Patents

Literature

35results about How to "Exert mechanical properties" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

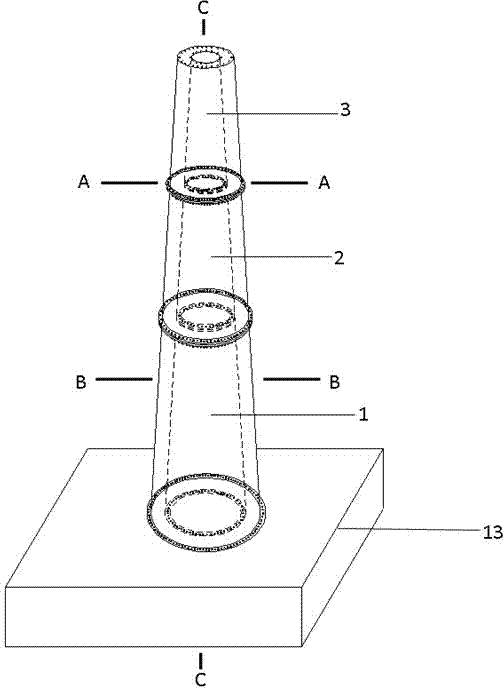

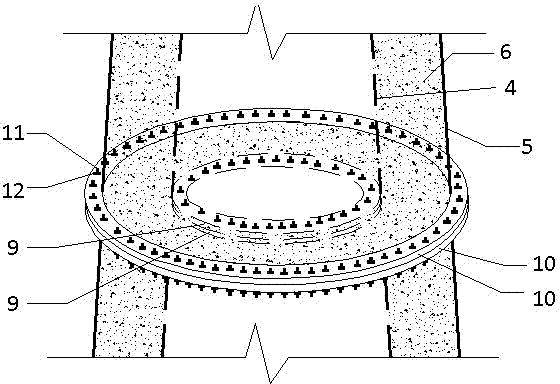

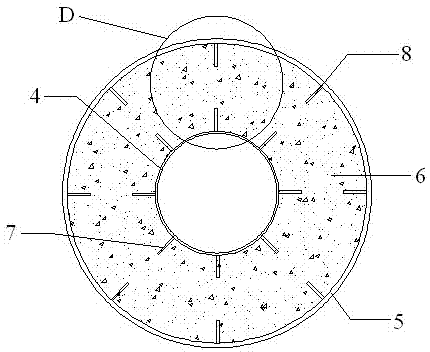

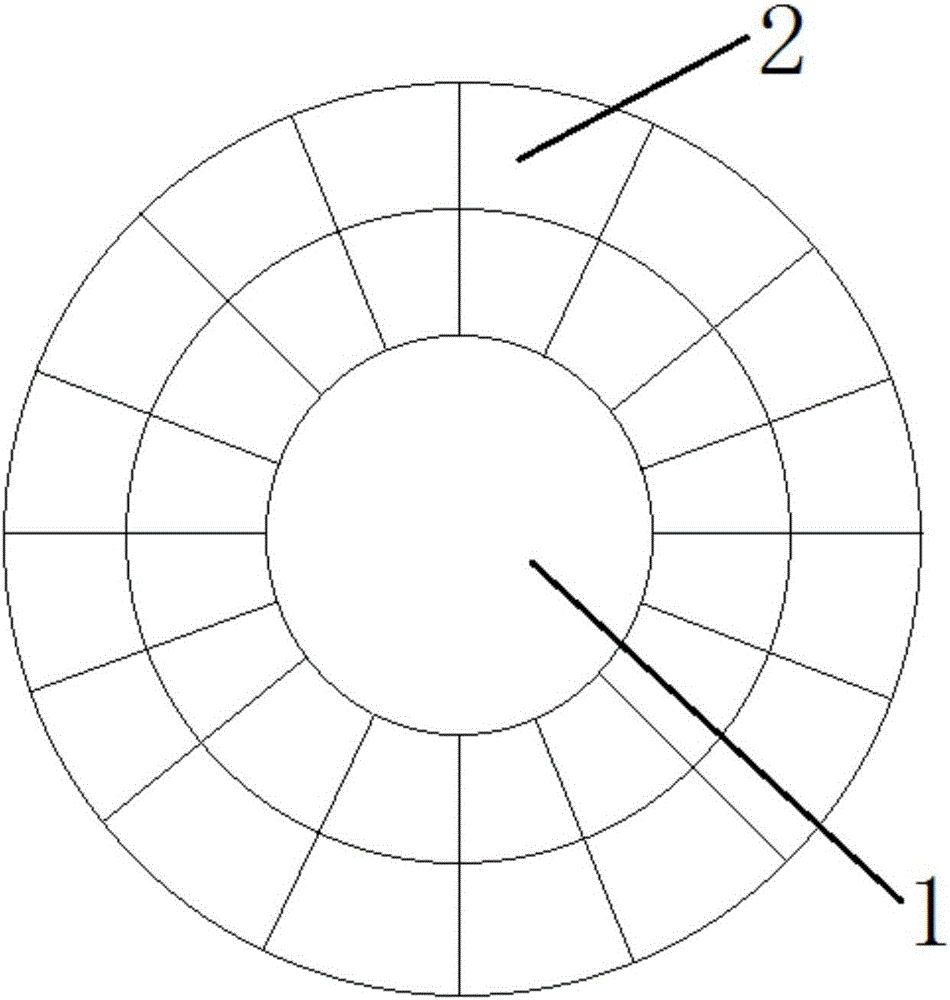

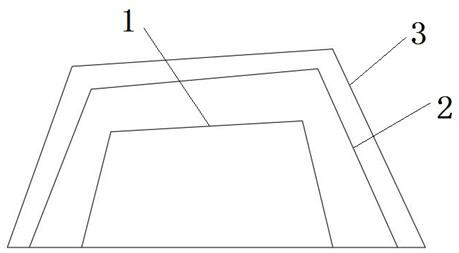

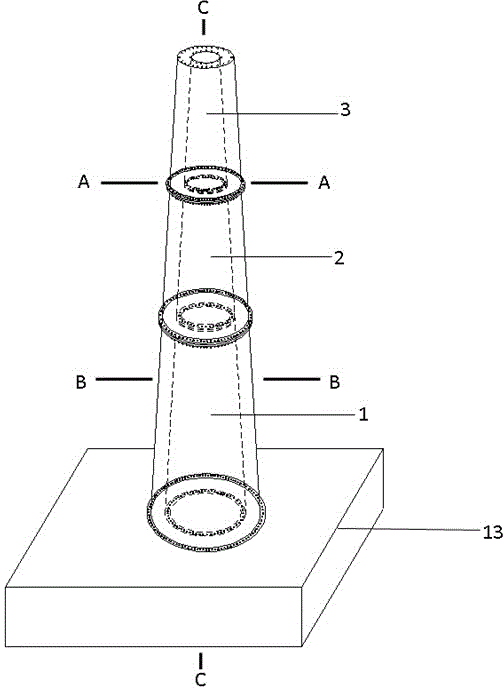

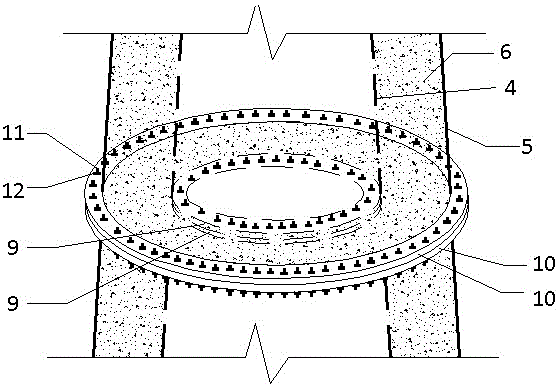

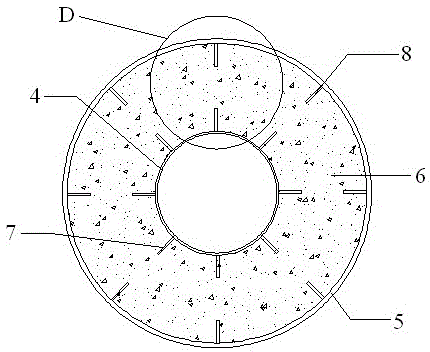

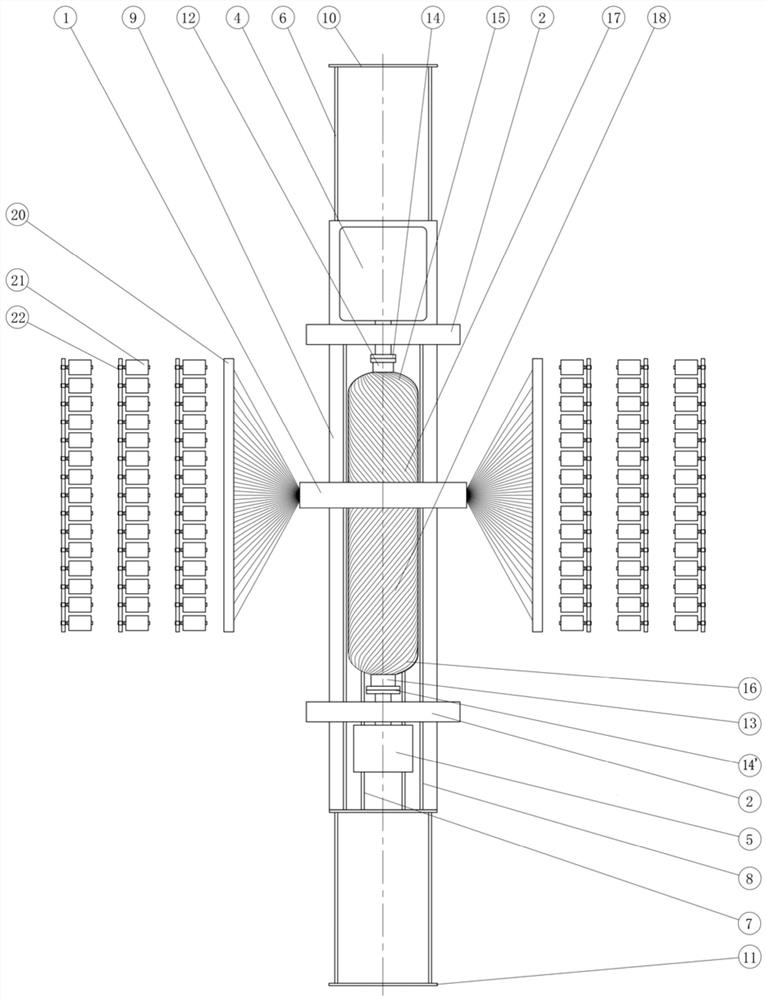

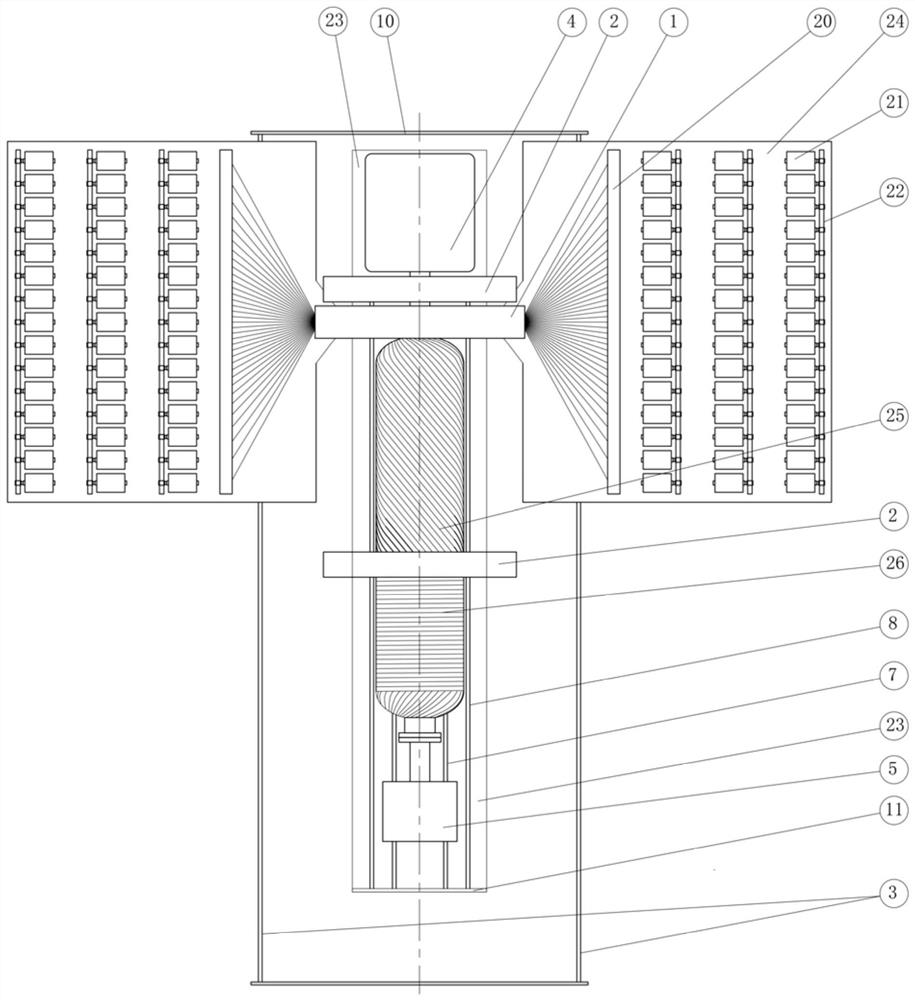

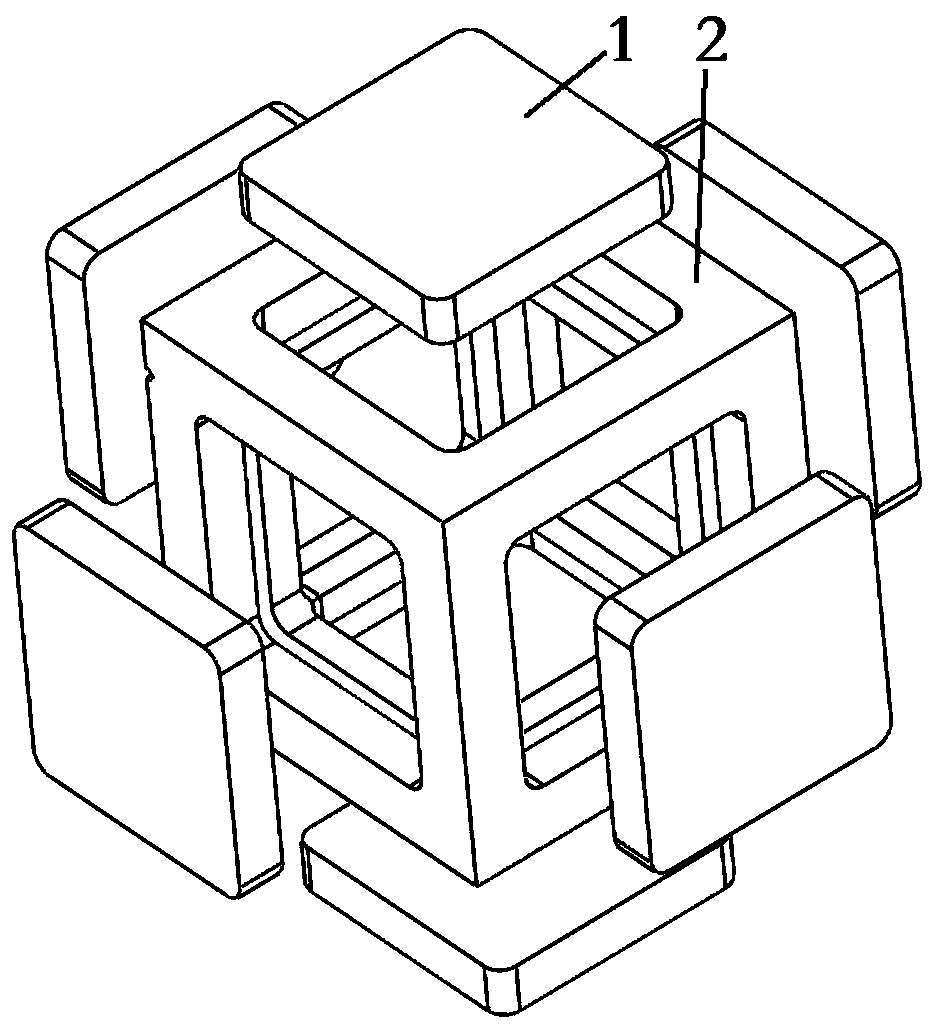

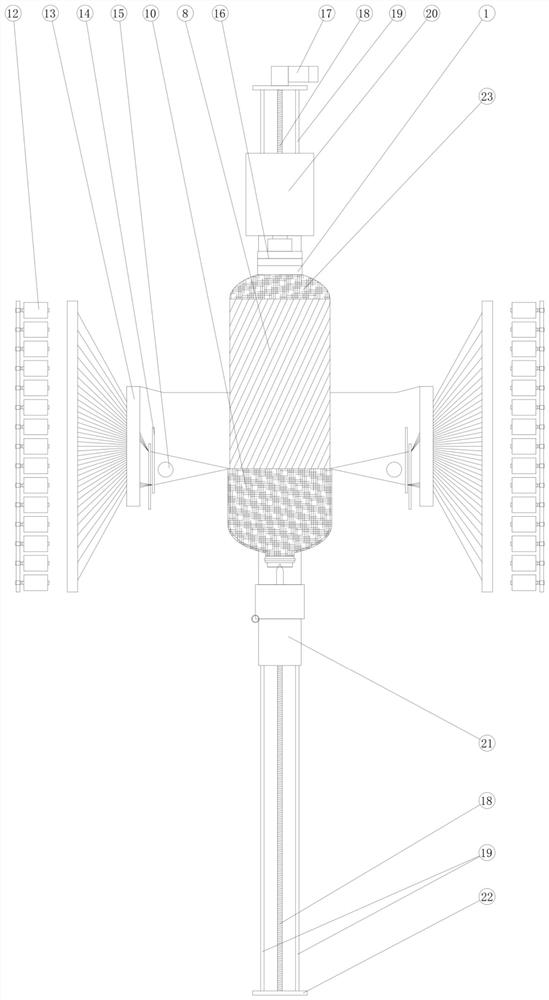

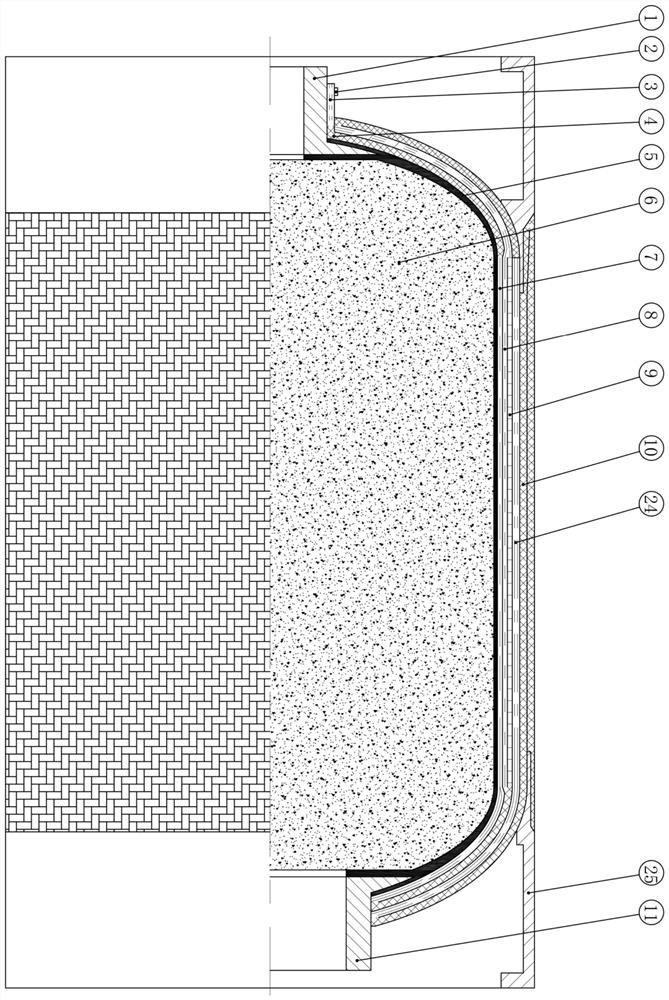

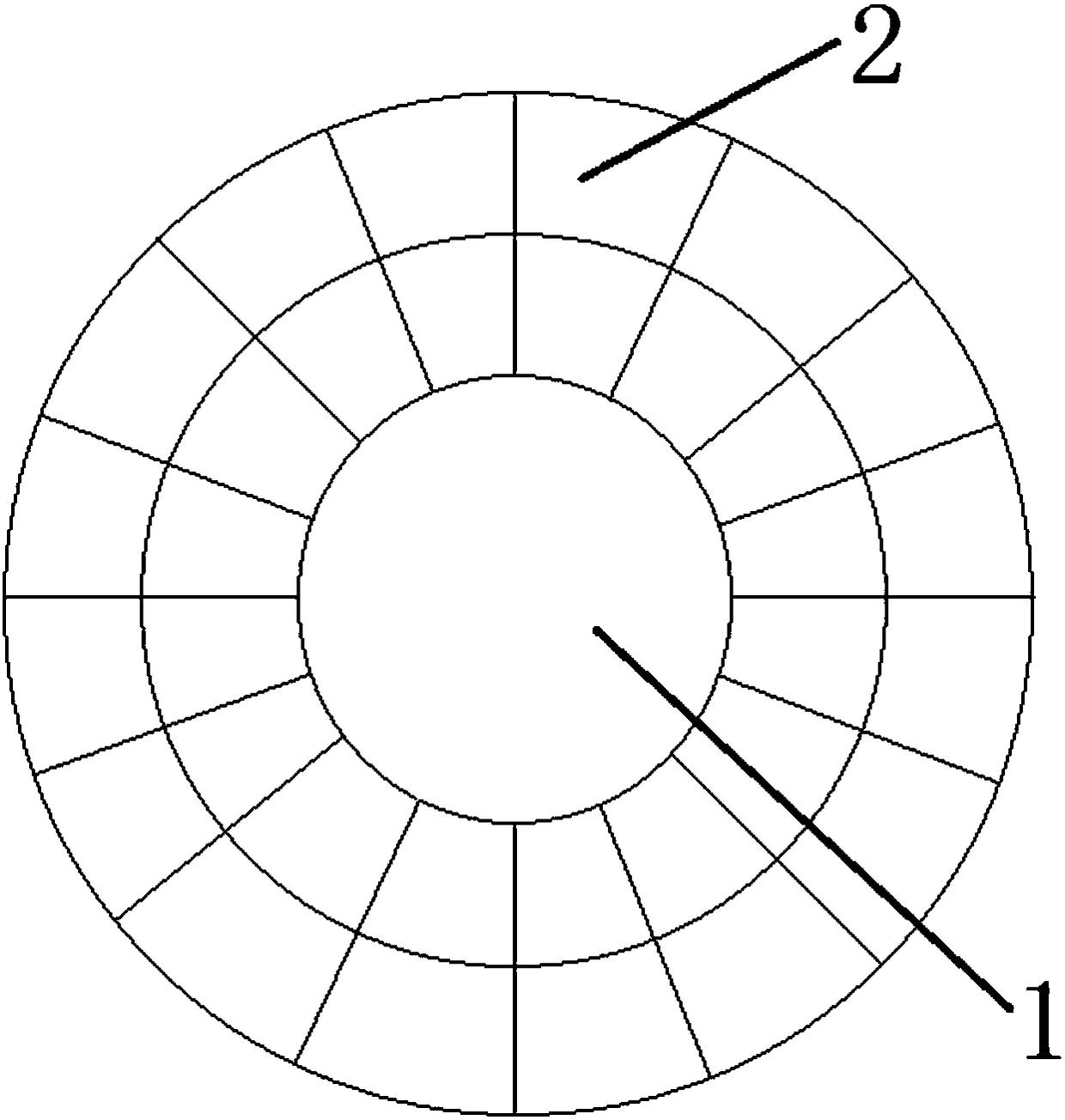

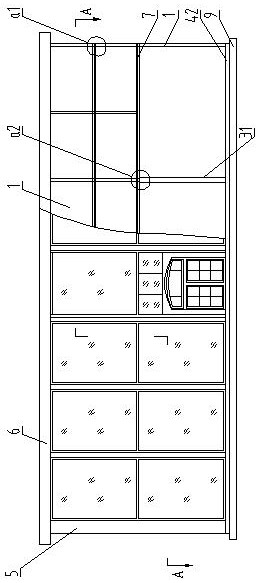

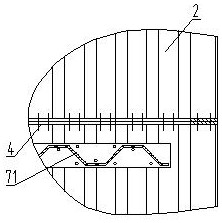

Hollow interlayer pipe wall compound steel pipe concrete wind power tower with ribs

The invention discloses a hollow interlayer pipe wall compound steel pipe concrete wind power tower with ribs. The tower comprises a cast-in-place reinforced concrete foundation and a steel pipe concrete tower section set. Steel pipe concrete tower sections are connected through horizontal flange discs to form a vertical tower cylinder, meanwhile, the bottom of the tower cylinder is fixed on the cast-in-place reinforced concrete foundation, the steel pipe concrete tower sections comprise inner steel pipes, outer steel pipes and concrete layers cast in the interlayers between the inner steel pipes and the outer steel pipes, first reinforced ribs are arranged on the peripheries of the outer walls of the inner steel pipes, and second reinforced ribs are arranged on the peripheries of the inner walls of the outer steel pipes. Compared with an existing steel tower, the compound steel pipe concrete structure with a hollow interlayer and with the pipe walls provided with the ribs is used, the reinforced ribs are arranged on the pipe wall sides where the inner steel pipes and the outer steel pipes are in contact with concrete, the interface binding force of the steel pipes and the concrete is enhanced, the bearing capacity and the ductility of the tower are improved, and early local buckling damage of the thin-wall steel pipes can be avoided or delayed.

