Tenon type insertion novel fabricated steel-concrete composite joint

A combined node and prefabricated technology, applied in building types, truss structures, protective buildings/shelters, etc., can solve the problem that the post-cast concrete cannot be vibrated and compacted, the construction period and labor cost increase, and the sleeve grouting process Cumbersome and other problems, to achieve the effect of strong concrete holding shear resistance, good overall connectivity, and promoting sustainable development

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

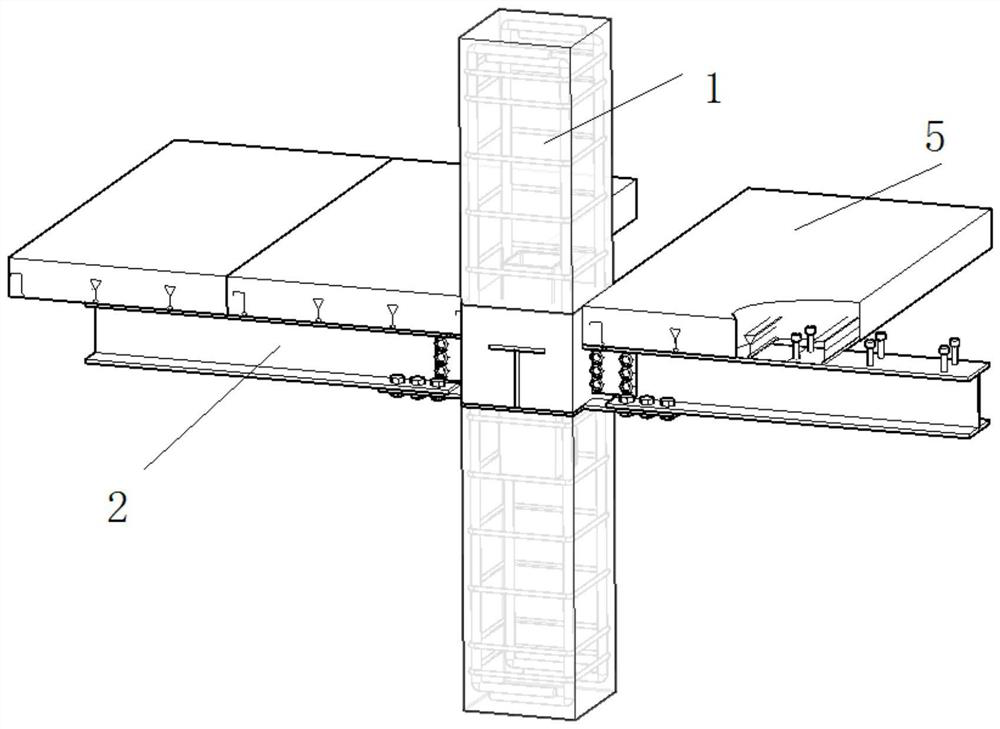

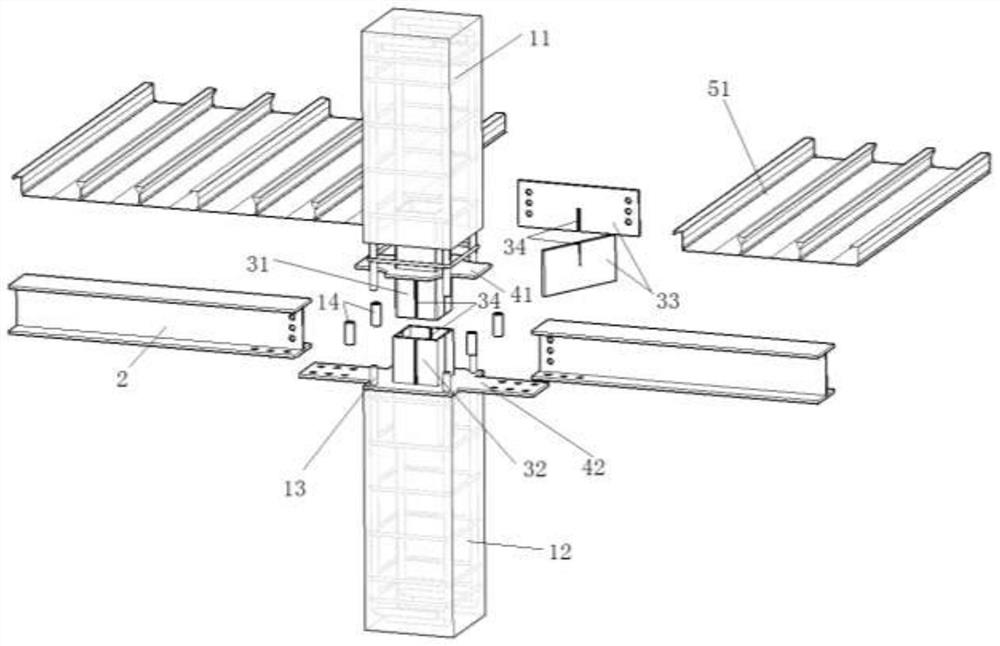

[0047] Such as Figure 1-2 As shown, the new prefabricated steel-concrete composite node with tenon-type insertion according to the present invention includes reinforced concrete column 1, H-shaped steel beam 2, tenon-type insertion assembly 3, circumferential connecting plate 4 and composite floor slab 5.

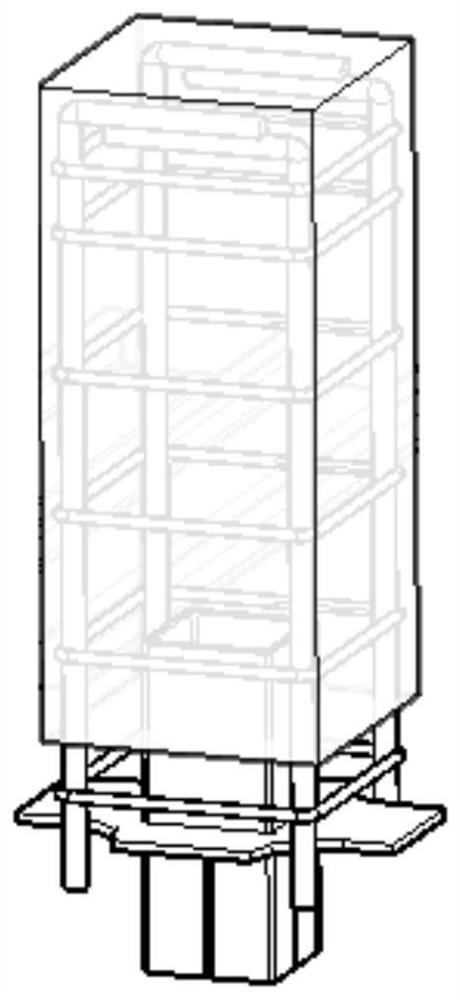

[0048] Among them, the reinforced concrete column includes an upper reinforced concrete column 11 and a lower reinforced concrete column 12, wherein the reinforcement cage includes stirrups and longitudinally stressed steel bars 13, and the upper reinforced concrete column 11 and the lower reinforced concrete column 12 pass through the tenon-type plug-in assembly 3 Connection, the upper reinforced concrete column 11 and the lower reinforced concrete column are connected with the H-shaped steel beam 2 through the tenon-type plug-in assembly 3 and the ring connection plate.

[0049] The tenon joint assembly 3 includes the tenon joint inner sleeve 31 , the tenon joint outer s...

Embodiment 2

[0066] The difference between this embodiment and Embodiment 1 is that the cross-sections of the tenon-type insertion inner sleeve and the tenon-type insertion outer sleeve are both circular, and the others are the same as Embodiment 1. Such as Figure 10 shown.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com