Double-steel-pipe concrete joint of externally-wrapped composite winding pipe and preparation method of double-steel-pipe concrete joint

A technology of double-steel concrete and outer steel pipes, which is applied in the direction of construction and building construction, can solve the problems that the pole position cannot be set arbitrarily, the construction process is difficult, and the connection form is limited, so as to improve the level of industrialization, simplify the difficulty of construction, The effect of a reliable connection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

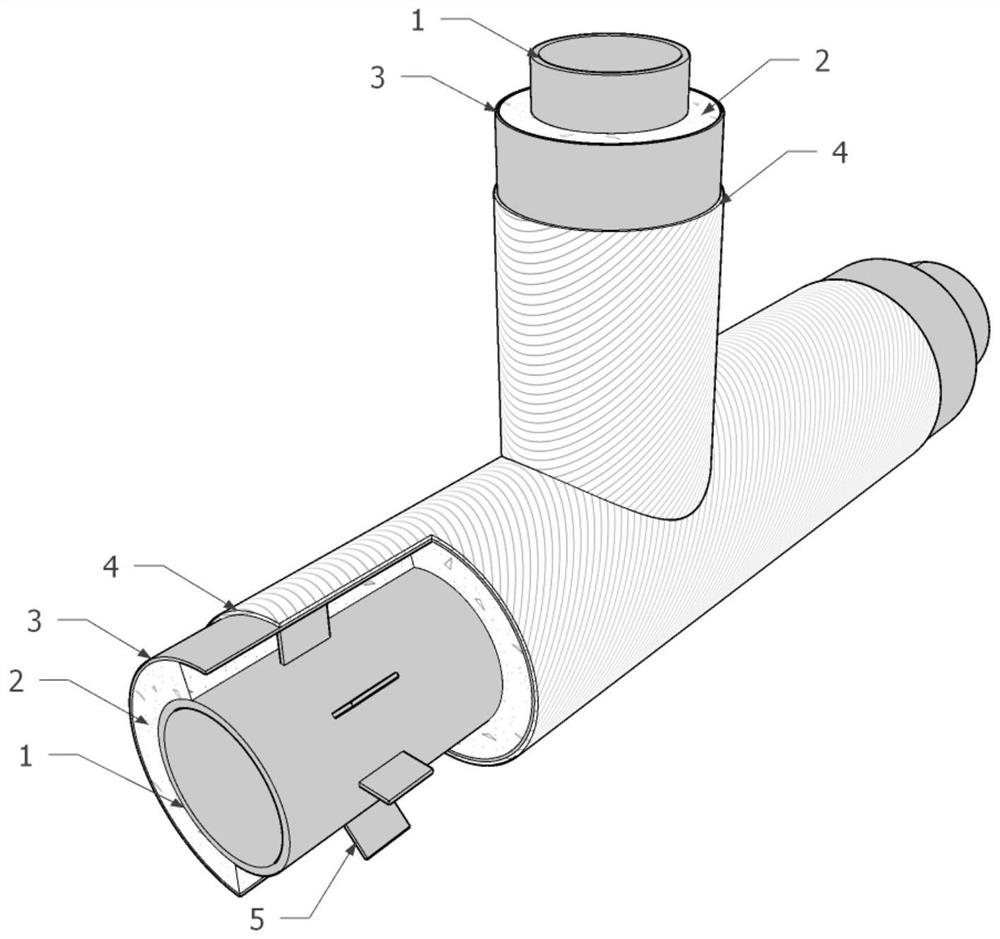

[0041] A double-steel-concrete concrete joint with composite material winding pipe, including a main member and at least one auxiliary member. The structure of the main member is the same as that of the auxiliary member, and both include a composite material winding pipe layer, an outer steel pipe layer, The concrete layer and the inner steel pipe layer; the concrete layer is set between the inner steel pipe layer and the outer steel pipe layer by pouring; multiple connecting parts are arranged between the outer steel pipe layer and the inner steel pipe layer, and the connecting parts connect the inner steel pipe layer and the outer steel pipe layer The layers are fixedly connected to form a double steel pipe segment; the double steel pipe segment of the secondary component is fixedly connected with the outer steel pipe outer wall of the double steel pipe segment of the main component.

