Densely-arrayed spiral stirrup confined concrete shear wall structure and construction method thereof

A technology for constraining concrete and spiral stirrups, applied in the direction of walls, building components, building structures, etc., can solve the problem of small quantity, and achieve the effect of reducing seismic action, using more area, and reducing the self-weight of the structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

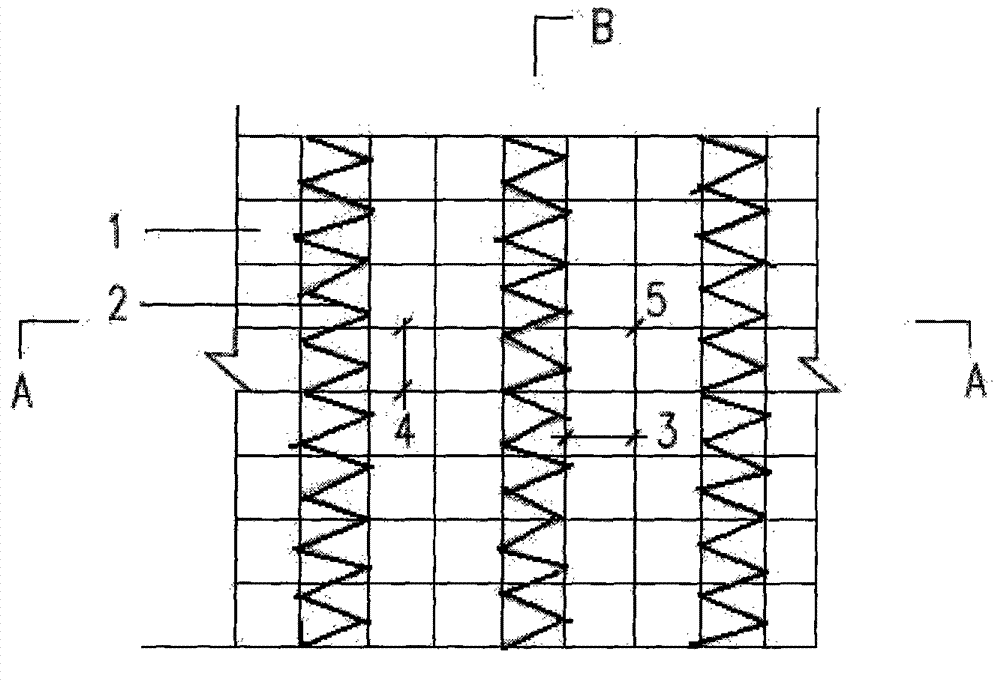

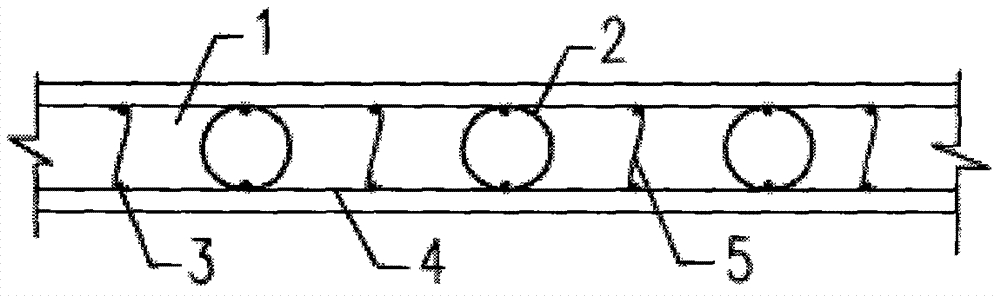

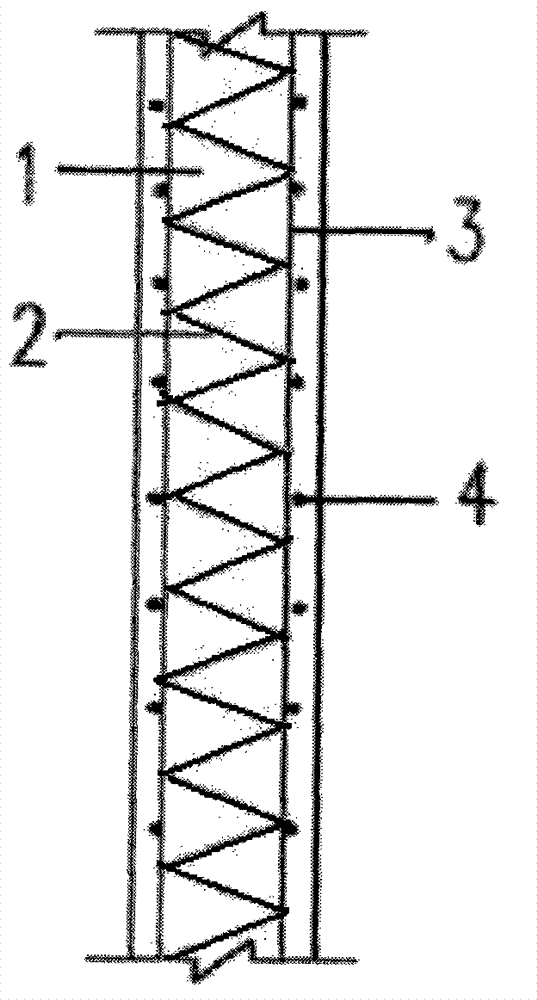

[0025] Such as figure 1 As shown, the densely packed spiral stirrup constrained concrete shear wall structure of a preferred embodiment of the present invention includes concrete 1 and spiral stirrups 2 uniformly distributed along the section of the concrete shear wall. Distributed reinforcing bars 3, horizontally distributed reinforcing bars 4, tie reinforcing bars 5 and longitudinal reinforcing bars arranged at the positions of constraining members on both sides of the spiral stirrup 2. The vertical spacing of the spiral stirrups 2 is 50-100mm. The spiral stirrups 2, the vertically distributed steel bars 3 and the horizontally distributed steel bars 4 form a double-layer distributed steel mesh in the wall. 2 to 6 times the spacing of the layer distribution reinforcement mesh, the distribution spacing of the vertical distribution reinforcement 3 and the horizontal distribution reinforcement 4 is 100-300mm, and the distribution spacing of the tie reinforcement 5 is 300-600mm. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com