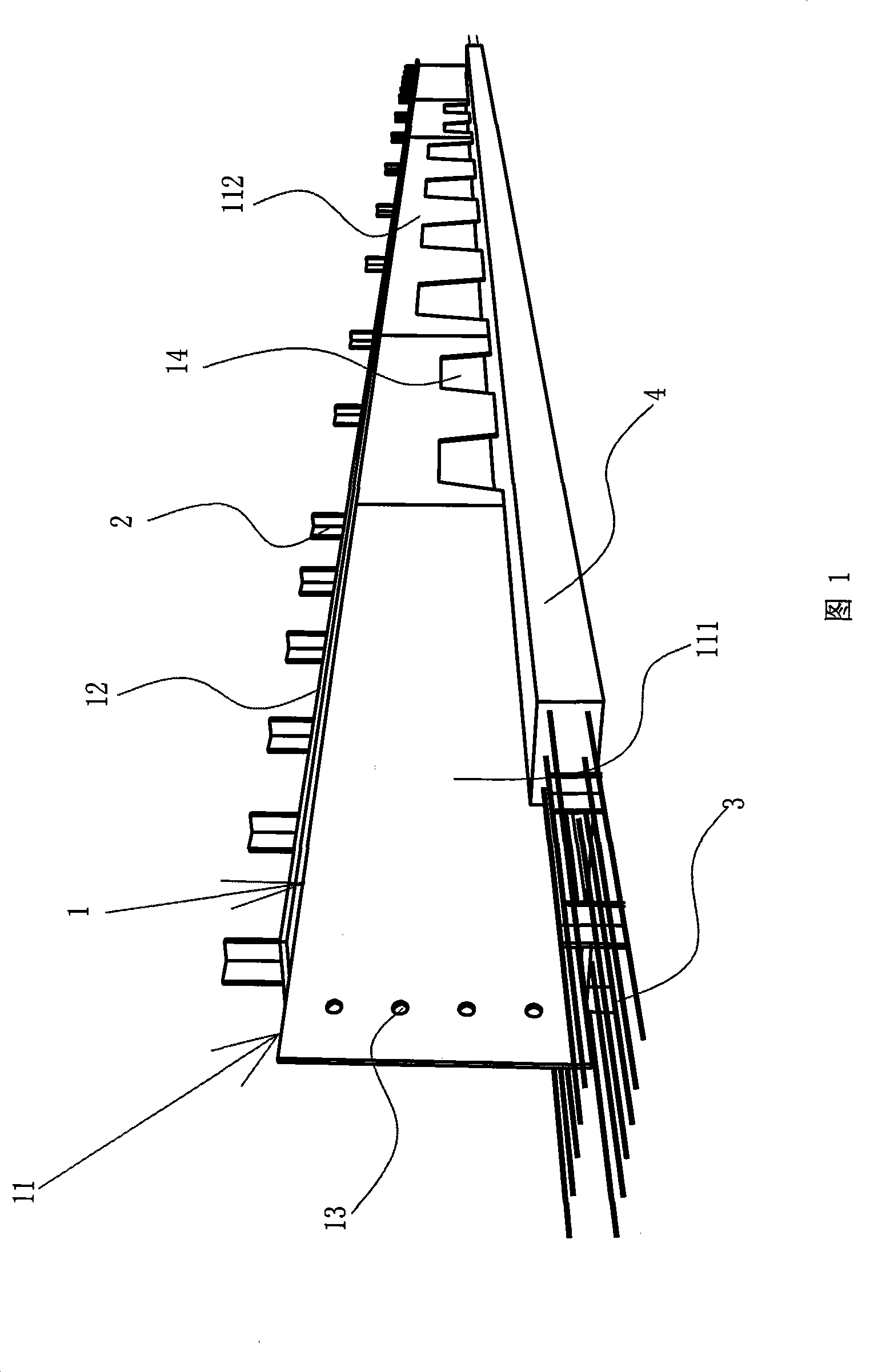

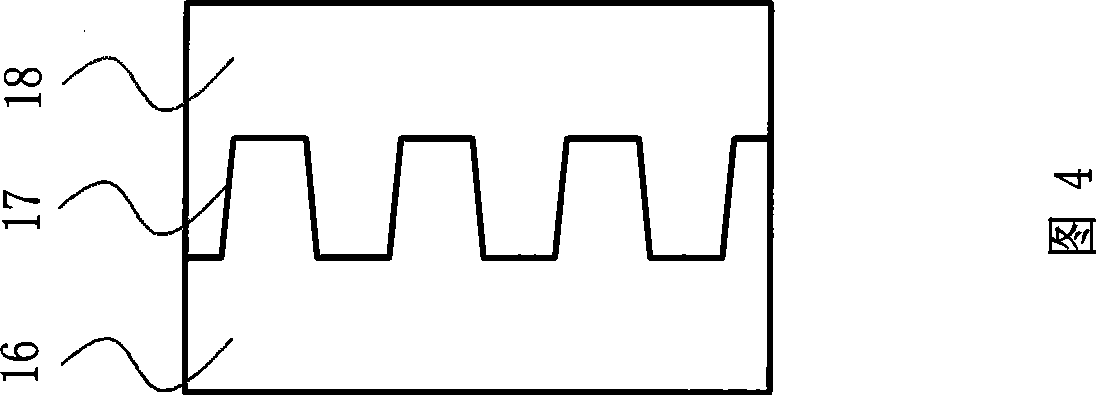

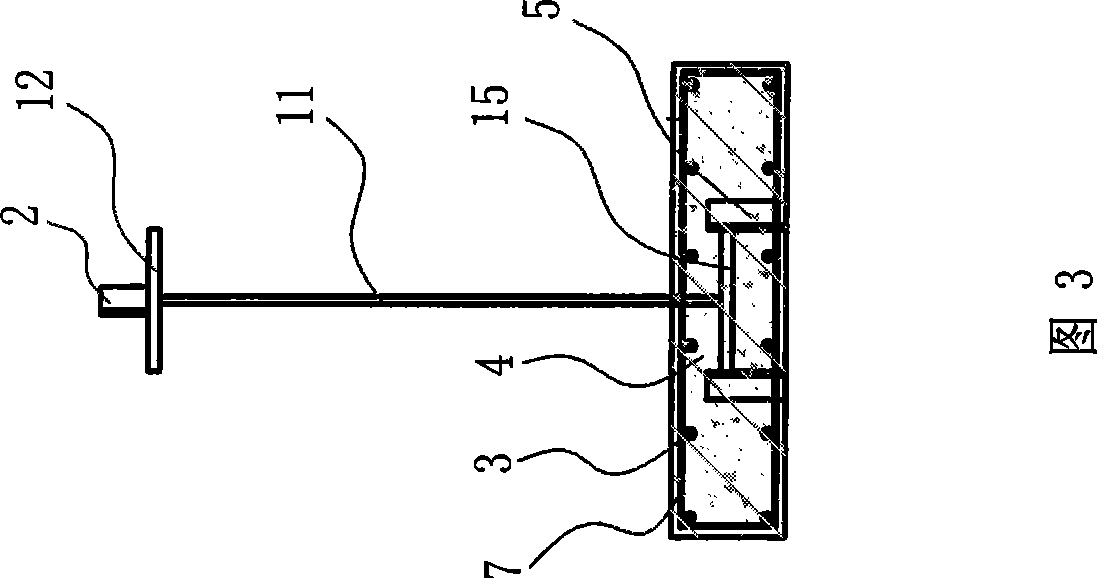

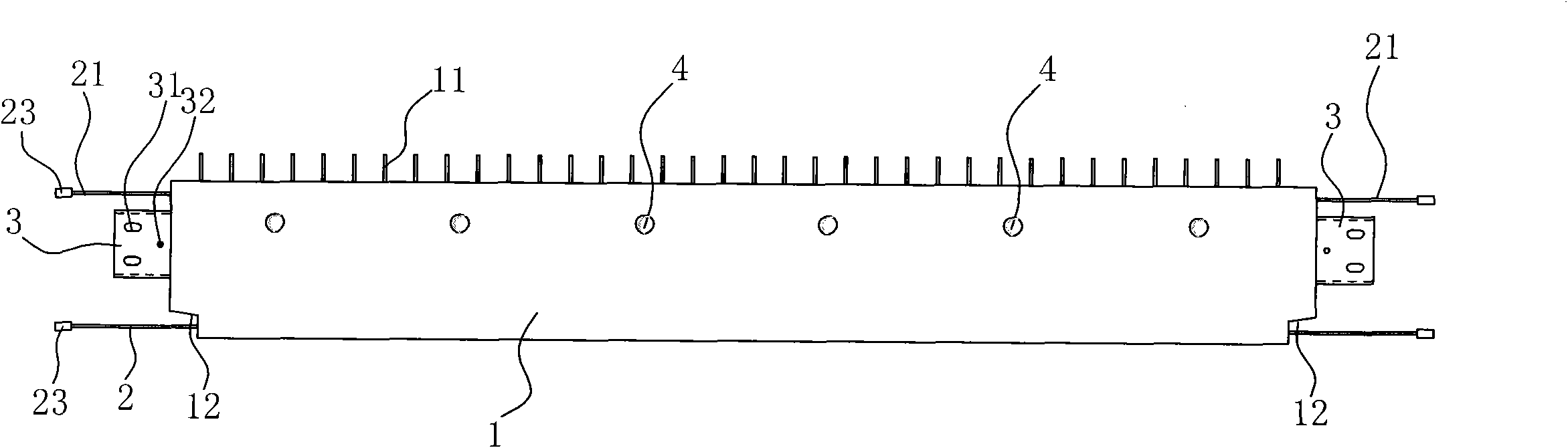

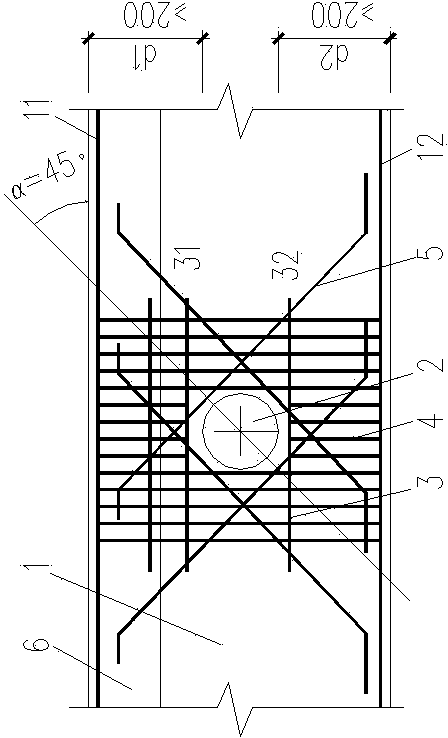

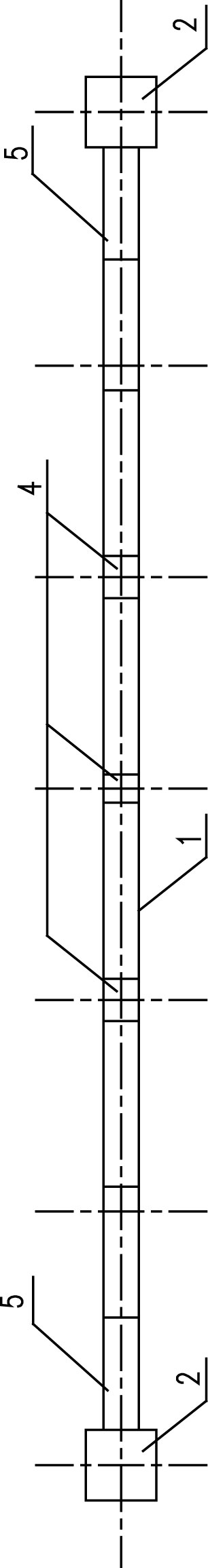

Pretensioned prestressing composite girder and method for producing the same

ActiveCN101418630ASmall beam heightReduce the overall heightLoad-supporting elementsBuilding material handlingShaped beamSheet steel

Provided is a pre-tensioned prestressed composite beam, which is an I-shaped beam composed of H-shaped steel and concrete, the web plate of the H-shaped steel is provided with trapezoidal holes (14) at intervals, the upper flange and the lower flange of the H-shaped steel are welded with shearing nails, the outer periphery of the lower flange is enclosed with concrete to form a steel-concrete lower flange (4), and the inside of the steel-concrete lower flange is embedded with prestressed steel twisted wire by pretensioning method. The manufacturing method of the composite beam is that: a steel plate is cut into two tooth-shaped plates along tooth-shaped line to be respectively as the trapezoidal hole plates of the H-shaped steel flange, the trapezoidal hole plates are welded with steel plates to form the web plate, the web plate is welded with the upper flange and the lower flange to form the H-shaped steel (1) having trapezoidal holes, the H-shaped steel is put on a base surface with the lower flange downward, the two sides of the lower flange are provided with side molds, a stirrup (7) is arranged and steel twisted wires (3) are longitudinally fastened between the two side molds, the steel twisted wire is tensioned to tensioning state, the concrete for enclosing the H-shaped lower flange is poured and tamped between the two side molds, the steel-concrete lower flange (4) is formed after demolding, and the steel twisted wire at tensioning state is loosened after the concrete reached to predetermined strength and is cut off at predetermined position. The invention is suitable for beams of buildings.

