Floor radiation cooling/heating module and manufacturing method thereof

A ground radiation, cooling and heating technology, applied to floors, buildings, building structures, etc., to achieve the effect of simple construction technology, fast and convenient movement, and improved disease resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

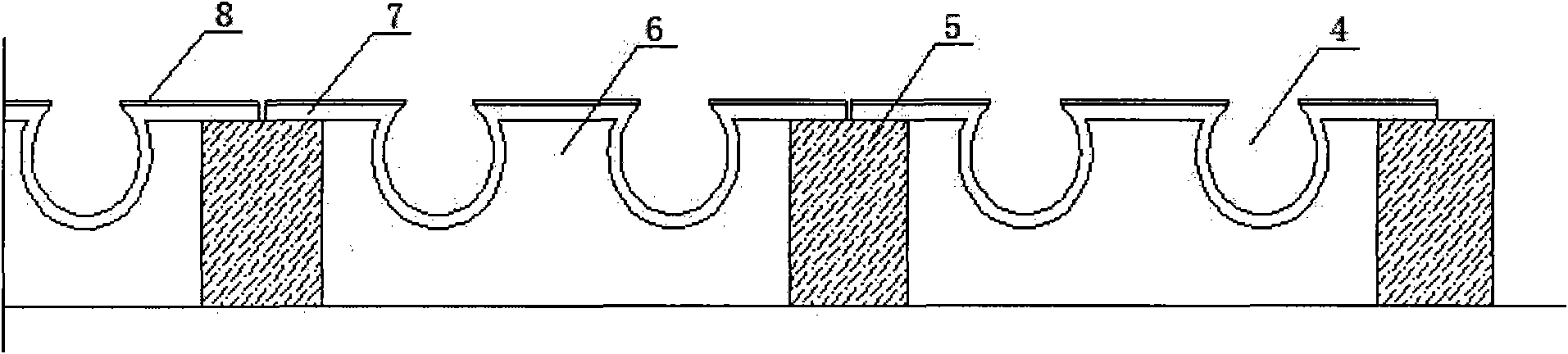

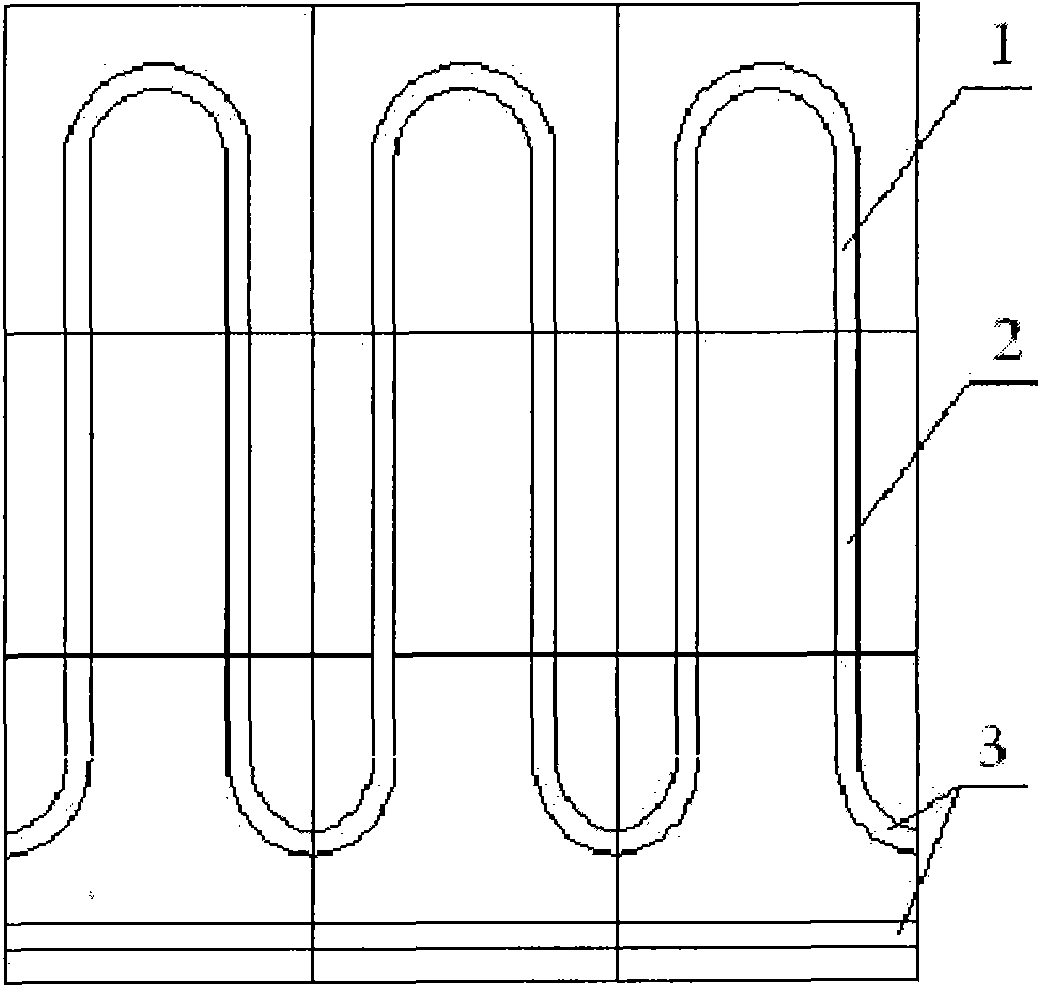

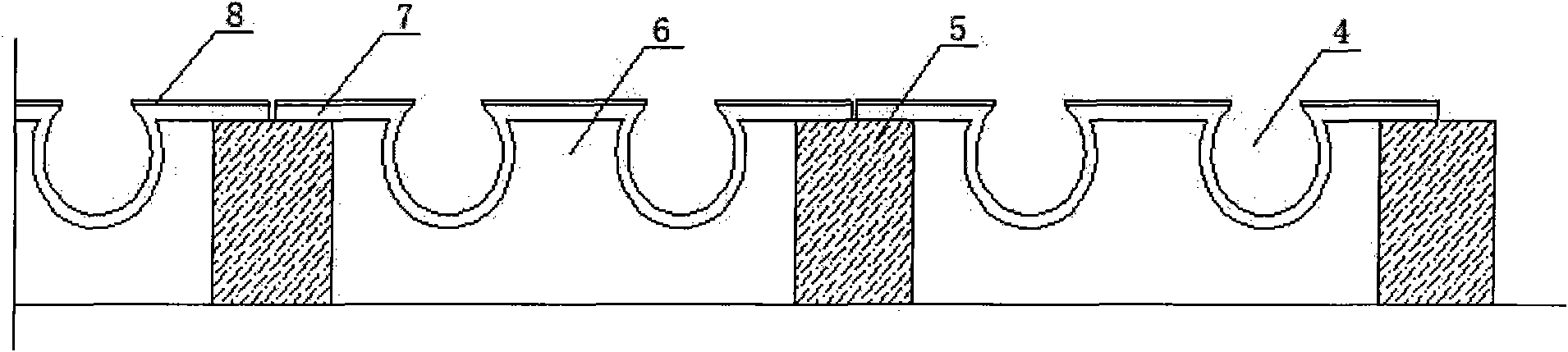

[0017] The structure of the cooling and heating module is as follows: figure 1 As shown, a ground radiant cooling and heating module includes a thermal insulation layer 6 and a heat transfer aluminum plate 7. It is characterized in that: the thermal insulation layer 6 and the heat transfer aluminum plate 7 are closely bonded and connected together, and the thermal insulation layer 6 and the heat transfer aluminum plate 7 is equipped with a groove 4, and the two sides of the notch of the groove 4 are buckled inwardly, forming an inverted Ω arc-shaped groove.

[0018] The diameter of the groove 4 matches the diameter of the hot and cold water pipes, and the direction of the groove 4 is a 180° curved groove 1, or a 90° curved groove, or a straight groove 2, or a combined direction groove 3.

[0019] The surface of the heat transfer aluminum plate 7 is provided with a far-infrared radiation coating 8 .

[0020] The far-infrared radiation coating 8 .

[0021] The production metho...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com