Liquid supply system

A liquid supply and liquid technology, applied in the direction of liquid displacement machinery, refrigeration and liquefaction, lighting and heating equipment, etc., can solve problems such as difficult high pressure, bellows buckling, etc., to suppress buckling, improve pump function, and improve stability sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

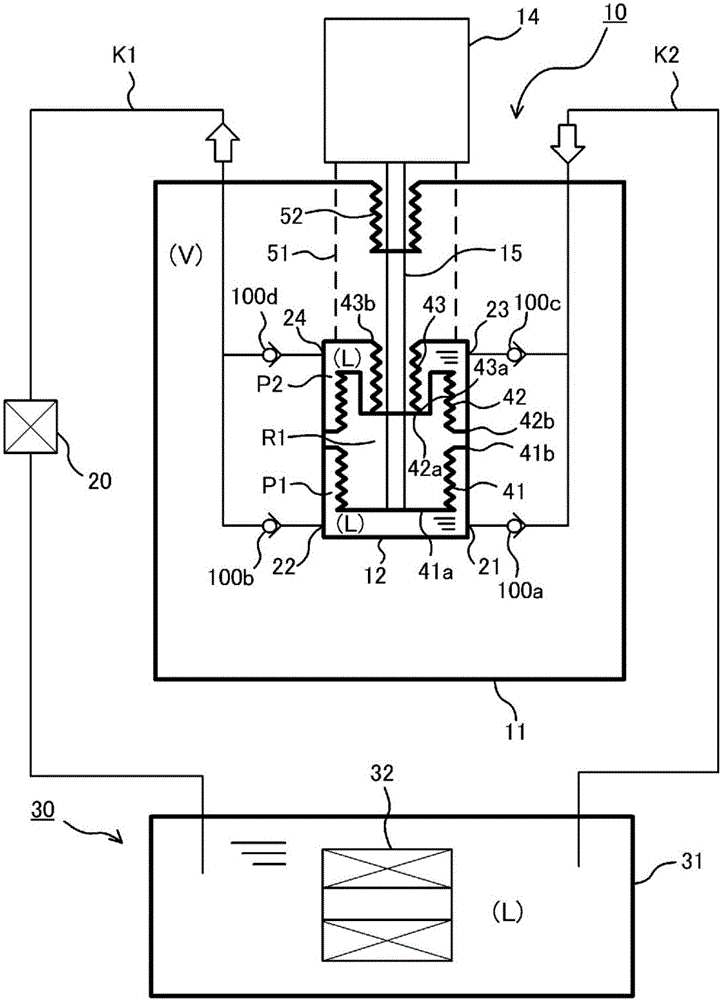

[0040] refer to figure 1 , the liquid supply system of the embodiment of the present invention will be described. figure 1 is a schematic configuration diagram of a liquid supply system according to an embodiment of the present invention.

[0041] The liquid supply system 10 is a pump device for cryogenic fluid, and in order to keep the superconducting cable 32 in the cooling device 30 equipped with the superconducting cable 32 inside the resin container 31, it is continuously supplied to the container. The ultra-low temperature liquid L is supplied in 31 . Specific examples of the cryogenic liquid L include liquid nitrogen and liquid helium.

