Method for manufacturing recycled concrete column partially wrapped by prefabricated honeycomb profile steel

A technology of recycled concrete and a production method, which is applied in the direction of manufacturing tools, ceramic molding machines, etc., to achieve obvious economic benefits, suppress local buckling, and facilitate construction.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

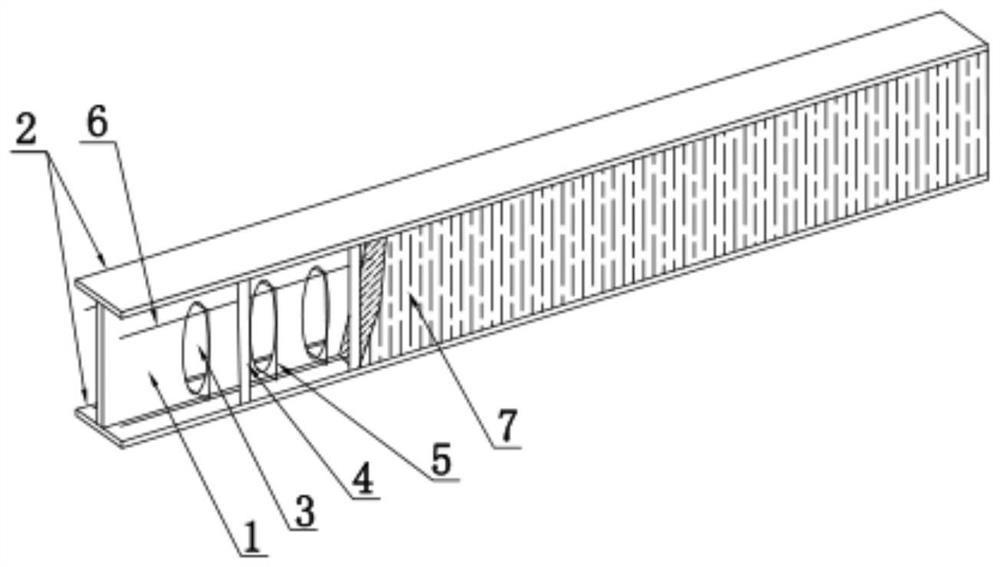

[0032] A method for manufacturing a prefabricated honeycomb-shaped steel partially wrapped recycled concrete column, comprising the following steps:

[0033] a. Production of honeycomb section steel: The honeycomb section steel includes a web 1 and a flange 2. There are a plurality of circular through holes 3 on the web. The circular through holes are arranged in sequence to form honeycomb holes. The upper and lower ends of the web are flanges. A tie rod 4 is welded between the flange at the upper end of the plate and the flange at the lower end of the web; the honeycomb steel fabrication includes the following steps:

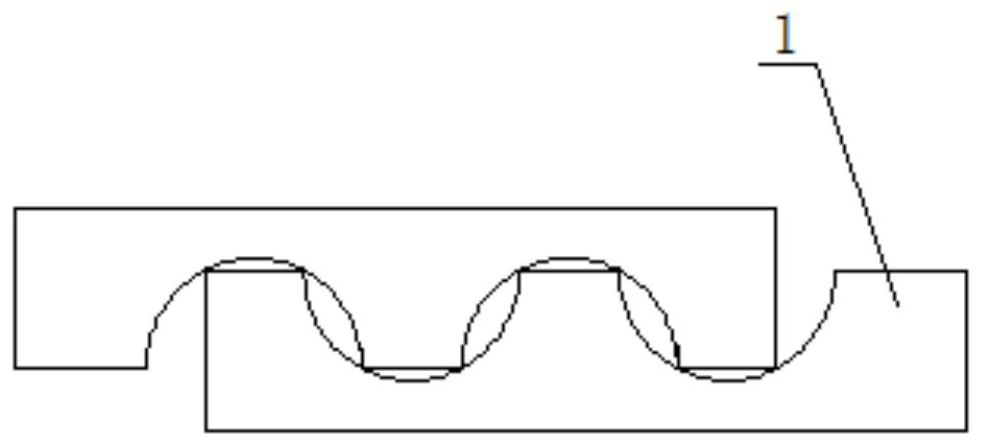

[0034] s1. Web cutting: Take I-beam or H-beam, and use a CNC multi-head automatic cutting machine to cut the web according to the preset arc. The cutting method is as follows: figure 2 The cut is made in the arrangement shown, and the cut webs are then staggered and cooled.

[0035] s2. Welding of the web: Align the semi-circular groove on the upper half of t...

Embodiment 2

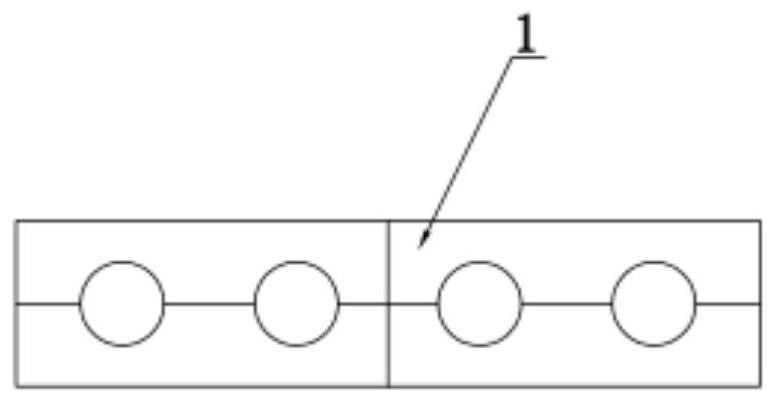

[0050] This embodiment is basically the same as Embodiment 1, the difference is: image 3 As shown, the honeycomb steel is welded by flanges and honeycomb webs, wherein the flange size is flexibly selected according to actual needs, and the honeycomb webs are a plurality of webs arranged in sequence, each web and the end of the web The parts are welded and fixed to each other, and the webs are spliced in multiple pieces. When cutting the webs, the plates can be fully utilized to avoid waste. At the same time, a certain number of webs can be selected for welding according to actual needs. For example, choose 2 or more The webs are welded firmly after splicing each other, the length of the web can be flexibly adjusted according to the actual needs, and the width and length of the flange can also be flexibly selected according to the actual needs, making the selection of the section size of the honeycomb steel more flexible.

Embodiment 3

[0052] This example is basically the same as Example 1, the difference is that the concrete partially wrapped by the honeycomb steel is a recycled concrete made by partially replacing natural aggregates with recycled aggregates. The mechanical properties of aggregates will be improved. On the other hand, compared with ordinary concrete, the use of recycled aggregates to partially replace natural aggregates can "turn waste into treasure" from construction waste, thereby bringing certain social benefits and environmental benefits.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com