Inspection fixture for printed wiring board

A technology for printed wiring boards and fixtures, applied in the directions of measurement leads/probes, measurement devices, instruments, etc., can solve problems such as insufficient response and increase in the outer diameter of the probe needle, and achieve easy exchange and stability. The effect of support

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

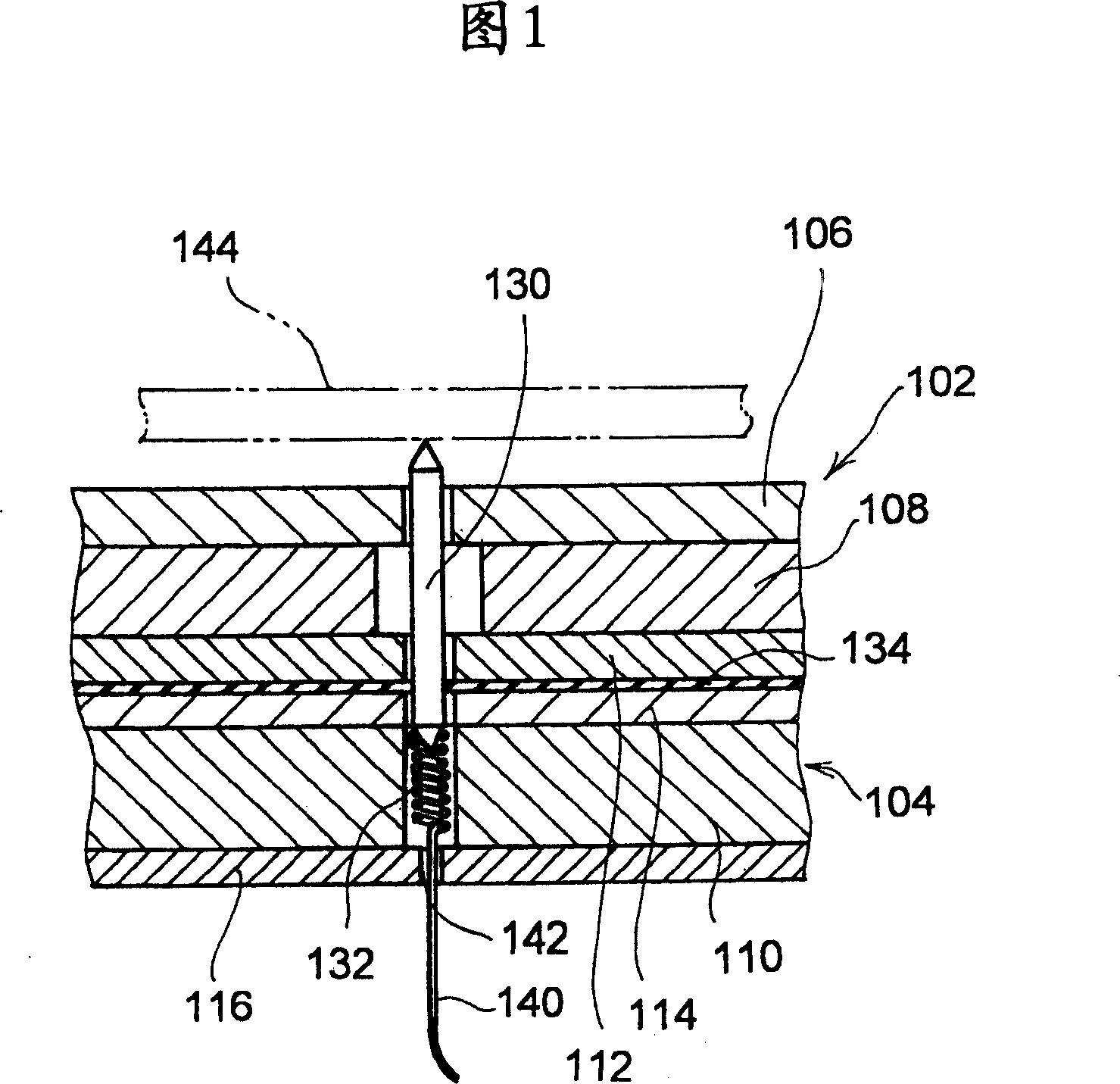

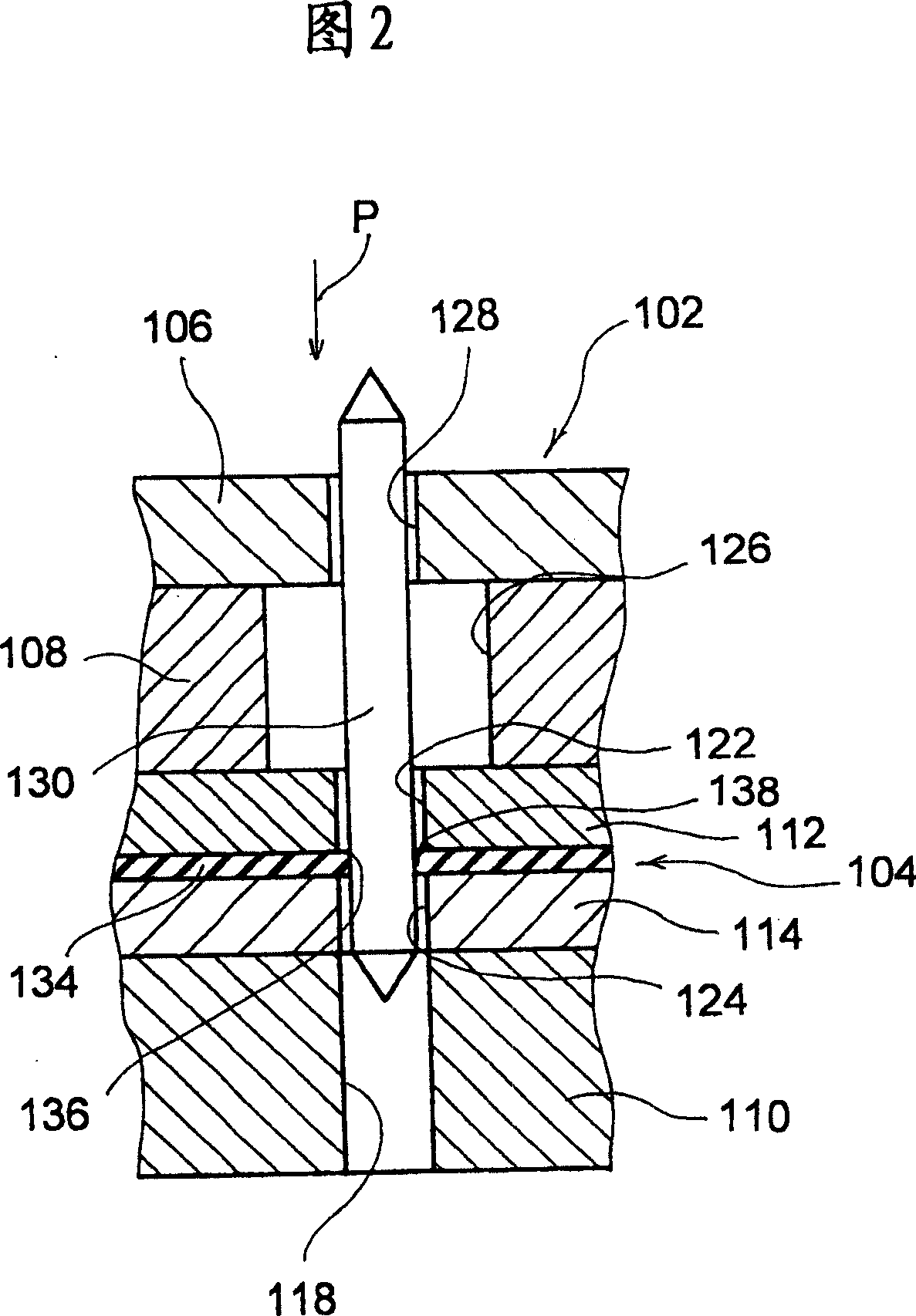

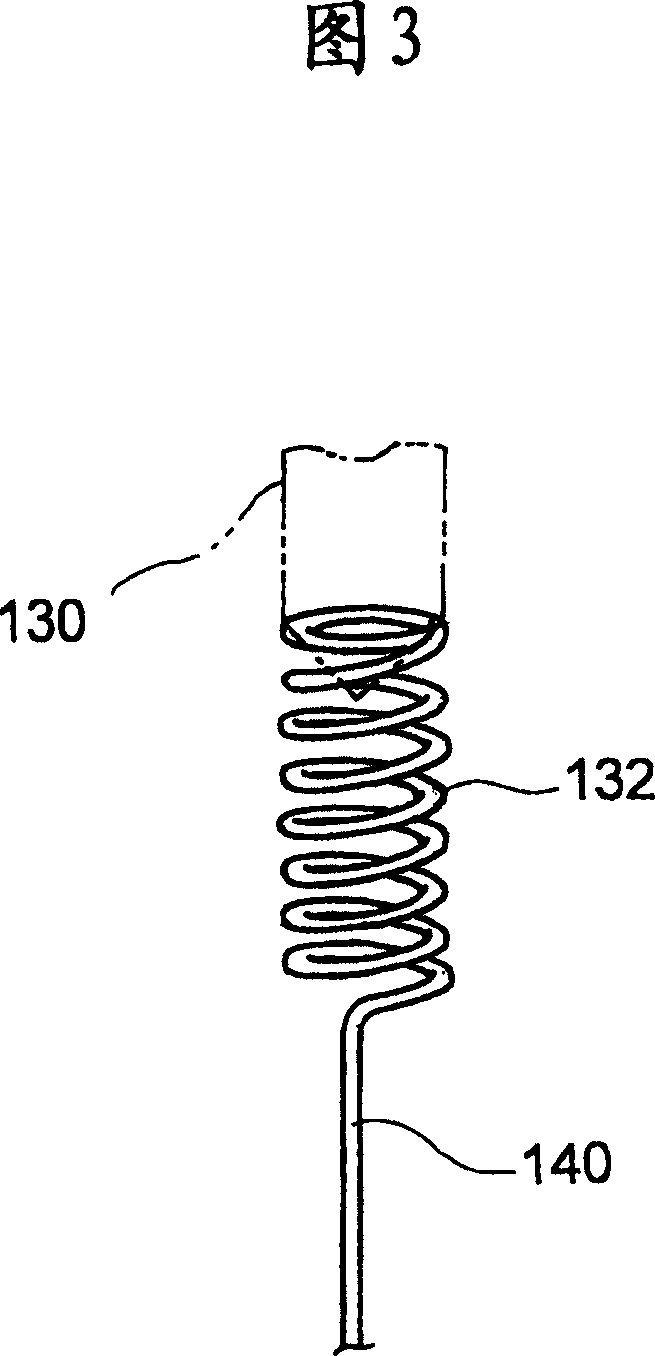

[0047] Hereinafter, the best embodiment of the printed wiring board inspection jig according to the present invention will be described with reference to FIGS. 1 to 5 . Fig. 1 is a sectional view showing an embodiment of the inspection fixture according to the present invention, Fig. 2 is an enlarged sectional view showing the main part of the inspection fixture in Fig. Front view of a magnified representation of a helical spring.

[0048] In FIGS. 1 and 2 , the inspection jig 102 shown in the figures includes a needle plate 104 , a protection plate 106 and a spacer plate 108 . The protection plate 106 is disposed on one side of the needle head plate 104 (the upper side in FIG. 1 and FIG. 2 ), and the isolation plate 108 is interposed between the needle head plate 104 and the protection plate 106 . These plates 104·106·108 are attached and fixed using, for example, nuts and bolts for fixing. In addition, the protective plate 106 and the isolation plate 108 are made of electron...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com