[0042] In this embodiment, before the concrete layer is poured between the inner steel pipe...

Embodiment 2

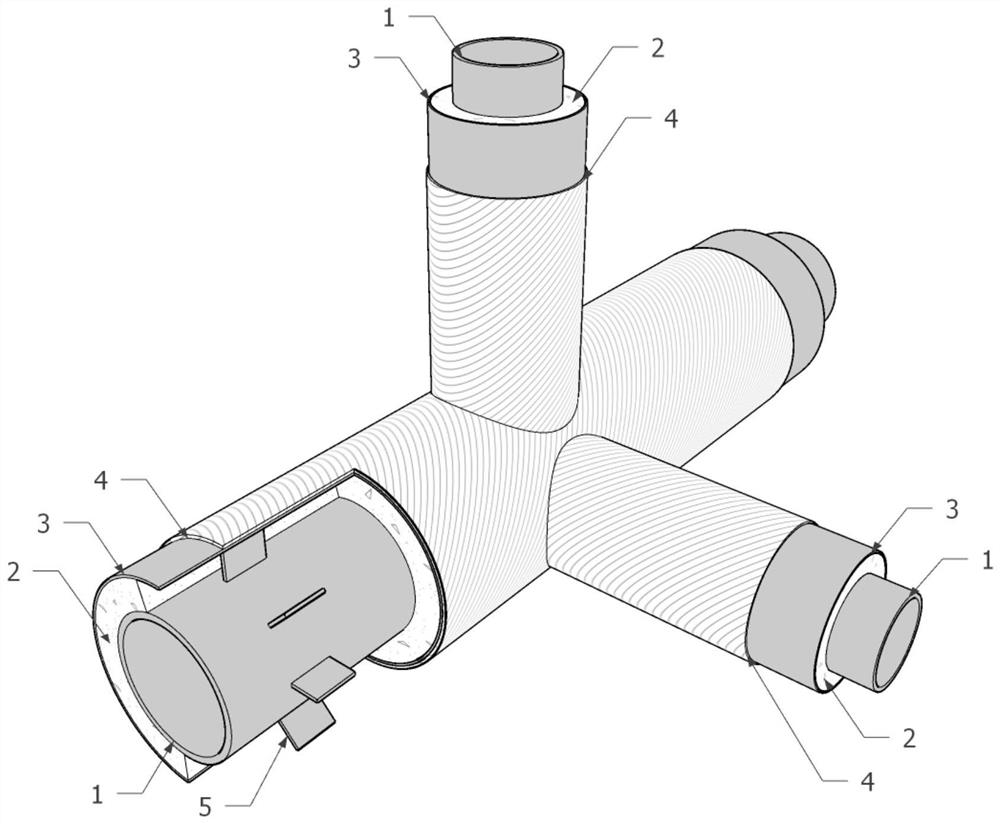

[0069] In this embodiment, a double-steel-concrete-steel-concrete node of an outer-wrapped composite wound pipe is used as an N-shaped node of a rigid frame structure.

[0070] In this embodiment, a double-steel-concrete-concrete joint of wrapped composite-wrapped pipes consists of a main member and two auxiliary members (ie, chords, vertical webs, and oblique webs) in the joint area.

[0071] In this embodiment, the inner side of the steel tube of the inner steel tube layer of the main component is not filled with a concrete layer, and the inner side of the steel tube of the inner steel tube layer of the secondary component is not filled with a concrete layer.

[0072]In this embodiment, the concrete layer between the inner steel pipe layer and the outer steel pipe layer of the main member and the auxiliary member is filled after the wrapping composite material winding pipe layer is made.

