Steel structure anti-seismic frame structure and building

A technology of anti-seismic frame and steel structure, which is applied to buildings, elongated structural members for load-bearing, structural elements, etc. It can solve the problems of insufficient anti-seismic effect, achieve high construction efficiency, good anti-seismic performance, and reduce stress concentrated effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

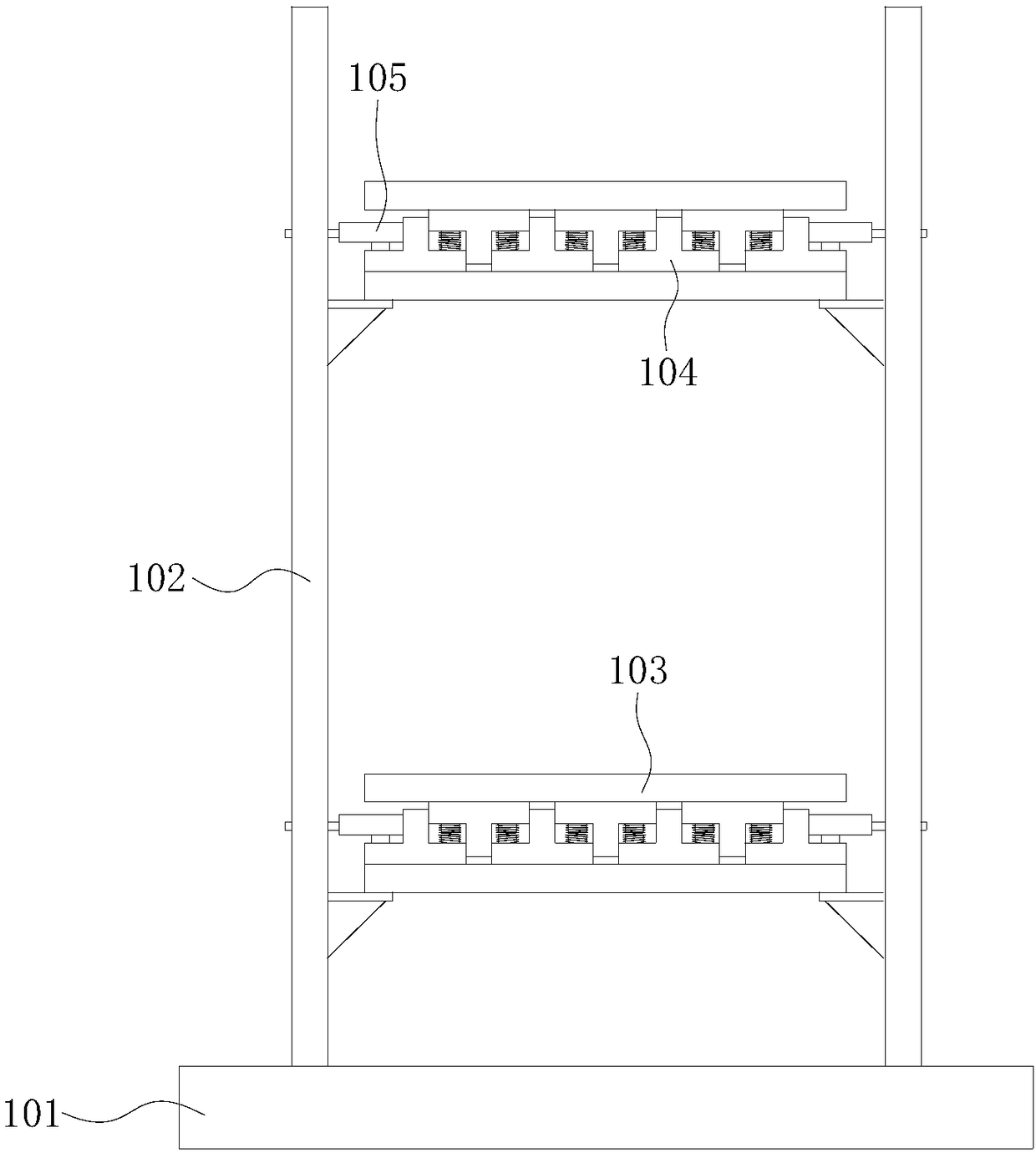

[0046] refer to Figure 1 to Figure 8 , this embodiment provides a steel structure anti-seismic frame structure,

[0047] The steel structure anti-seismic frame structure includes a foundation floor 101, a plurality of spaced steel columns 102 vertically connected to the foundation floor 101; adjacent steel columns 102 are connected by steel beams 103 along the horizontal direction; a plurality of steel columns 102 and a plurality of steel beams 103 are interconnected to form a steel structure frame form;

