Preparation method and application of epoxy asphalt compatibilizer

An epoxy bitumen and epoxy bitumen material technology, which is applied in building components, building insulation materials, buildings, etc., can solve the problems of construction workers' physical and environmental impact, harmful bitumen fumes, and high production energy consumption, and achieve overall delivery. Low link density, high local crosslink density, and improved compatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0047] The invention provides a kind of preparation method of epoxy asphalt compatibilizer, comprises the following steps:

[0048] a) Heating the heavy aromatic oil to 60-180°C;

[0049] b) Add a certain proportion of the mixture of isocyanate, initiator and anti-degradation agent into the heavy aromatic oil, and stir for 0.5-2 hours under heating to prepare the epoxy asphalt compatibilizer.

[0050] Preferably, the content of heavy aromatics in the heavy aromatic oil is 30-85% (by mass), more preferably 50-80%, more preferably 60-75%.

[0051] Preferably, the heating temperature of the heavy aromatic oil is 60-180°C, more preferably 80-160°C, more preferably 120-150°C.

[0052] Preferably, the amount of the isocyanate is 3-10% by weight of the heavy aromatic oil, more preferably 5-9%, more preferably 6-8%.

[0053] Preferably, the DHBP is used in an amount of 0.5-5% by weight of the heavy aromatic oil, more preferably 1-4%, more preferably 1-3%.

[0054] Preferably, the a...

Embodiment 1

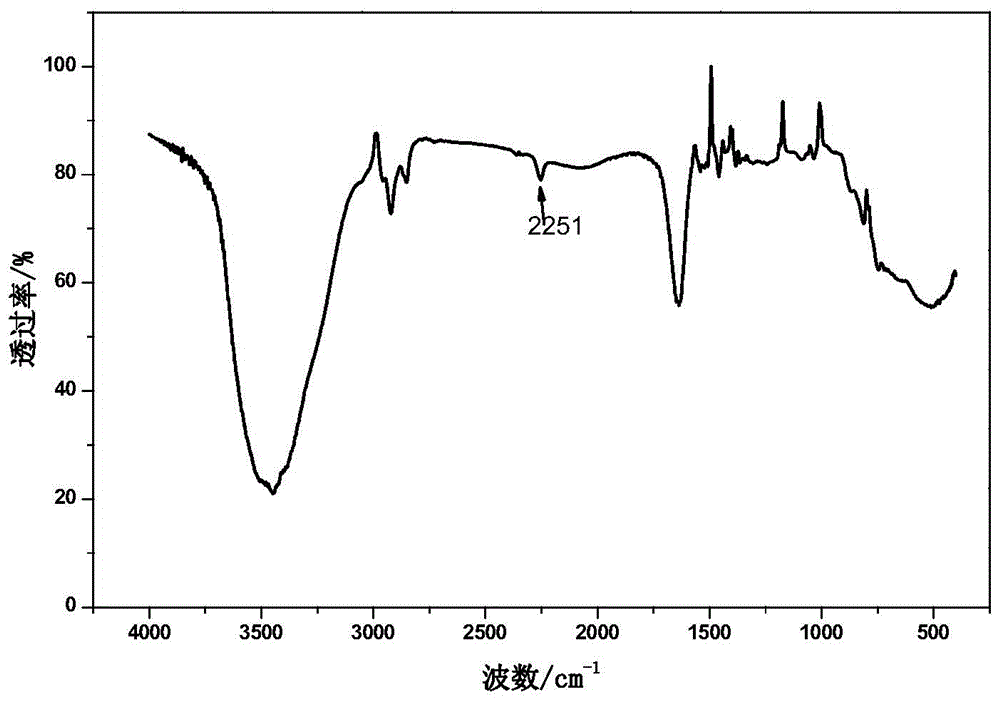

[0082] Put 100 g of heavy aromatic oil (purchased from Wuhan Baohua Petrochemical New Material Development Co., Ltd., the same below) into a three-necked bottle with a stirrer, heat it to 150 ° C with an oil bath, and after keeping the temperature for 15 min, slowly add 3- Isopropyl-α, α-dimethylbenzyl isocyanate (TMI) (purchased from ALDRICH Company, the same below) 7.5g, styrene (St) (purchased from Sinopharm Chemical Reagent Co., Ltd., the same below) 7.5g and 2,5-Dimethyl-2,5-bis(tert-butylperoxy)hexane (DHBP) 2g (purchased from Chengdu Lijing Xiwang Fine Chemical Co., Ltd., the same below), after stirring for 1h, cooling, The epoxy asphalt compatibilizer of the present invention can be obtained. figure 1 Infrared spectrogram of the epoxy asphalt compatibilizer prepared in this embodiment.