Owner:HOHAI UNIV

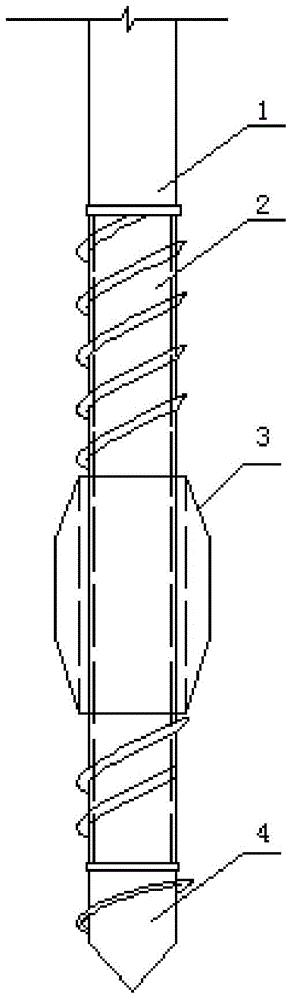

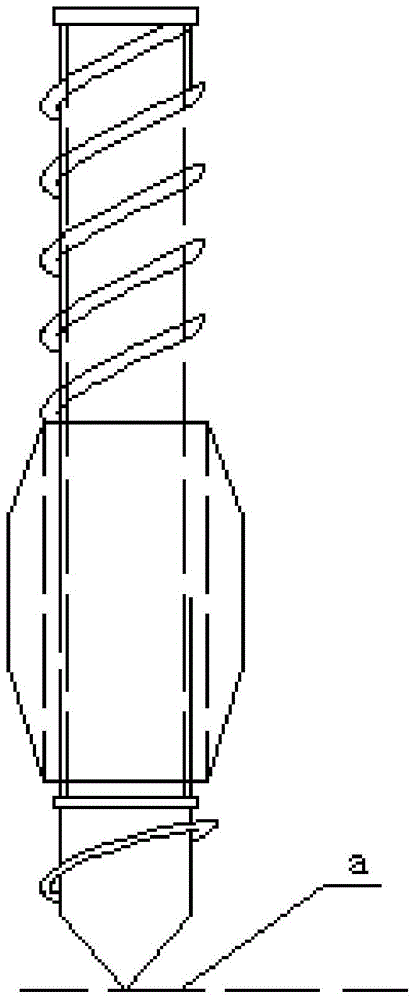

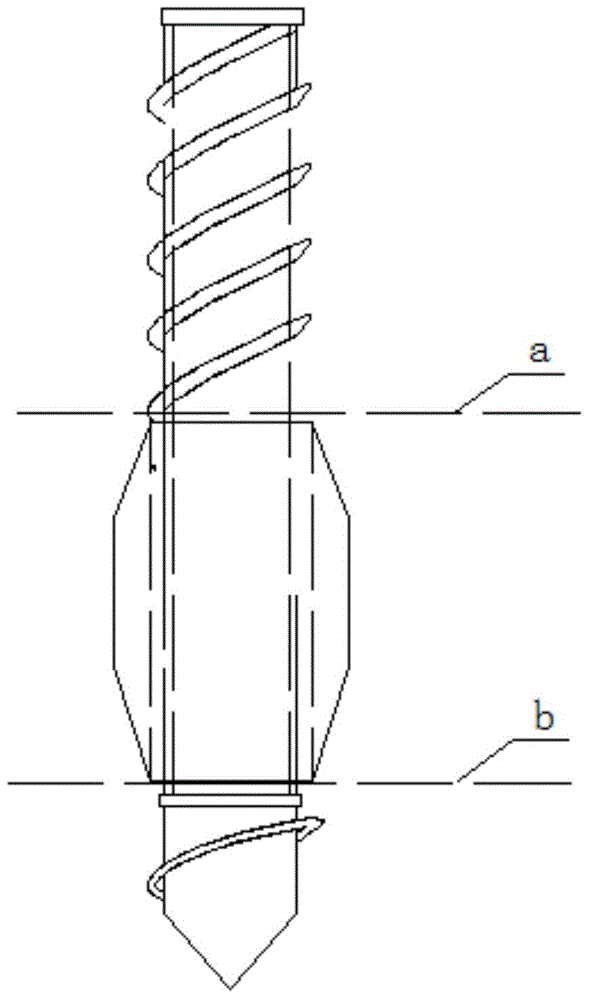

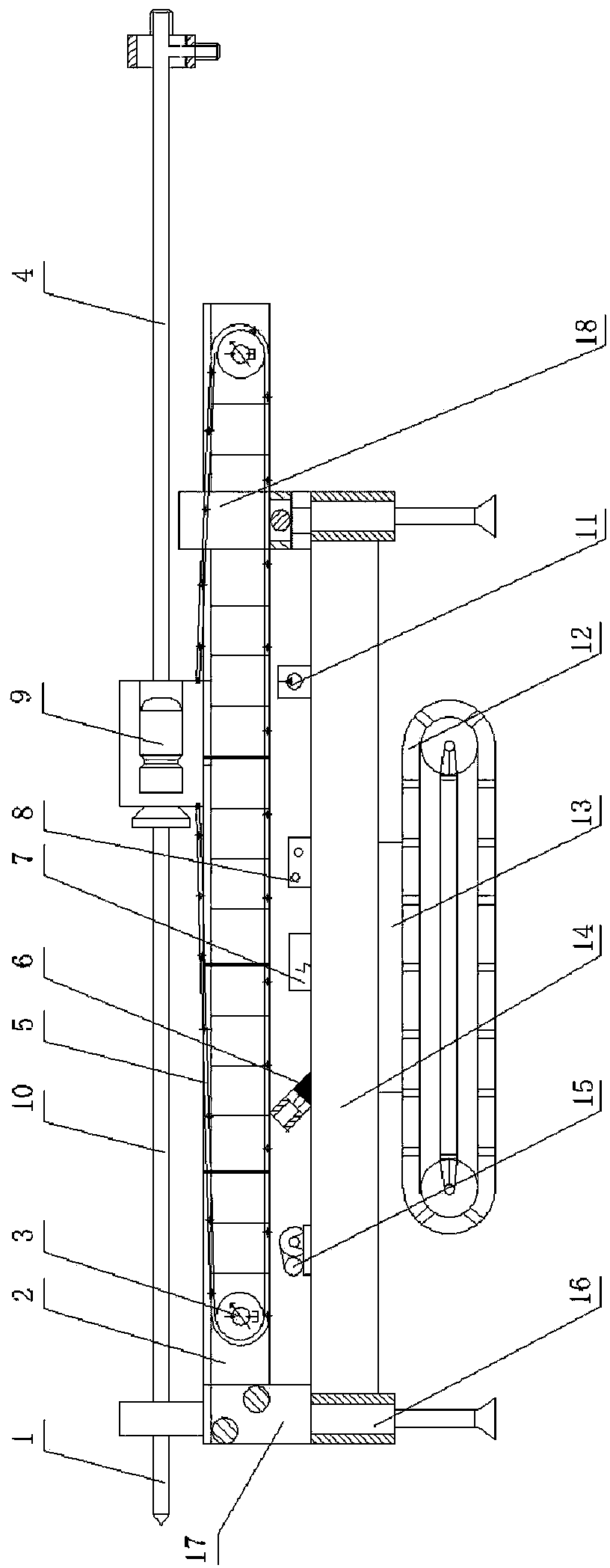

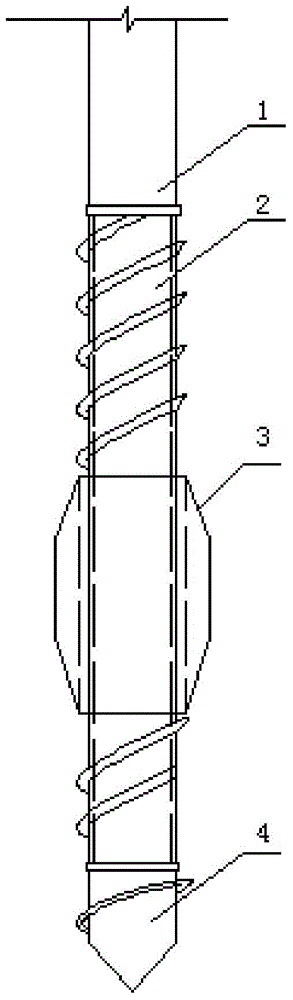

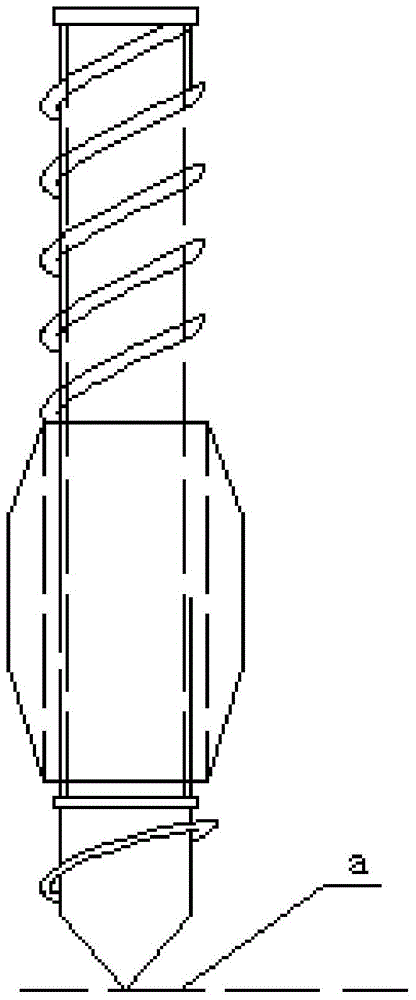

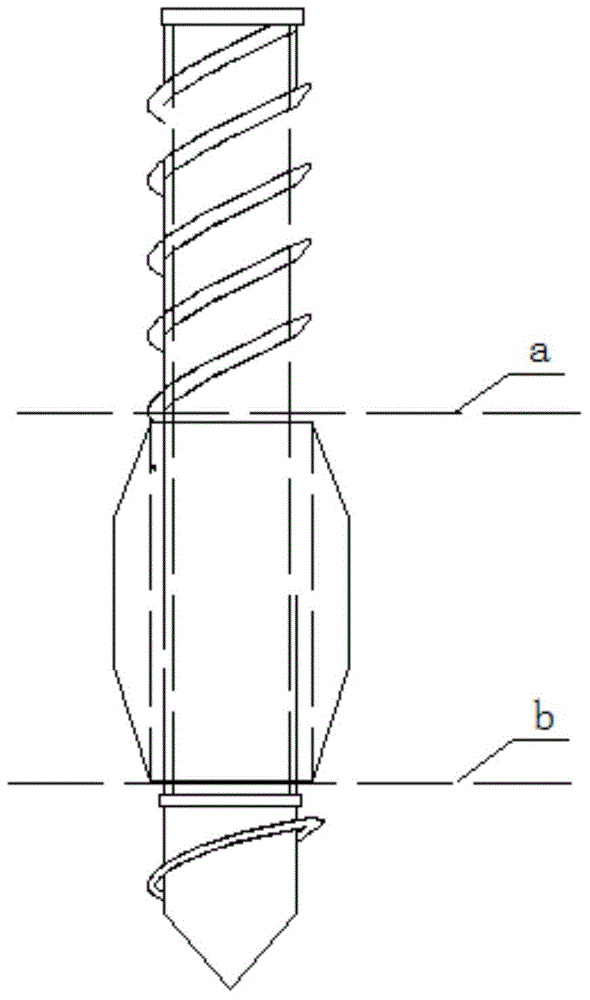

Reducing screw displacement pile drilling tool and construction method thereof

ActiveCN104018792AVariable diameter position adjustableTake full advantage of mechanical propertiesDrilling rodsDrilling without earth removalScrew threadCounter rotation

The invention discloses a reducing screw displacement pile drilling tool and a construction method. The drilling tool comprises a hollow inner drill stem; the inner drill stem is a cylinder on the outer wall of which external threads are formed; a displacement body with internal threads is connected to the outside of the inner drill stem by use of the threads; the displacement body is a spindle body which is thin in two ends and thick in middle part. A method for carrying out construction by using the drilling tool comprises the following steps: the power head of an in-position drilling machine rotates forward and the displacement body reaches a first supporting course depth; the inner drill stem continue drilling downwards until a screw drill bit reaches in a second supporting course position; the power head rotates backwards, concrete is poured, the drilling tool is lifted, and then the screw pile body is formed; when the screw drill bit goes up to the first supporting course position, the power head rotates forwards and concrete is poured continuously, and the displacement body rotates and is lifted so that the cylindrical pile is formed; the drilling tool is pulled out and then the pile body is formed.

