Intelligent algorithm-based method for optimizing tire building-vulcanizing production energy consumption in real time

A technology of tire building and intelligent algorithm, applied in computing, manufacturing computing systems, instruments, etc., can solve problems such as scheduling based on energy consumption information lag, production concentration, and complex optimization process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0061] The technical solution and application principle of the present invention will be described in further detail and complete below in conjunction with the accompanying drawings and specific embodiments:

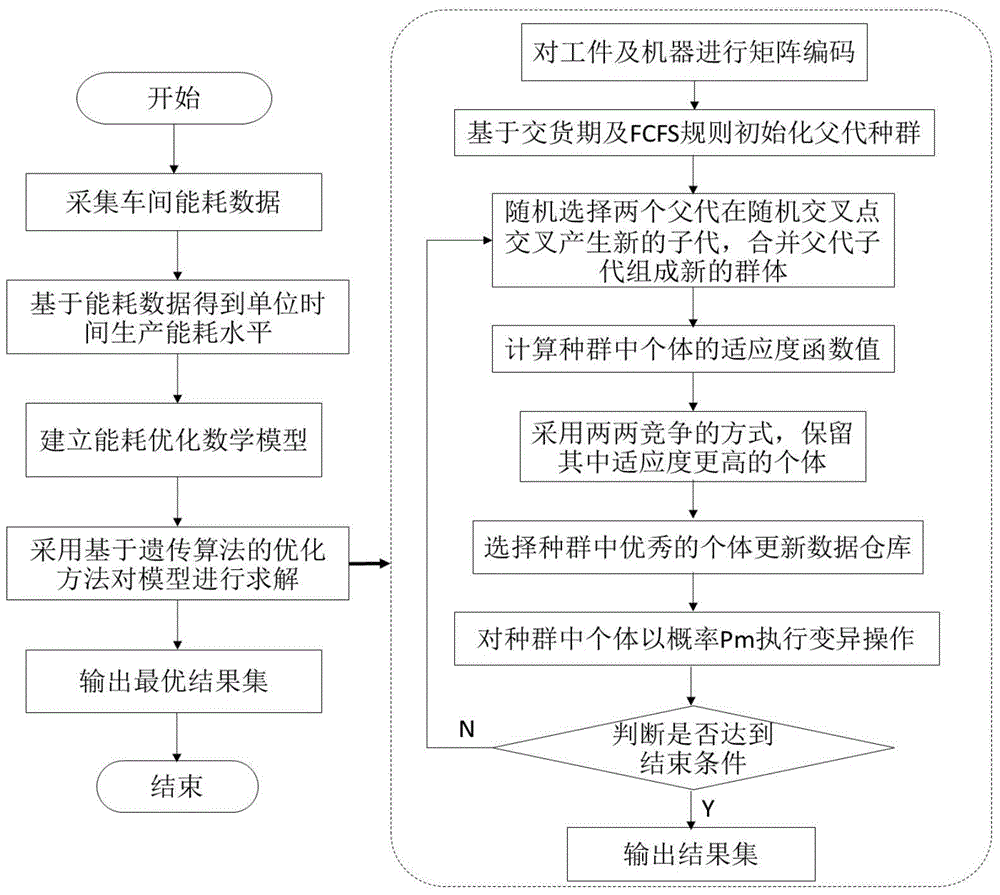

[0062] refer to figure 1 , which is a step-by-step flowchart of a genetic algorithm-based tire building-vulcanization production energy consumption optimization method in this embodiment, and the specific implementation steps are as follows:

[0063] Step 1: Based on the existing IoT sensing technology, collect process data and real-time energy consumption information by arranging data acquisition equipment and wireless sensing equipment in the workshop, and upload them to the upper management system. The data acquisition equipment includes electric meters , temperature sensor, pressure sensor; wireless sensing equipment includes ZigBee Ethernet wireless module; specifically includes:

[0064] Step 1.1: The data acquisition equipment collects the main energy-consuming p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com