Method for treating landslide and slide slope hazards

A landslide mass and sliding surface technology, applied in the field of geological disaster control measures, can solve the problems of exacerbation, hardship and danger, and difficulty of anti-sliding piles, so as to achieve strong compressive performance and overcome hardship and danger. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

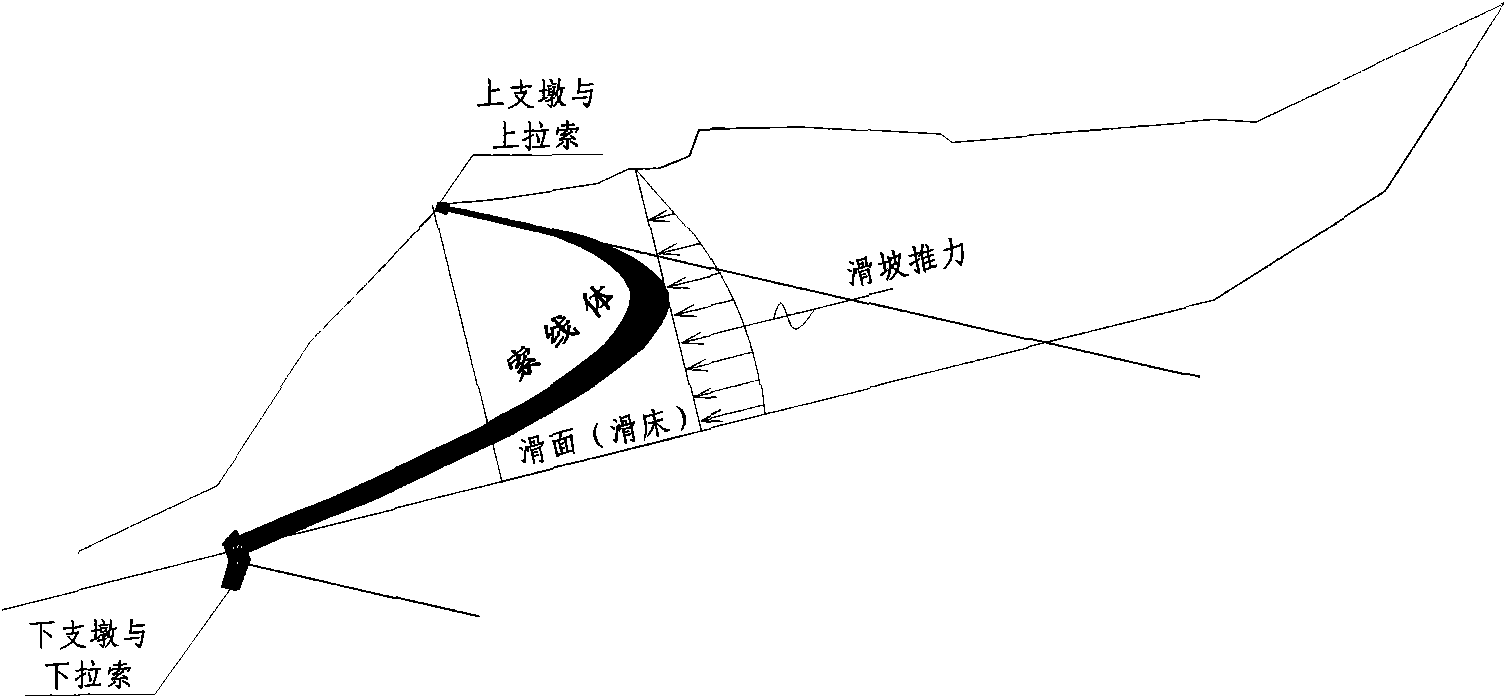

[0029] The following is an embodiment of the present invention.

[0030] 1. Analysis and calculation of original data and cables

[0031] Raw data:

[0032] Landslide thrust (6m) = 2154t

[0033] Single width thrust = 359t

[0034] Depth of sliding surface: H=44m

[0035] Calculation distance: D=6m

[0036] Thrust distribution coefficient: K=2.225207

[0037] Upper cable tension: P0=528t

[0038] Upper cable inclination: α=23°

[0039] (Note: The tension of the upper cable and the inclination angle of the upper cable are obtained by adjusting the shape of the cable)

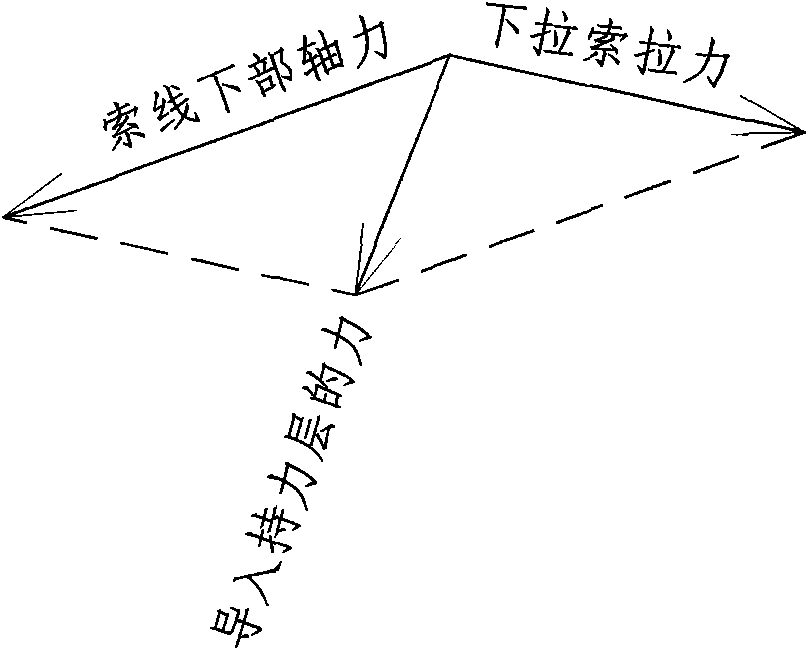

[0040] 2. Mathematical and mechanical analysis of cables

[0041] a. Cable equation

[0042] ∫ 0 y 0 f ( y ) ( y - y 0 ) dy = py cos α + ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com