Shaver

A razor and blade technology, applied in the field of assembled razors, can solve problems such as inconvenience of carrying

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

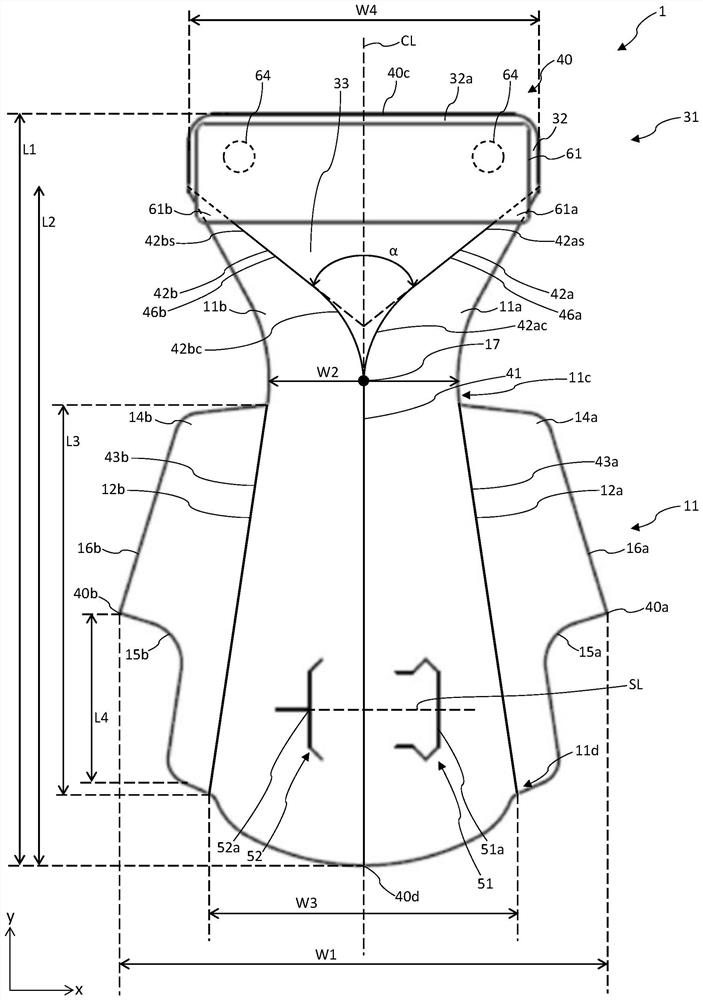

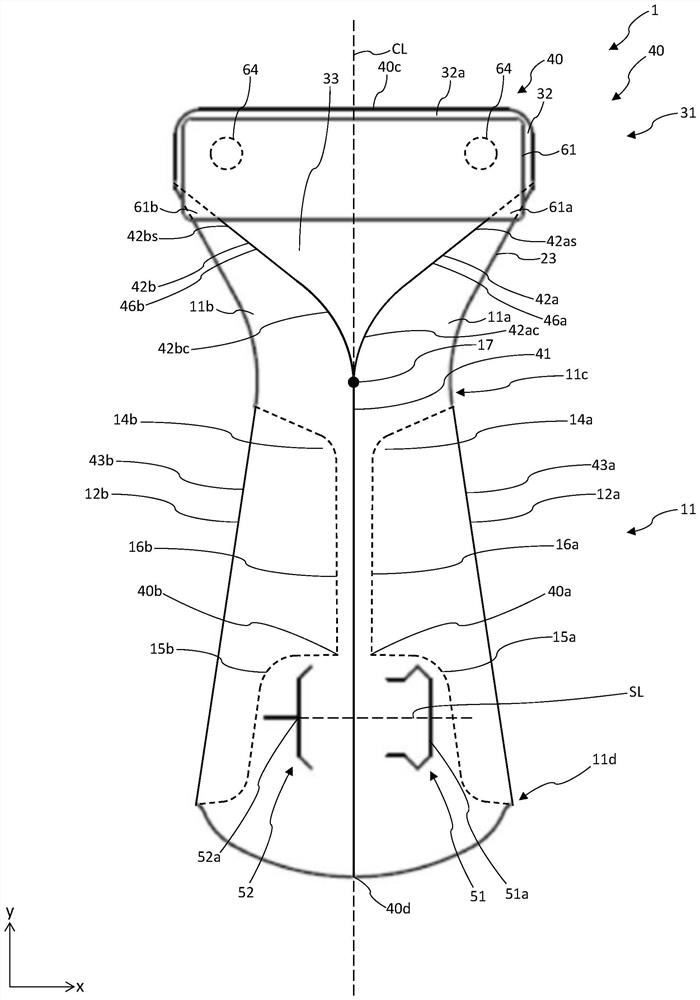

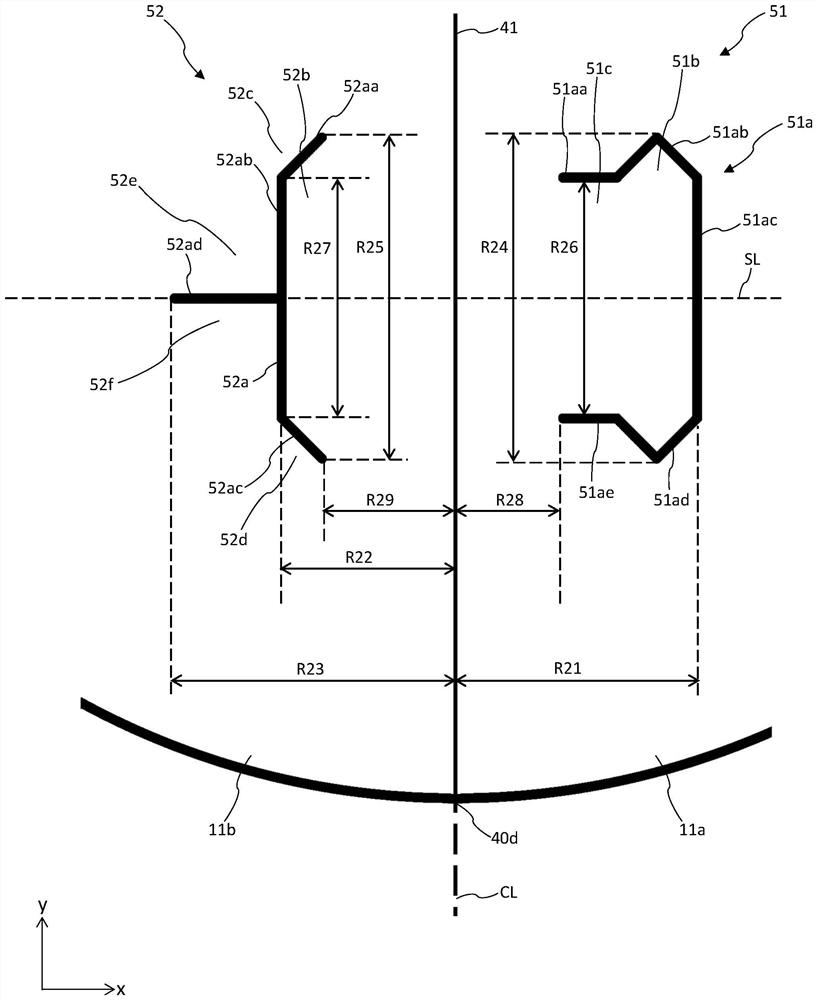

[0262] Figure 12 It is a plan view of the shaver at the time of completion of manufacture of the modification 1 of the embodiment, as seen from the front. The shaver 2 of the modified example 1 of the embodiment is the same as the figure 1Compared with the shaver 1 shown, the bending parts 14a and 14b are not provided, and the external shape of the grip part 11 is different. Since the shaver 2 does not have the bent parts 14a and 14b, by connecting the main body 40 and the shaver head 61, it becomes as follows Figure 12 Finished product shown. In this way, since the manufacturing can be simplified by reducing the bending work by the configuration in which the bent portions 14a and 14b are not provided, the manufacturing cost of the shaver 2 can be reduced. Moreover, since the usage-amount of paper can be reduced, the material cost in manufacture of the shaver 2 can be reduced.

[0263] The outer shape of the grip portion 11 of the shaver 2 is formed so that the entire lo...

Deformed example 2

[0265] Figure 13 It is a top view of the shaver at the time of completion of manufacture of the modification 2 of embodiment seen from the front. Figure 14 Yes Figure 13 An enlarged view of the vicinity of the incision portion of the shaver shown. like Figure 13 as well as Figure 14 As shown, the shaver 3 of Modification 2 of the embodiment is the same as the