Patents

Literature

31results about How to "Inhibition of buckling" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

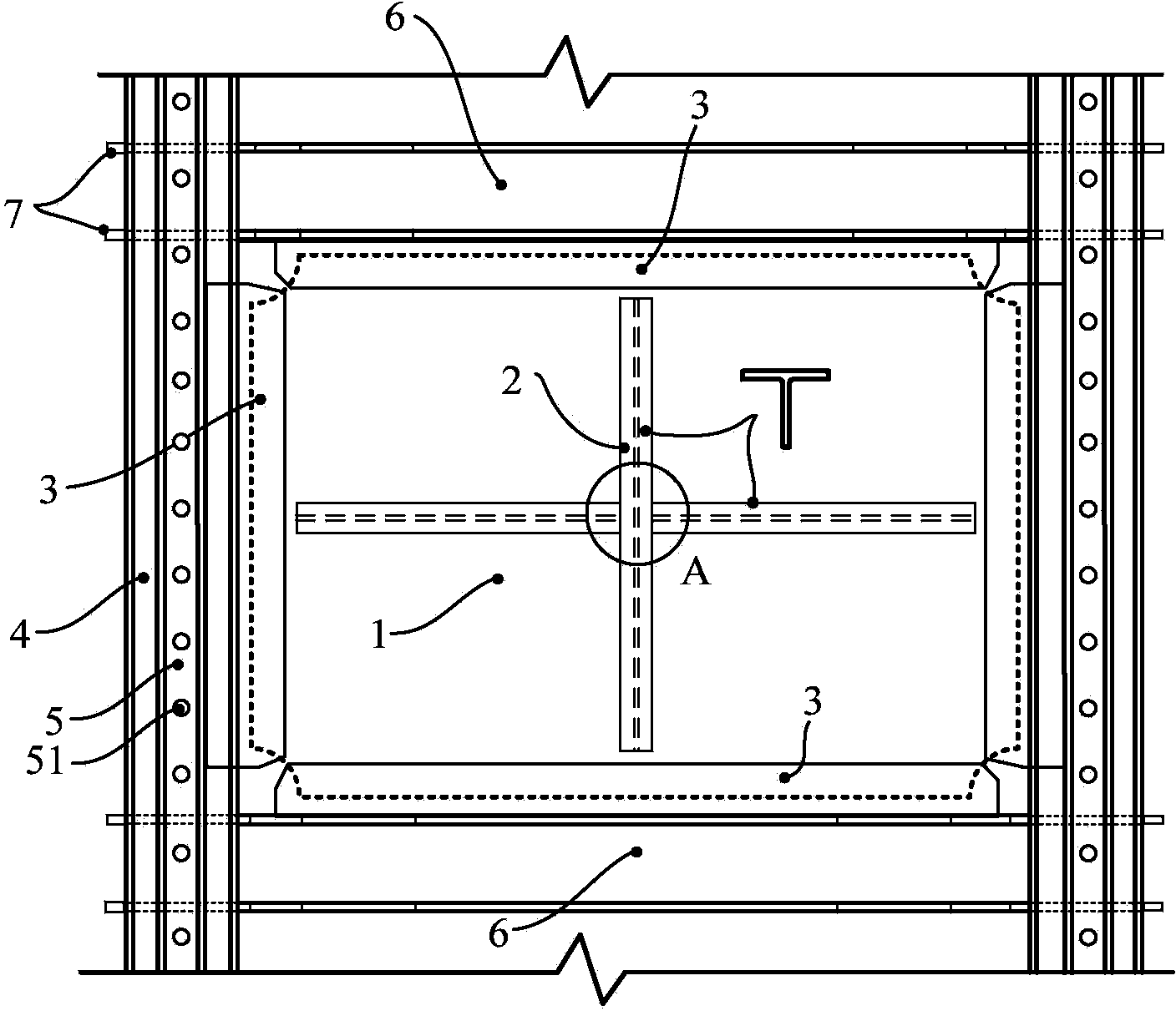

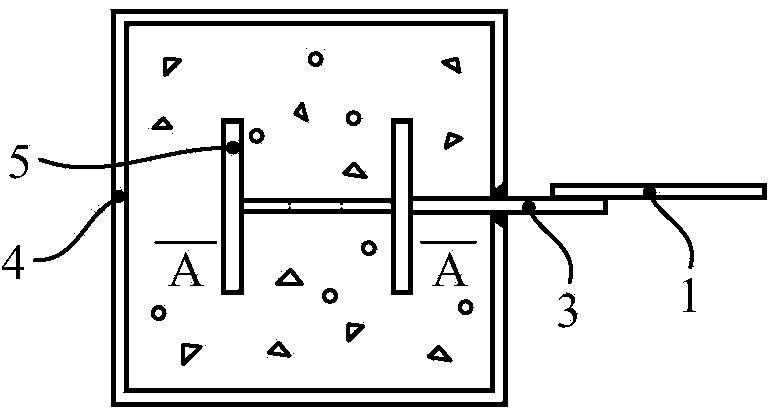

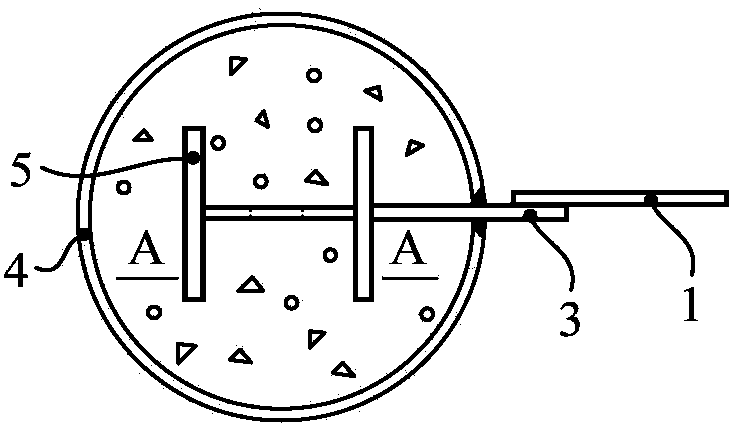

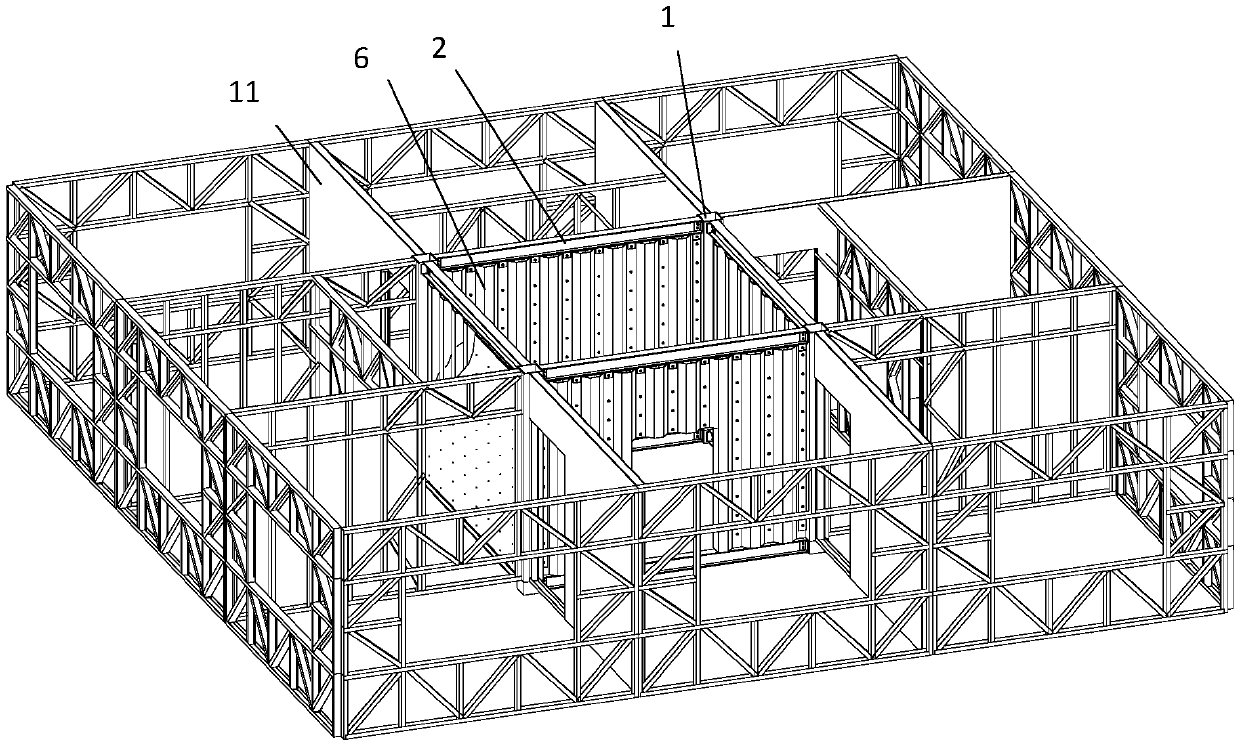

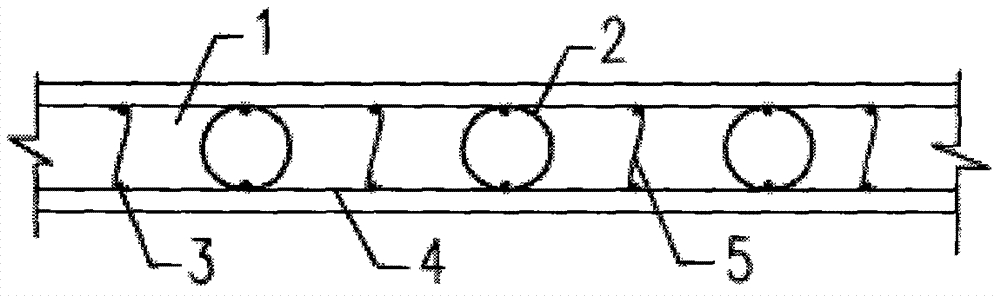

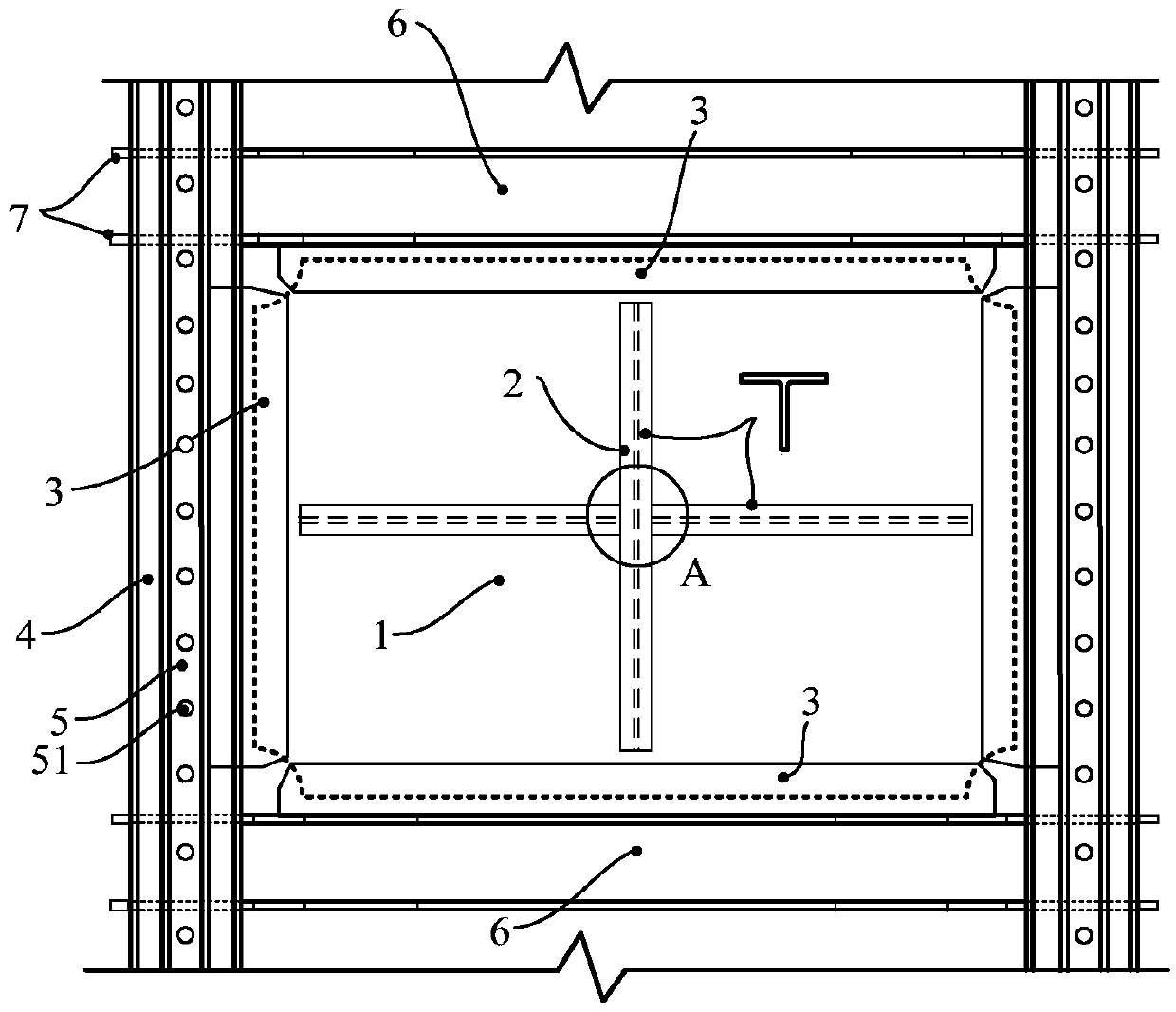

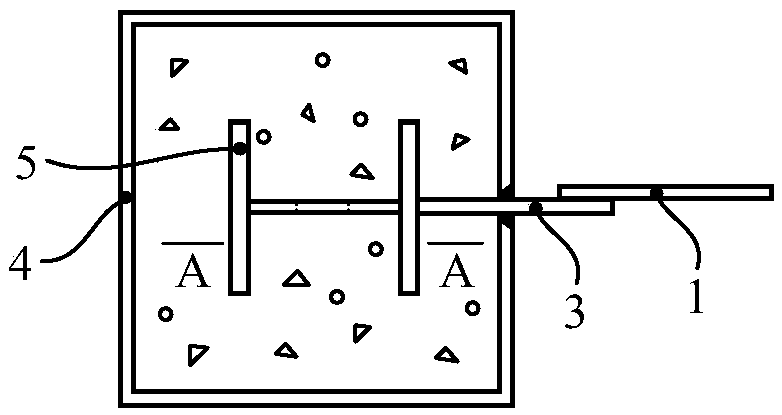

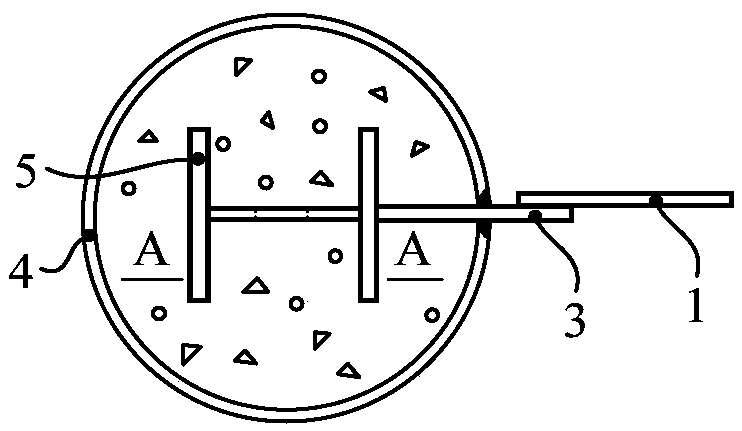

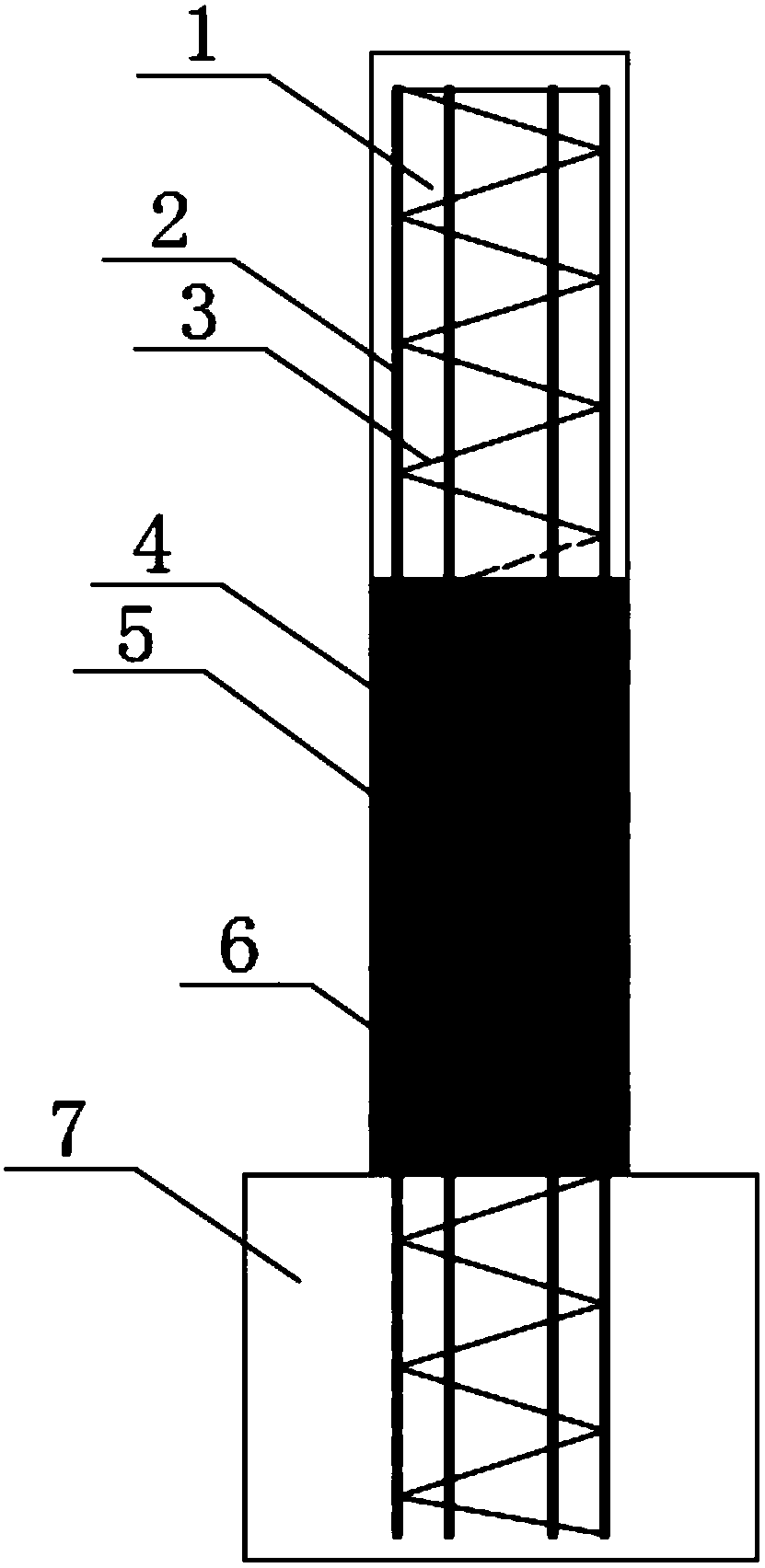

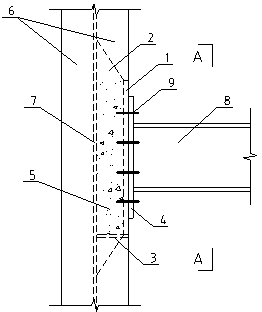

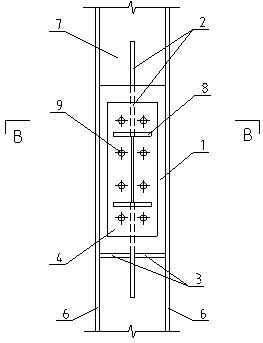

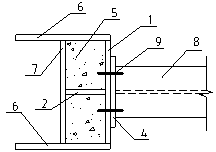

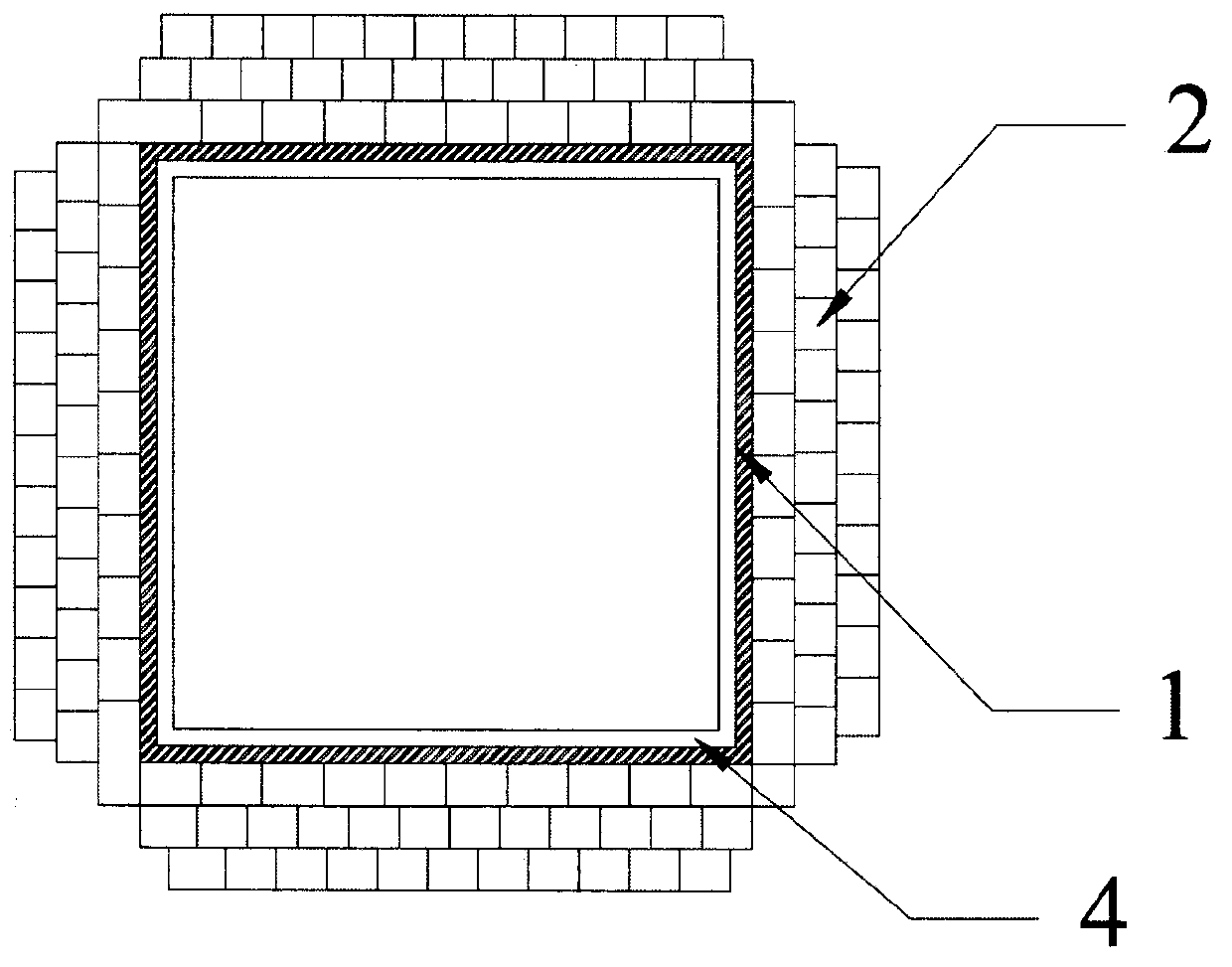

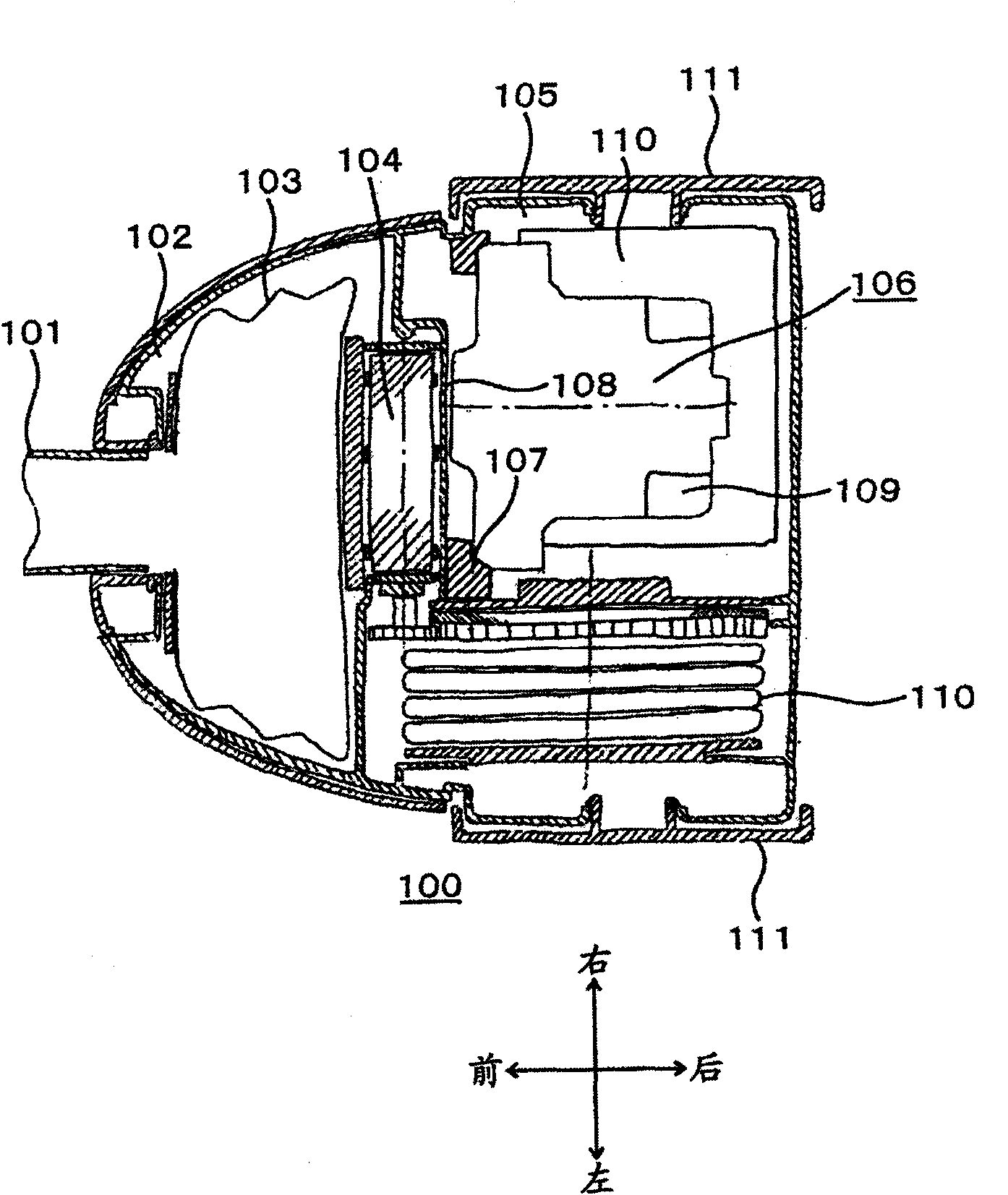

Internally-disposed-profile-steel steel pipe concrete frame low-yield-point steel plate shear wall structure

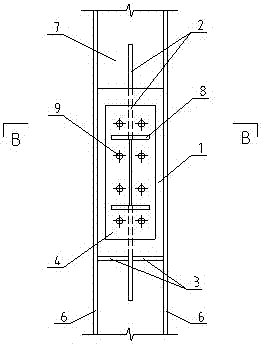

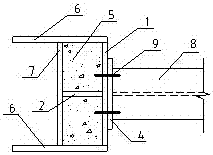

The invention discloses an internally-disposed-profile-steel steel pipe concrete frame low-yield-point steel plate shear wall structure which comprises steel pipe concrete side columns, steel cross beams and an internally-embedded steel plate. Profile steel is generally arranged inside the steel pipe concrete side columns, each vertical lateral side of the internally-embedded steel plate is connected with a fishtail plate, the fishtail plates penetrate the side walls of the steel pipe concrete side columns to be connected with the profile steel in a welded manner, and positions where the fishtail plate are intersected with the side walls of the steel pipe concrete side columns are in welded connection. The profile steel is throughly arranged along the height direction of each steel pipe concrete side column, the profile steel and the steel pipe concrete side columns are jointly stressed, the profile steel plays a role as a shear connector and also plays a role of improving vertical bearing capacity of the steel pipe concrete side columns, so that using efficiency of the profile steel is improved. Sectional size of the side columns can be substantially reduced while requirements of the bearing capacity of the steel pipe concrete side columns are met, dead weight of the structure is reduced, seismic ductility of the structure is improved, building using space is effectively increased, and the structure is especially suitable for high-rise and ultrahigh-rise building structures.

