Overhead traveling crane lifting appliance for steel tube pickling

A crane and pickling technology, applied in the direction of load hanging components, transportation and packaging, can solve problems such as increasing the risk of employees and reducing production efficiency, reducing the chance of exposure to acid and acid mist, and improving the utilization rate , the effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

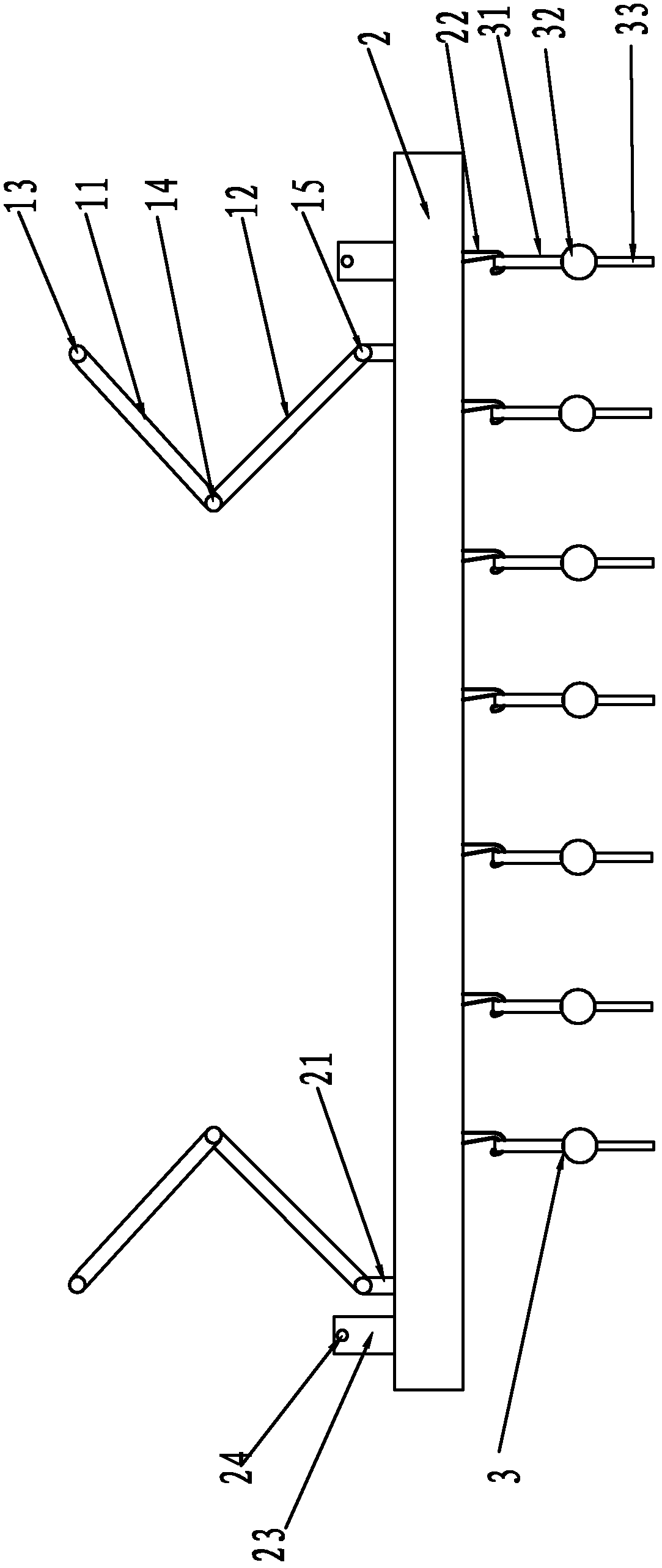

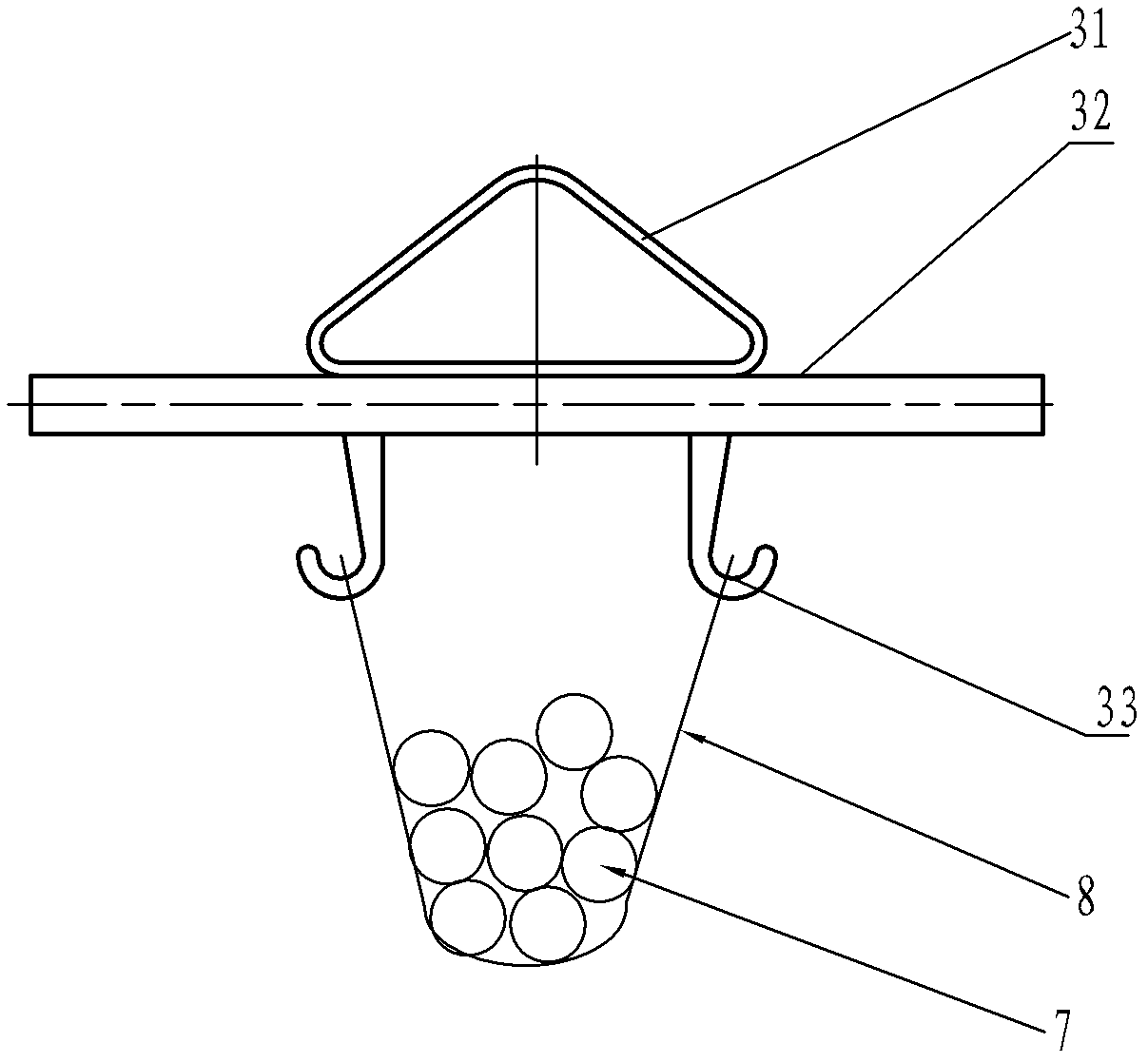

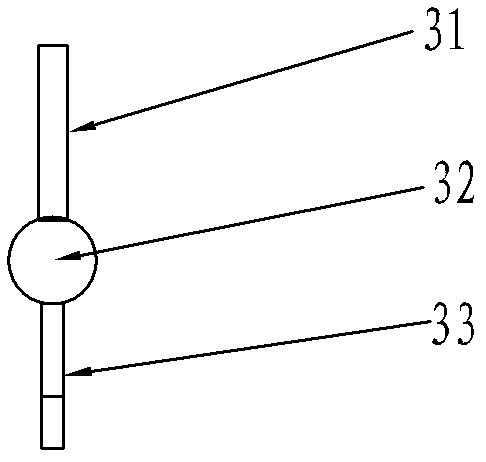

[0021] Such as figure 1 As shown, the crane hanger used for steel pipe pickling in the present invention includes a balance device, a beam 2 and a plurality of hooks 3, the balance device includes two first balance plates 11, two second balance plates 12, each first The upper end of balance board 11 is installed with the first rotating shaft 13, and the lower end of each first balance board 11 is connected with the upper end of second balance board 12 by second rotation shaft 14, between the first balance board 11 and the second balance board 12 With an included angle, the first and second balance boards 11 and 12 can rotate around the second rotating shaft 14, so the included angle between the first balance board 11 and the second balance board 12 can be adjusted. The lower end of each second balance board 12 is respectively connected with the connecting block 21 on the top of the crossbeam 2 through the third rotating shaft 15, and several hooks 22 are arranged at the bottom...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com