Pre-tensioning method broken-line reinforcement idler wheel bending device shaped like Chinese character ''fei''

A technology of folded line reinforcement and bending device, which is applied in construction, building structure, processing of building materials, etc., can solve the problems of easy formation of stress concentration, many processing and manufacturing processes, and complicated structure of the bending device, so as to avoid Inflection point and inflection point effect, low processing cost, and the effect of maintaining prestressing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

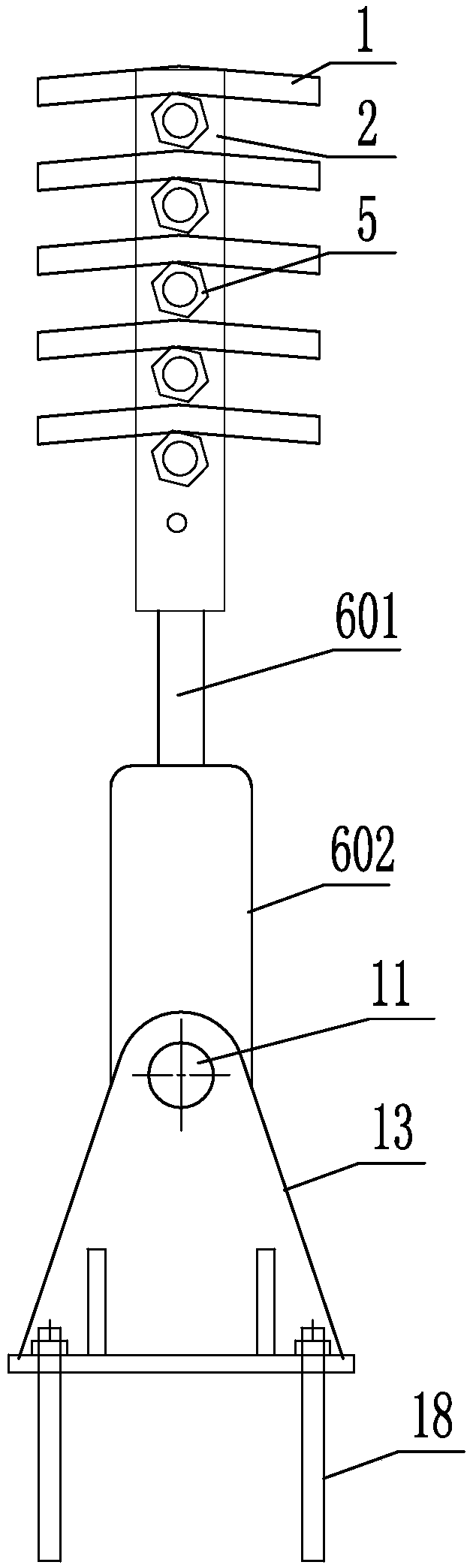

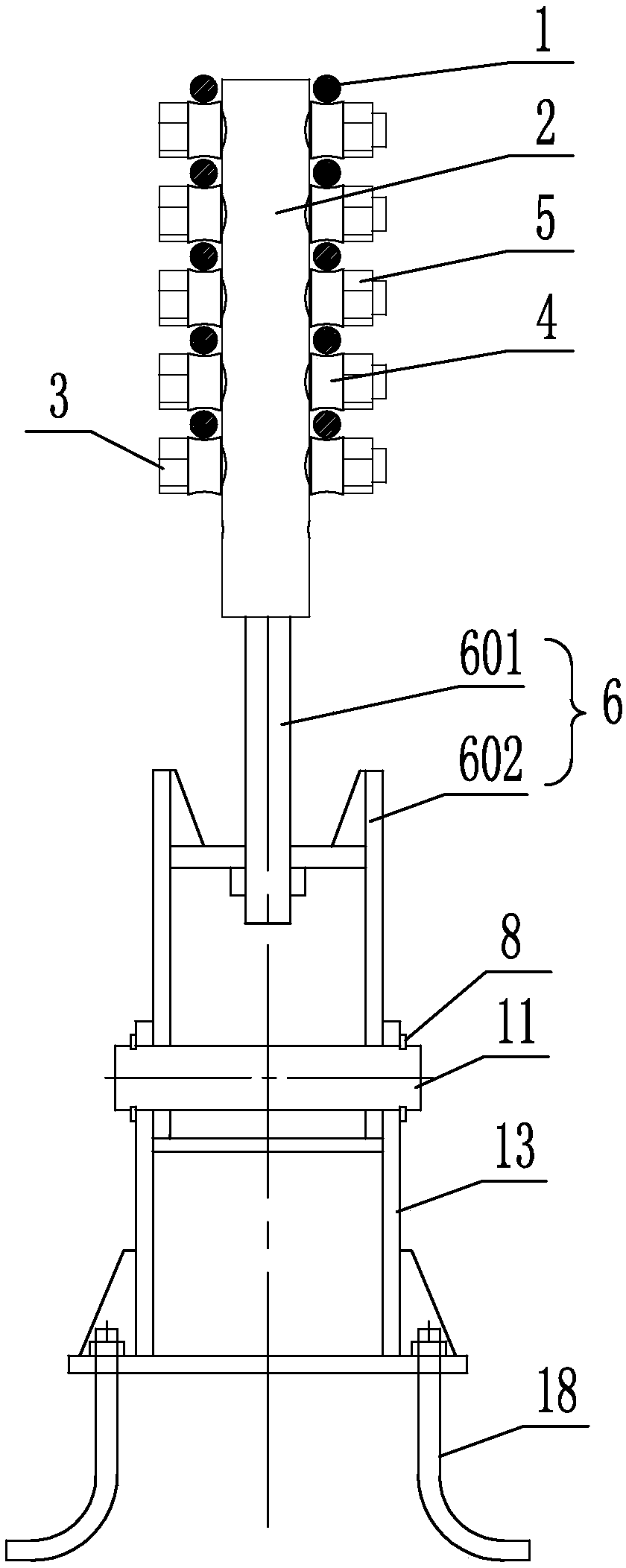

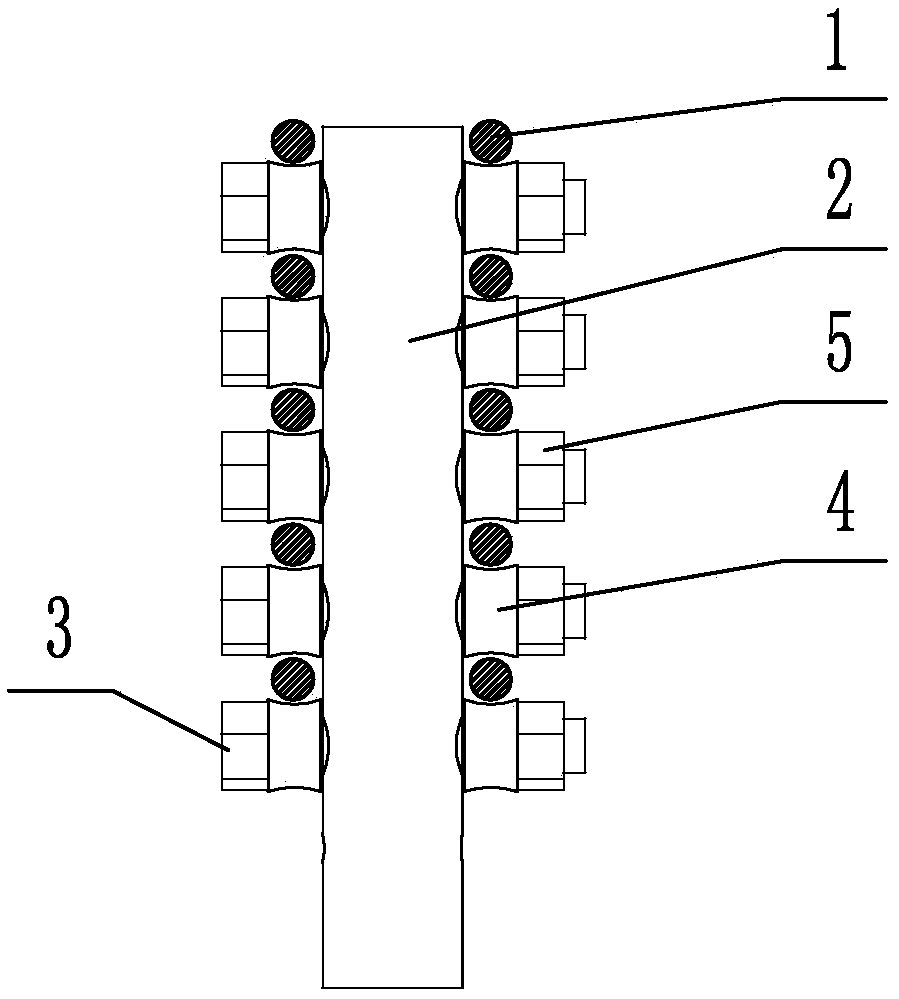

[0061] A non-shaped roller bender for pretensioning broken line reinforcement (see Figure 1-Figure 2 ), including a bender, an installation base 13, an anchor bolt 18, and a connection device 6 connecting the bender and the installation base 13, the connection device 6 includes a connecting rod 601 and an intermediate pull plate I602, and the bender is A non-shaped roller bender, the non-shaped roller bender includes a support tube 2, a roller 4 and a fixing bolt 3 that acts as a connecting pin (see image 3 );