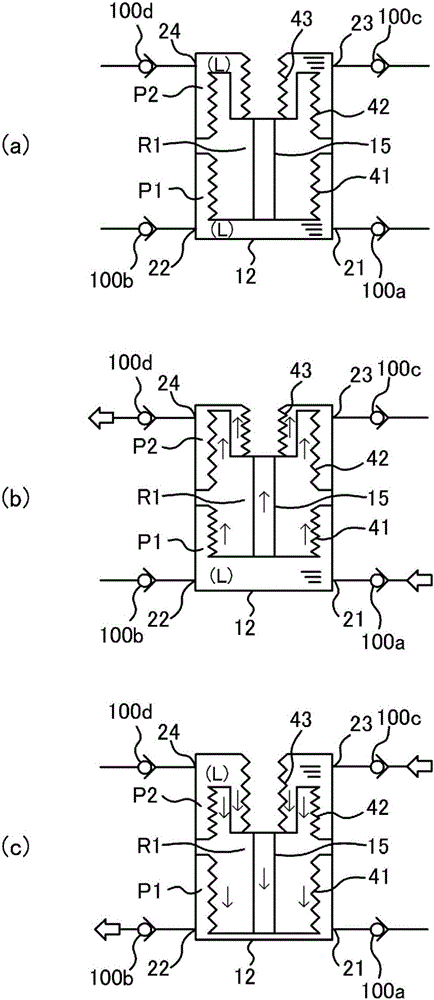

[0042] The liquid supply system 10 roughly includes a first container (outer container) 11 with a vacuum inside, and a second container 12 arranged inside the first container 11 and surrounded by a vacuum space. In the second container 12 , three bellows 41 , 42 , 43 are arranged in series in respective expansion and contraction di...

Embodiment 2

[0063] In the first embodiment described above, the closed space R1 is a vacuum space, but in the second embodiment of the present invention, the closed space R1 is filled with gas. The other configurations are the same as those in Embodiment 1, and the same reference numerals are assigned to the same configurations, and description thereof will be omitted.

[0064] As the gas enclosed in the closed space R1, for example, neon gas, helium gas, etc., which are unlikely to undergo state changes such as liquefaction and freezing in the operating environment of this system, are used. In addition, the pressure of the gas enclosed in the closed space R1 is set to a range from vacuum (-100 kPa) to a required discharge pressure (preferably 1 / 2 of the discharge pressure).

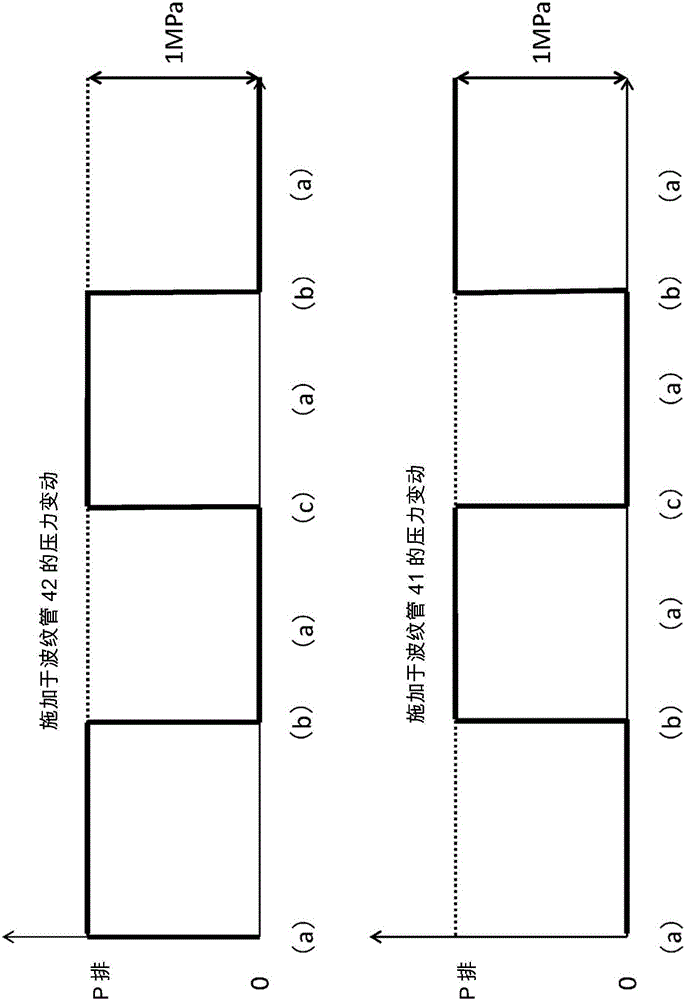

[0065] Figure 4 It is a graph roughly showing the variation of the discharge pressure of the liquid supply system of the second embodiment, the upper half shows the variation of the pressure applied to the bellows 4...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com