Steel-bamboo combination pipe and manufacturing method thereof

A technology of combining pipes and inner steel pipes, which is applied in the direction of joists, girders, truss beams, etc., can solve the problems of surface corrosion, reduce the use efficiency of steel pipe materials, and consume large materials, so as to improve the bearing capacity and anti-deformation ability, and improve the quality of buildings. The effect of ecological beauty and strengthening mechanical strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

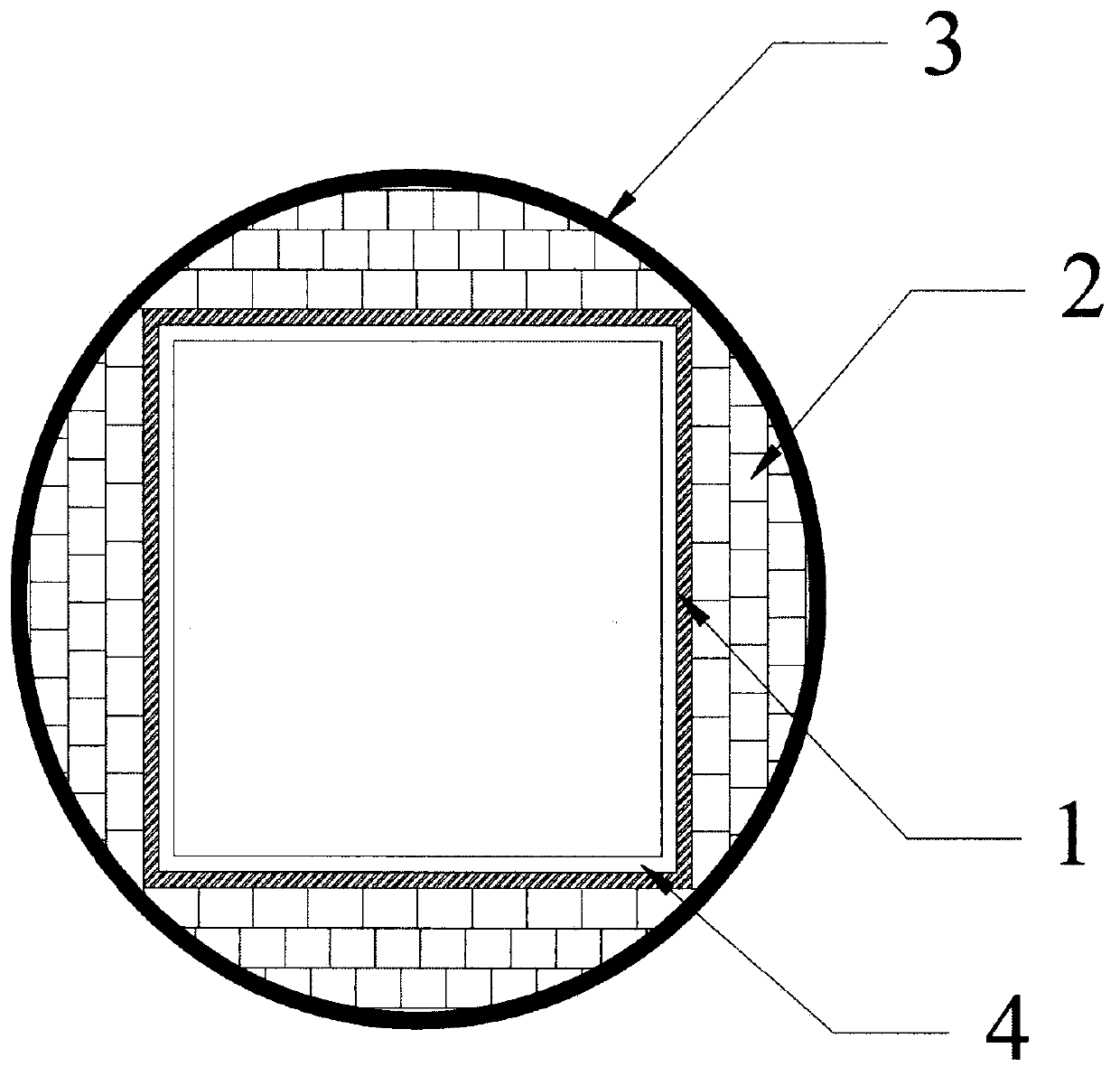

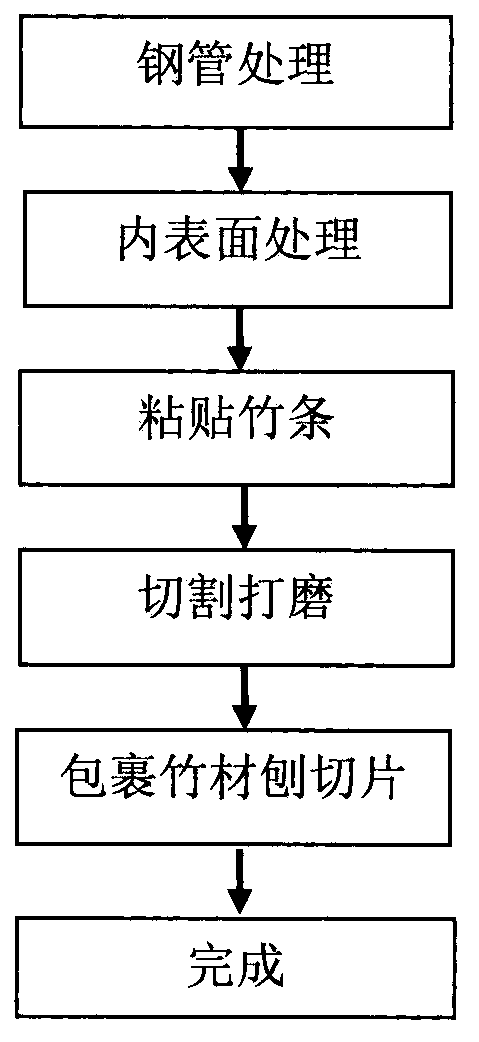

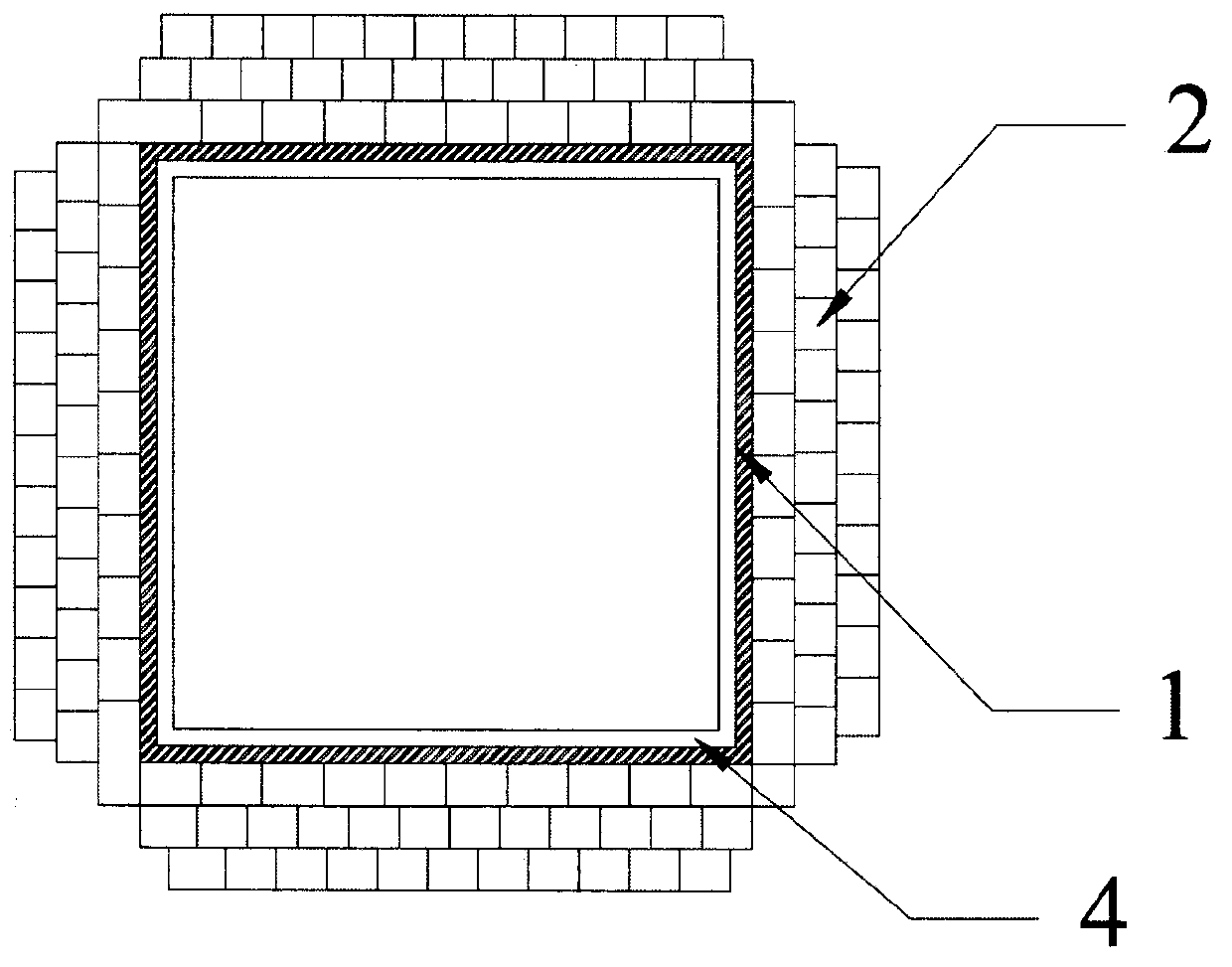

[0041] Attached image 3 , Figure 4 Respectively, the outer surface of the inner steel pipe 1 pasted with bamboo strips 2 is a steel-bamboo composite pipe (rectangular steel tube circular section) with a schematic cross-sectional view of the outer surface of the inner steel pipe with bamboo strips pasted and a schematic cross-sectional diagram with bamboo strips pasted. In concrete implementation, select the steel pipe 1 of the rectangular cross-section of suitable size, brush the inner protection layer 4 on the inner surface of the inner steel pipe 1, brush the resin glue on the outer surface of the inner steel pipe 1 and paste more than one layer of bamboo strips 2, bamboo strips 2 The length direction is consistent with the height direction of the inner steel pipe 1, and the adjacent two layers are glued together to form a predetermined cross-sectional shape, and the bamboo strips 2 are guaranteed to fully wrap the surface of the inner steel pipe 1, and resin is applied to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com