Owner:BEIJING JIAOTONG UNIV

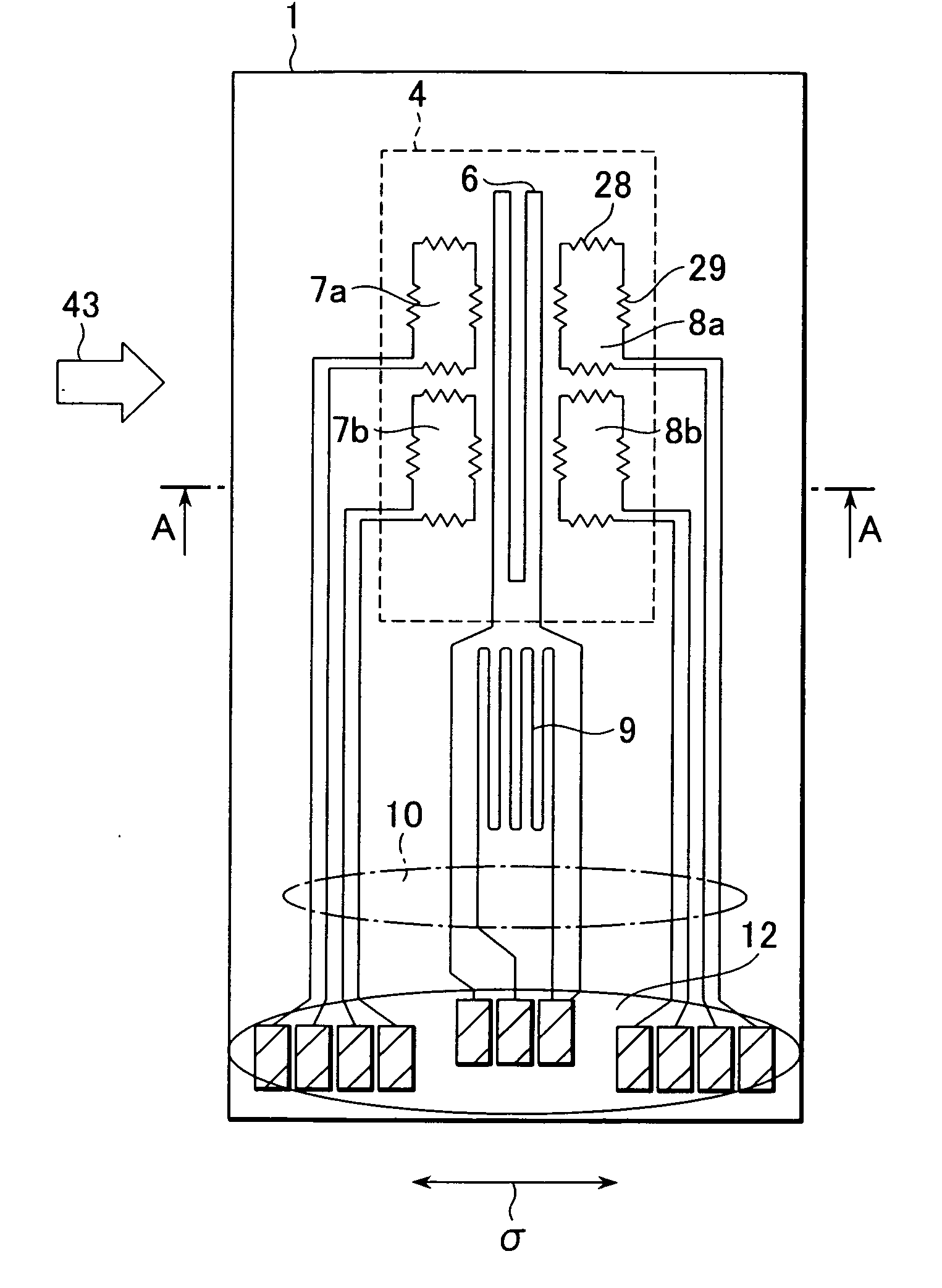

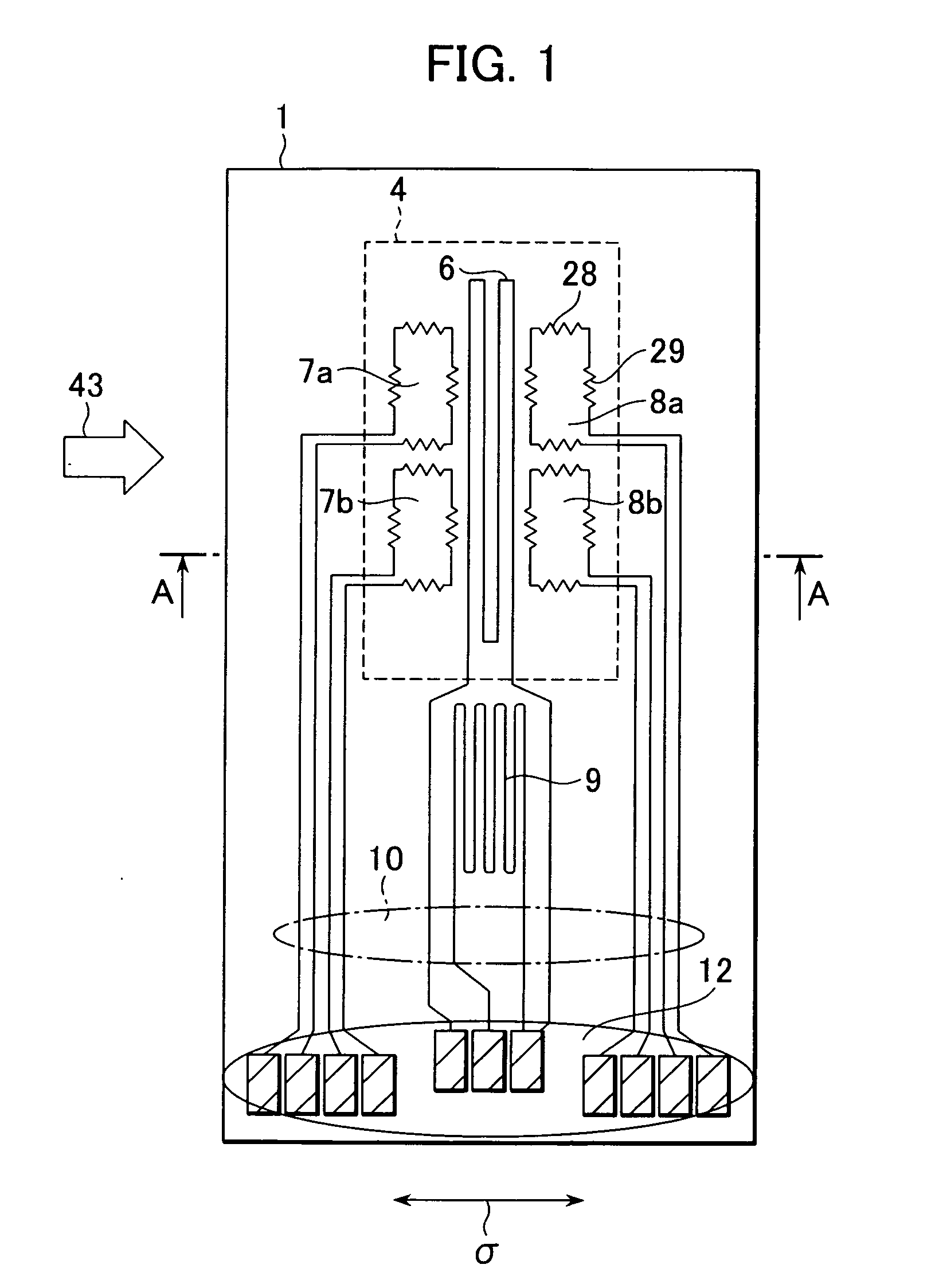

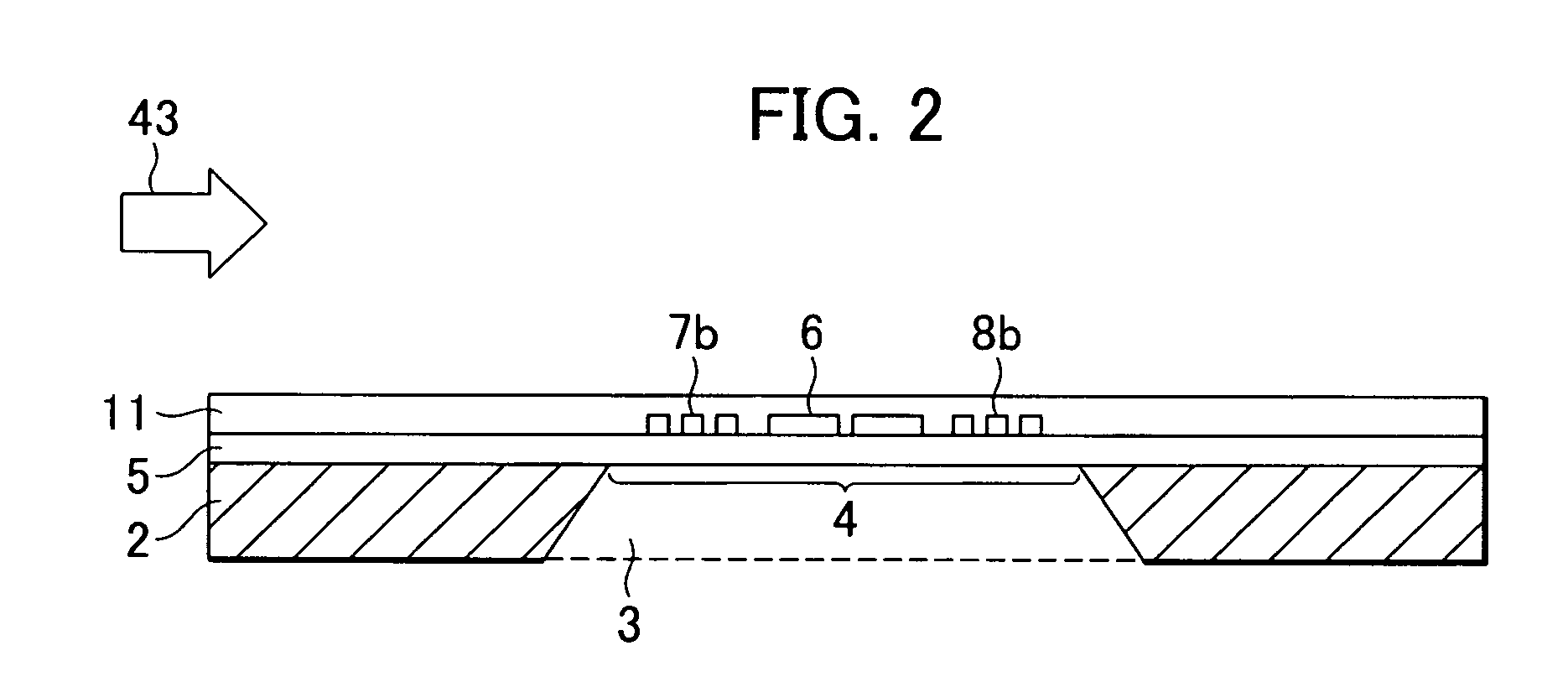

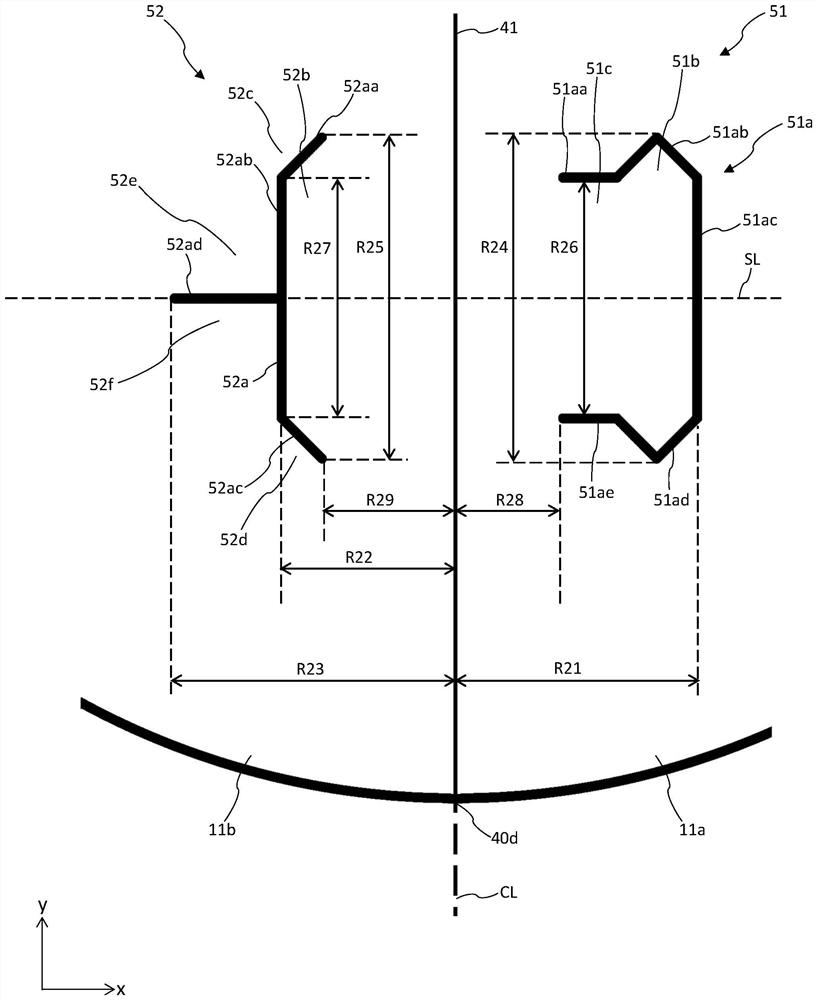

Physical quantity sensor

ActiveUS20060220662A1Reduce the impactHigh precision measurementResistance/reactance/impedenceVolume/mass flow by thermal effectsElectrical resistance and conductanceEngineering

A highly accurate physical quantity sensor which can ensure reliability in strength and reduce resistance changes caused by stresses. Assuming, with respect to stress σ imposed on a substrate in a predetermined direction (e.g., direction in which maximum stress is imposed), a parallel direction to be a horizontal direction and a perpendicular direction to be a vertical direction, each of resistors of the sensor has a horizontal resistance component Rl and a vertical resistance component Rt. When a ratio of a piezoresistance coefficient πl of the horizontal resistance component Rl, which is provided when the stress imposed on the substrate is applied to the horizontal resistance component Rl, to a piezoresistance coefficient πt of the vertical resistance component Rt, which is provided when the stress is applied to the vertical resistance component Rt, is πl:πt=−n:1 (n:integer), a resistance value ratio of the vertical resistance component Rt to the horizontal resistance component Rl is set substantially equal to the ratio of the piezoresistance coefficient πl to πt.

