Compound spherical shell oriented to omnidirectional movement spherical robot, and preparation method thereof

A spherical robot and composite ball technology, applied in coatings, polyurea/polyurethane coatings, etc., can solve the problems of increasing the manufacturing cost of spherical robots, affecting the reliability and service life of spherical robots, and achieving good acid and alkali corrosion resistance and protection. Safe operation and the effect of precise control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

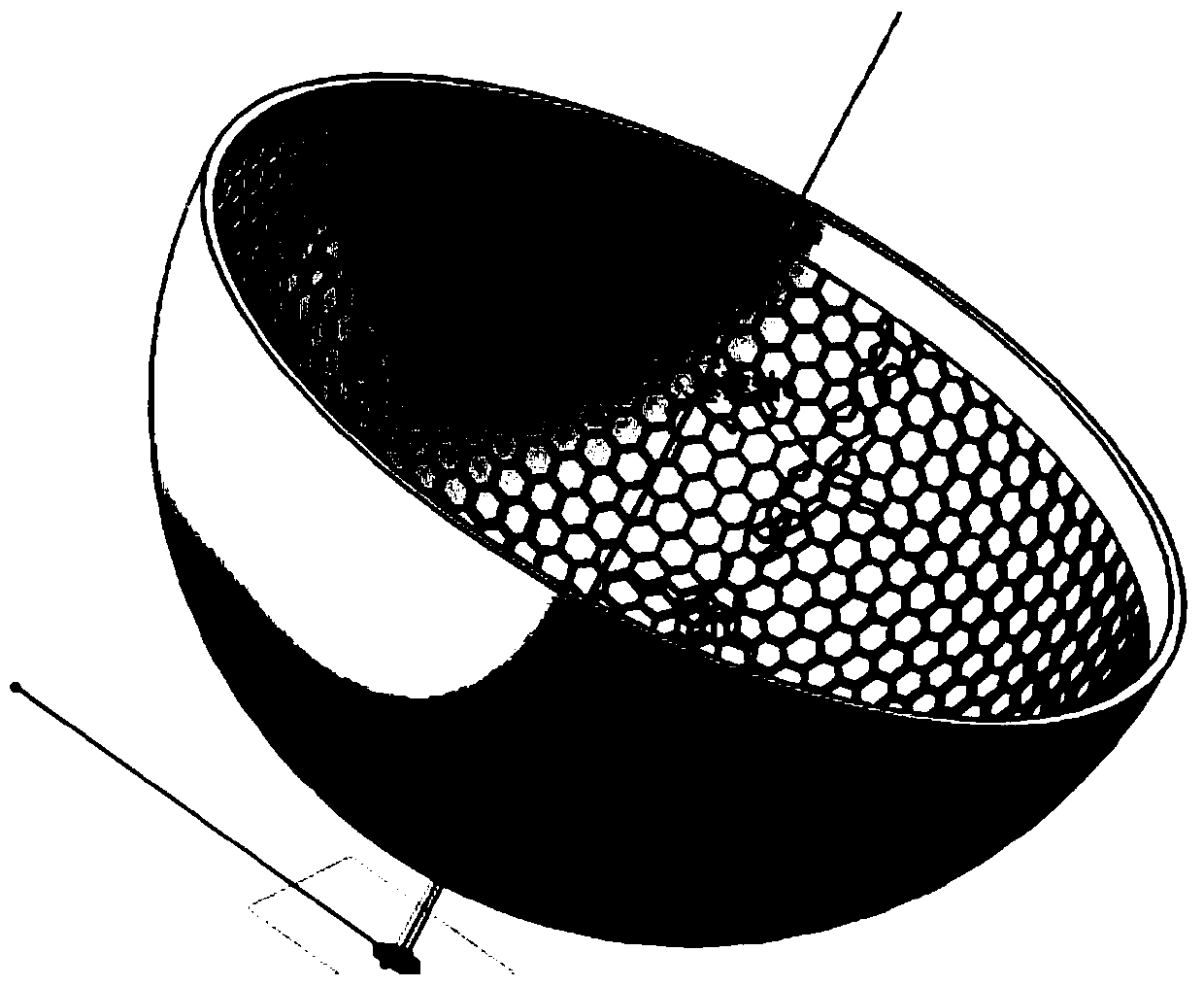

Image

Examples

Embodiment 1

[0010] A composite spherical shell for an omnidirectional moving spherical robot and a preparation method thereof, characterized in that:

[0011] (1) Add 8 parts of hydrogenated rosin resin, 50 parts of epoxy resin, 2 parts of diethylenetriamine, and 2 parts of diketone acrylamide into a reaction kettle at 38°C, and react for 1 hour at a stirring speed of 200r / min , to obtain a pre-cured liquid resin. Take 5 layers of glass fiber cloth as a reinforcement, and place the fiber filaments of adjacent glass fiber cloth in different directions, so that the angle between the fiber filaments of adjacent glass fiber cloth is 36°. Spread the pre-cured liquid resin mixture evenly on the glass fiber cloth by hand to make it soak evenly, then put it into a vacuum bag for vacuuming (0.1MPa) to make the liquid resin cover the entire fiber cloth layer, and remove the vacuum bag to reinforce the fiber The resin pre-solid is placed inside the concave hemispherical steel mold and compacted by ...

Embodiment 2

[0014] A composite spherical shell for an omnidirectional moving spherical robot and a preparation method thereof, characterized in that:

[0015] (1) Add 6 parts of hydrogenated rosin resin, 40 parts of epoxy resin, 1 part of diethylenetriamine, and 1 part of diketone acrylamide into a reaction kettle at 38°C, and react for 1.5 minutes at a stirring speed of 230r / min. h, to obtain a pre-cured liquid resin. Two layers of basalt fiber cloth are used as reinforcements, and the fiber filaments of adjacent basalt fiber cloth are stacked in different directions so that the angle between the fiber filaments of adjacent basalt fiber cloth is 90°. Spread the pre-cured liquid resin mixture evenly on the glass fiber cloth by hand to make it soak evenly, then put it into a vacuum bag for vacuuming (0.1MPa) to make the liquid resin cover the entire fiber cloth layer, and remove the vacuum bag to reinforce the fiber The resin pre-solid is placed inside the concave hemispherical steel mold...

Embodiment 3

[0018] A composite spherical shell for an omnidirectional moving spherical robot and a preparation method thereof, characterized in that:

[0019] (1) Add 6 parts of hydrogenated rosin resin, 62 parts of epoxy resin, 3 parts of diethylenetriamine, and 3 parts of diketone acrylamide into a reaction kettle at 38°C, and react for 1.1 hours at a stirring speed of 150r / min. h, to obtain a pre-cured liquid resin. Three layers of carbon fiber cloth are used as reinforcements, and the fibers of adjacent carbon fiber cloths are stacked in opposite directions so that the angle between the fibers of adjacent carbon fiber cloths is 60°. Spread the pre-cured liquid resin mixture evenly on the glass fiber cloth by hand to make it soak evenly, then put it into a vacuum bag for vacuuming (0.1MPa) to make the liquid resin cover the entire fiber cloth layer, and remove the vacuum bag to reinforce the fiber The resin pre-solid is placed inside the concave hemispherical steel mold and compacted ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com