Ultradeep sea oil-gas field engineering development system

A technology for engineering development and oil and gas fields, which is applied in drilling equipment, floating structures, earthwork drilling and production, etc. It can solve the problems of feasibility, safety and economic applicability that cannot meet the requirements, sharply increased risks of oil and gas mining operations, and harsh sea conditions, etc. problems, to achieve the effect of reducing design requirements and technical difficulty, good stability and high cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further described below in conjunction with the accompanying drawings.

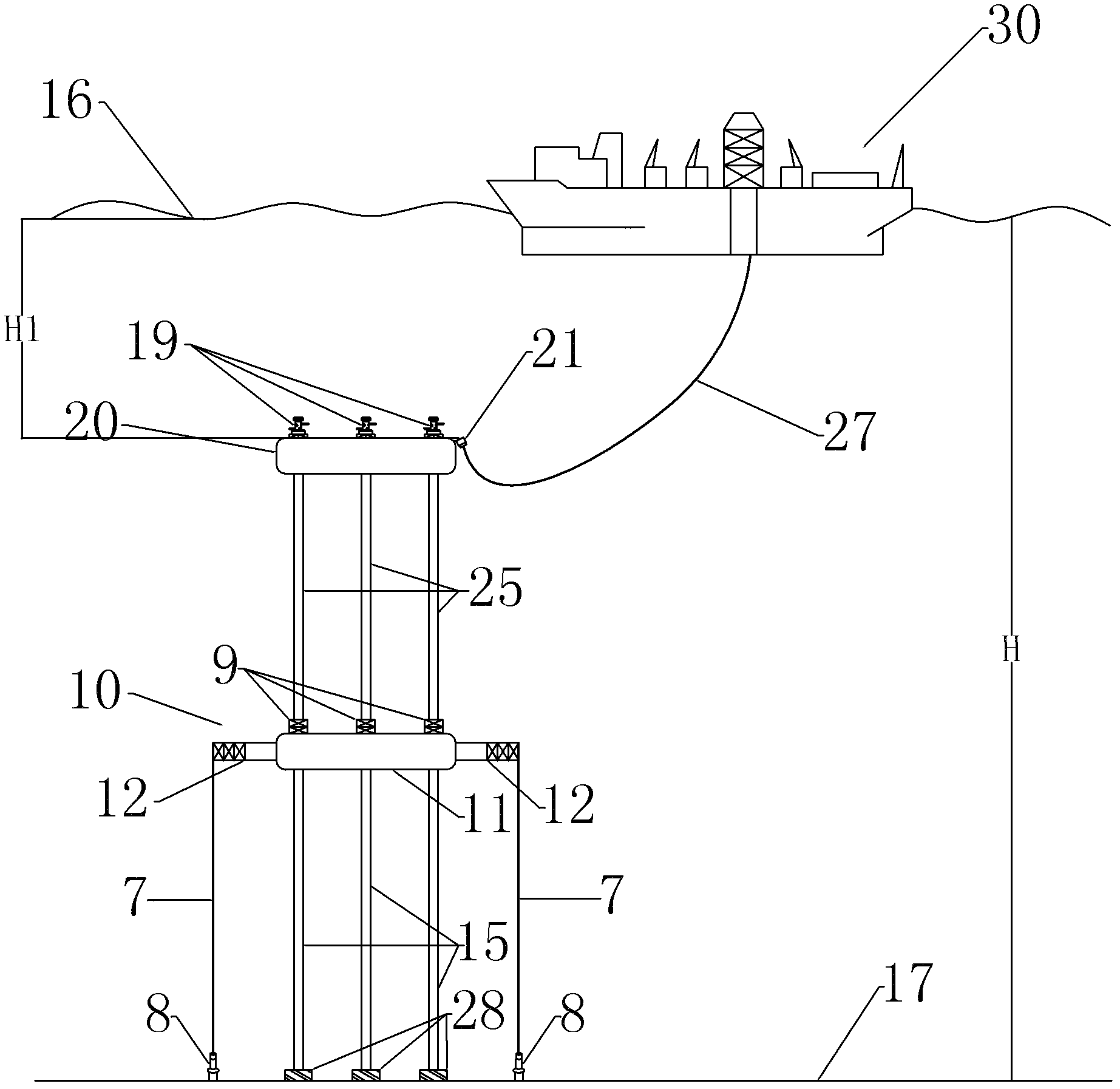

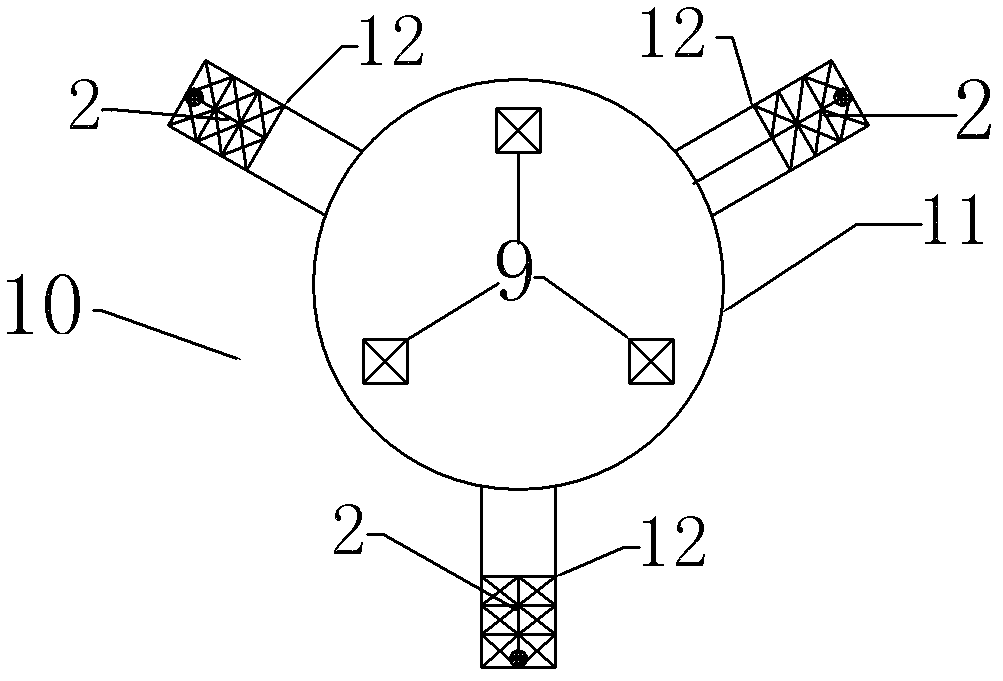

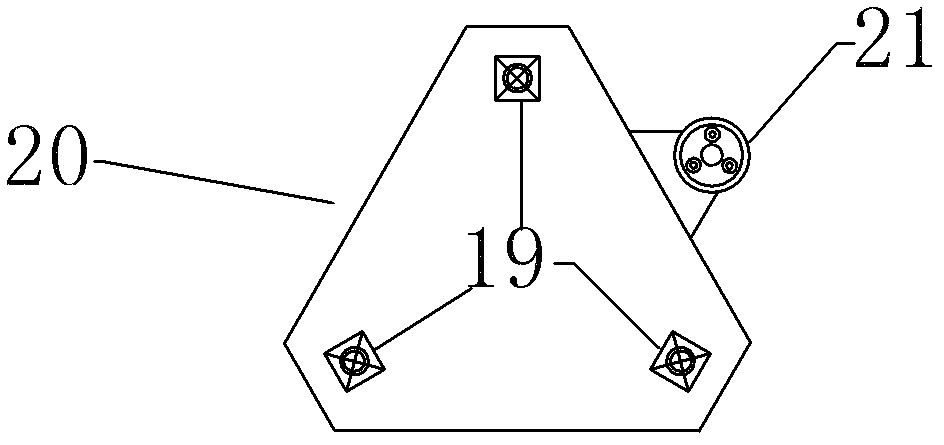

[0030] Such as figure 1 As shown, an ultra-deep offshore oil and gas engineering development system mainly includes a sea surface floating production device 30, a primary riser support buoy 10, a primary rigid riser 15, a secondary riser support buoy 20, and a secondary rigid riser 25. Oil production equipment in water 19, upper flexible jumper pipe 27, tension mooring device and subsea wellhead device 28.

[0031] For the convenience of describing the specific embodiment of the present invention, it is assumed that the sea area depth of the operation is H (H is greater than 3000m).

[0032] The first-level riser support buoy 10 is located at H / 2 below the sea surface, and is fixed on the pile foundation 8 on the seabed 17 through the tension cable 7, so that the first-level riser support buoy 10 is stably positioned in the underwater designated Location H / 2.

[00...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com