Construction method of adobe wall suitable for seismic fortification high-seismic-intensity area and adobes

A construction method and technology of adobe walls, applied in the direction of walls, anti-seismic, building components, etc., can solve problems such as difficult coordination of ring beams, weak anti-seismic ability of adobe walls, and poor concrete maintenance, so as to expand the scope of use and avoid personnel and property loss effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

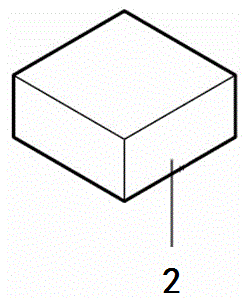

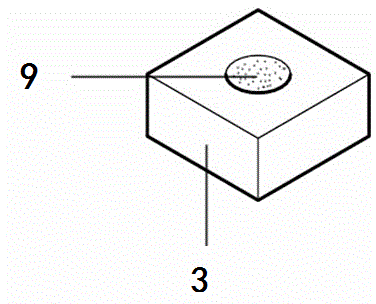

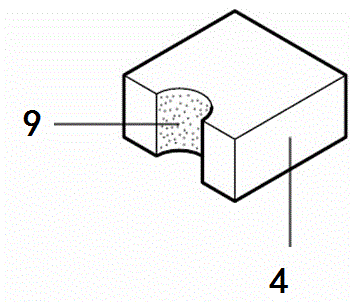

[0058] Embodiment 1: According to the layout of the adobe wall in the architectural design, first construct the reinforced concrete strip foundation 1 of the adobe wall, and pre-bury a diameter of every 0.6~1.8m on the center line of the adobe wall on the reinforced concrete strip foundation 1. 12~16mm vertical hidden column pre-embedded threaded steel bar 13. according to Figure 1-7 Among them, prepare different quantities of standard adobe 2, adobe with round holes in the center 3, adobe with semicircular holes in the side 4, standard groove adobe 5, groove adobe 6 with round holes in the center, and groove adobe 7 with semicircular holes in the side. Short adobe 8 with round holes on the side. Brush emulsified asphalt 9 on the curved surface of the adobe 3 with round holes in the center, adobe 4 with semi-circular holes in the side, and short adobe 8 with round holes in the side as a water-proof and viscous energy-dissipating layer. 1. The groove inner wall of the groove...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com