Owner:HITACHI ASTEMO LTD

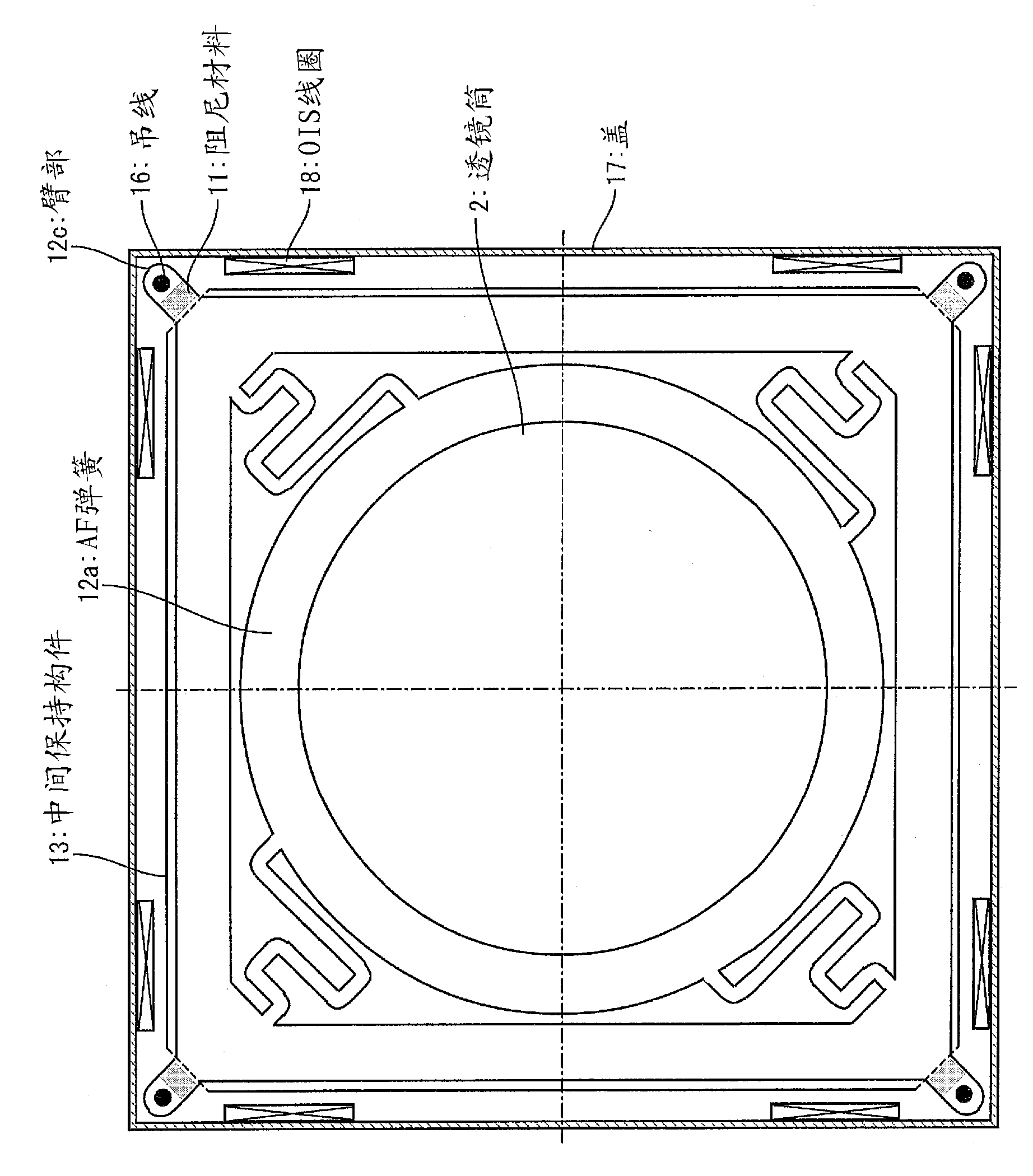

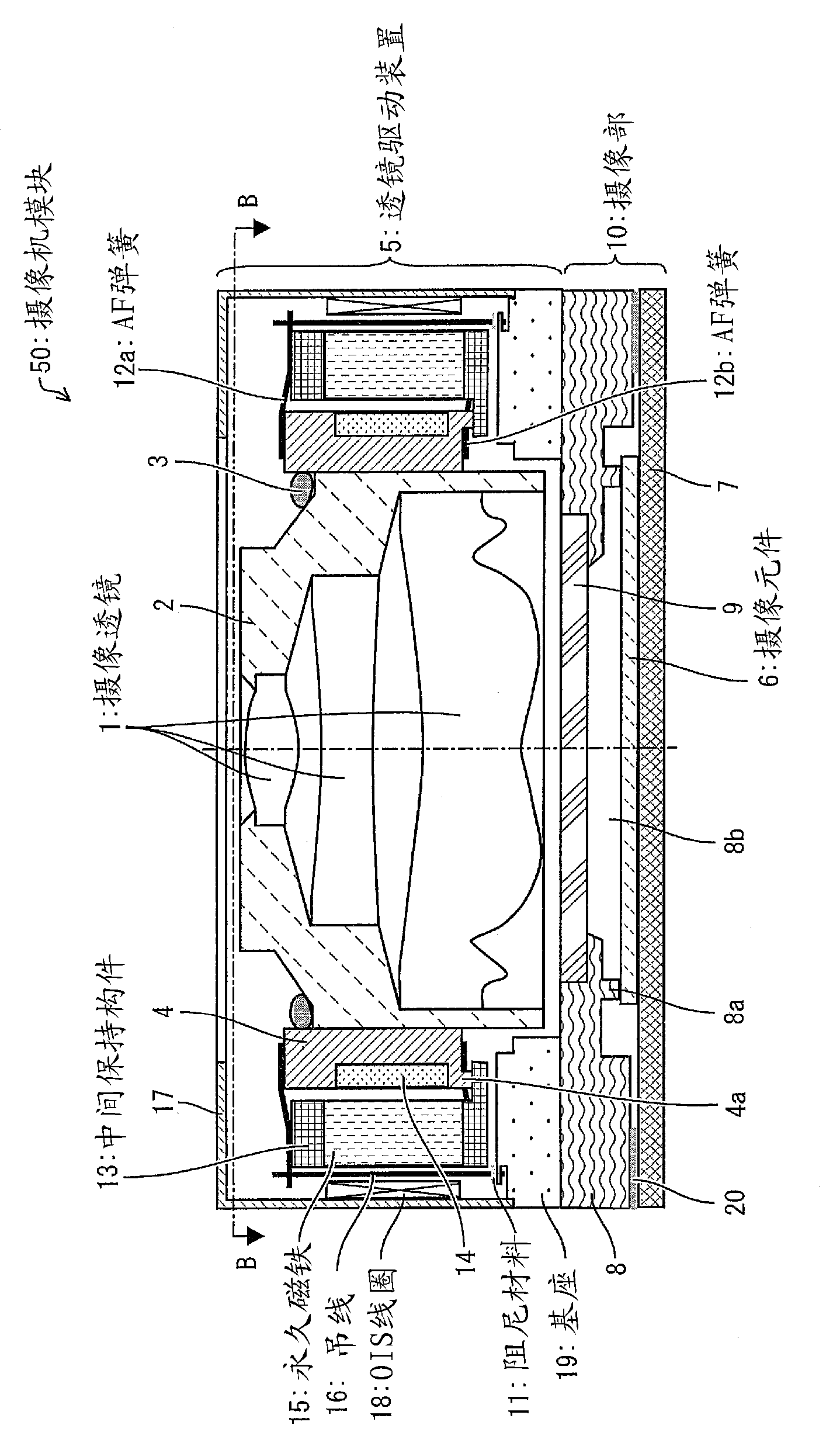

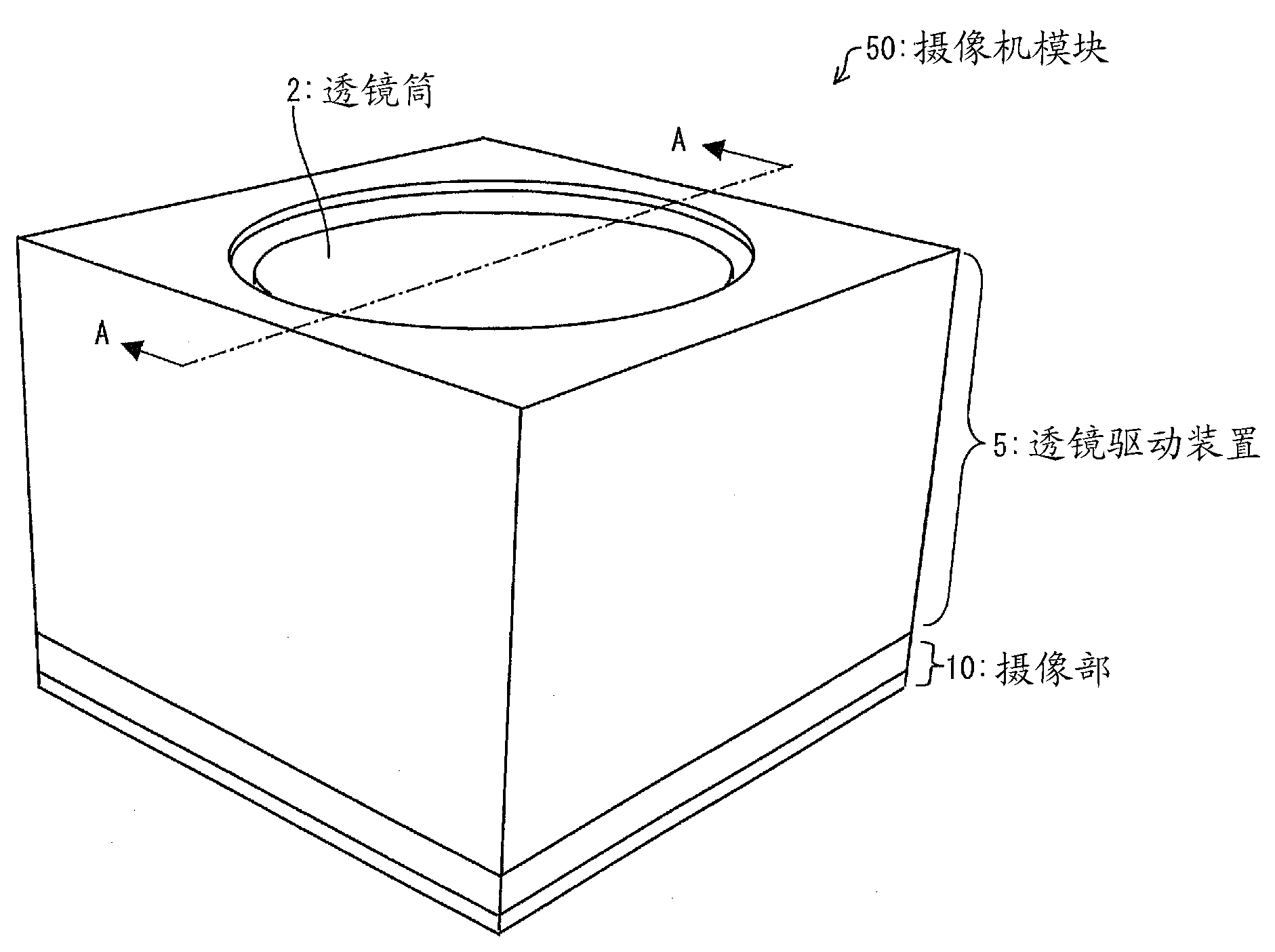

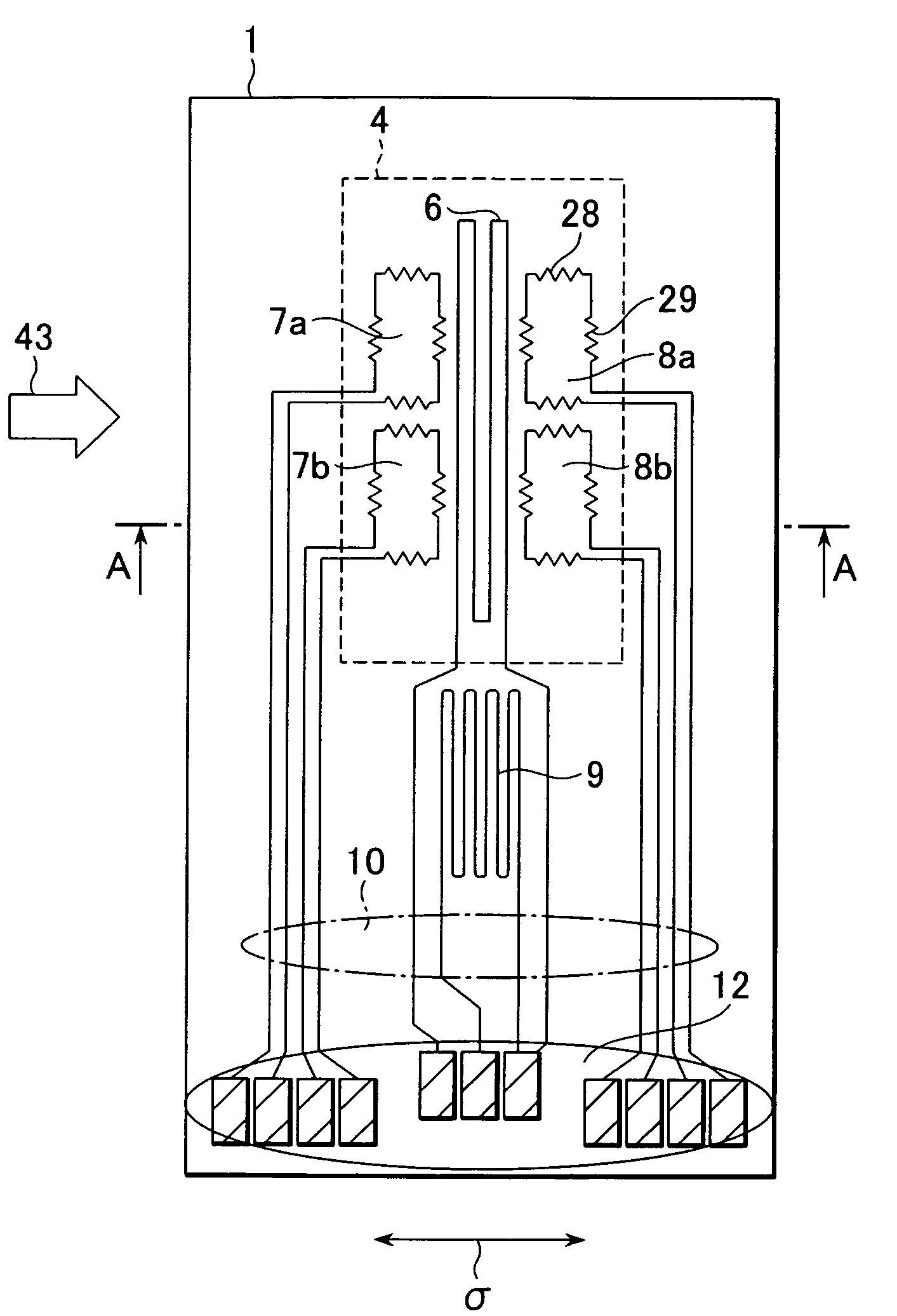

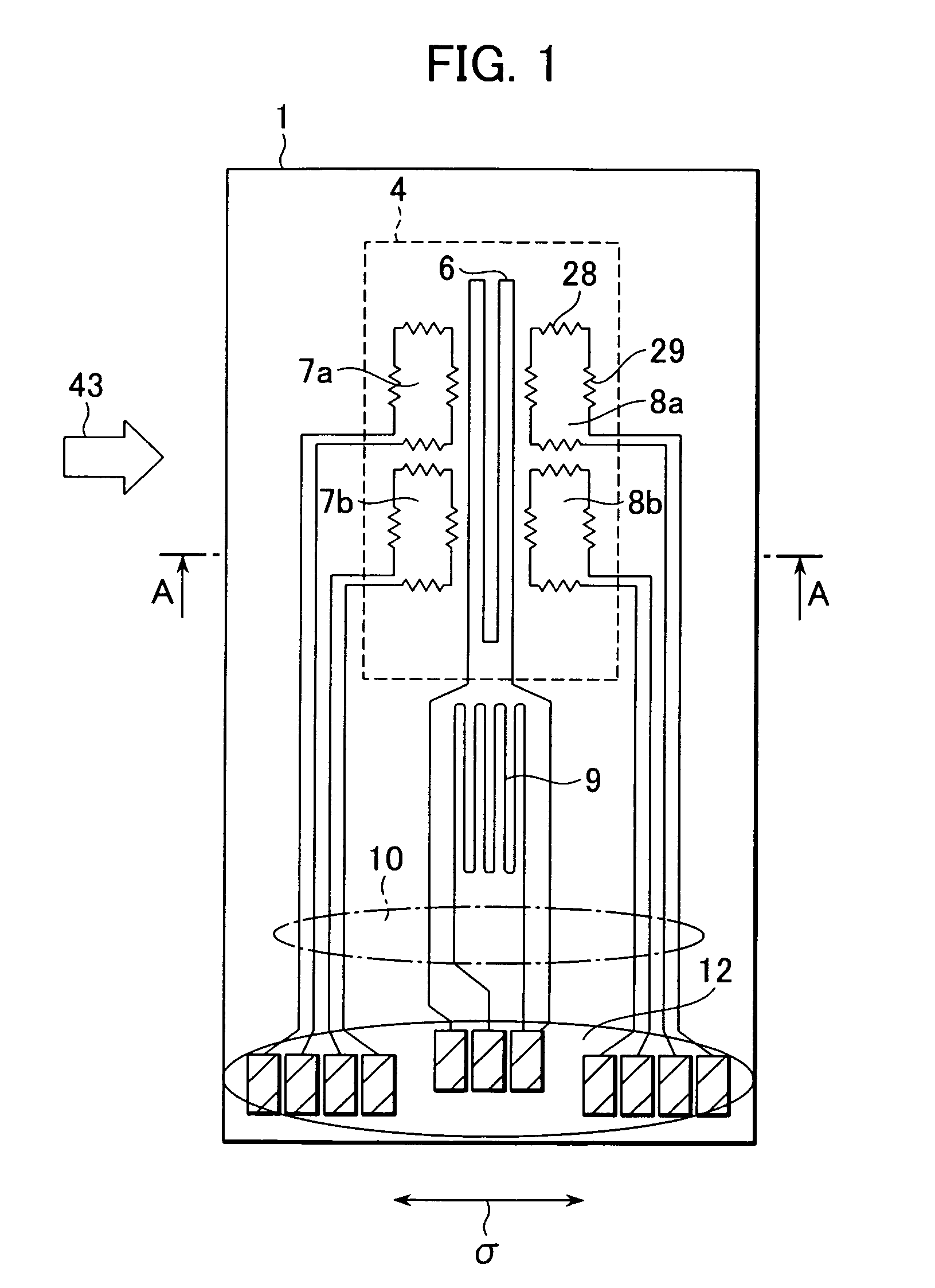

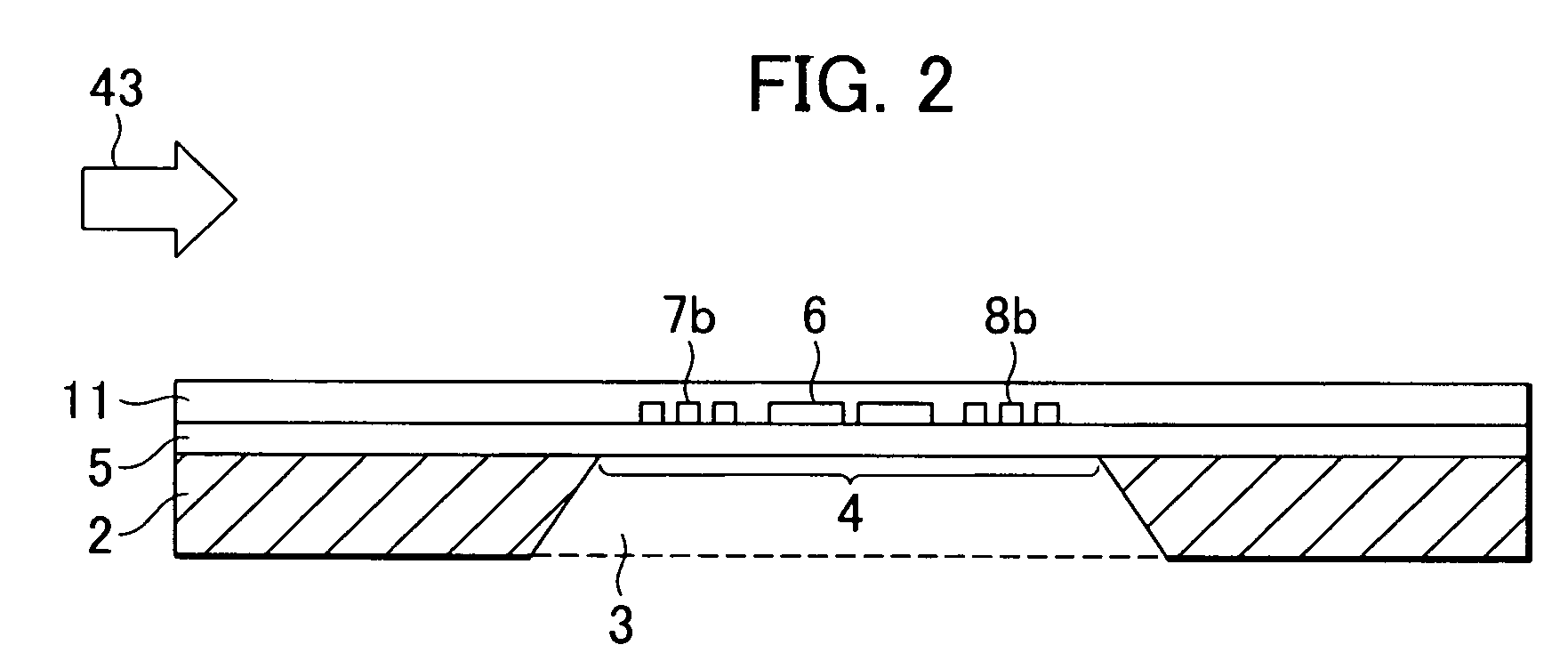

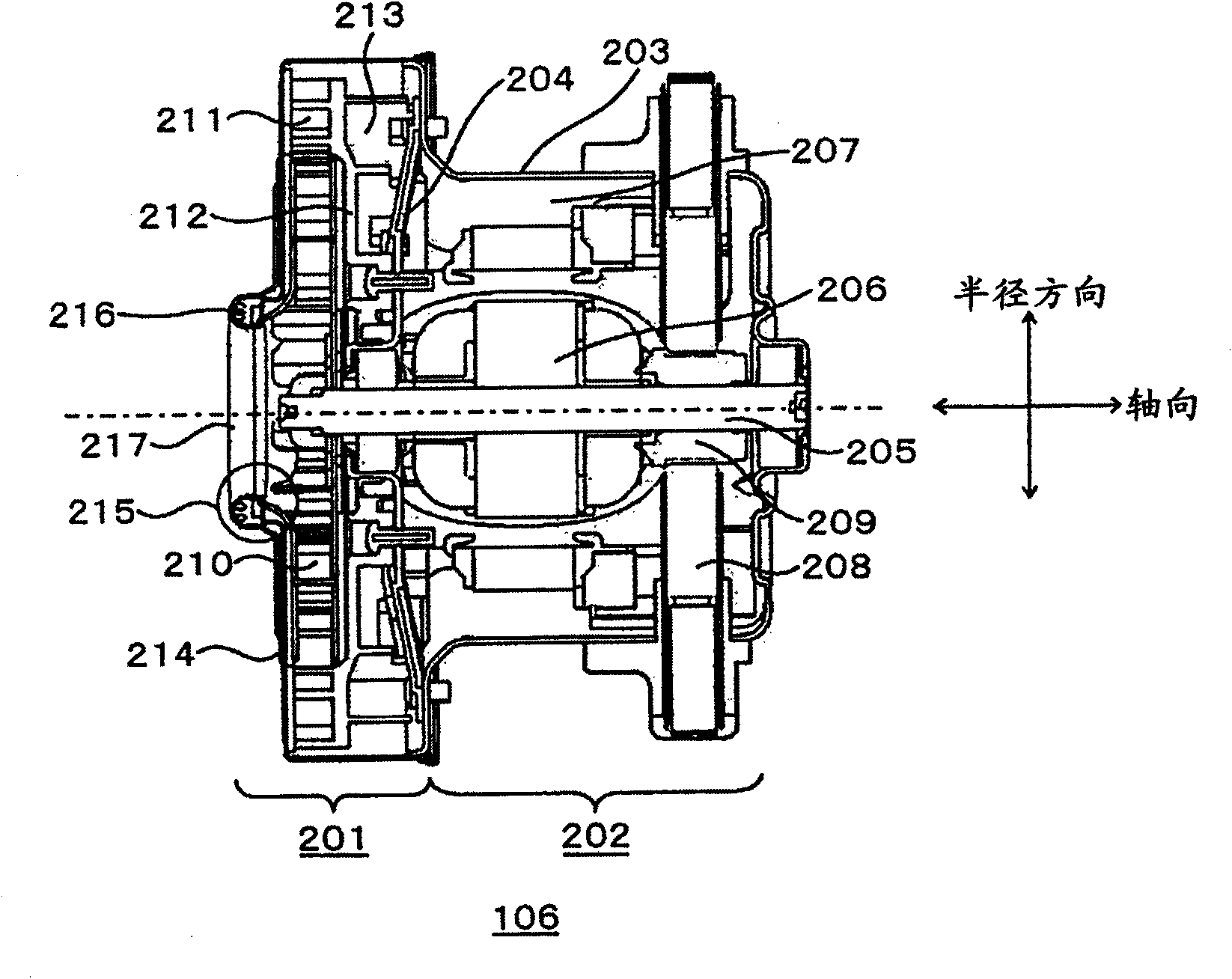

Camera module

ActiveCN103814328AWith hand shake correction functionInhibition of bucklingTelevision system detailsPrintersComputer moduleCamera module

A camera module (50) is provided with a suspension wire (16) and an AF spring. The spring constant of the suspension wire (16) and the AF spring is set so that the maximum value of stress specified according to the degree of deformation in the longitudinal direction of the suspension wire (16) does not exceed the buckling stress or the yield stress of the suspension wire (16) when a movable section moves within a movement range.

Owner:SHARP KK

Physical quantity sensor

ActiveUS7555944B2Inhibition of bucklingReduce internal stressVolume/mass flow by thermal effectsResistance/reactance/impedenceElectricityElectrical resistance and conductance

Owner:HITACHI ASTEMO LTD

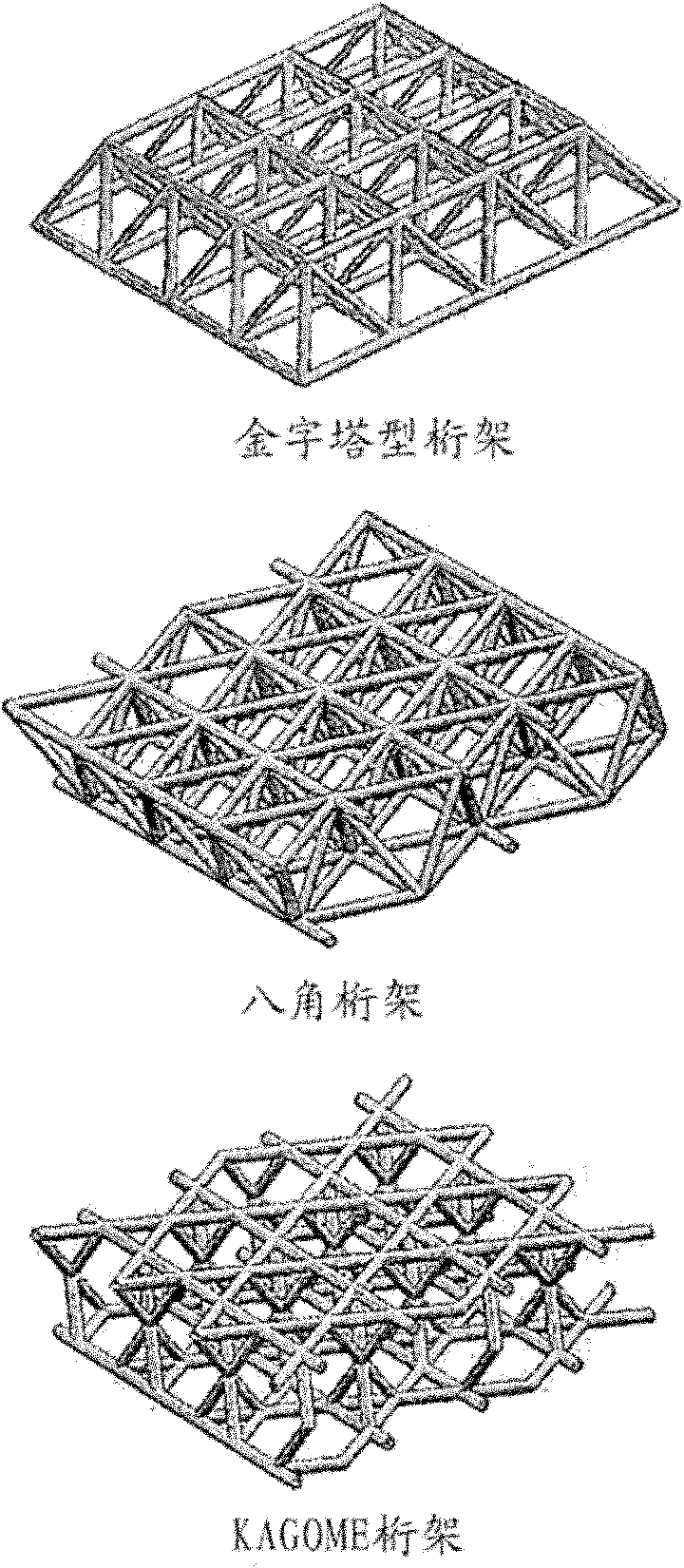

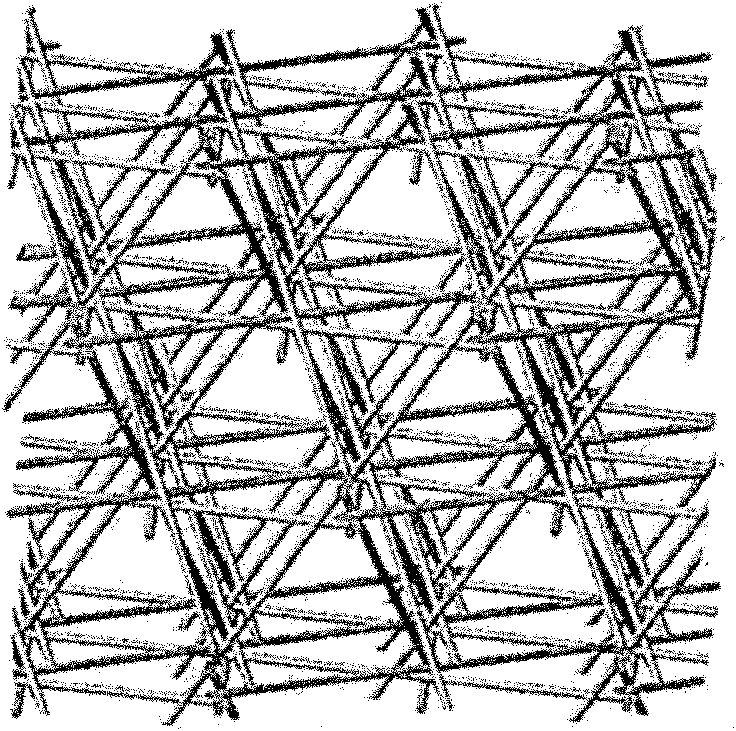

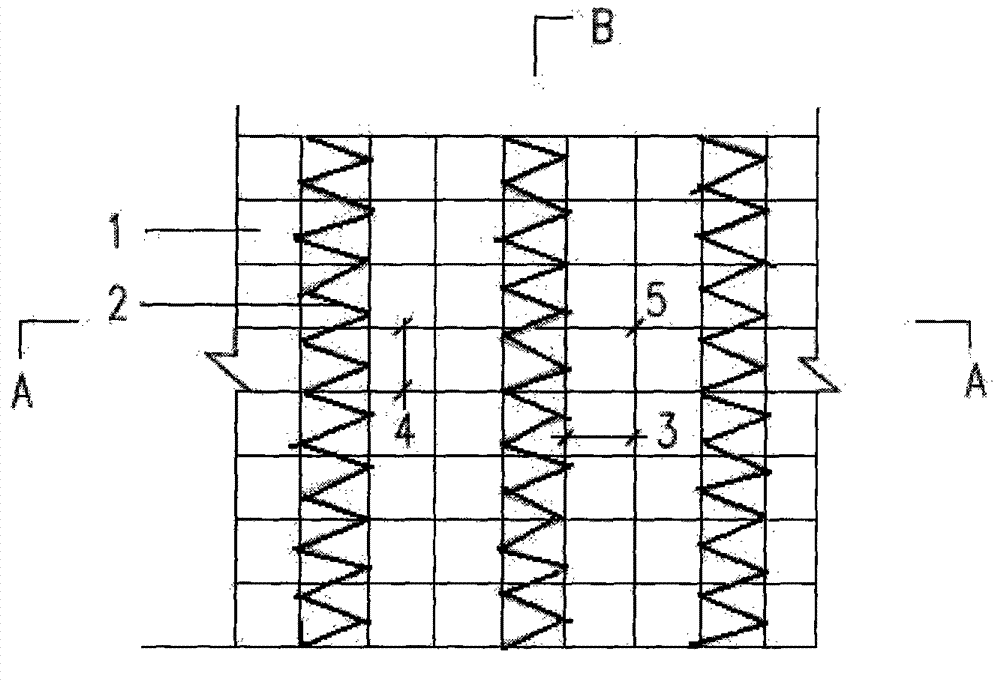

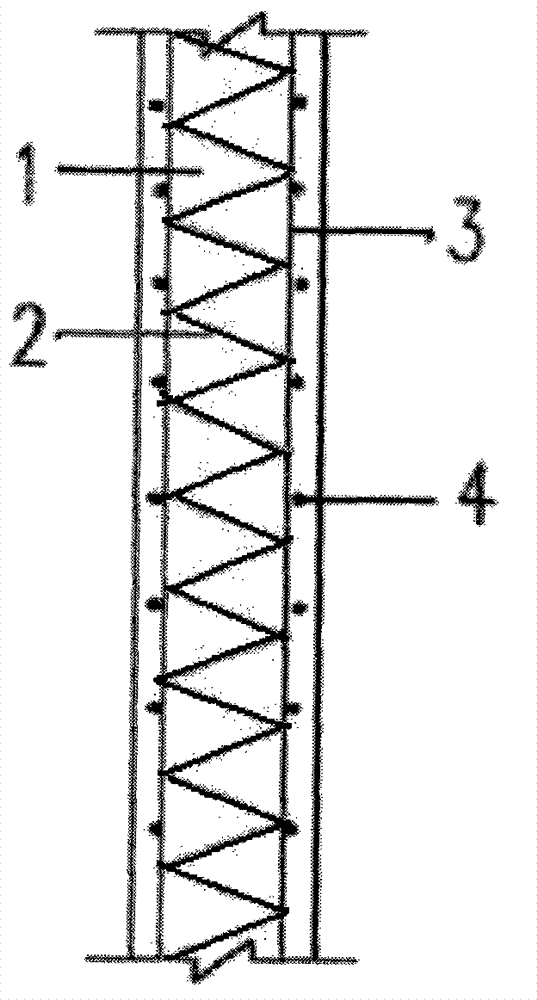

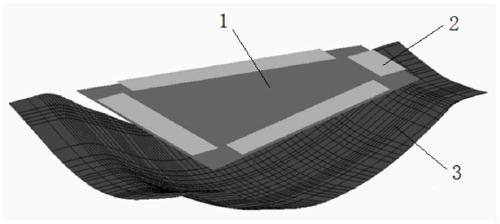

Truss type periodic cellular materials having internal cells, some of which are filled with solid materials

InactiveCN102105239AInhibition of bucklingReduce intensityWire networkBuilding componentsAnguilliformesSynthetic resin

Provided are three-dimensional truss type periodic cellular materials, wherein a plurality of internal cells are formed periodically and part of the internal cells are filled with solid material like as metal, ceramic, synthetic resin, or composite materials for the purpose of preventing buckling of the truss elements when external compressive or shear loads is applied to the truss structure. By filling only parts of internal eel Is provided in the truss with appropriate solid materials, the buckling of truss elements can be suppressed maximally and effectively, and even if the buckling accidentally occurs, the sharp decline of strength can be prevented so as to ensure sufficient structural stability of the truss type periodic cellular materials.

Owner:IND FOUND OF CHONNAM NAT UNIV

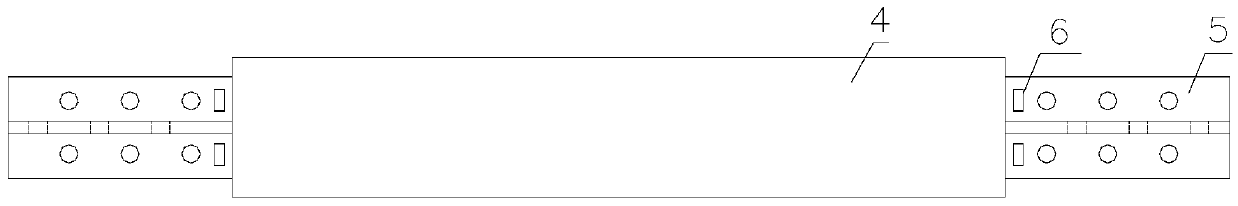

Fiber-reinforced composite material-wood-steel combined buckling-restrained brace

InactiveCN105507441AShort manufacturing cycleSmall additional weightShock proofingConstruction engineeringFiber-reinforced composite

The invention discloses a fiber-reinforced composite material-wood-steel combined buckling-restrained brace. The fiber-reinforced composite material-wood-steel combined buckling-restrained brace comprises an inner core and an outer combined restraint sleeving the inner core, wherein the outer combined restraint comprises cushion blocks, a plurality of protecting plates, wood blocks and a fiber-reinforced composite material, the protecting plates are arranged on the periphery of the inner core longitudinally, each two adjacent protecting plates are connected through the cushion block arranged at the outer ends of the cushion blocks so as to form an enclosed structure accommodating the inner core, the wood blocks are arranged on the outer surfaces of the protecting plates connectively, and the fiber-reinforced composite material is wound on the integral outside of the cushion blocks, the protecting plates and the wood blocks longitudinally. The fiber-reinforced composite material-wood-steel combined buckling-restrained brace has the advantages of low self weight, short manufacturing period, convenience in transportation, simplicity in mounting and replacement and the like while bearing and energy-dissipating capabilities are guaranteed, can be applied to multi-story buildings and high-rise buildings with concrete structures and steel structures and can solve the problem of safety of building structures under the action of earthquakes.

