Cover die for construction of composite-section ribbed floor and construction method thereof

A technology of densely ribbed floor and construction method, which is applied in the field preparation of formwork/formwork/work frame, building components, construction, etc., which can solve problems such as non-conformity and long construction period, so as to improve efficiency and reduce formwork costs , The effect of shortening the construction period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

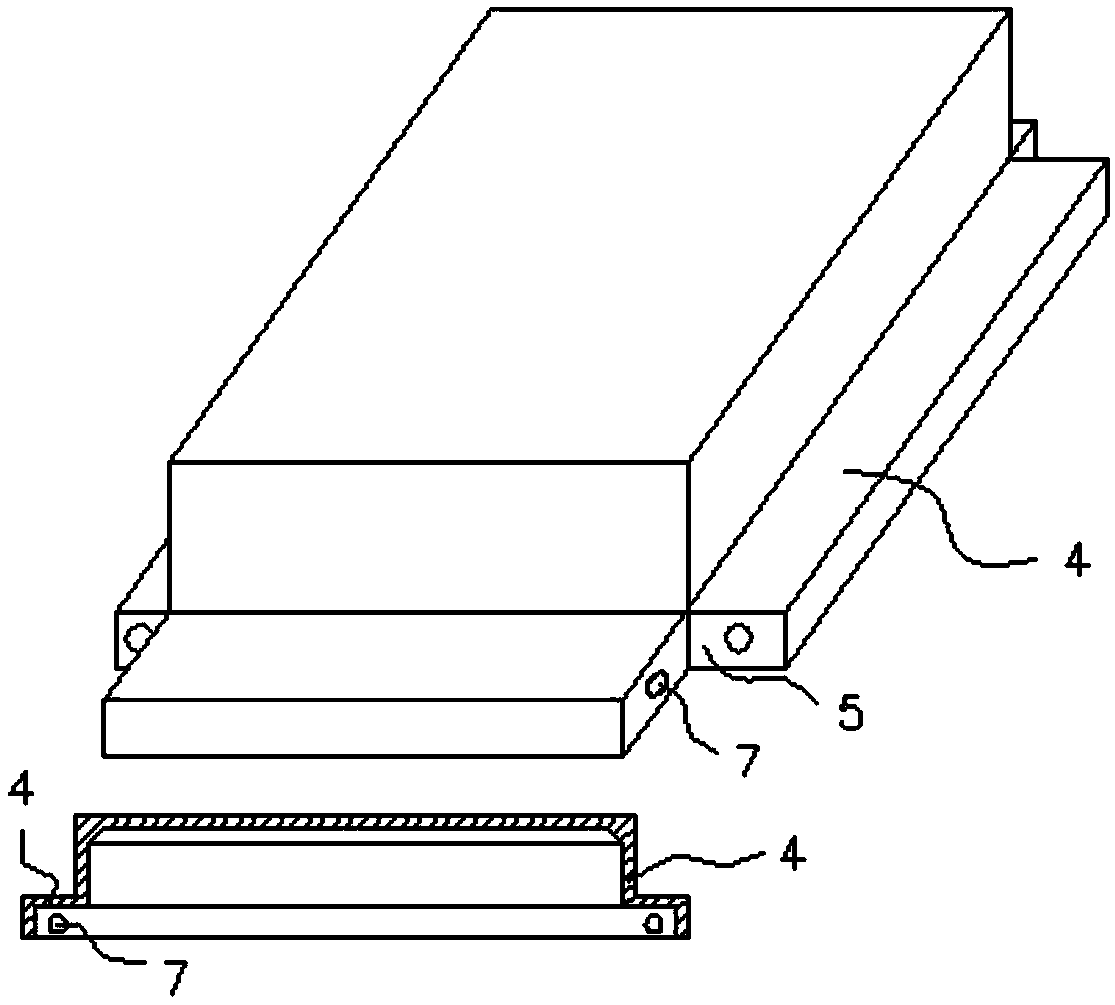

[0056] Embodiment 1: as attached figure 1 As shown, a cylinder is in the shape of a rectangular cylindrical enclosure, connected up and down, with a length and width of 1000 mm and a height of 250 mm. It is hot-pressed and formed by recycled waste plastic thin wall material, and it is mass-produced in a factory, with a wall thickness of 3 mm.

[0057] There is a 9cm wide inner extension plate 3 at the upper end of the plastic cylinder, and a 9cm wide outer extension plate 4 at the lower end of the cylinder. The four corners of the outer extension plate 4 are missing corners 5. There are connecting holes 7 with a diameter of 3 cm on the connecting plates at 5 places for the temporary connection of the construction site and the floor support 6 of the construction.

