Environment-friendly high-and low-temperature resistant oil-resistant polyvinyl chloride cable sheathing compound

A technology of oil-resistant polyvinyl chloride and cable sheathing materials, which is applied in the direction of circuits, electrical components, plastic/resin/wax insulators, etc., and can solve the problem of low temperature resistance, oil resistance, heat resistance, and abrasion resistance. , Cables are difficult to meet the normal use, increase the cost of materials and other problems, to achieve the effect of reasonable ratio, excellent heat resistance, and improved heat resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

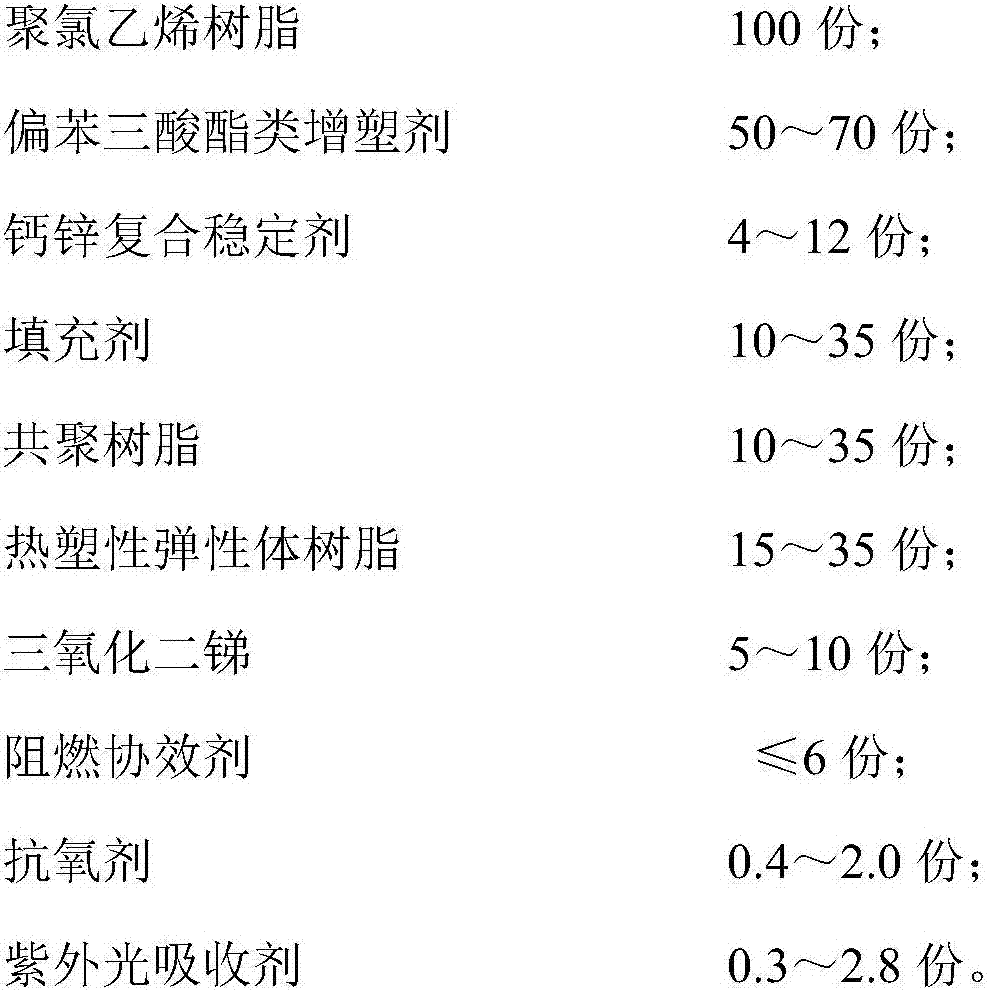

[0023] An environment-friendly high-temperature and low-temperature oil-resistant polyvinyl chloride cable sheathing material, the formula of which is as follows in parts by weight:

[0024]

[0025]

[0026] During preparation, first add the components of the above-mentioned Example 1 into a high-speed kneader and mix evenly, then transfer to a twin-screw extruder for melt extrusion, cool and pelletize to obtain an environmentally friendly high-temperature resistant, low-temperature oil-resistant and flame-retardant polymer Vinyl chloride cable sheathing material; or the components of Example 1 are firstly added to a banbury mixer for banbury mixing, and then transferred to a twin-screw extruder for melt extrusion. The plastic components are mixed, plasticized, and granulated to make environmentally friendly high-temperature-resistant, low-temperature oil-resistant and flame-retardant PVC cable sheath material particles.

Embodiment 2

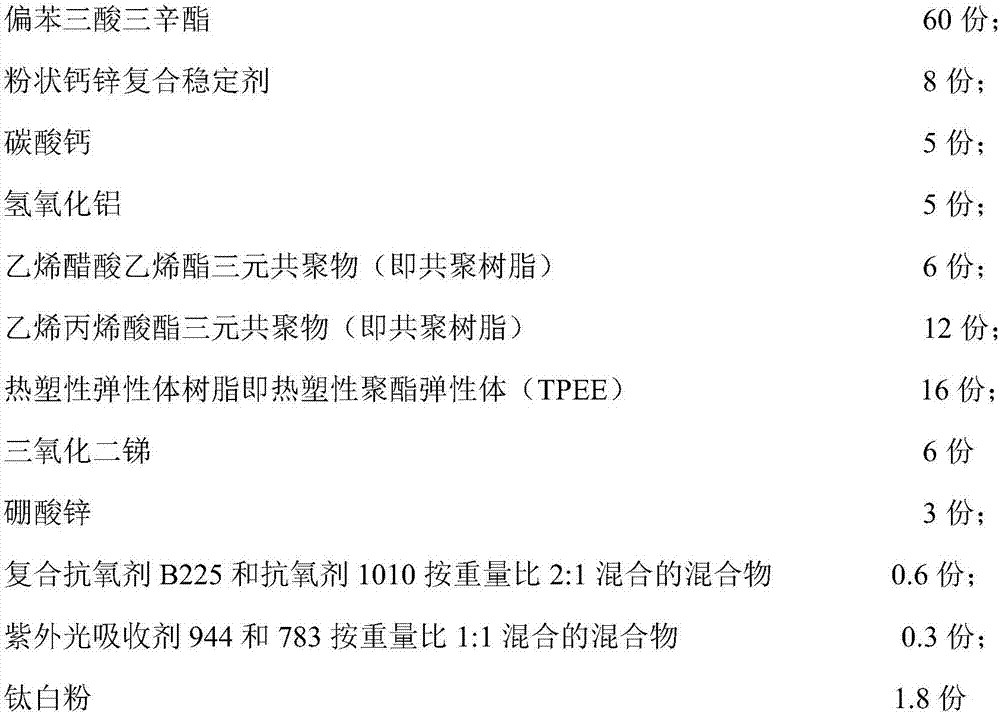

[0028] An environment-friendly high-temperature and low-temperature oil-resistant polyvinyl chloride cable sheathing material, the formula of which is as follows in parts by weight:

[0029]

[0030] The content not mentioned in this embodiment is the same as the description of Embodiment 1.

Embodiment 3

[0032] An environment-friendly high-temperature and low-temperature oil-resistant polyvinyl chloride cable sheathing material, the formula of which is as follows in parts by weight:

[0033]

[0034] The content not mentioned in this embodiment is the same as the description of Embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| degree of polymerization | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com