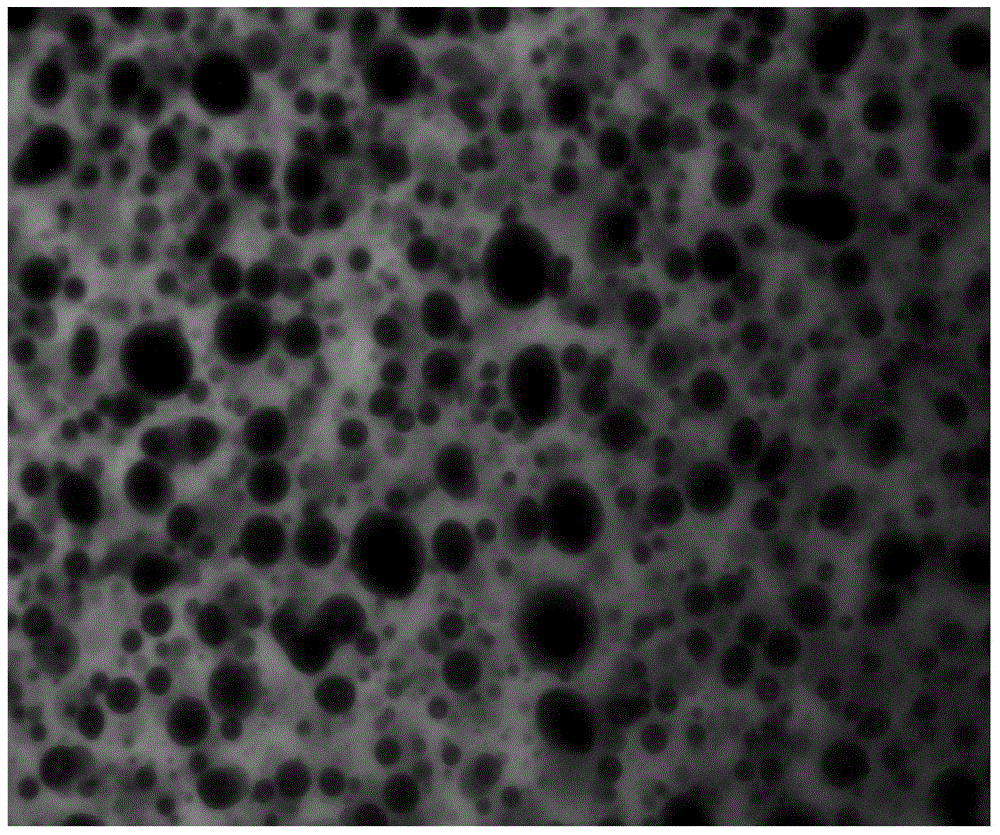

[0083] Accurately take by weighing 30g asphalt (brand is No. 70 Shell asphalt, the same below), 12g epoxy asphalt compatibilizer, 10g epoxy asphalt thinner styrene (purchased from Sin...

Embodiment 2

[0096] Put 100g of heavy aromatic oil in a three-necked flask with a stirrer, heat it to 60°C with an oil bath, keep the temperature for 15min, and slowly add 3-isopropyl-α,α-dimethylbenzyl isocyanate (TMI) 3g, styrene (St) 3g and 2,5-dimethyl-2,5-bis(tert-butylperoxy)hexane (DHBP) 0.5g, after stirring for 1h, cooling, the present invention can be obtained The epoxy asphalt compatibilizer.

[0097] Accurately weigh 30g asphalt, 10g epoxy asphalt compatibilizer, 5g epoxy asphalt diluent styrene, 5g epoxy resin thinner 632, 20g epoxy resin, join in the common reaction kettle of 80 ℃ and stir 30min, obtain Part A of the epoxy bituminous material.

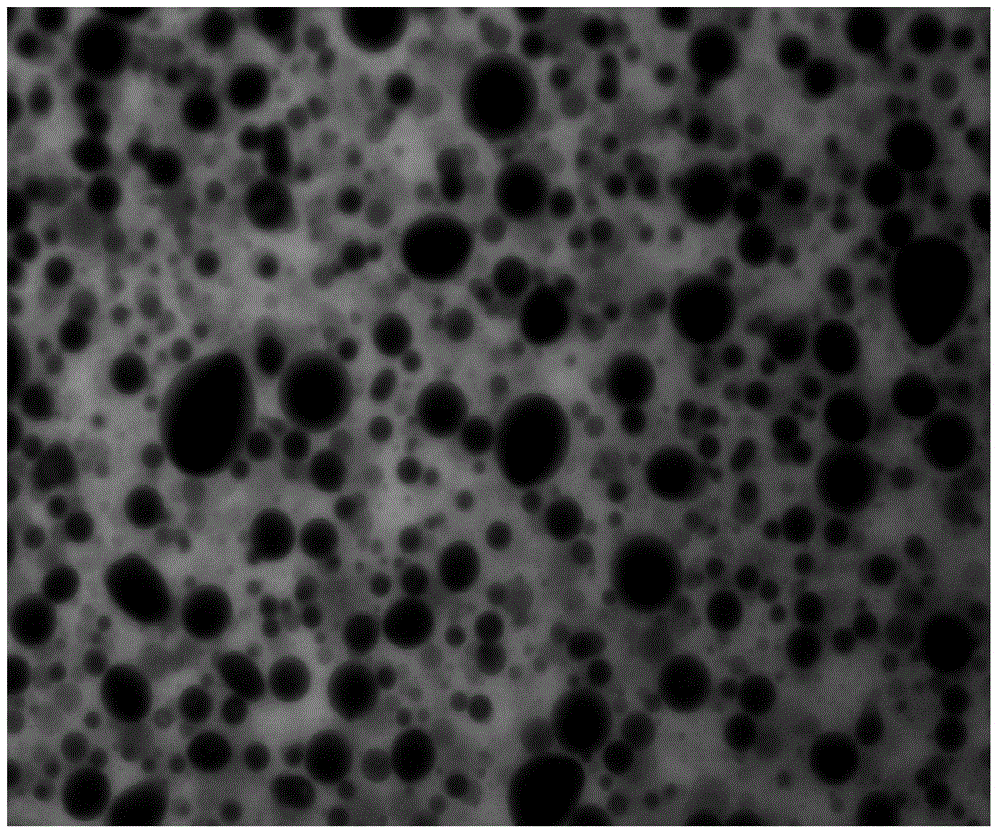

[0098] Add part A of the epoxy asphalt material, 5g of epoxy curing agent polyamide 650, and part B of the epoxy asphalt material into a normal temperature reaction kettle and stir for 20 minutes. After mixing evenly, cool the obtained mixture to room temperature to obtain epoxy resin. asphalt material. image 3 Fluorescence microgr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com