Owner:邢占东 +2

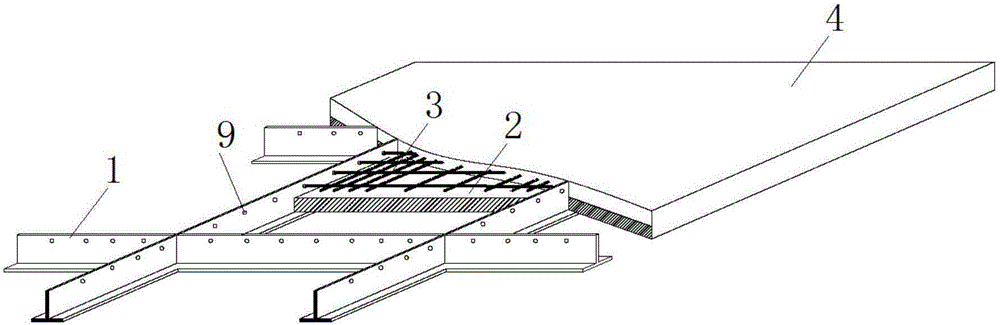

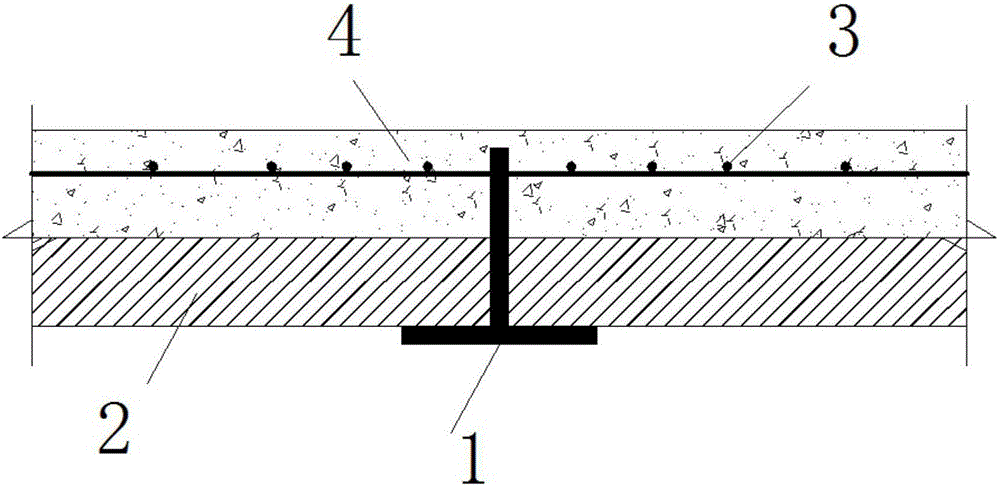

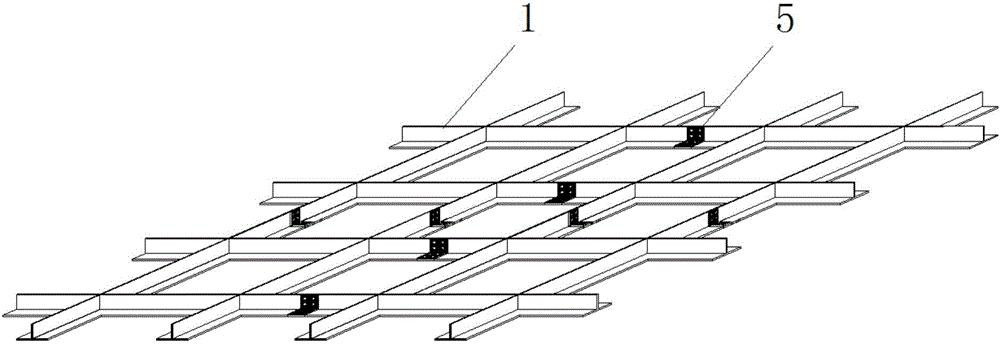

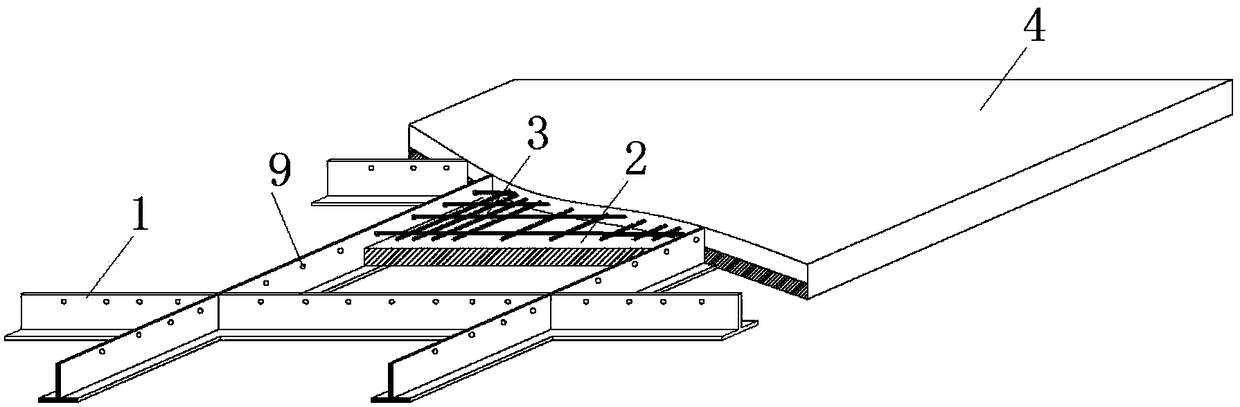

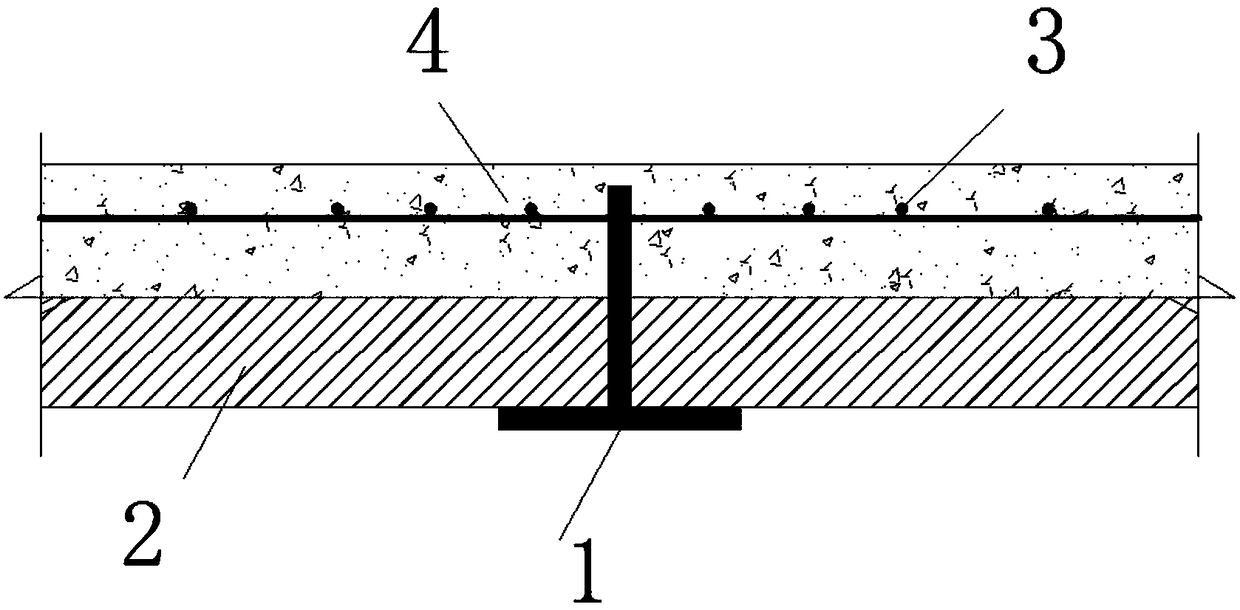

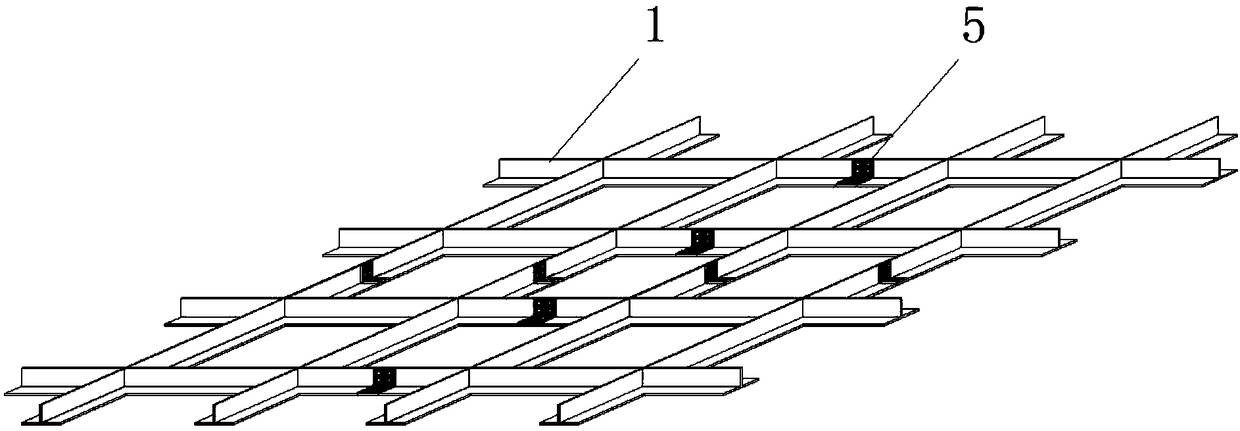

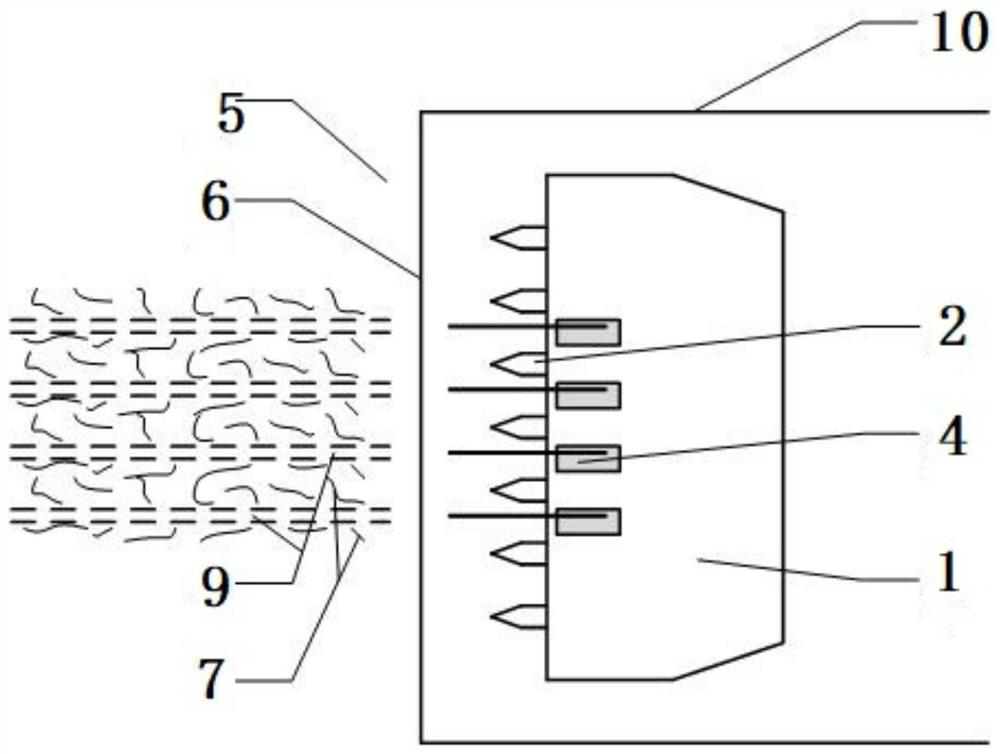

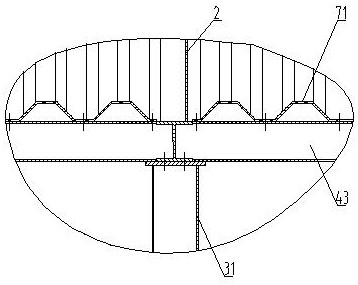

Novel bidirectional inverted-T-shaped beam combined floor

The invention provides a novel bidirectional inverted-T-shaped beam combined floor which is applied to building structures in the engineering field. The novel bidirectional inverted-T-shaped beam combined floor comprises octothorpe-shaped components which are composed of a plurality of inverted-T-shaped steel beams. A plurality of small holes are sequentially formed in webs of the inverted-T-shaped steel beams of the octothorpe-shaped components. Steel bars are arranged between the small holes in the webs of the inverted-T-shaped steel beams in a crossed mode. The multiple octothorpe-shaped components form a bidirectional steel rib structure through splicing joints, and the bidirectional steel rib structure has a stress function during construction. Light prefabricated plates serving as a permanent formwork of the floor sequentially arranged in all cells of the bidirectional steel rib structure, and concrete is evenly poured on the bidirectional steel rib structure and the light prefabricated plates. The novel bidirectional inverted-T-shaped beam combined floor has the characteristics of being high in strength and rigidity and good in ductility; and formwork supporting is not needed, construction is easy, operation is easy, the self weight is low, the height of a structural layer is small, the effective service space is increased, and the economic benefits are good.

Owner:CHINA UNIV OF MINING & TECH

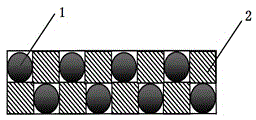

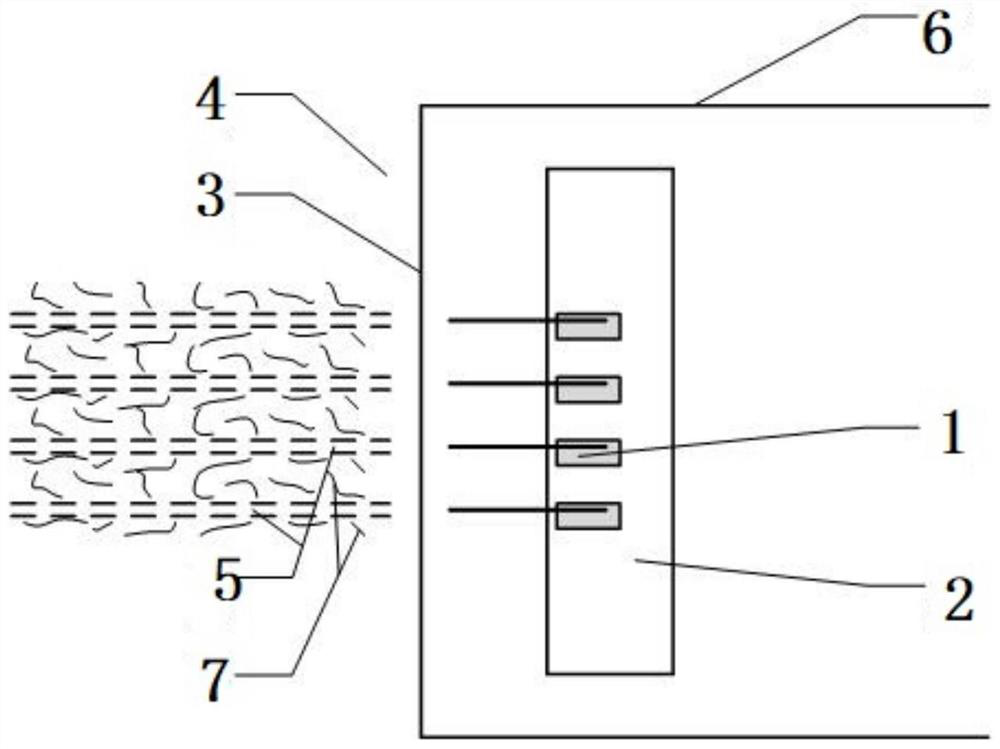

Preparation method of carbon fiber/glass fiber hybrid invisible composite material

The invention discloses a preparation method of a carbon fiber / glass fiber hybrid invisible composite material. The preparation method includes the following steps: with carbon fibers as core yarns and glass fibers as weaving yarns, spinning the core yarns and the weaving yarns to form carbon fiber / glass fiber covered yarns through a two-dimensional weaving technology; weaving the core fiber / weaving fiber covered yarns into cloth, and performing composite curing to the cloth and epoxy resin through a resin transfer molding process to prepare the carbon fiber / glass fiber hybrid invisible composite material. Through the carbon fiber / glass fiber covered yarn structure, electromagnetic wave can enter the interior of the covered yarns as most as possible by means of wave transmission performance of the glass fiber, and then the electromagnetic energy is converted into thermal energy or energy in other forms by means of resistive loss of the carbon fibers, thus dissipating the energy. The carbon fibers are employed as core yarns, so that the material is basically in a straight status, thereby effectively achieving the mechanical performance of the material. The hybrid invisible composite material has excellent mechanical performance.

