Spout member and packaging bag utilizing same

A technology for packaging bags and spouts, which is applied in the field of spout parts and packaging bags using the spout parts, which can solve the problems of being vulnerable to external force impact, operation convenience and pollution prevention, and easy movement of spout parts. , to achieve excellent anti-pollution, excellent sanitation management and quality management, excellent sanitation management effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

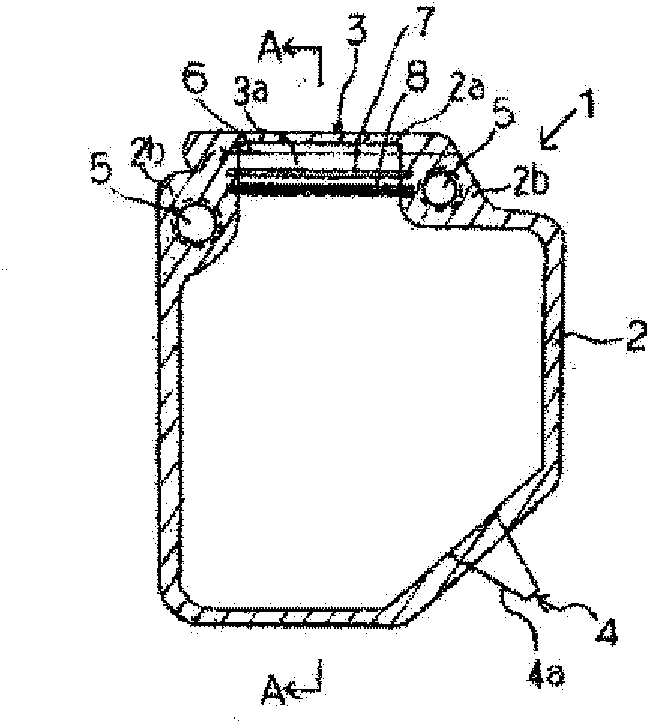

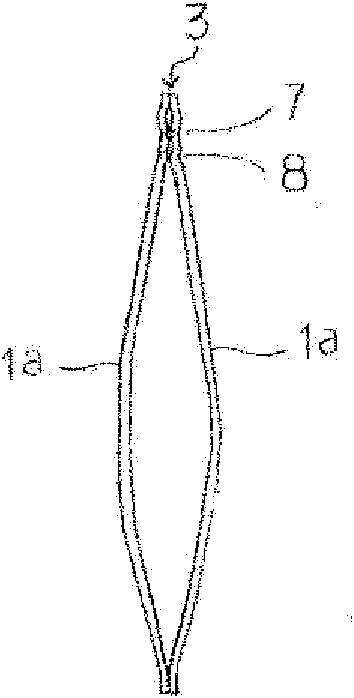

[0043] [Embodiment 1] The present invention will be described in further detail below in conjunction with the accompanying drawings. figure 1 A front view showing a packaging bag according to an embodiment of the present invention, figure 2 express figure 1 A-A sectional view of the package shown. exist figure 1 , 2 Among them, the peripheral parts 2 of the two films 1a, 1a are sealed by welding or the like as a sealing part (shown by oblique lines in the figure) to form the main body part of the packaging bag 1 . When filling the contents, a portion of the peripheral portion of the packaging bag is used as an unsealed portion and the rest is formed, and the unsealed portion is used as a filling port to fill the contents, and then the unsealed portion is sealed. Figure 14 A front view showing a packaging bag according to an embodiment of the present invention, Figure 15 express Figure 14 The structure of the X-X section of the packaging bag shown, Figure 16 express...

Embodiment approach 2

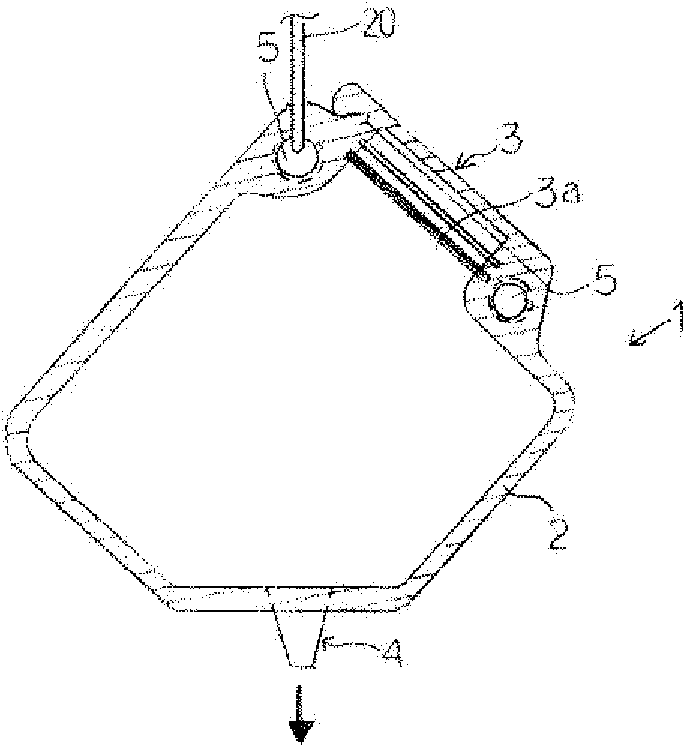

[0059] [Embodiment 2] The packaging bag according to the present invention is not limited to the above-mentioned embodiment, and the following arrangements of the injection part and the injection part can also be exemplified as the arrangement that can be poured out when hanging. Figure 9 It is a front view of another embodiment of the packaging bag of the present invention. exist Figure 9 In the present invention, the peripheral parts 22 of two films are sealed by means of welding or the like to form a sealing part (shown by oblique lines in the figure) to form the main body part of the packaging bag 21 . The peripheral portion 22 of the packaging bag 21 is provided with an injection portion 23 and an injection portion 24 . The injection part 23 is provided at a corner of the upper edge part 22a side of the peripheral part 22, and the unsealed part forming the injection port protrudes from the corner of the packaging bag. The sealing portion on both sides of the unsealed ...

Embodiment approach 3

[0060] [Embodiment 3] Figure 10 It is a front view of another embodiment of the packaging bag of the present invention. exist Figure 10 Among them, the peripheral parts 32 of two films are sealed by means of welding or the like as a sealing part (shown by oblique lines in the figure) to form the main body part of the packaging bag 31. The peripheral portion 32 of the packaging bag 31 is provided with an injection portion 33 and an injection portion 34 . The structure of the injection part 33 and figure 1 The injection part 3 in the shown packaging bag 1 is the same, and it is arranged on the upper edge part 32a side of the peripheral part 32, and two holes 35, 35 are formed through the film at the sealing parts on both sides of the unsealed part forming the injection port. 35 as the hanging mechanism when pouring out and the holding mechanism when operating the packaging bag with fingers. The spout part 34 is provided at the bottom edge part facing the injection port.

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com