figure 1 The shaver 1 shown is provided with a cutout portion 71 instead of the bent portions 14a and 14b, the insertion portion 51, and the insertion hole portion 52, and the outer shape of the grip portion 11 is different. Since the shaver 3 does not have the bent parts 14a and 14b, by connecting the main body 40 and the shaver head 61, it becomes as follows Figure 13 Finished product shown. In this way, since the manufacturing can be simplified by reducing the bending work by the structure in which the bent portions 14a and 14b are not provided, the manufacturing cost of the shaver 3 can be reduced. In add...

Deformed example 3

[0277] Figure 16 It is a top view of the shaver at the time of completion of manufacture of Modification 3 of the embodiment, as seen from the front. like Figure 16 As shown, the shaver 4 of Modification 3 of the embodiment is similar to the figure 1 Compared with the shaver 1 shown, in place of the bent portions 14a and 14b, the insertion portion 51 and the insertion hole portion 52, a right protruding portion 81, an upper left protruding portion 82a, and a lower left protruding portion 82b are provided, and the grip portion 11 different appearance. Since the shaver 4 does not have the bent parts 14a and 14b, by connecting the main body 40 and the shaver head 61, it becomes as follows Figure 16 Finished product shown. In this way, since the manufacturing can be simplified by reducing the bending work by the configuration in which the bent portions 14a and 14b are not provided, the manufacturing cost of the shaver 4 can be reduced. In addition, since the amount of pape...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com