Owner:南通欣丰桥架有限公司

Three-dimensional printing method of metal-based composite material

The invention discloses a three-dimensional printing method of a metal-based composite material and belongs to the technical field of formation of composite materials. The method comprises the following steps: laying CAD models of parts of the metal-based composite material along direction Z, and generating section outline information of the parts; respectively printing liquid metal and reinforcing materials layer by layer according to the section outline information; after all layers are printed, obtaining the metal-based composite material by machining. The method is simple in formation process, high in operability and high in designability because the reinforcing material can be randomly orientated according to a design angle.

Owner:ADVANCED MFG TECH CENT CHINA ACAD OF MASCH SCI & TECH

Preparation method of diamond-ceramic composite material based on photocuring molding

ActiveCN113149002ASolve the accuracy problemSolve complexityAdditive manufacturing apparatusDiamondParaffin waxCeramic composite

The invention provides a preparation method of a diamond-ceramic composite material based on photocuring molding, which comprises the following steps: weighing diamond powder and titanium powder, and plating titanium on the surface of diamond through a molten salt method to obtain a diamond titanium-plated layer; coating the titanium-plated surface of the diamond with paraffin through a ball milling method, and obtaining a paraffin layer; weighing the secondarily coated diamond particles and glass phase ceramic powder, uniformly mixing in a ball mill, then drying in a drying oven, taking out and sieving to obtain diamond-glass phase ceramic mixed powder; putting the obtained mixed powder, light-cured resin, a dispersing agent and the like into a homogenizer, and uniformly mixing to obtain light-cured diamond-ceramic composite material slurry; then, performing DLP printing in an additive manufacturing technology; and carrying out thermal sintering to obtain the photo-cured DLP printed part containing the diamond-glass phase ceramic composite material. The part prepared through the method has the beneficial effects of being high in forming precision, high in shape complexity and good in comprehensive mechanical property.

Owner:JIHUA LAB

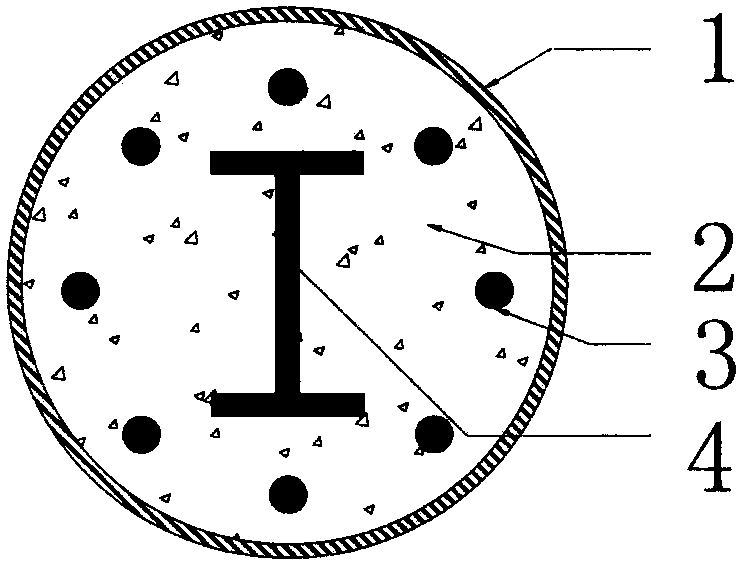

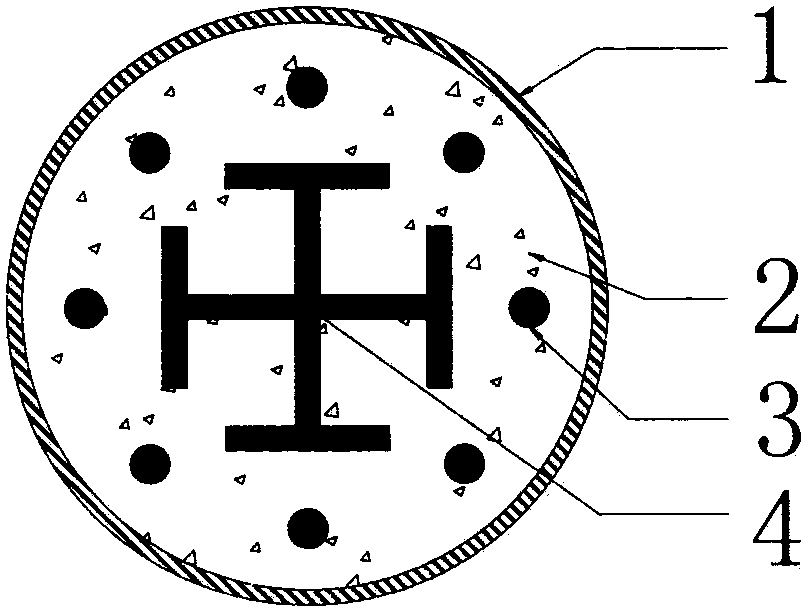

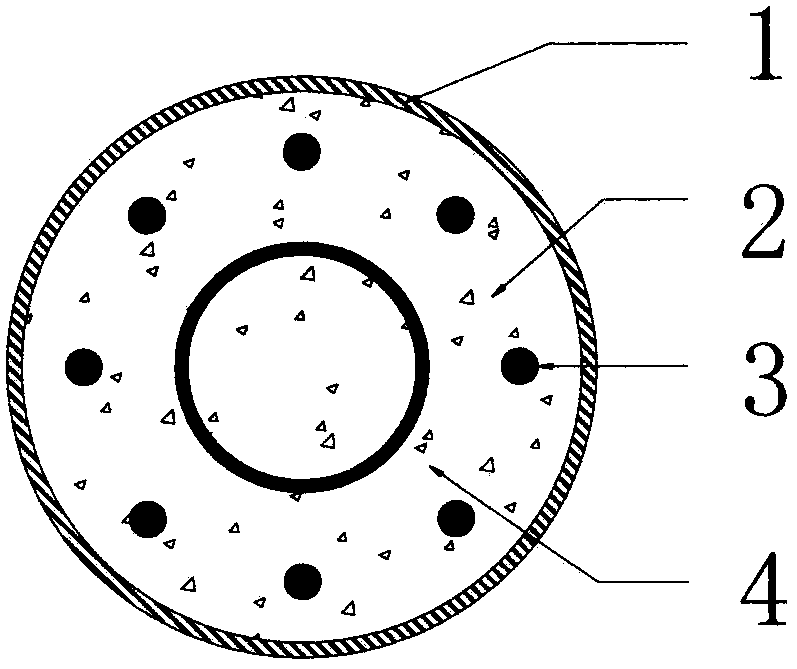

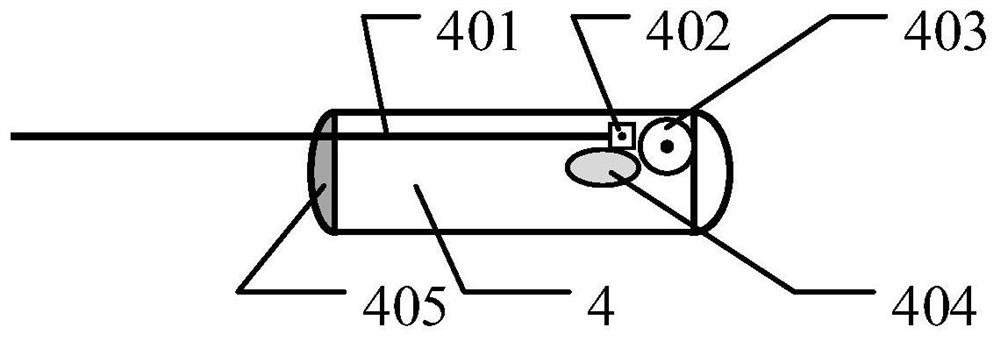

FRP (fiber reinforced plastic)-steel bone reinforced composite column structure

Disclosed is an FRP (fiber reinforced plastic)-steel bone reinforced composite column structure. The FRP-steel bone reinforced composite column structure is characterized by comprising an FRP layer (1), concrete (2), ribs (2) and a steel bone (4); the ribs (3) and the steel bone (4) are in the axial direction of the composite column structure and are coated with the concrete (2), the steel bone (4) is located in the center of the section, the ribs (3) are uniformly distributed along the inner side of the edge of the section, and the FRP layer (1) wraps the concrete (2) from the periphery. By the arrangement, shortcomings existing in the publicly known steel bone concrete structure and concrete-filled steel tube structure are overcome, the internal steel bone is bound more effectively by FRP layer constrained concrete, sufficient bearing capacity storage and stretchability of the structure are achieved, requirement on constructive scaffolds and formwork is reduced, the structure is convenient in construction and low in cost, good comprehensive benefits of the structure are realized, and the composite column structure is applicable to members of columns, piers and the like in the field of civil engineering.

Owner:南京市交通工程质量监督站 +1

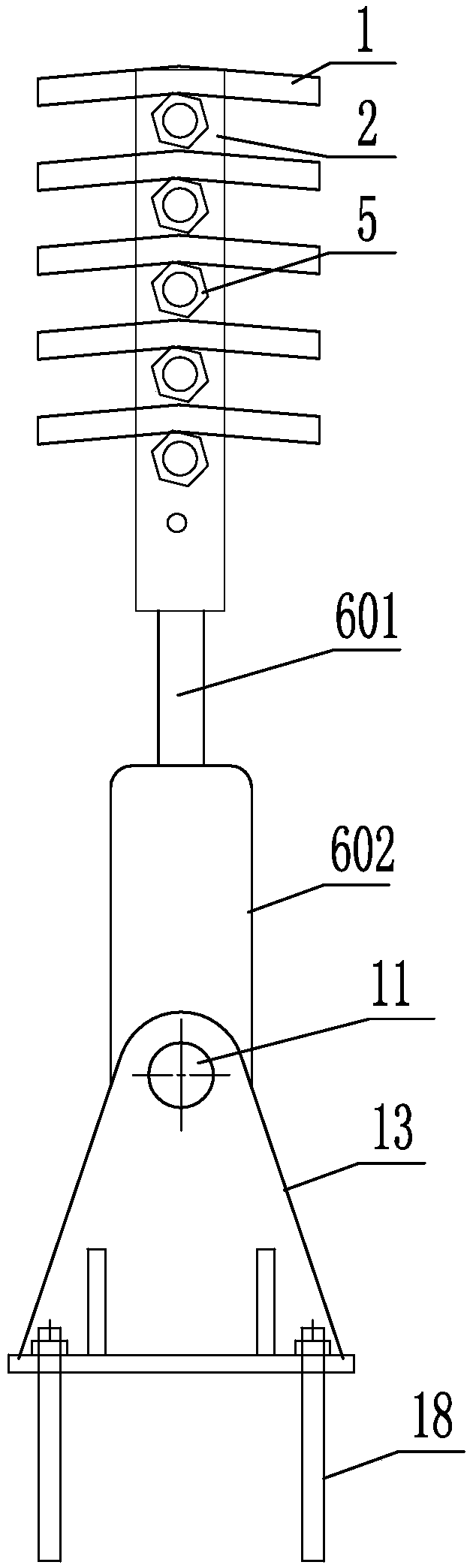

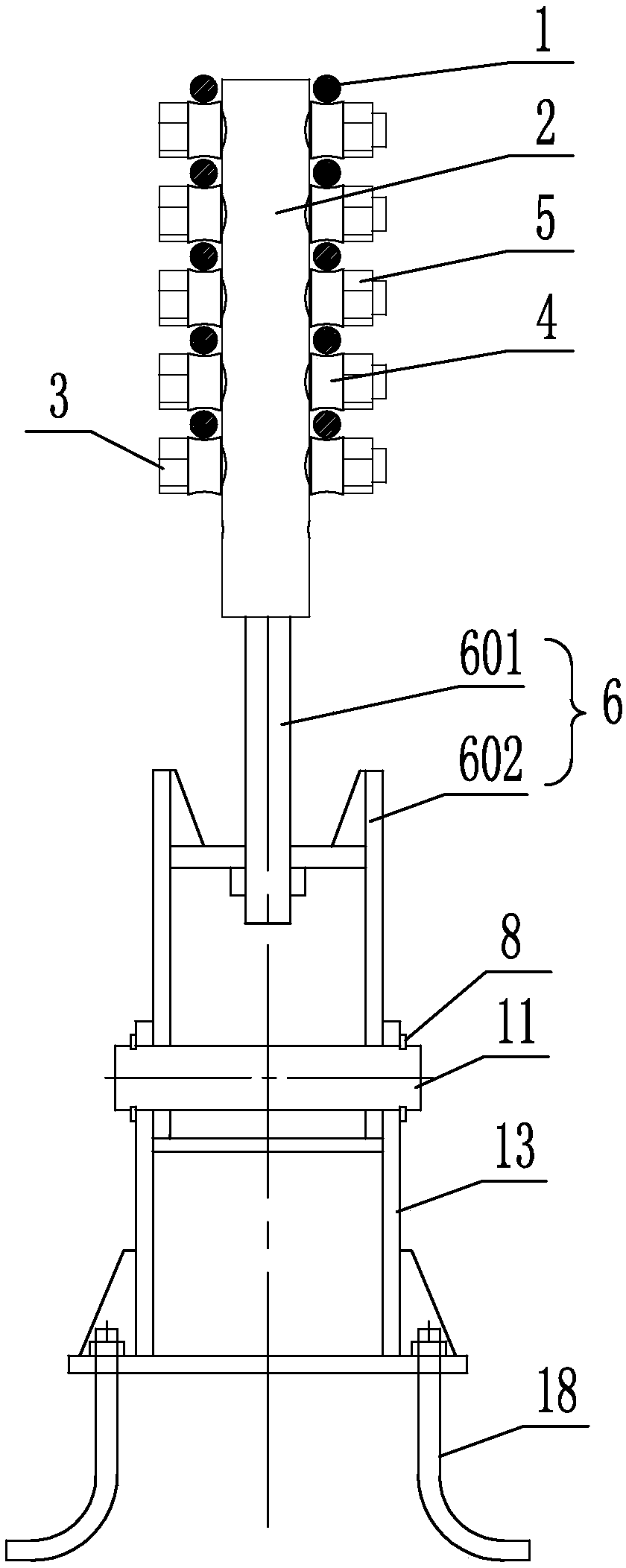

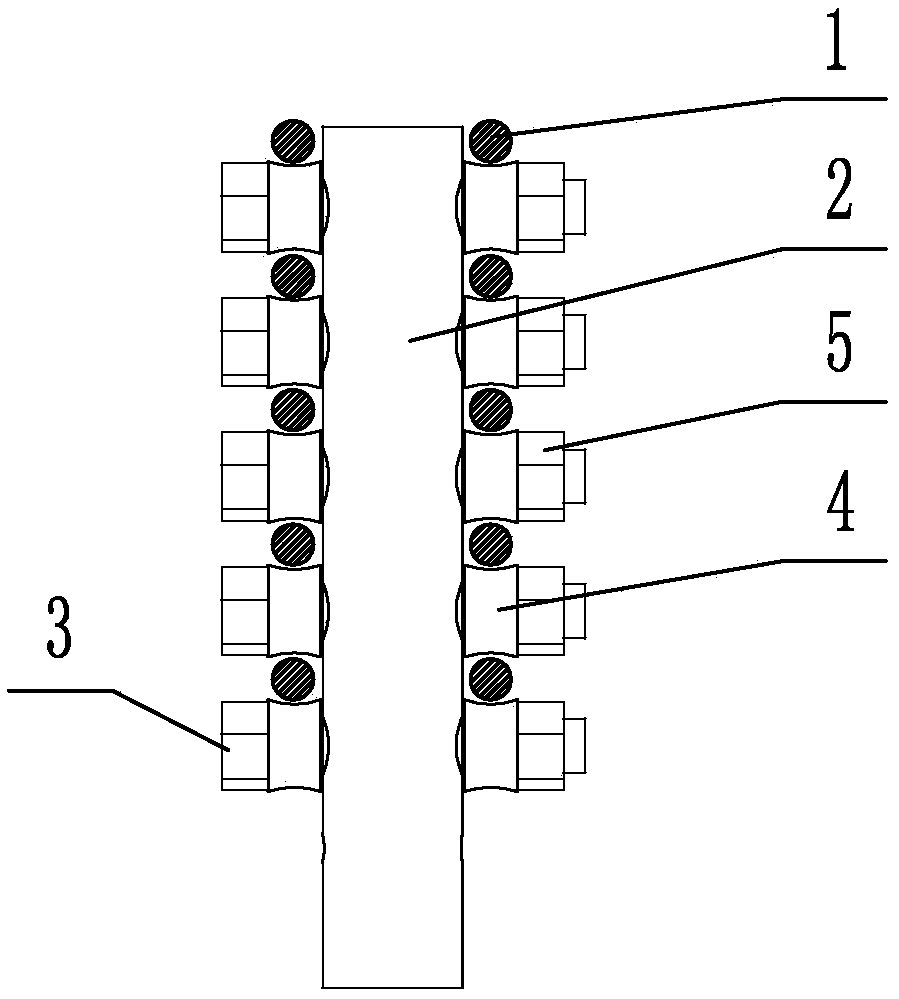

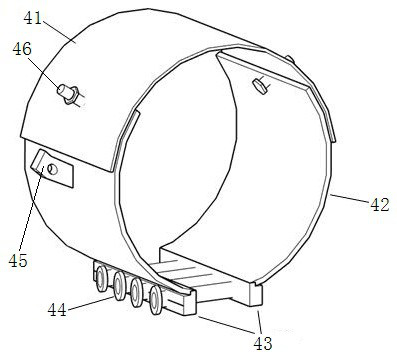

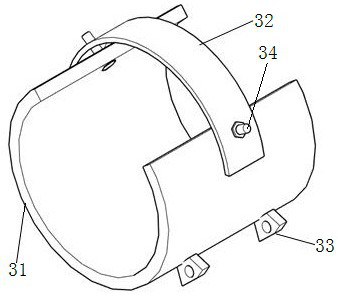

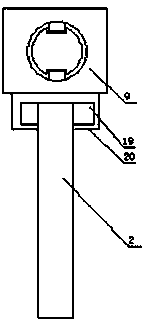

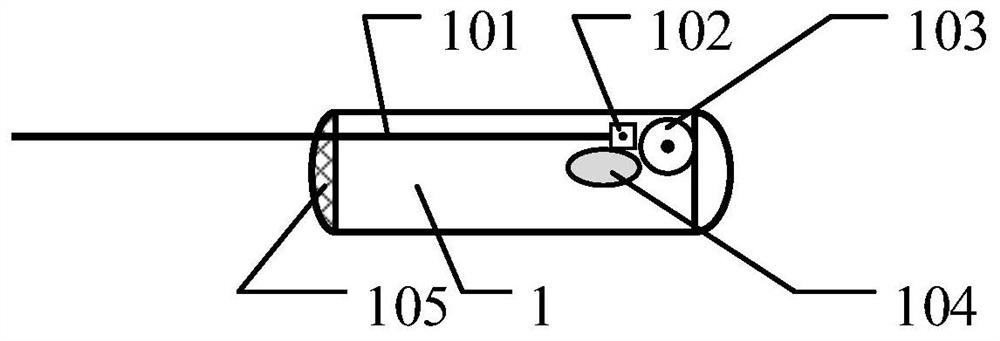

Pre-tensioning method broken-line reinforcement idler wheel bending device shaped like Chinese character ''fei''

