Pier repairing apparatus and method based on lightweight prestressed stainless steel sheath

A prestressed sleeve, stainless steel technology, applied in bridge maintenance, bridges, bridge parts, etc., to achieve the effect of saving later maintenance costs, saving costs, and inhibiting buckling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] In order to further understand the content, characteristics and effects of the present invention, the following examples are given, and detailed descriptions are as follows in conjunction with the accompanying drawings:

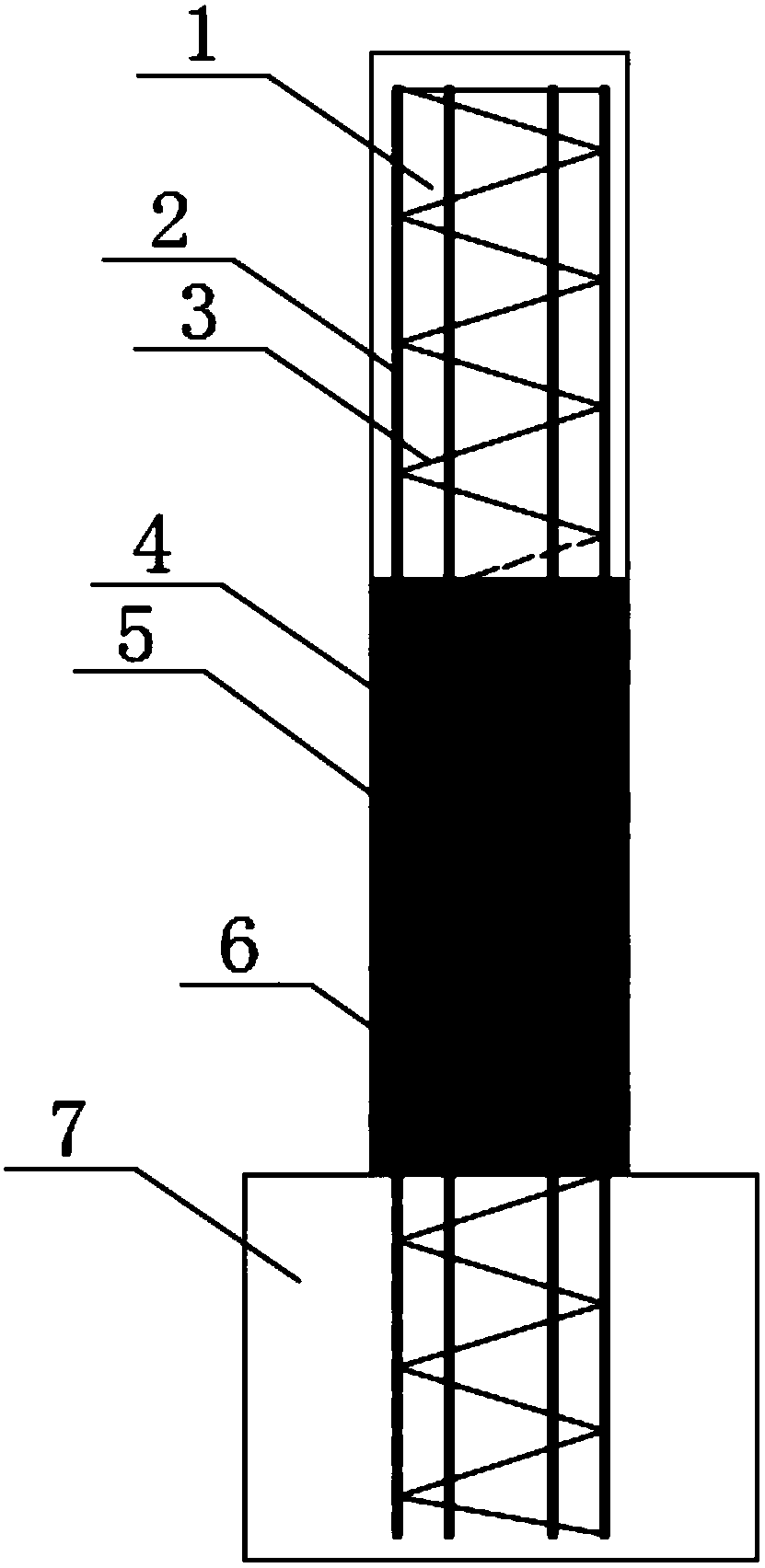

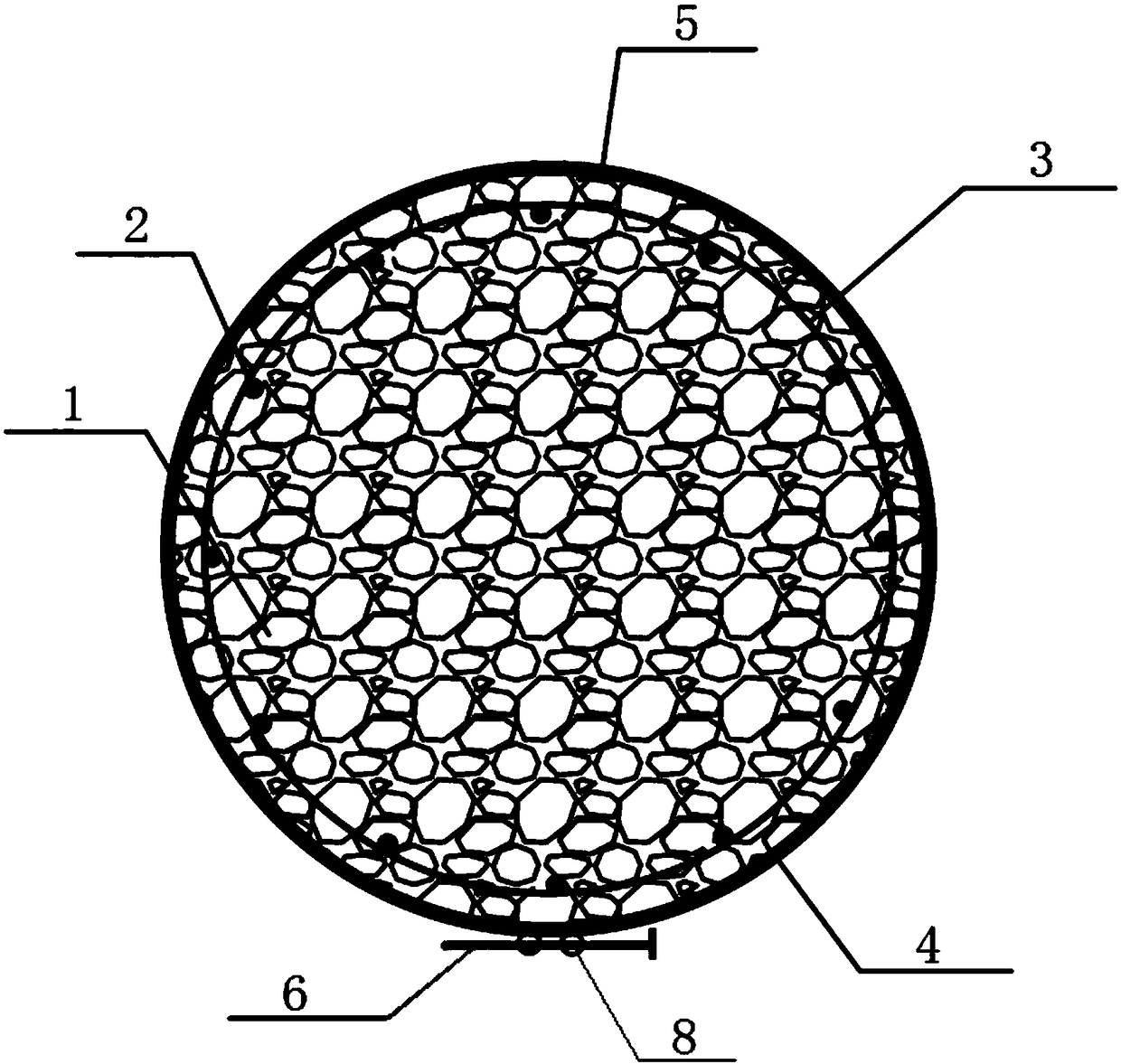

[0025] The pier 1 involved in the present invention is provided with a pier cap 7 at the bottom, and a longitudinal steel bar 2 and a spiral stirrup 3 are provided inside.