Owner:杨峰

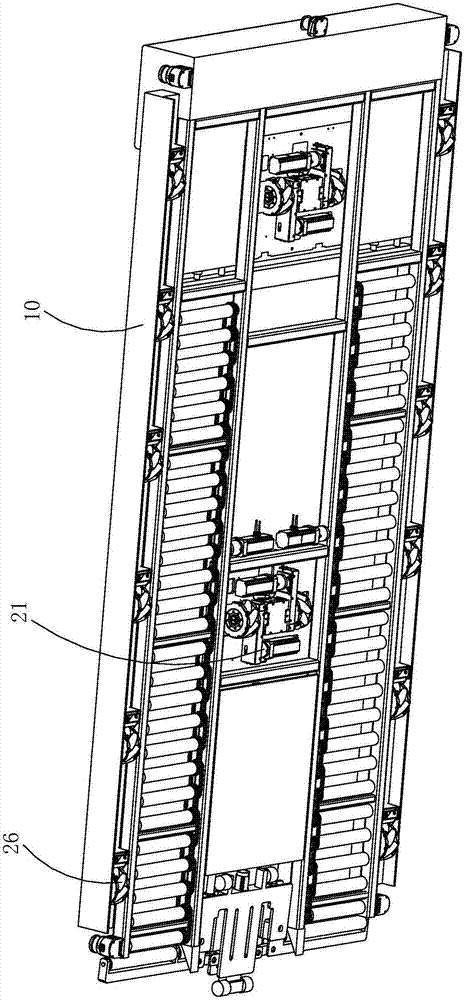

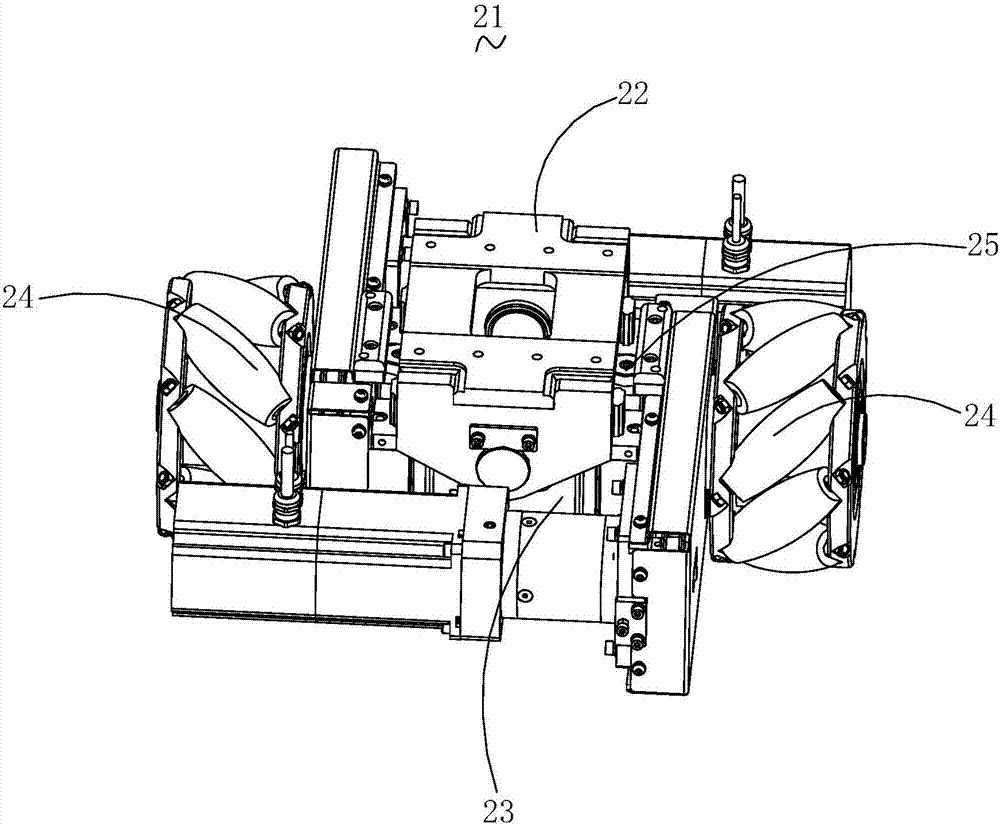

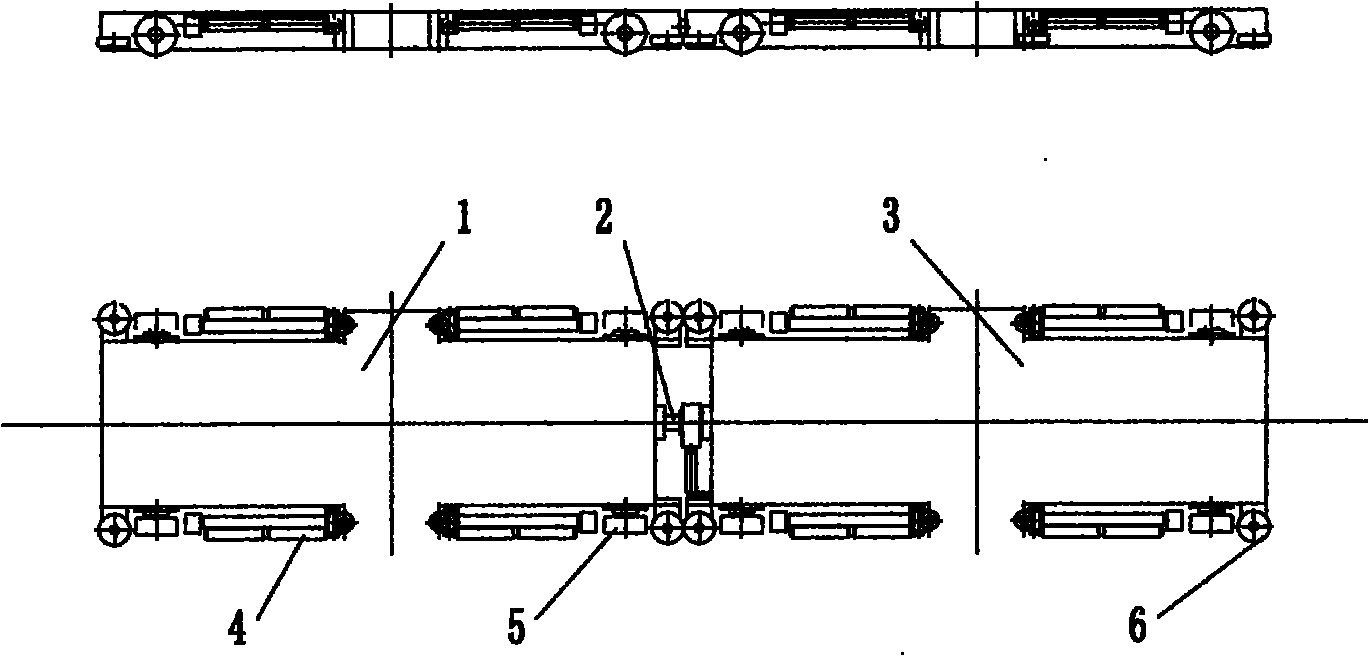

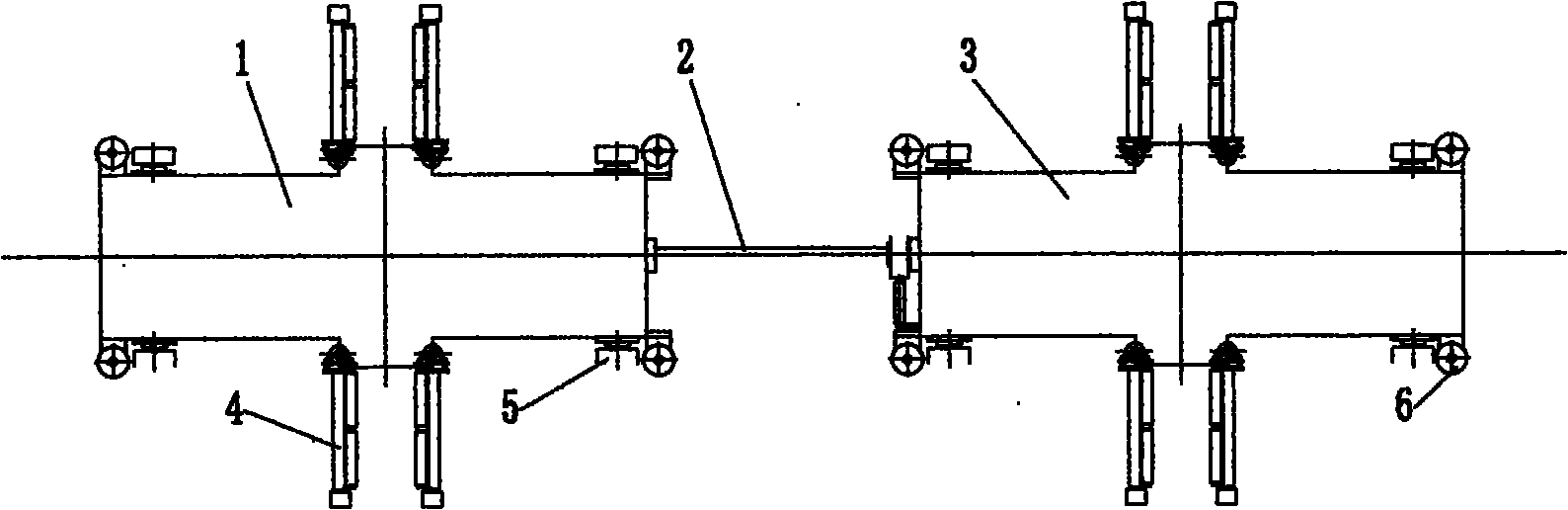

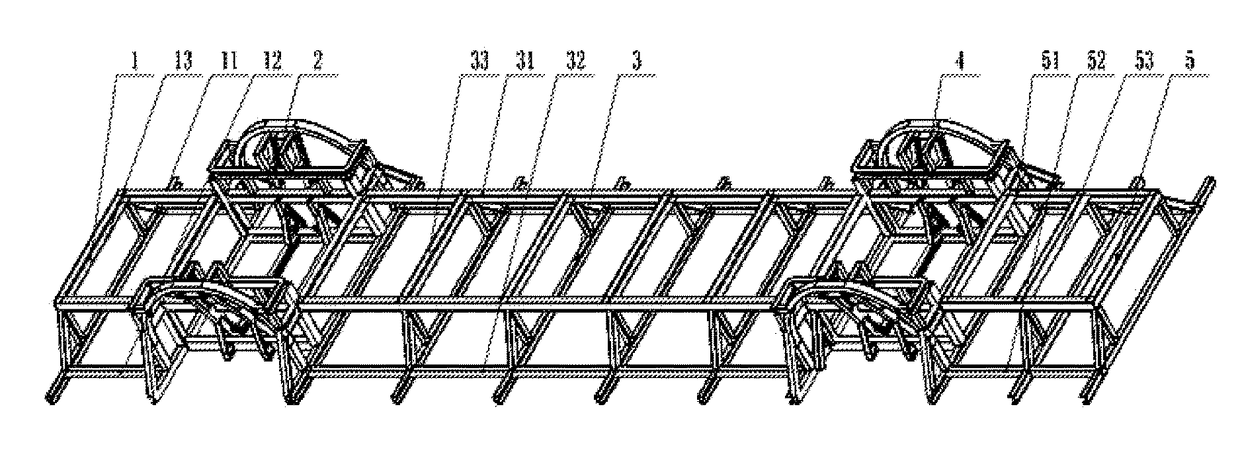

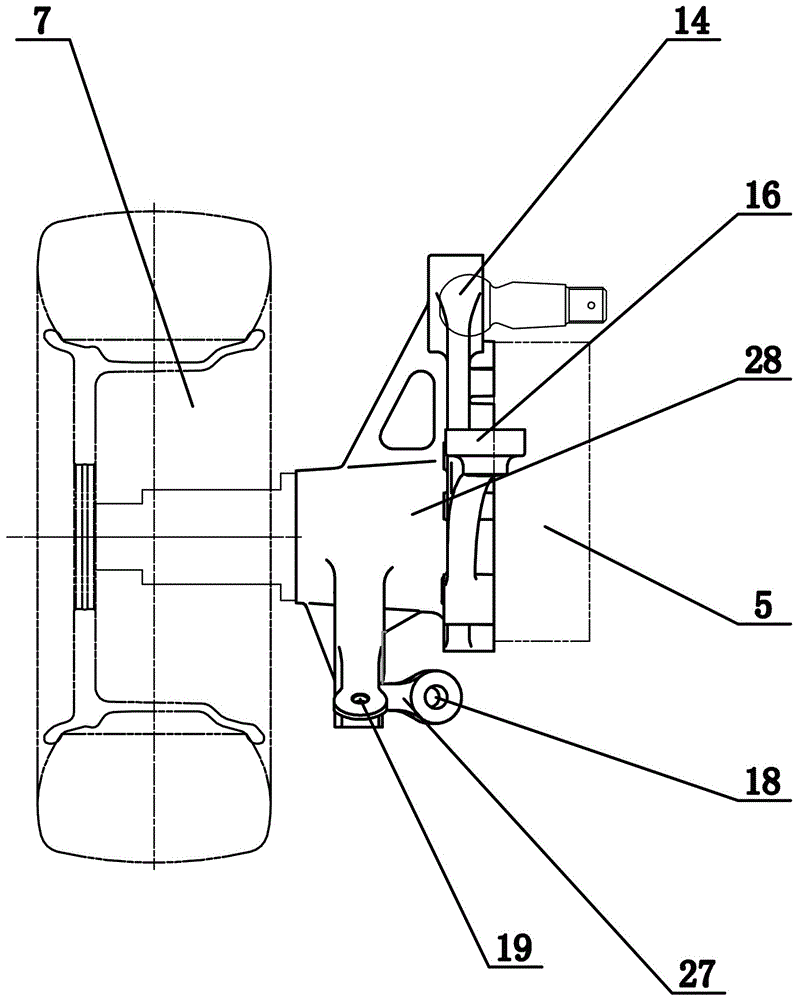

AGV conveying robot and positioning and orienting method used for robot

Provided is an AGV conveying robot and a positioning and orienting method used for the robot. The AGV conveying robot comprises a vehicle frame, and running devices, a clamping arm device, a front blocking device, a conveying device and an electronic control system installed on the vehicle frame correspondingly. The clamping arm device and the front blocking device are located on two sides of the vehicle frame correspondingly, and the conveying device is located on the top of the vehicle frame. The clamping device comprises a clamping arm base, two clamping arms arranged on two sides of the clamping arm base correspondingly, a pushing arm mechanism arranged on the clamping arm base, a pushing base mechanism installed on the vehicle frame and a connecting rod for connecting the clamping arm base. One end of each clamping arm is pivotally connected to a base body and a pushing arm mechanism, and the connecting rod is hinged with the pushing base mechanism. The clamping arms can be driven by the pushing arm mechanism to rotate around the clamping arm base, the clamping arm base is driven by the pushing base mechanism to stretch out and retract into the vehicle frame, and then matches conveying motion of the conveying device, so that the parking and picking automobiles can be achieved. According to the AGV conveying robot and the positioning and orienting method, a vehicle loading tray and a comb-shaped frame for parking vehicles that are essential in a traditional garage can be omitted, and the garage cost is reduced.

Owner:DONGGUAN SONGSHAN LAKE TECHXINST CO LTD

Airbag core mold component cast hollow floor construction method

InactiveCN105908887AMulti-building use spaceFlexible layoutFloorsBuilding material handlingSupporting systemSurface layer

The invention provides an airbag core mold component cast hollow floor construction method, and belongs to the field of construction methods. The airbag core mold component cast hollow floor construction method comprises the following steps: I, erecting a support system; II, paving bottom tendons and rib tendons; III, mounting a fixing device, wherein the fixing device is used for fixing airbag core mold components; IV, paving the airbag core mold components, and fixing the airbag core mold components through the fixing device; V, paving surface-layer reinforcing steel ribs; VI, casting concrete. By adopting the construction method, the self weight of floors can be reduced, the construction cost can be lowered, and the utilization rate of lands can be increased.

Owner:CHONGQING DAOTONG BUILDING MATERIAL CO LTD

Method for Manufacturing a Composite Construction Element

ActiveUS20090115097A1Large radiusReduce weightWood working apparatusCeramic shaping apparatusComposite constructionEngineering

A method for producing a composite construction element comprises the steps of:a) providing a composite construction element, which comprises a thermoplastic core layer between two fiber-reinforced thermoplastic cover layers;b) providing one or more interruptions in a fiber-reinforced thermoplastic cover layer of the panel;c) positioning a fiber-reinforced thermoplastic reinforcing layer over and / or near the interruption;d) deforming situated along the interruption and, if desired, the thermoplastic reinforcing layer, preferably while simultaneously locally compacting the core layer, so that a thermoplastic construction element having a recess which is delimited by fiber-reinforced thermoplastic walls is obtained.

Owner:FITS HLDG

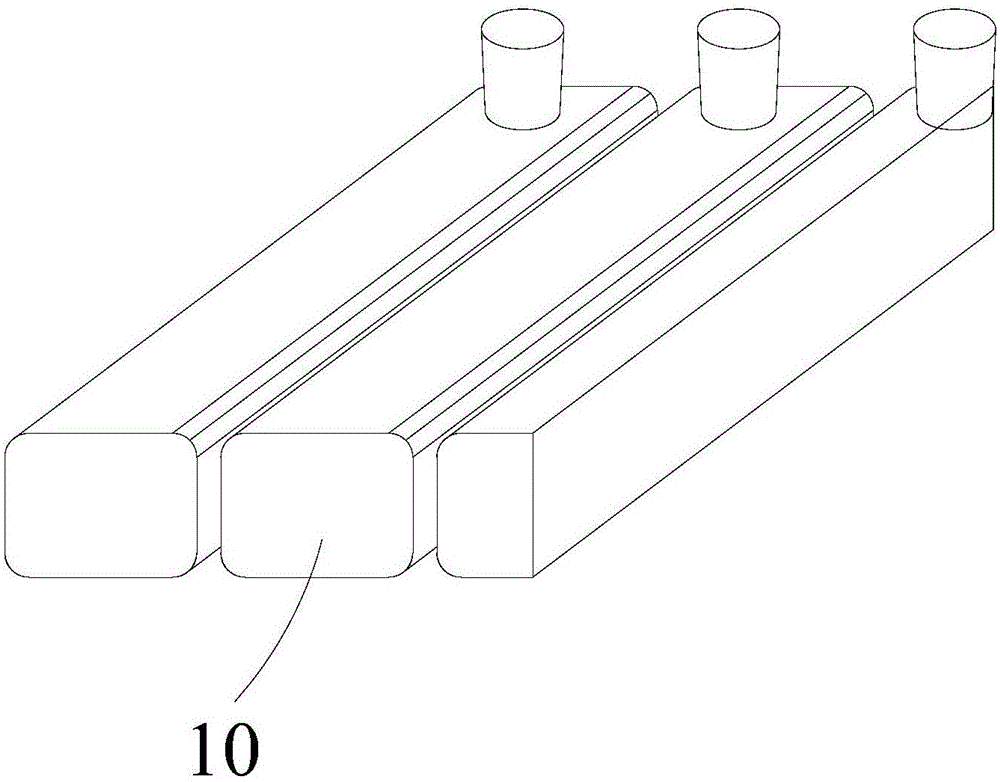

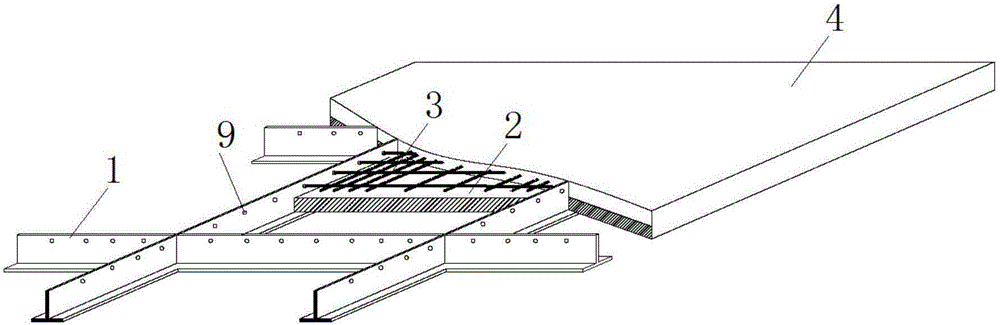

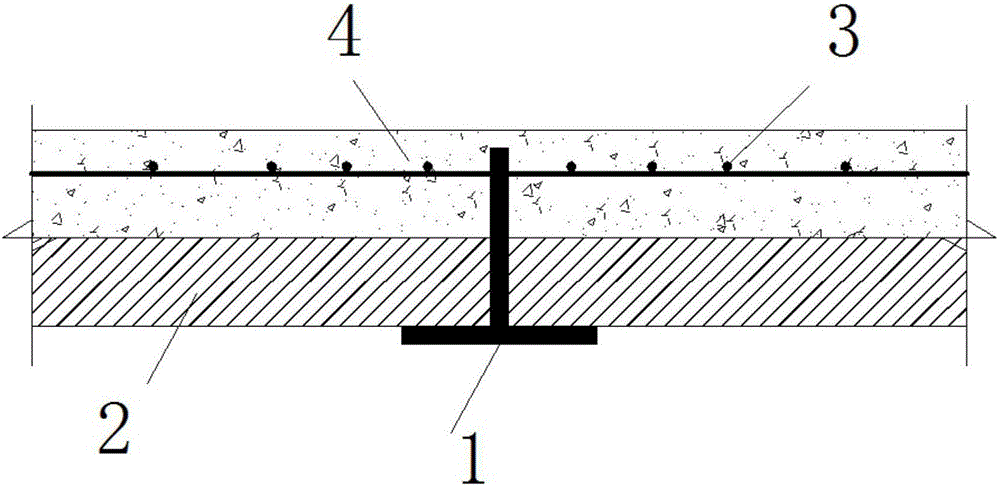

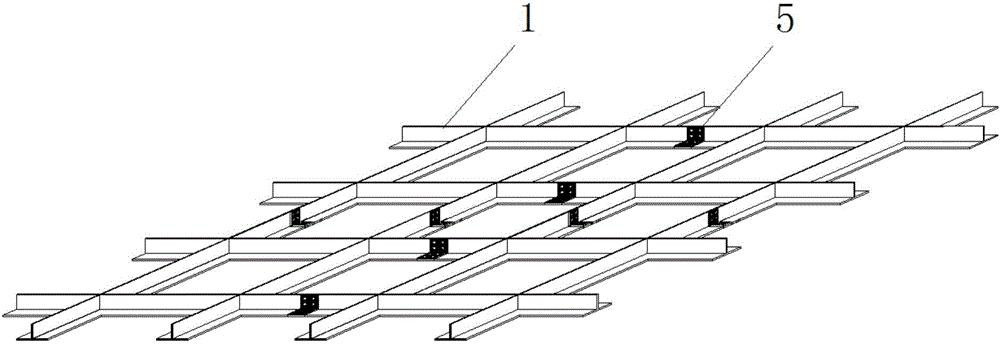

Novel bidirectional inverted-T-shaped beam combined floor

The invention provides a novel bidirectional inverted-T-shaped beam combined floor which is applied to building structures in the engineering field. The novel bidirectional inverted-T-shaped beam combined floor comprises octothorpe-shaped components which are composed of a plurality of inverted-T-shaped steel beams. A plurality of small holes are sequentially formed in webs of the inverted-T-shaped steel beams of the octothorpe-shaped components. Steel bars are arranged between the small holes in the webs of the inverted-T-shaped steel beams in a crossed mode. The multiple octothorpe-shaped components form a bidirectional steel rib structure through splicing joints, and the bidirectional steel rib structure has a stress function during construction. Light prefabricated plates serving as a permanent formwork of the floor sequentially arranged in all cells of the bidirectional steel rib structure, and concrete is evenly poured on the bidirectional steel rib structure and the light prefabricated plates. The novel bidirectional inverted-T-shaped beam combined floor has the characteristics of being high in strength and rigidity and good in ductility; and formwork supporting is not needed, construction is easy, operation is easy, the self weight is low, the height of a structural layer is small, the effective service space is increased, and the economic benefits are good.

Owner:CHINA UNIV OF MINING & TECH

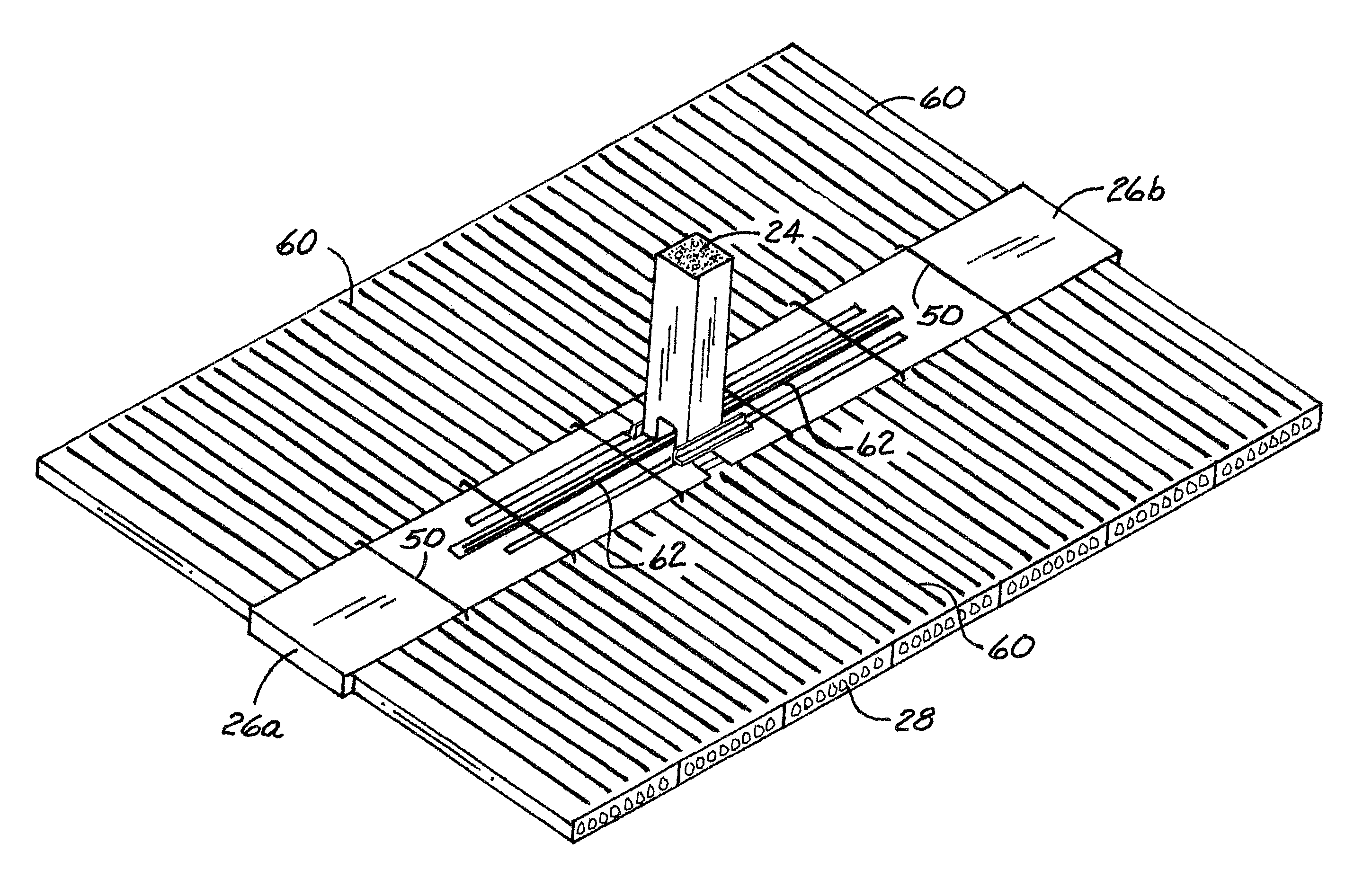

Shallow flat soffit precast concrete floor system

A precast concrete floor system that eliminates the need for column corbels and beam ledges while being very shallow. The main advantages of the present system include a span-to-depth ratio of 30, a flat soffit, economy, consistency with prevailing erection techniques, and fire and corrosion protection. The present system consists of continuous precast columns, prestressed rectangular beams, hollow-core planks, and cast-in-place composite topping. Testing results have indicated that a 12 inch deep flat soffit precast floor system has adequate capacity to carry gravity loads (including 100 psf live load) in a 30 ft×30 ft bay size. Testing has also shown that shear capacity of the ledge-less hollow-core-beam connections can be accurately predicted using the shear friction theory.

