Hollow interlayer pipe wall compound steel pipe concrete wind power tower with ribs

A concrete-filled steel tube and interlayer technology, which is applied to towers, building types, buildings, etc., can solve problems such as reducing the bearing capacity of components and local buckling of the tube wall, and achieve the effects of improving seismic capacity, enhancing interfacial adhesion, and improving mechanical properties.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

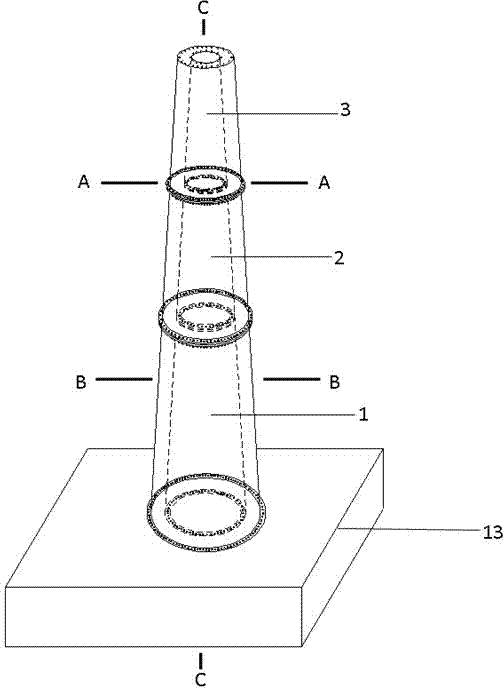

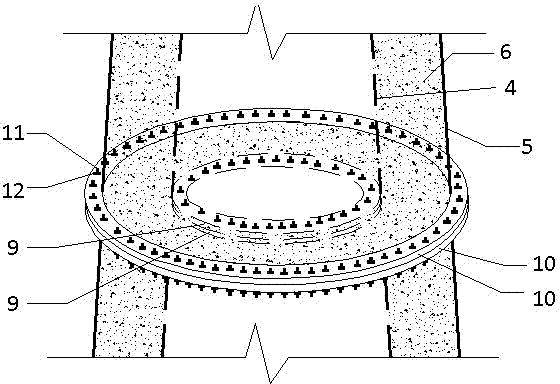

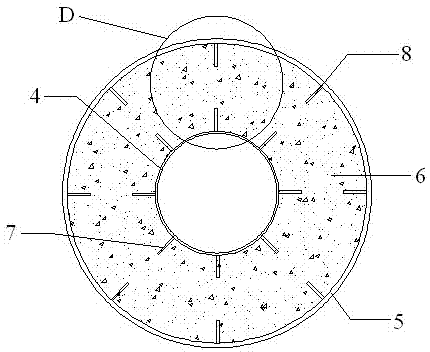

[0028] Embodiment 1: A kind of hollow interlayer pipe wall ribbed composite steel pipe concrete wind power tower, such as figure 1 As shown, including cast-in-place reinforced concrete foundation 13, three-section concrete-filled steel pipe tower section 1; 2; 3, as image 3 As shown, each steel pipe concrete tower section 1; 2; 3 includes the inner steel pipe 4, the outer steel pipe 5 and the concrete layer 6 poured between the inner steel pipe 4 and the outer steel pipe 5, and the thickness of the inner steel pipe 4 and the outer steel pipe 5 is 25mm , the cross sections are all circular, not prone to buckling, and have good and stable bearing capacity. The outer wall of the inner steel pipe 4 in contact with the concrete layer 6 is evenly welded with eight first stiffeners 7, and the outer steel pipe 5 is in contact with the concrete layer 6. There are eight second stiffeners 8 uniformly welded around the inner wall of the inner wall, the stiffener cross-sections are all re...

Embodiment 2

[0031] Embodiment 2: roughly the same as Embodiment 1, the difference is that the cross-section of the inner steel pipe 4 is a square, and the cross-section of the outer steel pipe 5 is circular, as Image 6 As shown, two first stiffeners 7 are arranged symmetrically on each side of the inner steel pipe 4 to ensure the bonding force between each side of the square steel pipe and the concrete, so that the inner steel pipe 4 and the concrete layer 6 are tightly bonded and local buckling is not easy to occur. Improve the bearing capacity of the tower; such as Figure 7 As shown, the diameter of the outer steel pipe 5 gradually decreases from bottom to top to form a taper.

Embodiment 3

[0032] Embodiment 3: as Figure 8 As shown, it is roughly the same as Example 1, except that the cross section of the inner steel pipe 4 is a regular hexagon, and a first stiffener 7 is arranged on each side of the regular hexagon, so the inner steel pipe 4 is divided into six directions on average. Make the first stiffener 7 go deep into the concrete layer 6, and firmly bond with the concrete to enhance the cohesive force. At the same time, the regular hexagon can weaken the stress concentration phenomenon at the corners of the inner steel pipe 4, make the stress distribution on the section more uniform, and avoid forming The weak area prevents local buckling of the inner steel pipe 4 and improves the seismic capacity of the tower.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com