Owner:SOUTHEAST UNIV

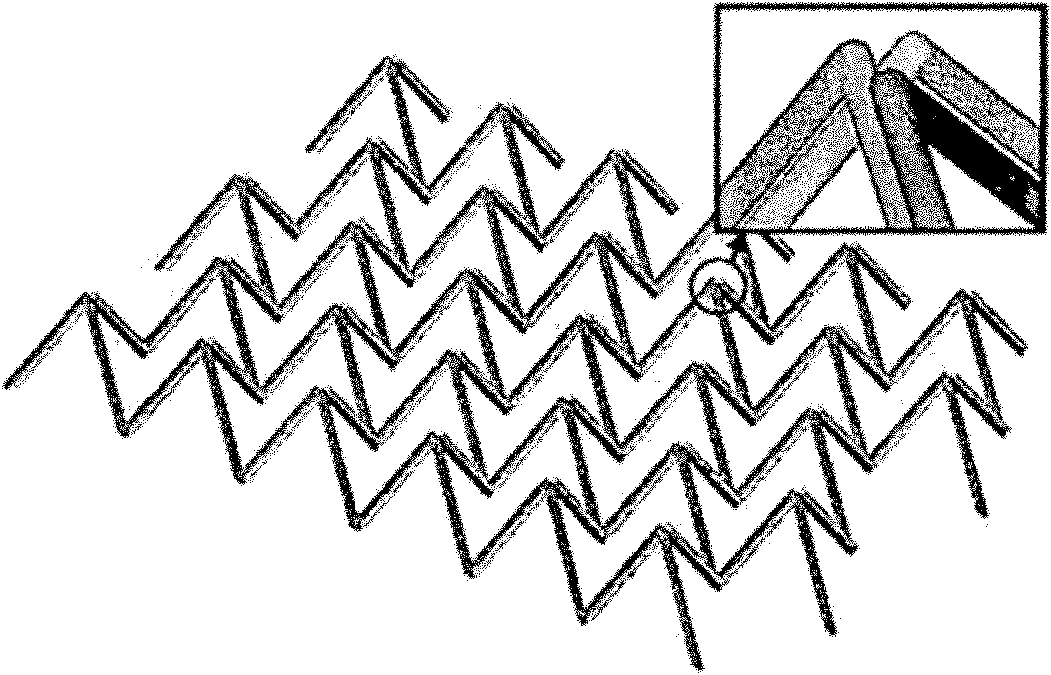

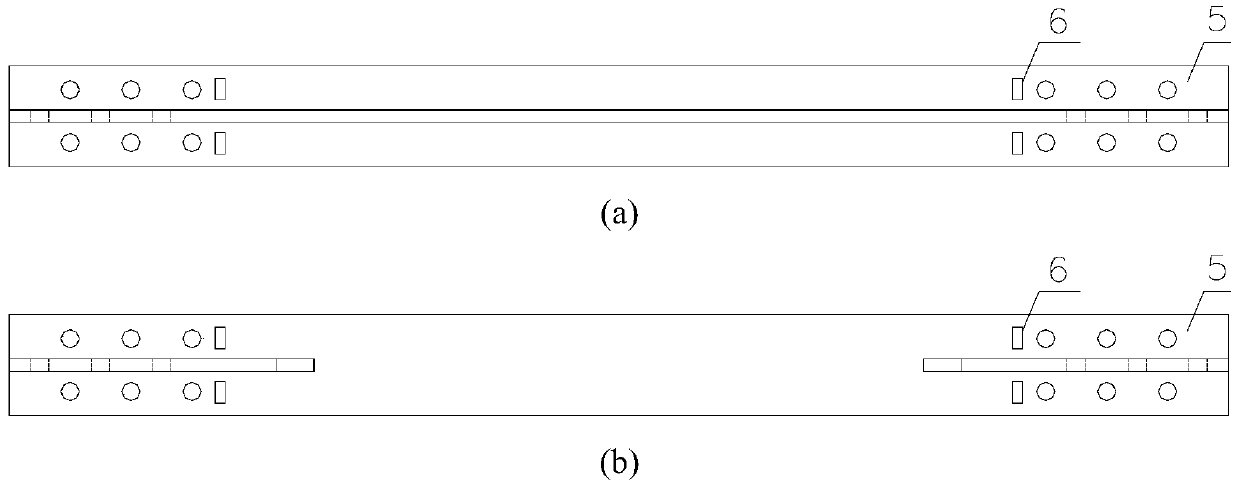

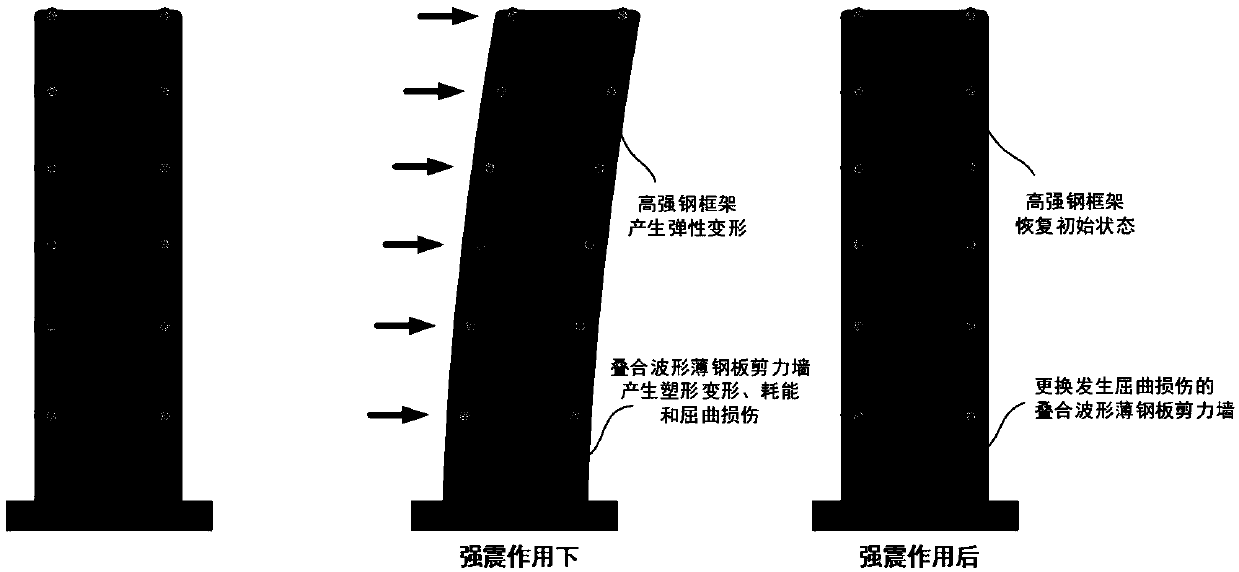

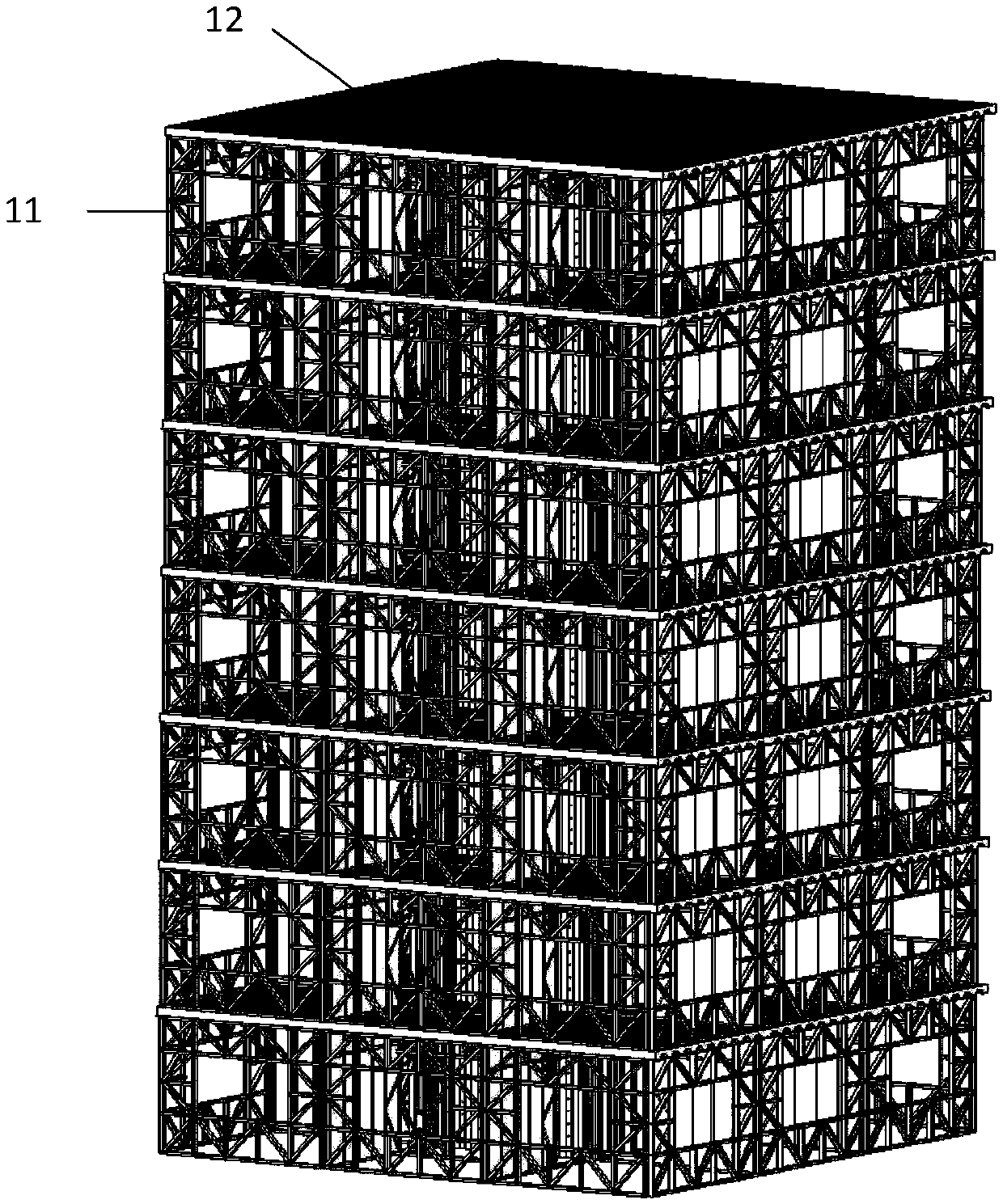

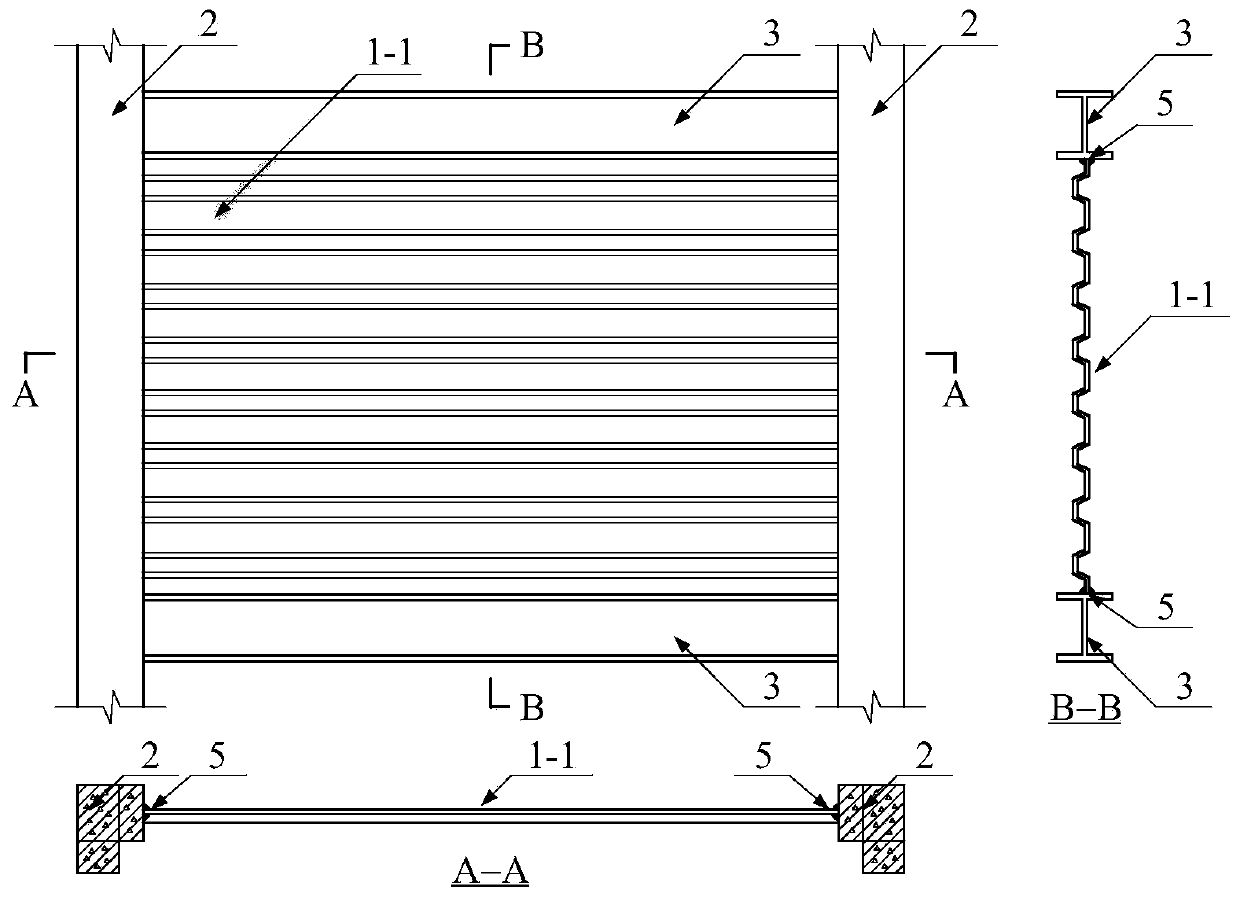

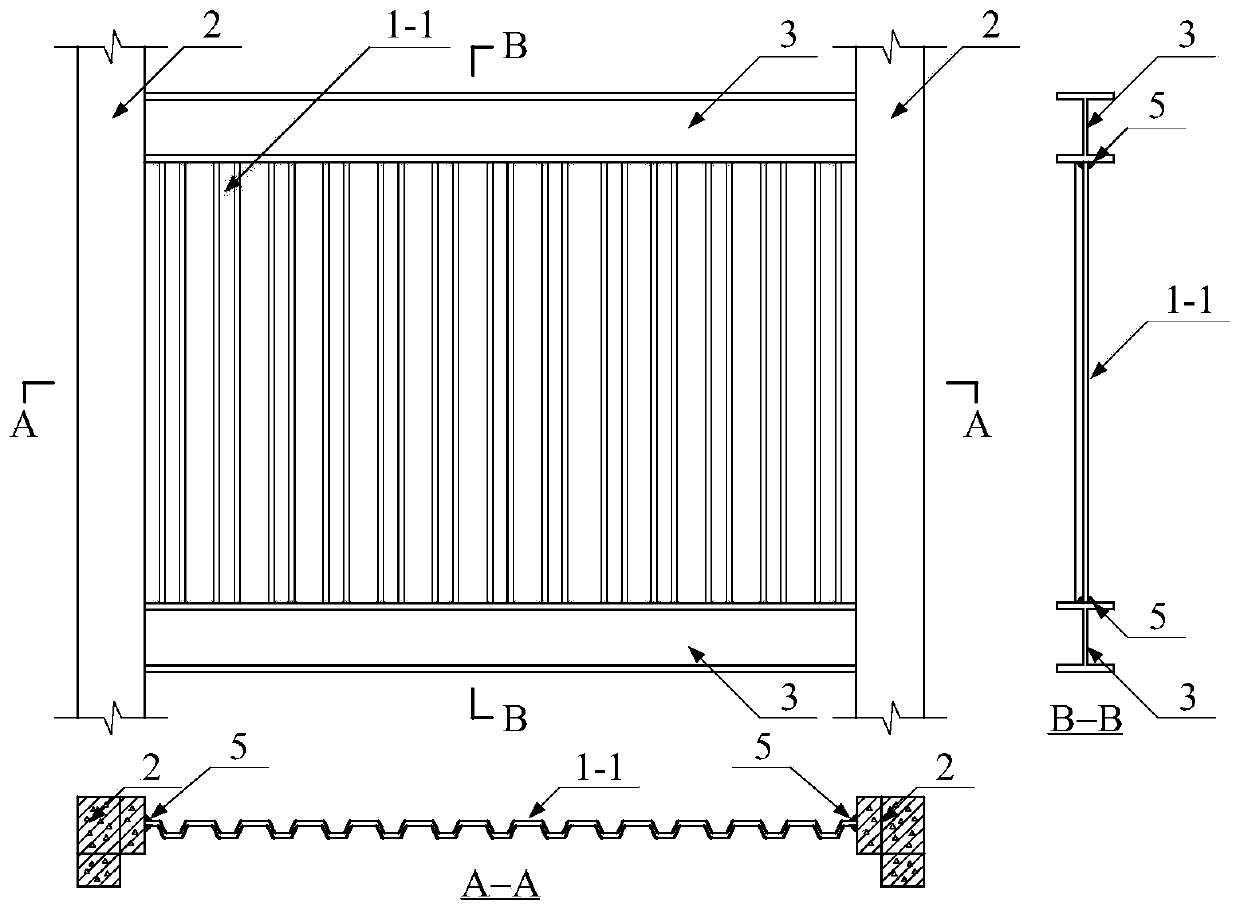

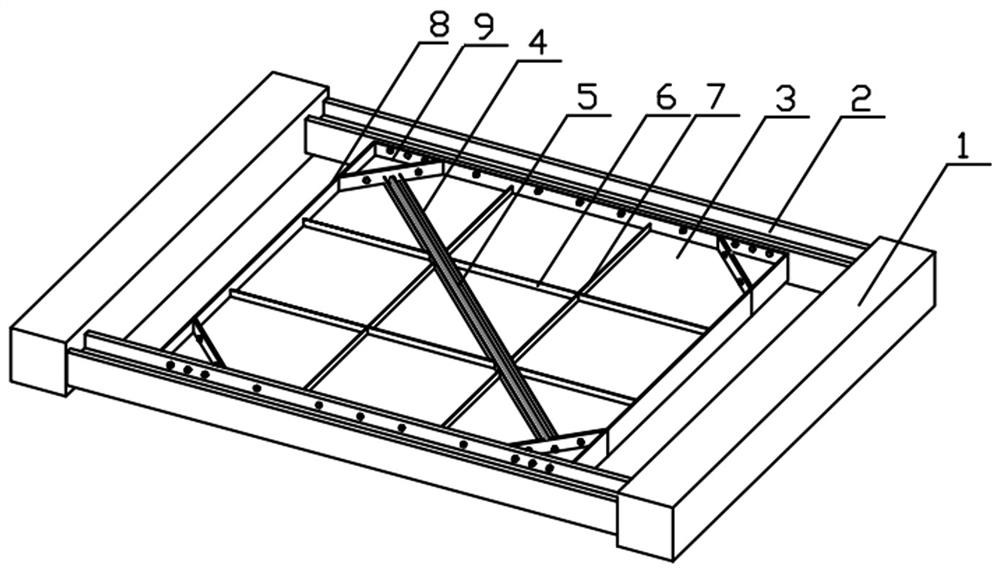

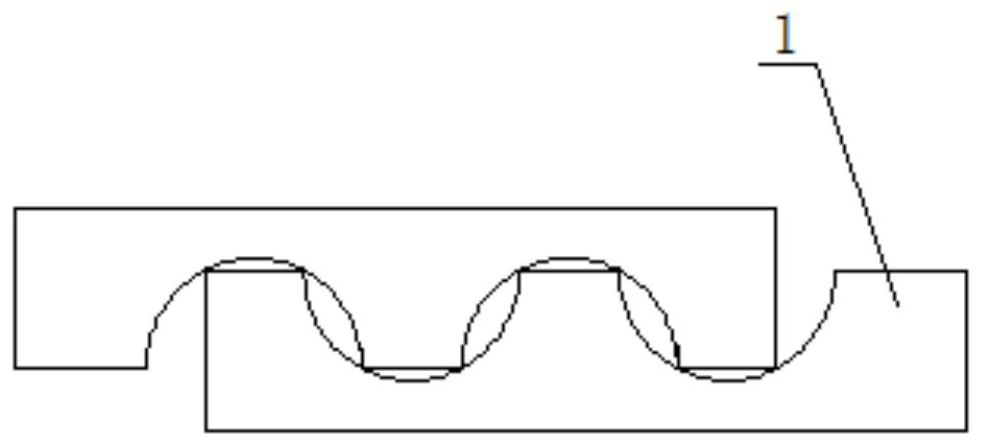

High strength steel frame-laminated corrugated steel sheet wall side-resistant cold-formed thin-walled steel structure

PendingCN109680796AGuaranteed replaceableGuaranteed on-site assembly constructionBuilding constructionsSheet steelCold formed

The invention relates to a high strength steel frame-laminated corrugated steel sheet wall side-resistant cold-formed thin-walled steel structure and belongs to the field of structure engineering. Thehigh strength steel frame-laminated corrugated steel sheet wall side-resistant cold-formed thin-walled steel structure comprises rectangular high strength steel columns, I-shaped high strength steelbeams, connection angle steels, zigzag fish plates, fish plates, corrugated steel sheets, bolts, self-tapping screws, a thermal-insulation, damp-prevention and sound-insulation material, decorative wall boards, cold-formed thin-walled steel composite wall bodies and a profiled steel sheet composite floor, wherein the I-shaped high strength steel beams are arranged at web plates at the two ends andare connected with the corresponding connection angle steels on the corresponding rectangular high strength steel columns through bolts to form a high strength steel frame; and a laminated corrugatedsteel sheet wall is vertically arranged, the upper edge and the lower edge of the laminated corrugated steel sheet wall are connected with the corresponding zigzag fish plates through bolts, the right edge and the left edge of the laminated corrugated steel sheet wall are connected with the corresponding fish plates through bolts, and the high strength steel frame-laminated corrugated steel sheetwall side-resistant structure is formed. The high strength steel frame-laminated corrugated steel sheet wall side-resistant cold-formed thin-walled steel structure improves the deficiency of anti-seismic property of a traditional cold-formed thin-walled composite wall body, has the advantages of strong energy-dissipating capacity, capability of restoration after an earthquake and integration of functions of a structure and a building and can be widely applied to multi-layer building engineering.

Owner:CHONGQING UNIV

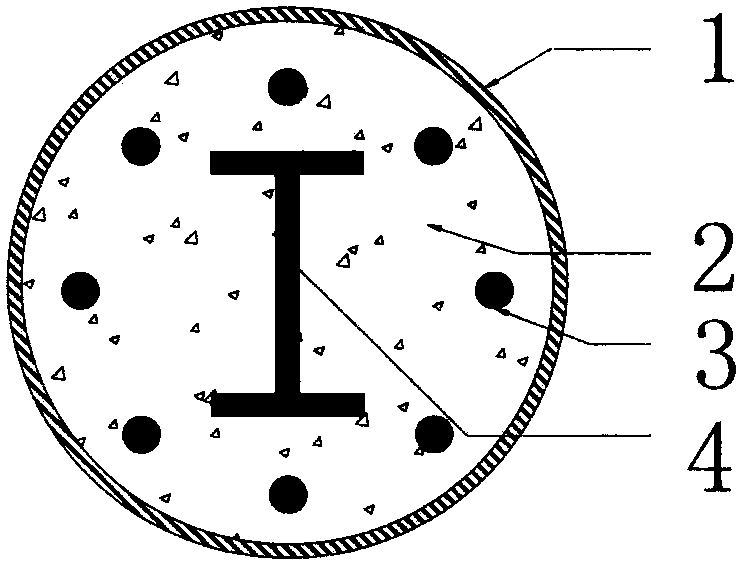

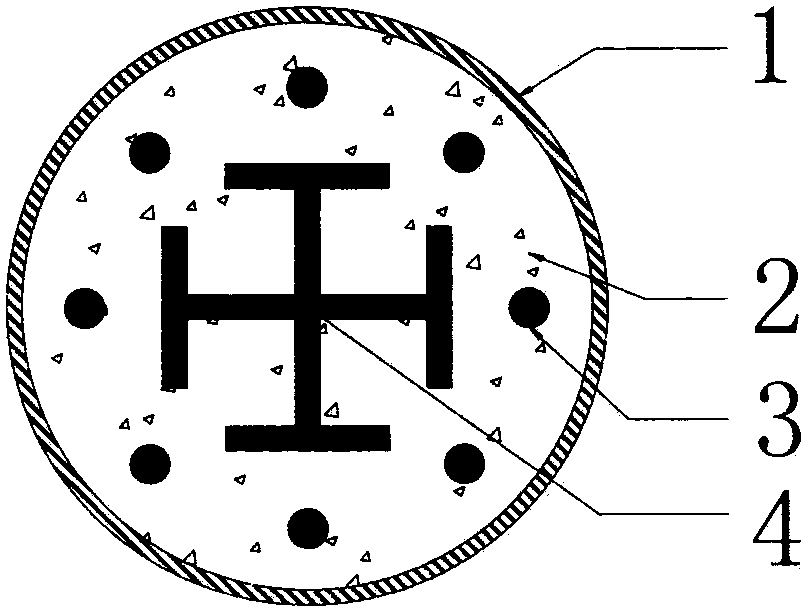

FRP (fiber reinforced plastic)-steel bone reinforced composite column structure

Disclosed is an FRP (fiber reinforced plastic)-steel bone reinforced composite column structure. The FRP-steel bone reinforced composite column structure is characterized by comprising an FRP layer (1), concrete (2), ribs (2) and a steel bone (4); the ribs (3) and the steel bone (4) are in the axial direction of the composite column structure and are coated with the concrete (2), the steel bone (4) is located in the center of the section, the ribs (3) are uniformly distributed along the inner side of the edge of the section, and the FRP layer (1) wraps the concrete (2) from the periphery. By the arrangement, shortcomings existing in the publicly known steel bone concrete structure and concrete-filled steel tube structure are overcome, the internal steel bone is bound more effectively by FRP layer constrained concrete, sufficient bearing capacity storage and stretchability of the structure are achieved, requirement on constructive scaffolds and formwork is reduced, the structure is convenient in construction and low in cost, good comprehensive benefits of the structure are realized, and the composite column structure is applicable to members of columns, piers and the like in the field of civil engineering.

Owner:南京市交通工程质量监督站 +1

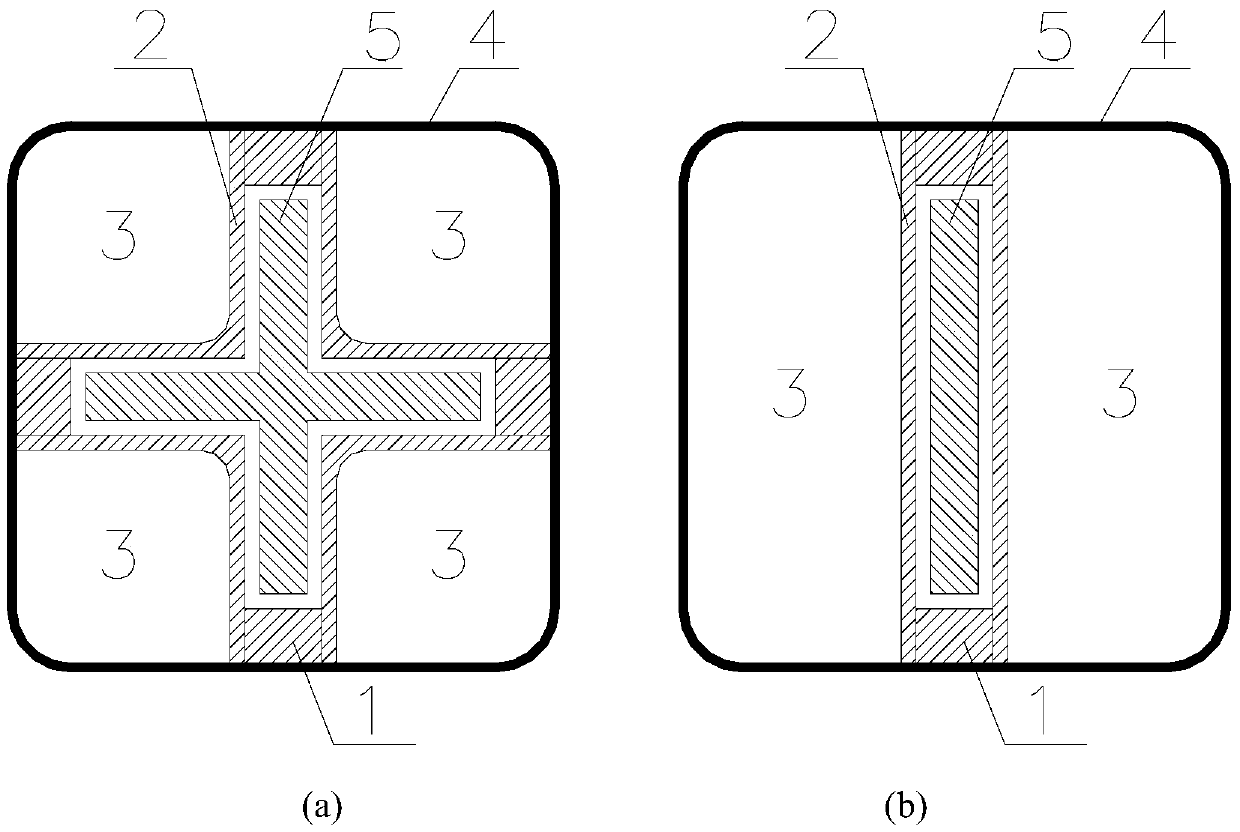

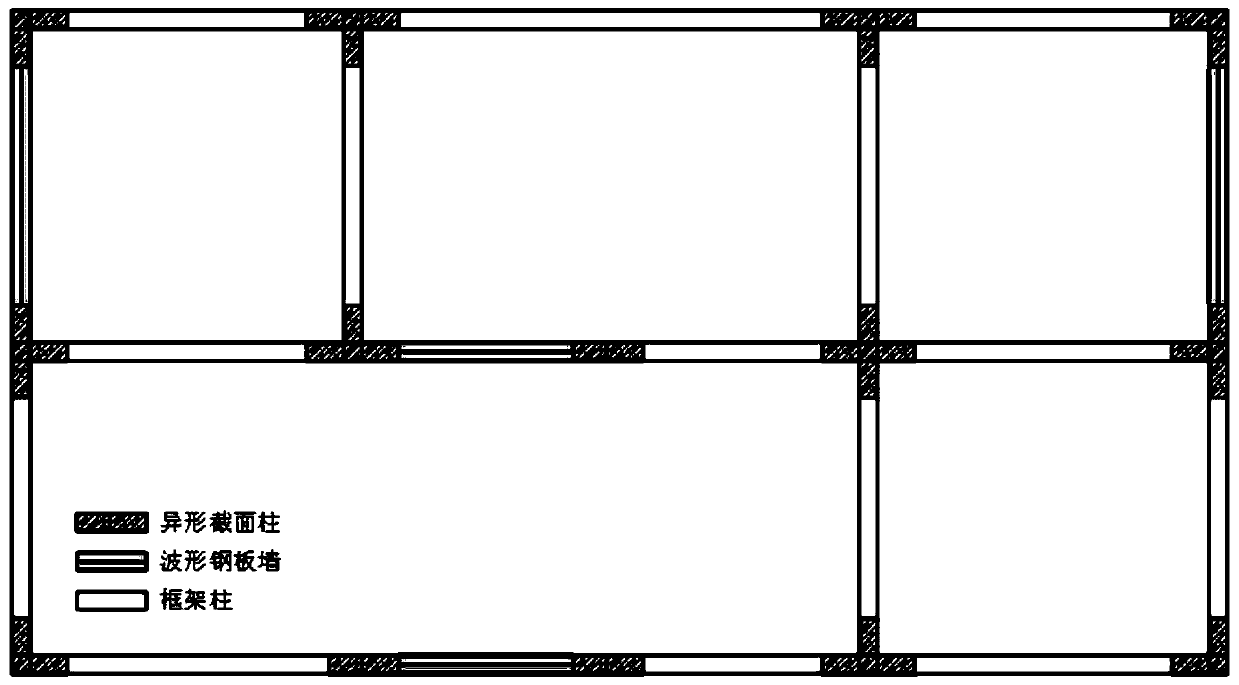

Structure system composed of special-shaped cross section column frame and corrugated sheet steel wall

PendingCN111188433AMeet the requirements of flexible layoutOvercome the problem of exposed beams and exposed pillarsConstruction materialWallsSheet steelSteel columns

The invention relates to a structure system composed of a special-shaped cross section column frame and a corrugated sheet steel wall, and belongs to the technical field of structure engineering. Thespecial-shaped cross section column frame-corrugated sheet steel wall structure system is composed of the special-shaped cross section column frame and the corrugated sheet steel wall embedded in theframe. The special-shaped cross section column frame adopts L-shaped, T-shaped and cross-shaped special-shaped cross section steel columns and special-shaped cross section steel pipe concrete columns.The corrugated sheet steel wall adopts a single corrugated sheet steel wall, a stiffening corrugated sheet steel wall, a double corrugated sheet steel wall in a parallel buckle connection mode, and adouble corrugated sheet steel wall in an orthogonal buckle connection mode. The stiffening corrugated sheet steel wall is formed by arranging stiffening ribs such as angle steel or U-steel on a corrugated sheet steel. The structure system provided by the invention has the characteristics of being flexible in plane arrangement, good in building impression, small in steel use amount, good in bearing performance, convenient to transport and install and capable of achieving corrugated sheet steel bolt connection, and has great economic benefits by being applied to residential structures.

Owner:TSINGHUA UNIV

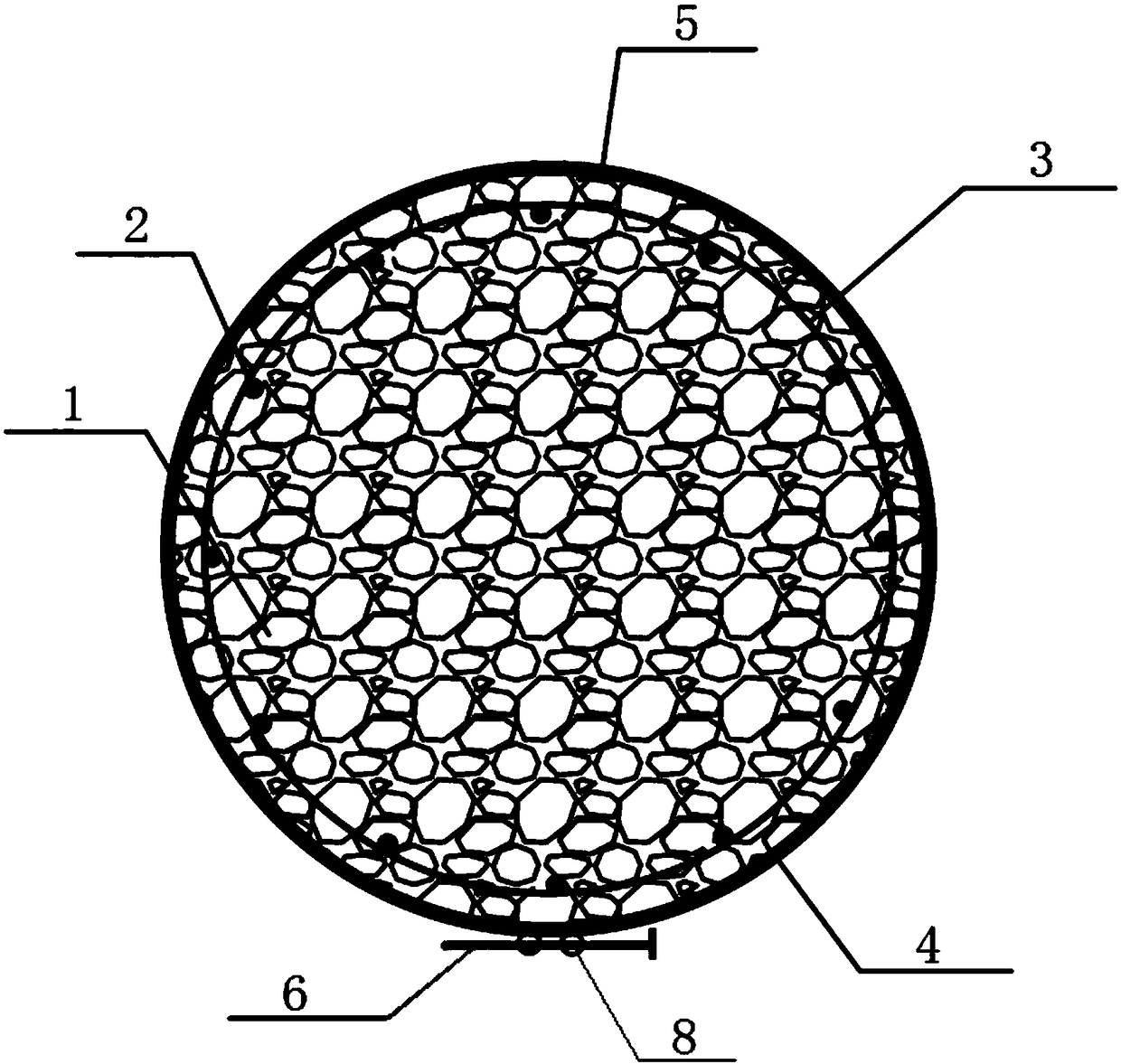

Densely-arrayed spiral stirrup confined concrete shear wall structure and construction method thereof

InactiveCN103590514AImprove bearing capacityImprove the bending capacityWallsBuilding material handlingHorizontal distributionReinforced concrete

The invention discloses a densely-arrayed spiral stirrup confined concrete shear wall structure and a construction method of the densely-arrayed spiral stirrup confined concrete shear wall. The shear wall structure comprises concrete and spiral stirrups. The spiral stirrups are evenly distributed along the section of the concrete. Vertical distribution steel bars, horizontal distribution steel bars and pulling steel bars are arranged in front and back of the spiral stirrups. Longitudinal steel bars are arranged at the positions of edge confining components on the two sides of the spiral stirrups. Because the spiral stirrups are embedded into an ordinary reinforced concrete shear wall, the bearing capacity of the concrete is improved through the confining effect of the spiral stirrups, and accordingly the sectional dimension of the components, the self-weight of the structure and earthquake actions are reduced under the condition of same designed axial force.