[0073] In this embodiment, the double-steel-concrete joints of the wrapped composite-w...

Embodiment 3

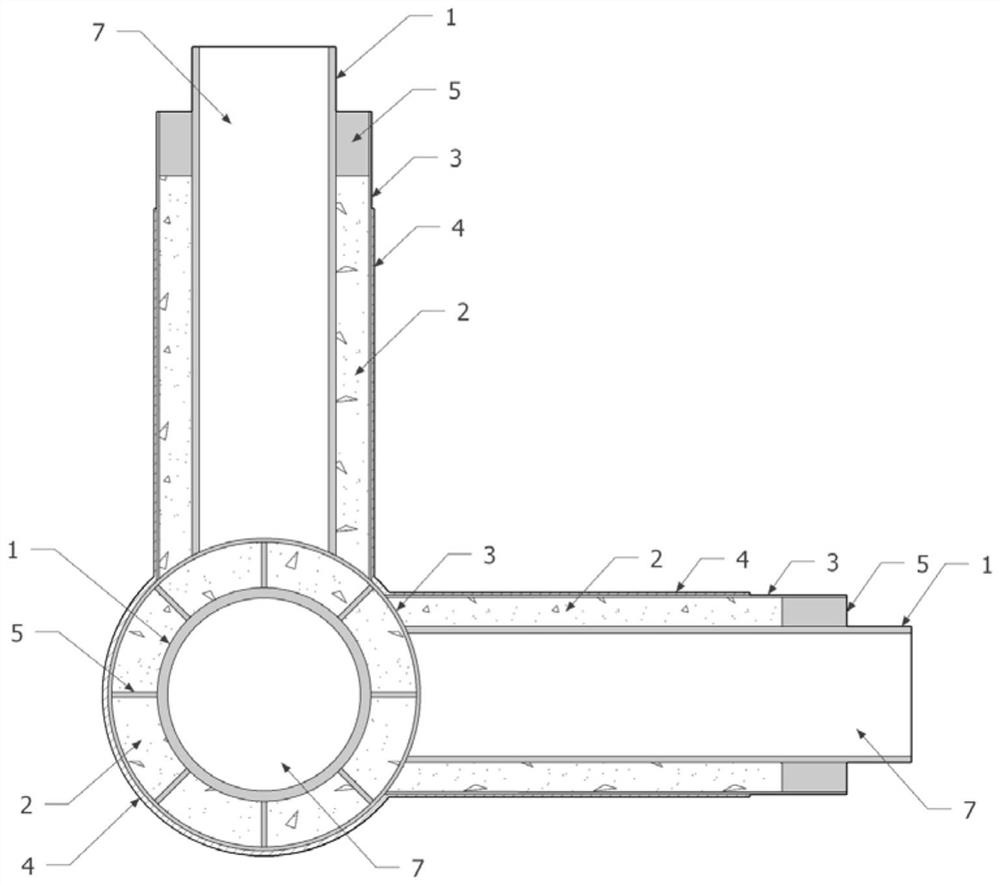

[0080] In this embodiment, a double-steel-concrete joint of a composite wound pipe is used as the space joint of the arch rib of the arch bridge structure.

[0081] In this embodiment, a double-steel-concrete-concrete joint of wrapped composite material winding pipe is composed of a main member and two auxiliary members, that is, the main arch rib (main member), column (auxiliary member), and cross brace (auxiliary member) are connected in the node area composition.

[0082] In this embodiment, the inner side of the steel tube of the inner steel tube layer of the main component is not filled with a concrete layer, and the inner side of the steel tube of the inner steel tube layer of the secondary component is not filled with a concrete layer.

[0083] In this embodiment, the concrete layer between the inner steel pipe layer and the outer steel pipe layer of the main member and the auxiliary member is filled after the wrapping composite material winding pipe layer is made.

[...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com