Construction method of batter pile construction drilling machine

A technology for drilling rigs and inclined piles, which is applied to drilling equipment and methods, sheet pile walls, drilling equipment, etc. It can solve the problems of high cost and unreasonable force of support structures, etc., so as to improve bearing capacity, save building materials, The effect of reducing the amount of sedimentation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

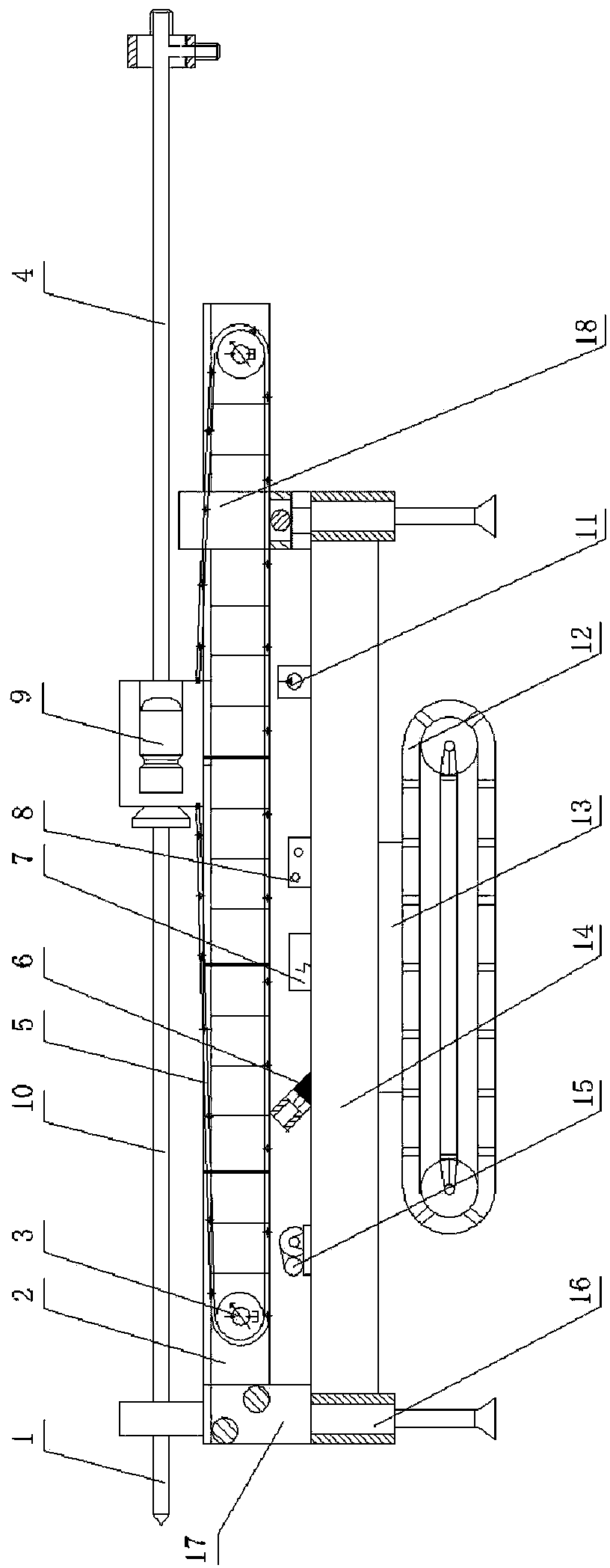

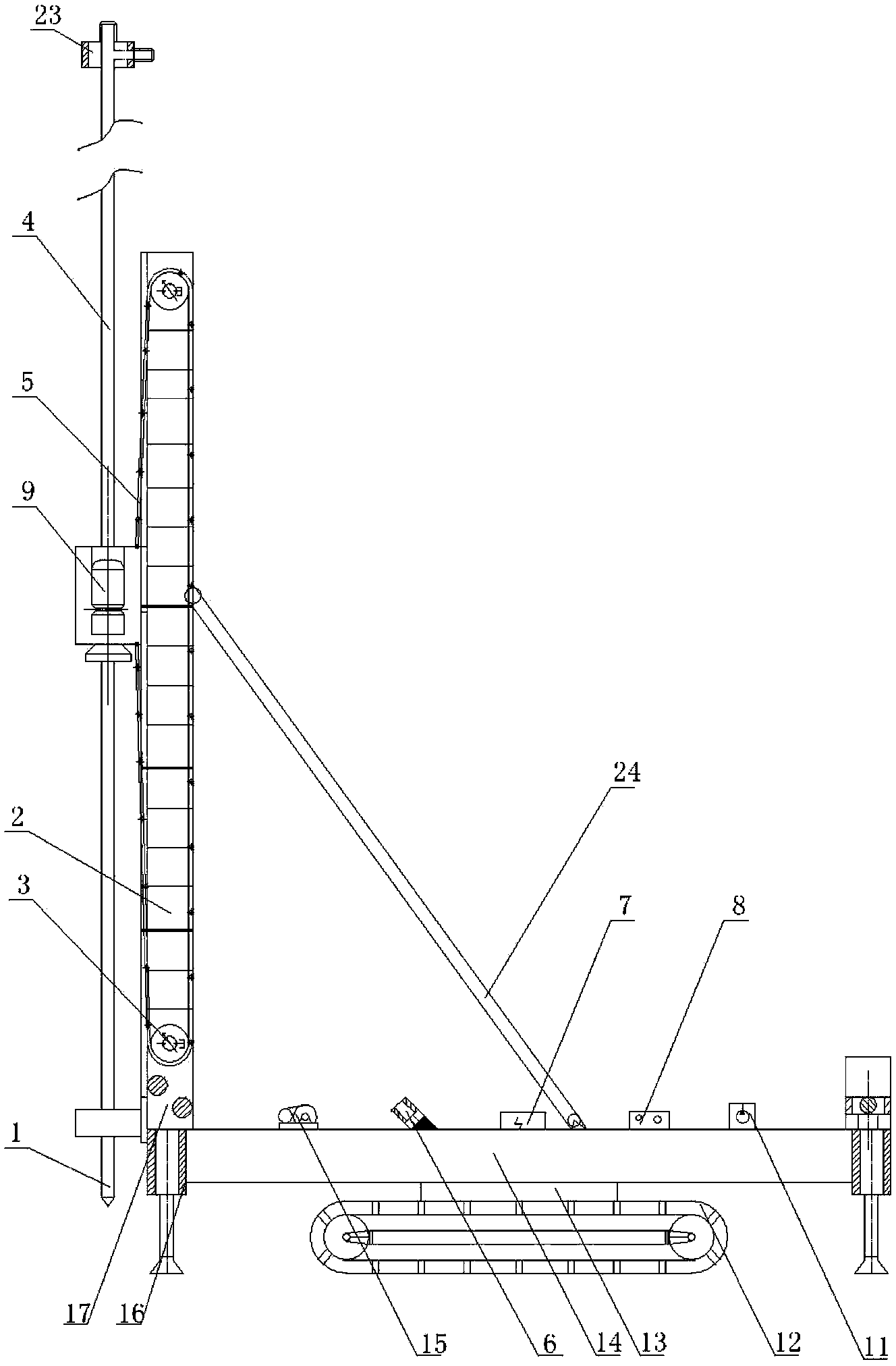

[0030] Reference attached figure 1 , 2 , a drilling rig for inclined pile construction, comprising a drilling tool, a base assembly 14, a hydraulic outrigger 16 arranged on the base assembly 14, a running device 12 arranged below the base assembly 14, a running device located on the base assembly 14 and a The slewing mechanism 13 between 12, the base assembly 14 is also provided with a power distribution system 7, a hydraulic pump station 11 and a control system 8; the drilling tool is installed on the tower 2, and the drilling tool includes the upper casing 4 arranged in sequence , the power head 9, the lower casing 10 and the drill bit 1; the two ends of the base assembly 14 are respectively provided with a front bracket 17 and a rear bracket 18, and the base is provided with a tower 2; one end of the tower 2 and the front bracket 17 on the base pass through the rotating shaft Rotatably connected, the other end is a free end, and an adjustment cylinder 6 for adjusting the a...

Embodiment 2

[0032] On the basis of Embodiment 1, the preferred technical solution of the present invention is: the transmission pair is a sprocket chain pair or a rack and pinion pair.

Embodiment 3

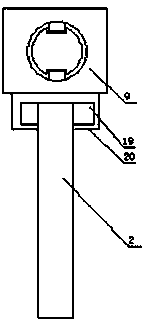

[0034] On the basis of embodiment 2, the preferred technical solution of the present invention is: figure 1 , 2 , the two ends of the sprocket tower 2 are respectively equipped with a hydraulic motor 3, the transmission pair is a sprocket chain pair, the sprocket is connected with the hydraulic motor 3, the chain 5 is connected with the power head 9, and the hydraulic motor 3 and the chain 5 are used to drive Power head 9 moves along slip slideway 19 directions.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com