Modified epoxy resin adhesive and its preparation process

A technology of epoxy resin and modified resin, applied in the direction of epoxy resin glue, adhesive, adhesive type, etc., can solve the problems of environmental pollution, inability to meet the curing time and long curing time of packaging materials, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

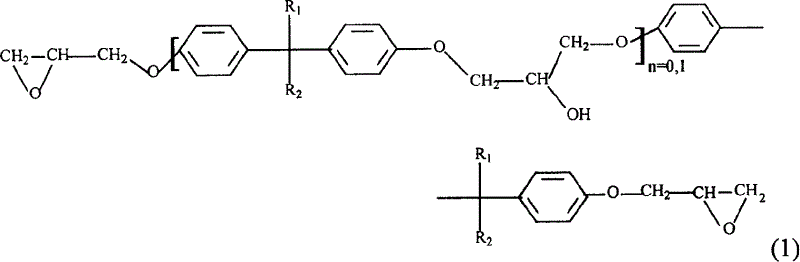

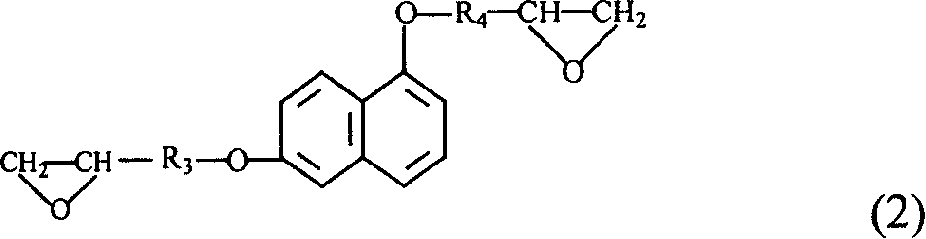

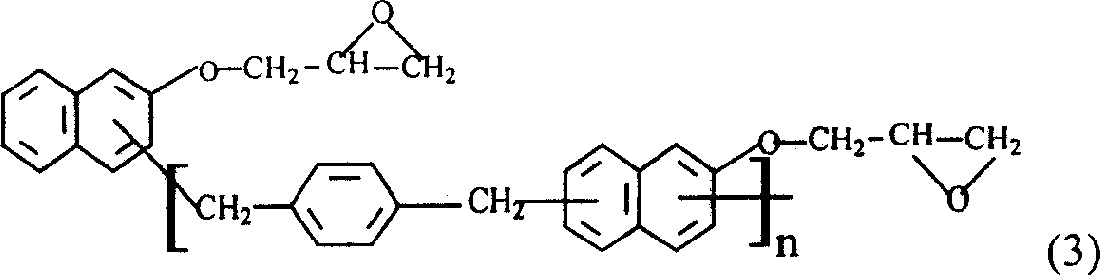

Method used

Image

Examples

Embodiment 1

[0053] The molecular structural formula of reactant 4-(4-aminobenzyl)aniline is as follows:

[0054]

[0055] reaction process:

[0056] Add 29.7 g (0.15 mol) of ambenzylaniline and 17.6 g (0.1 mol) of 1-chlorodecane into a glass reactor, add 80 ml of 15% NaOH alkaline solution, and stir at 1500 rpm. The reaction temperature was 90°C, and after rising to the reaction temperature, the reaction was carried out for 3 hours. After the reaction, extract with cyclohexane and remove the solvent by rotary distillation to obtain the product as a colorless or light yellow transparent liquid. Viscosity 320mp, curing conditions: curing above 60°C, no effect at low temperature.

Embodiment 2

[0058] The structural formula of reactant 4-(2-aminoethyl)-1-methylcyclohexylamine is as follows:

[0059]

[0060] reaction process:

[0061] The reactant 4-(2-aminoethyl)-1-methylcyclohexylamine 46.9g (0.3mol) and 12.1g (0.1mol) were added to the glass reactor, and 15% Na 2 CO 3 100ml, stir quickly. The reaction temperature is 120°C, and the reaction is 6h. After the reaction, it was extracted with n-hexane. After three times, the solvent was removed by rotary distillation to obtain a light yellow transparent viscous liquid. The viscosity is 280mp. Low temperature has no effect, and it can be cured when the temperature is raised to 45°C.

[0062] Surface active treatment of II fillers

Embodiment 3

[0063] The surface treatment of embodiment 3 silica powder

[0064] In 50ml organosiloxane solution, add 4.5% methanol solution of fused silicon micropowder (the maximum diameter of silicon micropowder should be less than 10μm), stir vigorously at 5000rpm to promote the full dispersion of silicon micropowder in the system, then heat up to reflux, and stir at a medium speed , Reaction time 1h, continue to heat up and steam methanol. Control the temperature within 80-100°C, and react within this temperature range for 20 hours. After the surface treatment is completed, excess siloxane is distilled off under reduced pressure. The system was cooled to room temperature. After separation and drying, wash and filter repeatedly with distilled water or deionized water, dehydrate with absolute ethanol, and grind into fine powder after vacuum drying to obtain 2.6 g of surface-treated fused silica powder filler.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com