ActiveCN108643581AIncrease bend radiusAvoid inflection point kink effectBuilding material handlingChinese charactersPre stress

The invention relates to a pre-tensioning method broken-line reinforcement idler wheel bending device shaped like a Chinese character ''fei''. The pre-tensioning method broken-line reinforcement idlerwheel bending device comprises an idler wheel bending device shaped like the Chinese character ''fei'', a mounting base, an anchor bolt and a connecting device connecting the idler wheel bending device shaped like the Chinese character ''fei'' with the mounting base, wherein the idler wheel bending device shaped like the Chinese character ''fei'' comprises a supporting pipe, idler wheels and fixing bolts; the supporting pipe is a round pipe, a base mounting blind hole connected with the upper end of a connecting rod is formed in the bottom of the supporting pipe, and a row of n mounting holesthrough which screws of the fixing bolts penetrate are formed in the upper part of the supporting pipe; and grooves are formed in the middles of the idler wheels, circular holes are formed in the centers of the cross sections of the idler wheels, and idler wheel spacer bushes are installed in the circular holes in a sleeved mode. In the state of installation and use, the screws of the fixing bolts penetrate through the mounting holes in the round pipe, and the idler wheels are installed at the two ends of the screws correspondingly in a sleeving mode. The idler wheels are locked by the head portions of lock nuts and the fixing bolts, and the round pipe and the two rows of idler wheels form a shape like the Chinese character ''fei''. The bending device can avoid the bending point and breaking point effect, protects pre-stressed ribs from being bitten or indented, has convenient construction and good structural mechanical properties, and can prevent the pre-stressed ribs from slipping out.

Owner:LIUZHOU OVM MASCH CO LTD

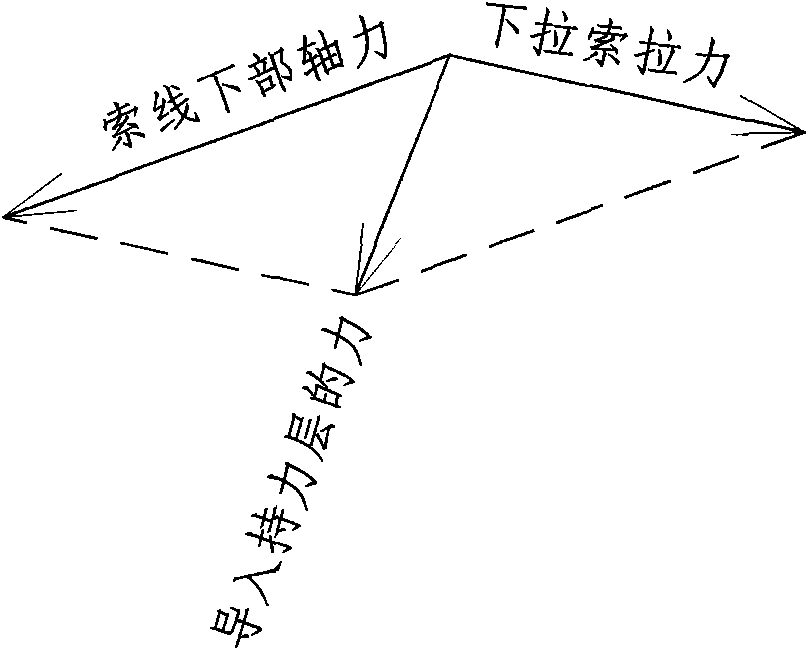

Prestress FRP and high-strength steel wire rope combined wood beam reinforcing device and method

PendingCN112392288AReduce disturbanceImprove reliabilityBuilding repairsBuilding material handlingIndustrial engineeringWire rope

The invention relates to a prestress FRP and high-strength steel wire rope combined wood beam reinforcing device and method. The device comprises FRP cloth pasted to the bottom face of a log beam in the length direction, a middle supporting piece is installed in the middle of the log beam, end reinforcing anchoring pieces are installed at the two ends of the log beam correspondingly, a plurality of layers of FRP hoops are pasted on the log beam and located between the middle supporting piece and the end part reinforcing anchoring pieces at intervals in the length direction, and high-strength steel wire ropes with the two ends connected to the corresponding end part reinforcing anchoring pieces are arranged on the two sides of the middle supporting piece correspondingly. The device and themethod overcome the defects of rigidity, bearing capacity and the like of flexural members such as wood beams in actual engineering, and meanwhile, through combined use of a prestress steel wire ropeand the FRP cloth, the safety reserve is improved, two defense lines are provided for the damaged wood beams, and the ductility is improved.

Owner:FUZHOU UNIV

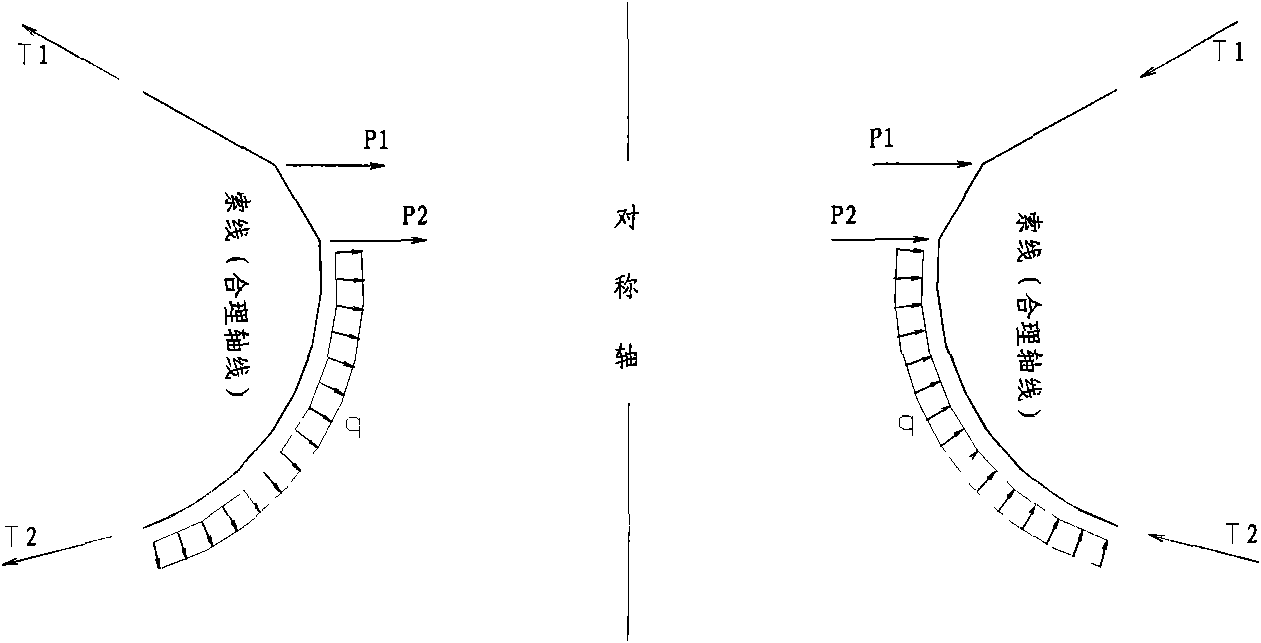

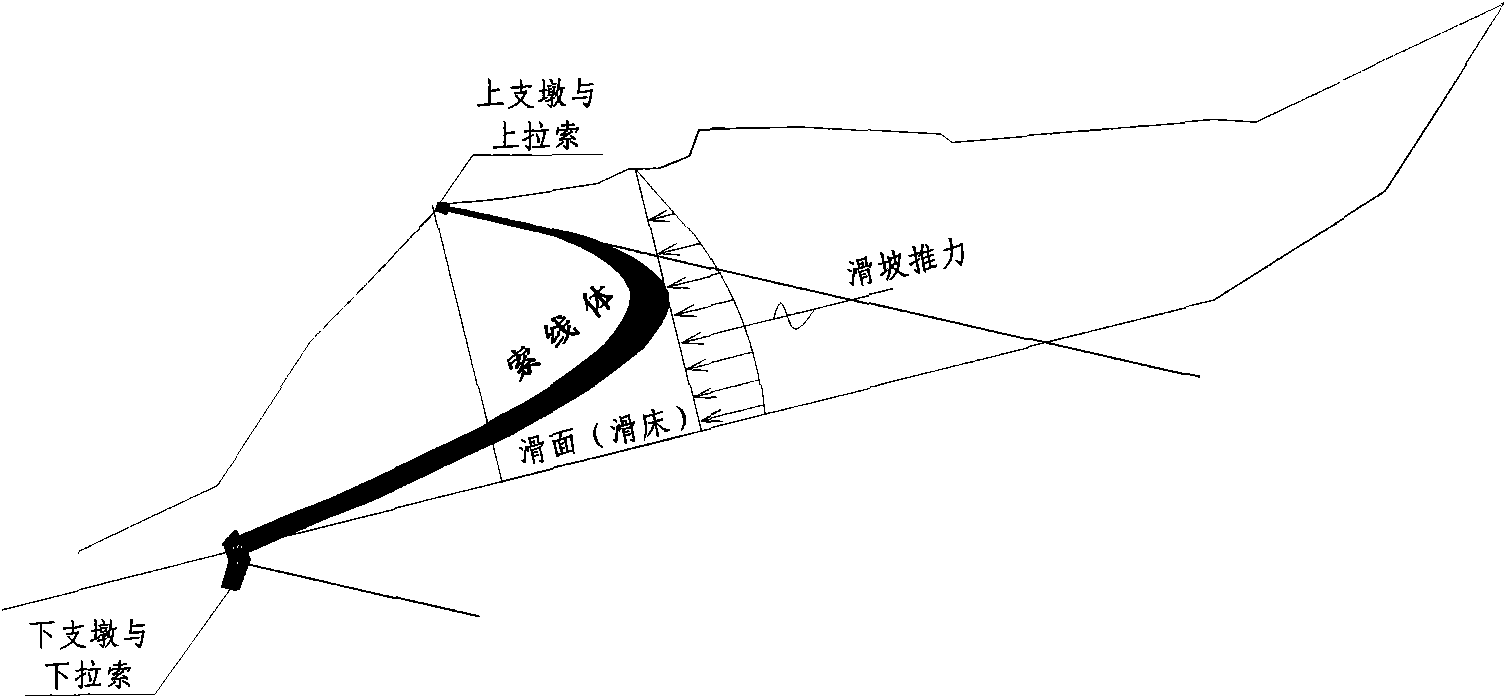

Method for treating landslide and slide slope hazards

The invention discloses a technical scheme for treating geologic hazards of a landslide, a side slope and the like, which is as follows: according to the design requirement, lower buttress piers are arranged below the crossed part of a lower slope toe and a sliding surface at intervals, upper buttress piers are arranged above the sliding surface corresponding to various lower buttress piers, guy cables are respectively arranged on the upper buttress piers and the lower buttress piers and a guy cable body which is similar to a catenary and made of elastic material is arranged in a slide slope body between the upper buttress piers and the lower buttress piers which mutually correspond, wherein the protruded part of the guy cable body points to the thrust direction of the slide slope. The distances among the guy cables meet the stable conditions of the slide slope body between two adjacent guy cables. In the method, the planes on which the guy cable bodies are positioned are preferably vertical with the water surface curve, but the included angle which is within 90+ / -8 degrees between the planes of the guy cable bodies and the water level can be permitted according to different geological conditions.

Owner:NORTHWEST RES INST CO LTD OF C R E C

A Two-way Inverted T Beam Composite Floor Slab

Owner:CHINA UNIV OF MINING & TECH

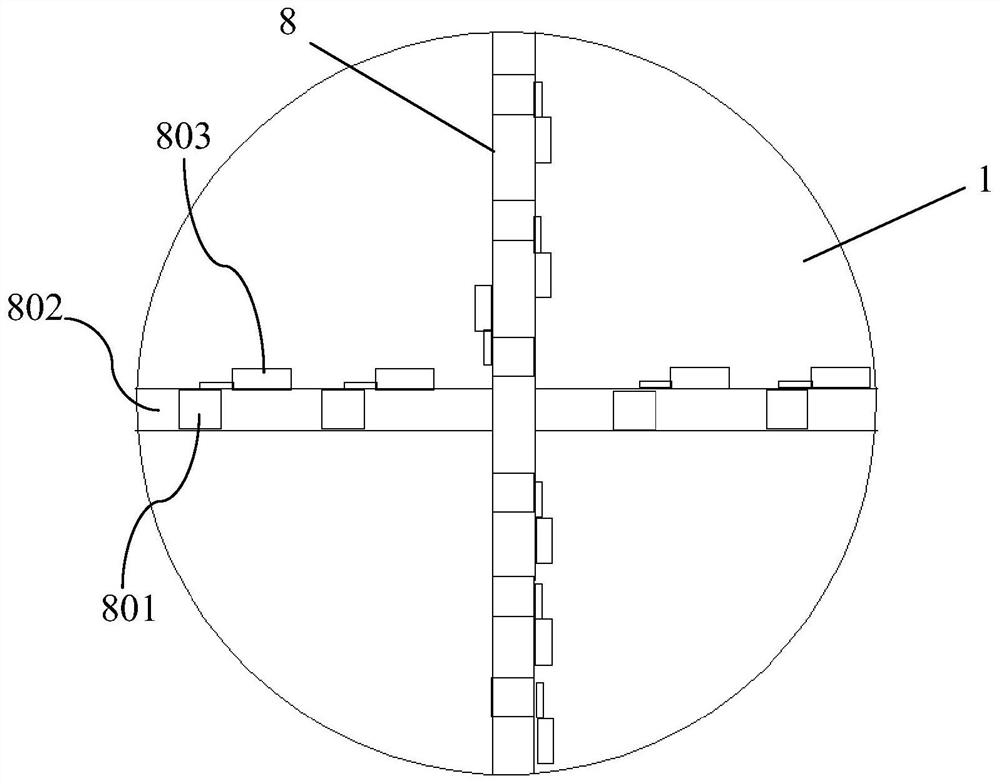

Tunneling device with drilling distance being adjustable and tunneling machine

The invention discloses a tunneling device with the drilling distance being adjustable and a tunneling machine. The tunneling device comprises a cutterhead, multiple heads, a fixing mechanism and drilling mechanisms, and the heads are vertically arranged on the cutterhead and slidably connected with the cutterhead. The fixing mechanism is used for fixing the heads sliding on the cutterhead onto the cutterhead so as to adjust the positions of the heads on the cutterhead. The drilling mechanisms are arranged on the cutterhead and comprise drill rods capable of stretching out and drawing back inthe axial direction on the cutterhead. The drilling mechanisms are arranged on the cutterhead, drilling pre-breaking to to-be-excavated rock mass is completed through the drilling mechanisms, then theheads are arranged on the cutterhead and slidably connected with the cutterhead, the positions of the heads on the cutterhead are adjusted, finally the to-be-excavated rock mass is tunneled through the cutterhead with the positions of the heads adjusted, the mechanical property of the heads can be better exerted, and therefore the aim of efficiently tunneling the to-be-excavated rock mass is achieved.

Owner:TSINGHUA UNIV +1

A kind of hollow interlayer tube wall ribbed composite steel tube concrete wind power tower

ActiveCN103573006BImprove bearing capacityImprove ductilityTowersReinforced concreteArchitectural engineering

The invention discloses a hollow interlayer pipe wall ribbed composite steel pipe concrete wind power tower, which comprises a cast-in-place reinforced concrete foundation, a group of steel pipe concrete tower sections, and the steel pipe concrete tower sections are connected by horizontal flanges to form a vertical tower. At the same time, the bottom of the tower is fixed on the cast-in-place reinforced concrete foundation. The steel pipe concrete tower section includes the inner steel pipe, the outer steel pipe and the concrete layer poured between the inner steel pipe and the outer steel pipe. The outer wall of the inner steel pipe is provided with a first stiffener. The inner wall of the outer steel pipe is provided with a second stiffener; compared with the existing steel tower, the present invention adopts a composite steel pipe concrete structure with a hollow interlayer and ribs on the pipe wall. Stiffeners enhance the interface bonding force between steel pipe and concrete, improve the bearing capacity and ductility of the tower, and can avoid or delay the premature local buckling failure of thin-walled steel pipes.