Owner:YANCHENG INST OF TECH +1

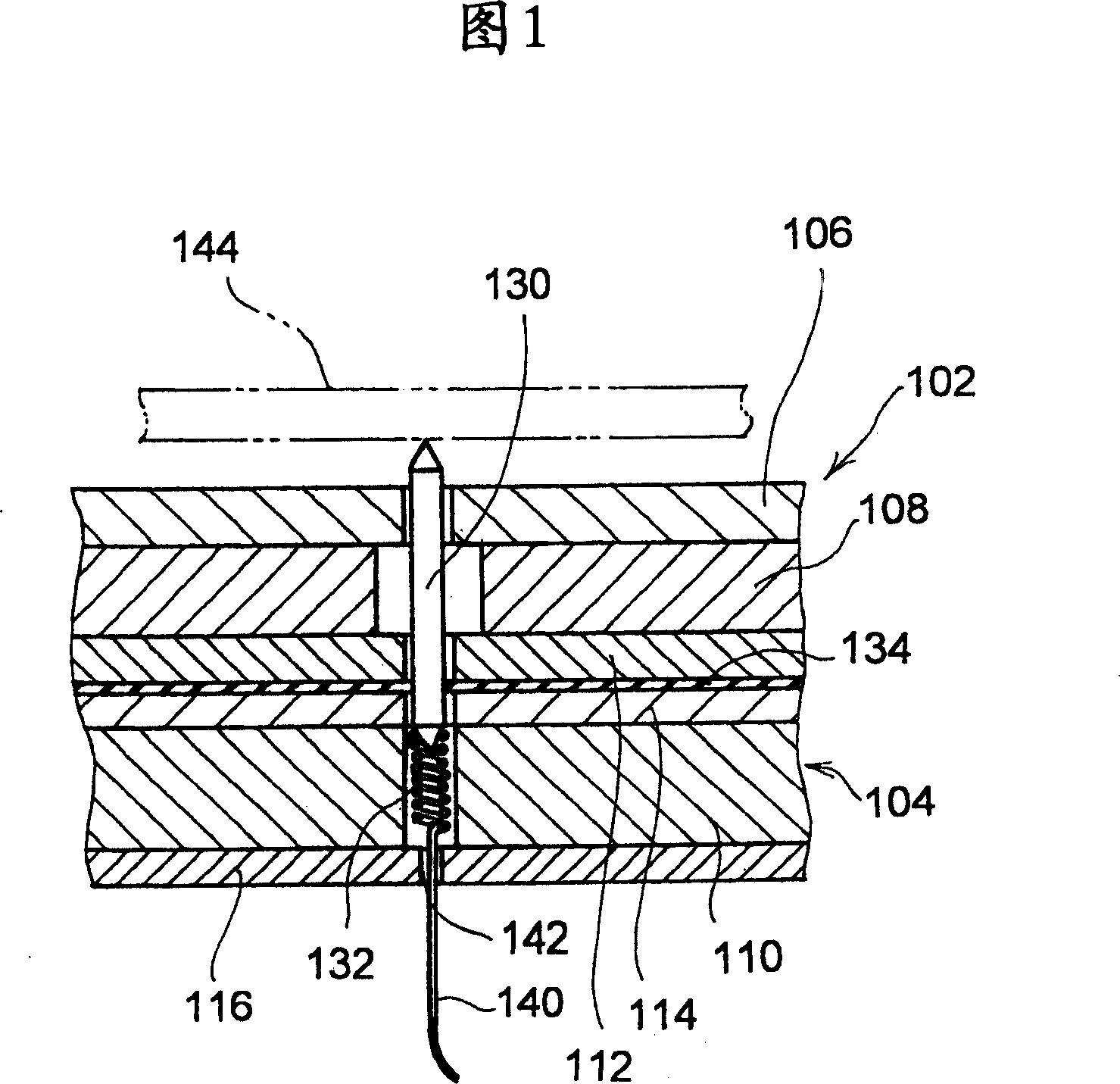

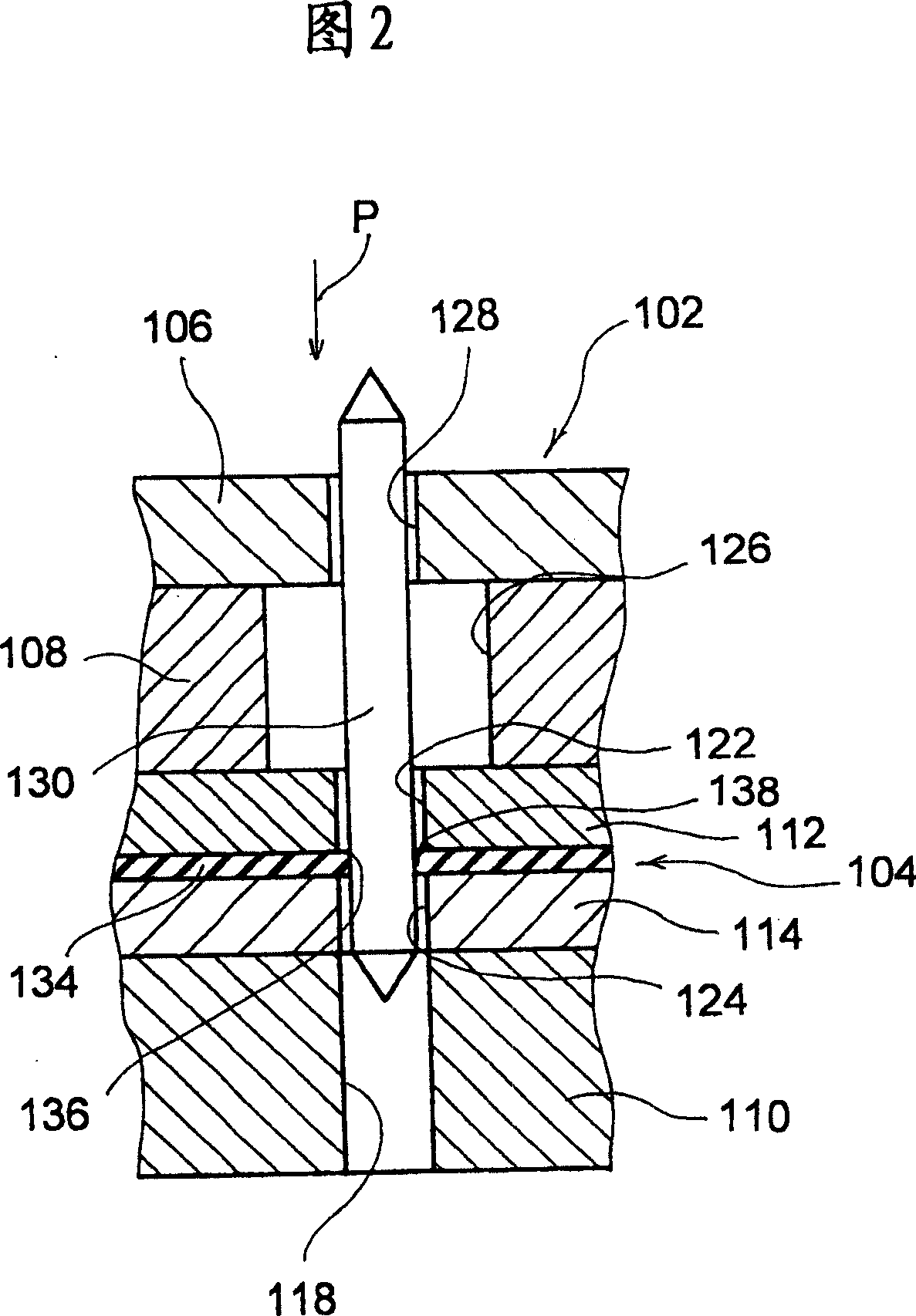

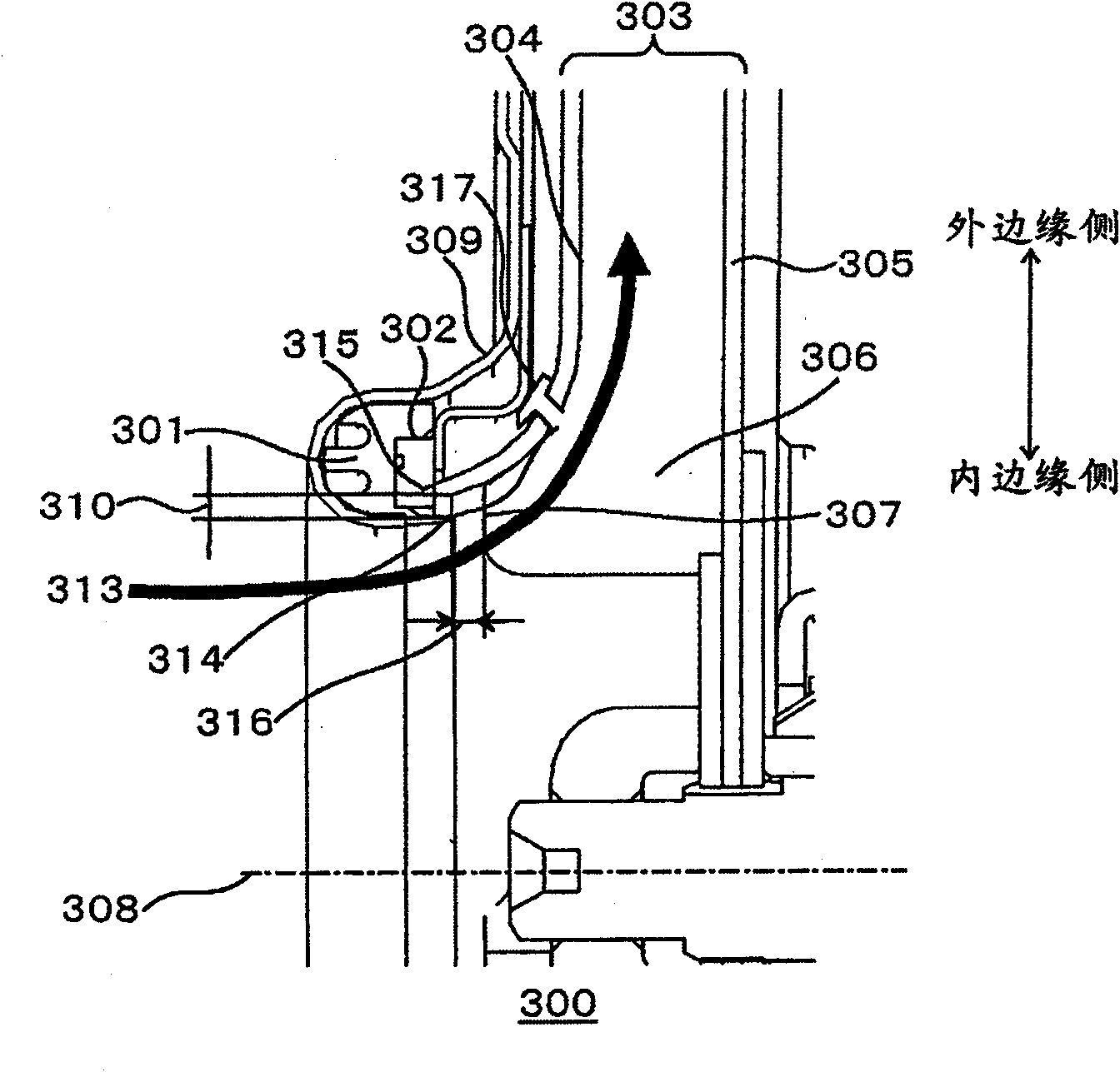

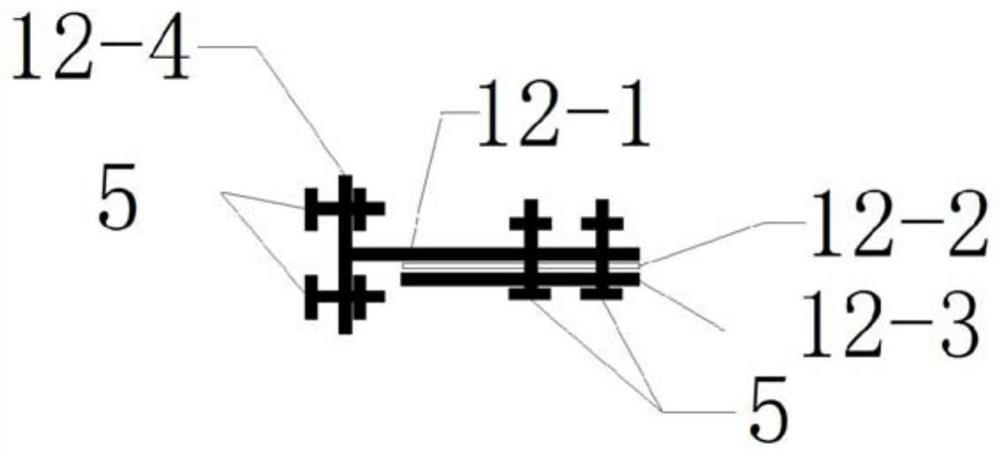

Inspection fixture for printed wiring board

InactiveCN1982896AKeep stablePromote exchangeElectrical testingMeasurement leads/probesHigh densityEngineering

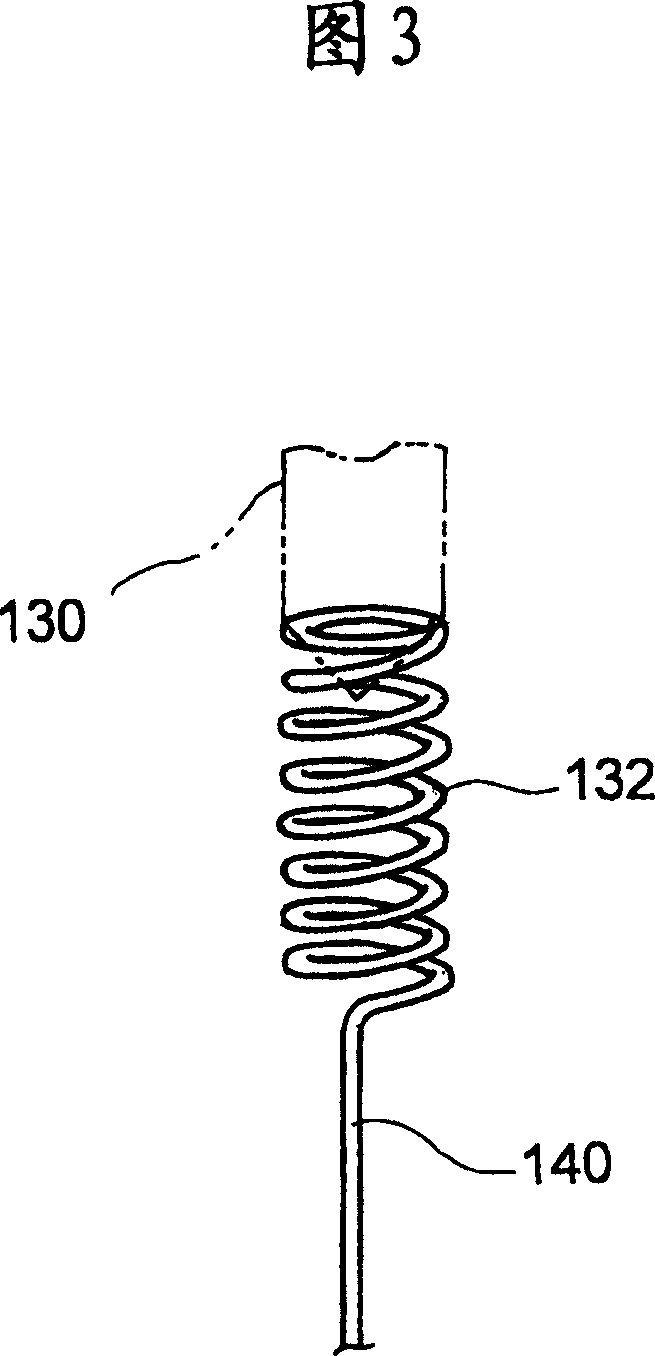

Provided is an inspection fixture for printed wiring board capable of holding probe pins as desired, changing probe pins easily, and coping with requirement of high-density arrangement for printed wiring board. The inspection fixture for printed wiring board includes a pin board 104 having an accommodating hole 118 and installation holes 122, 124, a protection board 106 having a guiding hole 128, a probe pin 130 inserted into the installation holes 122, 124 of the pin board 104 with a front end thereof passing through the guiding hole 128 of the protection board 106 and protruding to the outside, and a spring member accommodated within the accommodating hole 118 of the pin board 104. The pin board 104 includes a rubber board 134, while a resilient holding portion 138 of the rubber board 134 resiliently holding a peripheral surface of the probe pin 138.

Owner:OHNISHI ELECTRONICS

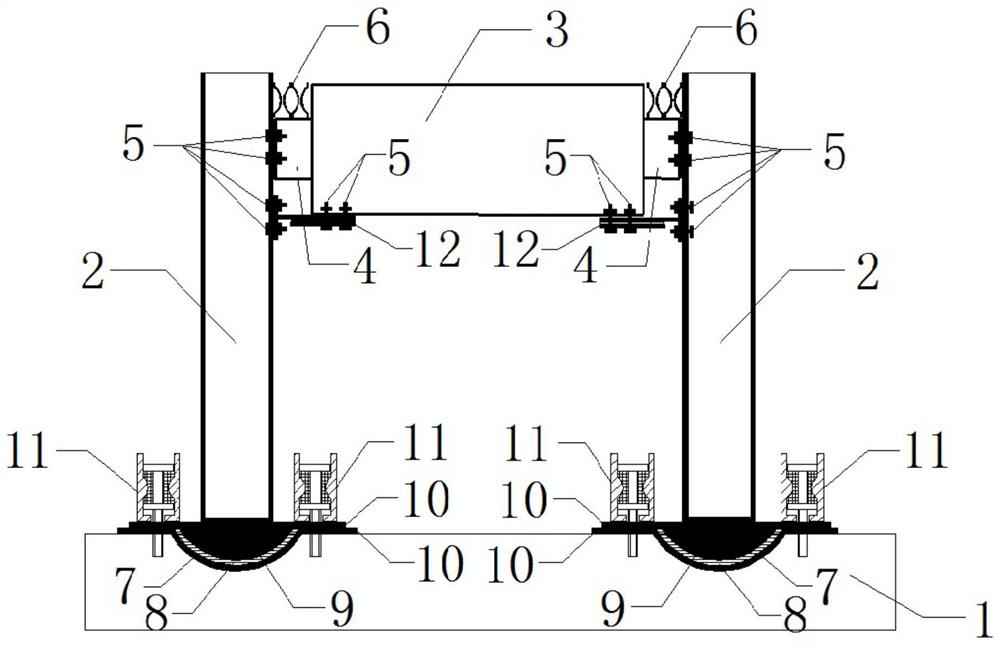

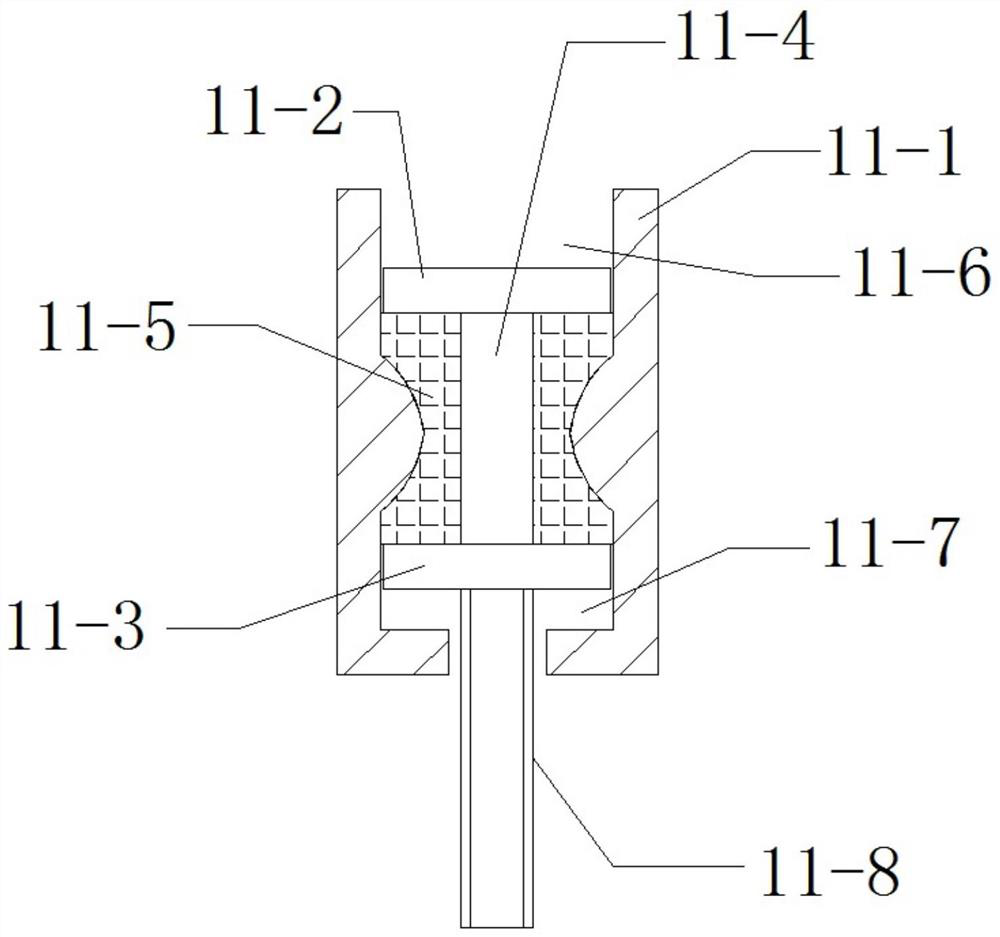

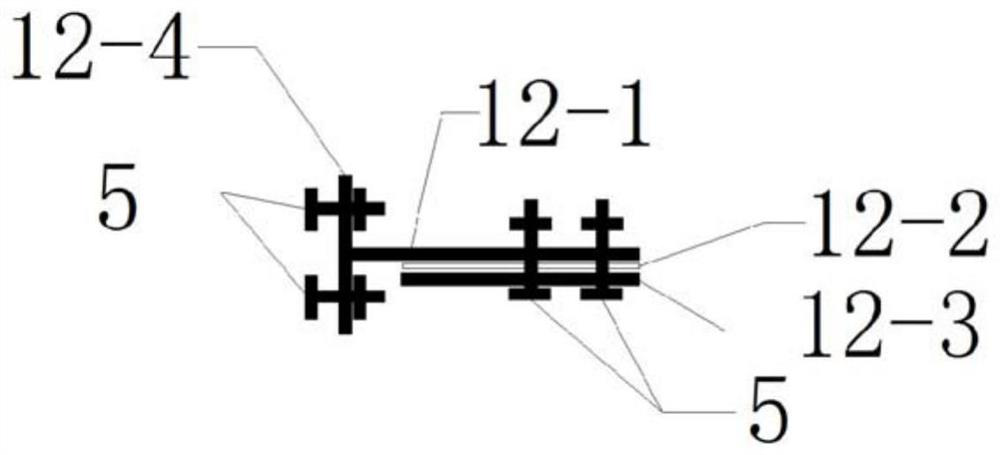

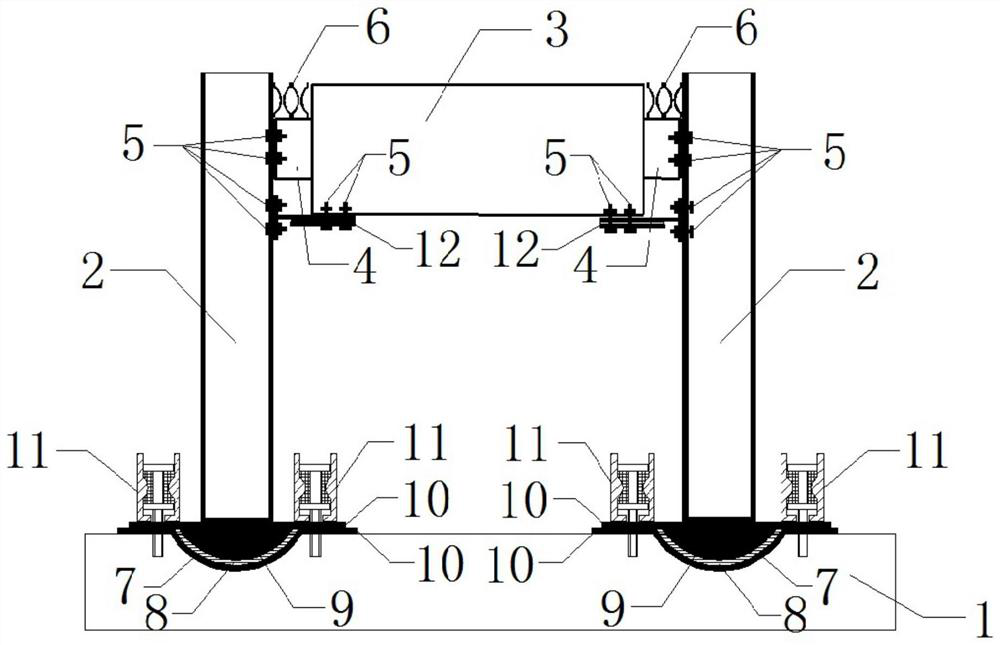

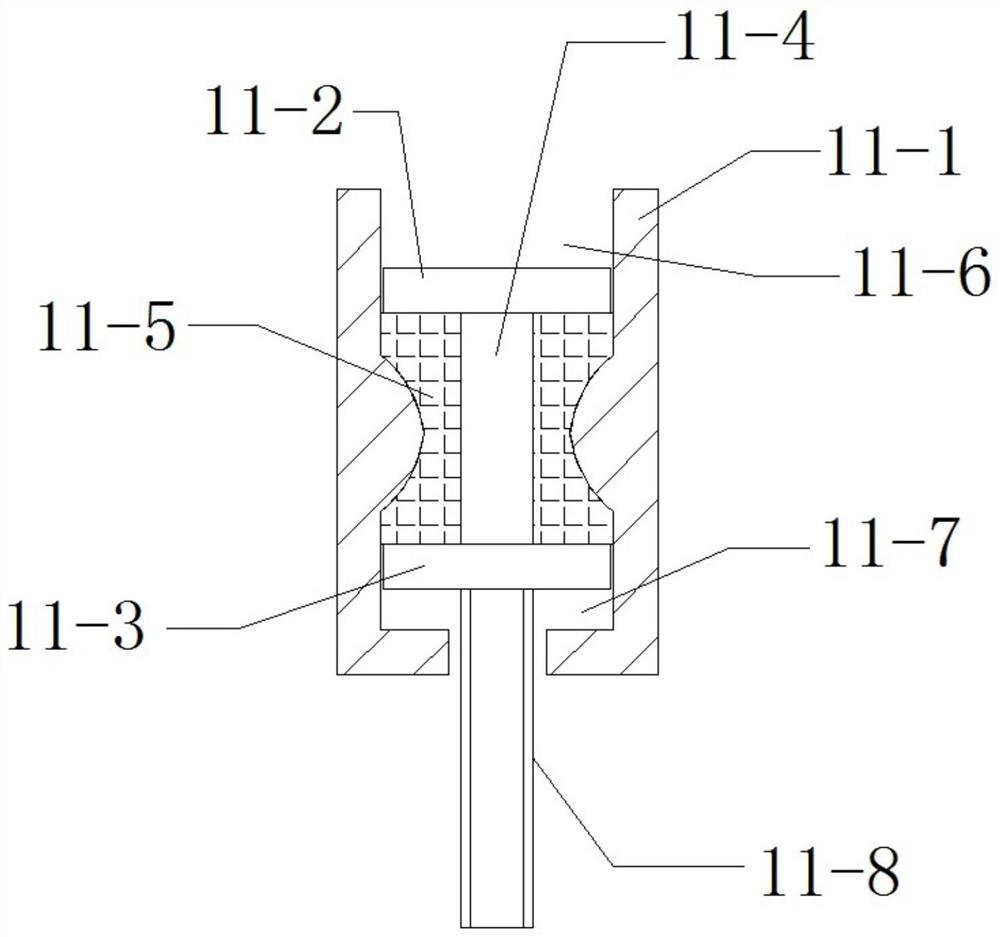

Fabricated bridge double-column pier with triple energy dissipation system

ActiveCN112502035AStrong energy consumptionEarthquake damage controllableBridge structural detailsSteel tubePier

The invention provides a fabricated bridge double-column pier with a triple energy dissipation system. The double-column pier comprises a bearing platform, the left side and the right side of the upper portion of the bearing platform are each provided with a concrete-filled steel tube pier, and extrusion dampers are arranged between the concrete-filled steel tube piers and the bearing platform; aconcrete-filled steel tube bent cap is installed between the concrete-filled steel tube piers on the two sides, steel shear-resistant lug plates are arranged at the left end and the right end of the concrete-filled steel tube bent cap respectively, one end of each steel shear-resistant lug plate is welded to the middle of the concrete-filled steel tube bent cap, and the other end of each steel shear-resistant lug plate is fixedly connected with the corresponding concrete-filled steel tube pier through bolts; cymbal-shaped disc reeds are arranged above the steel shear-resistant lug plates, andare positioned between the concrete-filled steel tube piers and the concrete-filled steel tube bent cap; a buckling-restrained plate assembly is arranged below each steel shear-resisting lug plate, one end of the buckling-restrained plate assembly is fixedly connected with the corresponding concrete-filled steel tube pier through bolts, and the other end of the buckling-restrained plate assembly is fixedly connected with the concrete-filled steel tube bent cap through bolts. By arranging a triple energy consumption system, design and construction are facilitated, and damage caused by strong earthquakes is avoided.