Owner:BOARD OF RGT UNIV OF NEBRASKA

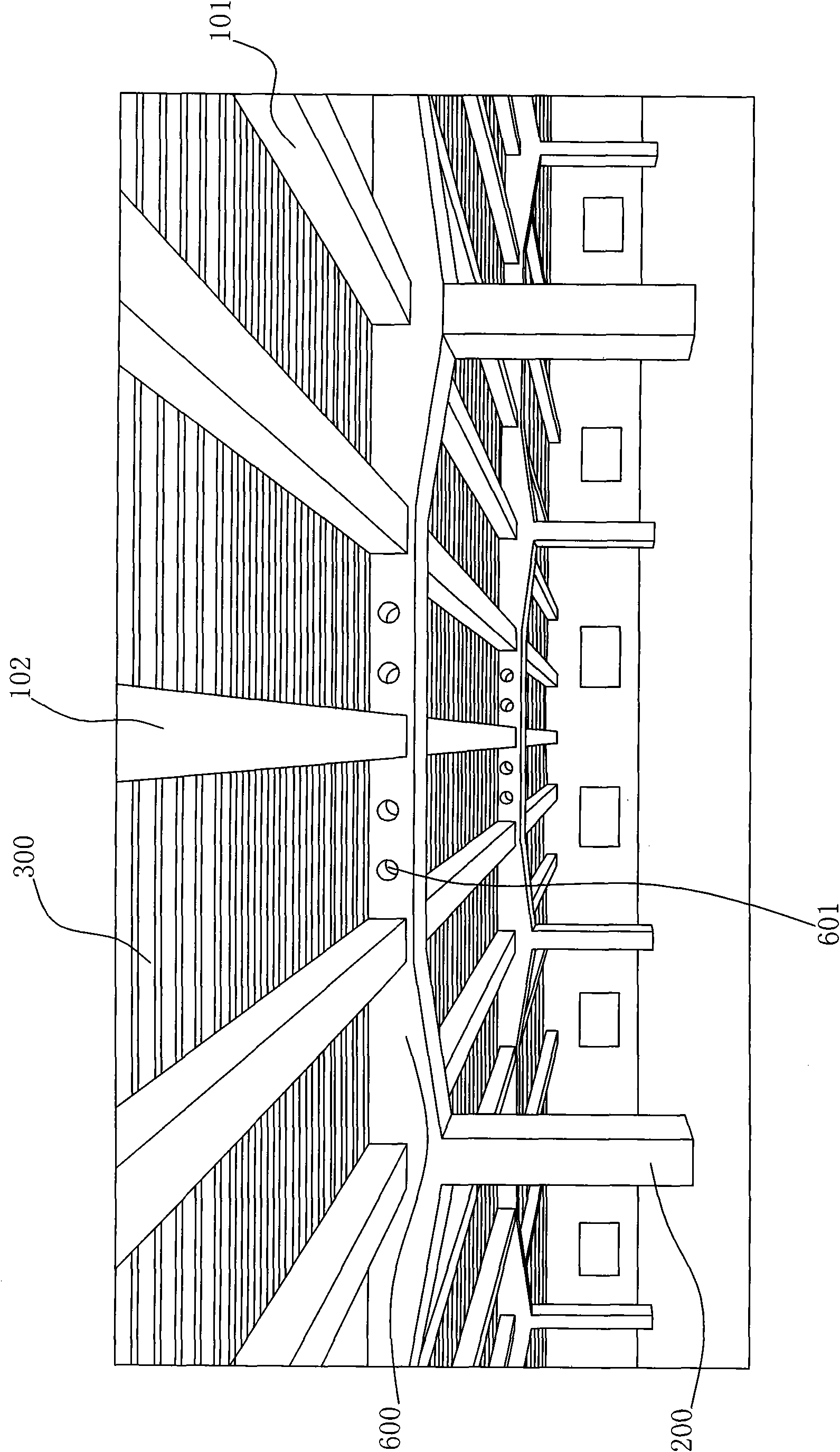

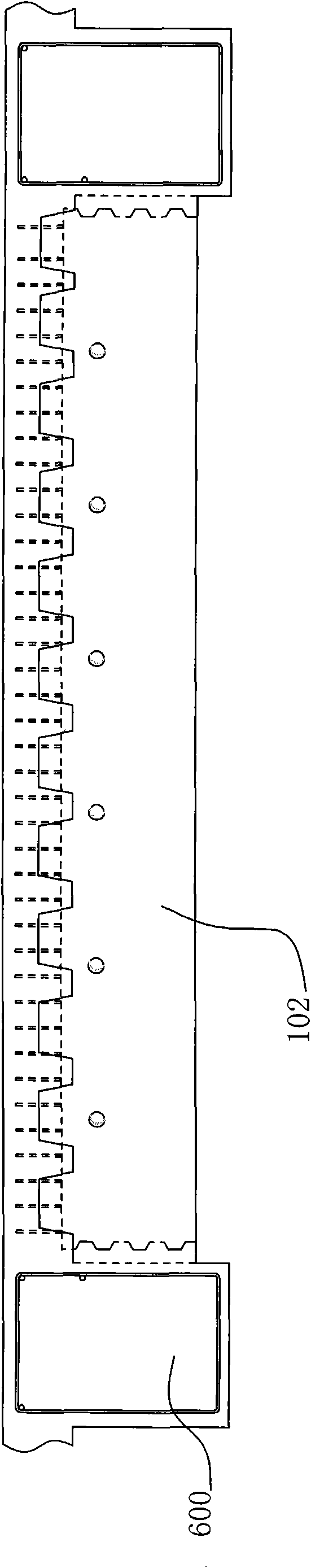

Automobile carrier

Owner:姜勇

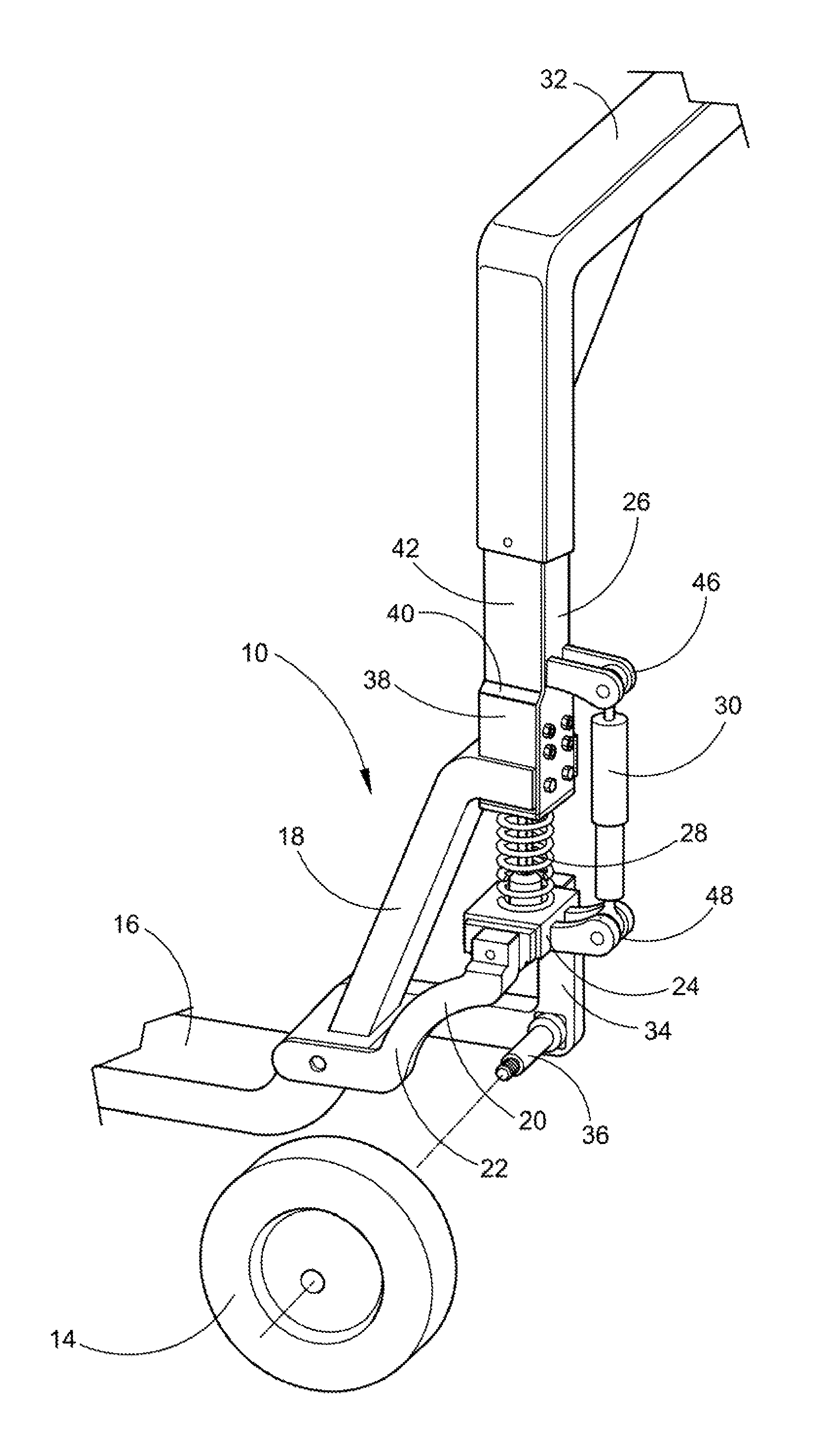

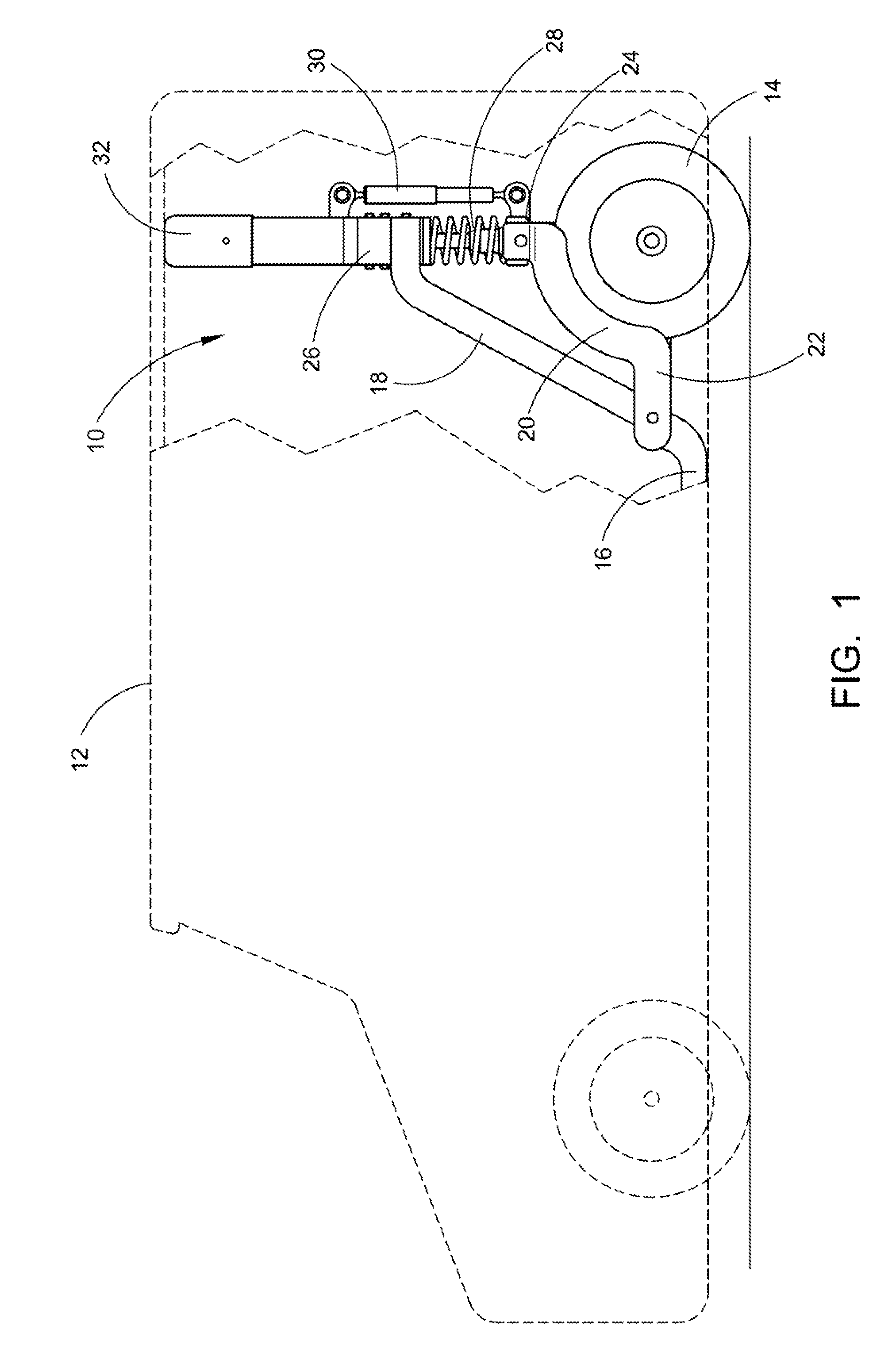

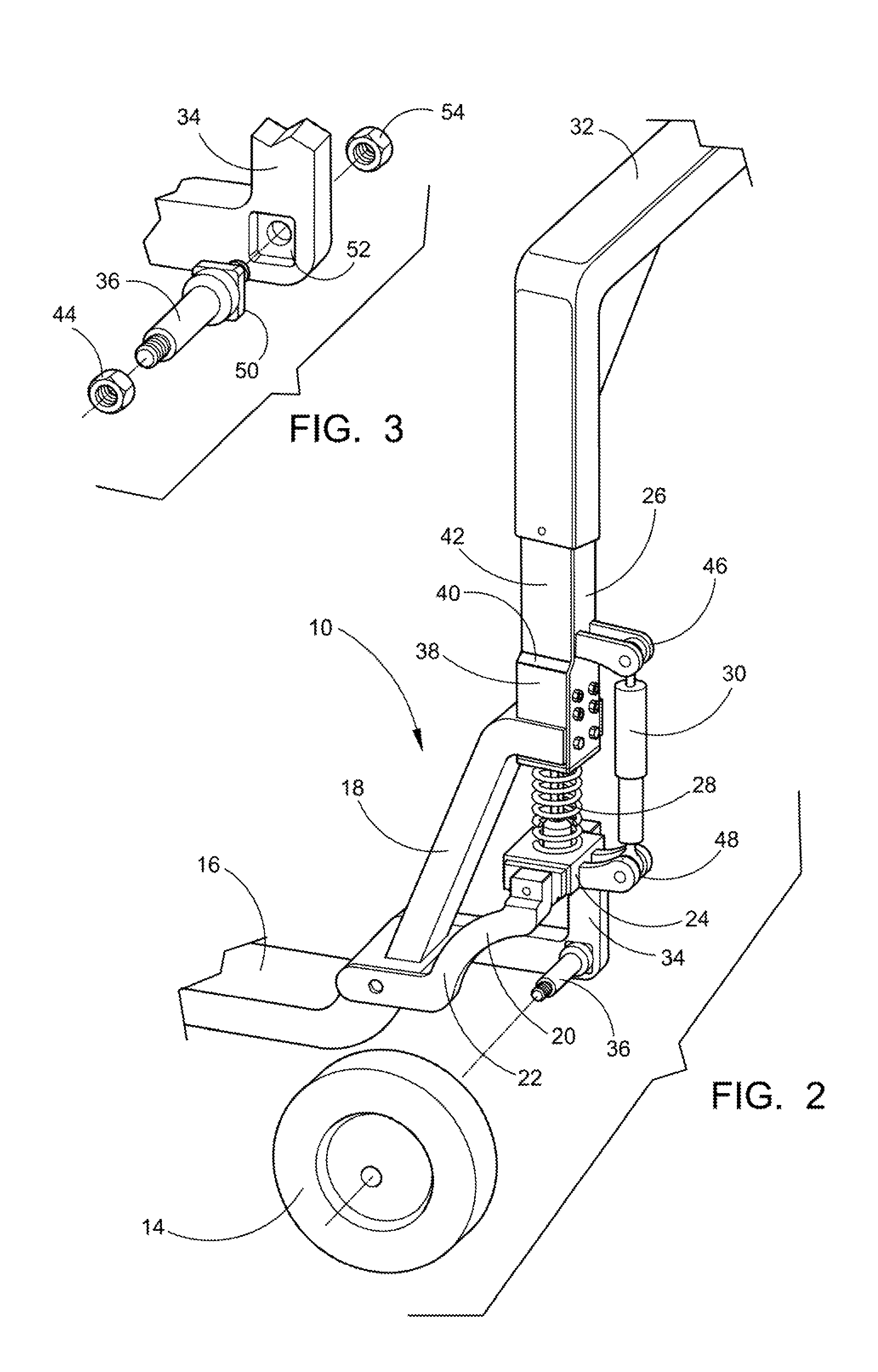

Raised axle and suspension system

ActiveUS8162335B1Avoid spendingLower center of gravityVehicle cleaning apparatusLoading/unloading vehicle arrangmentCushioningStub axle

The present invention is directed to a Raised Axle and Suspension System that consists of a unique design that is intended to be used on a wide variety of front wheel drive vehicles and trailers by raising the axle overarm to an overhead position. This is accomplished by having the wheels on stub axles attached to a pivoting wheel support castings that are attached to frame attachment members. Angular support members are fixably attached to the frame attachment members and suspension support members that connect to the axle overarm. The axle overarm extends from the left side of the vehicle to the right side. The suspension springs extend between the suspension base members that are pivotally connected to the wheel support castings and the suspension support members along with conventional shock absorbers creating a spring cushioning system.

