Intelligent tyre warehousing system and warehousing method

A warehousing system and tire technology, applied in the field of warehousing, can solve problems such as inability to systematically manage and intelligently manage, inability to manage tires reasonably, and large equipment footprint, so as to achieve less human intervention, improve sorting efficiency and production costs , the effect of high degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

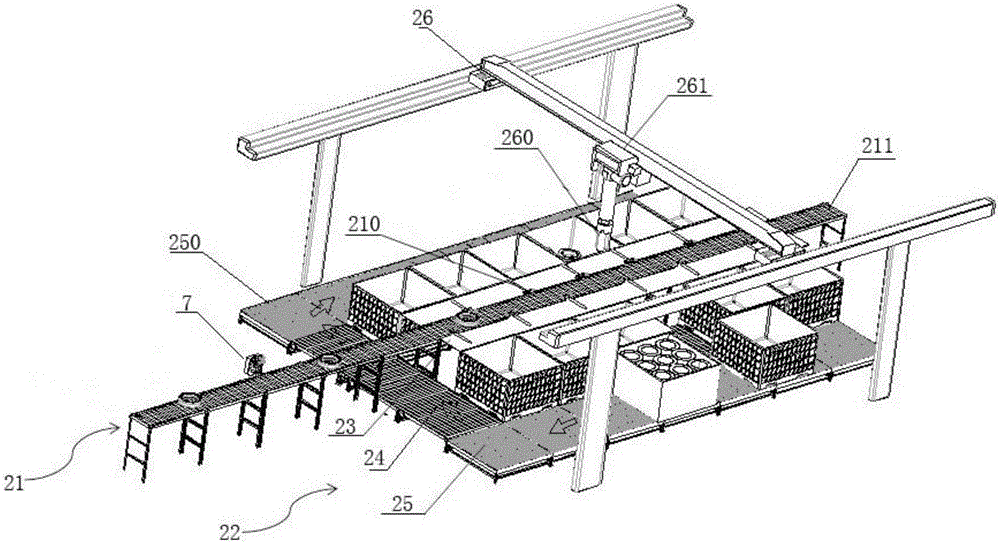

[0063] Such as figure 1 The tire sorting system 20 shown includes a main conveying line 21, a sorter 26 and conveying branch lines 22 arranged on both sides of the main conveying line 21, and each conveying branch line 22 includes a sorting area 23 and a case-putting area 24 arranged in sequence and container transportation area 25; the conveying main line 21 is provided with a code scanning device 7 and a plurality of hydraulically controlled push hands 210, and the push hands 210 selectively push the tires to the corresponding points according to the information fed back by the code scanning device 7 The sorting area 23, and the tires that are not pushed into the sorting area 23 are output from the recovery port 211 on the conveying main line. The height of the boxes in the box-putting area 24≤the height of the sorting area 23 is convenient for the pusher 210 to push the tires in the sorting area 23 into the box in the box-putting area 24. The sorting machine 26 includes a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com