Owner:INST OF DISASTER PREVENTION

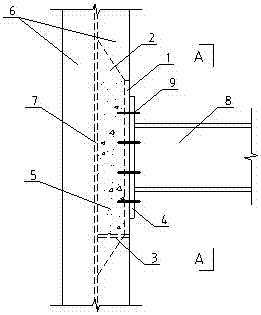

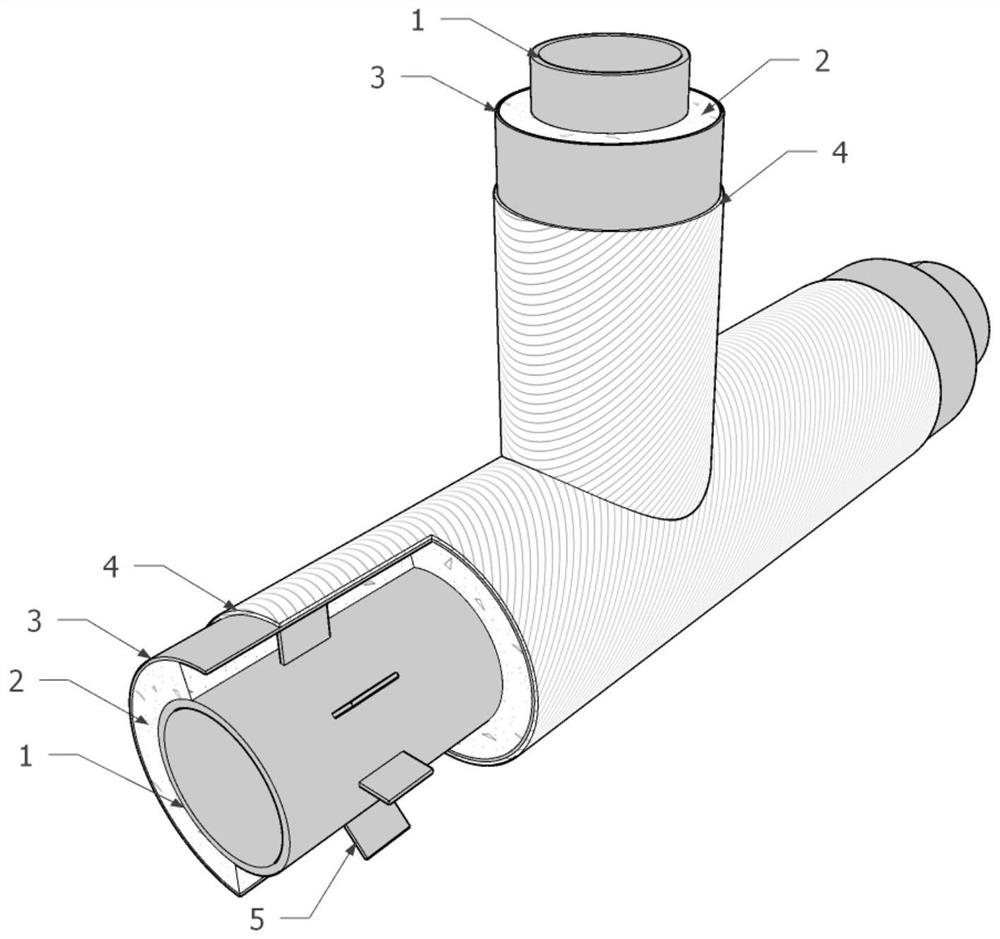

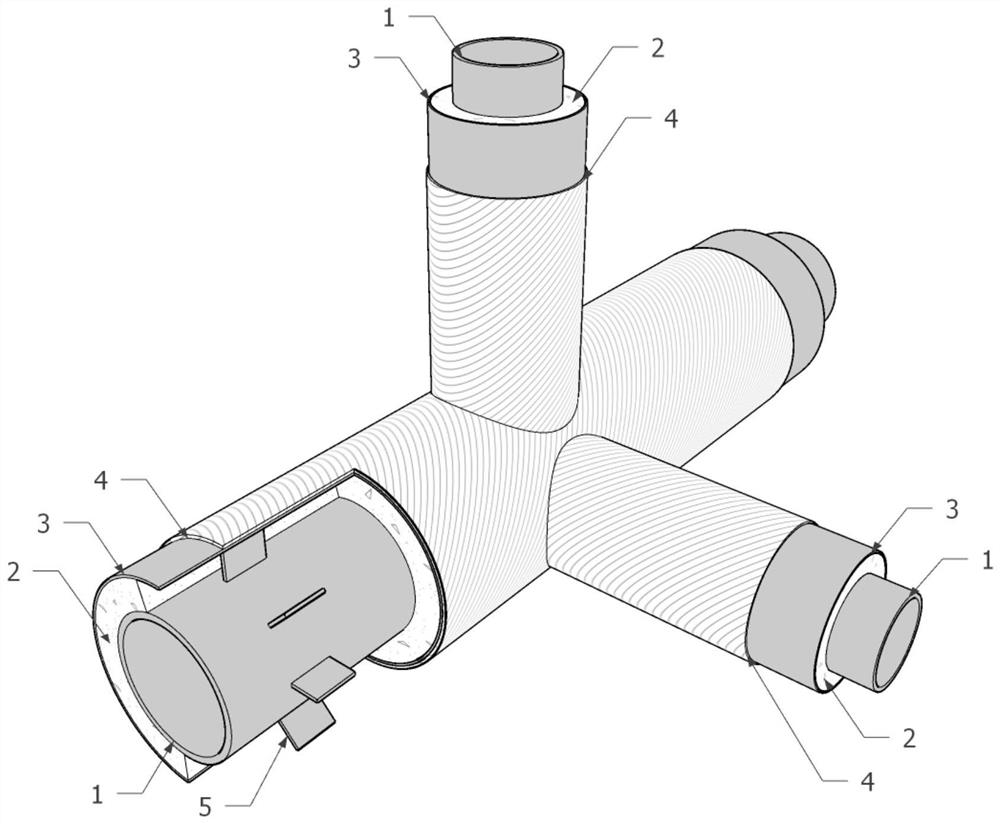

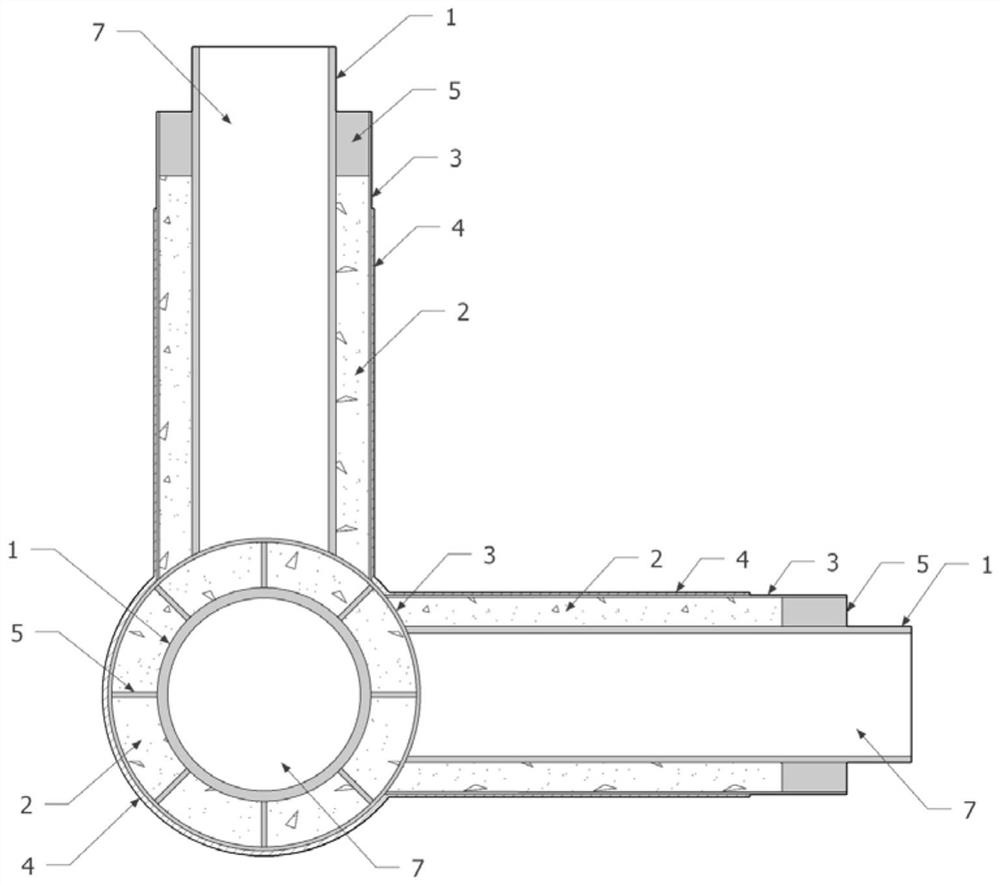

A low-yield-point steel plate shear wall structure with built-in steel tubular concrete frame

InactiveCN103912073BImprove vertical load carrying capacityGood synergyWallsShock proofingSheet steelHigh rise

The invention discloses an internally-disposed-profile-steel steel pipe concrete frame low-yield-point steel plate shear wall structure which comprises steel pipe concrete side columns, steel cross beams and an internally-embedded steel plate. Profile steel is generally arranged inside the steel pipe concrete side columns, each vertical lateral side of the internally-embedded steel plate is connected with a fishtail plate, the fishtail plates penetrate the side walls of the steel pipe concrete side columns to be connected with the profile steel in a welded manner, and positions where the fishtail plate are intersected with the side walls of the steel pipe concrete side columns are in welded connection. The profile steel is throughly arranged along the height direction of each steel pipe concrete side column, the profile steel and the steel pipe concrete side columns are jointly stressed, the profile steel plays a role as a shear connector and also plays a role of improving vertical bearing capacity of the steel pipe concrete side columns, so that using efficiency of the profile steel is improved. Sectional size of the side columns can be substantially reduced while requirements of the bearing capacity of the steel pipe concrete side columns are met, dead weight of the structure is reduced, seismic ductility of the structure is improved, building using space is effectively increased, and the structure is especially suitable for high-rise and ultrahigh-rise building structures.

Owner:BEIJING JIAOTONG UNIV

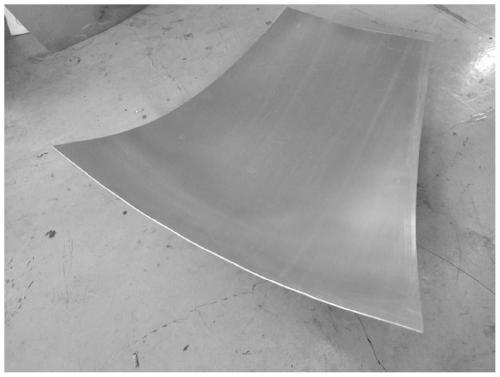

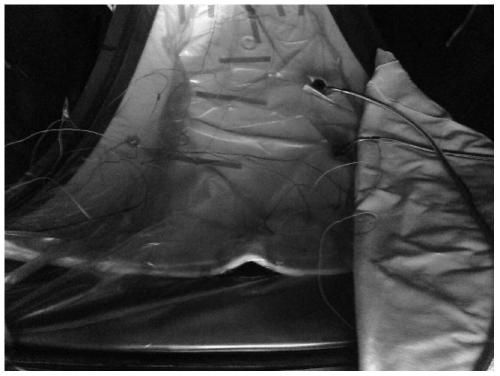

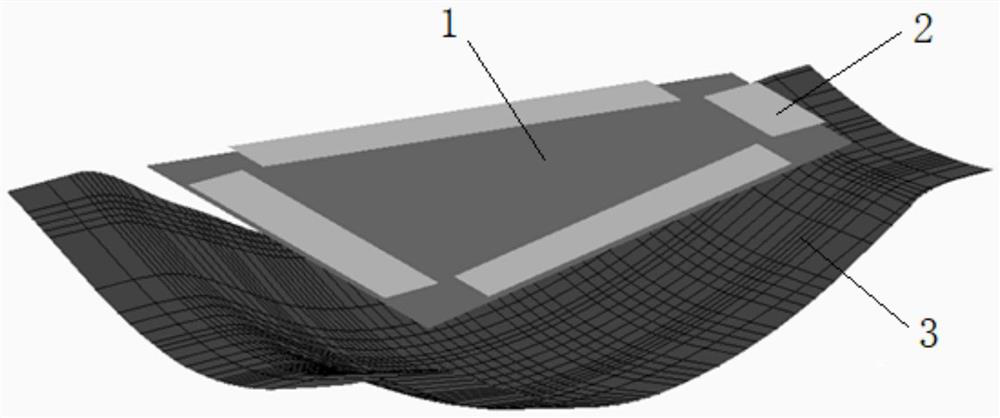

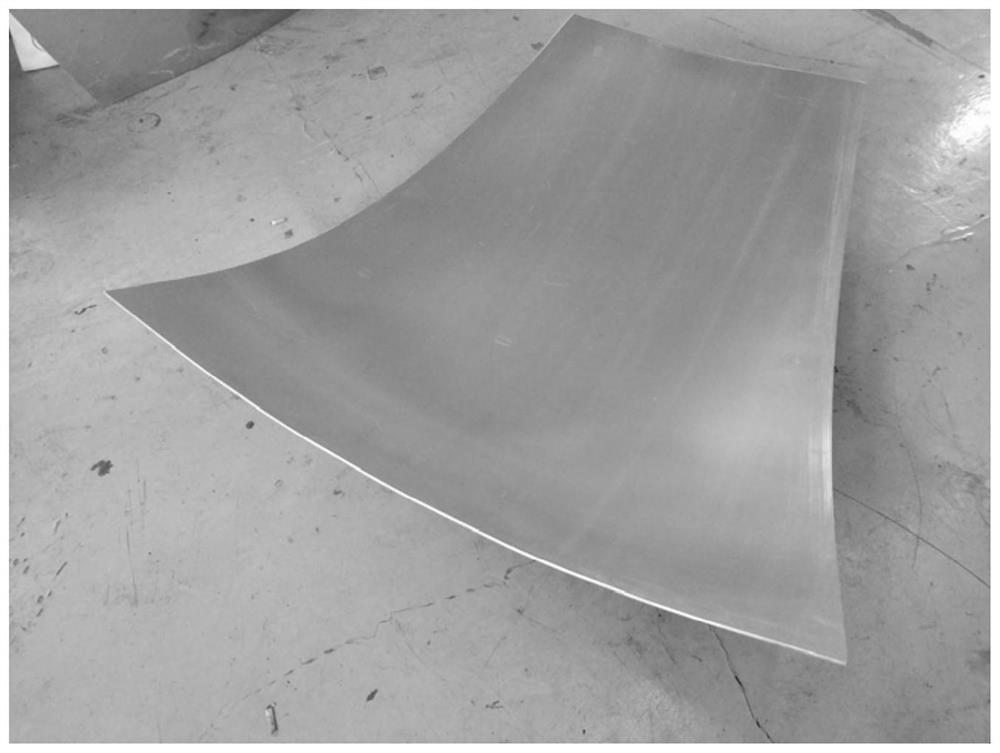

Method for inhibiting buckling of aluminum alloy member with complicated curvature during creep age forming

ActiveCN111575615AIncrease stiffnessInhibition of bucklingFurnace typesHeat treatment furnacesStructural engineeringHot pressing

The invention discloses a method for inhibiting buckling of an aluminum alloy member with a complicated curvature during creep age forming. The method comprises the steps of firstly, pasting and fixing a restricting plate around the upper surface of a parent aluminum alloy plate, then wrapping a ventilated felt around the restraining plate and the parent aluminum alloy plate, laying and pasting avacuum bag to form a closed space, and after vacuumizing treatment, putting the treated aluminum alloy plate, the restricting plate and a mold into a hot-pressing tank as a whole for creep age formingto obtain the aluminum alloy member with a complicated curvature. According to the method, in consideration of the fact that in the loading process, the member has insufficient stiffness and is proneto buckling under pressure, buckling is inhibited by configuring the restricting plate at the bearing side of the member, a device for additionally applying blank holder force is omitted, and the method can be applied to the hot pressure tank device commonly used in creep aging forming, which can effectively restrain the generation of buckling and improve the forming quality. In addition, the risk of damage to vacuum film is lowered, the forming precision is improved, and the success probability of the member is increased; and meanwhile, there is no need to reserve a blank holder area beforeplate forming, which is beneficial to near-net forming of the member.

Owner:CENT SOUTH UNIV

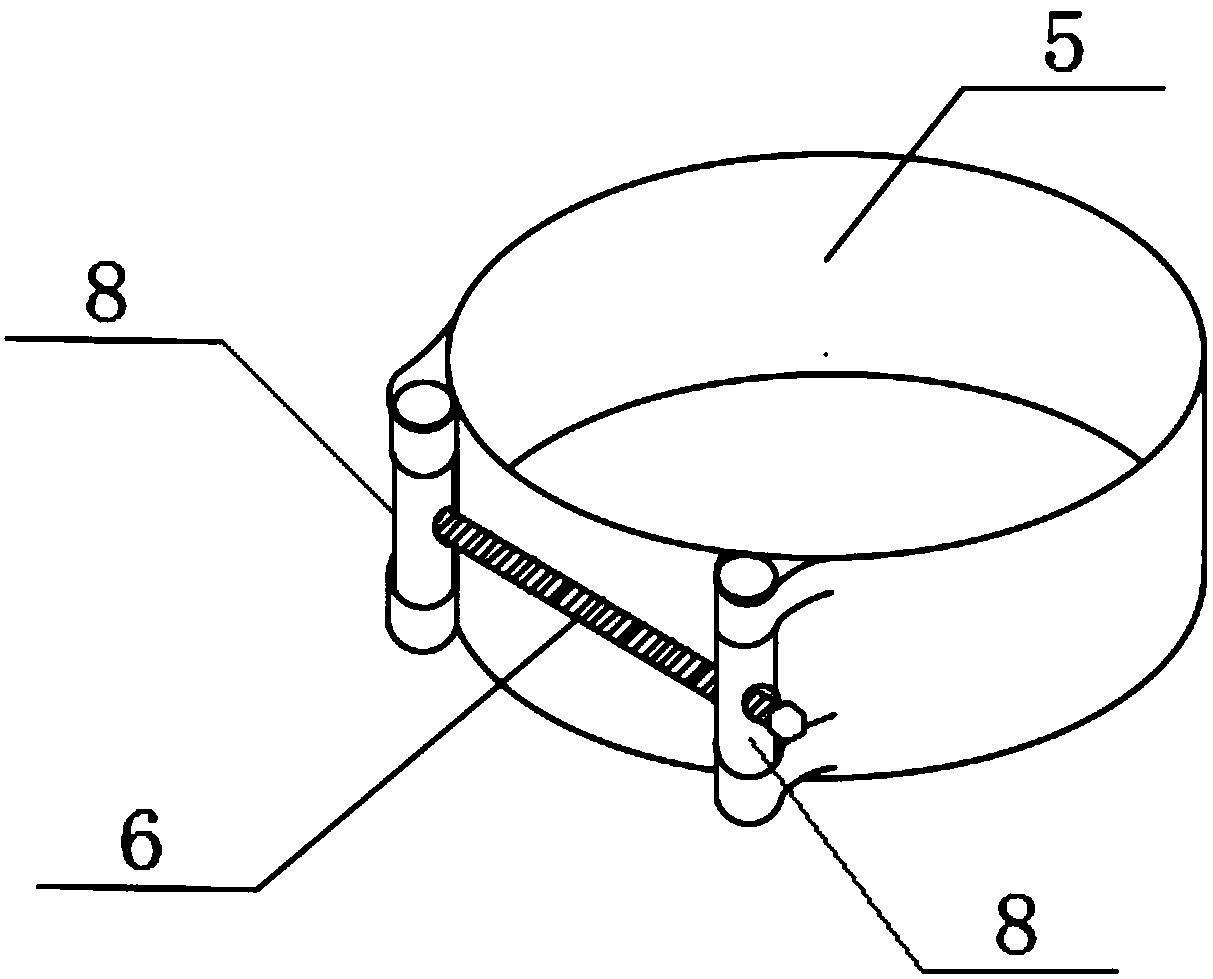

Pier repairing apparatus and method based on lightweight prestressed stainless steel sheath

PendingCN108396663AQuick fixEfficient repairBridge structural detailsBridge erection/assemblyPost disasterPre stress

The invention discloses a pier repairing apparatus based on a lightweight prestressed stainless steel sheath, comprising the sheath that sleeves an under-repair part of a pier, and a plurality of prestressed hoops arranged outside the sheath; one side of each prestressed hoop is provided with a tightening device. The method comprises: (1) cleaning loose concrete of a damaged region, and straightening bent rebars; (2) casting early strength fast-hardening concrete to the damaged region so that the cross-sectional area of the damaged region is restored to the original pier column level; (3) fixing stainless steel sheets that are cut in advance in a factory, to the outside of the damaged region of a pier, and connecting by welding after wrapping; (4) mounting prestressed hoops outside the sheets, and tightening the prestressed hoops with a wrench. The pier repairing apparatus based on the lightweight prestressed stainless steel sheath has the advantages that a damaged pier can be repairedwithin 24 hours, large-sized machinery for operation is not required, and operating can be performed only with few workers; the bearing capacity and ductility of the repaired prier can reach or exceed those of the original pier, and the requirements of post-disaster repairing for high speed and good economy can be met.

Owner:TIANJIN UNIV

H section steel girder-column minor axis connecting end plate node and preparing method of H section steel girder-column minor axis connecting end plate node

ActiveCN104213644AImprove overall stiffness and bearing capacityHigh compressive strengthBuilding constructionsSteel columnsMinor axis

The invention discloses an H section steel girder-column minor axis connecting end plate node and a preparing method of the H section steel girder-column minor axis connecting end plate node, wherein the H section steel girder-column minor axis connecting end plate node is characterized in that a T-shaped combined body consisting of a node plate and a stiffening plate is welded on an H section steel column, a supporting plate is welded at the bottom of the T-shaped combined body, an end plate is welded at one end of the H section steel column, the node plate and the end plate are connected through high-strength bolts, and two spaces defined by the H section steel column, the T-shaped combined body and the supporting plate are filled with concrete fillers. The preparing method comprises the following steps that the node plate and the stiffening plate are welded into the T-shaped combined body; the T-shaped combined body and the supporting plate are welded on the H section steel column; the end plate is welded on the H section steel column; the end plate and the node plate are connected by the high-strength bolts; a rectangular region of a node area is poured with concrete. The H section steel girder-column minor axis connecting end plate node and the preparing method have the advantages that the respective advantages of steel and concrete are fully utilized, the anti-seismic performance is good, the bearing capability is great, and the construction is simple and convenient.

Owner:INNER MONGOLIA UNIV OF SCI & TECH

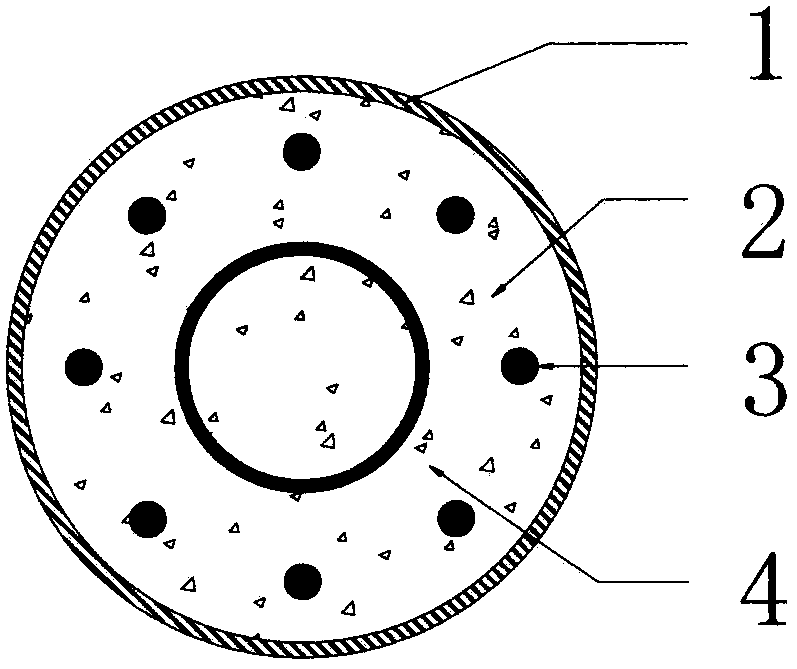

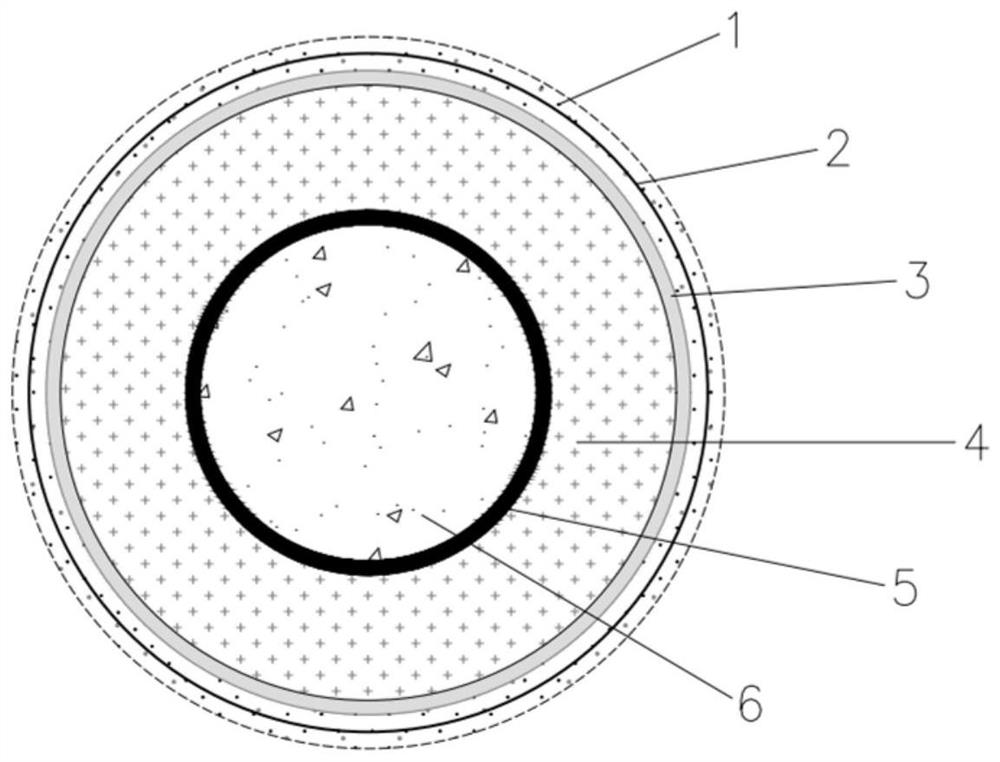

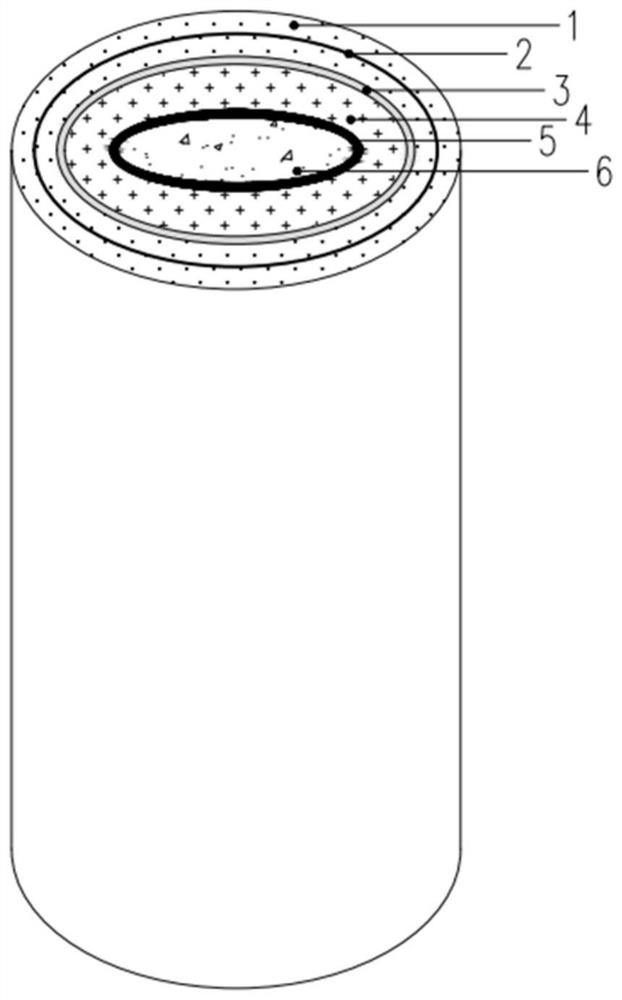

Concrete-filled steel tube column with ECC reinforced protective layer and FRP confined concrete core column and construction method and application of concrete-filled steel tube column

PendingCN113089933ALighten the burden of restraintConstrained Lateral ExpansionStrutsClimate change adaptationSteel tubeGeotechnical engineering

The invention relates to a concrete-filled steel tube column with an ECC reinforced protective layer and an FRP confined concrete core column. The concrete-filled steel tube column comprises an ECC layer, a steel tube layer, a concrete layer, an FRP tube layer and a core concrete core column which are sequentially arranged from outside to inside, wherein the concrete layer is made of common concrete, high-strength concrete, expansive concrete, fly ash concrete, lightweight aggregate concrete and the like, and the core concrete core column is made of common concrete, high-strength concrete, expansive concrete, fly ash concrete, lightweight aggregate concrete and the like. The invention further relates to a construction method of the concrete-filled steel tube column with the ECC reinforced protective layer and the FRP confined concrete core column and application of the concrete-filled steel tube column with the ECC reinforced protective layer and the FRP confined concrete core column. According to the concrete-filled steel tube column, the stress performance, the fire resistance and the durability can be improved, and the concrete-filled steel tube column belongs to the technical field of building structures.