Owner:PRESS RICHARD U

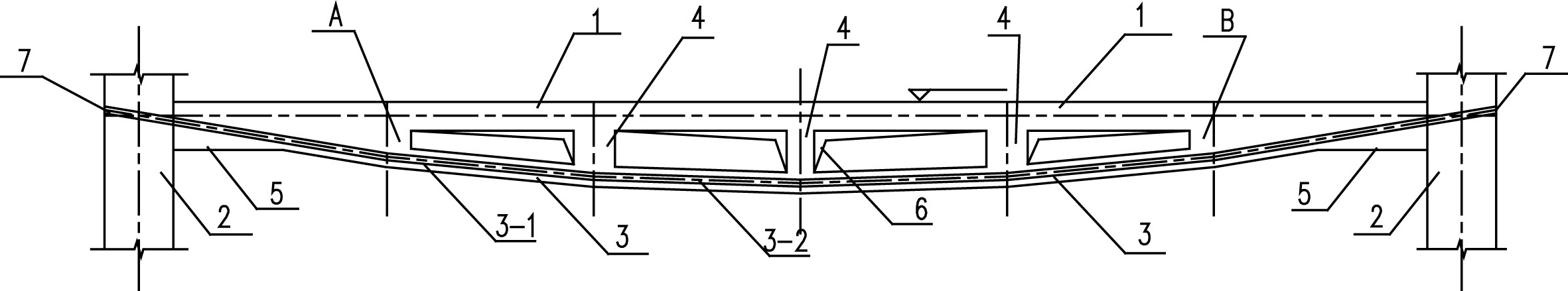

Prefabrication integral casting building structure system with cast-in-site haunched beams, and construction method for prefabrication integral casting building structure system

The invention discloses a prefabrication integral casting building structure system with cast-in-site haunched beams. The prefabrication integral casting building structure system comprises cast-in-site pillars, the cast-in-site haunched beams, prestress superposed beams, and cast-in-site floor slabs; each prestress superposed beam comprises a prestress prefabrication beam and a cast-in-site part, wherein the prestress prefabrication beam comprises a beam body and a prestress steel stranded wire which is embedded into the beam body and is taken as a main rib; a plurality of form erection holes are formed in the beam body in the longitudinal direction; the cast-in-site haunched beams are connected to an adjacent pillar along one direction; the prestress superposed beams comprise main beams and secondary beams; and the main beams are connected with the adjacent pillar which is vertical to the haunched beams in the other direction, and the secondary beams are connected with the haunched beams. The haunched beams are used as the main beams, so that the middle height of the main beams can be reduced effectively, and pipelines can be arranged on the middle parts of the beams; therefore, the story height of a building can be reduced. Through holes, through which the pipelines can pass, of the middle parts of the main beams can reduce the story height further.

Owner:杨峰

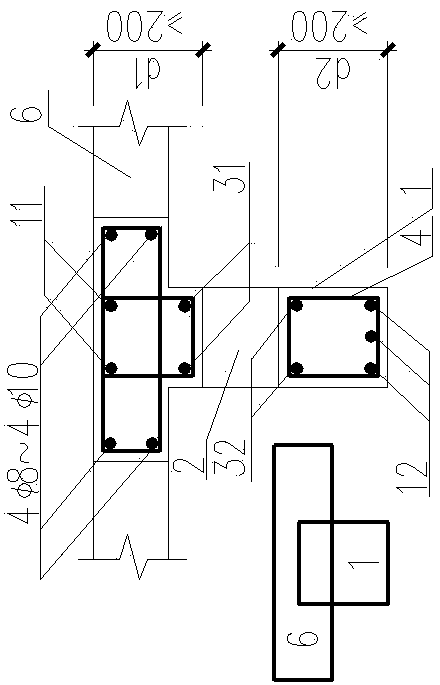

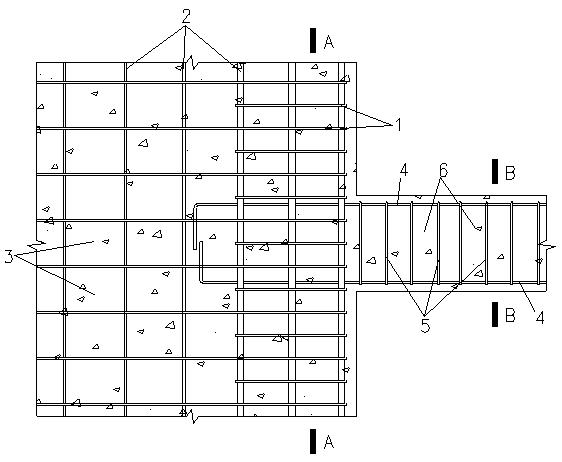

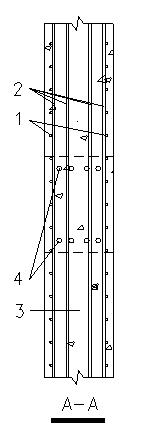

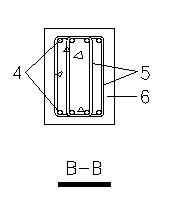

Opening structure of reinforced concrete beam

The invention discloses an opening structure of a reinforced concrete beam. The opening structure is characterized in that a position of an opening formed in the abdomen of the cast-in-place reinforced concrete beam is reserved, and reinforcing steel bars, confined stirrups and steel tie bars are configured at the opening; the reinforcing steel bars comprise opening upper-part reinforcing steel bars and opening lower-part reinforcing steel bars which are configured at the upper part and the lower part of the opening respectively; the opening upper-part reinforcing steel bars and beam upper-part reinforcing steel bars are wound with the confined stirrups, and the opening lower-part reinforcing steel bars and beam lower-part reinforcing steel bars are wound with the confined stirrups; and the steel tie bars are also configured nearby the opening of the beam, pulled from the lower part of a side wall of one side of the beam to the upper part of a side wall of the other side of the beam and extend into a beam plate. The reinforcing steel bars, the confined stirrups and the steel tie bars are configured nearby the opening of the beam, and by means of characteristics and performance of region constraints, the intensity and ductility reduction which is caused by opening of the beam abdomen is effectively reduced, the anti-bending and shear-resisting capacity of the reinforced concrete beam is guaranteed, the phenomenon of stress concentration of the periphery of the opening is relieved, and the reliability of the structure is improved.

Owner:SUZHOU INDAL PARK DESIGN & RES INST

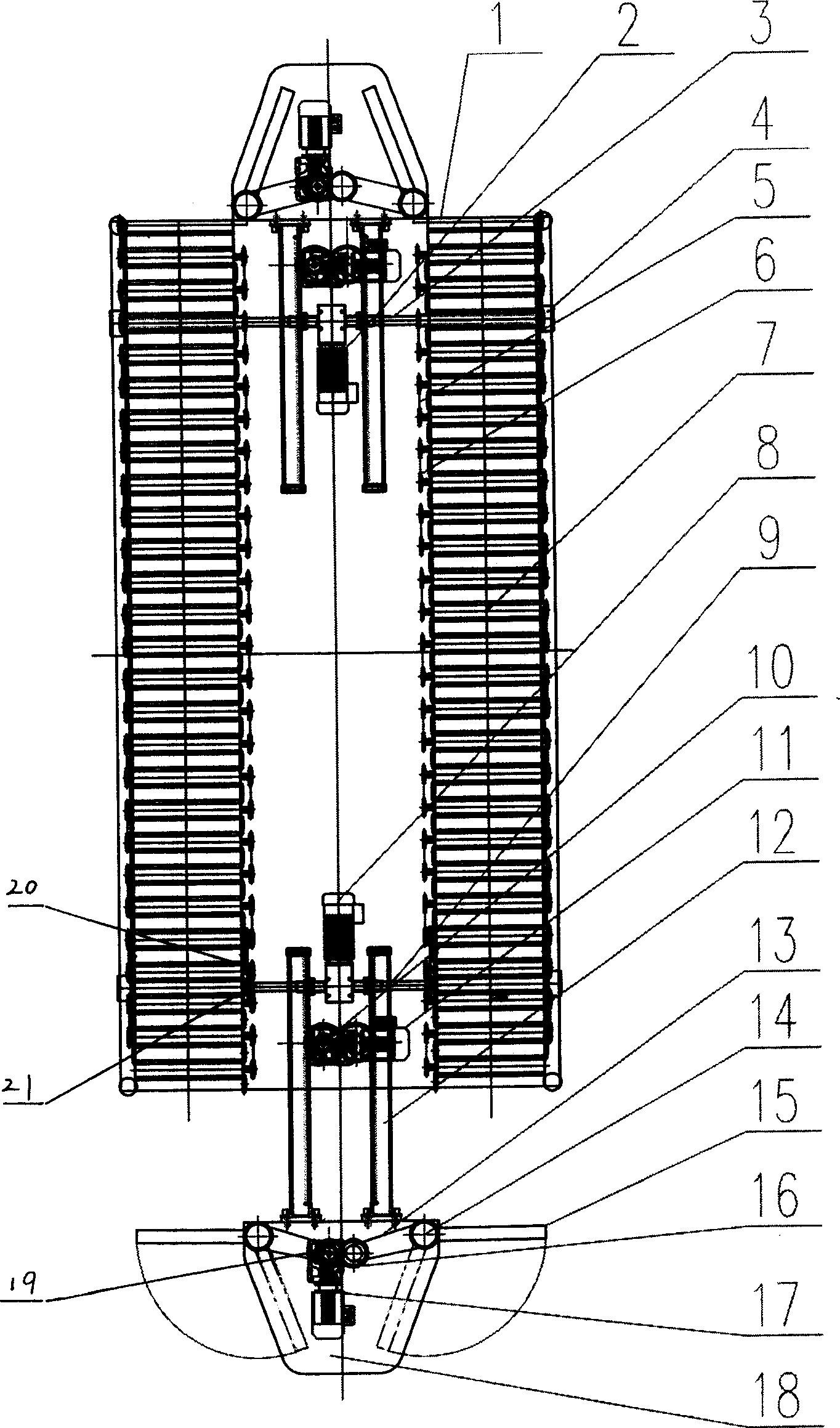

Cars hand-over transporting robot

The present invention relates to a robot for handing over and carrying car, including traveling carrying frame, traveling mechanism, carrier roller drive mechanism, telescoping mechanism and holding mechanism. Said traveling mechanism is mounted on the traveling carrying frame, and includes traveling wheels, retarding motor and drive shaft; the carrier roller drive mechanism includes carrier roller, carrier roller chain wheel, carrier roller chain, retarding motor, drive shaft, chain wheel and chain; it has two telescoping mechanisms, every telescoping mechanism includes retarding motor, gear and rack rod; it also has two holding mechanisms, every holding mechanism includes holding self-body, retarding motor, gear, chain wheel, mechanical arm, holding chain wheel and chain. Said invention also provides the concrete operation method of said robot.

Owner:江苏利创新能源有限公司

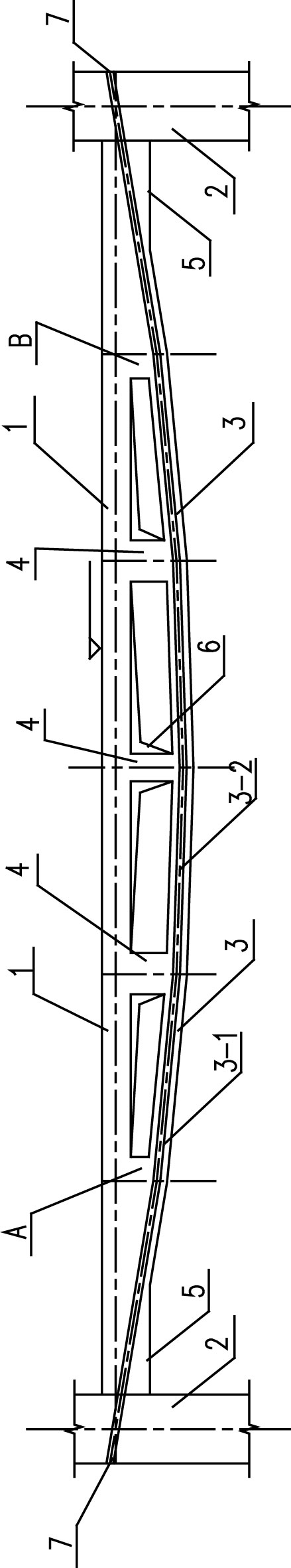

Prestressed concrete mansard rigid-frame beam

The invention discloses a prestressed concrete mansard rigid-frame beam, which relates to a rigid-frame beam used for floor load bearing and aims to solve the problem that the conventional wide flat beams in high buildings are unfavorable for earthquake resistance due to a large dead weight and occupy floor heights to relatively increase indoor energy consumption. A downwards folded beam is a minor-arc beam formed by connecting a plurality of straight beams and positioned under an upper beam to form a minor-bow outline with the upper beam. One end of a flat beam is rigidly connected with a first joint to form a whole, and one end of another flat beam is rigidly connected with a second joint to form a whole. Between the upper beam and the downwards folded beam, a plurality of upright posts with different heights are arranged and a plurality of holes with different sizes and used for passing electric and water pipelines and small air conditioner pipes through are formed. The downwards folded beam is internally provided with prestressed tendons. Compared with solid beams provided with the prestressed tendons under the same condition and with the uniform cross section, the prestressed concrete mansard rigid-frame beam can reduce the concrete usage and the dead weight by 50 percent and the normal steel bar usage by 25 percent.

Owner:白福波

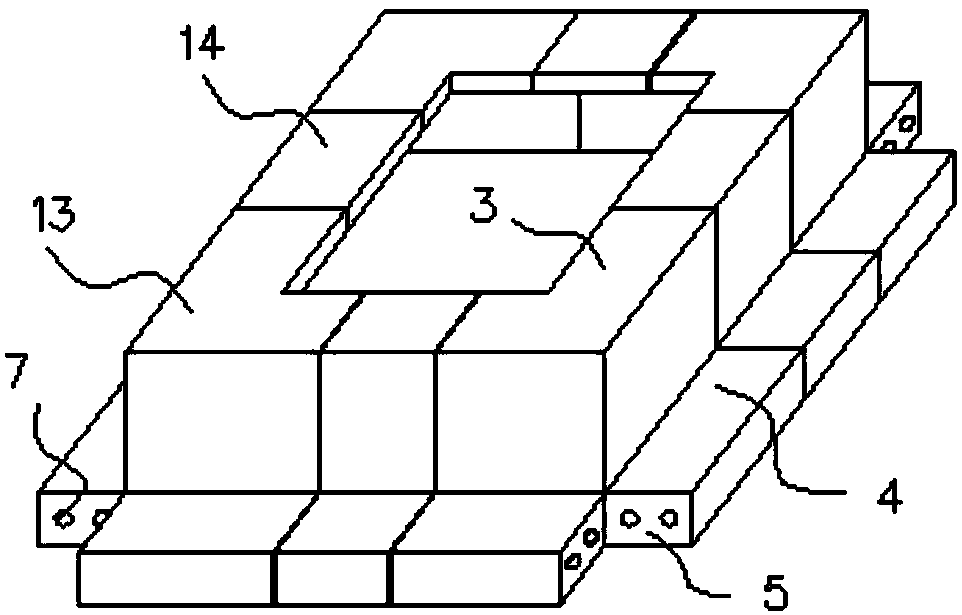

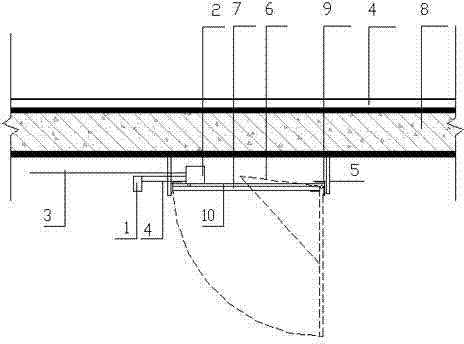

Cover die for construction of composite-section ribbed floor and construction method thereof

ActiveCN109680929ASolve mold problemsReduce production processForms/shuttering/falseworksReinforced concreteEngineering

The invention discloses a cover die for construction of a composite-section ribbed floor and a construction method thereof. The cover die comprises two cylinders or one cylinder and one box or two boxes, wherein each cylinder is of a cylindrical surrounding body structure of which the upper part and lower part are communicated; the cylinders comprise a cylinder I and / or a cylinder II; each box isof a cavity body structure of which one end is opened and the other end is sealed; the boxes comprise a box I and / or a box II; the cylinder I is sheathed above the exterior of the cylinder II, and / orthe box I is sheathed above the exterior of the cylinder II, and / or the box I is sheathed above the exterior of the box II; a lower flange die cavity of a cast-in-situ concrete rib is formed between the cylinder and / or the box; a web plate die cavity of a cast-in-situ concrete dense rib is formed between the adjacent cylinders and / or the boxes. One of the cover die is reserved in a reinforced concrete prefabricated rib cylinder or box, and the other one is a detachable and repeatedly used cylinder die, or is a prefabricated concrete cylinder reserved in the floor. The cover die is a construction die with the advantages that the production is simple; the construction is convenient; the construction period is short; the manufacturing cost is low; the good use effect is obtained.