Embodiment 2

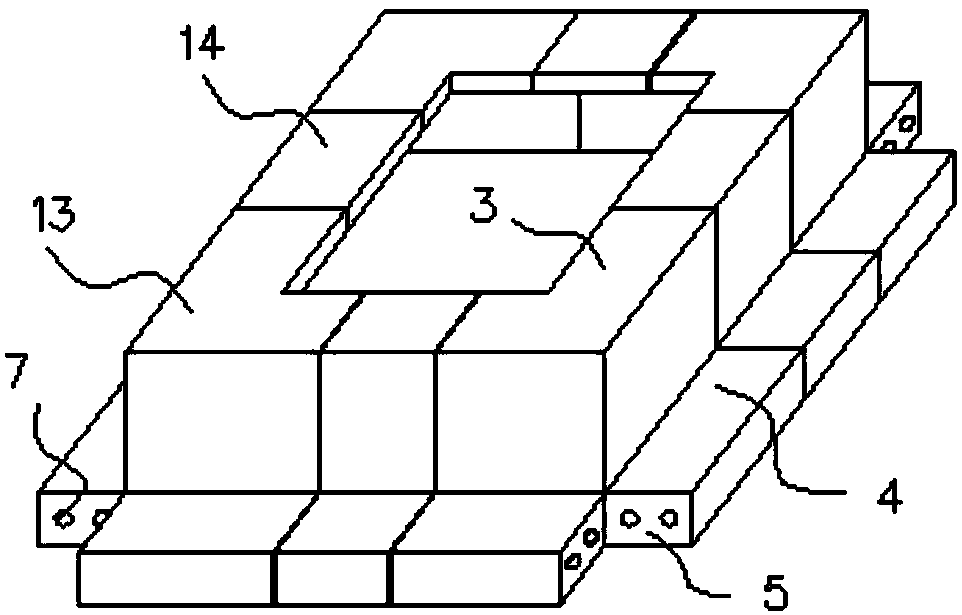

[0058] Example 2: as figure 1 As shown, a cylinder is in the shape of a rectangular cylindrical enclosure, connected up and down, and has a height of 250 mm. Aluminum alloy thin wall material is used for hot pressing and mass production in factory, with a wall thickness of 5mm. The cylinder body is composed of angle mold 13 and adjustment mold 14. The length and width of angle mold 13 are both 50cm. The width of adjustment mold 14 is divided into two specifications: 20cm and 30cm. Adjusting mold+angle mold, angle mold+adjusting mold+adjusting mold+angle mold, two directions adopt one of the above three combinations.

[0059] There is a 9cm wide inner extension plate 3 at the upper end of the aluminum alloy cylinder, and a 9cm wide outer extension plate 4 at the lower end of the cylinder. The four corners of the outer extension plate 4 are missing corners 5. There is a connecting hole 7 with a diameter of 3 cm on the connecting plate at the corner 5 for the temporary connecti...

Embodiment 3

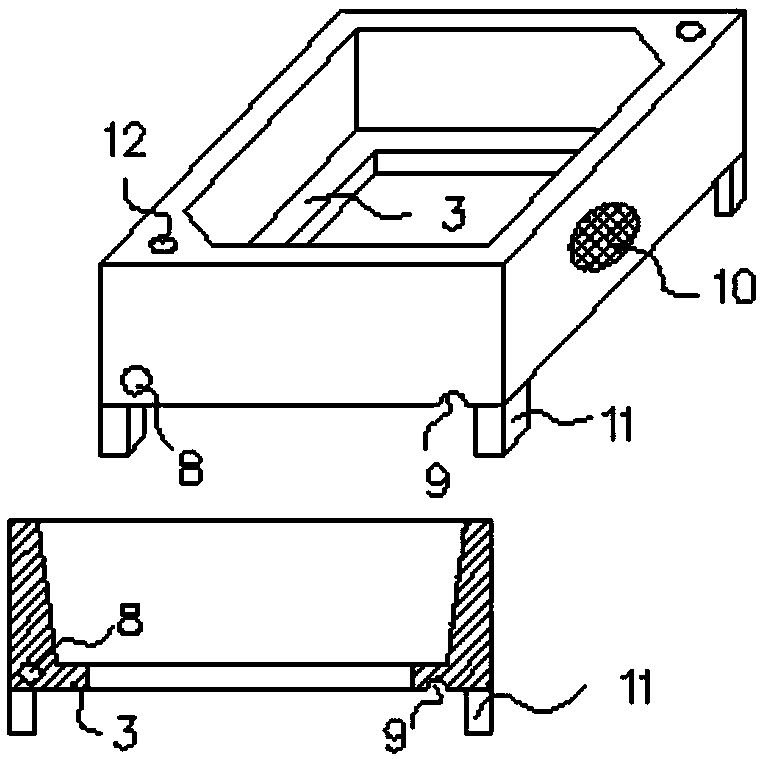

[0060] Example 3: as image 3 As shown, a box body is shaped as a rectangular cavity, one side is open and the other end is closed, the length and width are 1000 mm, and the height is 250 mm. It is hot-pressed and formed by recycled waste plastic thin wall material, and it is mass-produced in a factory, with a wall thickness of 3 mm.

[0061] The open end of the plastic box body has a 9cm wide overhanging plate 4, the four corners of the overhanging plate 4 are missing corners 5, and the end of the overhanging plate 4 is a 9cm high connecting plate, and the connecting plate at the 5 missing corners has a connecting plate with a diameter of 3cm. The hole 7 is used for the temporary connection between the construction site and the floor support 6 under construction.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com