High-temperature-resistant bending-resistant ethylene propylene rubber insulated cable for rail transit, preparation method thereof and insulating material

An ethylene-propylene rubber insulation and rail transit technology, applied in the field of cables and cable materials, can solve problems such as low pressure and temperature resistance, slow vulcanization speed, and complicated process flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

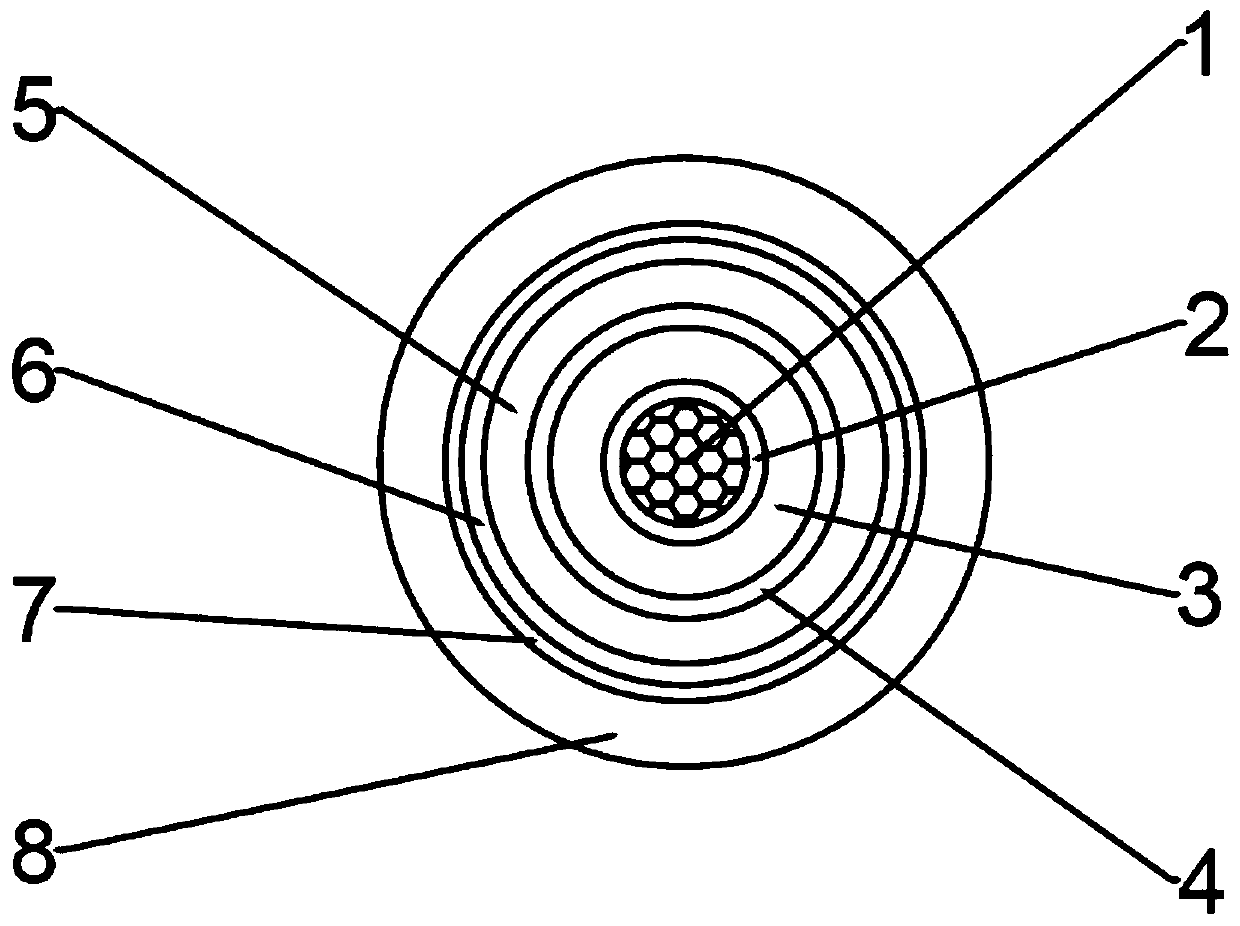

[0073] Such as figure 1 The shown high temperature and bending resistant ethylene-propylene rubber insulated cable for rail transit includes conductor 1, which uses six types of annealed copper conductors, is resistant to bending, and has a large bending radius; the conductor is wrapped with a first polyetheretherketone The film wrapping layer 2 and the second polyether ether ketone film wrapping layer 4 make the cable have excellent mechanical properties, electrical properties, high temperature resistance (the mechanical strength does not decrease at a high temperature of 240°C), and good flame retardancy: no need High flame retardancy, excellent electrical insulation properties due to the use of flame retardant additives: high dielectric strength, stable dielectric properties at various temperatures, frequencies and temperatures, radiation resistance, hydrolysis resistance and a wide range of chemical resistance : Insoluble in all common solvents—excellent acid, alkali, lubr...

Embodiment 2

[0075] A method for preparing an ethylene-propylene rubber insulated cable for high-temperature and bending-resistant rail transit, comprising the following steps:

[0076] 1) Preparation of conductor:

[0077] 1-1) Wire drawing: first draw a copper rod with a diameter of 3mm on a LT2-15 / 350 copper wire drawing machine into a copper wire with a diameter of 0.99mm, and the dimensions of the drawing dies are: 2.76, 2.55, 2.35, 2.16, 1.99, 1.83, 1.69, 1.56, 1.43, 1.32, 1.02mm; the copper wire outlet speed is 10-20m / s, the maximum annealing current is 1200A; Small drawing machine wires are drawn into copper wires with a diameter of 0.3-0.5 mm. The size of the wire drawing dies can be: 0.83, 0.74, 0.65, 0.59, 0.52, 0.46, 0.40, 0.35, 0.31 mm, and the copper wires appear at a speed of 8~16m / s, the maximum annealing current is 600A;

[0078] 1-2) Bundling: 23 to 63 copper wire bundles with a diameter of 0.3 to 0.5 mm are formed into strands through a DF-GJ / 500 wire bundle machine, a...

Embodiment 3

[0097] A 150°C low-smoke halogen-free flame-retardant modified irradiated ethylene-propylene rubber insulating material, including the following components in parts by mass:

[0098] EPDM rubber: 45 parts, superfine polyimide resin powder: 18 parts, dioctyl phthalate: 5 parts, graphene: 1 part, white oil: 3 parts, maleic anhydride: 1 part , trimethylolpropane trimethacrylate: 1 part, magnesium hydroxide inorganic flame retardant: 5 parts, RCA aluminate coupling agent: 0.1 part, antioxidant and anti-copper agent 1024: 0.3 part, stearic acid Zinc: 0.5 parts.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com