Owner:贵州皆盈科技开发有限公司

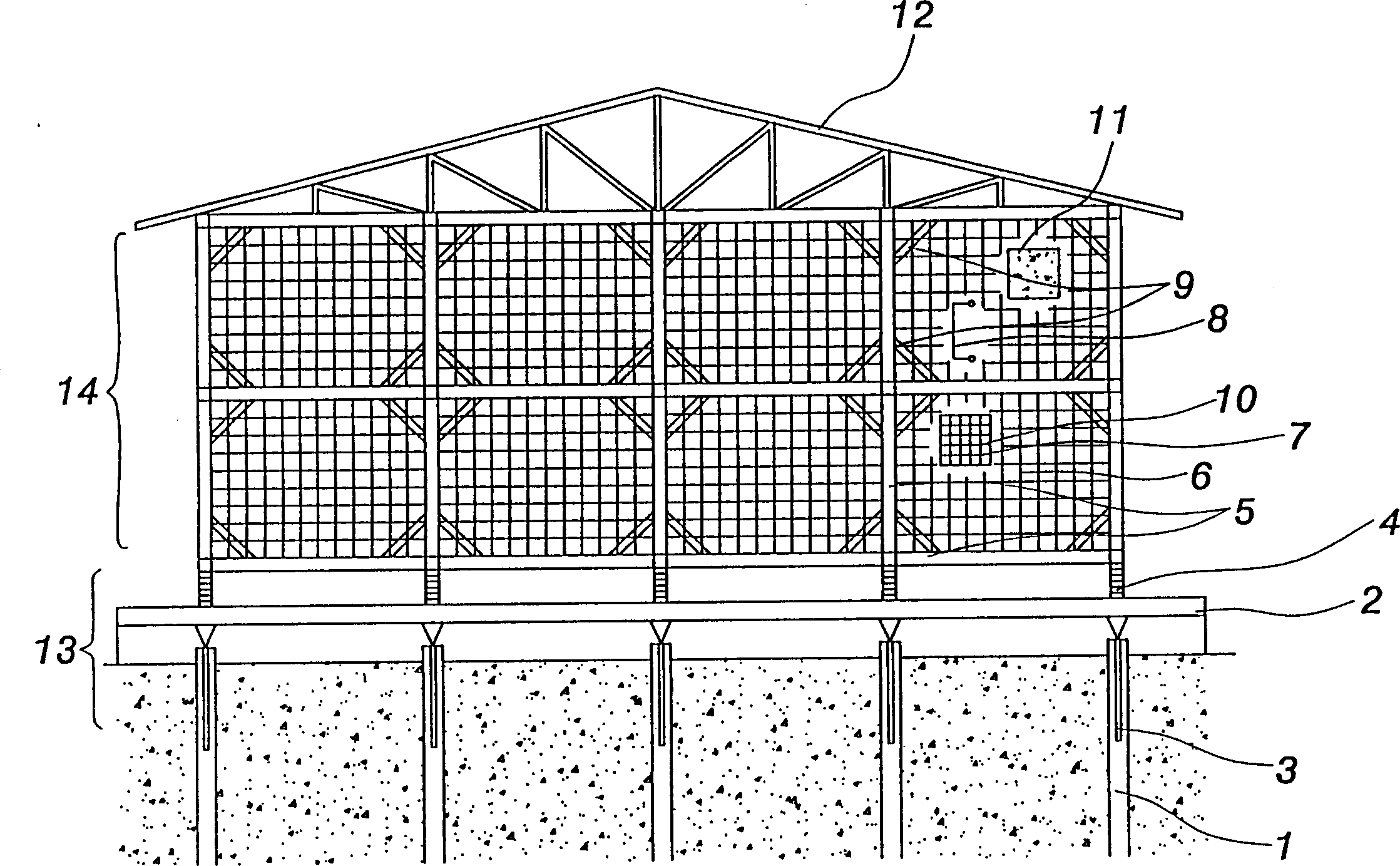

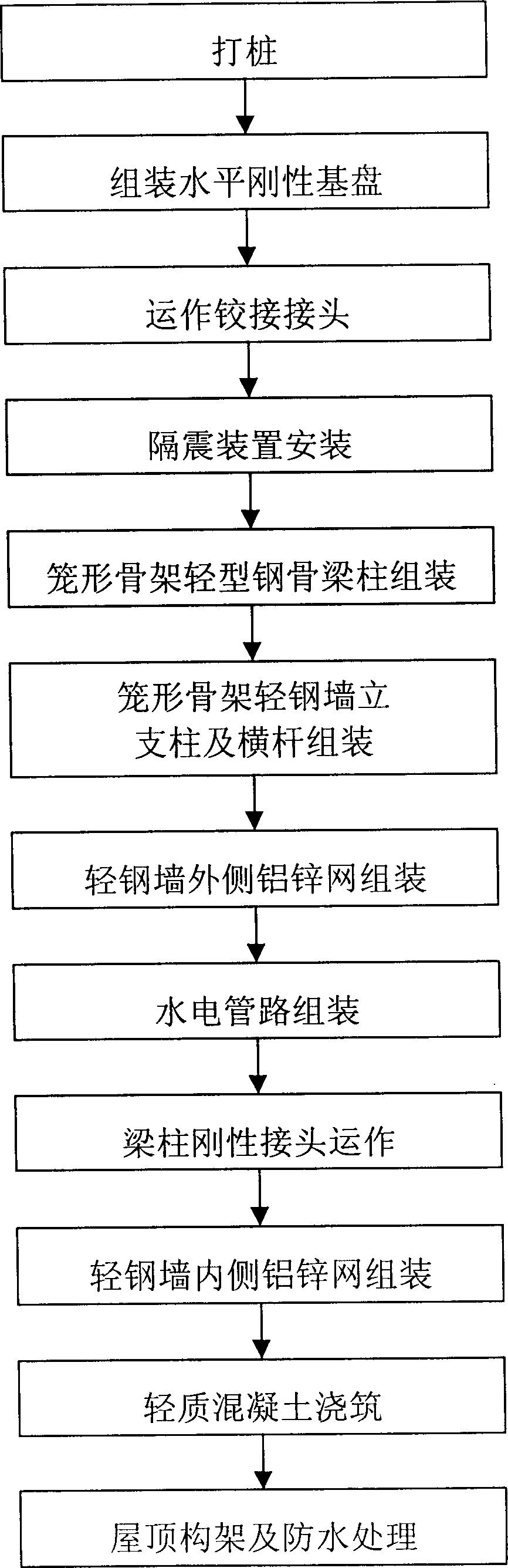

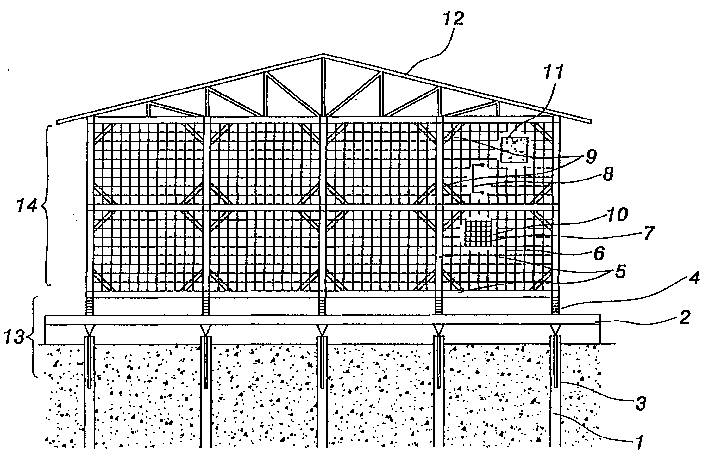

Light reinforced bar concrete binary structure system and method thereof

A light steel skeleton-concrete construction system is disclosed, which is aimed at damping earthquake energy and isolating vibration by eliminating vibration energy. It is composed of cage-shaped light steel skeleton system and light concrete filled in said light steel skeleton systems. It has also beams, columns, slabs and shear walls. Its advnatages are low story height, less steps of stairs, low cost, and high effect on resisting earthquake, typhoon, fire accident and insulating heat and sound.

Owner:刘志鹏

Double beam floor structure

Owner:杨大刚

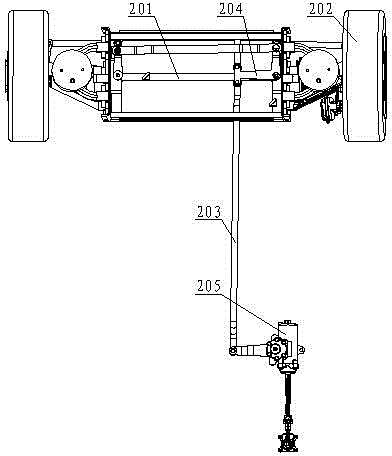

Wheel beam type axleless vehicle frame

ActiveUS20170349214A1Mass production be facilitateStandardize assemblyUnderstructuresVehiclesModularityVehicle frame

The present application discloses a wheel beam type axleless vehicle frame that comprises five sections in sequence from front to back, including a front hanging rack, a front wheel carrier, an intermediate coupling rack, a rear wheel carrier, and a rear hanging rack. Every two adjacent sections amongst the five sections are manufactured and connected in a unified and standardized integrated mode; a modular combination structure is used; and the five sections, which are independent respectively, may be assembled and adjusted according to requirements, and have sufficient strength and stiffness as well as completely independent interchangeability. The vehicle frame has the advantages that match with the needs of an electric vehicle, and thus may be used as the optimum configuration frame for the electric vehicle; and the vehicle frame may be improved according to requirements to be applicable to various fuel and hybrid electric passenger vehicles and commercial vehicles.

Owner:SHANGHAI LUNLIANG MECHANICAL & ELECTRICAL SCI TECH CO LTD

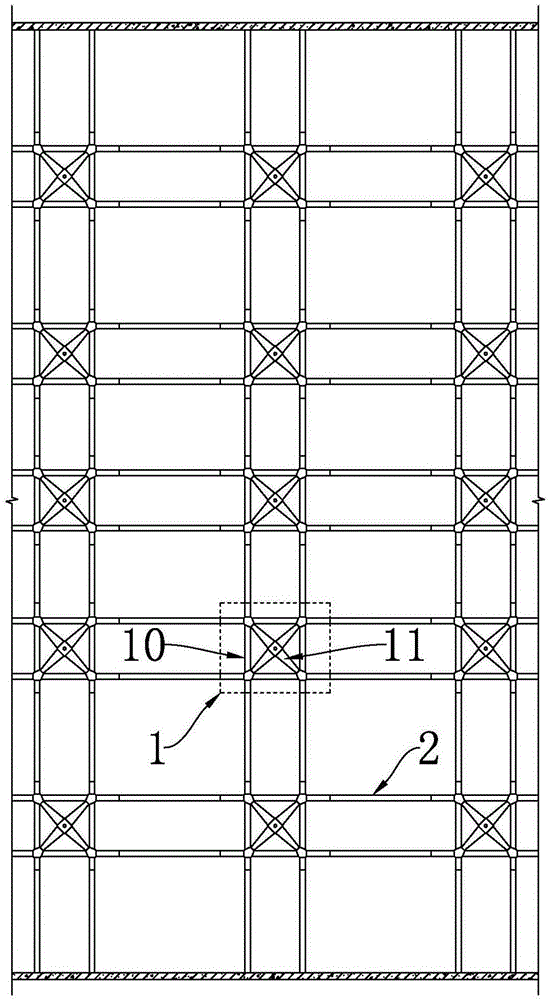

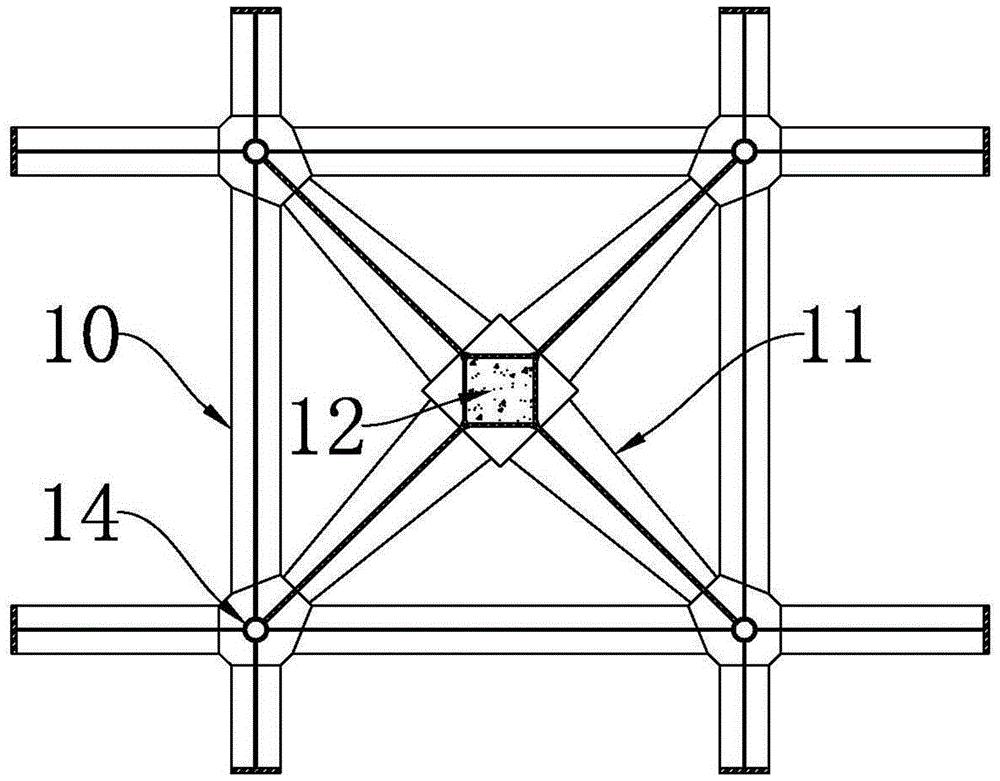

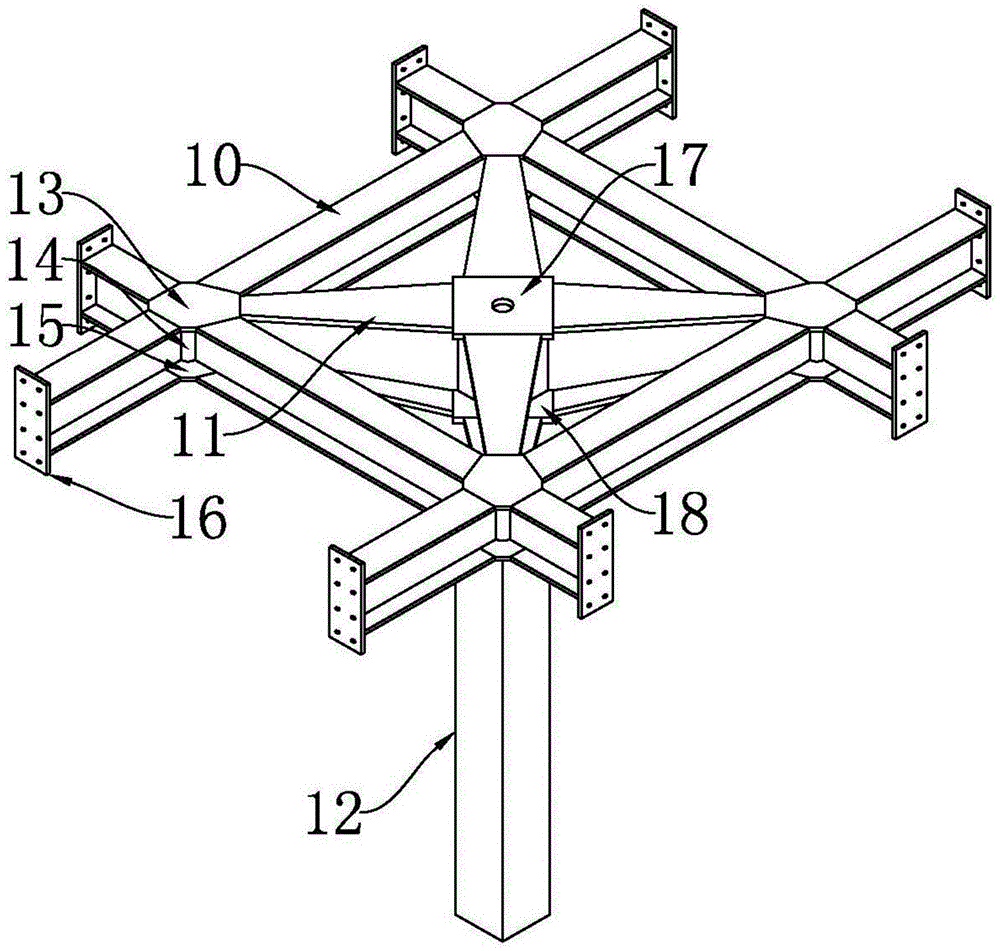

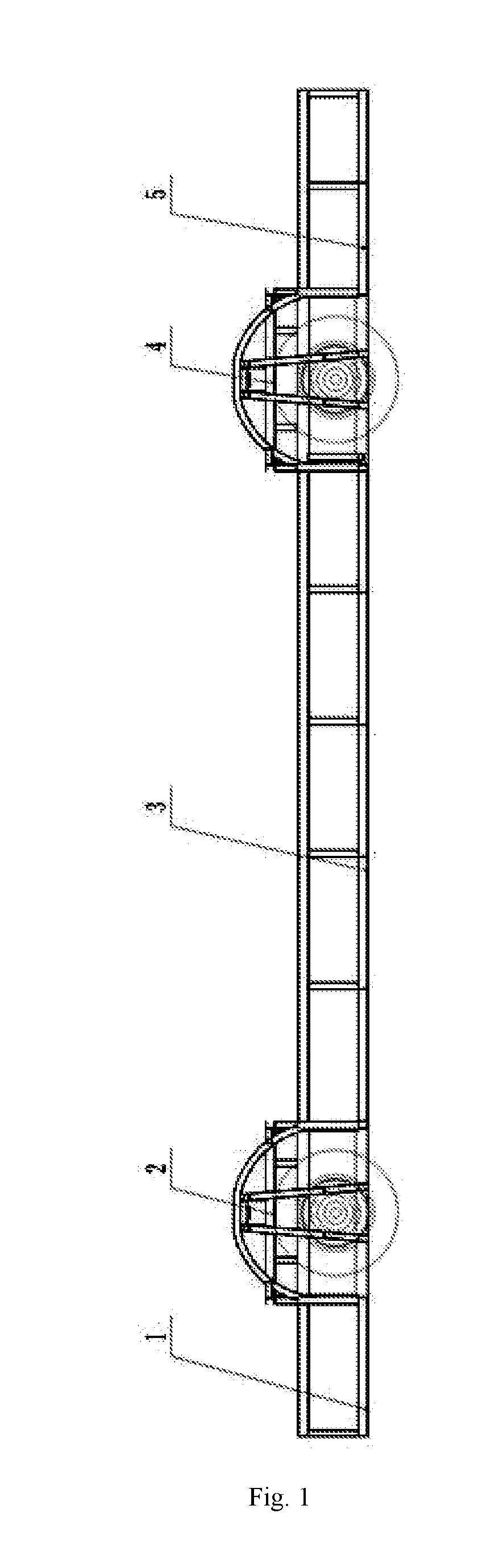

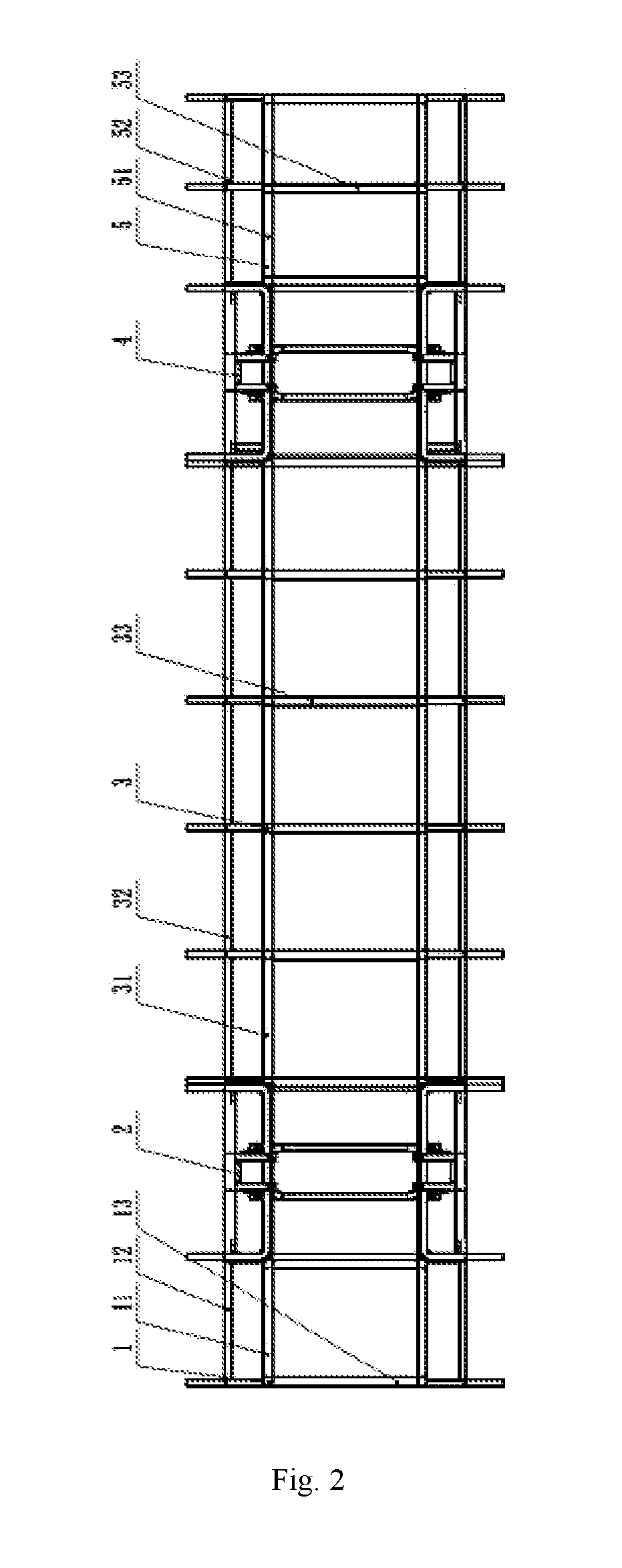

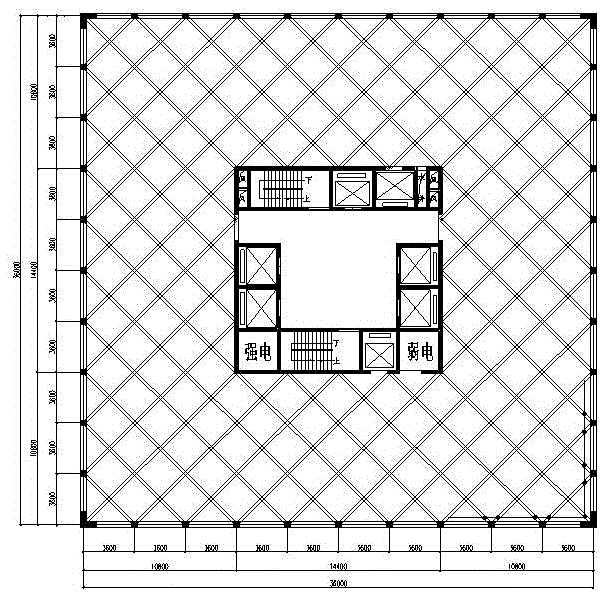

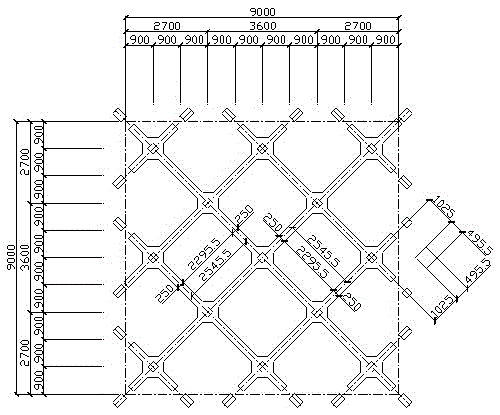

Fabricated concrete orthogonal-diagonal lattice space grid box type tube-in-tube structure and making method thereof

InactiveCN105625566AImprove mechanical propertiesIncrease lateral stiffnessBuilding constructionsLateral stiffnessEngineering

The invention relates to a fabricated concrete orthogonal-diagonal lattice space grid box type tube-in-tube structure. One ends of floor open-web girders and peripheral lattice frame columns are in rigid connection in a two-to-one mode, and the other ends of the open-web girders and tube core shear walls are in rigid connection in a two-to-one mode; a horizontal open-web floor and a peripheral lattice frame are prefabricated in a unitized mode and then installed in a layered mode; the relationship between a peripheral lattice frame column grid a1 and a floor grid a2 is a2=a1sian45 degrees; lateral stiffness is improved by 30%, the influence of shear lag on four-corner columns is reduced, and construction cost is reduced by 25%; indoor rooms can be divided freely, the limitation that girders are required where walls exist is avoided, and storey height is reduced and the number of layers of towers is increased under the condition that maximum tower height and storey clear height are unchanged.