Owner:博菱(苏州)科技有限公司

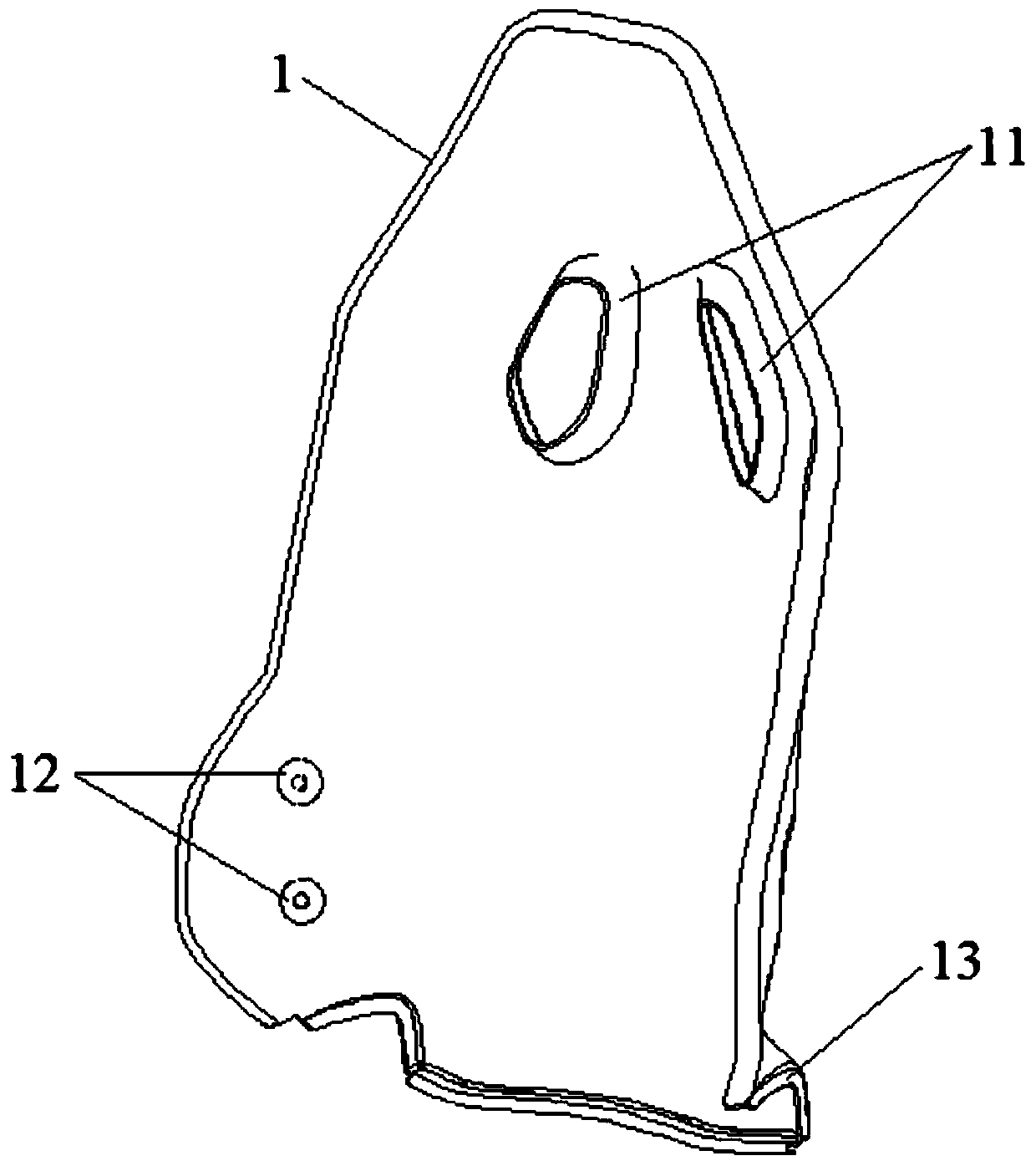

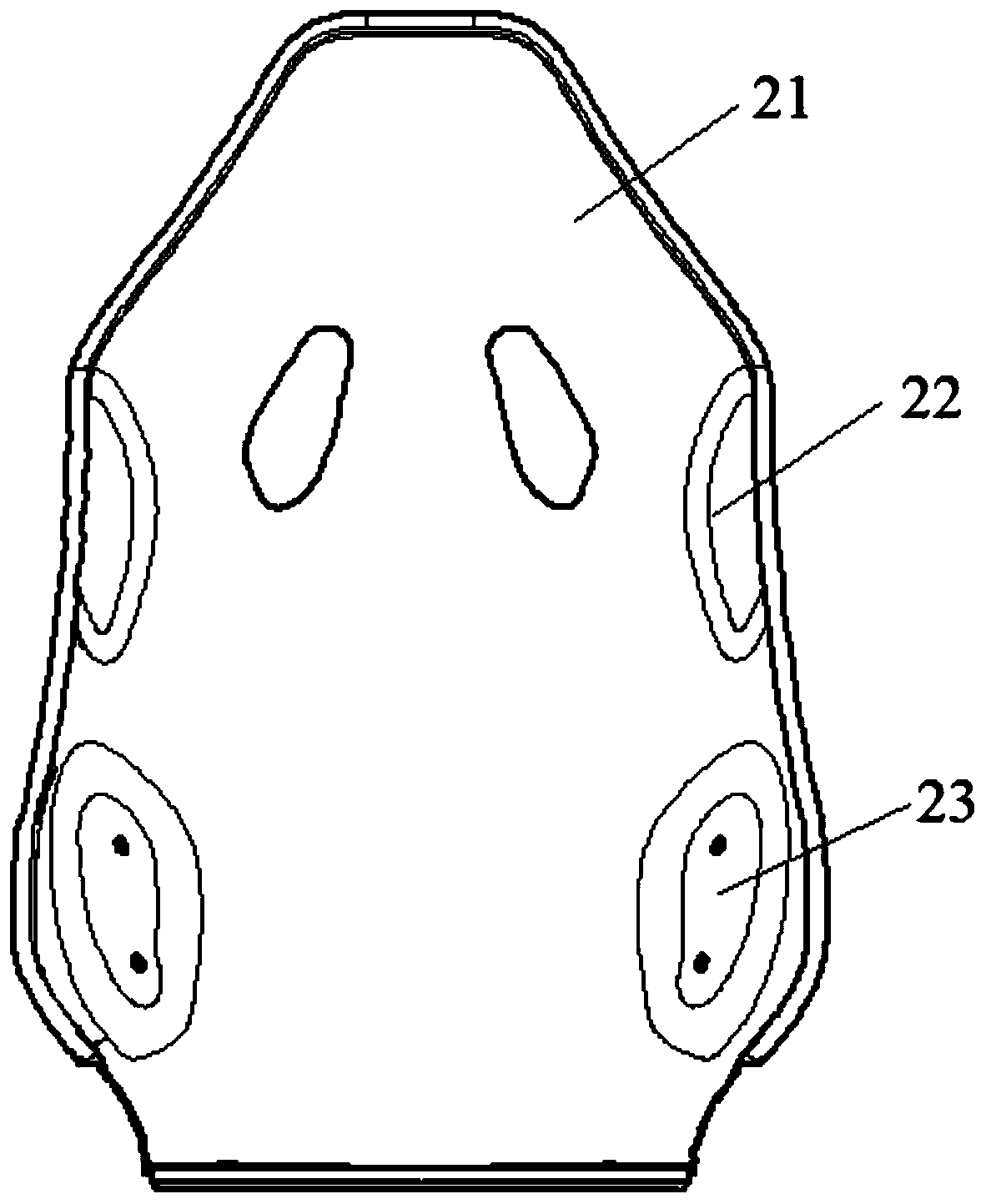

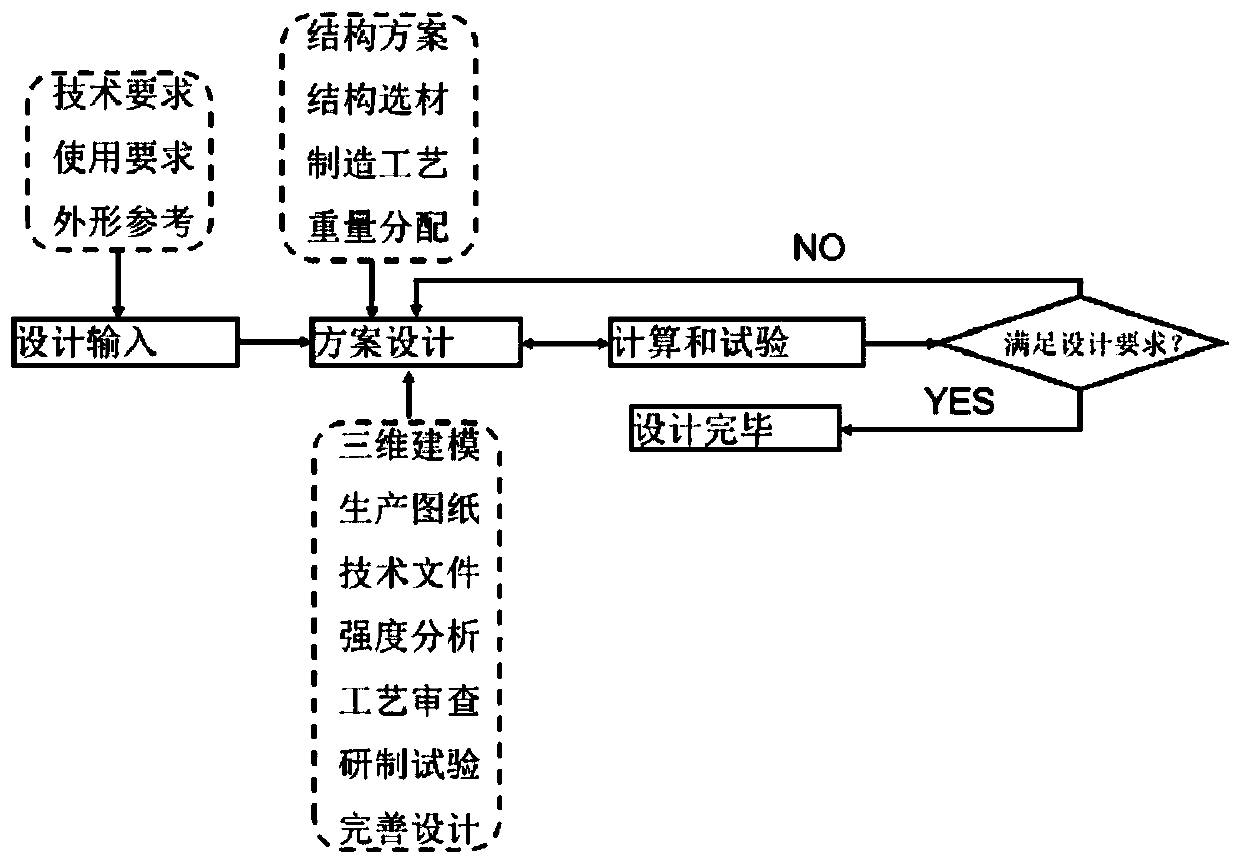

Carbon fiber composite seat backrest framework and design method thereof

InactiveCN111055739AMeet lightweight requirementsFew partsBack restsSeat framesCar seatFibrous composites

The invention discloses a carbon fiber composite seat backrest framework and a design method thereof. The carbon fiber composite seat backrest framework comprises a framework body, and the framework body comprises wrapping buckle ring mounting surfaces, metal piece mounting surfaces and angle adjuster mounting surfaces; the two wrapping buckle ring mounting surfaces are symmetrically arranged on the framework body; the number of the metal piece mounting surfaces is two, and the metal piece mounting surfaces are symmetrically arranged on the framework body. The number of the angle adjuster mounting surfaces is two, and the angle adjuster mounting surfaces are symmetrically arranged on the framework body. Three laying areas with different thicknesses are laid on the framework body. By meansof the mode, the requirement for light weight of the automobile seat framework can be met, the mechanical performance of the carbon fiber composite material on the seat is brought into full play, andparts of the automobile seat framework are reduced.

Owner:JIANGSU HENGRUI CARBON FIBER TECH CO LTD +1

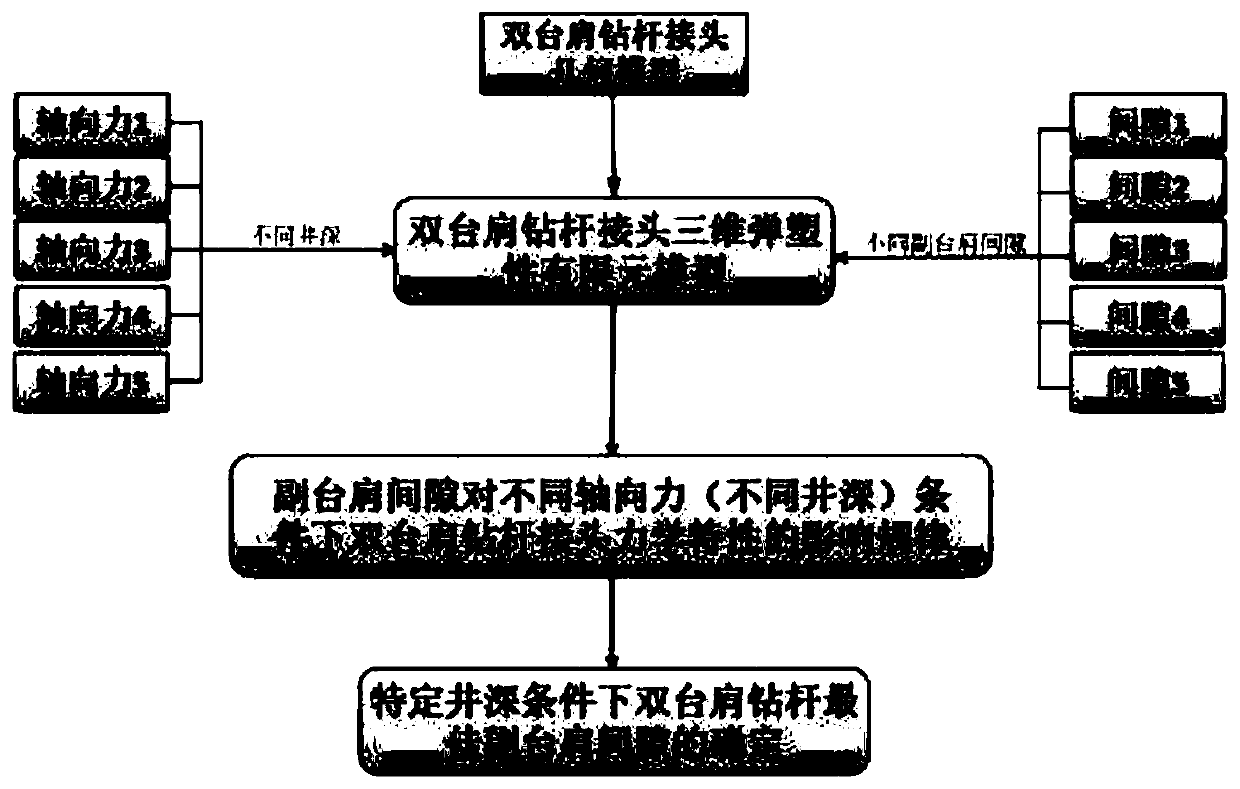

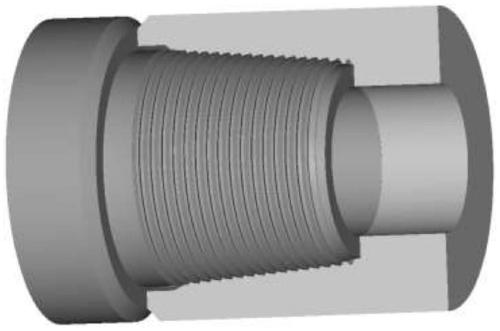

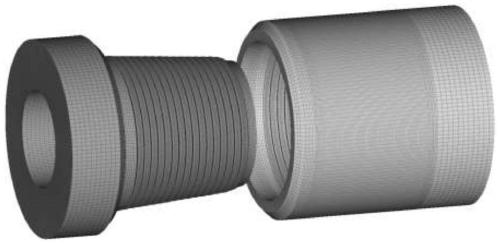

Method for determining gap between auxiliary shoulders of double-shoulder drill pipe joint

InactiveCN111411903AHighlight substantiveSignificant technological progressSurveyDrilling rodsWell drillingElement analysis

The invention provides a method for determining a gap between auxiliary shoulders of a double-shoulder drill pipe joint. The method comprises the steps that a three-dimensional geometric model of thedouble-shoulder drill pipe joint is established according to the measured size data, and is subjected to grid division based on a multiblock grid method, and a three-dimensional elastoplastic finite element calculation model of the double shoulder drill pipe joint is established; on this basis, the three-dimensional force characteristics of double-shoulder drill pipe joints with different auxiliary shoulder gaps under the action of different axial forces are obtained based on the three-dimensional elastoplastic finite element analysis; and the gap between the auxiliary shoulders of the double-shoulder drill pipe joint which is most suitable for the axial force characteristics of a well section is preferably determined according to the depth characteristics of each section of a drill stem in ultra-deep well drilling operation. The method can determine the optimal gap between the auxiliary shoulders of the double-shoulder drill pipe joint so as to meet the requirements of different welldepth operations, and has very important significance on the improvement of the usability of the double-shoulder drill pipe joint, the prolonging of the service life of the double-shoulder drill pipejoint, and the reduction of the operation cost.

