Cars hand-over transporting robot

A technology for handling robots and cars, which is applied in the field of automatic parking equipment and car handover and handling robots, can solve the problems of high product cost of parking equipment, low equipment space utilization, long access time, etc., to improve the effective utilization rate. Effect with parking density, lower floor height, lower cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

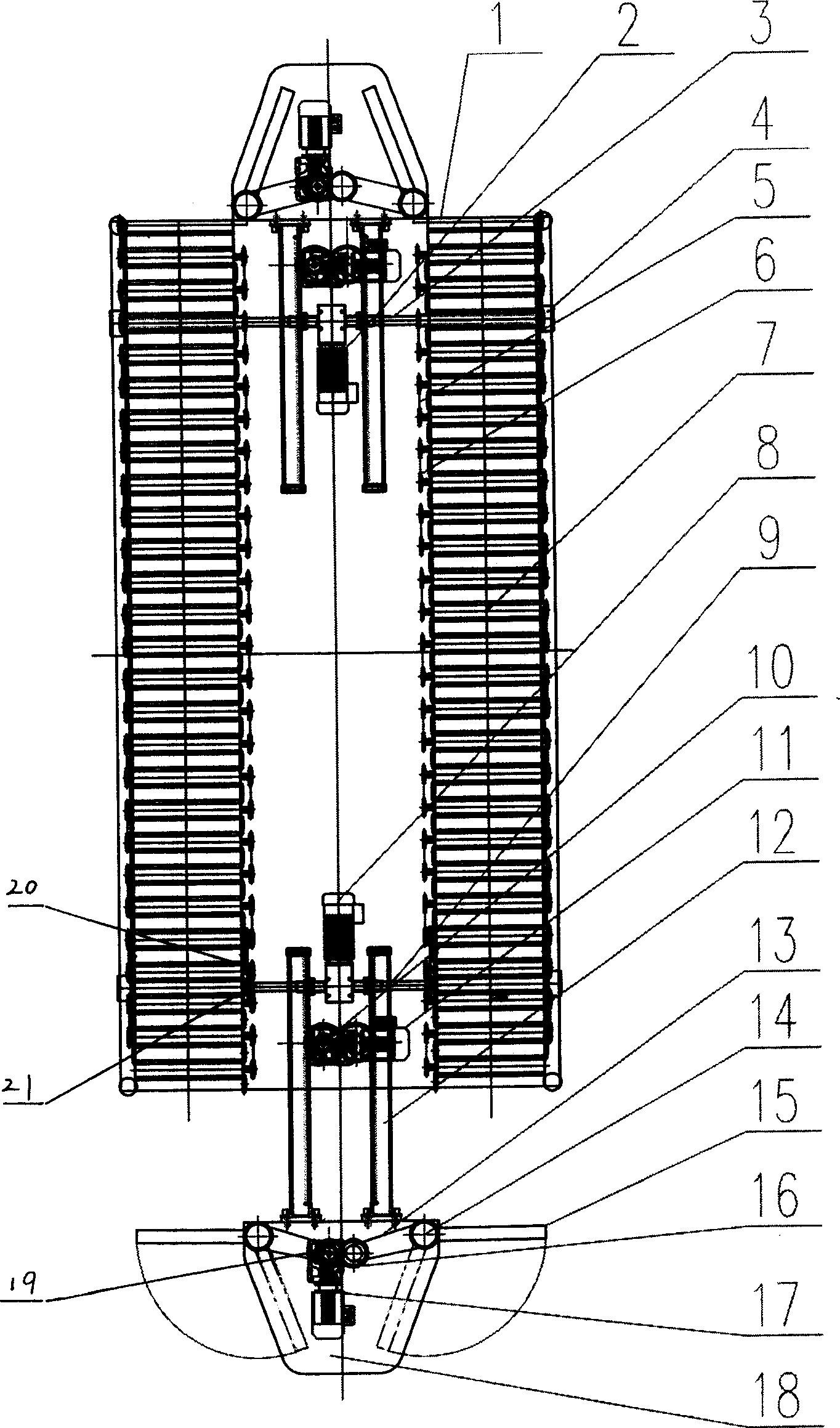

[0017] see figure 1 , the car handover and handling robot of the present invention mainly consists of a walking transport frame, a walking mechanism, a roller driving mechanism, a telescopic mechanism and a clamping mechanism.

[0018] The walking transport frame is the supporting body of the car transport robot, on which other mechanisms are installed to carry the weight of the transported car and the transport robot itself.

[0019] Described walking mechanism is installed on the walking carrying frame 1, mainly is made of traveling wheel 4, reduction motor 2 and transmission shaft 3 etc. Driving wheel 4 has many (four among the figure), is installed in the bottom of walking carrier frame 1. There is one geared motor 2, which is installed in the middle of the front of the rear end of the walking carrier 1. There are two transmission shafts 3, one on the left and one on the right. , the other end links to each other with traveling wheel 4. The transmission shaft 3 is drive...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com