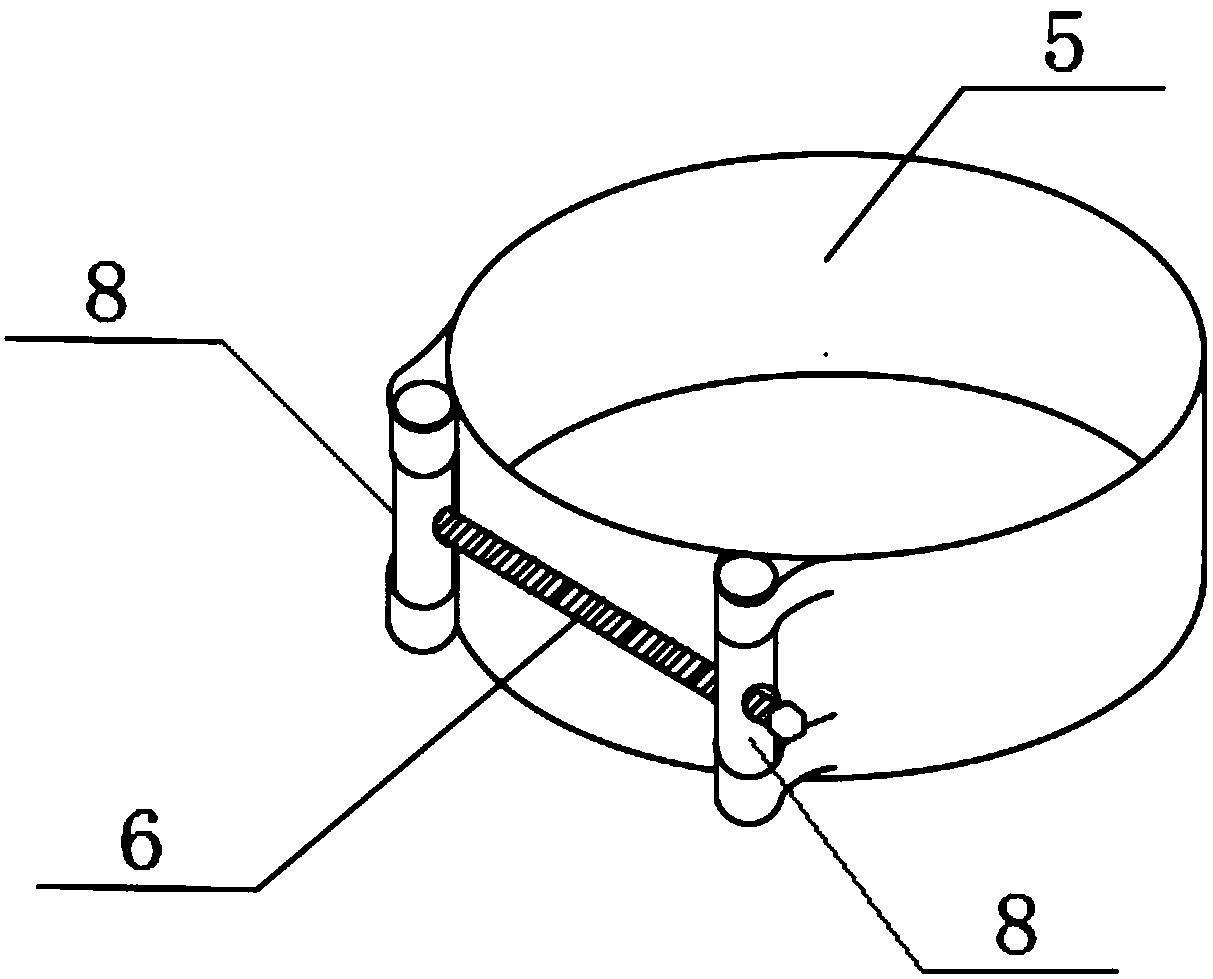

[0026] as attached Figure 1 to Figure 3 As shown, a bridge pier repair device based on a light prestressed stainless steel sheath includes a casing 4 and a prestressed hoop 5 . The presence of the prestressed hoop 5 can inhibit the buckling of the sleeve 4, and the sleeve 4 can also prevent the prestressed hoop 5 from cutting concrete and cause cracking, and the prestress can be retained.

[0027] The casing 4 is welded by thin stainless steel plates, and is wrapped around the outside of the repaired part of the pier 1 . The casing 4 is a thin stainless steel plate pre-cut in th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com