Owner:WEIFANG CHANGDA CONSTR GROUP +5

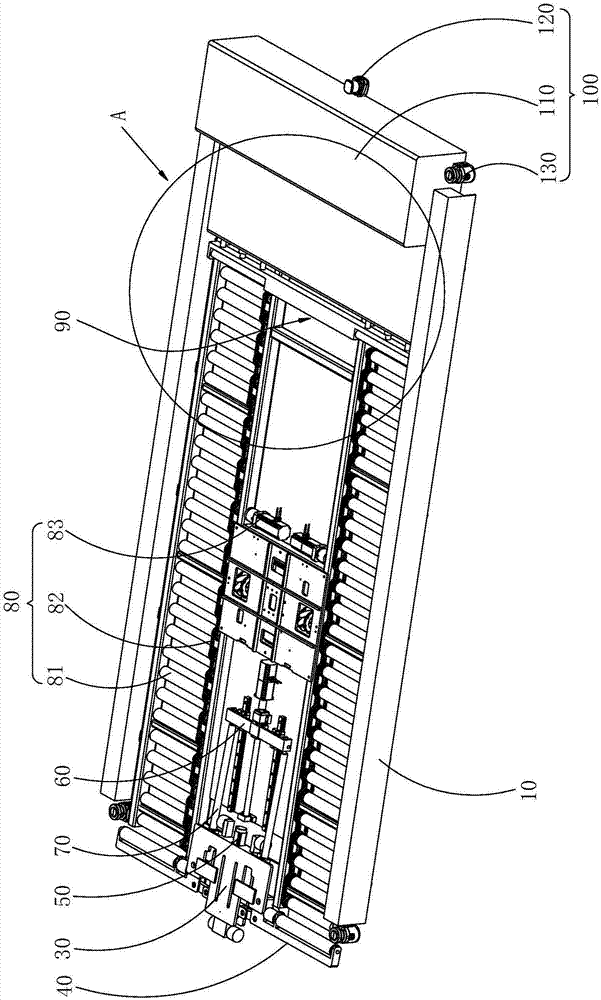

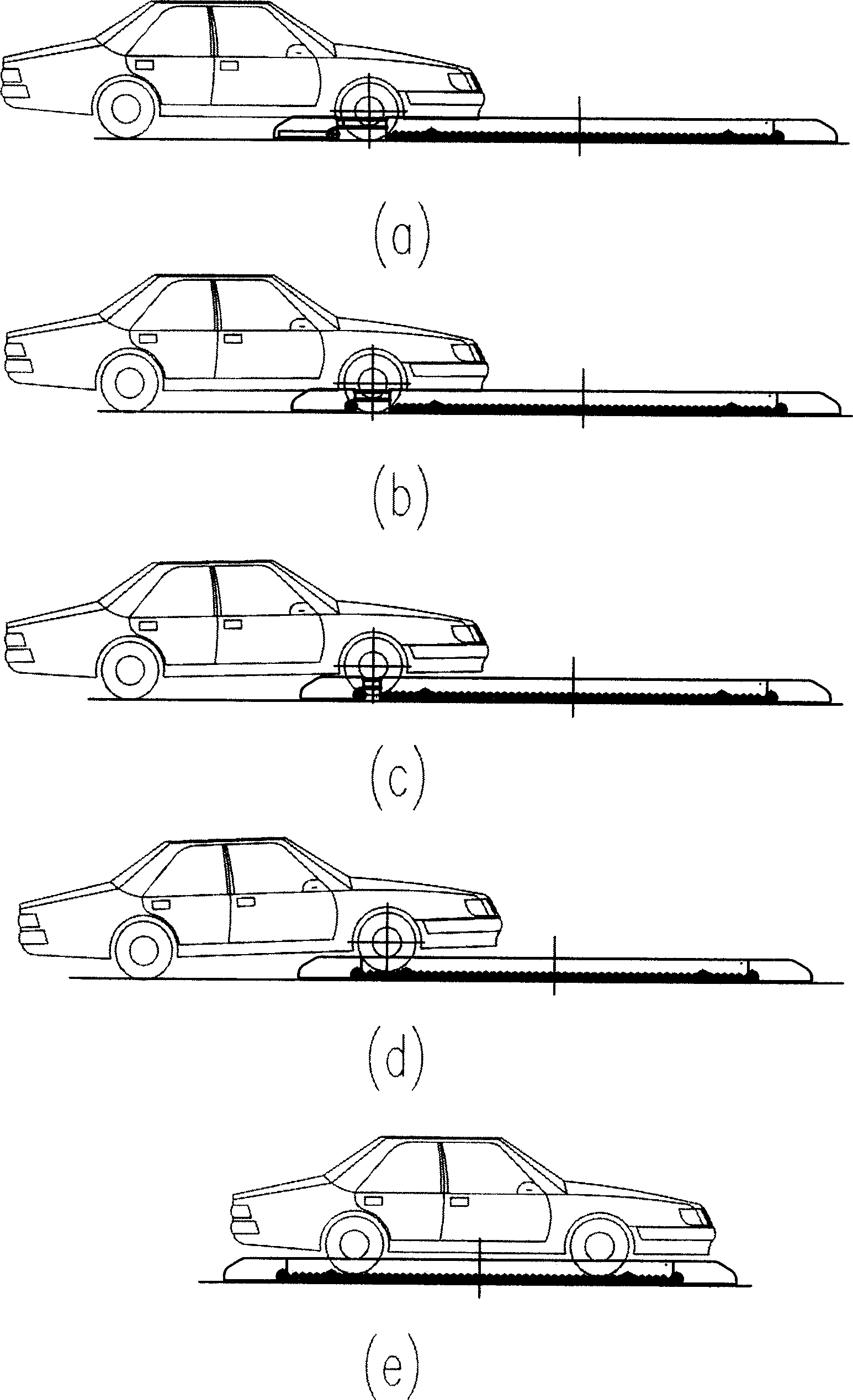

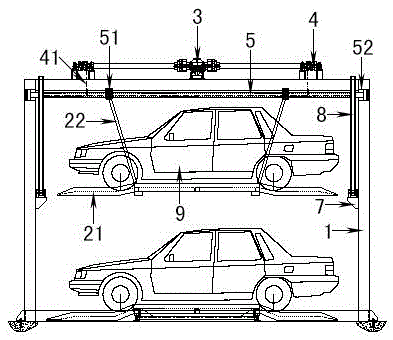

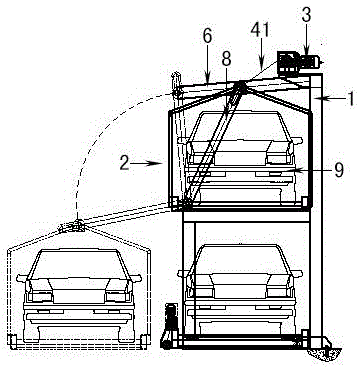

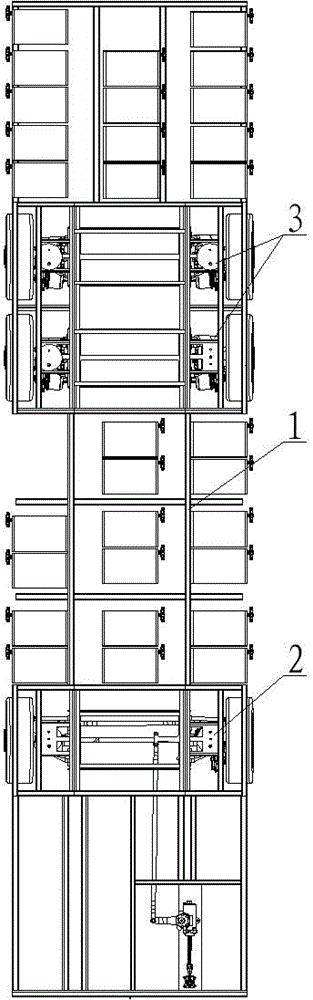

Hanging basket type stereoscopic garage and method for automobile to go in and out of garage

Provided are a hanging basket type stereoscopic garage and a method for an automobile to go in and out of the garage. The automobile stops on an automobile carrying plate of a hanging basket, a lifting shaft and the hanging basket are controlled to move through a steel wire rope of a wind-up and pay-off winch, and therefore the automobile is lifted and put down. The hanging basket is hinged to the lifting shaft, and the automobile can be always parallel to the ground in the lifting and putting-down process. Fixed bases are arranged on a framework frame, and swing rods are hinged to the bases and can rotate around the bases. When the automobile goes in the garage, the winch winds up the steel wire rope, and the automobile firstly rotates around the bases along with the hanging basket and the lifting shaft along with the swing rods. When rolling wheels at the two ends of the lifting shaft enter inclined guide rails, the rolling wheels roll in the inclined guide rails, and the automobile and the hanging basket do linear motion along with the lifting shaft along the inclined guide rails. When the automobile goes out of the garage, the steel wire rope is paid off, and the motion states of the lifting shaft, the hanging basket and the automobile are opposite to those in the garage going-in process. According to the hanging basket type stereoscopic garage and the method, the story height of the upper layer of the garage can be reduced, and building cost can be reduced. The hanging basket is hinged to the lifting shaft through hinge lugs, and therefore it can be ensured that the automobile stably ascends and descends in the hanging basket.

Owner:ZHUZHOU HUASHENG IND CO LTD

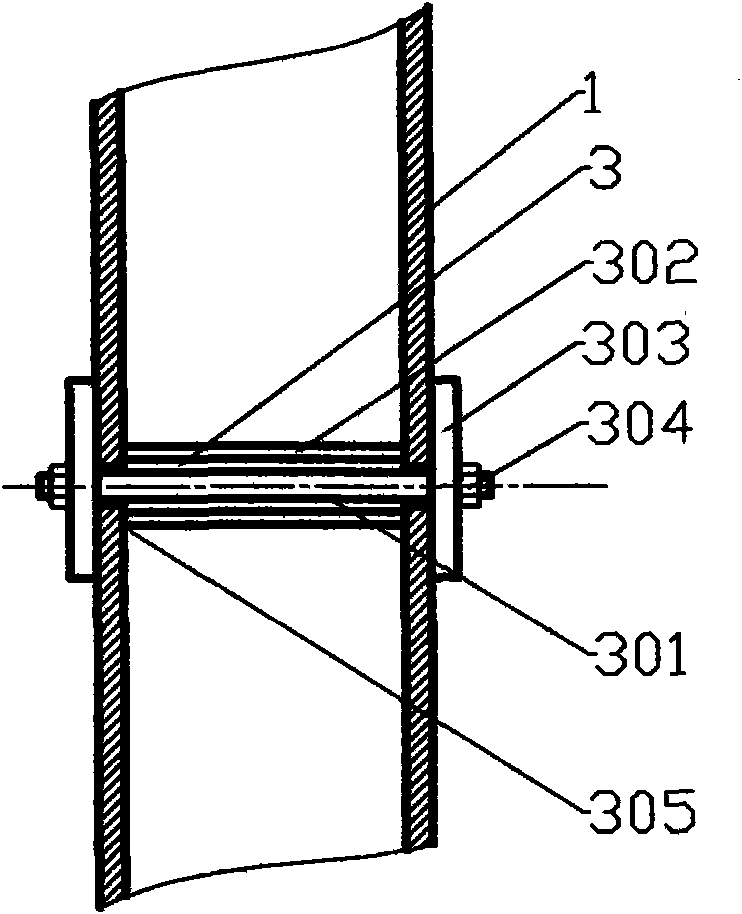

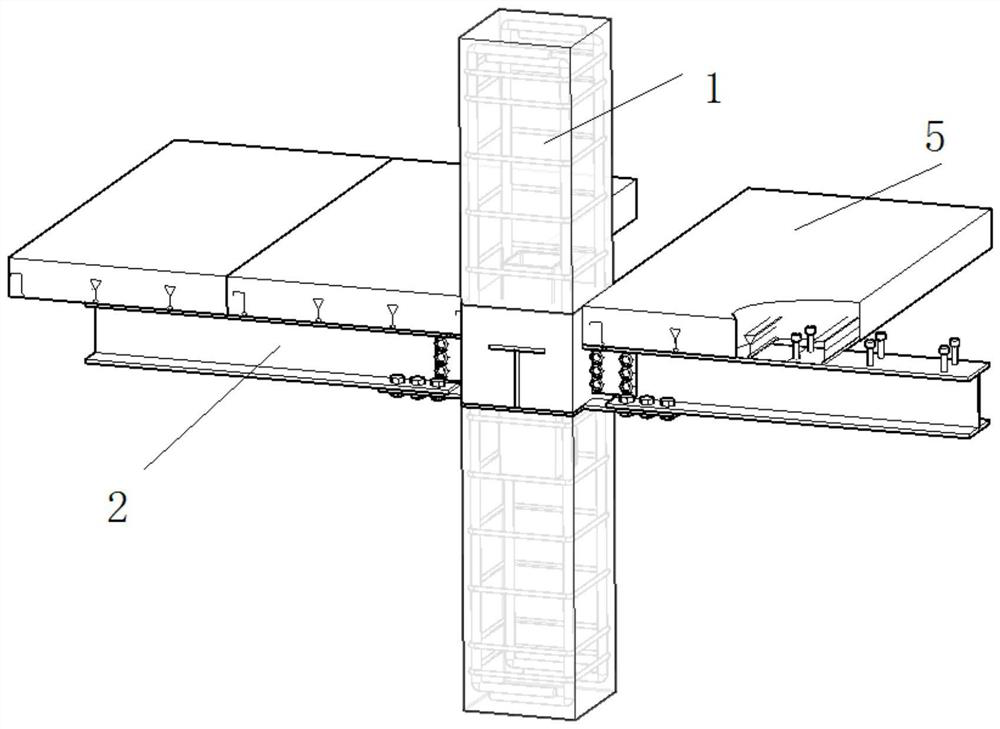

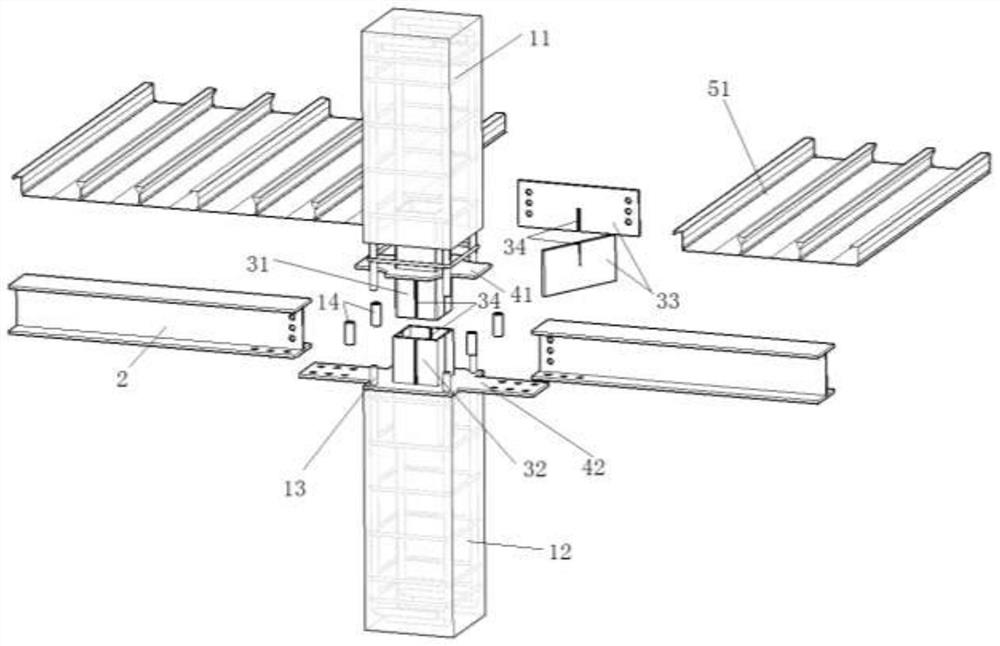

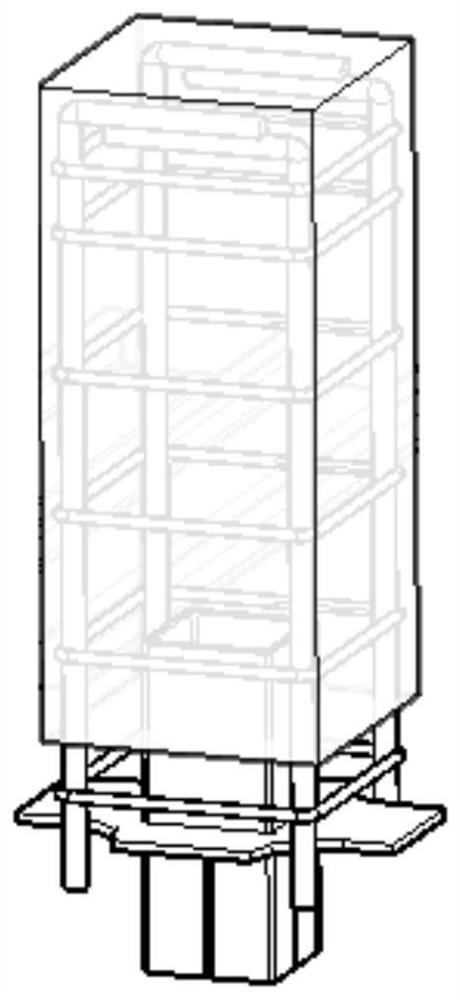

Tenon type insertion novel fabricated steel-concrete composite joint

ActiveCN112144668AFlexible connectionReduce complexityStrutsFloorsReinforced concrete columnEarthquake resistance

The invention relates to the field of building structures, and discloses a tenon type insertion novel fabricated steel-concrete composite joint. The tenon type insertion novel fabricated steel-concrete composite joint comprises a reinforced concrete column, an H-shaped steel beam, a tenon type insertion assembly, an annular connecting plate and a composite floor slab, the tenon type insertion assembly comprises a tenon type insertion inner sleeve, a tenon type insertion outer sleeve and a cross plate, the annular connecting plate comprises an upper flange annular connecting plate and a lower flange annular connecting plate, an upper reinforced concrete column body and a lower reinforced concrete column body are connected through the tenon type insertion assembly, the reinforced concrete column and the steel beam are connected through the tenon type insertion assembly and the annular connecting plate, and the composite floor slab is fixedly connected with the H-shaped steel beam. According to the tenon type insertion novel fabricated steel-concrete composite joint, steel beams in different directions can be flexibly connected through the tenon type insertion assembly and the annularconnecting plate in the core area, the bearing capacity and shear resistance of the joint core area can be remarkably improved, machining and prefabrication are easy and convenient, and good overallconnectivity, bearing capacity and anti-seismic property are achieved.

Owner:QINGDAO TECHNOLOGICAL UNIVERSITY

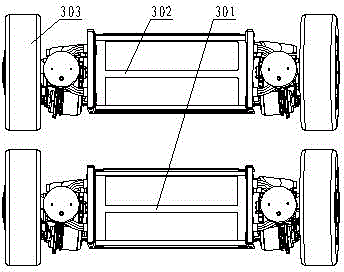

Three-axle single-tire loaded electric bus

InactiveCN104129263AReduce volumeLower seat heightSteering linkagesElectric propulsion mountingElectric driveTransaxle

The invention discloses a three-axle single-tire loaded electric bus. The bus comprises a chassis, a steering mechanism and a driving mechanism, wherein the steering mechanism and the driving mechanism are fixed on the chassis, the steering mechanism is positioned on the front side of the driving mechanism, and the steering mechanism comprises a steering axle and two steering wheels respectively arranged on both sides of the steering axle; the driving mechanism comprises driving axles, electric drive systems and driving wheels, the driving axles comprise a first driving axle and a second driving axle which are both horizontally arranged and in parallel each other, the driving wheels and the electric drive systems enabling the driving wheels to rotate are respectively arranged on the left sides and the right sides of the first driving axle and the second driving axle, and the electric drive systems are fixed on the driving axles. When the bus disclosed by the invention is applied, the steering wheels, the driving wheels and the electric drive systems, of which the volumes are small, can be adopted, so that altitude differences between bosses, corresponding to the mounting positions of the steering wheels, the driving wheels and the electric drive systems, on a bottom plate of a carriage, and the floor of the carriage can be reduced. After seats are arranged on the bosses, crews can take seats and stand up conveniently.