Owner:SHANGHAI UNIV

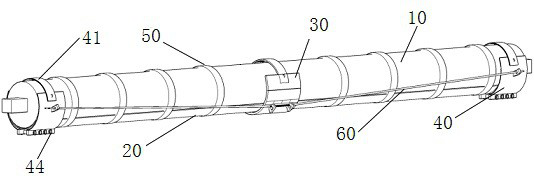

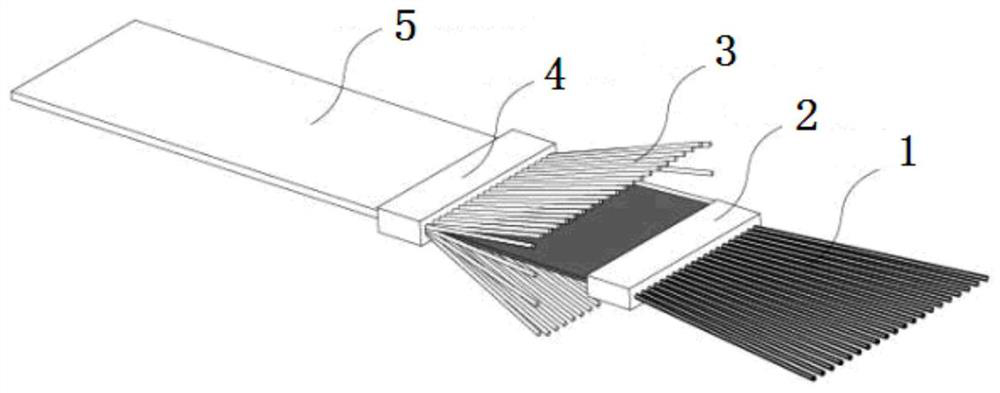

Fiber winding machine and winding method

PendingCN113386329AReduce cross bendExert mechanical propertiesDomestic articlesWinding machineEngineering

The invention discloses a fiber winding machine and a winding method. The fiber winding machine comprises a moving device, a core mold, a warp winding head, weft winding heads and warp supply devices; the warp winding head is arranged on the outer side of the moving device in a surrounding mode, the core mold is arranged on the moving device, and the core mold and the warp winding head are coaxially arranged; the weft winding heads are arranged at the positions, on the two sides of the warp winding head, of the moving device; and the warp supply devices are arranged on the two sides of the moving device and connected with the warp winding head. The helical angles of warps on the same layer flat laid on a cylindrical surface relative to the axis of the core mold are the same, and mutual overlapping does not exist; the adjacent warp layers in the radial direction of the cylindrical surface do not overlap with each other, so that cross bending of fibers is reduced, the mechanical property of the high-strength fibers can be better exerted, and winding bodies are firmer and lighter; and compared with a traditional fiber winding machine, the production efficiency of the winding machine can be greatly improved.

Owner:XIAN YINGLIKE ELECTRIC TECH CO LTD

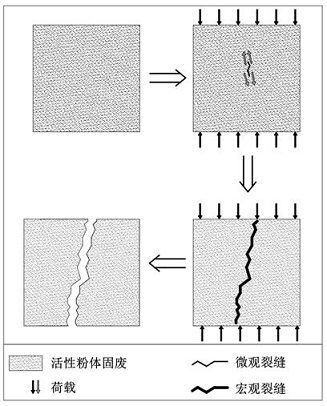

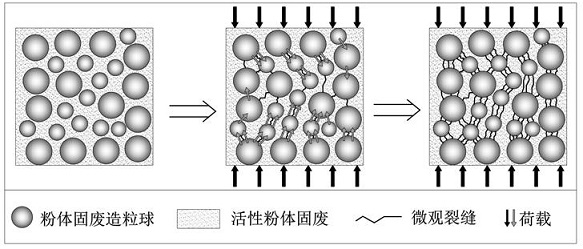

Powder solid waste granulation baking-free brick and preparation method thereof

The invention discloses a powder solid waste granulation baking-free brick and a preparation method thereof, and belongs to the technical field of solid waste building material resource utilization. The preparation method comprises the following steps: taking 80-90% by weight of powder solid waste and 10-20% by weight of a hydraulic cementing material, and adding water and a water reducing agent for granulation to prepare solid waste particles with the particle size of 1-30mm; taking 70-80% by weight of powder solid waste and 20-30% by weight of a hydraulic cementing material, and mixing the powder solid waste and the hydraulic cementing material to prepare a cementing material; and preparing the baking-free brickby taking the following components in percentage by weight: 20-30% of a cementing material, 20-40% of solid waste particles with the particle size of less than 5mm and 30-60% of solid waste particles with the particle size of greater than 5mm, adding water and a water reducing agent, mixing and molding. According to the method, powder solid waste granulation is used for blocking crack propagation, the mechanical property established by active solid waste powder forming can be exerted to the maximum extent, and a more practical and reliable new path is provided for powder solid waste recycling.

Owner:徐州佳汇新材料科技有限公司

Epoxy floor coating and preparation method thereof

The invention provides an epoxy floor coating, which comprises the following raw materials in parts by weight: 100 parts of a bisphenol A epoxy resin solution, 10-15 parts of a graphene microchip, 2-6parts of zinc powder, 0.5-1 part of polyamide wax slurry, 3-8 parts of n-butanol, 25-60 parts of xylene, 0.08-0.2 part of dibutyl phthalate and 0.1-0.2 part of polydimethylsiloxane. The graphene of the epoxy floor coating is uniformly dispersed and highly dispersed, so that the mechanical property of the graphene is brought into play, the impact resistance of the epoxy floor coating is effectively improved, the problem of electrical corrosion of the graphene is avoided, and the service life of the floor coating layer is effectively prolonged.

Owner:江苏道蓬科技有限公司

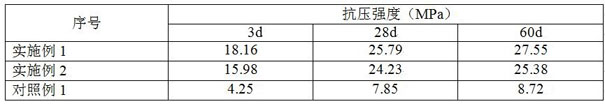

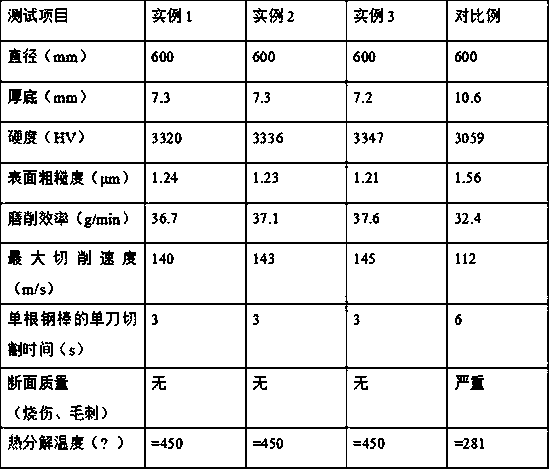

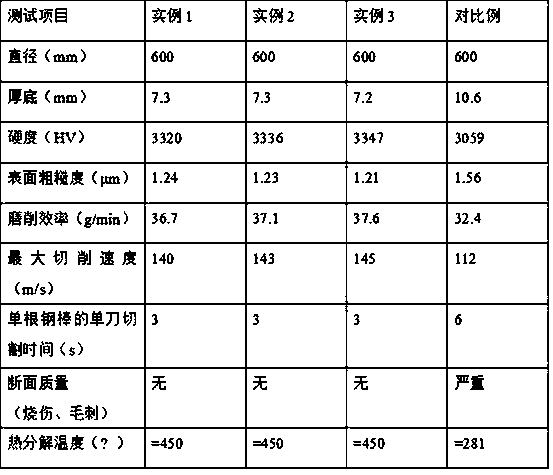

A kind of preparation method of high strength and high heat resistance resin grinding wheel

ActiveCN108857954BIncrease resistanceExert mechanical propertiesAbrasion apparatusGrinding devicesEpoxyCarbide silicon

The invention relates to the technical field of metal cutting tool preparation, in particular to a preparation method of a high-strength high-heat-resistant resin grinding wheel. The method comprisesthe steps that silicon carbide is put into an arc chamber to be subjected to discharging heating so as to generate a discharging product, then graphite powder serves as a raw material to obtain an oxidation product, then the oxidation product is mixed with tetrabutyl titanate to obtain a dried product, and finally, epoxy resin, the discharging product, the dried product and the like are mixed andmelted uniformly, and then poured into a mold to be solidified to obtain the high-strength high-heat-resistant resin grinding wheel. The heat generated by the silicon carbide during energization is huge, so that iron is melted and evaporated into gas, thereby playing a very good role in catalytic action for the generation of a silicon carbide nano material; the oxidation of potassium permanganateand hydrogen peroxide causes that the surface of graphene introduces oxygen-containing groups and forms carbon vacancies, so that the graphene and titanium dioxide molecules are attached and bonded more easily, thereby improving the hardness and heat resistance of the resin grinding wheel, and the application prospects are broad.

Owner:河北鑫旭德耐磨材料科技有限公司

Walnut shell based ecological composite structure material and preparation method thereof

The invention relates to a walnut shell based ecological composite structure material and a preparation method thereof. The method comprises the following steps: (1) simply processing walnut shells byremoving kernels and drying; (2) arranging the dried walnut shells in a mold; (3) heating an additive, and pouring the additive into the mold; (4) in the additive cooling process, carrying out stamping, air hole removing and cooling forming on a material in the mold; and (5) taking out the material from the mold and machining the material to obtain the walnut shell based ecological composite structure material. Compared with the prior art, the method has the advantages that the process is simple, the universality is high, the method can be popularized in walnut original places, walnut shell productivity is consumed, and economic development of villages and towns is promoted.

Owner:SHANGHAI JIAO TONG UNIV

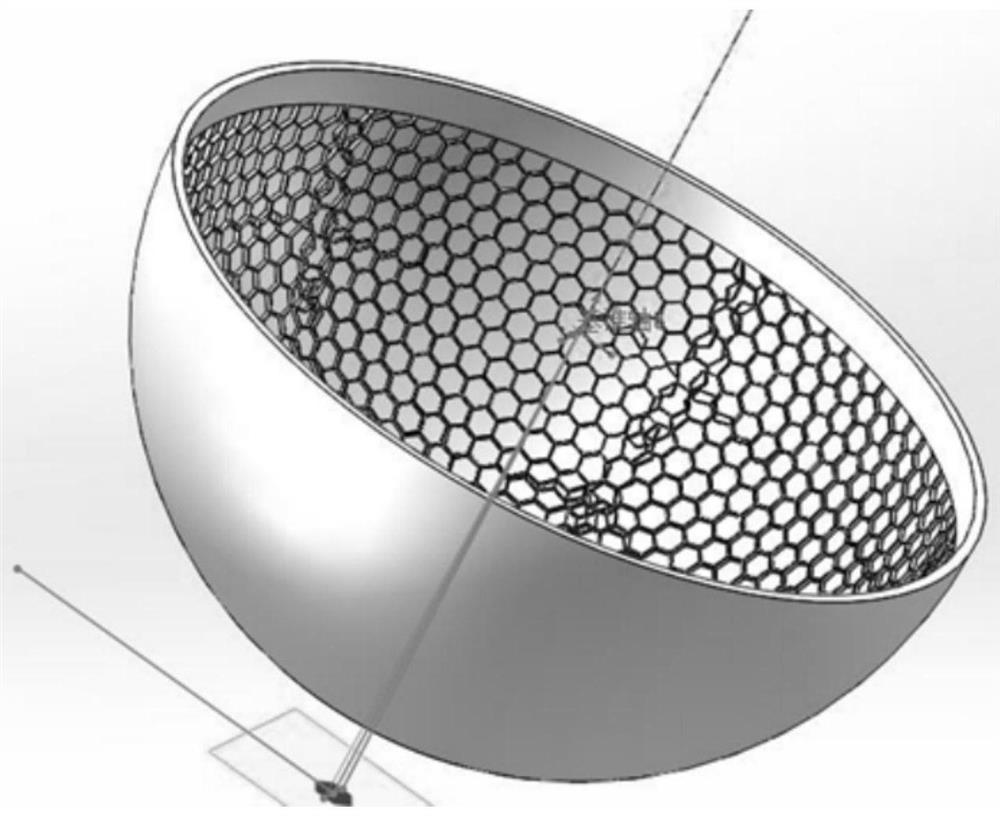

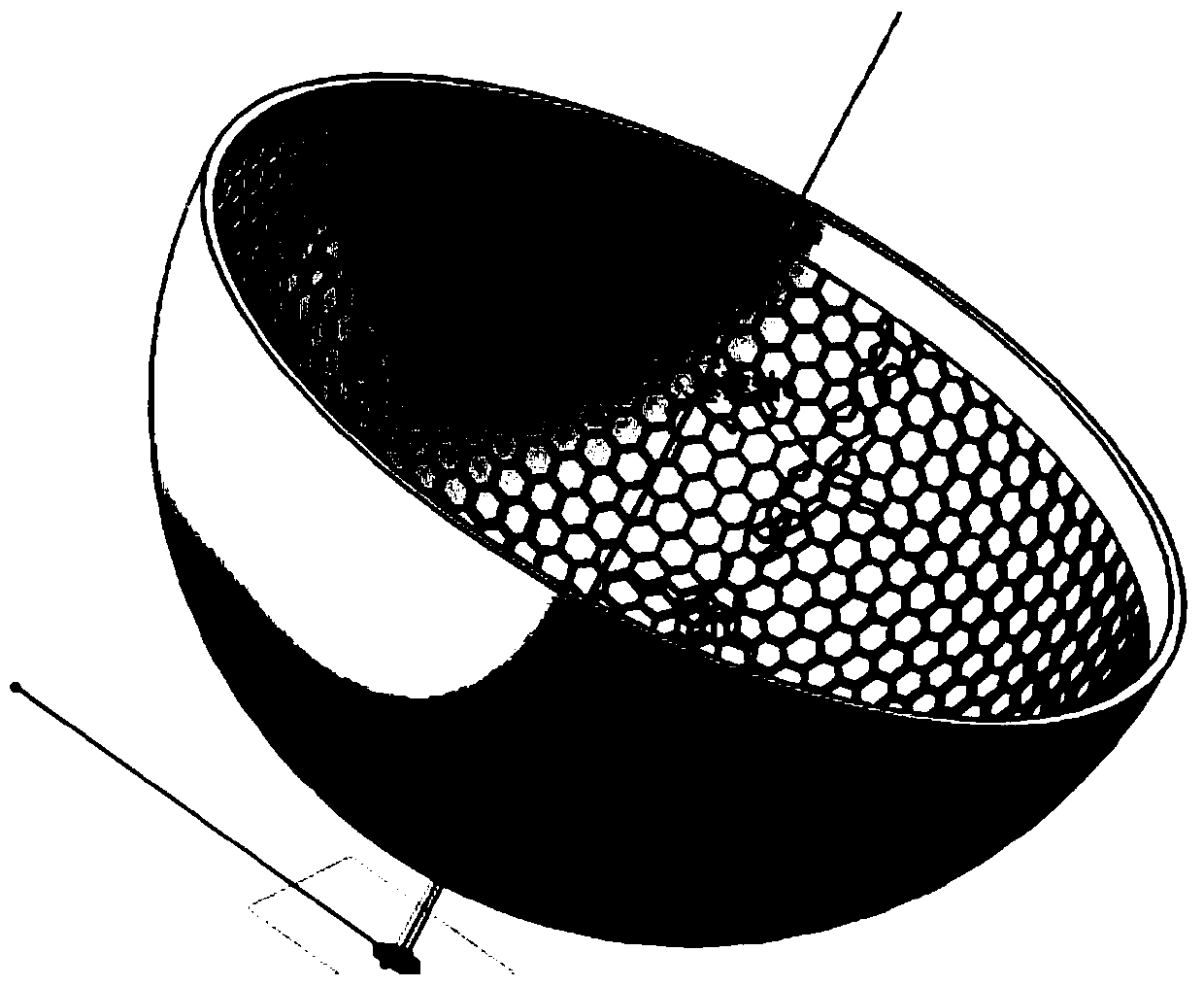

A composite spherical shell for omnidirectional motion spherical robot and preparation method thereof

ActiveCN109880299BStrong acid and alkali corrosion resistanceGood damping functionPolyurea/polyurethane coatingsElastomerResin matrix

The patent of the present invention provides a composite spherical shell of a spherical robot. The spherical shell composite structure includes a rigid matrix shell and a flexible coating layer. The rigid matrix shell is a structural fiber-reinforced composite material, which is composed of reinforcing fibers and a thermosetting resin matrix. Honeycomb stiffeners are arranged on the inner surface of the rigid matrix shell. The stiffener material is thermosetting resin, which can be combined with the rigid matrix shell. Integrated thermoforming; flexible coating layer adopts copolymer elastomer material. The lightweight composite spherical shell has high specific strength, specific stiffness, rolling friction coefficient, impact energy dissipation coefficient and quick repair function. The spherical shell and the corresponding spherical robot are used as an open automatic control platform, and a variety of functional spherical robots can be developed on the basis of the spherical robot composite spherical shell.

