Preparation method of a carbon fiber/glass fiber hybrid stealth composite material

A glass fiber, composite material technology, applied in textile, yarn, textile and papermaking, etc., can solve the problems of reducing the mechanical properties of composite materials, wave impedance matching, etc., and achieve good wave transmission performance, reduced reflection, good mechanical properties Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

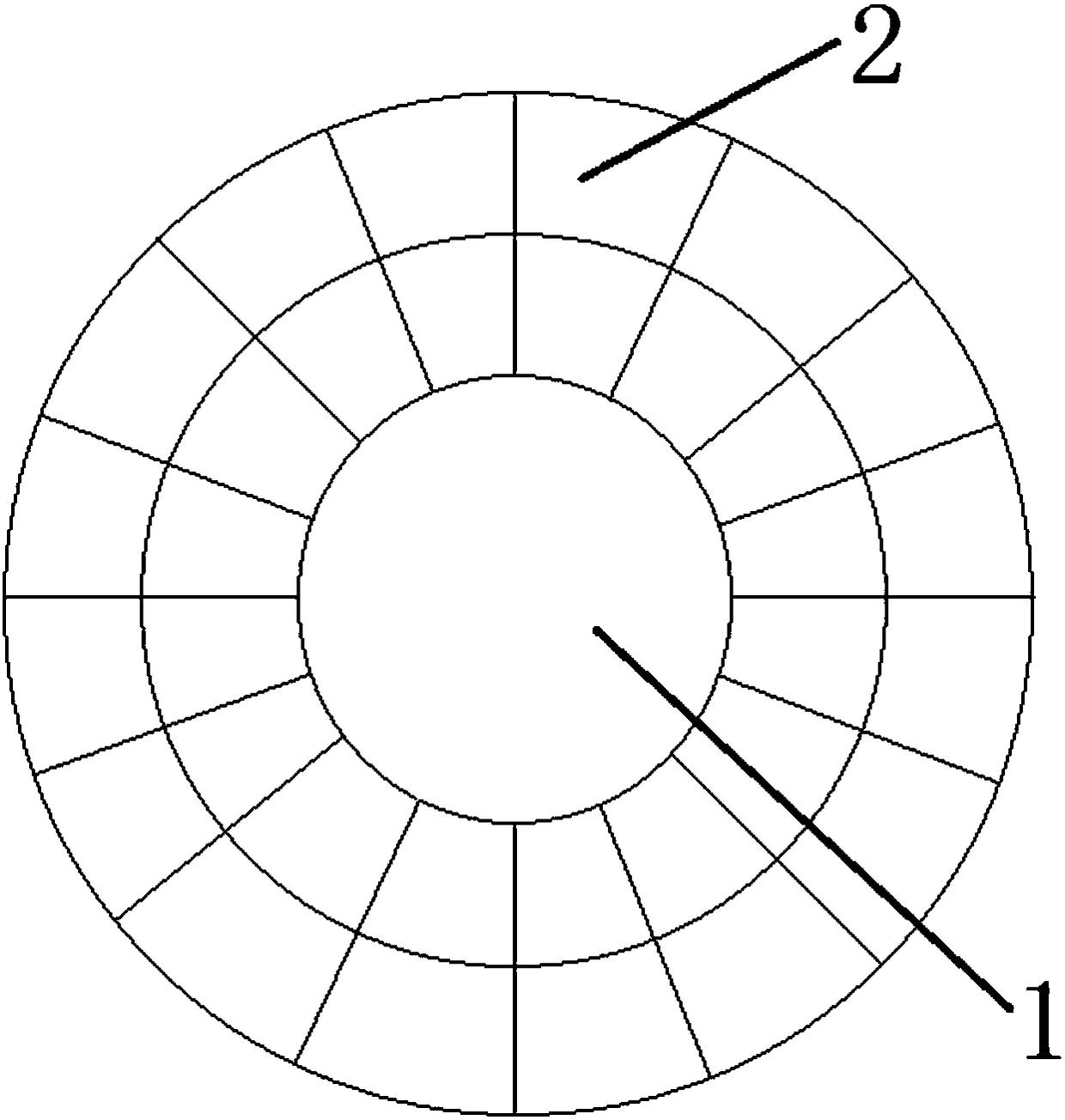

[0033] Carbon fiber is used as the core yarn, S glass fiber is used as the weaving yarn, and the core yarn and weaving yarn are woven into carbon fiber / glass fiber core-spun yarn using two-dimensional weaving technology. The weaving angle between the weaving yarn and the core yarn is 20°. The yarn ratio is 40 / 60, plain weave is used to weave cloth, and the weaving structure is diamond weaving 1 / 1.

[0034] Mix TDE-86 epoxy resin, HK-021 anhydride (curing agent) and dimethylbenzylaminoaniline (catalyst) according to the mass ratio of 100:85:1 and then inject them with cloth. After the injection molding is completed, the material is put into an oven for internal curing. The curing method is 130°C-2h, 105°C-1h, 160°C-8h, 180°C-3h, and the carbon fiber / glass fiber hybrid stealth composite material is obtained.

Embodiment 2

[0036] Carbon fiber is used as the core yarn, S glass fiber is used as the weaving yarn, and the core yarn and weaving yarn are woven into carbon fiber / glass fiber core-spun yarn by using two-dimensional weaving technology. The yarn ratio is 40 / 60, plain weave is used to weave cloth, and the weaving structure is regular weaving 2 / 2.

[0037] Mix TDE-86 epoxy resin, HK-021 anhydride (curing agent) and dimethylbenzylaminoaniline (catalyst) according to the mass ratio of 100:85:1 and then inject them with cloth. After the injection molding is completed, the material is put into an oven for internal curing. The curing method is 130°C-2h, 105°C-1h, 160°C-8h, 180°C-3h, and the carbon fiber / glass fiber hybrid stealth composite material is obtained.

Embodiment 3

[0039] Carbon fiber is used as the core yarn, S glass fiber is used as the weaving yarn, and the core yarn and weaving yarn are woven into carbon fiber / glass fiber core-spun yarn by using two-dimensional weaving technology. The yarn ratio is 40 / 60, plain weave is used to weave cloth, and the weave structure is 3 / 3 of Hercules weave.

[0040] Mix TDE-86 epoxy resin, HK-021 anhydride (curing agent) and dimethylbenzylaminoaniline (catalyst) according to the mass ratio of 100:85:1 and then inject them with cloth. After the injection molding is completed, the material is put into an oven to cure. The curing method is 130°C-2h, 105°C-1h, 160°C-8h, 180°C-3h, and the carbon fiber / glass fiber hybrid stealth composite material is obtained.

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com