Bipolar plate structure of proton exchange membrane fuel cell, fuel cell stack and control method thereof

A technology of fuel cell stacks and proton exchange membranes, applied in fuel cells, fuel cell additives, fuel cell heat exchange, etc., can solve problems affecting fuel cell power generation performance, stability, service life, and preload distribution Uniformity, complex battery design and other issues, to achieve the effect of reducing process complexity and stack manufacturing costs, improving uniformity, and realizing lightweight design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

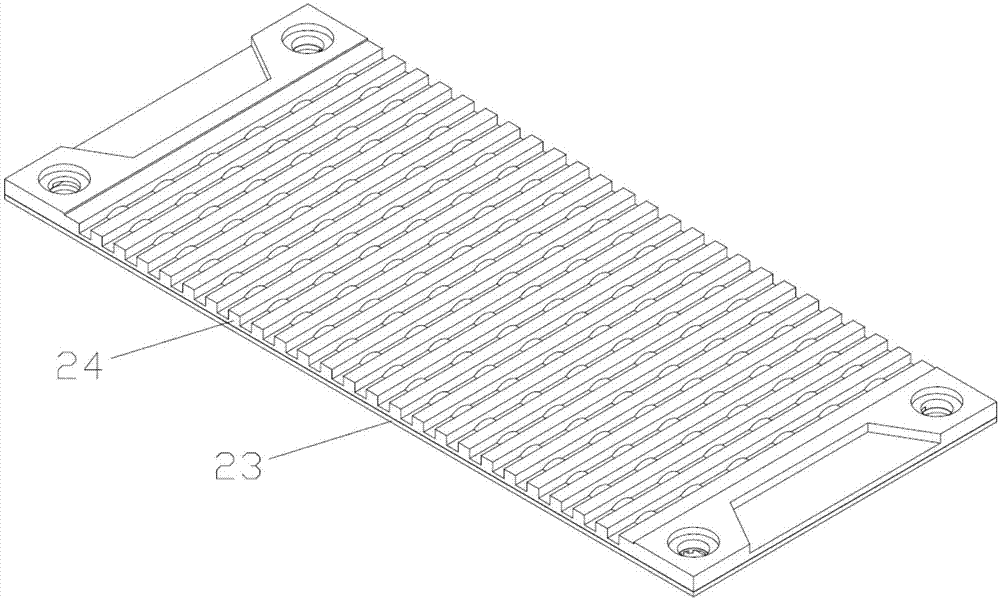

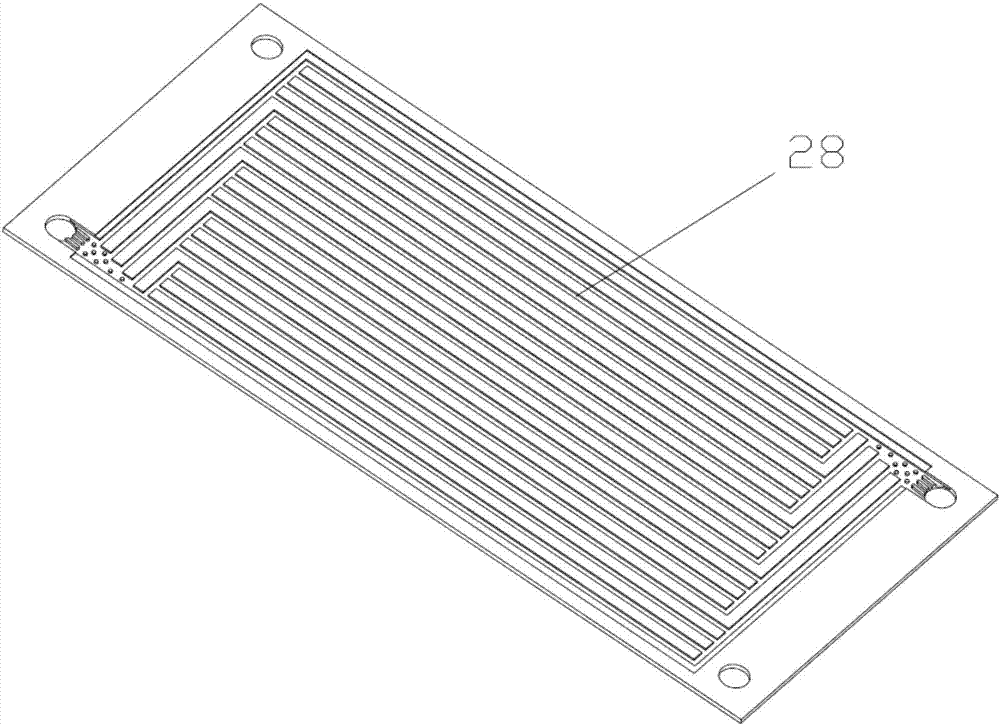

[0058] A 50-section fuel cell stack was assembled using the novel fuel cell stack design of the present invention, and a performance comparison test was performed with a conventional air-cooled fuel cell stack under the same environmental conditions. Both fuel cell stacks have a single cell with an active area of 150 cm 2 , the hydrogen flow fields are all parallel flow fields, the groove depth of the hydrogen flow field is 0.3mm, the groove width is 1.0mm, the ridge width is 1.0mm, the air flow field is 2.5mm in groove width, and the ridge width is 2.0mm, the coolant is water, the shape of the cross-section of the coolant flow field is a circular arc composed of a sub-arc and a line segment, and the area of the cross-section is 1.3mm 2 , the ridge width is 1.5mm, and the coolant flow channel groove 32 is embedded in the air flow channel groove 30 in the novel fuel cell stack of the present invention, so that the cross section of the air flow channel groove 30 is periodica...

Embodiment 2

[0067] A 50-section fuel cell stack was assembled using the novel fuel cell stack design of the present invention, and a performance comparison test was performed with a conventional air-cooled fuel cell stack under the same environmental conditions. Both fuel cell stacks have a single cell with an active area of 190 cm 2 , the hydrogen flow fields are all parallel flow fields, the groove depth of the hydrogen flow field is 0.5mm, the groove width is 0.5mm, the ridge width is 1.2mm, the air flow field is 3.5mm in groove width, and the ridge width is 1.5mm, the coolant is water, the shape of the cross-section of the coolant flow field is a circular arc composed of a sub-arc and a line segment, and the area of the cross-section is 0.3mm 2 , the ridge width is 1.2mm, the cooling liquid flow channel groove 32 is embedded in the air flow channel groove 30 in the novel fuel cell stack of the present invention, so that the cross section of the air flow channel groove 30 is period...

Embodiment 3

[0070] A 50-section fuel cell stack was assembled using the novel fuel cell stack design of the present invention, and a performance comparison test was performed with a conventional air-cooled fuel cell stack under the same environmental conditions. Both fuel cell stacks have a single cell with an active area of 160 cm 2 , the hydrogen flow fields are all parallel flow fields, the groove depth of the hydrogen flow field is 0.4mm, the groove width is 1.5mm, the ridge width is 0.7mm, the air flow field is 2.2mm in groove width, and the ridge width is 1.8mm, the coolant is water, the shape of the cross-section of the coolant flow field is a circular arc composed of a sub-arc and a line segment, and the area of the cross-section is 0.8mm 2 , the ridge width is 1.1 mm, and the coolant flow channel groove 32 is embedded in the air flow channel groove 30 in the novel fuel cell stack of the present invention, so that the cross section of the air flow channel groove 30 is periodic...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com