Owner:SOUTH CHINA UNIV OF TECH

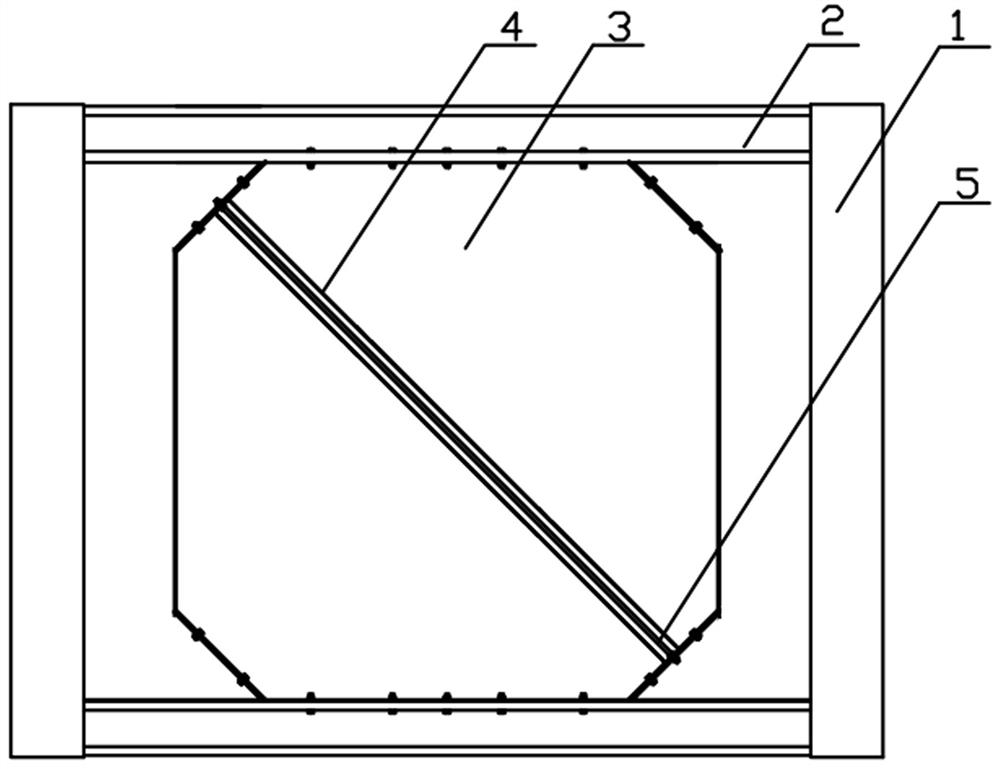

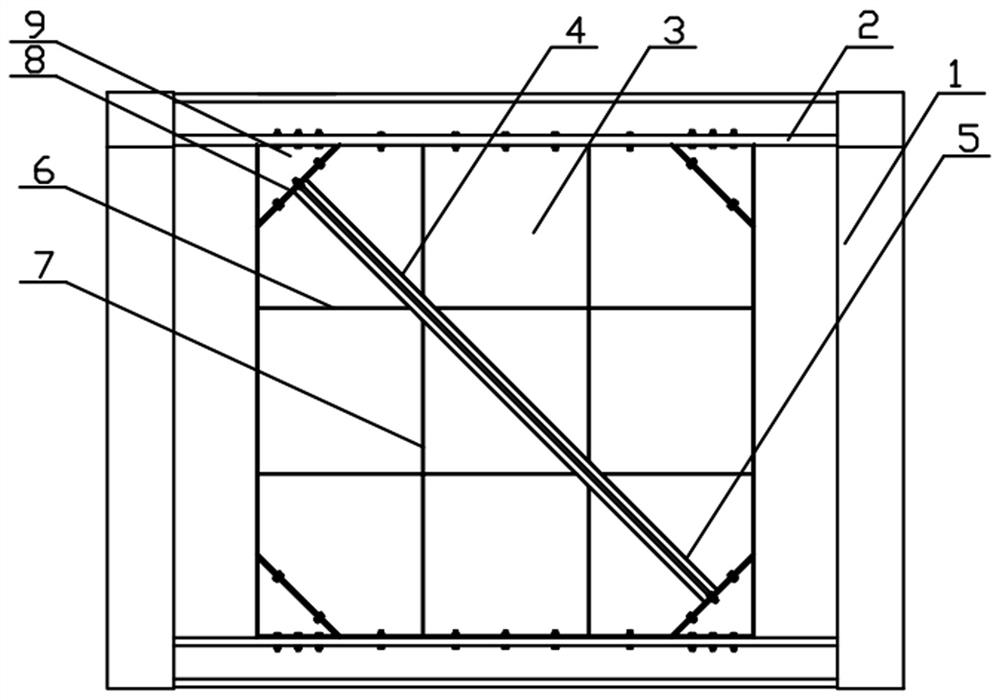

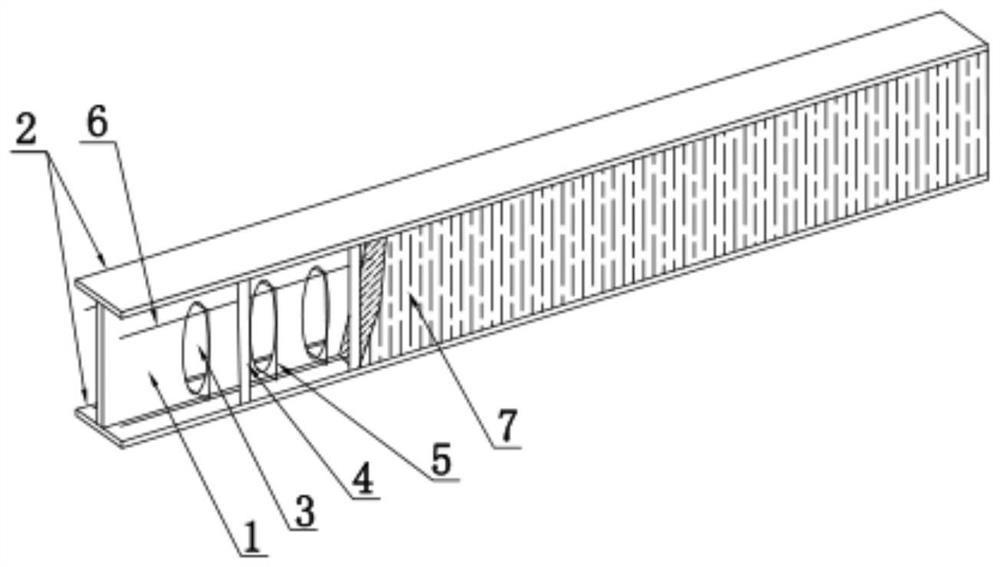

SMA-based self-resetting assembly type steel plate shear wall and construction and installation method thereof

PendingCN112854541AAchieving self-resetting capabilityPreventing destructive collapse of structuresWallsProtective buildings/sheltersMechanical engineeringSteel plate shear wall

The invention provides an SMA-based self-resetting assembly type steel plate shear wall and a construction and installation method thereof. The shear wall comprises two structural columns, wherein at least two I-shaped steel beams are arranged between the two structural columns in parallel, an embedded steel plate with at least one set of parallel opposite sides is installed between any two adjacent I-shaped steel beams, one set of parallel opposite sides of the embedded steel plate are fixedly installed on the two I-shaped steel beams through bolts respectively, and a distance exists between the structural columns and the embedded steel plate; an SMA stranded wire unit is arranged on the embedded steel plate and comprises an SMA stranded wire channel and an SMA stranded wire, the SMA stranded wire channel comprises two stiffening ribs arranged on the embedded steel plate in parallel, the SMA stranded wire is located in the SMA stranded wire channel, and the two ends of the SMA stranded wire are fixedly installed on the embedded steel plate respectively; and the shear wall further comprises a plurality of auxiliary connecting devices, and the two side edges of each auxiliary connecting device are connected with the I-shaped steel beams and the embedded steel plate through bolts respectively.

Owner:ZHENGZHOU UNIV

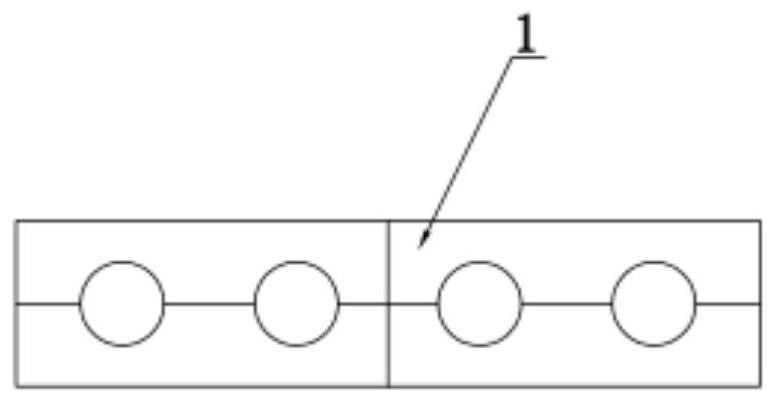

Method for manufacturing recycled concrete column partially wrapped by prefabricated honeycomb profile steel

PendingCN114800769ANode connection is convenientImprove fire performanceCeramic shaping apparatusConstruction engineeringHoneycomb

The invention relates to a manufacturing method of a prefabricated honeycomb profile steel partially wrapped recycled concrete column. The manufacturing method is characterized by comprising the following steps of a, honeycomb profile steel manufacturing, b, steel reinforcement framework manufacturing and mounting, c, recycled concrete manufacturing, d, recycled concrete pouring and e, formwork dismounting. By the adoption of the technical scheme, recycled concrete can be effectively utilized, and low carbon and environment friendliness are achieved; the flexural rigidity of the column body is greatly improved, the bearing capacity of the component is effectively improved, and the corrosion / fire resistance is better; in addition, the meshing force between the section steel and the recycled concrete in the recycled concrete column partially wrapped by the honeycomb section steel is greatly enhanced, single-face one-time pouring can be achieved during prefabricated pouring, use of formworks is greatly reduced, construction is easy, and the construction time is greatly shortened.

Owner:SOUTHWEST UNIVERSITY

A Method for Inhibiting Buckling in Creep-Aging Forming of Aluminum Alloy Components with Complex Curvature

ActiveCN111575615BIncrease stiffnessInhibition of bucklingFurnace typesHeat treatment furnacesAge formingAluminium alloy

The invention discloses a method for suppressing buckling in the creep aging forming of aluminum alloy components with complex curvature, which comprises first pasting and fixing a restraint plate on the peripheral position of the upper surface of the base metal aluminum alloy plate, and then attaching the restraint plate and the base metal aluminum alloy plate together Wrap it in air felt, and lay a vacuum bag to form a closed space. After vacuum treatment, put the above-mentioned treated whole and mold together into an autoclave for creep aging forming to obtain an aluminum alloy component with complex curvature. The invention considers that the stiffness of the member is insufficient during the loading process, and the buckling is suppressed by arranging a restraint plate on the load-bearing side of the member to suppress buckling, and does not need an additional device for applying blank holder force, and can be applied to hot pressing commonly used in creep aging forming In the tank device, the occurrence of buckling is effectively suppressed, and the forming quality is improved; the risk of vacuum film damage is reduced, the forming accuracy is improved, and the probability of component success is increased; at the same time, the blank holder area does not need to be reserved before sheet forming, Conducive to the near-net shape of the component.

Owner:CENT SOUTH UNIV

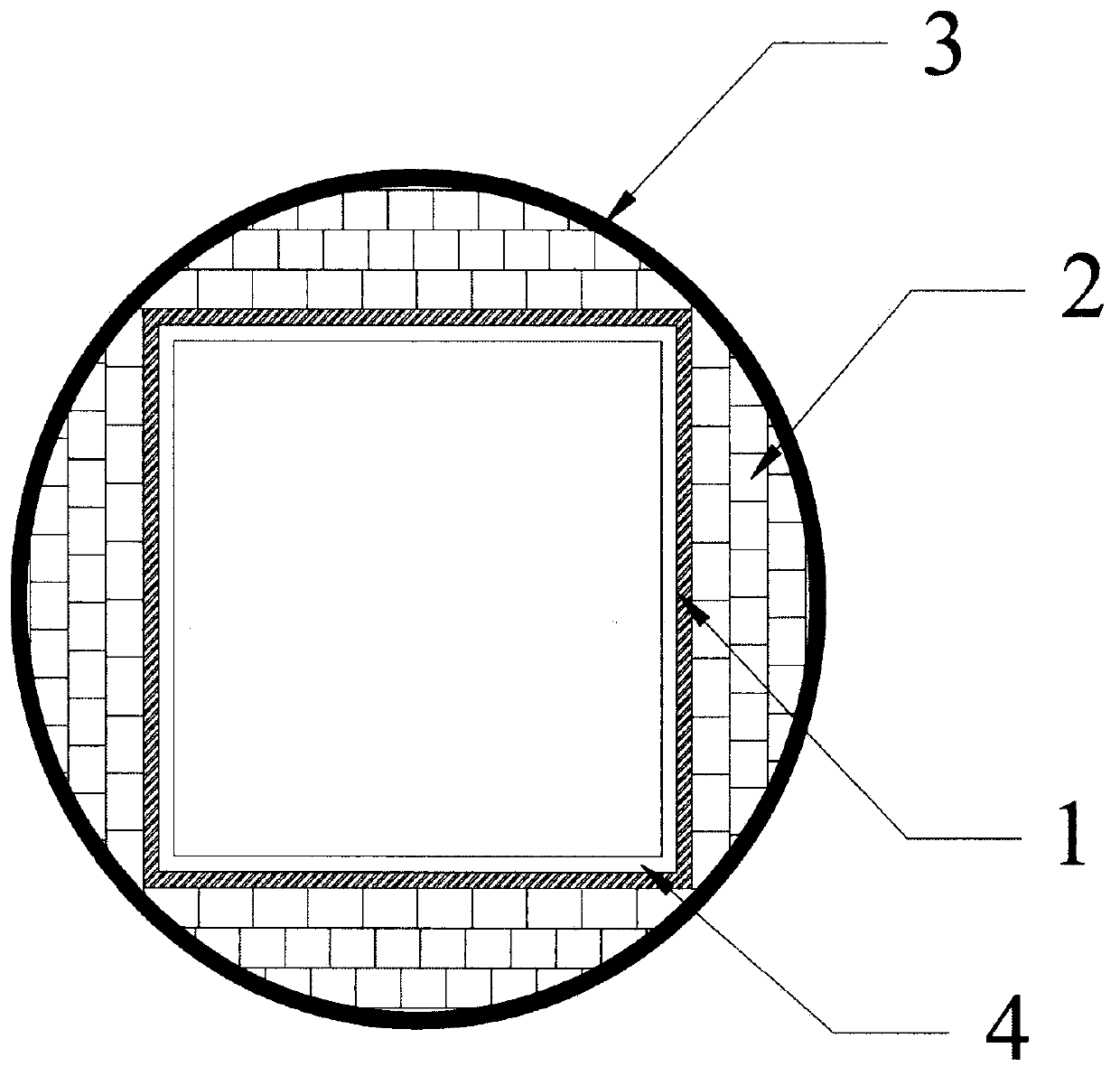

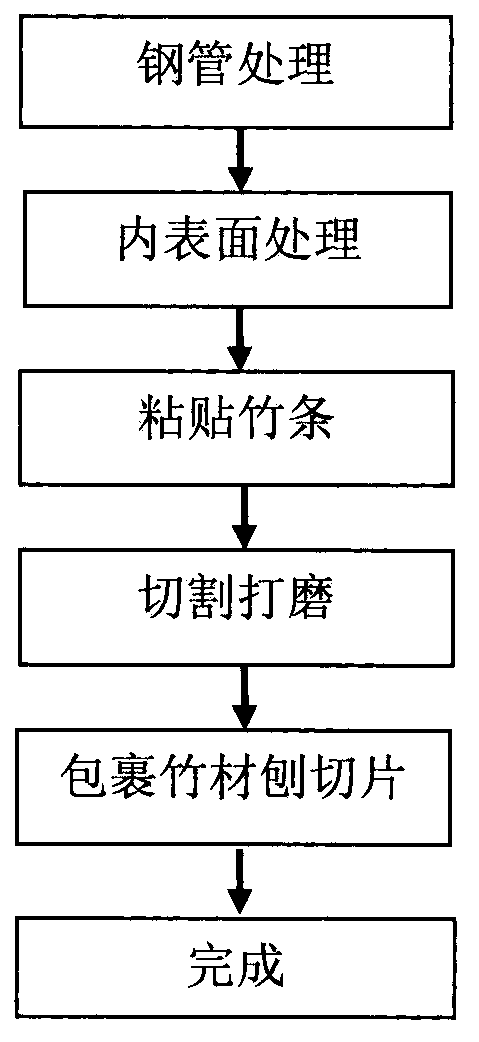

Steel-bamboo combination pipe and manufacturing method thereof

PendingCN110067307AImprove binding abilityDo not change dosageStrutsGirdersFiber orientationResin adhesive

The invention discloses a steel-bamboo combination pipe. The interior of an inner steel pipe is hollow, the inner surface of the inner steel pipe is coated with an inner protective layer, the outer surface of the inner steel pipe is glued with one or more layers of bamboo strips through resin adhesive, cross-sectional areas of the one or more layers of bamboo strips are not less than 1.5 times ofa cross-sectional area of the inner steel pipe, the length direction of the bamboo strips is consistent with the height direction of the inner steel pipe, every two adjacent layers of bamboo strips are glued and spliced with each other to be combined into a predetermined cross-sectional shape, the outside of the outermost layer of bamboo strips is continuously wrapped with one or more layers of bamboo slicing slices to constitute a protective barrier and an outer restraint, and the bamboo fiber direction of the bamboo slicing slices is perpendicular to an axis of the inner steel pipe. The steel-bamboo combination pipe is easy and convenient to manufacture, good in integrity, high in bearing capacity, good in durability, and high in architectural aesthetics, the composite bamboo strips glued on the periphery have the function of auxiliary bearing, the wound bamboo slicing slices have the strong restraint function, thus buckling of the steel pipe is restrained, and according to the steel-bamboo combination pipe, a new product is provided for construction of ecological buildings.

Owner:NANJING FORESTRY UNIV

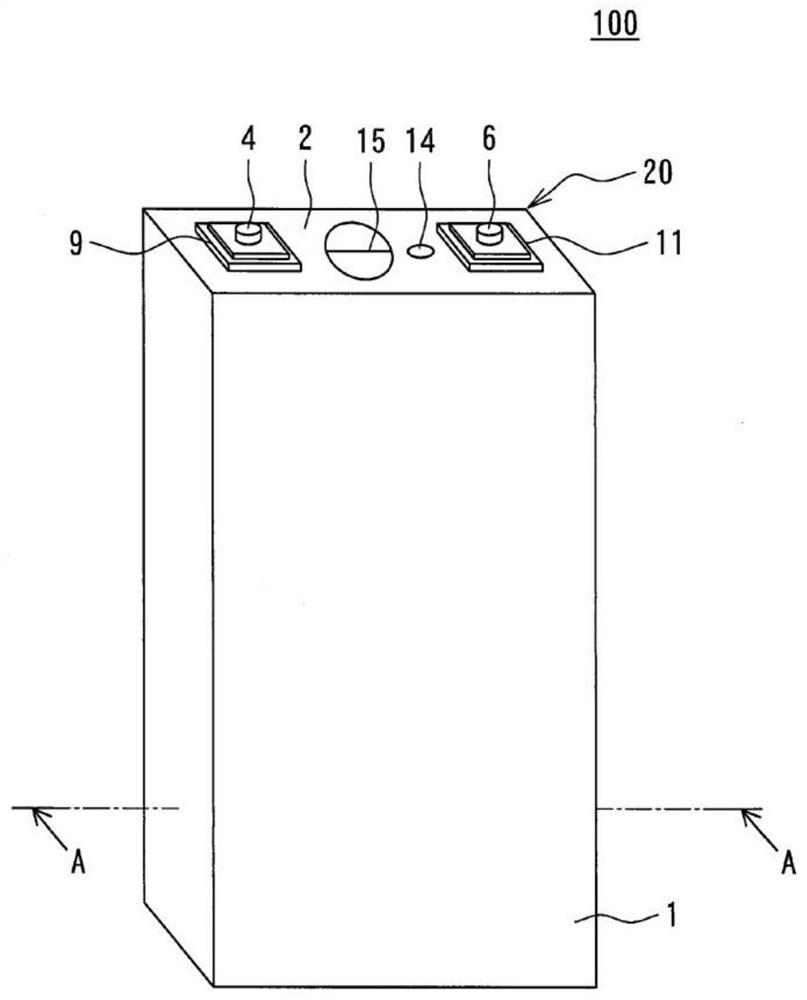

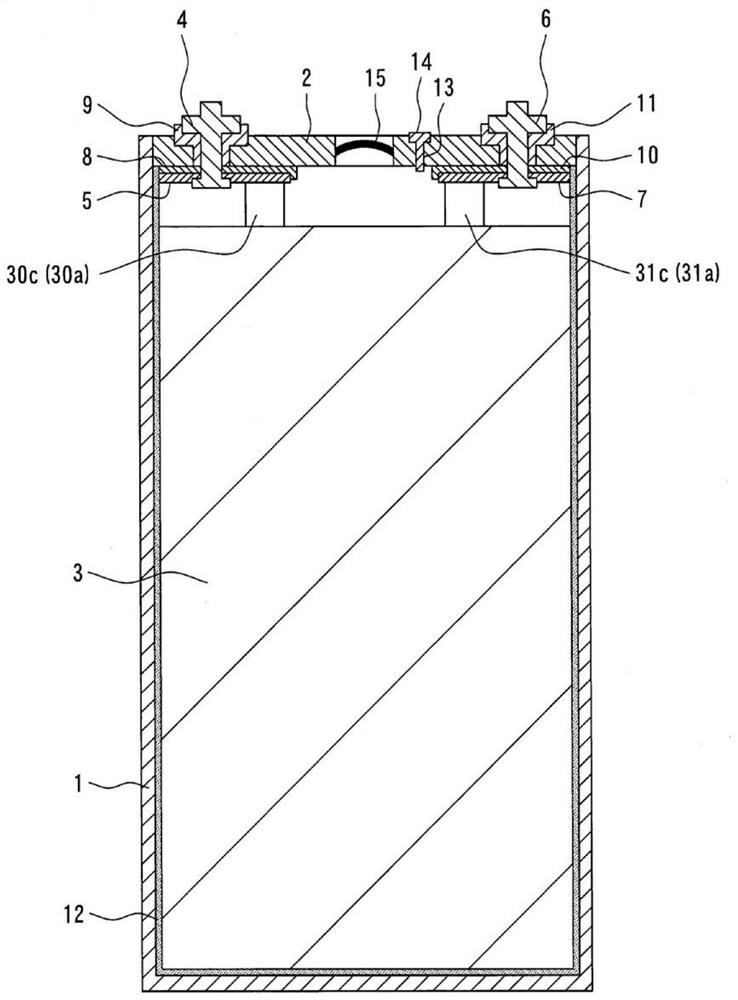

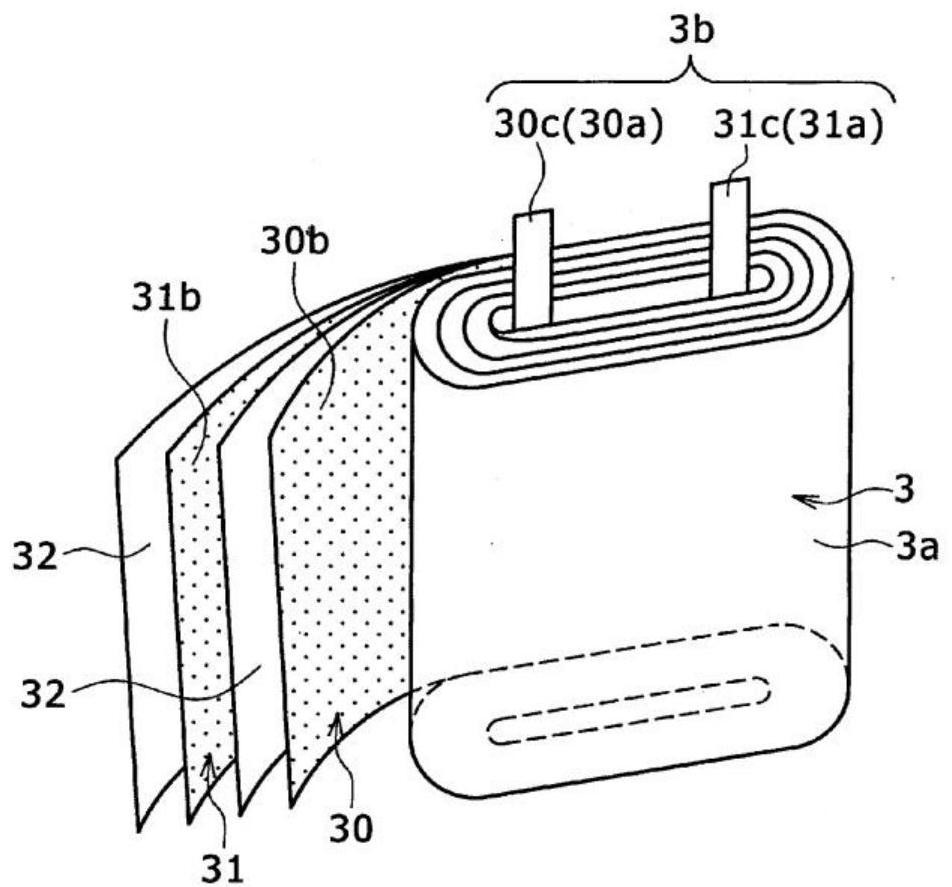

Method for manufacturing nonaqueous electrolyte secondary battery and nonaqueous electrolyte secondary battery

PendingCN113396492ACrack suppressionInhibition of bucklingFinal product manufactureWound/folded electrode electrodesLithium metalMixed materials

The nonaqueous electrolyte secondary battery according to one embodiment of the present invention includes a flat wound electrode body in which a positive plate and a negative plate are wound via a separator and is characterized in that the positive plate has a positive core and a positive mixed material layer that is formed on both sides of the positive core, the positive mixed material layer includes a lithium metal composite oxide represented by general formula Li1+xMaO2+b (in the formula, x, a, and b satisfy the conditions x+a=1, -0.2<x <= 0.2, and -0.1<=b<=0.1, and M includes Ni and Co and at least one element selected from the group consisting of Mn and Al), and the positive plate has a flexibility index of 15 to 19. Such a positive plate is capable of having a high packing density while suppressing cracks in the positive mixed material layer and buckling of the positive plate and the negative plate.

Owner:SANYO ELECTRIC CO LTD

Electric pressure fan and electric dust collector having the same

ActiveCN102235384BPrevent peelingInhibition of refluxPump componentsSuction cleanersDust collectorAirflow

The invention provides an electric pressure fan and an electric dust collector having the same, with which the situation that air flow from a shield to a wheel hub becomes uneven is prevented; the matching between a static blade disposed at the downstream of a rotating blade and the airflow is realized; the internal loss of the rotating blade and the peeling loss of the internal static blade are reduced. As for the blade, near an inlet, the shield side of the blade inclines towards a rotation direction and then faces the outer edge of the blade. The inclination of the shield side approaches awheel hub side, turning into an approximately two-dimensional shape facing the outer edge of the blade, and the shield side of the blade inclines towards a direction opposite to the rotation direction. When the blade approaches to the outer edge, the inclination towards the direction opposite to the rotation direction is reduced and an approximately two-dimensional shape is formed near the outer edge. Observed from an axial direction, two approximately two-dimensional shapes are provided from the inner edge of the blade to the outer edge of the blade, and inclining shapes with changed rotation direction are provided before and after the approximately two-dimensional shapes.

Owner:HITACHI GLOBAL LIFE SOLUTIONS INC

H-shaped steel beam-column weak axis connection end plate joint and preparation method

ActiveCN104213644BIncrease stiffnessImprove bearing capacityBuilding constructionsSteel columnsMinor axis

The invention discloses an H section steel girder-column minor axis connecting end plate node and a preparing method of the H section steel girder-column minor axis connecting end plate node, wherein the H section steel girder-column minor axis connecting end plate node is characterized in that a T-shaped combined body consisting of a node plate and a stiffening plate is welded on an H section steel column, a supporting plate is welded at the bottom of the T-shaped combined body, an end plate is welded at one end of the H section steel column, the node plate and the end plate are connected through high-strength bolts, and two spaces defined by the H section steel column, the T-shaped combined body and the supporting plate are filled with concrete fillers. The preparing method comprises the following steps that the node plate and the stiffening plate are welded into the T-shaped combined body; the T-shaped combined body and the supporting plate are welded on the H section steel column; the end plate is welded on the H section steel column; the end plate and the node plate are connected by the high-strength bolts; a rectangular region of a node area is poured with concrete. The H section steel girder-column minor axis connecting end plate node and the preparing method have the advantages that the respective advantages of steel and concrete are fully utilized, the anti-seismic performance is good, the bearing capability is great, and the construction is simple and convenient.