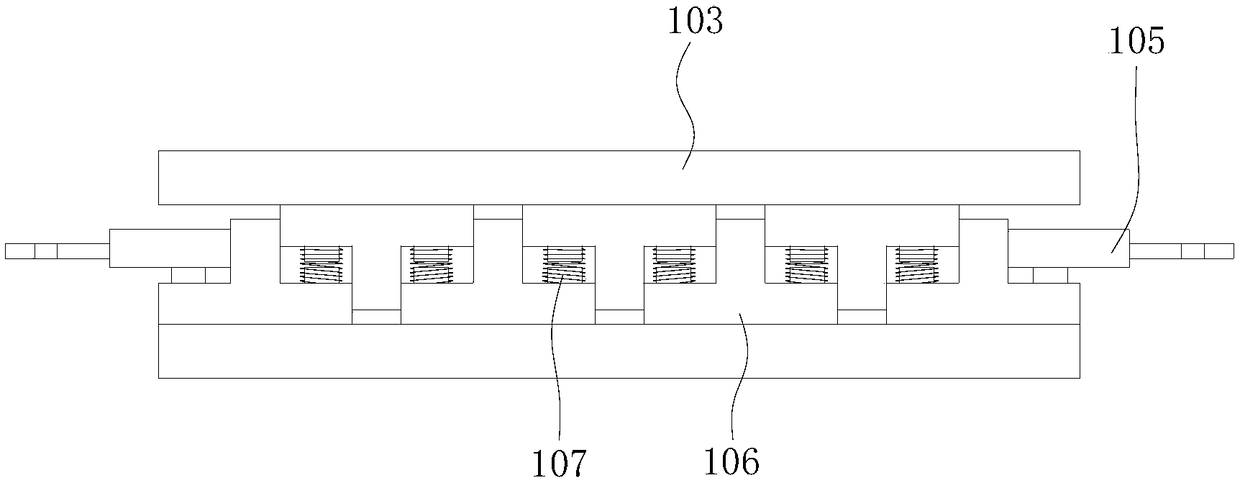

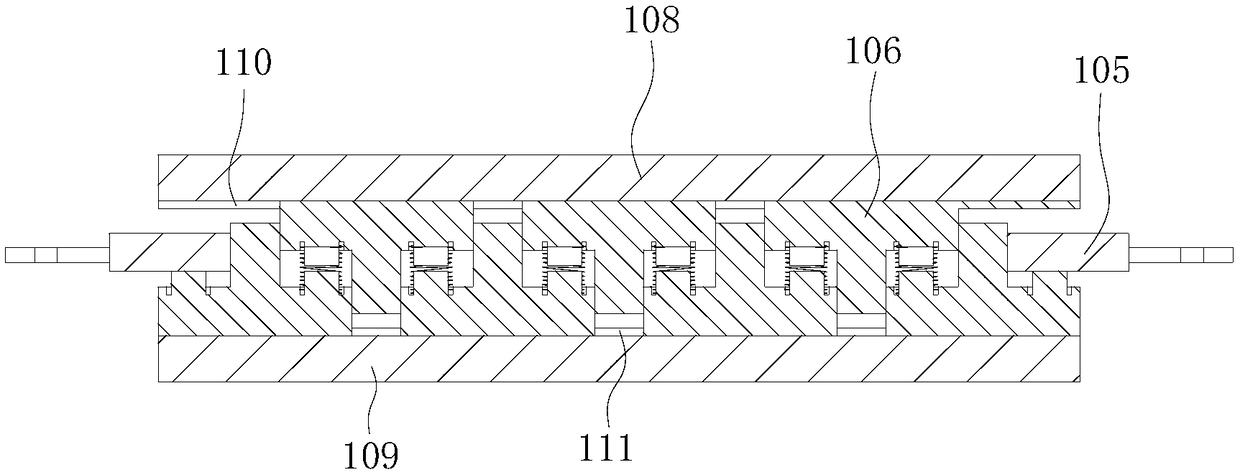

[0048] The steel beam 103 comprises an I-shaped beam body, and the beam body includes an upper support plate 108, a lower support plate 109 and a web 112 connected between the upper support plate 108 and the lower support plate 109;

[0049] Both sides of the web 112 are respectively provided with elastic support assemblies 104 supported between the upper support plate 108 and the lower support plate 109; T" shape, the support block 106 includes a horizontal block 113 and...

Embodiment 2

[0062] This embodiment provides a building, including the above steel structure anti-seismic frame structure.

[0063] In the building provided by this embodiment, the elastic support assembly 104 is added in the steel beam 103, which can effectively improve the vertical bearing capacity of the steel beam 103, and has better seismic performance.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com