Owner:中植新能源汽车有限公司

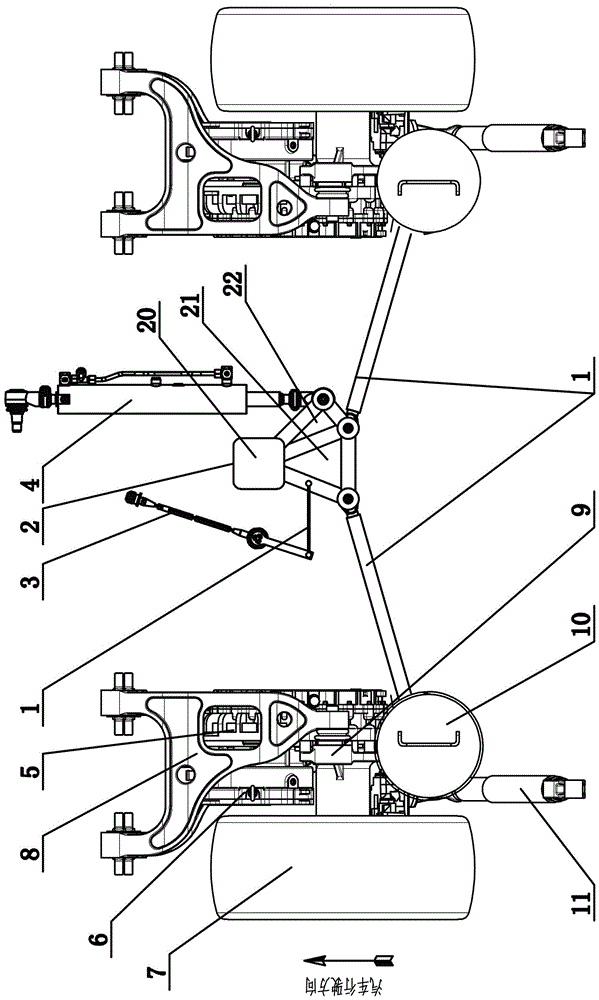

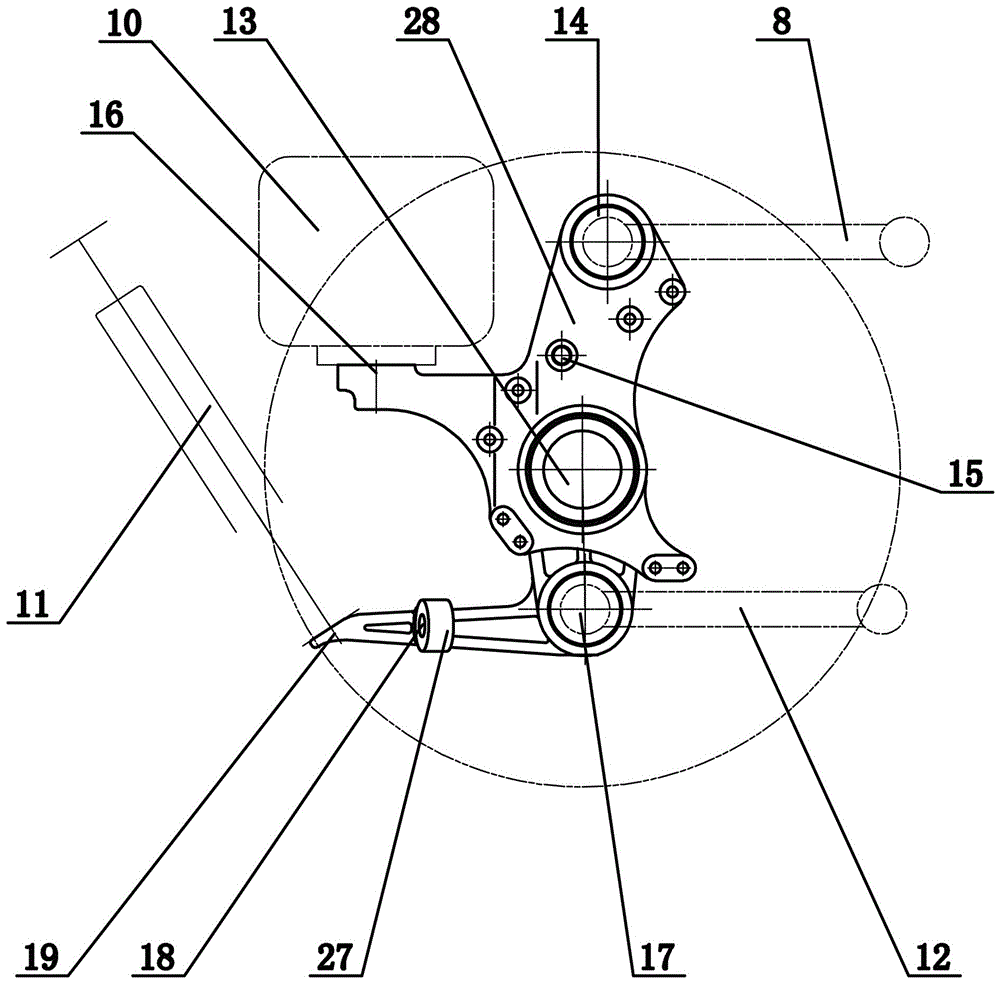

Double-trailing arm type steering independent suspension for electric bus driven by wheel-side motors

InactiveCN106364309ALower the altitudeImprove layout space and corner requirementsMotor depositionResilient suspensionsElectric machineTrailing arm

The invention relates to a double-trailing arm type steering independent suspension for an electric bus driven by wheel-side motors. The double-trailing arm type steering independent suspension comprises a left suspension, a right suspension, steering linkages, a steering rocker arm, an angle sensor and a steering actuating cylinder. According to the double-trailing arm type steering independent suspension disclosed by the invention, drive motors are arranged at wheel positions of the bus; each drive motor is located on the side of an output shaft of each of speed reducers; each speed reducer is fixed to each of supporting arms; the output shaft of each speed reducer penetrates through a center hole of each supporting arm and is connected with each of wheel-side structures of the bus, and a wheel of each wheel-side structure is driven to rotate, so that the driving to the bus is realized; the supporting arms are designed with high load-bearing performance to replace a conventional supporting arm structure, so that a shock absorber and a steering mechanism can be directly connected with the supporting arms, the steering and the locking of the bus are facilitated, and beside, the purposes of increasing the interior space of the bus and reducing the height of a bus floor can be realized.

Owner:ZHENGZHOU JINGYIDA AUTO PARTS

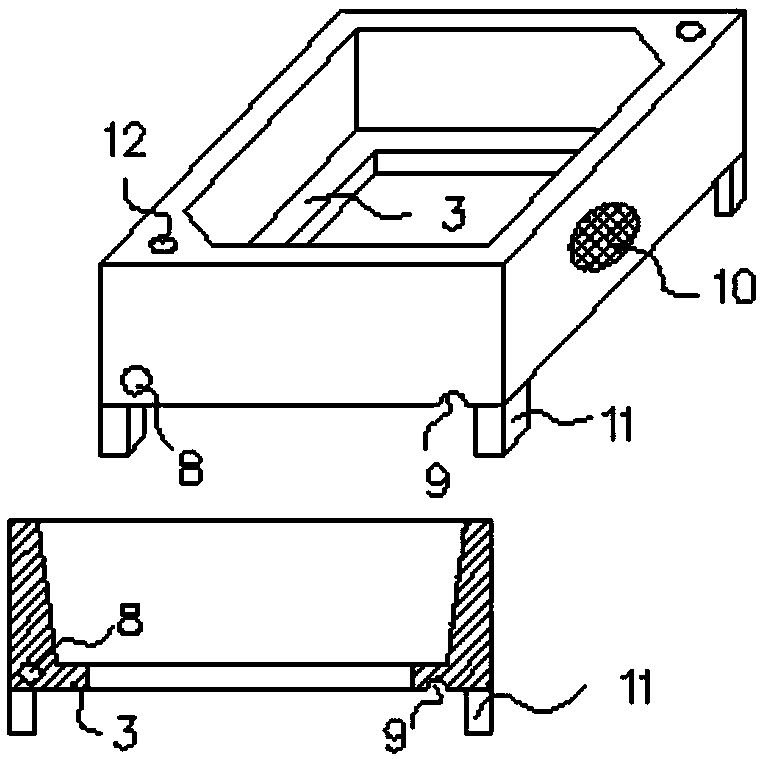

Perforated steel plate concrete shear wall connecting beam provided with stud

The invention discloses a perforated steel plate concrete shear wall connecting beam provided with a stud, and belongs to the field of building engineering. The connecting beam consists of a beam longitudinal rib 4, a connecting beam stirrup 5, connecting beam concrete 6, a steel plate 10, the stud 9 and steel plate perforations 11; and the perforated steel plate concrete shear wall connecting beam provided with the stud is a building or a structure in a form of the perforated steel plate concrete shear wall connecting beam provided with the stud. Because the steel plate adopted in the connecting beam is a planar member, the trouble that a vertical steel bar in a node zone wall is required to go around the flange of a steel beam, and construction is facilitated; because of packaging of the external concrete, the problems of internal and external instability on the plane of the steel plate and fire resistance are effectively solved; through the stud arranged on the steel plate, anchorage and stability of the steel plate and cooperation of the concrete and the steel plate can be ensured; and the connecting beam is suitable for high-rise and super high-rise buildings.

