Connector

一种连接器、连接部的技术,应用在连接、连接装置的零部件、固定/绝缘接触构件等方向,能够解决部件数量增大、组装工序数增加、基板占有面积增大等问题,达到防止触点脱落、提高校准精度、准确定位的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

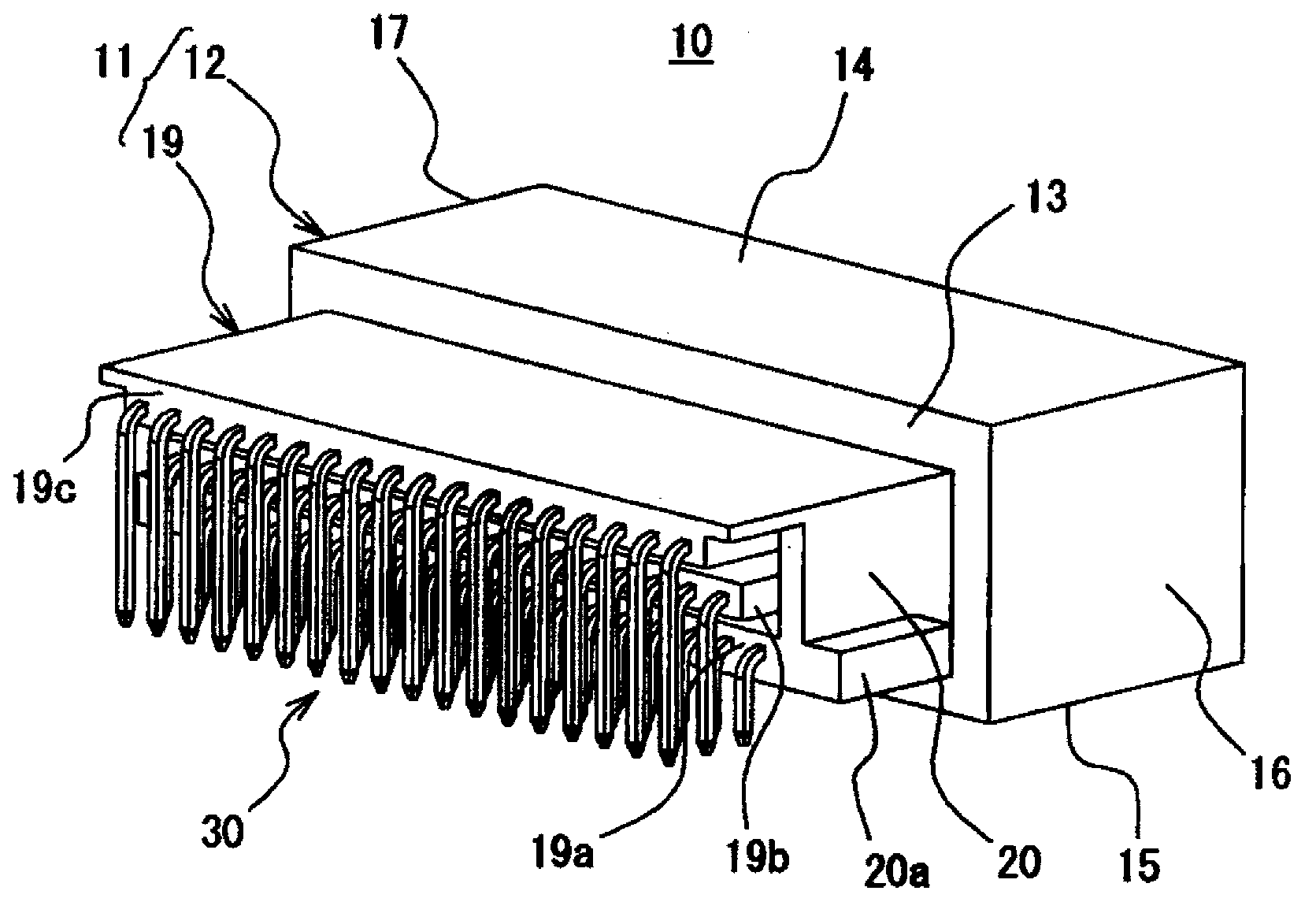

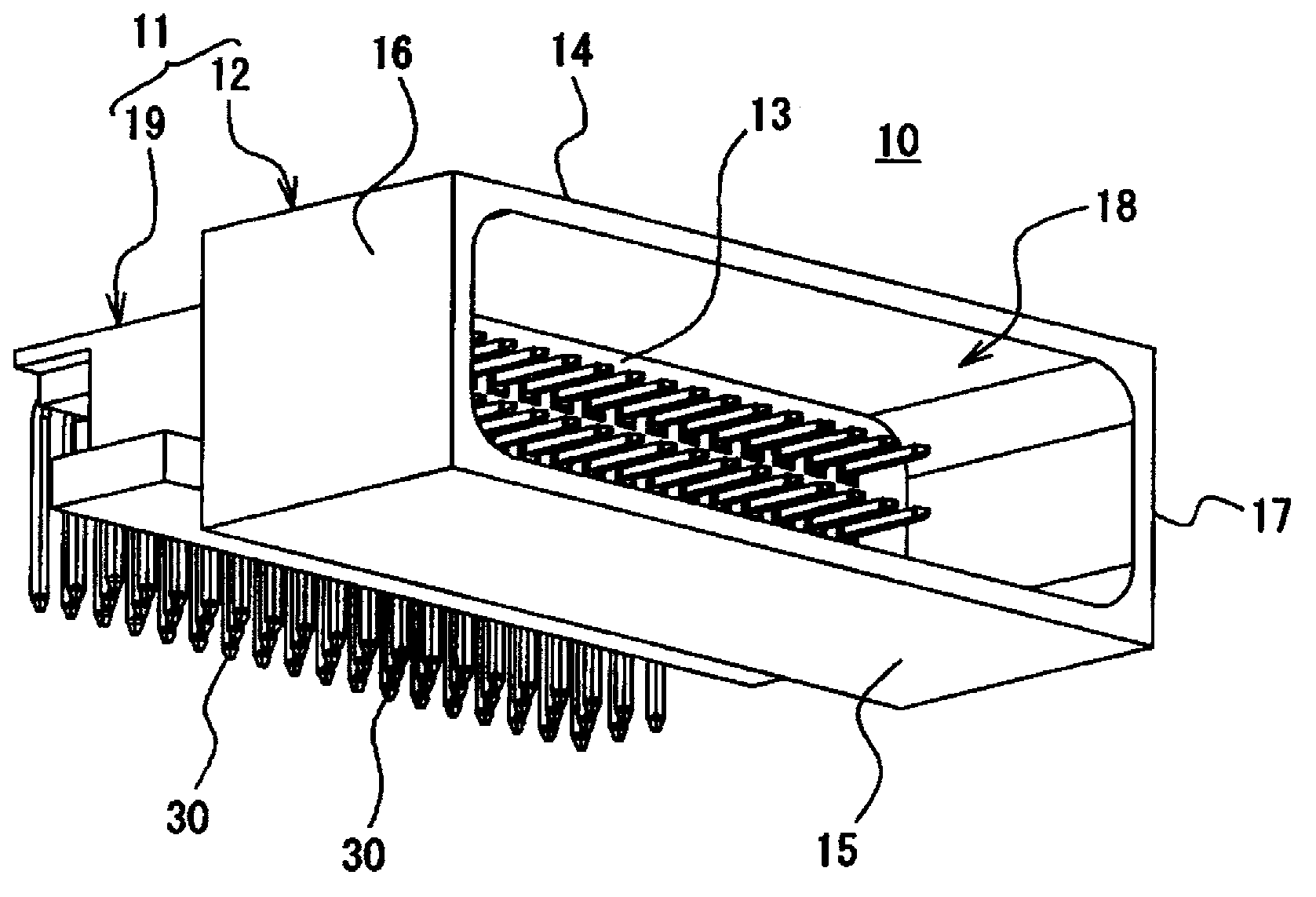

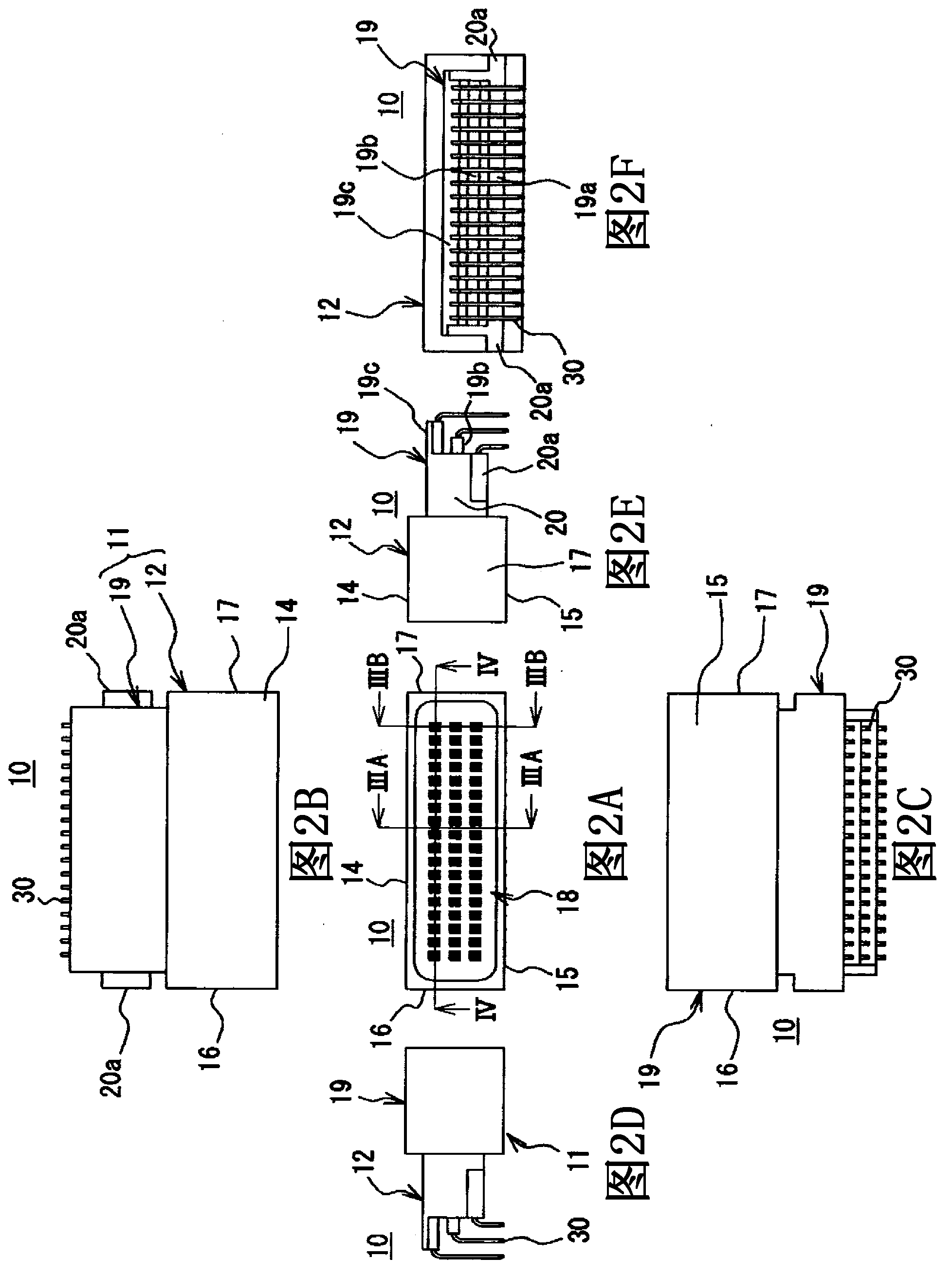

[0048] refer to Figure 1A ~ Figure 8B The connector of Embodiment 1 will be described. Such as Figure 1A , Figure 1B and Figure 2A-Figure 2F As shown, the connector 10 according to Embodiment 1 is constituted by a housing 11 formed of an insulating material, and a plurality of contacts 30 mounted on the housing 11 . In addition, the connector 10 of Embodiment 1 is a so-called side-type connector 10 in which the direction of the contacts 30 mounted on the housing 11 is parallel to the