Owner:BEIJING UNIV OF POSTS & TELECOMM

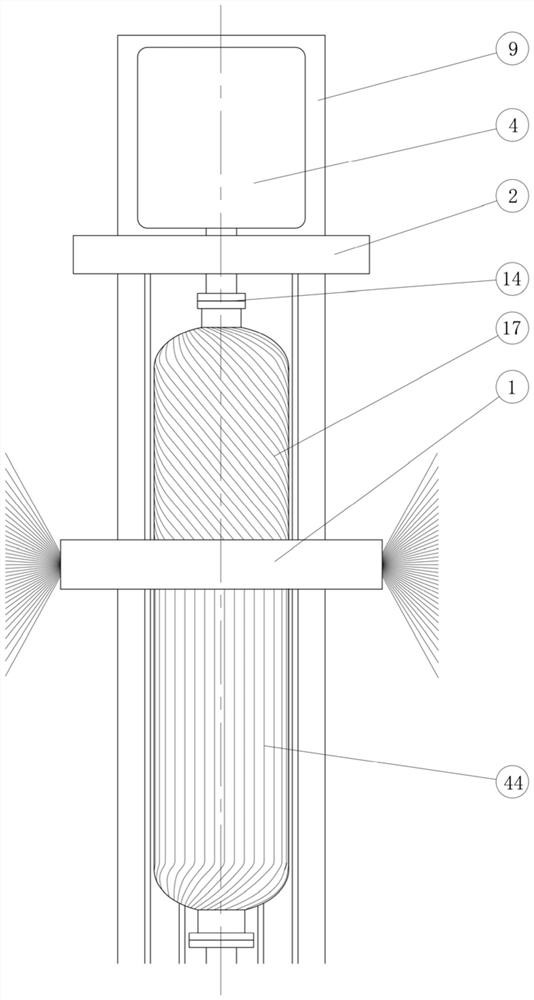

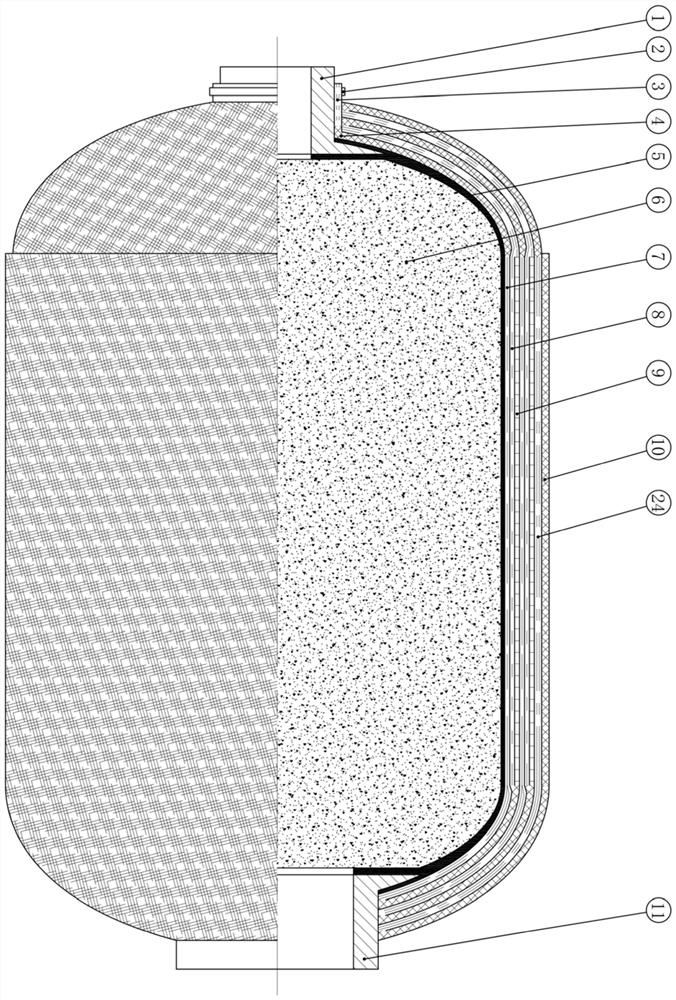

Circular knitting method of composite material high-pressure container

ActiveCN113370551AExert mechanical propertiesImprove and increase mechanical strengthWeft knittingDomestic articlesYarnFiber

The invention discloses a circular knitting method of a composite material high-pressure container. The circular knitting method comprises the following steps that firstly, the ends of warp yarns are uniformly distributed at the root of an end socket at one end of a core mold, and the warp yarns are tightened by using a ribbon; then circular knitting is started; then a shedding mechanism starts to normally move along with rotation of a main shaft of a circular knitting machine, meanwhile, the core mold moves reversely, circulation is conducted till the thickness of a fabric meets the requirement, and circular knitting is completed; and glue dripping, pressurizing, heating and curing are conducted on the structure subjected to circular knitting, and the composite material high-pressure container is obtained. The circular knitting machine is adopted for knitting the composite material high-pressure container, the spiral angles of all warp yarns flatly laid on the cylindrical surface relative to the axis of the core mold are the same, the spiral directions of the warp yarns of adjacent layers relative to the axis of the core mold are opposite, therefore, fiber cross bending caused by mutual overlapping does not exist between adjacent flatly laid warp yarn layers, and the mechanical property of high-strength fibers can be better exerted. The circular knitting method not only can be used for knitting a solid propellant rocket engine combustion chamber shell, but also can be used for producing composite material wings, large fan blades, telegraph poles and large high-pressure pipelines.

Owner:XIAN YINGLIKE ELECTRIC TECH CO LTD

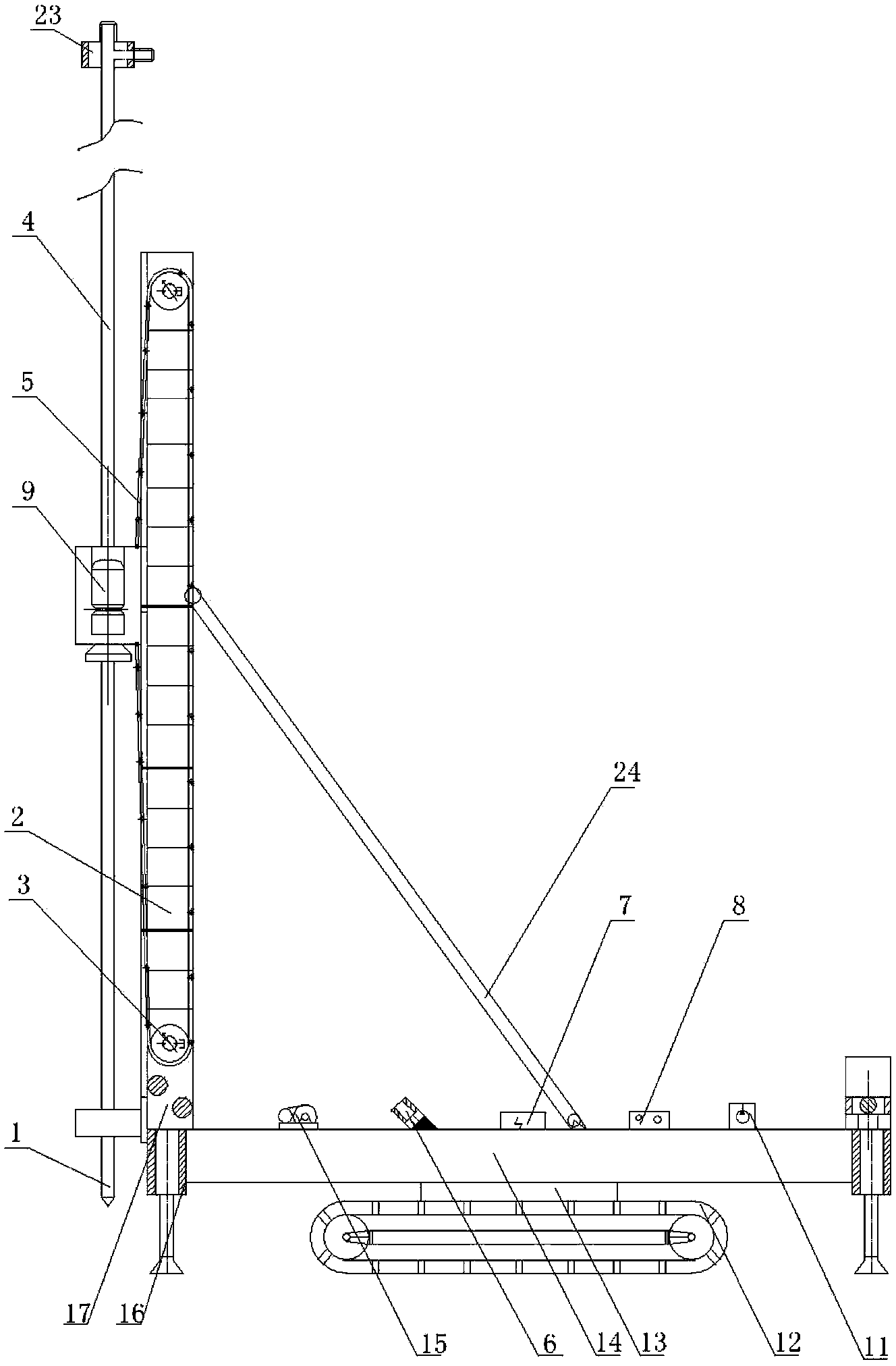

Construction method of batter pile construction drilling machine

ActiveCN102628336BReduce settlementImprove bearing capacityDerricks/mastsDirectional drillingArchitectural engineeringRebar

The invention relates to a batter pile construction drilling machine and a construction method, and can rapidly carry out the construction of batter piles inclined at needed angles. The invention adopts the following technical scheme: in the batter pile construction drilling machine, a rig is arranged on a base assembly, one end of the rig is rotatably connected with the base, the other end of the rig is a free end, moreover, an adjusting cylinder which is used for adjusting the angle between the rig and the base is arranged between the rig and the base, the rig is provided with a slip slide way along the length direction, a slip is matched with the slip slide way, and is connected with a drill tool, and two sets of drive pairs which are used for driving the drill tool to move along the length direction of the rig are respectively arranged on both sides of the rig. The method for carrying out construction by utilizing the batter pile construction drilling machine includes the following steps: (1) the rig is adjusted according to a designed angle until a drill bit reaches a designed depth; (2) a concrete pump or a mortar pump is started, so that a pile hole is filled up with concrete or mortar; (3) profile steels or a reinforcement cage are inserted into the concrete or mortar, so that a pile is formed; (4) the drilling machine is moved to the next pile position, and according to the sequence of the method, the piles are formed.

Owner:邢占东 +1

Preparation method of high-strength high-heat-resistant resin grinding wheel

ActiveCN108857954AIncrease resistanceExert mechanical propertiesAbrasion apparatusGrinding devicesEpoxyPotassium

The invention relates to the technical field of metal cutting tool preparation, in particular to a preparation method of a high-strength high-heat-resistant resin grinding wheel. The method comprisesthe steps that silicon carbide is put into an arc chamber to be subjected to discharging heating so as to generate a discharging product, then graphite powder serves as a raw material to obtain an oxidation product, then the oxidation product is mixed with tetrabutyl titanate to obtain a dried product, and finally, epoxy resin, the discharging product, the dried product and the like are mixed andmelted uniformly, and then poured into a mold to be solidified to obtain the high-strength high-heat-resistant resin grinding wheel. The heat generated by the silicon carbide during energization is huge, so that iron is melted and evaporated into gas, thereby playing a very good role in catalytic action for the generation of a silicon carbide nano material; the oxidation of potassium permanganateand hydrogen peroxide causes that the surface of graphene introduces oxygen-containing groups and forms carbon vacancies, so that the graphene and titanium dioxide molecules are attached and bonded more easily, thereby improving the hardness and heat resistance of the resin grinding wheel, and the application prospects are broad.

Owner:河北鑫旭德耐磨材料科技有限公司

Preparation method of a carbon fiber/glass fiber hybrid stealth composite material

The invention discloses a method for preparing a carbon fiber / glass fiber hybrid stealth composite material, specifically: carbon fiber is used as a core yarn, glass fiber is used as a weaving yarn, and two-dimensional weaving technology is used to weave the core yarn and the weaving yarn into carbon fiber / glass fiber Core-spun yarn; then the carbon fiber / glass fiber core-spun yarn is woven into cloth, and finally the cloth and epoxy resin are compounded and cured by resin transfer molding to obtain a carbon fiber / glass fiber hybrid stealth composite material. The present invention uses the carbon fiber / glass fiber core-spun yarn structure to utilize the wave-transmitting properties of glass fibers to allow electromagnetic waves to enter the interior of the core-spun yarn to the greatest extent, and then utilizes the resistance loss of carbon fibers to convert electromagnetic wave energy into heat energy or other forms. energy is dissipated. At the same time, as the core yarn, the carbon fiber is basically in a straight state, so that its mechanical properties can be effectively exerted, so that the fabricated stealth composite material has good mechanical properties.

Owner:南通欣丰桥架有限公司

Reducing screw displacement pile drilling tool and construction method thereof

ActiveCN104018792BVariable diameter position adjustableTake full advantage of mechanical propertiesDrilling rodsDrilling without earth removalScrew threadCounter rotation

The invention discloses a reducing screw displacement pile drilling tool and a construction method. The drilling tool comprises a hollow inner drill stem; the inner drill stem is a cylinder on the outer wall of which external threads are formed; a displacement body with internal threads is connected to the outside of the inner drill stem by use of the threads; the displacement body is a spindle body which is thin in two ends and thick in middle part. A method for carrying out construction by using the drilling tool comprises the following steps: the power head of an in-position drilling machine rotates forward and the displacement body reaches a first supporting course depth; the inner drill stem continue drilling downwards until a screw drill bit reaches in a second supporting course position; the power head rotates backwards, concrete is poured, the drilling tool is lifted, and then the screw pile body is formed; when the screw drill bit goes up to the first supporting course position, the power head rotates forwards and concrete is poured continuously, and the displacement body rotates and is lifted so that the cylindrical pile is formed; the drilling tool is pulled out and then the pile body is formed.

Owner:邢占东 +2

Compound spherical shell oriented to omnidirectional movement spherical robot, and preparation method thereof

ActiveCN109880299AHigh strengthStrong enoughPolyurea/polyurethane coatingsElastomerAutomatic control

The invention provides a compound spherical shell of a spherical robot. The compound structure of the spherical shell comprises a rigid substrate shell and a flexible coating layer, wherein the rigidsubstrate shell is made of structural type fiber reinforced compound material and is compounded by reinforced fibers and a thermosetting resin substrate; a honeycomb-shaped stiffening rib is arrangedon the inner surface of the rigid substrate shell, is made of thermosetting resin and can be subjected to integral hot press molding with the rigid substrate shell; the flexible coating layer is madeof copolymer elastomer materials. The light compound spherical shell has high specific strength, specific stiffness, rolling friction coefficients and impact energy dissipation factors and also has aquick repairing function. The spherical shell and the corresponding spherical robot serve as an open type automatic control platform, and various functional spherical robots can be developed and derived on the basis of the compound spherical shell of the spherical robot.

Owner:BEIJING UNIV OF POSTS & TELECOMM

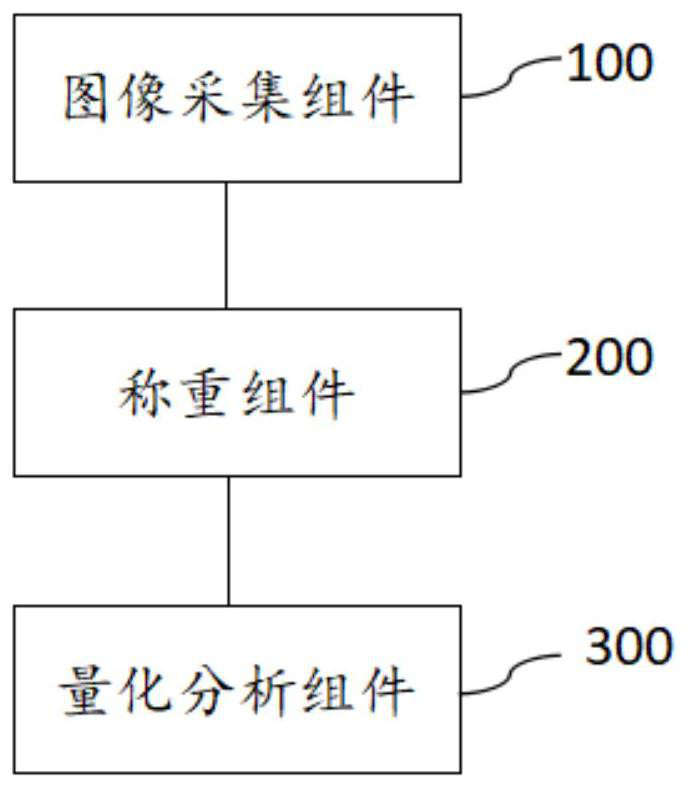

Intelligent drilling device for underground engineering and heading machine

PendingCN112196569AGood mechanical propertiesImprove mechanical performanceMining devicesTunnelsDrill holeEnvironmental geology

The invention discloses an intelligent drilling device for underground engineering and a heading machine. The drilling device comprises a drilling mechanism, a detection module and a control module. The drilling mechanism is arranged on a fixed disc and comprises a drill rod capable of axially extending and retracting on the fixed disc and a driving assembly used for driving the drill rod to axially extend and retract and axially rotate. The detection module is used for detecting rock debris in the process that the drilling mechanism drills into to-be-excavated rock mass and rock mass physicaland mechanical parameters of the to-be-excavated rock mass, and analyzing the lumpiness size and the weight distribution rule of the rock debris. The control module is used for adjusting the parameters generated when the driving assembly drives the drill rod to axially extend and retract and / or axially rotate according to the lumpiness size and the weight distribution rule of the rock debris. Parameter adjustment of the drilling mechanism is highly matched with the geological conditions of the to-be-excavated rock mass in real time, then the mechanical performance of the drilling device is better exerted, and the aim of rapid drilling is achieved.

Owner:TSINGHUA UNIV +1

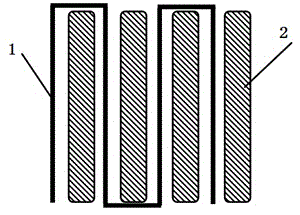

Pultrusion method for carbon fiber and glass fiber composite board

The invention discloses a pultrusion method for a carbon fiber and glass fiber composite board. The pultrusion method comprises the following steps of (1) unwinding yarns on a creel; 2) threading and combing yarns; 3) impregnating carbon fibers in a steeping vat; 4) pre-curing a carbon fiber mold, specifically, pre-curing impregnated carbon fiber yarns through a first pultrusion mold to form a pre-cured carbon plate; (5) impregnating glass fibers in the steeping vat; and (6) finally curing a product, specifically, after glass fiber yarns are impregnated, uniformly distributing the glass fiber yarns around the pre-cured carbon plate according to the specific number of glass fibers, entering a second pultrusion mold, and curing to obtain a carbon-glass mixed pultrusion plate. According to the method, the pultrusion plate which takes the carbon fibers as a sandwich layer and the glass fibers as an outer layer and is used for preparing a blade of a wind power generator can be prepared, the problems that existing carbon fibers are excessive in performance and high in price, and existing glass fibers are insufficient in performance and heavy in mass are solved, the carbon fiber layers in the plate can be neatly arranged in the plate, and the mechanical property of combining the two fibers is exerted to the greatest extent.

Owner:四川东树新材料有限公司

Quick mounting building and mounting method thereof

The invention relates to a quick mounting building and a mounting method thereof. According to a traditional steel structure building, a steel structure is used as a force bearing frame, welding is mainly adopted, and assembly line production cannot be achieved. A traditional prefabricated concrete building and a prefabricated steel structure building have the defects of large component dead weight and large assembly difficulty. The quick mounting building comprises quick mounting wallboards, wherein the quick mounting wallboards include corrugated plates / groove plates, the two side edges of the corrugated plates / groove plates are bent to form connecting columns, the upper ends and the lower ends of the corrugated plates / groove plates are provided with end beams or the upper ends and the lower ends of the corrugated plates / groove plates are connected with cross beams, the horizontal adjacent quick mounting wallboards are assembled and connected through the connecting columns to form a linear wall body or an L-shaped wall body or a T-shaped wall body or a cross-shaped wall body, and a building wall body is jointly formed after the quick mounting wallboards are assembled and connected; the end beams or the cross beams which are located on the top of the building wall body are connected with a roof; the end beams or the cross beams which are located at the bottom of the building wall body are connected with a foundation or are connected with the foundation through base beams; and the quick mounting building comprises doors and windows, and a heat preservation and insulation layer is installed on the peripheral building wall body.

Owner:刘旭

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com