Owner:中国建筑东北设计研究院有限公司

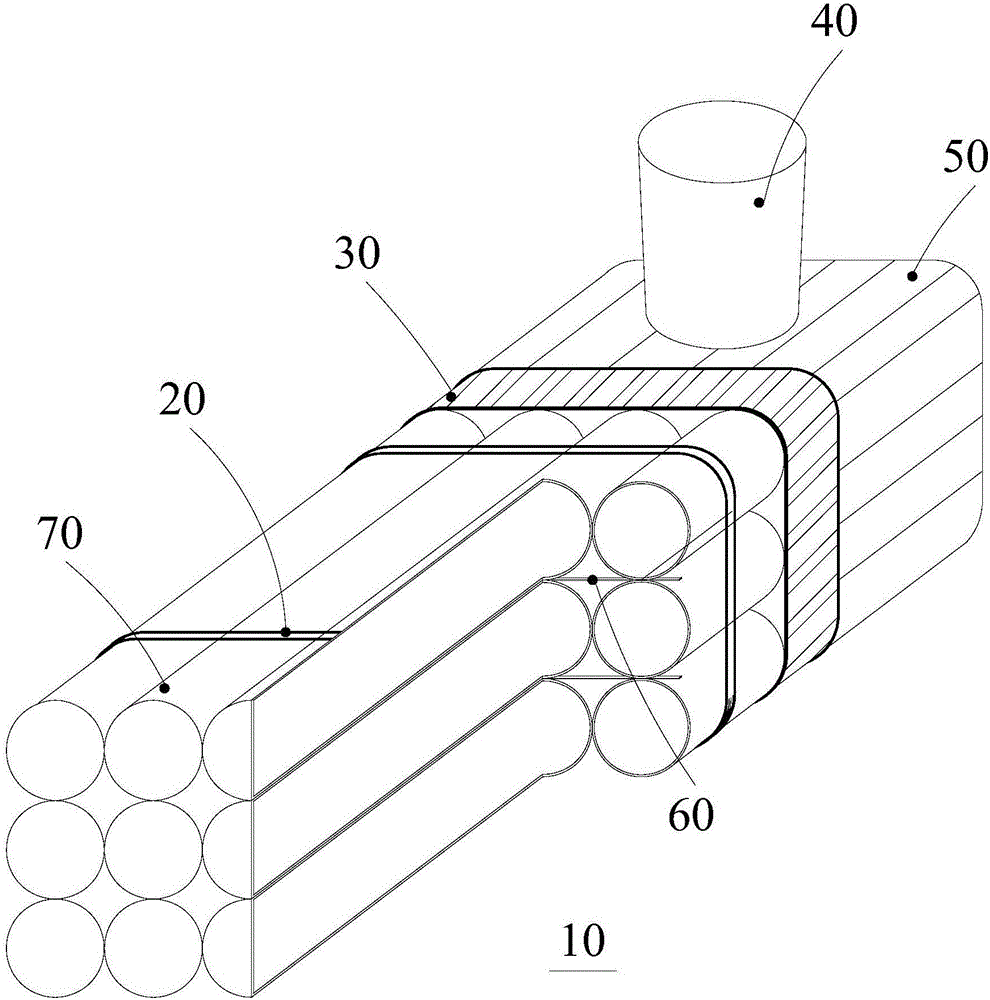

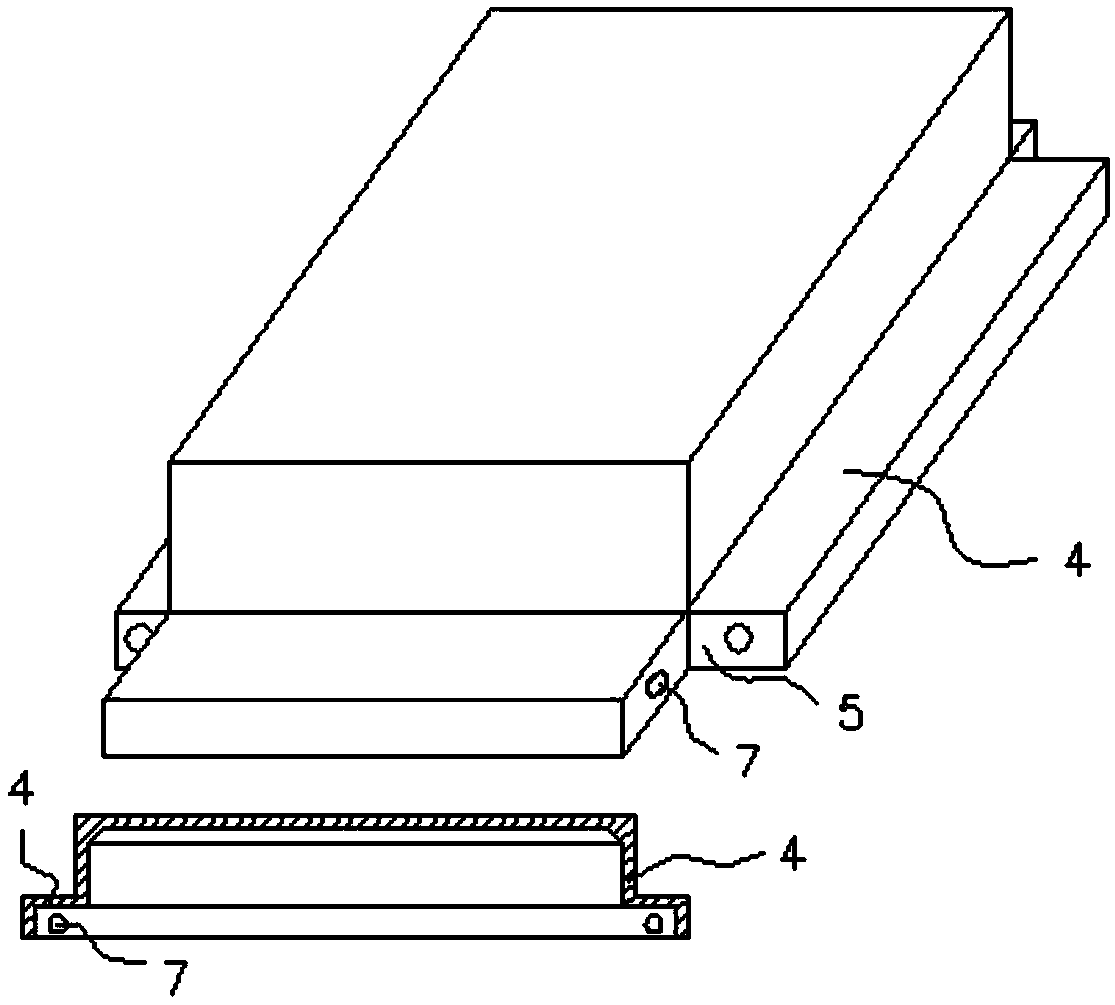

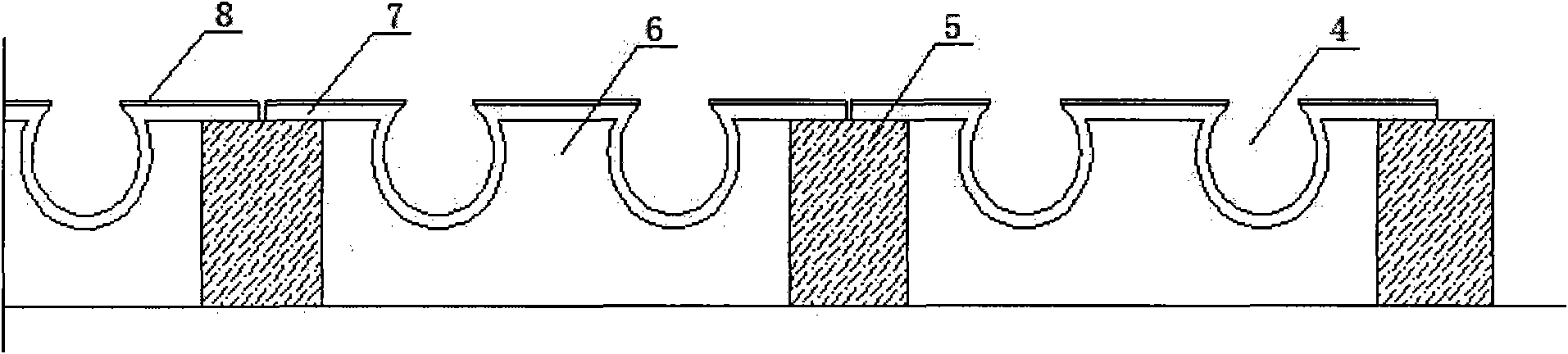

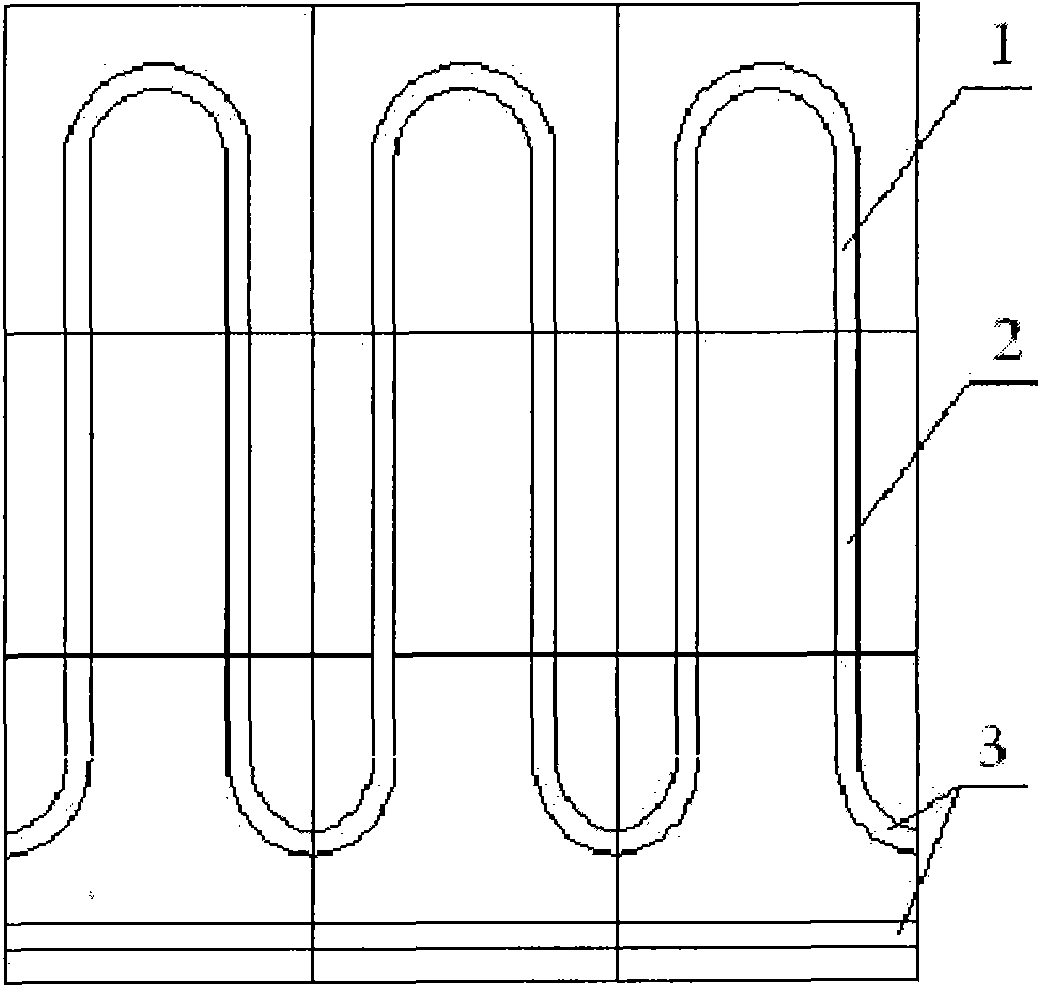

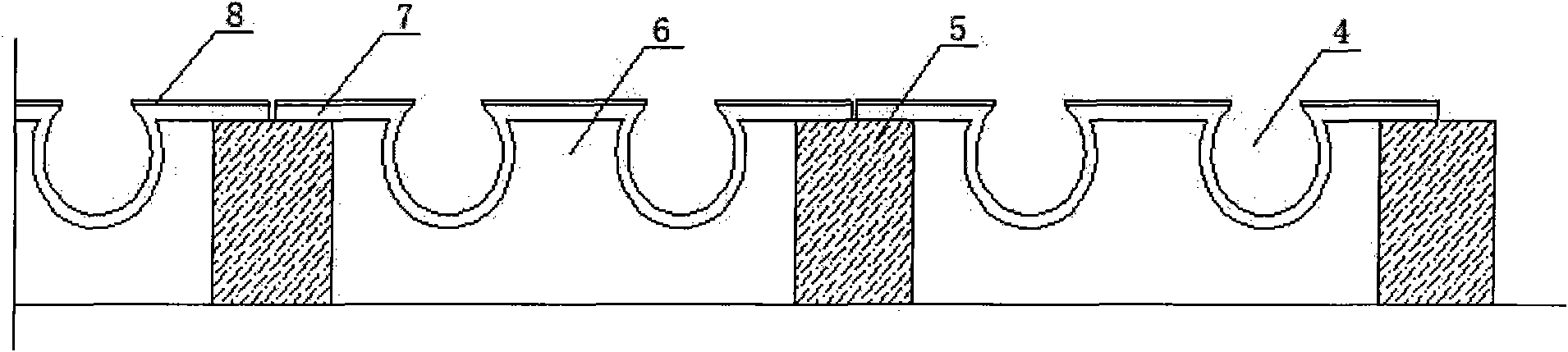

Floor radiation cooling/heating module and manufacturing method thereof

The invention belongs to the technical field of home floors and provides a floor radiation cooling / heating module. The floor radiation cooling / heating module is characterized in that an insulating layer and an aluminium sheet are closely fit and connected into a whole and are provided with grooves; the two side edges of the groove mouths bend inwards in opposite directions to form inverse omega shaped circular arc grooves; and a far infrared radiation coating is arranged on the surface of the heat transfer aluminium sheet. A manufacturing method of the floor radiation cooling / heating module comprises the following steps: 1) cutting the aluminium sheet and stamping the aluminium sheet into the inverse omega shaped circular arc grooves; 2) spraying polyurethane foaming materials on the back of the aluminium sheet to form the polyurethane insulating layer; and 3) finally selecting the far infrared coating according to the needed infrared band and spraying the far infrared coating on the surface of the aluminium sheet. The invention has the following positive effects: the cooling / heating module is thin and light, thus saving the floor height of the room and lightening the structural load of the floor; the inverse omega shaped circular arc grooves block and are securely connected with the water pipes; with the far infrared radiation coating, the aluminium sheet has the effects of promoting blood circulation and improving the disease resistance, which are beneficial to human health; and the cooling / heating module can be put into operation in batch in factories and undergo dry laying at the site.

Owner:SHANGHAI COLLODIN MATERIAL TECH DEV CO LTD +1

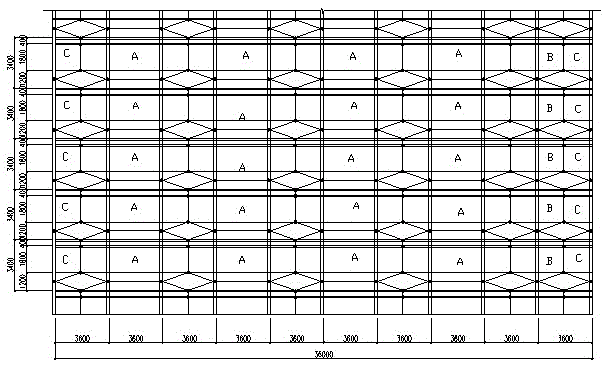

Large-span large-load prestressed grooved laminated slab used as basement roof

The invention discloses a large-span large-load prestressed grooved laminated slab used as a basement roof, which is characterized in that the large-span large-load prestressed grooved laminated slab has appearance of a grooved slab; a functional component is formed by the grooved slab and an upper laminating layer; due to the groove shape and the large load of the large-span large-load prestressed grooved laminated slab, the application requirement of an underground parking garage is met; due to the large span, parking spaces are saved; due to the grooved narrow slab surface, the cost and the story height are saved; and due to the suitable rib height, not only can the load requirement be met, but also the requirement for opening an air duct on a rib can be met, the story height is not increased and the grooved transverse air duct is easy to connect. When the large-span large-load prestressed grooved laminated slab is used at the top of an underground parking garage slab, the construction period can be quickened, the story height is reduced, the cost is reduced, column grids are saved, the parking spaces are increased, and the grade of the underground parking garage is improved.

Owner:QINGDAO JINCHAO SPECIAL CONCRETE PROD

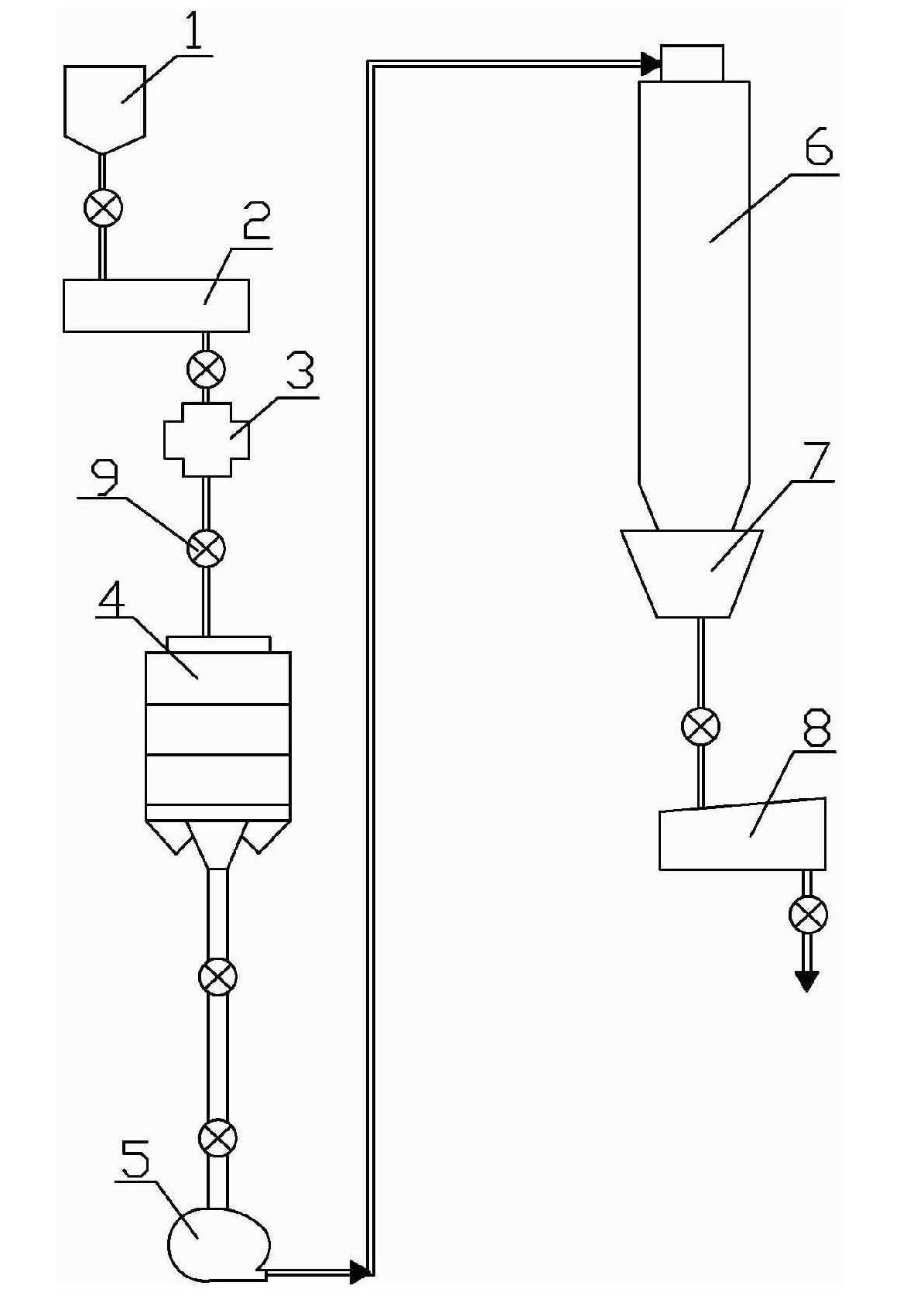

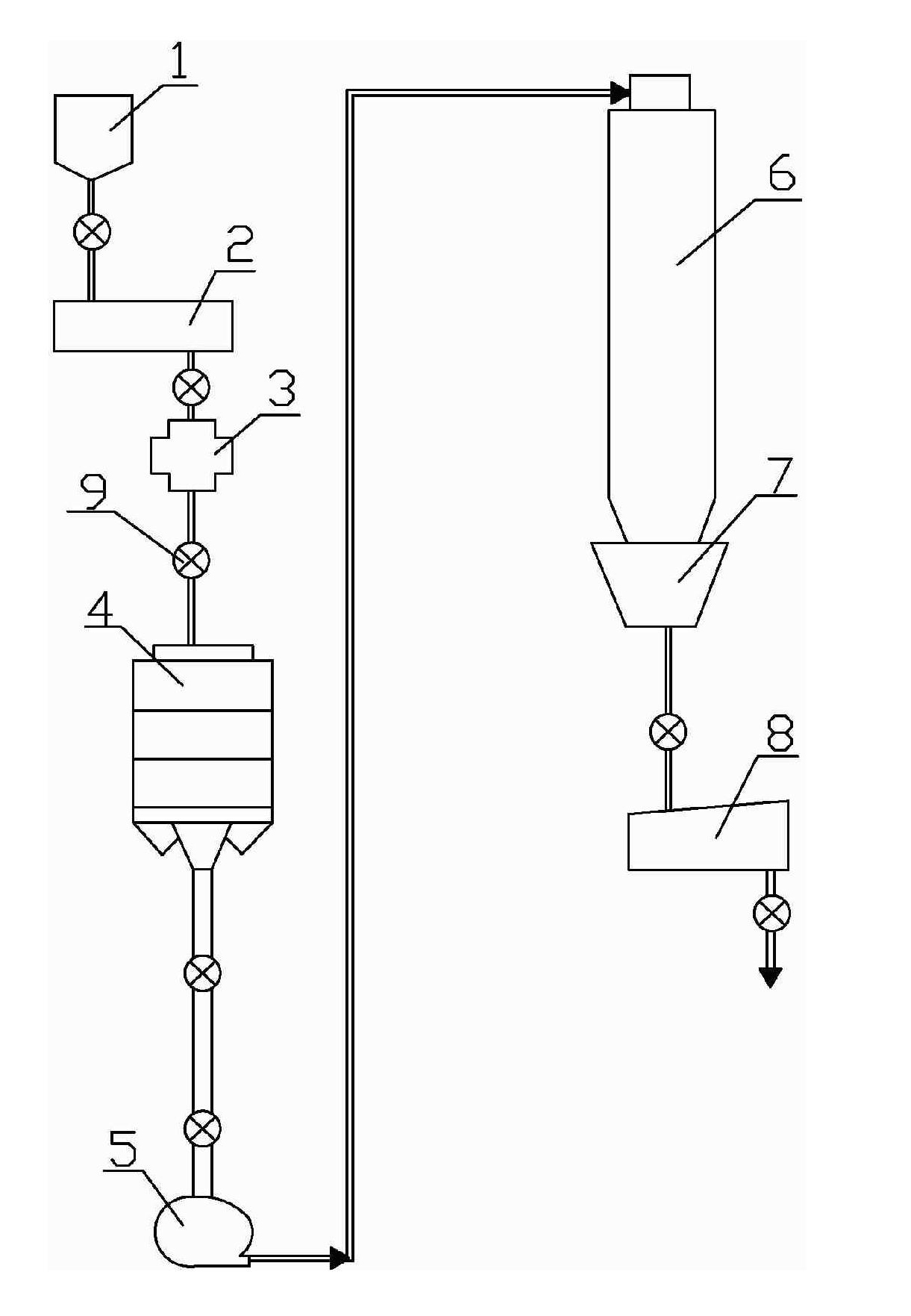

Solid state polymerization technique of polyester industry

The invention discloses a solid phase polymerization technique of the polyester industry. The technique comprises the following steps: the pre-crystallization processing of raw materials, then on-line dust removal, recrystallization, heat transport, main reaction, discharging of machinery, cooling and dust removal to obtain a finished product. The solid phase polymerization technique adopts a reasonable technological route and technological parameters and the whole technique is provided with reasonable production equipment for the solid phase polymerization of the polyester industry, thereby realizing high output, low energy consumption, convenient quality control and regulation and stable product quality.

Owner:ZHEJIANG UNIFULL IND FIBER

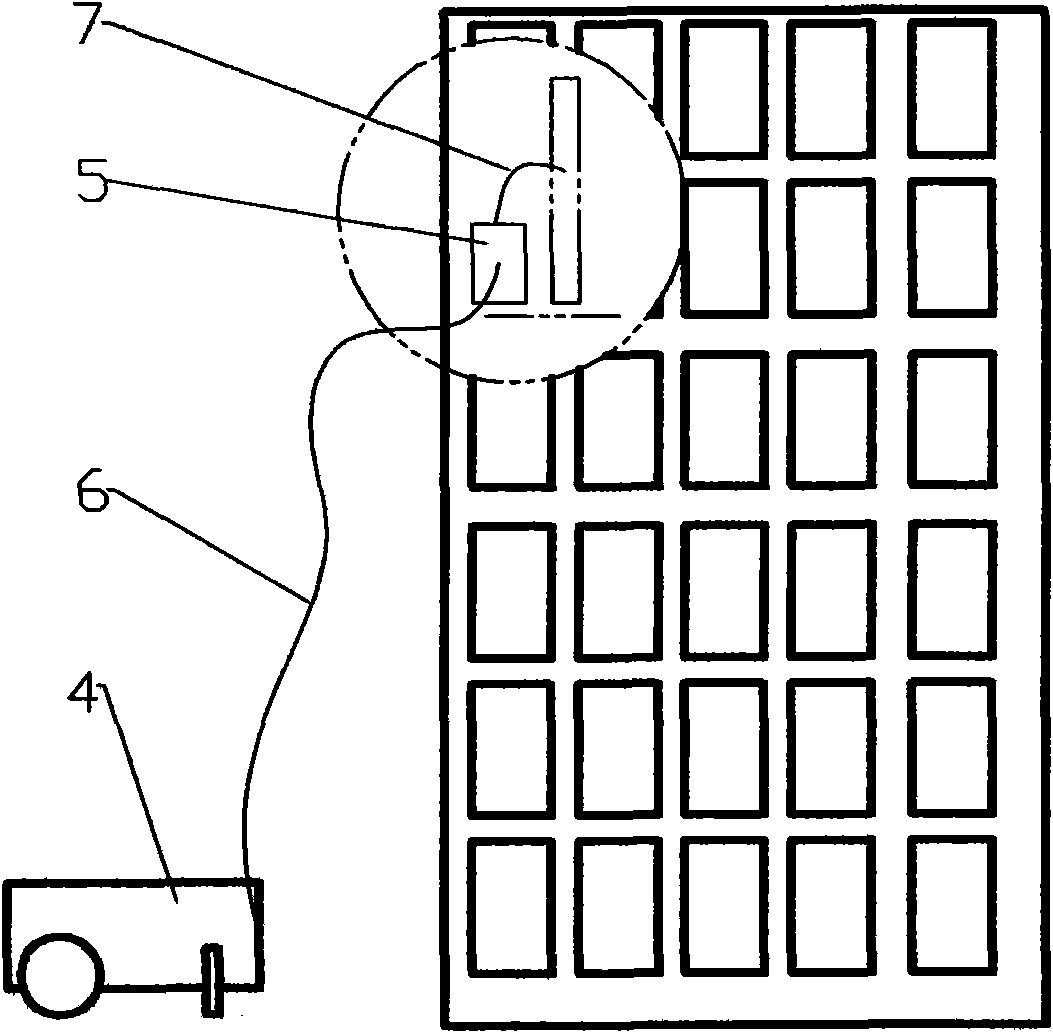

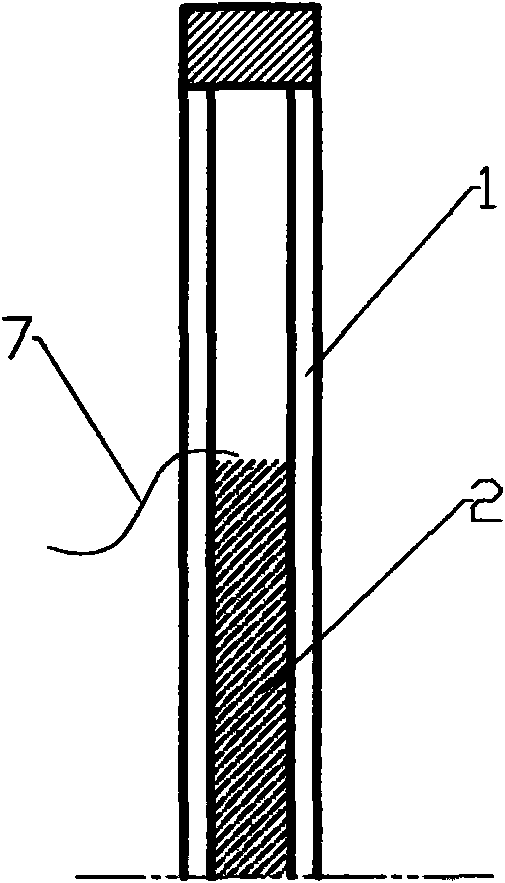

Flat slab ceiling screen

InactiveCN104721991ADoes not affect the spaceAct as a smoke blockFire rescueBoring toolsFloor slabHorizon

The invention discloses a flat slab ceiling screen. The flat slab ceiling screen comprises a smoke detector (1), a marking controller (2), a control line (3), connecting lines (4), a reserved steel bar (5), a telescoping device (6), a smoke barrier plate (7), a floor slab (8), angle iron (9) and a supporting frame (10). By adopting the above structure, the smoke barrier plate does not affect the space at normal time, and is horizontally fixed below the floor plate, and the smoke barrier plate automatically sags through the smoke detector and the controller when a fire hazard occurs in order to realize smoke baffle, so the floor height is reduced, and energy is saved. The invention also discloses a novel vehicle gateway height limiting rack. The novel vehicle gateway height limiting rack comprises a height limiting rack crossbeam (1), a signboard (2), a solar photovoltaic cell panel (3), a horizon (4), a height limiting rack column (5), a storage battery (6) and a charging controller (7). By adopting the above structure, the solar photovoltaic cell panel converts solar energy into electric energy stored in the storage battery during the day, and powers up the LED lamp of the signboard at night, so the renewable clean energy solar energy is used, and pollution is reduced.

Owner:赵治泰

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com