substrate 36 (see Figure 8A , Figure 8B ), therefore, the later-described end portion of the contact 30 is bent and formed at a substantially right angle so as to be perpendicular to the substrate 36 . In addition, in the connector 10 of Embodiment 1, the structure in which the contacts 30 are arranged in three rows will be described. Next, each configuration will be described.

[0049] The housing 11 of Embodiment 1 is composed of a fitting part 12 for fitting with a counterpart conne...

Embodiment approach 2

[0073] refer to Figure 9 ~ Figure 13B A connector according to Embodiment 2 will be described. In the connector of Embodiment 1, a so-called side-type connector was described, but the connector of Embodiment 2 is a so-called peak-type connector mounted vertically with respect to the board. In addition, in the connector of Embodiment 2, compared with the connector of Embodiment 1, only the shape of a part of the housing and the contacts is different, and the other parts are the same. Therefore, the same structure as the connector of Embodiment 1 The same reference numerals are attached, and detailed explanations are omitted.

[0074] Such as Figure 9 and Figure 10A-Figure 10C As shown, a connector 10A according to Embodiment 2 is composed of a housing 11A formed of an insulating material, and a plurality of contacts 30A mounted on the housing 11A. In addition, connector 10A of Embodiment 2 demonstrates the case where contacts 30A are aligned in a row. Furthermore, the c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com