Owner:INNER MONGOLIA UNIV OF SCI & TECH

A prefabricated bridge double-column pier with triple energy dissipation system

ActiveCN112502035BForce mechanism is clearEasy to analyzeBridge structural detailsArchitectural engineeringPier

The invention provides an assembled bridge double-column pier with a triple energy consumption system, which includes a bearing platform, a steel pipe concrete pier is installed on the left and right sides of the upper part of the bearing platform, and extrusion damping is arranged between the steel pipe concrete bridge pier and the bearing platform Concrete-filled steel tube cover beams are installed between the concrete-filled steel tube piers on both sides. The left and right ends of the concrete-filled steel tube cover beams are respectively equipped with steel shear ear plates. The other end is fixed to the concrete-filled steel pipe pier by bolts; a cymbal-shaped disc reed is arranged above the steel shear ear plate, and the cymbal-shaped disc reed is located between the concrete-filled steel pipe pier and the concrete-filled steel pipe cover beam; An anti-buckling plate assembly is installed under the ear-shearing plate. One end of the anti-buckling plate assembly is fixed to the concrete-filled steel tube pier through bolts, and the other end is fixed to the concrete-filled steel tube cap beam through bolts. By setting a triple energy dissipation system, the design is facilitated. And construction, to avoid damage and damage occurred under strong earthquakes.

Owner:INST OF DISASTER PREVENTION

Double-steel-pipe concrete joint of externally-wrapped composite winding pipe and preparation method of double-steel-pipe concrete joint

PendingCN113668695ASimplify construction difficultyAchieve transformationBuilding constructionsEngineeringPipe layer

The invention relates to a double-steel-pipe concrete joint of an externally-wrapped composite winding pipe, and belongs to the technical field of building structures. The double-steel-pipe concrete joint comprises a main part and at least one auxiliary part, the structure of the main part is the same as that of the auxiliary part, and each of the main part and the auxiliary part comprises a composite winding pipe layer, an outer steel pipe layer, a concrete layer and an inner steel pipe layer which are sequentially arranged from outside to inside; the concrete layer is arranged between the inner steel pipe layer and the outer steel pipe layer in a pouring mode; a plurality of connecting parts are arranged between the outer steel pipe layer and the inner steel pipe layer, and the inner steel pipe layer and the outer steel pipe layer are fixedly connected through the connecting parts to form a double-steel-pipe section; and the double-steel-pipe section of the auxiliary part is fixedly connected with the outer side wall of the outer steel pipe of the double-steel-pipe section of the main part. The invention further relates to a preparation method of the double-steel-pipe concrete joint of the externally-wrapped composite winding pipe. The double-steel-pipe concrete joint of the externally-wrapped composite winding pipe is convenient to splice, simple in construction process and easy to process and manufacture.

Owner:SOUTH CHINA UNIV OF TECH +1

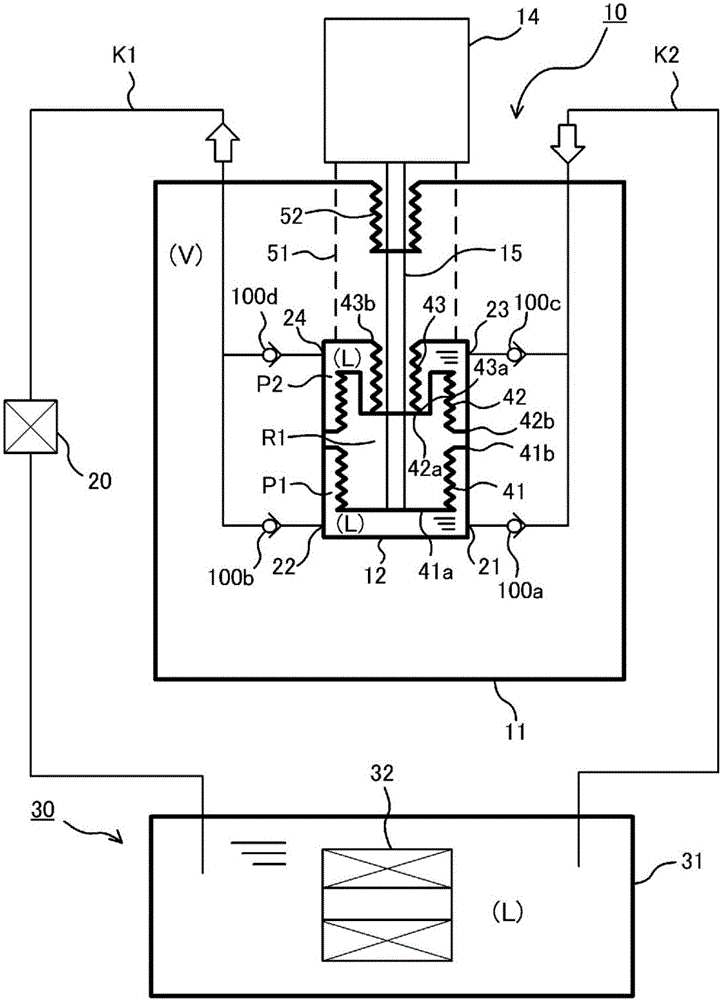

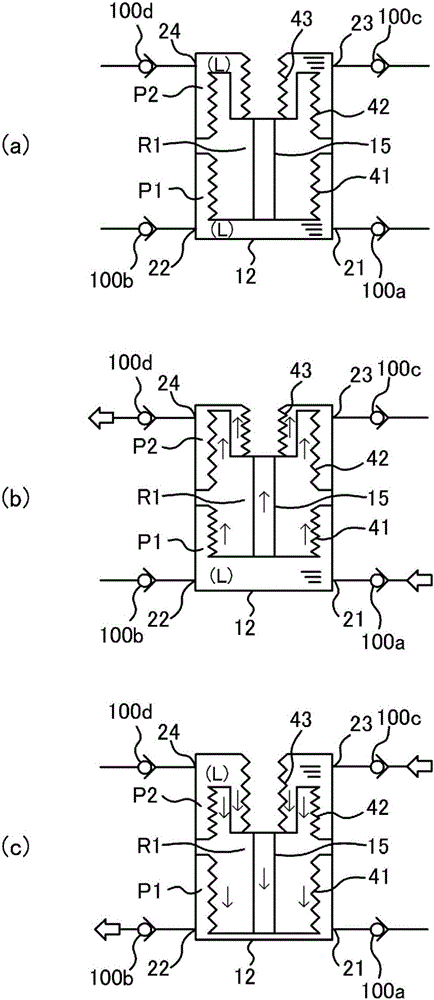

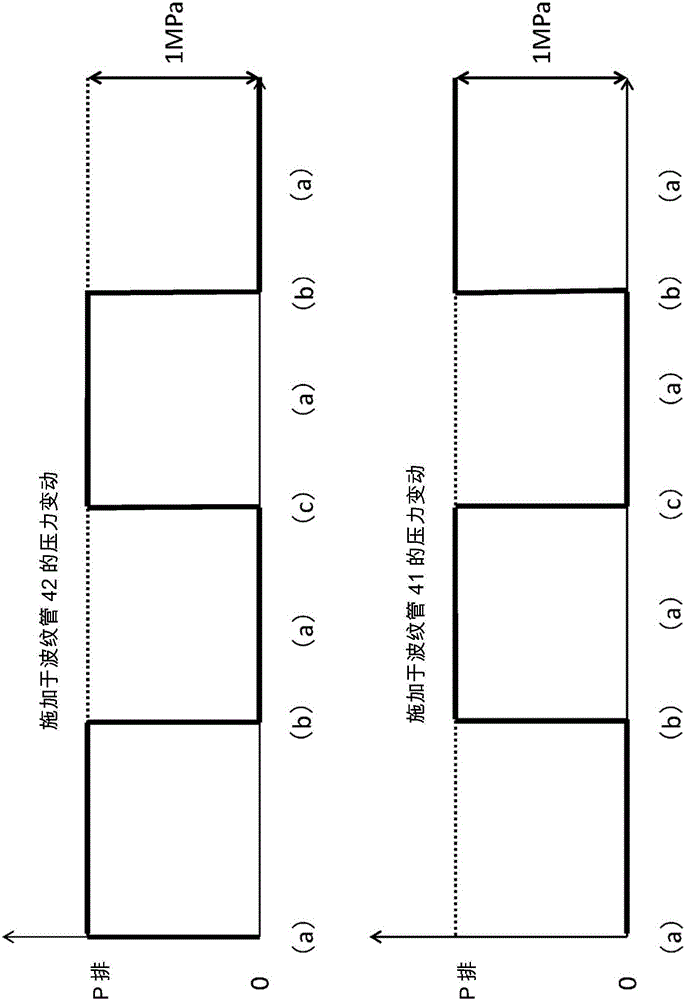

Liquid supply system

ActiveCN106662372AInhibition of bucklingImprove stabilityFlexible member pumpsCompression machinesPump chamberEngineering

Provided is a liquid supply system with an improved pumping function. The liquid supply system includes first and second bellows 41 and 42 arranged in series in an expanding / contracting direction thereof in a vessel 12 and having first end portions respectively, which are close to each other and fixed to an inner wall of the vessel 12, and also having second end portions respectively, which are distant from each other and movable in the expanding / contracting direction. An inner space of the vessel 12 located outside the first bellows 41 serves as a first pump chamber P1. An inner space of the vessel 12 located outside the second bellows 42 serves as a second pump chamber P2. An inner space of the vessel 12 located inside the first and second bellows 41 and 42 serves as a sealed space R1. A shaft 15 to which the respective second end portions of the first and second bellows 41 and 42 are fixed is reciprocally moved to expand / contract the first and second bellows 41 and 42.

Owner:EAGLE INDS

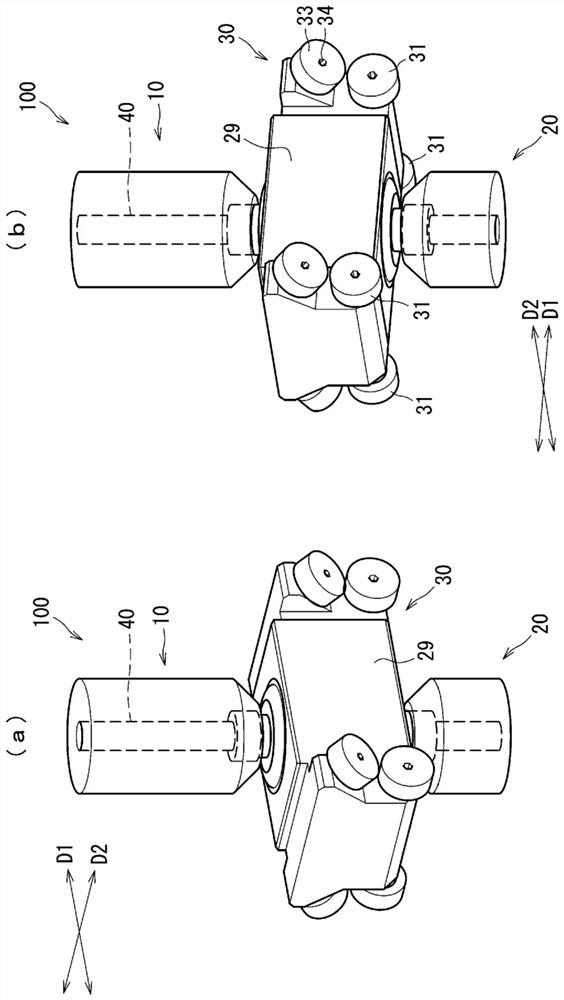

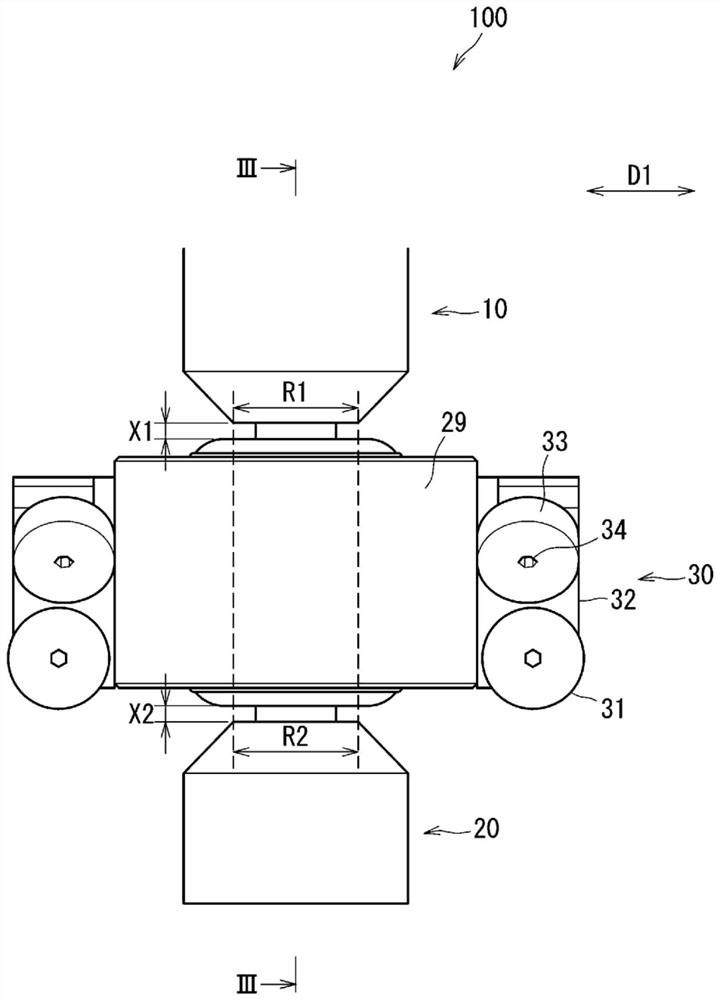

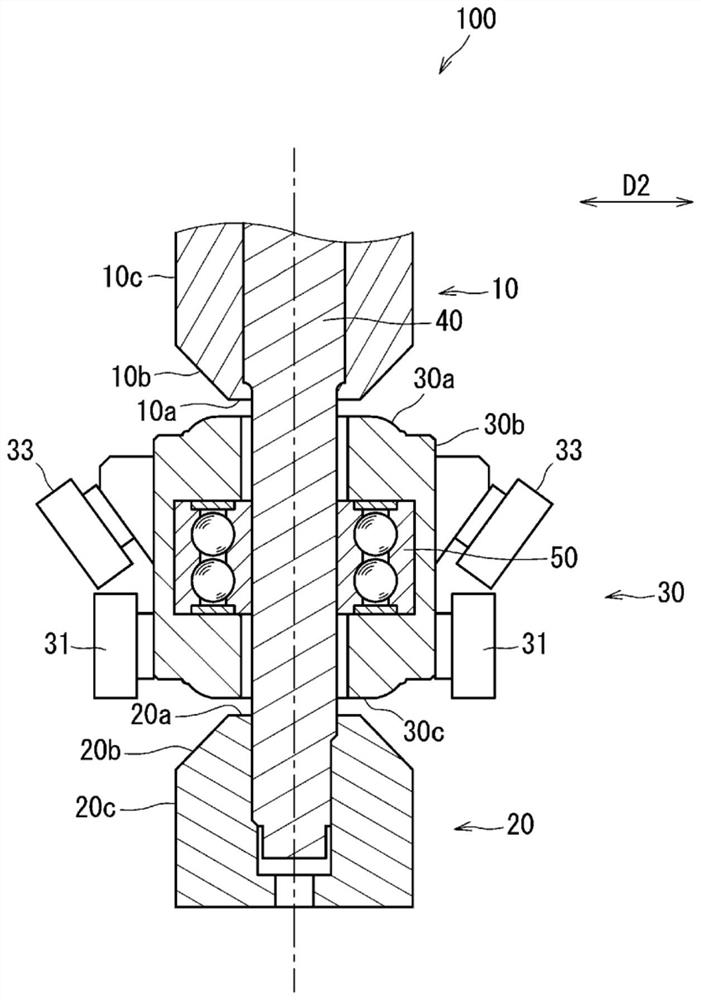

Friction stir welding tool and friction stir welding method

ActiveCN113015593AInhibition of bucklingIncreased durabilityMetal working apparatusHollow articlesEngineeringFriction stir welding

The present invention provides a friction stir welding tool and a friction stir welding method such that even if a resistance involved in a movement of a friction stir welding tool (100) for welding acts on end portions of works on sides where the friction stir welding tool is attached, an influence resulted therefrom on durability of the friction stir welding tool is suppressed, the end portions being abutted against each other. The friction stir welding tool (100) is provided with: a stir shaft; a first shoulder portion (10) and a second shoulder portion (20) which are provided so as to be incapable of rotating relatively between those and the stir shaft, and are rotated with the stir shaft when the stir shaft is rotated; and a third shoulder portion (30) attached on a position between the first shoulder portion (10) and the second shoulder portion (20) around the stir shaft. The third shoulder portion (30) has an inclination stopping unit (39) which is brought into contact with the work at a time when the stir shaft is moved along a welding line, and receives a reaction force (F3) from the work, thereby stopping an inclination of the stir shaft.

Owner:KAWASAKI HEAVY IND LTD

Shaver

ActiveCN114710953AInhibition of bucklingAvoid recoveryMetal working apparatusStructural engineeringKnife blades

The razor according to the present invention is provided with a grip section to be gripped by a user, a head support section integrally formed with the grip section, and a razor head mounted on the head support section, the razor being assembled by bending, the grip section and the head support section being all formed from paper, and the razor head being attached to the grip section. The whole shaver head is made of metal and is provided with a blade body and a frame body for accommodating the blade body, the head supporting part is provided with two end supporting parts for supporting at least two end parts of the shaver head in the width direction, and the frame body is provided with a notch part in at least one part of the peripheral edge part. And a cutout part which is formed from a side opposite to the head support part, through which hair cut by the blade body can pass, and which is provided with a force point part when the razor head is separated from the head support part.

Owner:KAI R&D CENT CO LTD

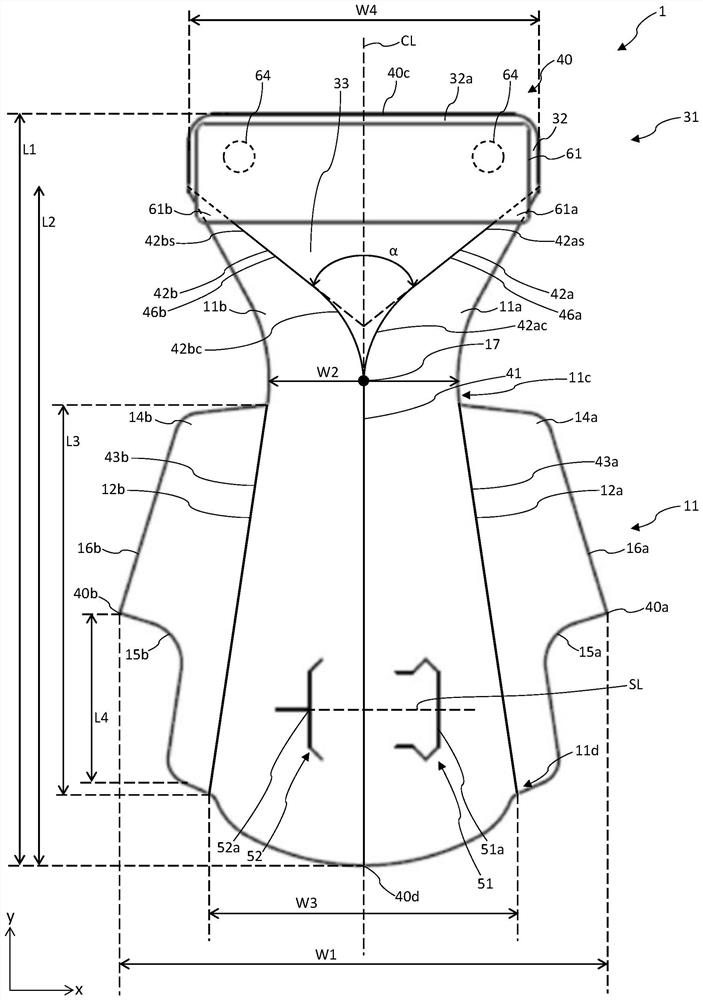

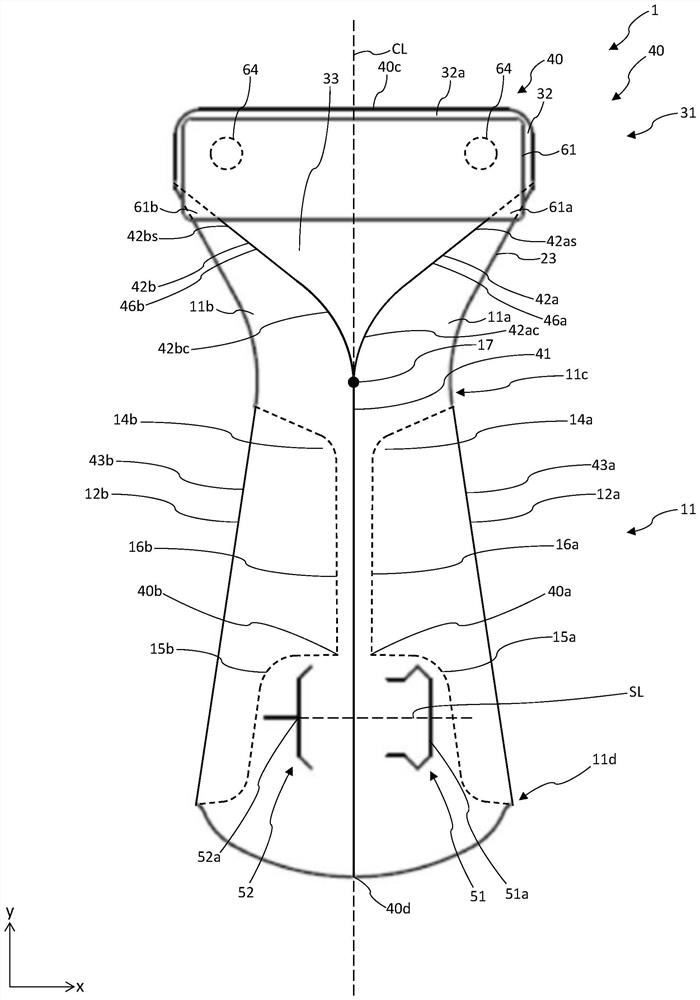

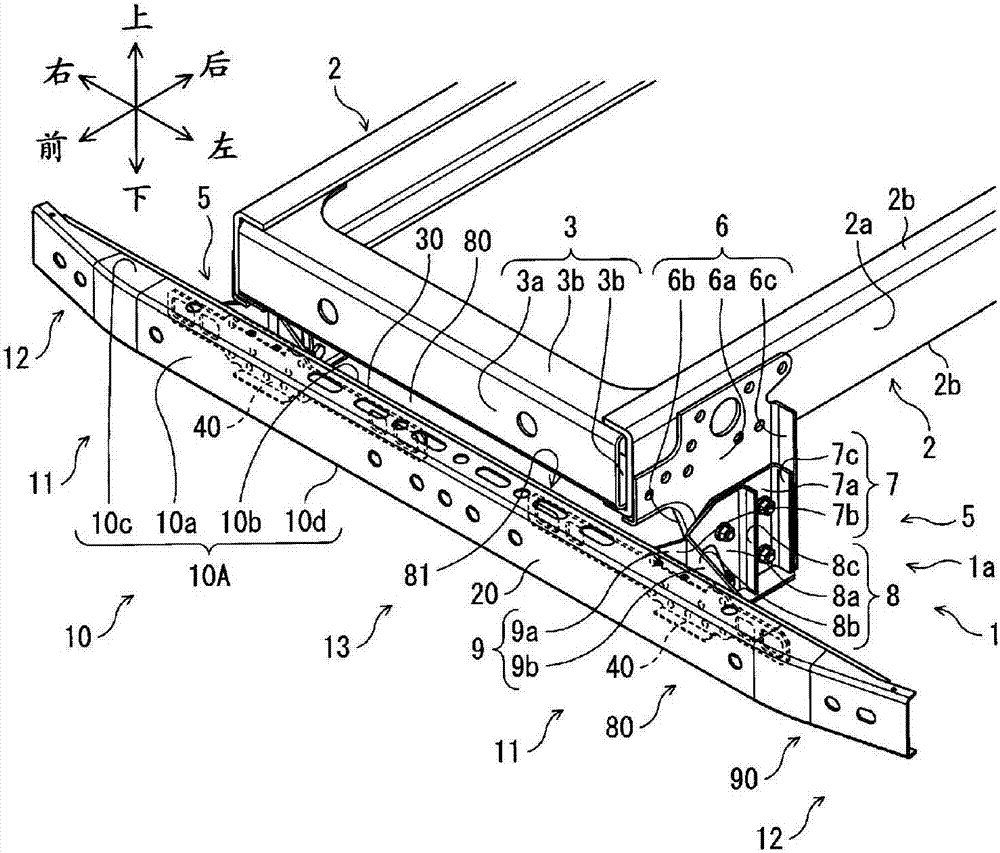

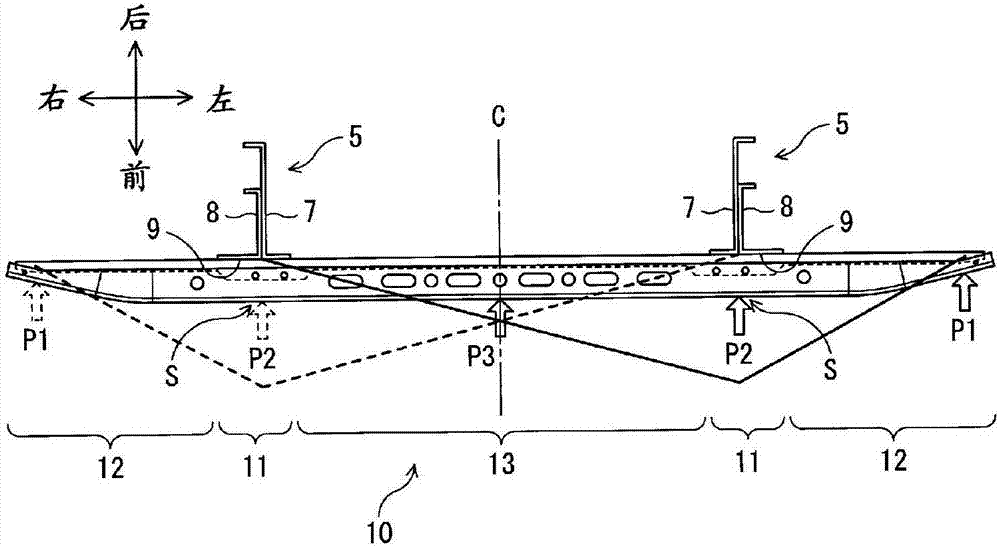

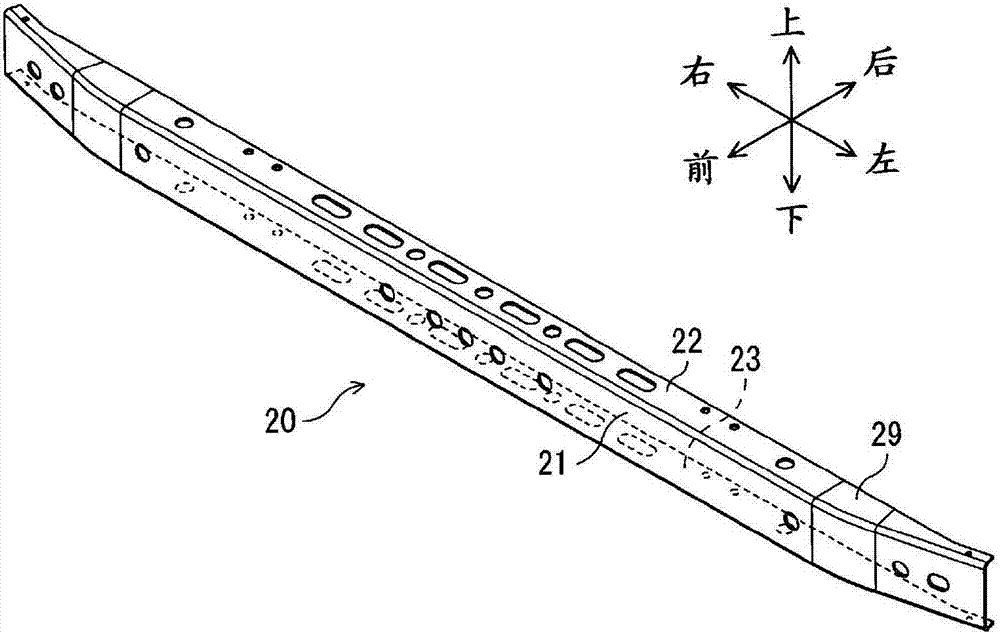

Structure of anti-drilling protection device

An underrun protection structure is provided which is low in weight, low in cost and avoids buckling. In the structure of the underrun protector (10) coupled to a plurality of brackets arranged at the front portion or the rear portion of the vehicle frame, arranged on the distal end side in the vehicle front-rear direction A distal panel (20) made of a channel-shaped steel plate is bonded to a proximal panel (30) arranged on the proximal side in the vehicle front-rear direction and made of a channel-shaped steel plate at a plurality of joint overlaps (91). , at each joint overlap, the edges (22a, 23a, 32a, 33a) of the corresponding flanges (22, 23, 32, 33) overlap; In the joint area where the respective brackets of each bracket are combined, a reinforcing panel made of steel plate is arranged in the hollow body so that the reinforcing panel is in contact with the inner face of one of the proximal panel (30) and the distal panel (20) And in contact with the joint overlapping portion (91), so that the structure has a multi-panel portion (85) formed of three or more overlapping panels.

Owner:DAIMLER TRUCK AG

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com