A low-yield-point steel plate shear wall structure with built-in steel tubular concrete frame

A steel plate shear wall, steel tube concrete technology, applied in the direction of walls, building components, building structures, etc., can solve the problems of insufficient utilization of steel materials, reduce the interaction between steel and concrete, and achieve superior seismic performance, hysteresis The curve is full and the effect of reducing welding deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] In order to illustrate the present invention more clearly, the present invention will be further described below in conjunction with preferred embodiments and accompanying drawings. Similar parts in the figures are denoted by the same reference numerals. Those skilled in the art should understand that the content specifically described below is illustrative rather than restrictive, and should not limit the protection scope of the present invention.

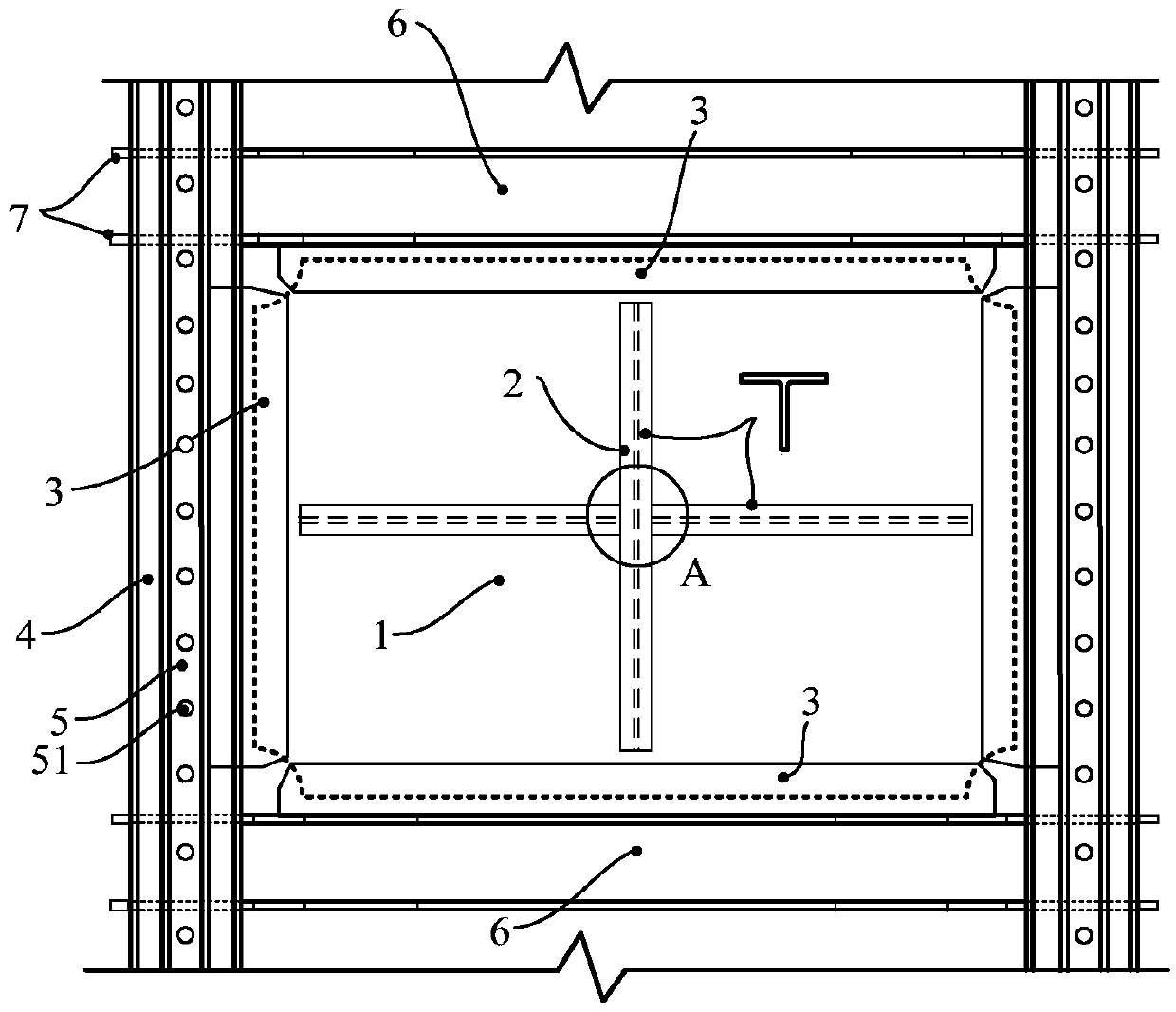

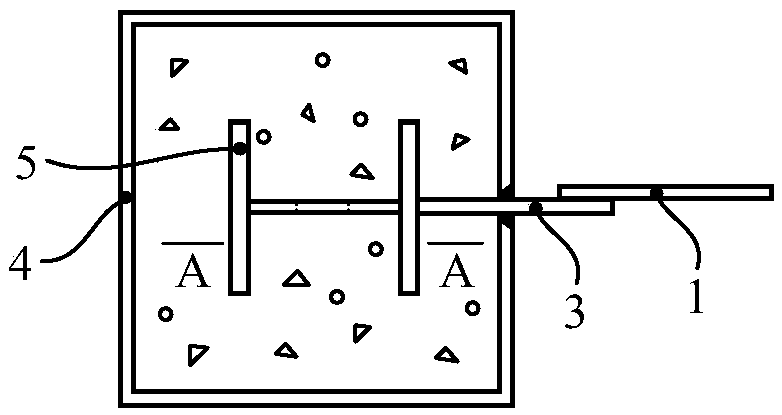

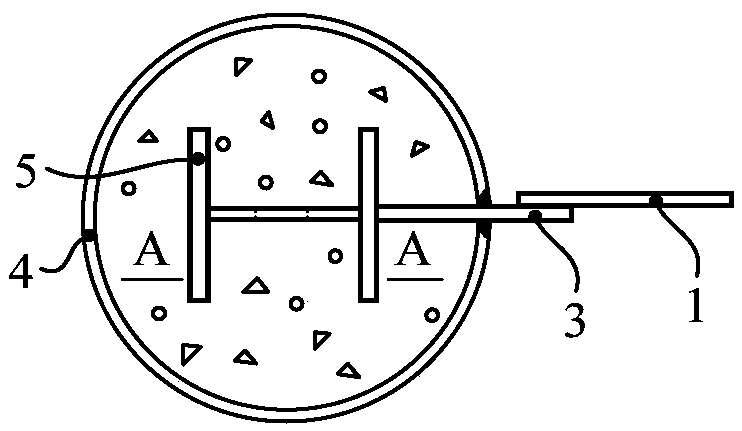

[0043] Such as Figure 1~4 As shown, a low-yield-point steel plate shear wall structure with a built-in steel-filled steel tube concrete frame of the present invention includes an embedded steel plate 1, a T-shaped stiffener 2, a fishplate 3, a steel tube concrete side column 4, shaped steel 5 and a "dog bone" Type” steel beams 6. The concrete-filled steel pipe side column 4 is a rectangular steel pipe structure or a circular steel pipe structure. The section steel 5 is arranged inside the steel pipe concrete side column ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com