[0062] Described support pipe 2 is a round pipe 201, and the bottom of round pipe 201 is provided with base installation blind hole 203, and round pipe 201 top is provided with a row of n mounting holes 202 for screw rods of fixing bolt 3 to pass through (see Figure 4 );

[0063] The middle of the roller 4 is provided with a groove 401, the groove 401 is a U-shaped groove or a V-shaped groove, the center of the section of the roller 4 is a circular hole 402, and t...

Embodiment 2

[0068] The non-shaped roller bender with a baffle has the same basic structure as the first embodiment, and the difference from the first embodiment is that:

[0069] The non-shaped roller bender also includes two baffle plates I19 with the same structure, the upper end of the baffle plate I19 is provided with a through hole 1901 matching the screw rod of the fixing bolt 3, and the bottom end of the baffle plate I19 is provided with A bolt hole 1902 connected with the round pipe 201 (see Figure 10 );

[0070] In the installed state, the two baffles I19 are respectively installed on the outer sides of the two rows of rollers 4, the through hole 1901 of the baffle I19 is set on the screw rod of the fixing bolt 3 at the uppermost end of the round tube 201, the lock nut 5 and the head of the fixing bolt 3 The upper part is installed on the outer side of two baffles Ⅰ19 to lock the roller 4, and the bottom ends of the two baffles Ⅰ19 are respectively connected to the round pipe b...

Embodiment 3

[0075] The basic structure of the pretensioned folding line reinforced non-shaped roller bender with quick decoupling device is the same as that of embodiment 1 or embodiment 2, and the difference from embodiment 1 or embodiment 2 lies in:

[0076] A quick uncoupling device is also installed between the connecting device 6 and the installation base 13 of the non-shaped roller bender of the pretensioned folded line reinforcement, and the quick uncoupling device includes a circlip 8 for the shaft, a transmission shaft I9, an intermediate Pull plate II10, rotating shaft II11, rotating shaft III12, rotating mechanical rod 14, upper wedge 15, locking screw 16 and lower wedge 17 (see Figure 16-Figure 17 );

[0077] In the state of installation and use, the installation base 13 is installed on the ground by the anchor bolts 18, the upper end of the connecting rod 601 is connected with the base installation blind hole 203 of the bender round pipe 201, and the lower end of the connect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com