Hot melting based X-type cold and hot water cross connecting block and cold and hot water pipe parallel laying system

A technology of cross-connection and connection block, which is applied in the direction of pipeline connection layout, pipeline laying and maintenance, pipe/pipe joint/pipe fitting, etc., which can solve the problems of large thickness at the intersection of pipelines, poor pipeline aesthetics, and reduced distance, etc., to achieve The pipeline system is safe and reliable, easy to lay, and the effect of reducing the thickness of the water pipe

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

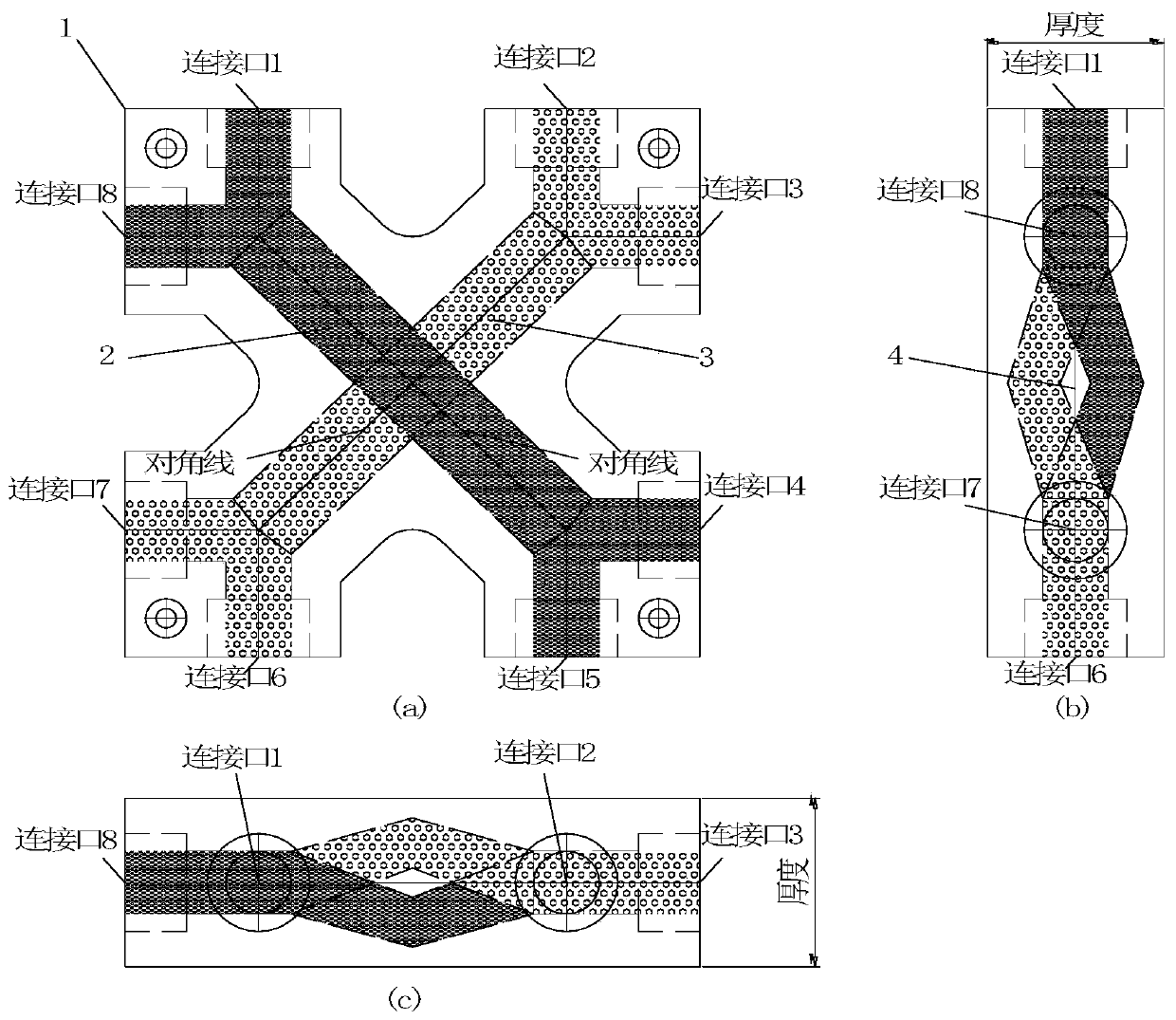

[0048] Example 1: Reference figure 1(a), the X-shaped cross connection block 1 is a hexahedral structure, its main body is a square structure, the upper and lower surfaces are square, and the two ends of the X-shaped crossed cold water flow channel 2 and hot water flow channel 3 are respectively connected to the square The four sides of the main body make the four sides of the square main body have one cold water and one hot water pipe connection port, which can be connected by pipes to form cold water and hot water pipelines that are perpendicular to each side and can be connected in parallel.

[0049] The crossing of the cold water pipeline and the hot water pipeline refers to: inside the X-shaped cross connection block 1, two independent water delivery channels are opened on the diagonal of a square, which are respectively called the cold water channel 2 and the hot water channel. Water flow channel 3, the two flow channels are not connected to each other, presenting a lett...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com